Process for producing silver-plated copper powder for low-temperature slurry

A technology of silver-plated copper powder and slurry, which is applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of low cumulative formation constant and unsuitable comprehensive performance of silver-plated copper powder, etc., and achieve replacement Effects of Reaction Rate Reduction, Excellent Electrical Conductivity, and Antioxidant Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

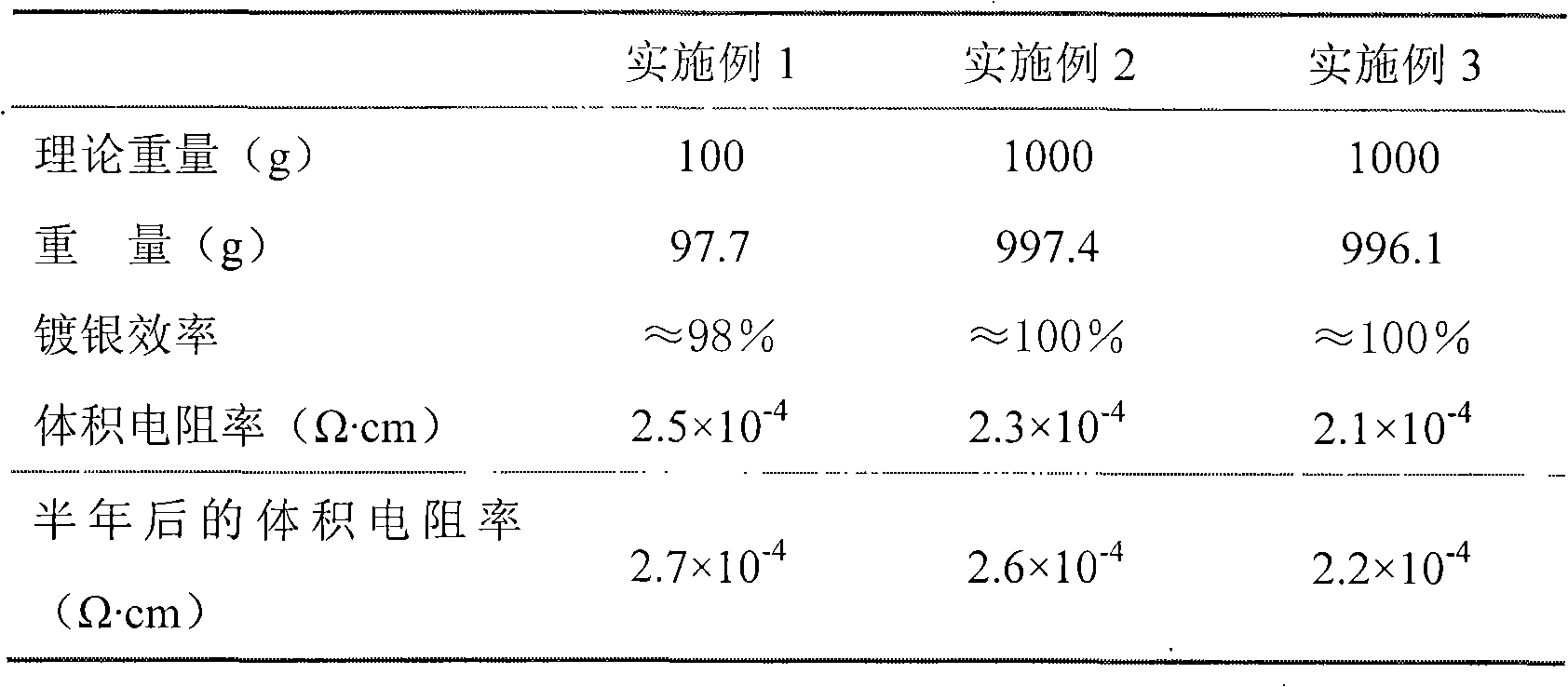

Embodiment 1

[0018] Embodiment 1: the preparation of 20% silver-plated copper powder of silver content

[0019] Add 60kg, 120kg, and 20kg of Φ3, Φ5, and Φ10 stainless steel balls into the stirring ball mill respectively. Take 10kg of electrolytic copper powder with a particle size of -325 mesh, 20g of PVP, 30g of stearic acid, and 20kg of absolute ethanol, and put them into a stirring ball mill to grind the copper powder to D 50 After the thickness is 10-20 μm, the material is discharged for use.

[0020] Take 86g of the above-mentioned copper powder, add 0.9L of water, 2g of OP dispersant, and 10ml of 98% sulfuric acid into a beaker, keep stirring and washing for 20min, and then wash with deionized water until neutral. Add 0.9L of water and 0.5g of OP dispersant to the cleaned copper powder, stir evenly with a stirrer and set aside.

[0021] Get silver nitrate 31.7g, dissolve with 200ml deionized water; Get main complexing agent tartaric acid 44.5g, auxiliary complexing agent mercaptosu...

Embodiment 2

[0022] Embodiment 2: the preparation of 30% silver-plated copper powder of silver content

[0023] The preparation method of flake copper powder is basically the same as that of Example 1. The difference is that the copper powder is atomized copper powder with an average particle size of 8 μm, and the antioxidants are polyether and dodecanoic acid, both of which are used in an amount of 25 g.

[0024] Take 0.81kg of the above-mentioned copper powder, add 8L of water, 20g of OP dispersant, and 80ml of 98% sulfuric acid into a beaker, keep stirring and washing for 20min, and then wash with deionized water until neutral. Add 8L of water and 5g of OP dispersant to the cleaned copper powder, stir evenly with a stirrer and set aside.

[0025] Get silver nitrate 476g, dissolve with 3L deionized water; Get main complexing agent tartaric acid 645g, auxiliary complexing agent nitrosonaphthol, each 2.5g of diethylaminodithioformic acid, after dissolving with 2.50L deionized water and T...

Embodiment 3

[0026] Embodiment 3: the preparation of 45% silver-plated copper powder of silver content

[0027] The preparation steps of the flake copper powder are basically the same as in Example 1. The difference is that the antioxidants are zinc stearate and polyethylene glycol, and the dosages are 30g and 20g respectively.

[0028] Take 0.683kg of the above-mentioned copper powder, add 7L of water, 17g of OP dispersant, and 70ml of 98% sulfuric acid into a beaker, keep stirring and washing for 20min, and then wash with deionized water until neutral. Add 7L of water and 4.5g of OP dispersant to the cleaned copper powder, stir evenly with a stirrer and set aside.

[0029] Get silver nitrate 714g, dissolve with 3.5L deionized water; Get main complexing agent tartaric acid 745g, auxiliary complexing agent phenanthroline, 8-hydroxyquinoline each 4.5g, after dissolving with 8L deionized water, mix with above-mentioned silver nitrate solution Mix evenly, add the silver-containing solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com