Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134 results about "Scratch test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

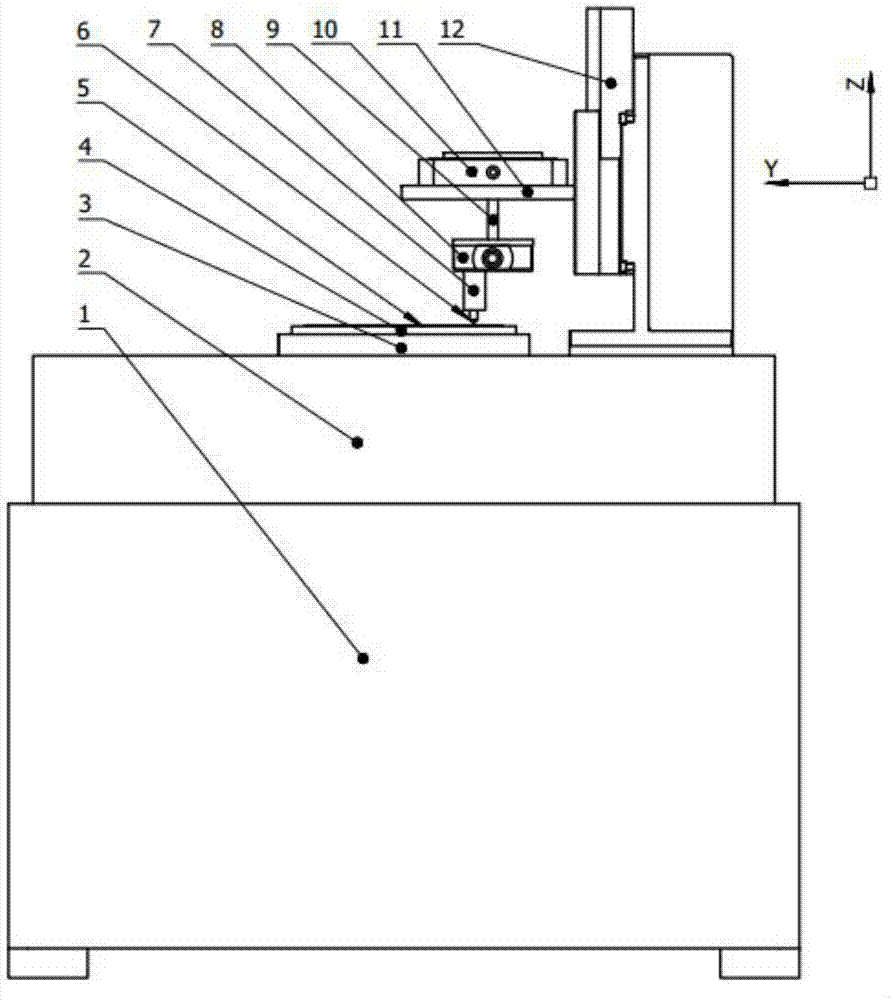

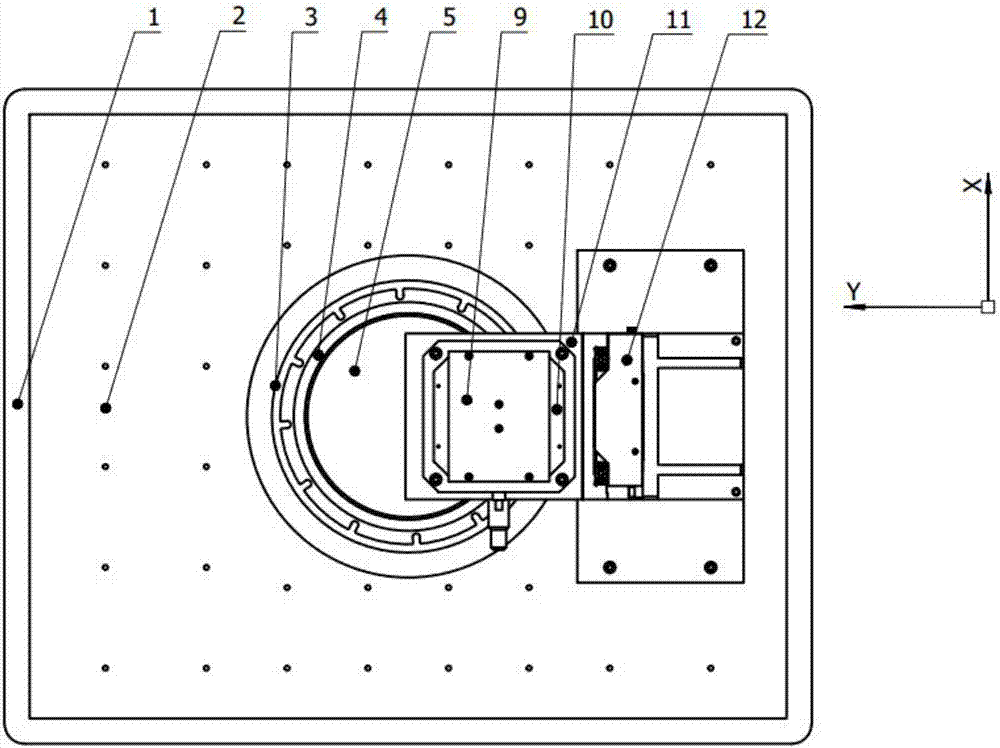

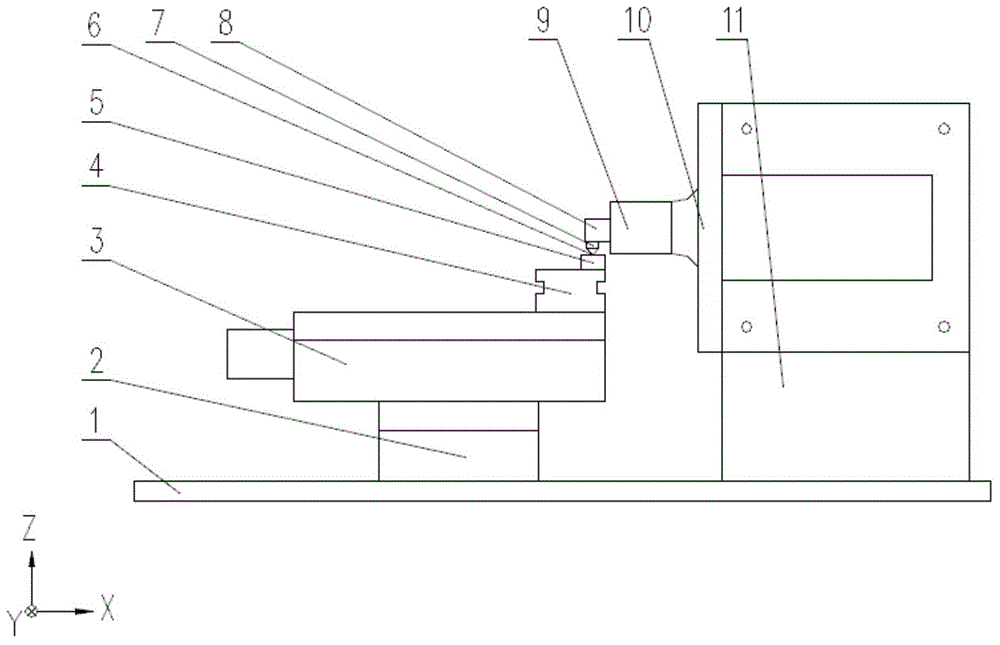

Micron-nano scale in-situ nano indentation and scratching test system

InactiveCN101876609AThe test method is accuratePrecision equipmentUsing optical meansInvestigating material hardnessImage resolutionEngineering

The invention relates to a micron-nano scale in-situ nano indentation and scratching test system which integrates driving, precise loading and signal detection, micron-nano scale mechanics performance testing, ultraprecise scratching processing and high resolution in-situ observing as one. The system is mainly composed of a precise positioning platform at X-axis and Y-axis directions, a precise linear positioning platform at Z-axis direction, a precise indentation driving unit, a load signal and displacement signal detection unit and a high resolution digital microscopic imaging system for observing and storing material deformation and damage conditions in the test process. The precise positioning platform at the X-axis and Y-axis directions is assembled on a base, the precise linear positioning platform at the Z-axis direction is assembled on a side plate, the precise indentation driving unit, a precise mechanical sensor for detecting the indentation material pressure of a diamond tool head and a precise displacement sensor for detecting the indentation depth of the diamond tool head to along the Z-axis direction are assembled on the precise linear positioning platform at the Z-axis direction, and the high resolution digital microscopic imaging system is assembled on a beam.

Owner:赵宏伟

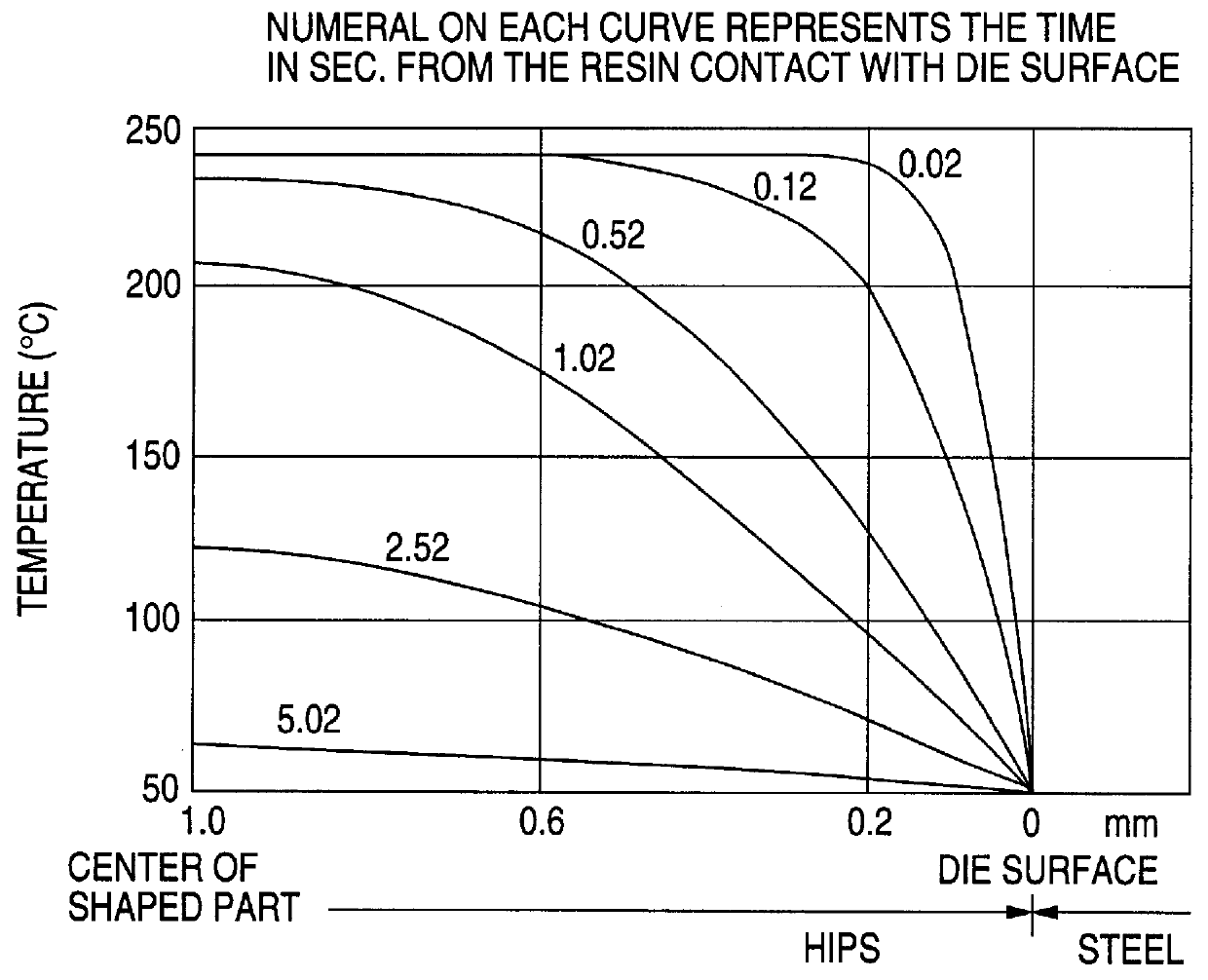

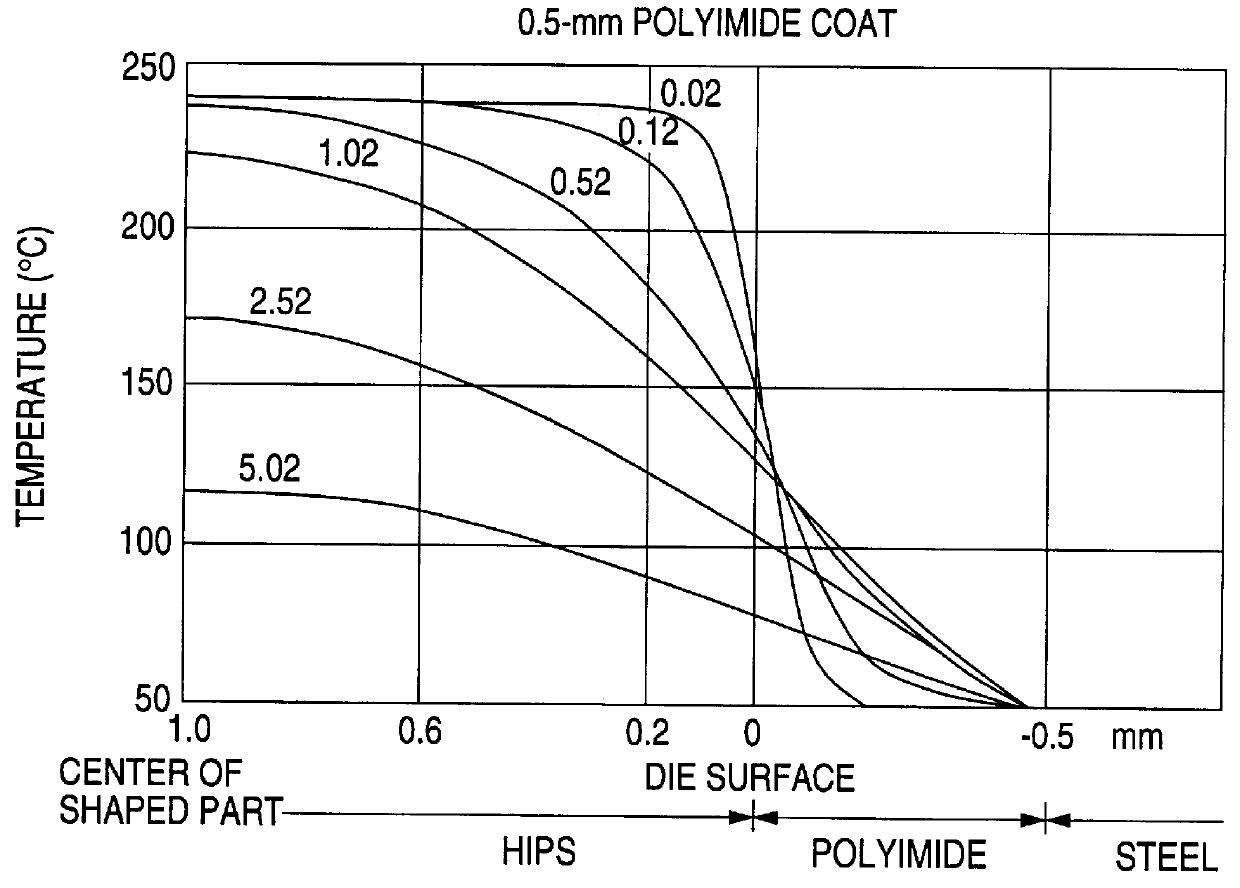

Dull-surfaced, injection molded synthetic resin articles and a method of shaping them

InactiveUS6077472AEfficient platingDiminished plating rateRecord information storageMagnetic recordingPolymer scienceShell molding

PCT No. PCT / JP95 / 01241 Sec. 371 Date Dec. 20, 1996 Sec. 102(e) Date Dec. 20, 1996 PCT Filed Jun. 21, 1995 PCT Pub. No. WO95 / 35194 PCT Pub. Date Dec. 28, 1995The purpose of the invention is to produce a shaped article having a uniform dull surface with less noticeable weld line and other surface detects. The injection molded synthetic resin article of the invention has a weld portion and is characterized in that the weld line on the surface of the injection molded article has a dent of no more than 2 mu m, the surface of the injection molded article is a dull surface with no more than 30% gloss, the general portion, the weld portion and the resin flow end portion of the surface of the injection molded article provide a uniform dull surface, said dull surface having such abrasion resistance that no visible flaws develops at a hardness of 2B and below in a pencil scratch test. Such molded article can be produced without post-molding paint application and yet it has practical utility, thus presenting a maximum economic advantage.

Owner:ASAHI KASEI KK

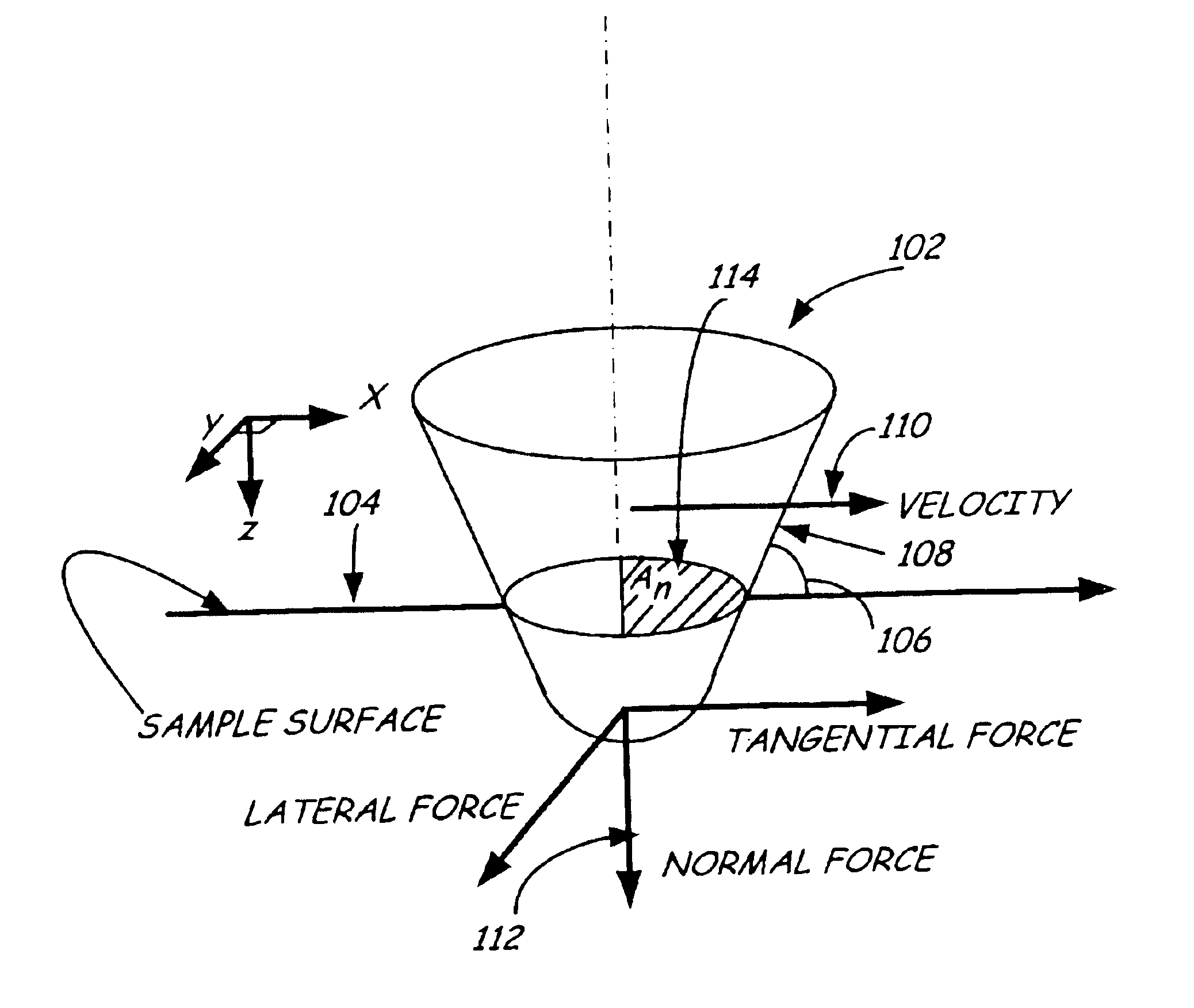

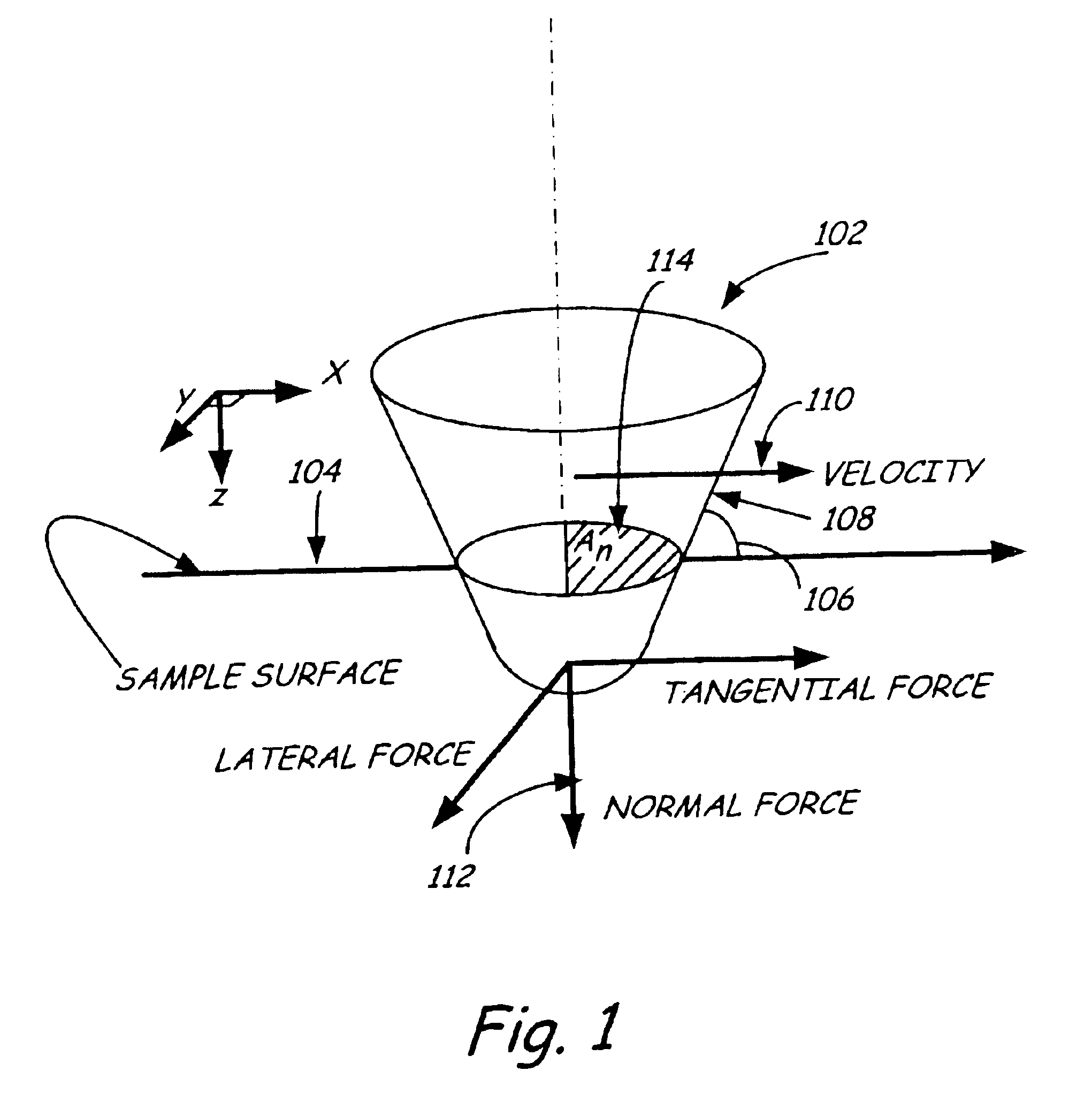

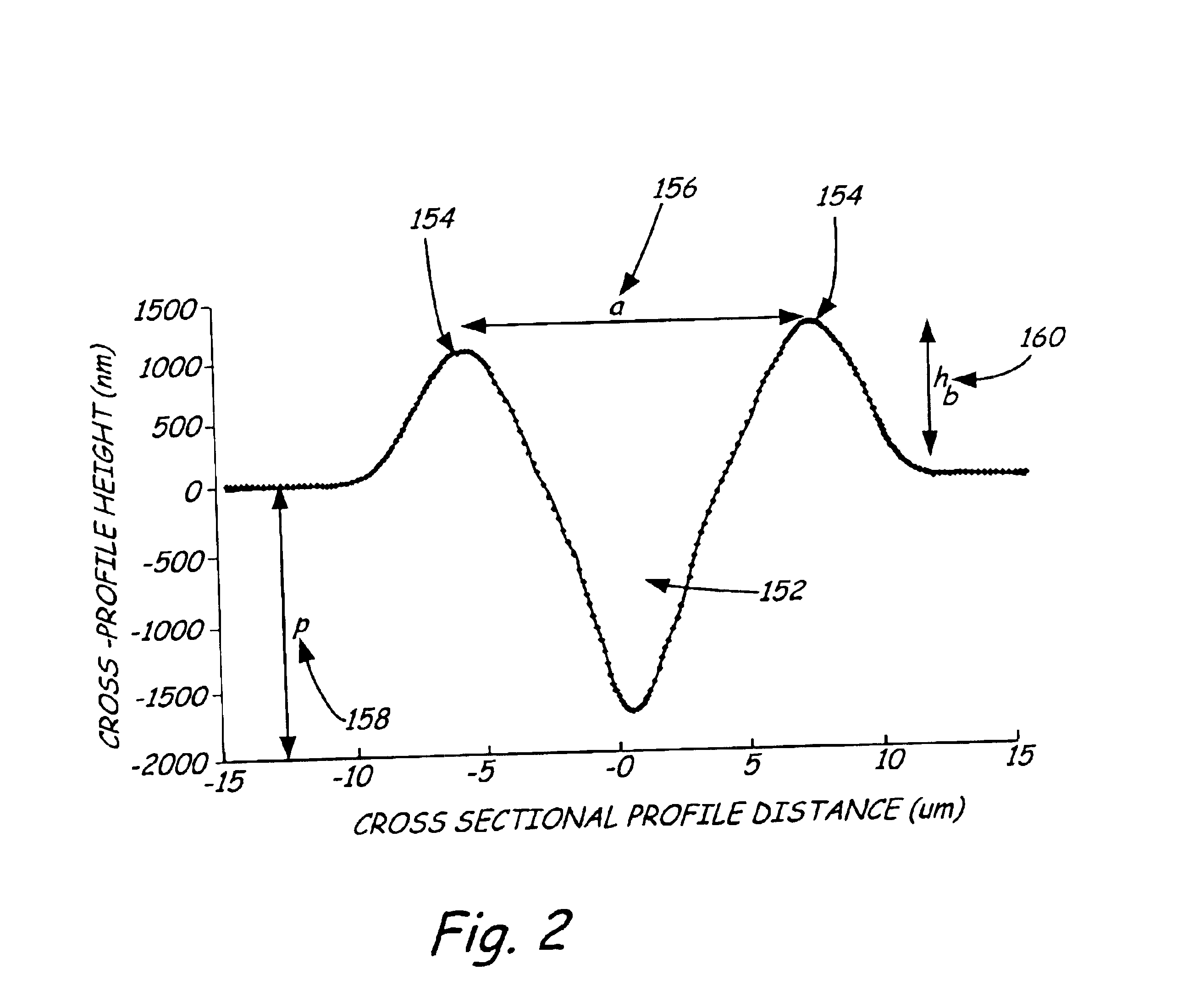

Characteristic strain and fracture resistance for scratch independently of indenter geometry

InactiveUS6945097B2Analysing solids using sonic/ultrasonic/infrasonic wavesForce measurementScratch testEnvironmental geology

The invention involves an apparatus and method for calculating characteristics of materials, such as equivalent strain, using an indenter where the method used is independent of indenter geometry. The method includes performing a scratch test to calculate the strain for each of a plurality of indenter shapes, such as a theoretical sphere and cone, using known equations. The strain of a composite indenter, such as a cone with a rounded tip, can then be determined taking into account contributions from each of the plurality of theoretical shapes.

Owner:KEYSIGHT TECH

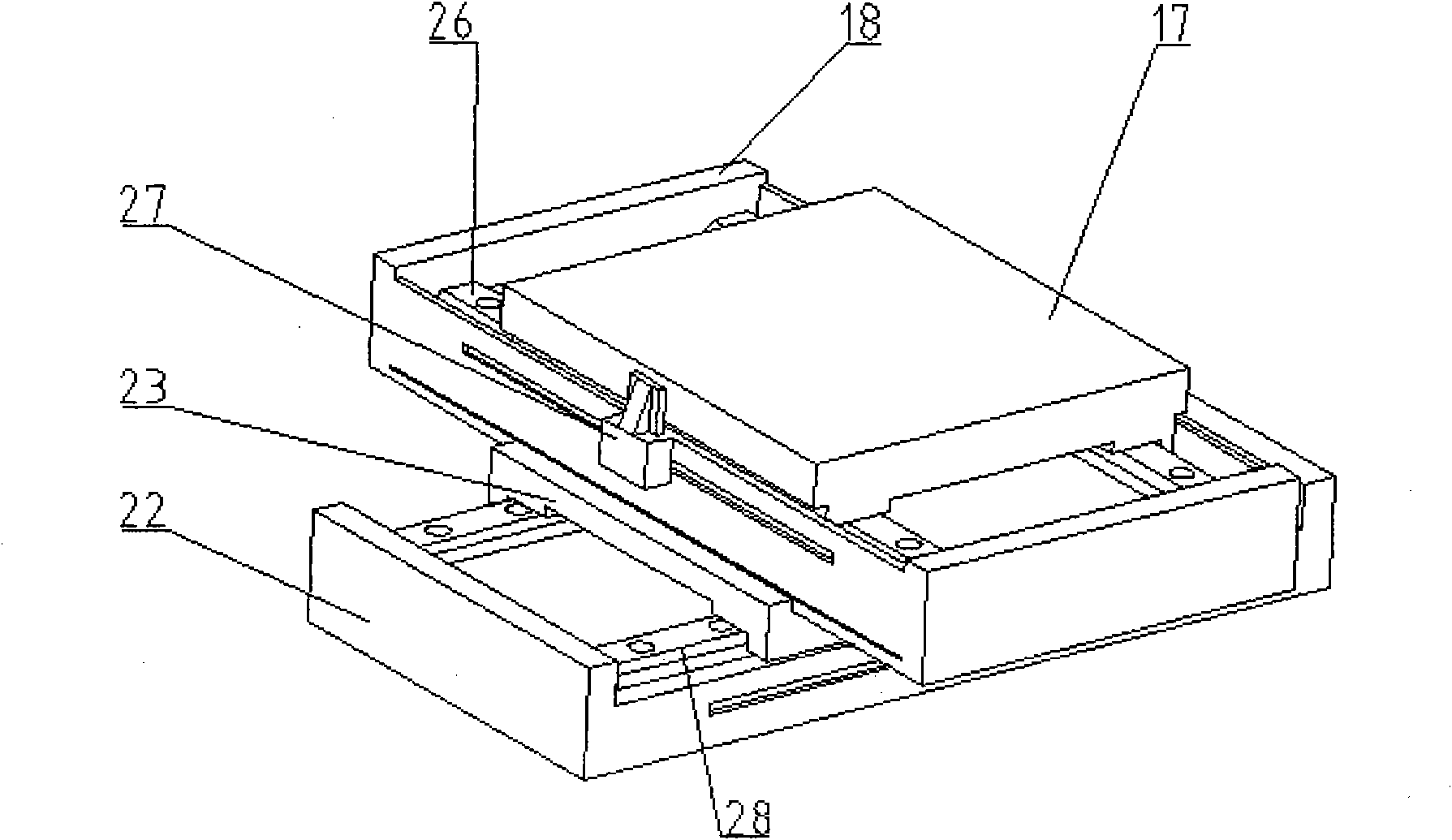

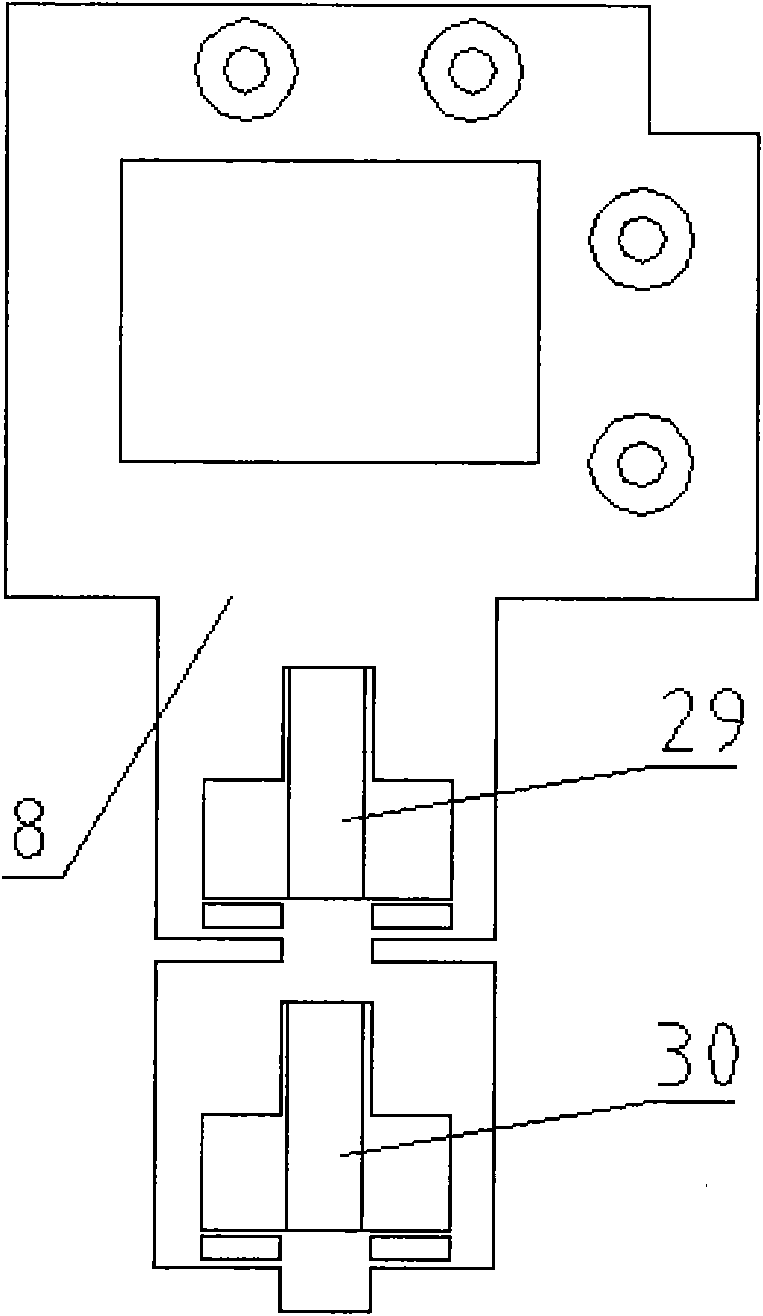

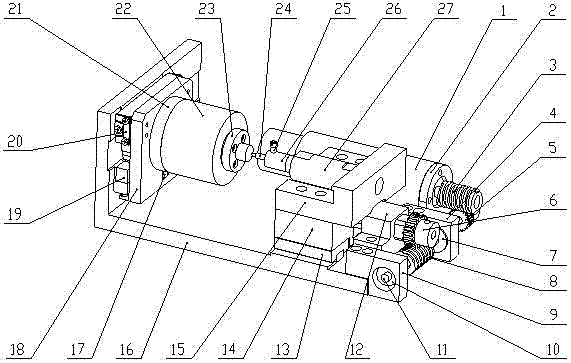

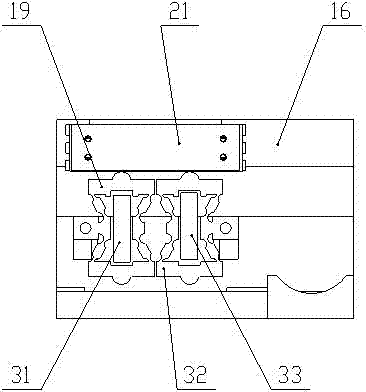

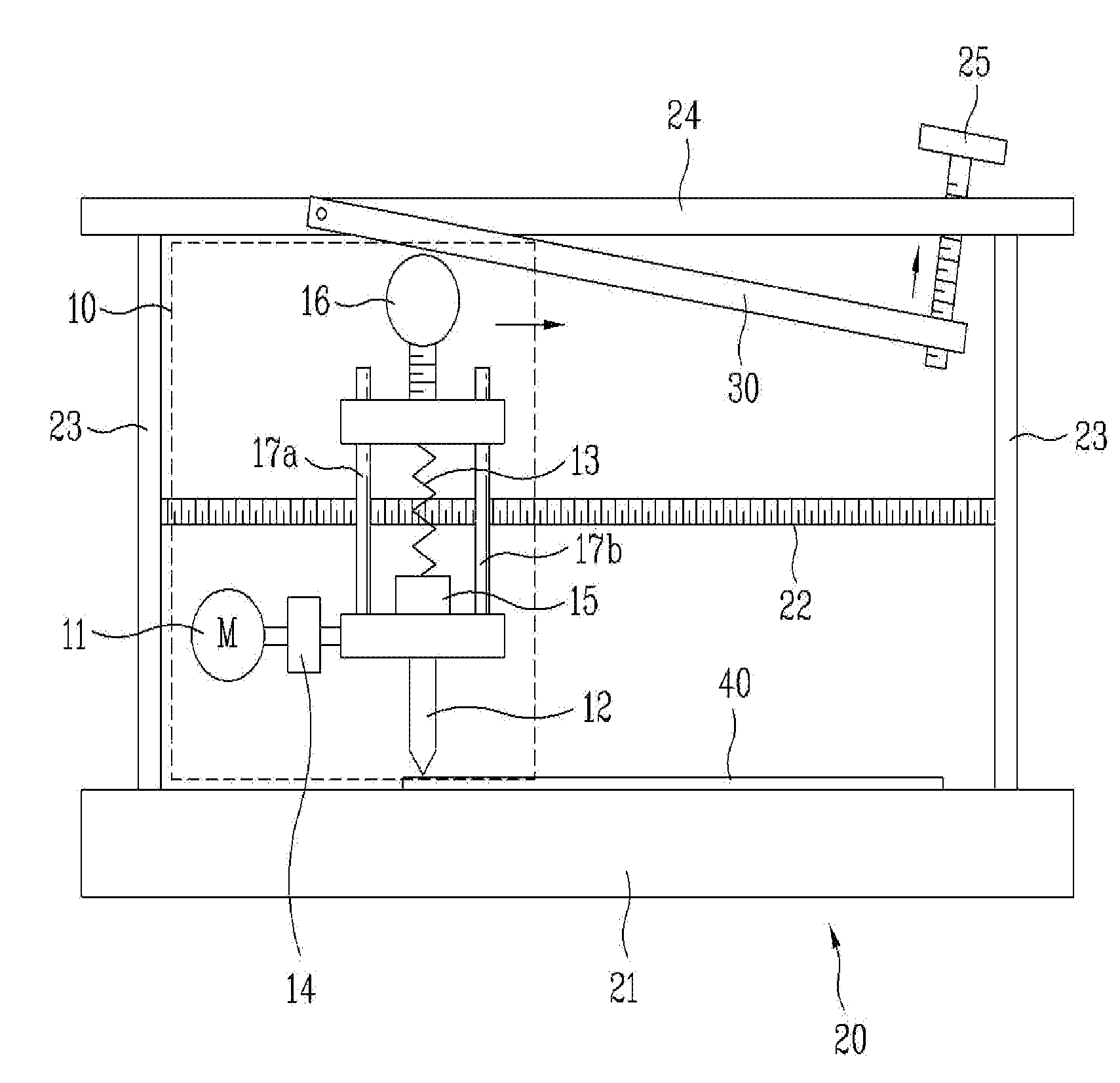

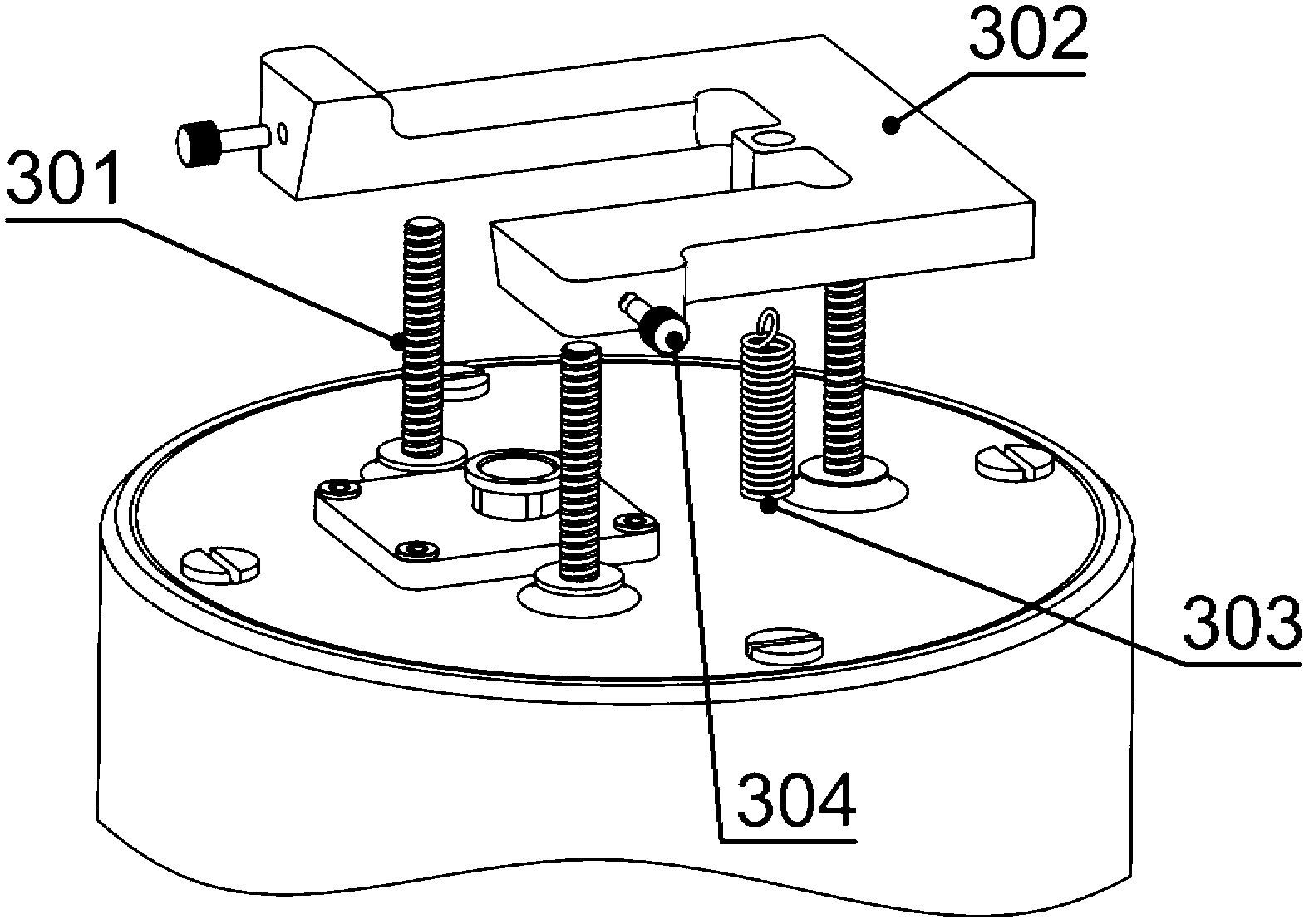

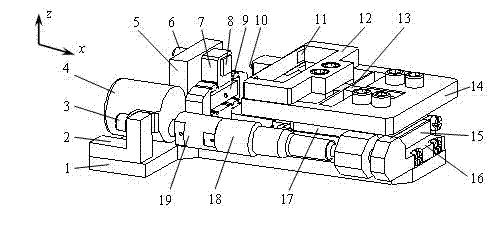

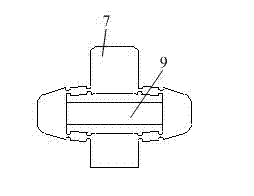

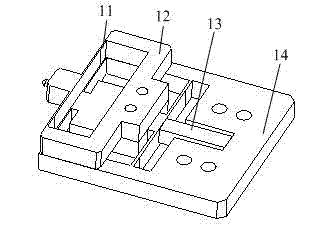

In-situ micro-nano indentation/scratch test platform and test method

ActiveCN104729911AOvercoming detectionOvercoming the lack of tangential forceInvestigating material hardnessMicro nanoScientific instrument

The invention relates to an in-situ micro-nano indentation / scratch test platform and a test method, and belongs to the field of electromechanical integrated precision scientific instruments. An X axis precision scratch unit and a Y axis large-stroke stick-slip drive scratch assembly are assembled at the tail of a base, a Z axis macro-movement adjusting mechanism is assembled at the middle of the base, a motor driving unit is assembled at the head of the base, a precision pressing driving and displacement signal detecting unit is installed on the Z axis macro-movement adjusting mechanism, and a precision three-axis force sensor used for detecting an indentation pressing force and a normal force and a tangential force of a scratch is installed on the X axis precision scratch unit. The in-situ micro-nano indentation / scratch test platform has the advantages of compact structure, miniaturization, integration, and capability of better ensuring the assembly precision, effectively improving the overall rigidity and dynamic properties and improving the overall test precision while overcoming the defect that an existing test platform cannot be used for quantitatively detecting the normal force and the tangential force in a scratch process.

Owner:JILIN UNIV

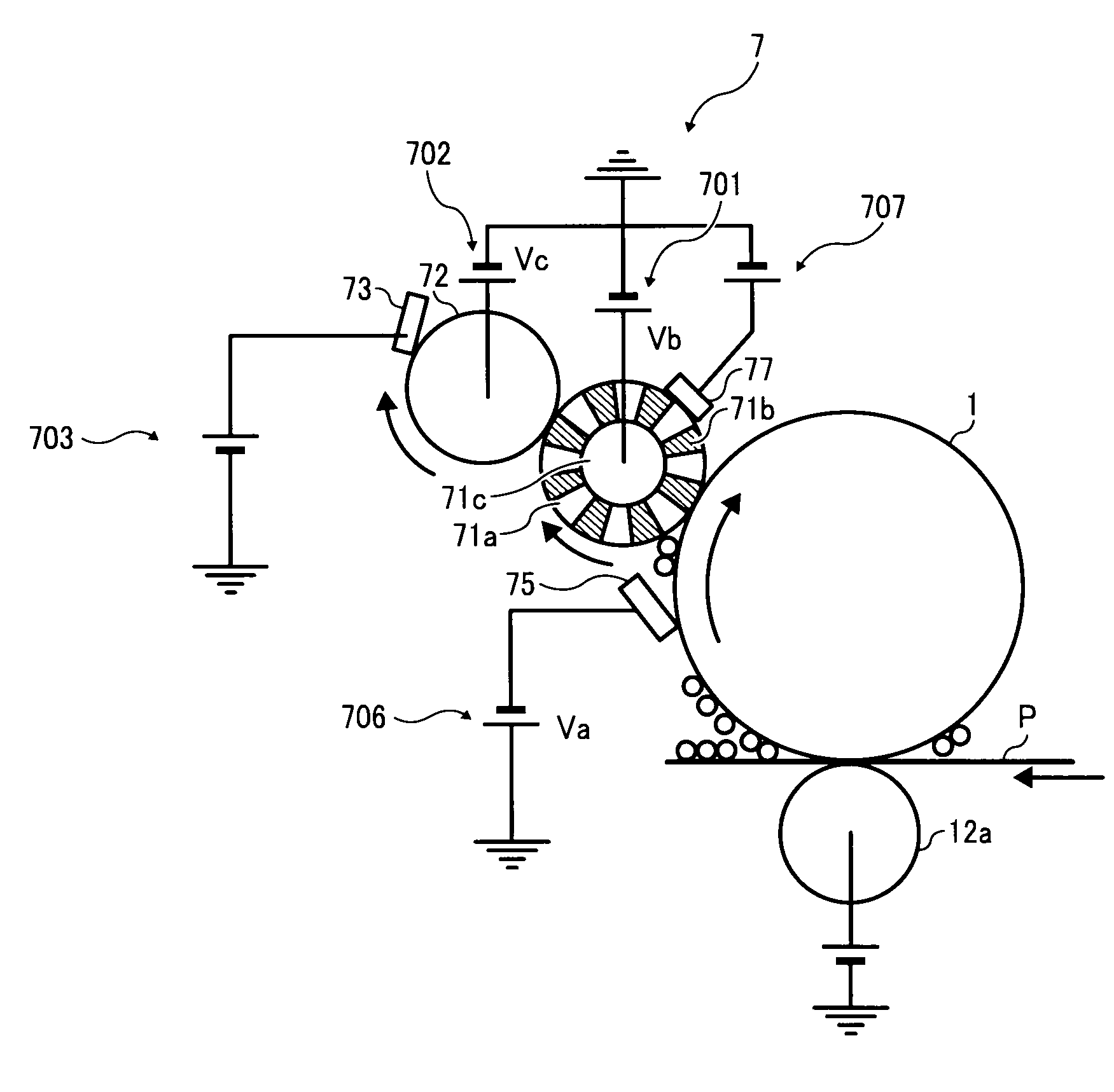

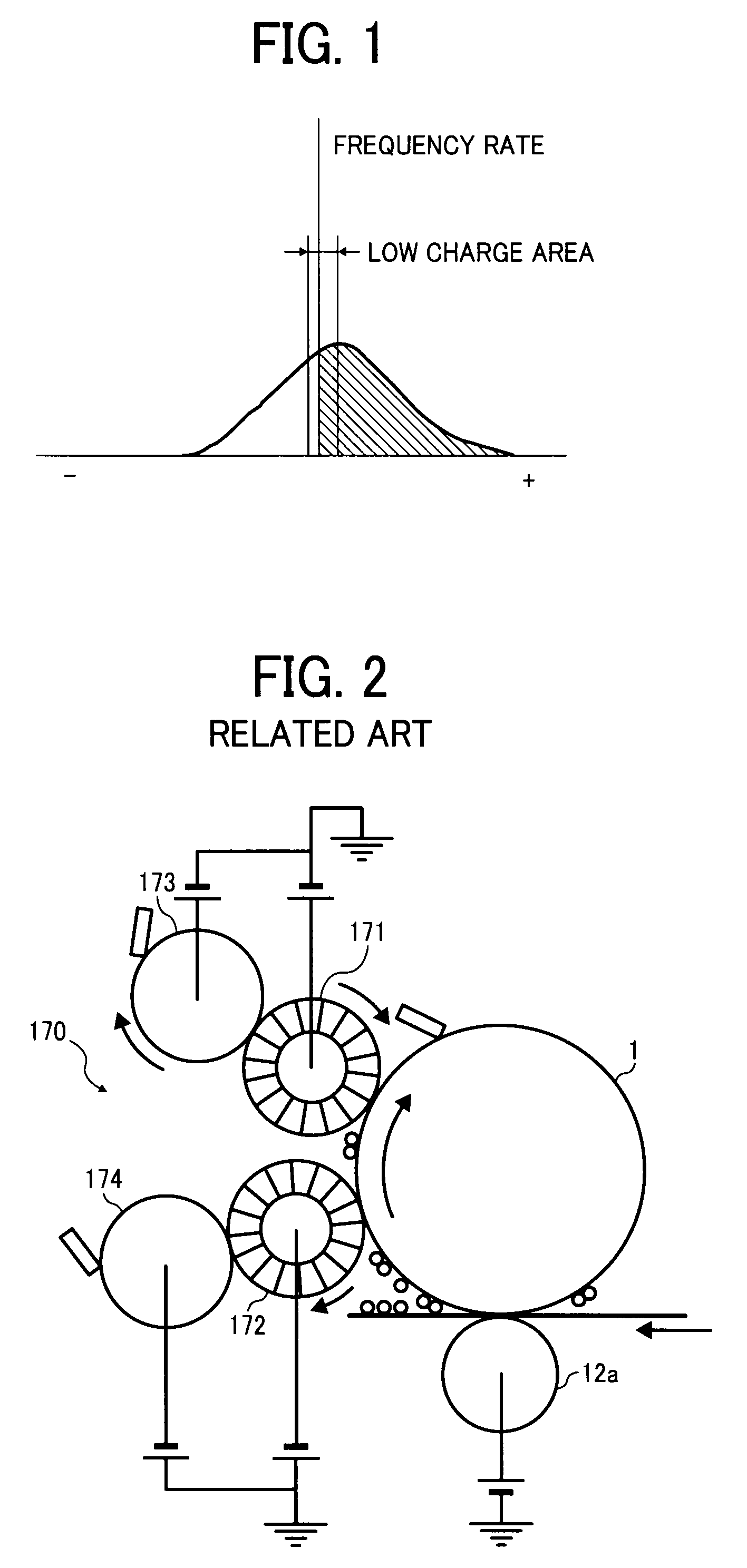

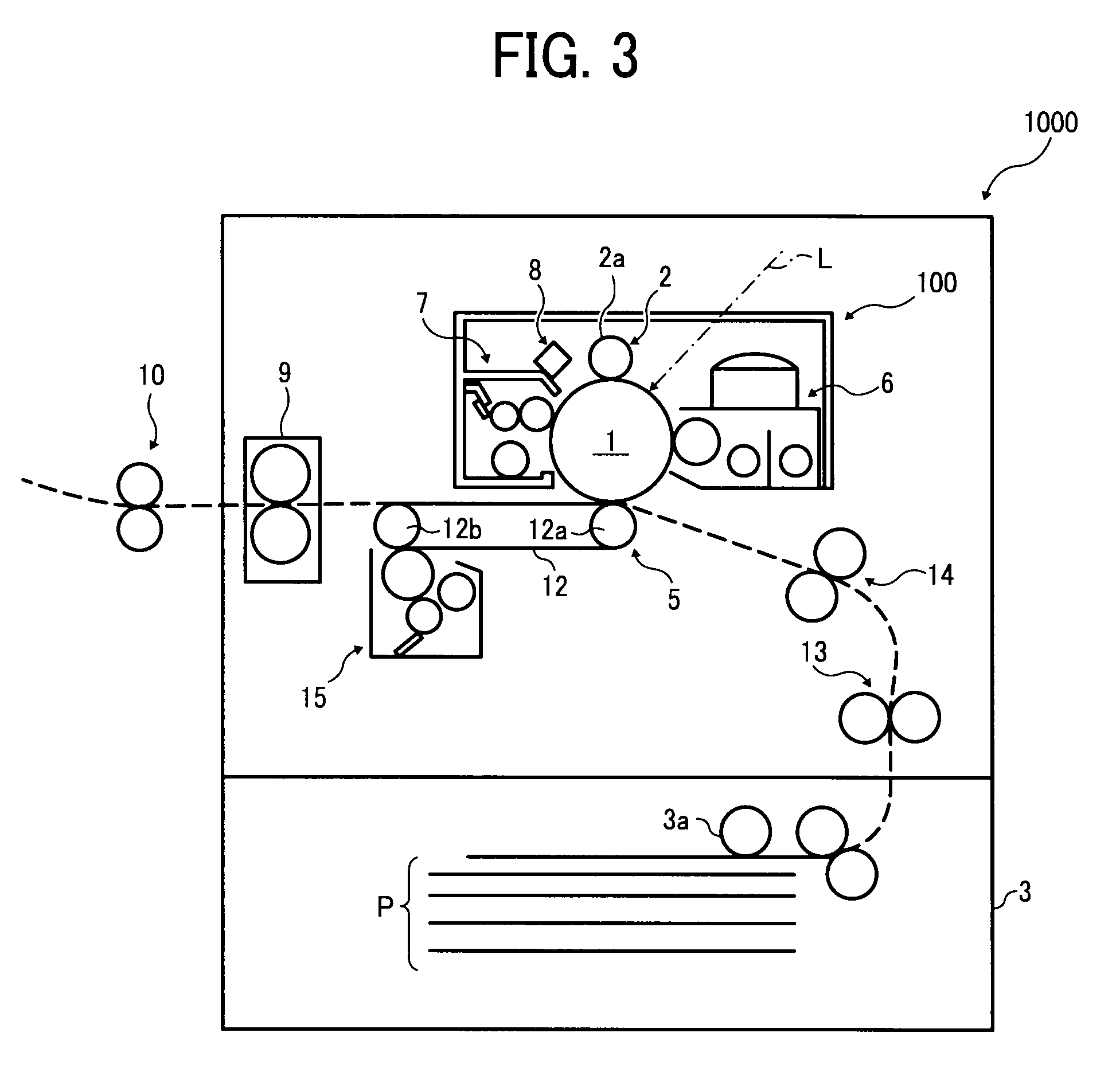

Cleaning device, image forming apparatus including the device, and process cartridge including the device

A cleaning device includes a cleaning member, a collection member, an electrical field generator, and a separation member. The cleaning member has a surface capable of moving while contacting a surface of a cleaning target to remove toner on the surface of the cleaning target. The collection member has a surface capable of moving while contacting the surface of the cleaning member to collect the toner on the surface of the cleaning member. The electrical field generator generates an electrical field to move the toner from the cleaning member to the collection member. The separation member contacts the surface of the collection member to separate the toner on the surface of the collection member. The collection member has a centerline average surface roughness of not more than 0.1 μm and shows a surface hardness rank of B or higher in a steel-wool scratch test.

Owner:RICOH KK

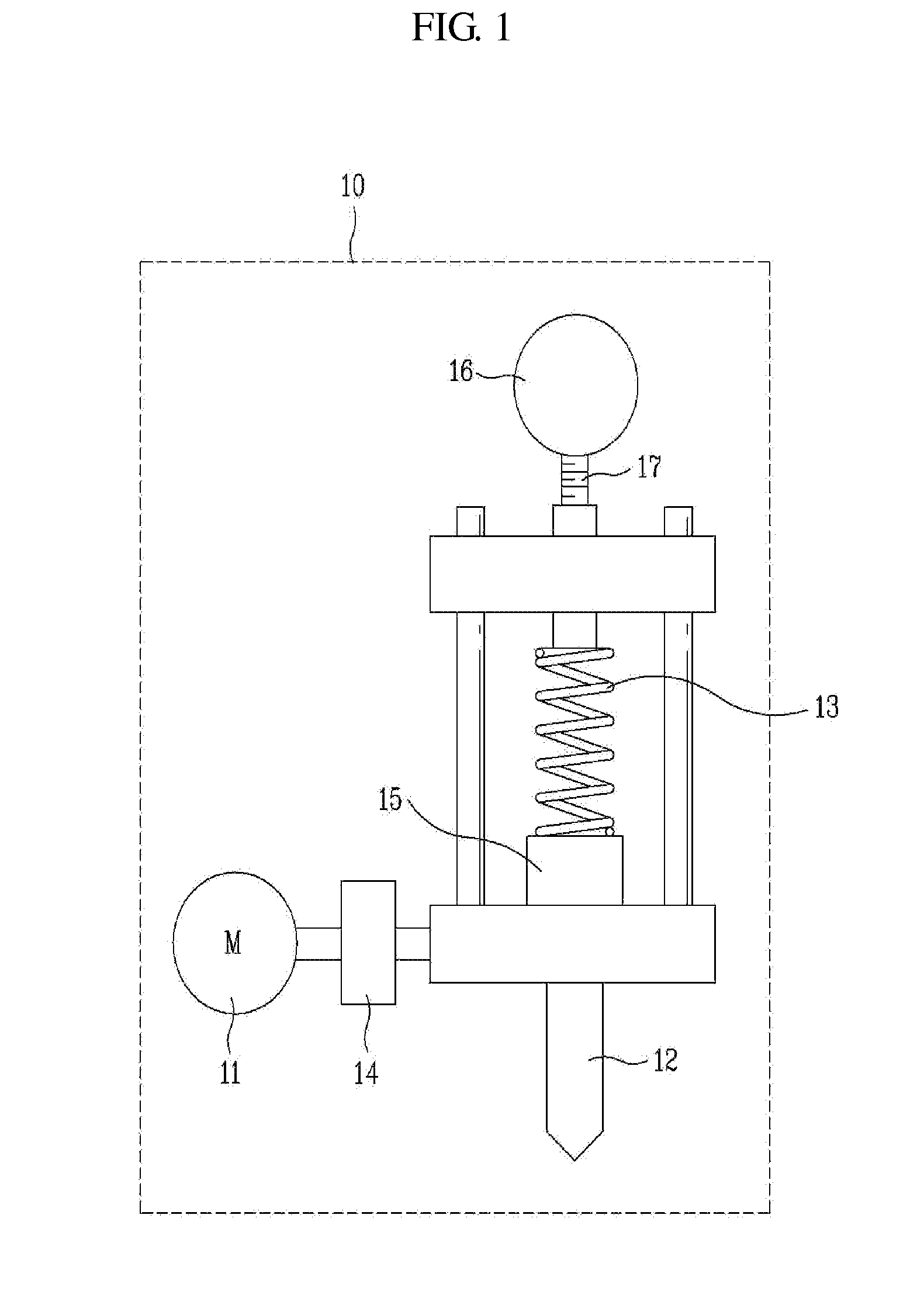

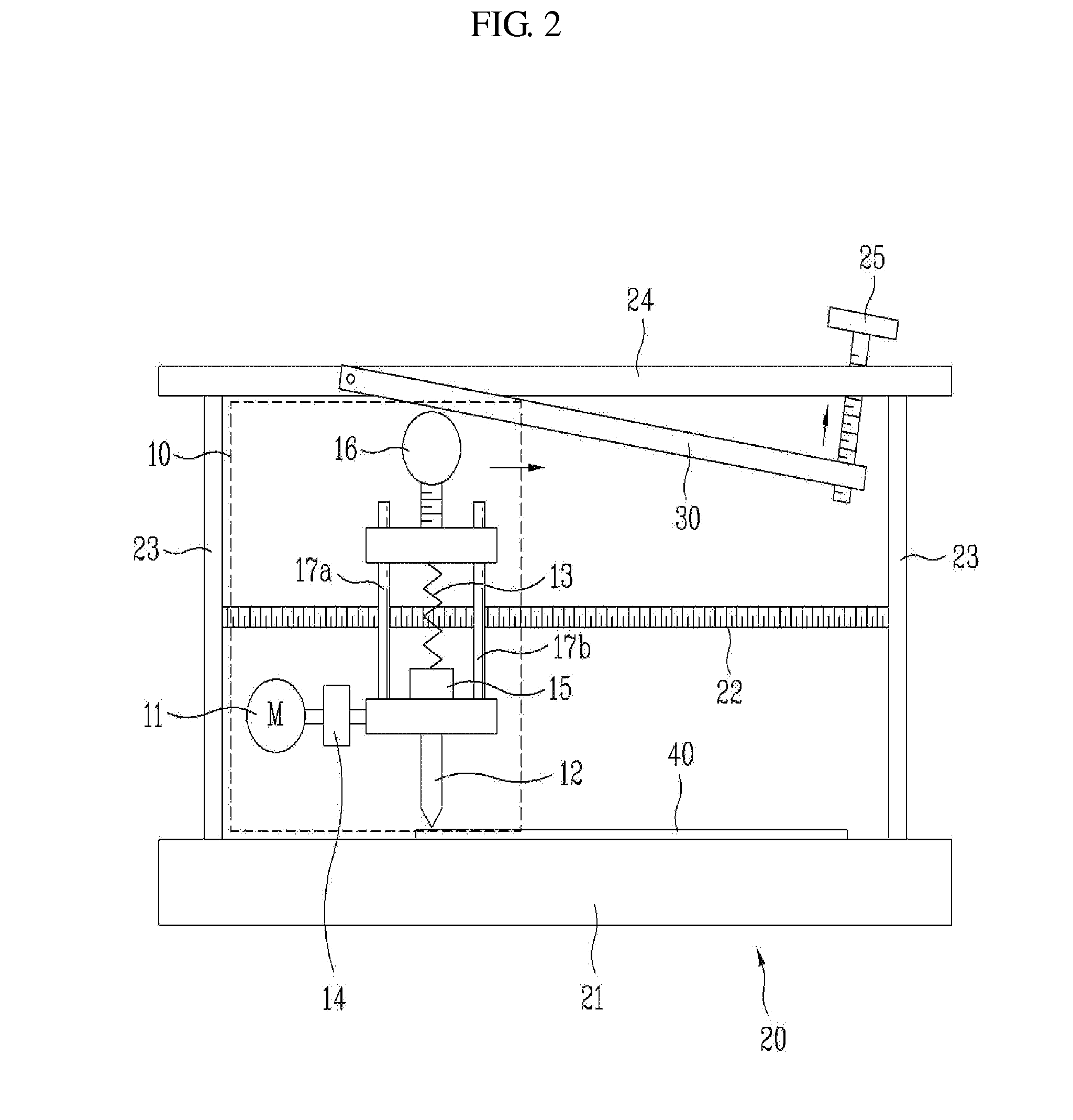

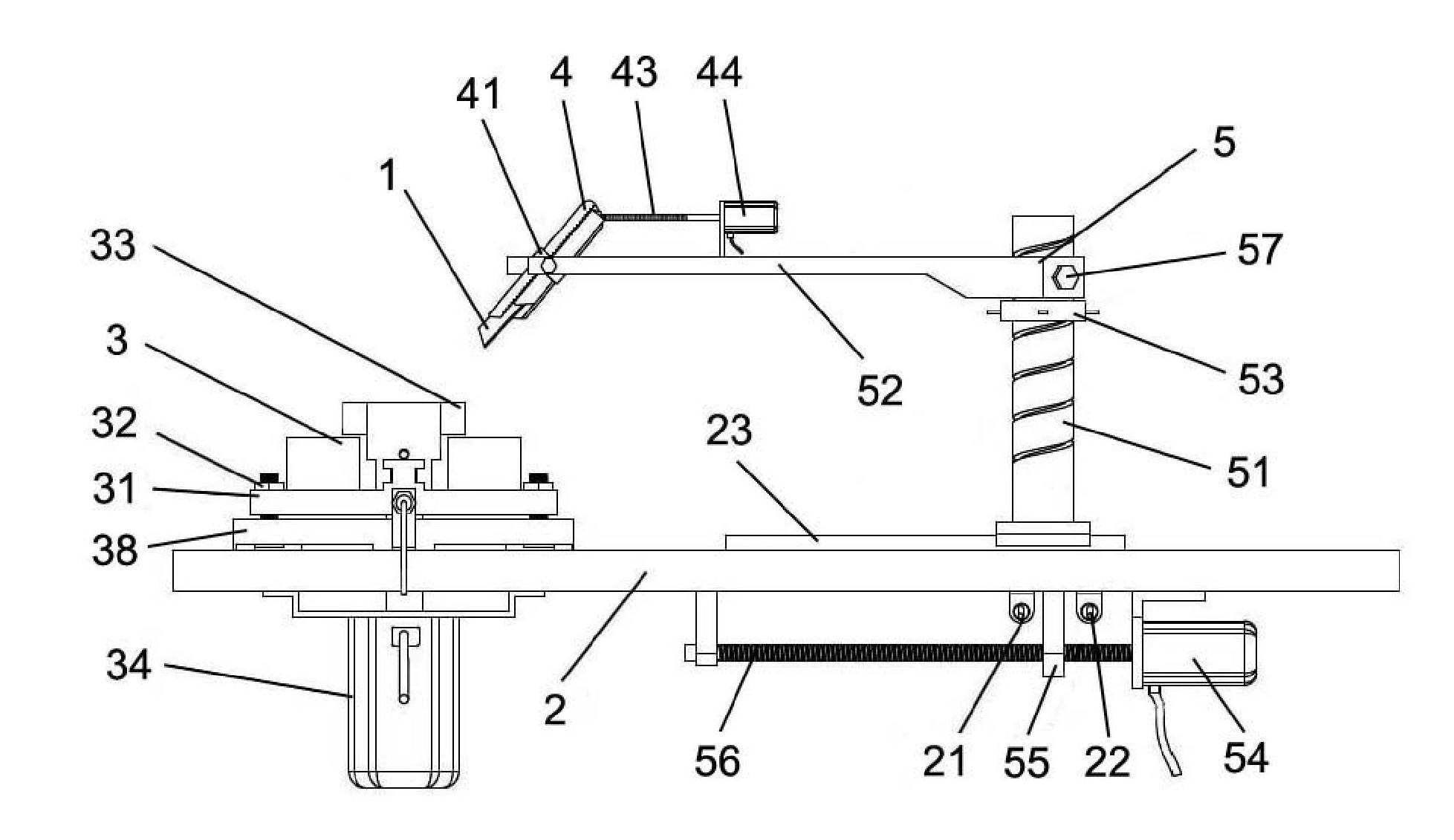

Scratch testing apparatus for performing scratching test while gradually increasing or decreasing load

ActiveUS20100206041A1Increase and decrease loadUsing mechanical meansInvestigating material hardnessEngineeringScratching

A scratch testing apparatus for performing a scratching test while gradually increasing or decreasing a load, in which a pressure applied to the surface of a test specimen gradually increases or decreases as a head unit, to which a tip is attached, moves horizontally. The scratching testing apparatus includes a head unit having a bottom to which a tip attached; a guiding unit for guiding the head unit to move horizontally; and a pressure changing unit for changing pressure applied to the tip while the head unit is moving along the guiding unit. Therefore, the scratch testing apparatus may perform a scratching test as gradually increasing or gradually decreasing a load applied to the test specimen by the tip by moving the head unit, to which the tip is attached, horizontally.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

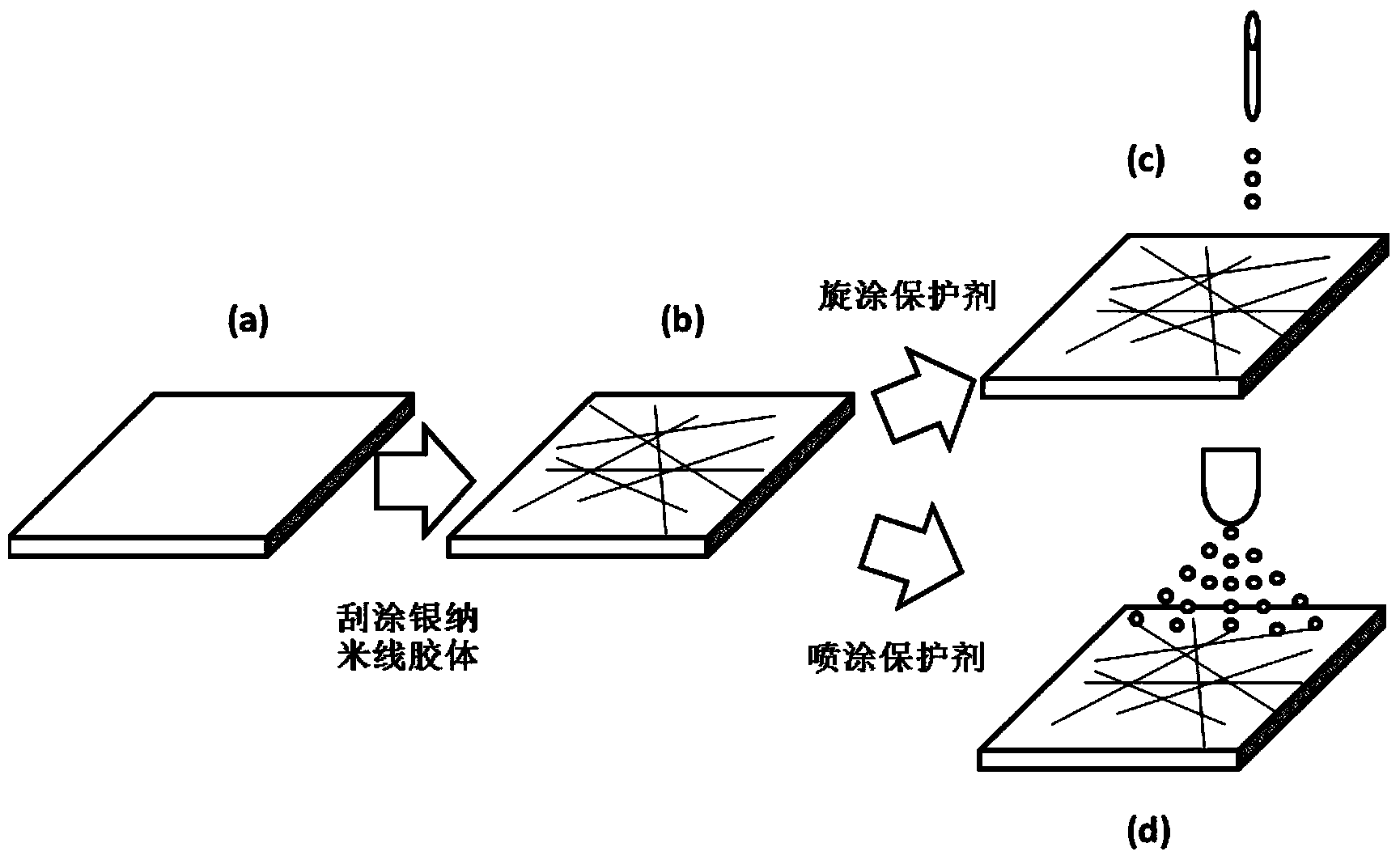

Preparation method for silver nano wire transparent conductive film capable of preventing corrosion of hydrogen sulfide gas

InactiveCN104112544AAvoid scratchesImprove conductivityCable/conductor manufactureHigh pressureHigh voltage

The invention discloses a preparation method for a silver nano wire transparent conductive film capable of preventing corrosion of a hydrogen sulfide gas. The method comprises: scratching or sparying a silver nano wire colloid on an appropriate substrate to obtain a low-conductivity silver nano wire transparent conductive film; then carrying out post treatment of high temperature, high voltage and the like to obtain a high-transparency high-conductivity silver nano wire transparent conductive substrate; and then preparing a protective agent solution, diluting the protective agent solution in a large proportion, according to the type and size of the substrate selected for the silver nano wire film, selecting an appropriate spraying instrument or a spin coating instrument, preparing a protective layer of a thin layer on the surface of the substrate film, and finally, solidifying the protective layer through natural drying, heating by use of a heating plate or blow-drying by use of a blower. The silver nano wire transparent conductive film prepared by use of the method provided by the invention can prevent corrosion of gases such as the hydrogen sulfide gas and the like, can prevent scratches and has good conductivity and transmittance through a 3M adhesive tape and a pencil scratch test. The operation is simple, the cost is low, and large scale production can be carried out.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

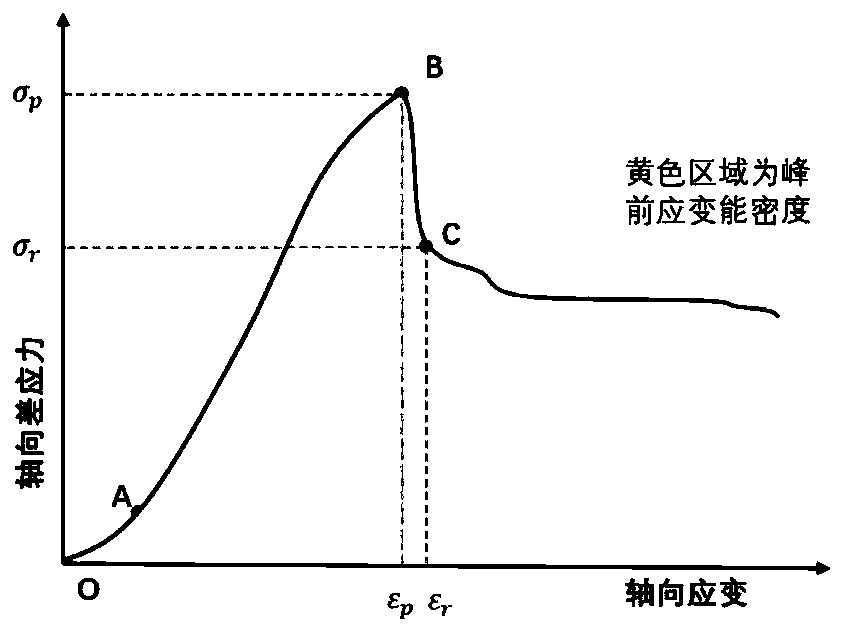

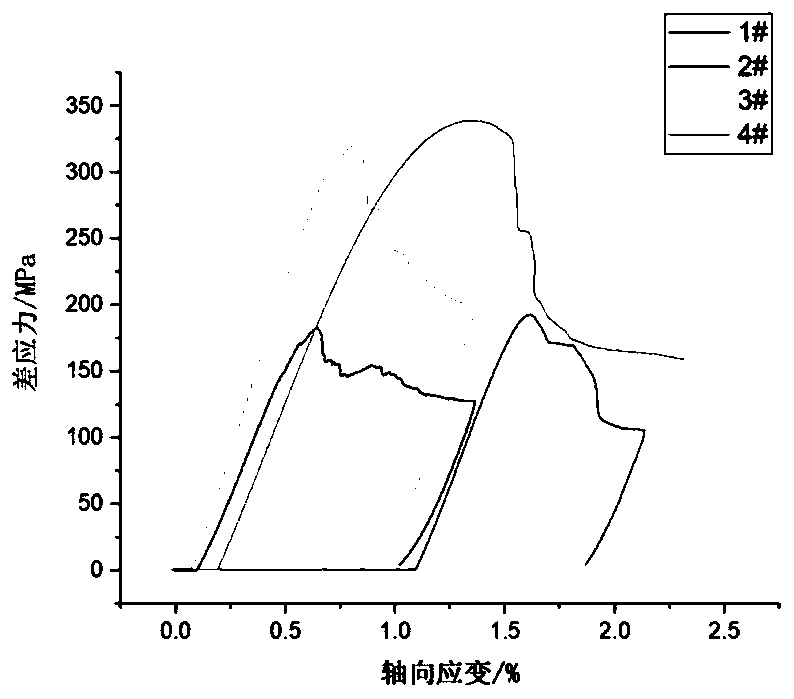

Rock brittleness evaluation method based on stress strain curve and scratch test

ActiveCN110006738AImprove accuracyStrong reliabilityMaterial strength using tensile/compressive forcesStress–strain curveStrain energy

The invention provides a rock brittleness evaluation method based on a stress strain curve and a scratch test. The method comprises the following steps that: evaluating rock from a crustal stress environment where the rock is positioned, and pore pressure, and obtaining the stratum condition of the rock; selecting a rock mechanical experiment of the environment where a rock sample to be tested ispositioned, wherein the experiment includes a conventional triaxial compression test or a triaxial compression test which considers pore pressure, and a scratch test; obtaining a pre-peak strain energy density value, a crack initiation stress value, a peak value stress value, a residual stress value as well as corresponding strain size and crack linear density; and determining the value range of an effective stress coefficient [Alpha] from the pore pressure of a tested rock sample, and substituting the pre-peak strain energy density value, the crack initiation stress value, the peak value stress value, the residual stress value as well as the corresponding strain size and crack linear density into a brittleness index calculation formula to obtain the brittleness index of the rock to be tested. By use of the brittleness evaluation method, the accuracy and the applicability of the rock brittleness evaluation can be improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

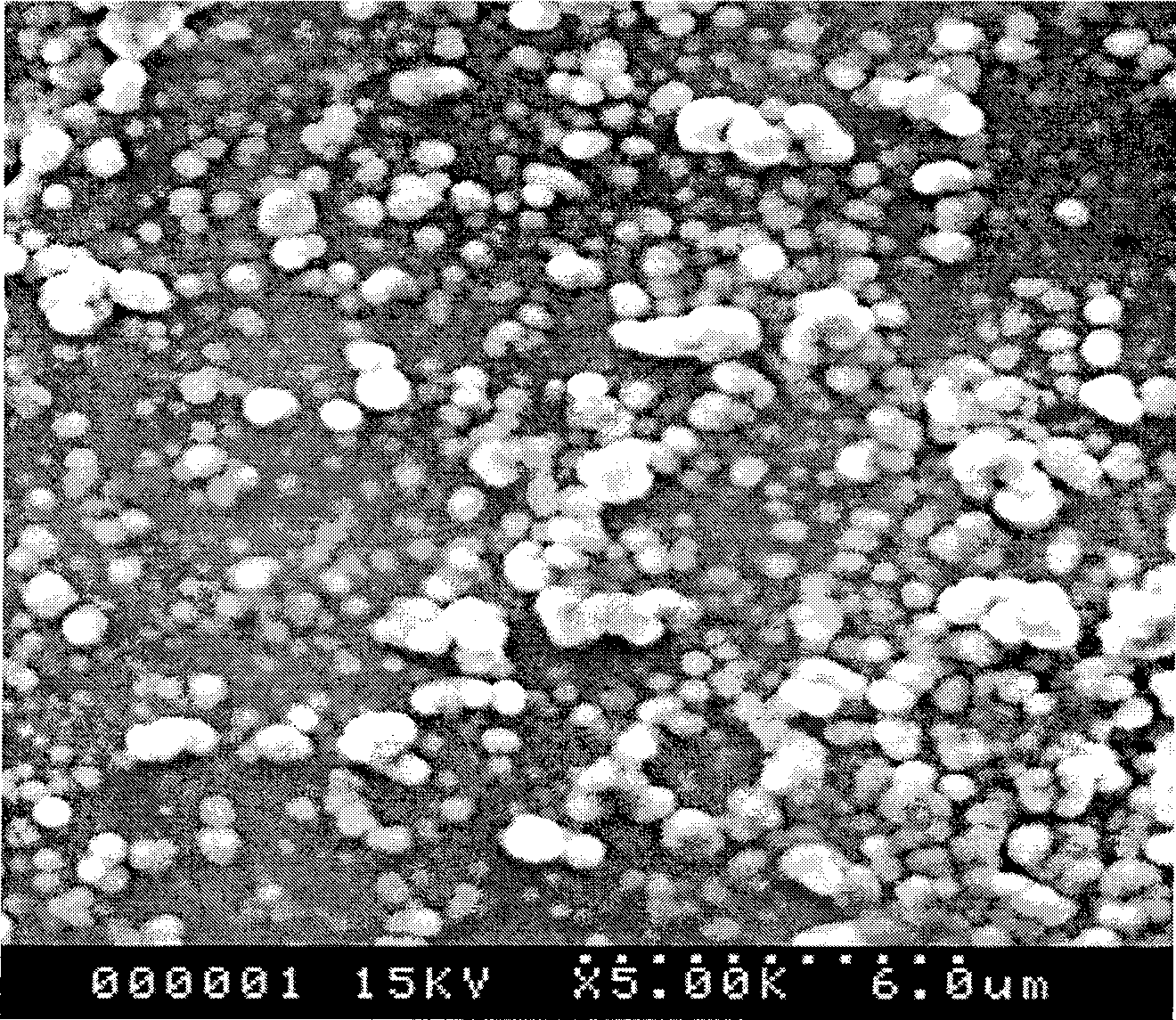

Technique used for ABS plastic substrate chemical plating pre-processing

InactiveCN101126156AThe composition of the process is simpleEasy to operateLiquid/solution decomposition chemical coatingChemical platingChemisorption

The invention relates to a new art applied in the chemical plating preprocess of ABS plastic body. With the biomacromolecule-chitosan (CTS) or the film forming performance of chitosan derivative and the chitosan-sorption to the target, the invention reduces and obtains the active site(Pd0) which can catalyze the chemical nickel plating at the body surface with chemical method; thus, the chemical sorption replaces the traditional physical sorption which is applied in the activation and sensitization of Pd / Sn colloid of chemical nickel plating preprocess of n-conducting body surface. The stabilization of the art is strengthened, the cost is reduced and the chrome and tin pollution to the environment in the traditional art are avoided; particularly, the chemical sorption replacing the physical sorption can increase the bonding force of the plating layer and body. The plating layer is evenly dense after the SEM detecting the shape of plating layer. And the heat vibration test and the scratch test show that the bonding force of the plating layer is great.

Owner:NANKAI UNIV

Device for testing nano scratch and friction stick-slip properties of film surfaces

InactiveCN103234848AMake up for limitationsMake up for being difficult to controlUsing mechanical meansInvestigating material hardnessHigh stiffnessSurface roughness

The invention discloses a device for testing the nano scratch and friction stick-slip properties of film surfaces. The device comprises a base, wherein the base is provided with a piezoelectric motion platform for holding test samples and a displacement platform capable of moving vertically and horizontally, the displacement platform is provided with a sensor holder, the front end of the sensor holder is fixedly provided with a nano scratch and stick-slip testing sensor, the scratching head of the nano scratch and stick-slip testing sensor is located right above the piezoelectric motion platform, and the base is also provided with an optical imaging system. According to the device disclosed by the invention, the motion platform and the sensor are organically combined, through different motion control modes, on the one hand, a nano scratch test on films can be completed, and therefore the defects that an AFM (Atomic Force Microscope) nano scratch device is limited in a loading range and difficult to control, and has high requirements on the surface roughness of samples are overcome; and on the other hand, the online test on the friction stick-slip properties of film surfaces can also be completed, therefore, the defect that a high-stiffness friction tester can not reflect the friction stick-slip properties of surfaces is overcome.

Owner:XI AN JIAOTONG UNIV

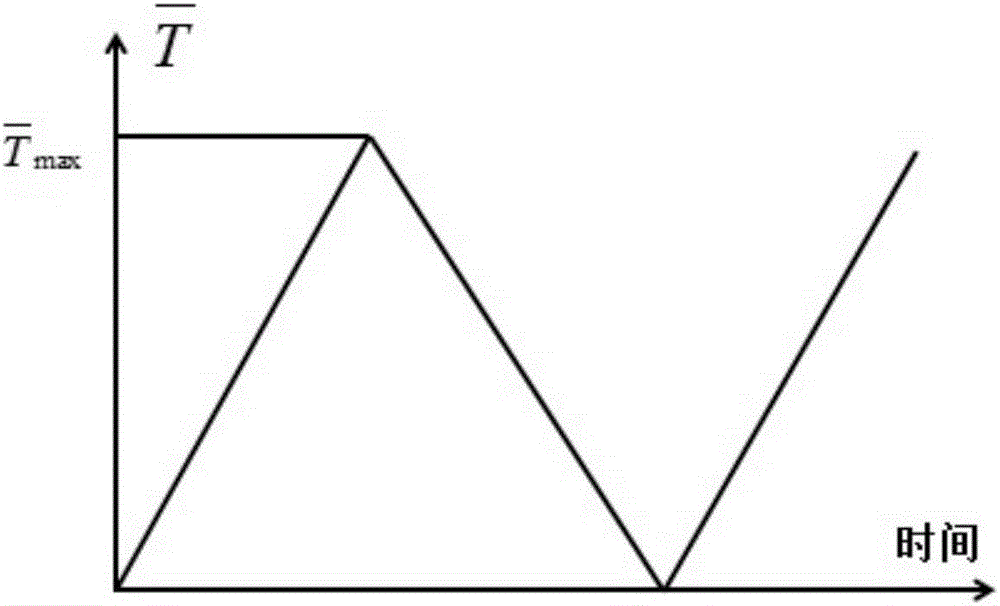

Test method for evaluating initial wear resistance of austenite high manganese steel under high impact load

The invention relates to a test method for evaluating the initial wear resistance of austenite high manganese steel under a high impact load. The test method comprises the following steps of: (1) performing a simple pendulum impact scratch test by using a simple pendulum scratch testing machine; (2) calculating energy E consumed in a scratch forming process; (3) calculating the volume V of a sample surface scratch; and (4) calculating specific dissipating energy e according to a formula e=E / V and judging the level of the initial wear resistance of the austenite high manganese steel under the high impact load according to the magnitude of the specific dissipating energy e under the same test parameter condition. The simple pendulum impact scratch test has a function of simulating the micro-plowing and micro-cutting of abrasive wear, and has the impact energy loading characteristic when a single abrasive particle scratches a material surface with a certain impact force and the working condition is similar to that of the austenite high manganese steel under the high impact load, so the specific dissipating energy e obtained under the simple pendulum impact scratch test can represent the initial wear resistance of the material under the high impact load.

Owner:DALIAN JIAOTONG UNIVERSITY

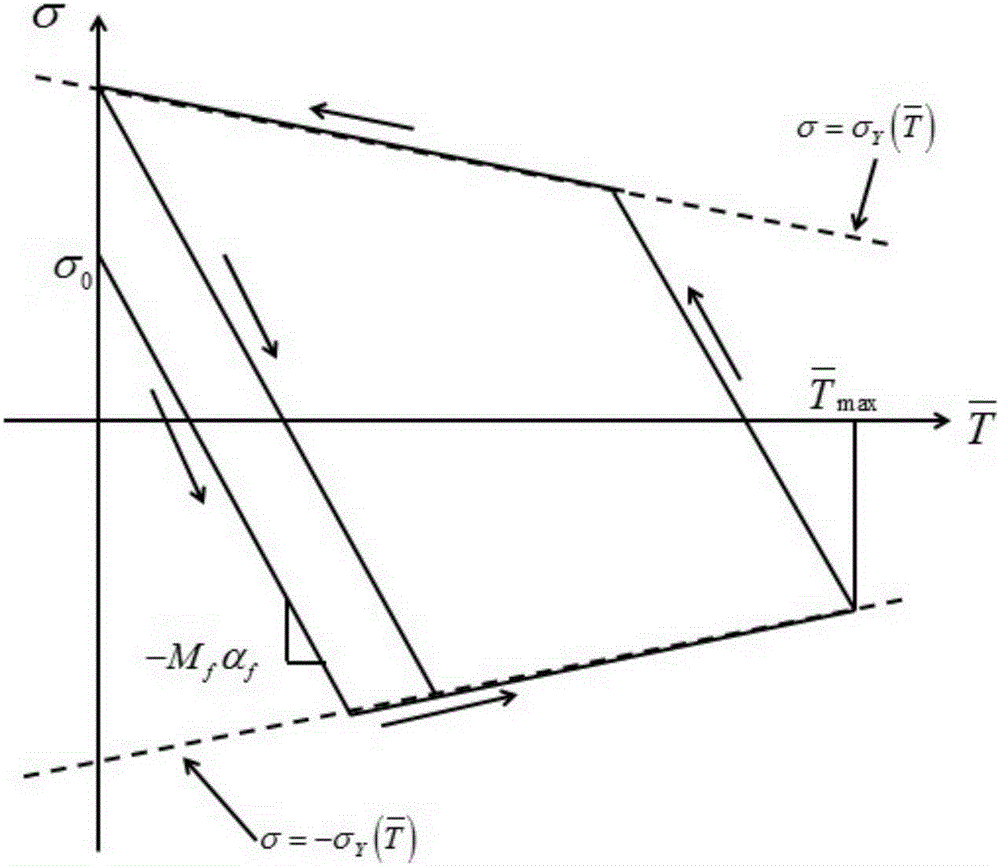

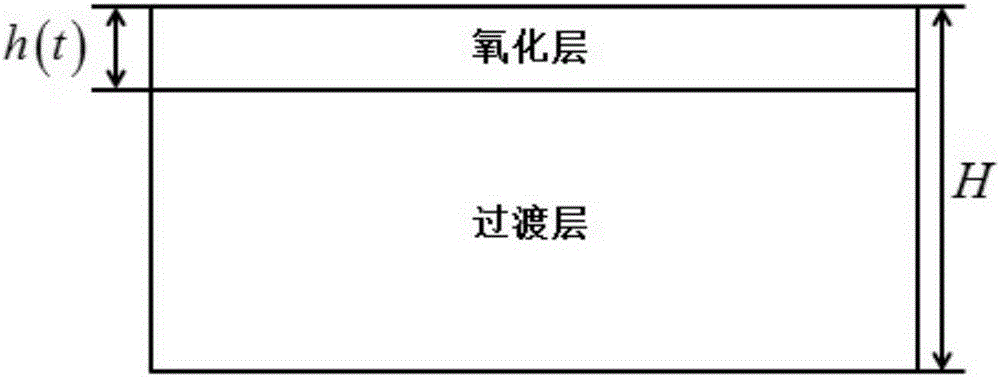

Coating service life prediction method based on stress and bonding strength evolvement mechanism

ActiveCN105223125AComprehensive life expectancyWeather/light/corrosion resistanceSpecial data processing applicationsPredictive methodsPhysical model

The invention provides a coating service life prediction method based on a stress and bonding strength evolvement mechanism and relates to a coating service life prediction method. The coating service life prediction method aims at solving the problem a comprehensive and objective coating service life prediction method is not disclosed at present. The coating service life prediction method comprises the steps that firstly, residual stress-time change relation and oxidation layer stress-time change relation are established, and a coating stress evolutionary physical model is established; secondly, a thermal-cycle sample aging acceleration test is performed, and the acceleration times of artificially accelerating sample aging are obtained according to the coating stress evolutionary physical model and sample stress value-time relation; thirdly, a scratch test instrument is adopted to test the bonding strength of the sample artificially accelerated in aging, the bonding strength-ageing time relation is fit and is drawn into a changing curve, the time corresponding to the intersection point of the changing curve and a timeline serves as the service life 1 of the sample artificially accelerated in aging, and L is equal to sample service life 1* final acceleration times k and serves as the predicted service life. The coating service life prediction method is applicable to the field of coating service life prediction.

Owner:HARBIN INST OF TECH

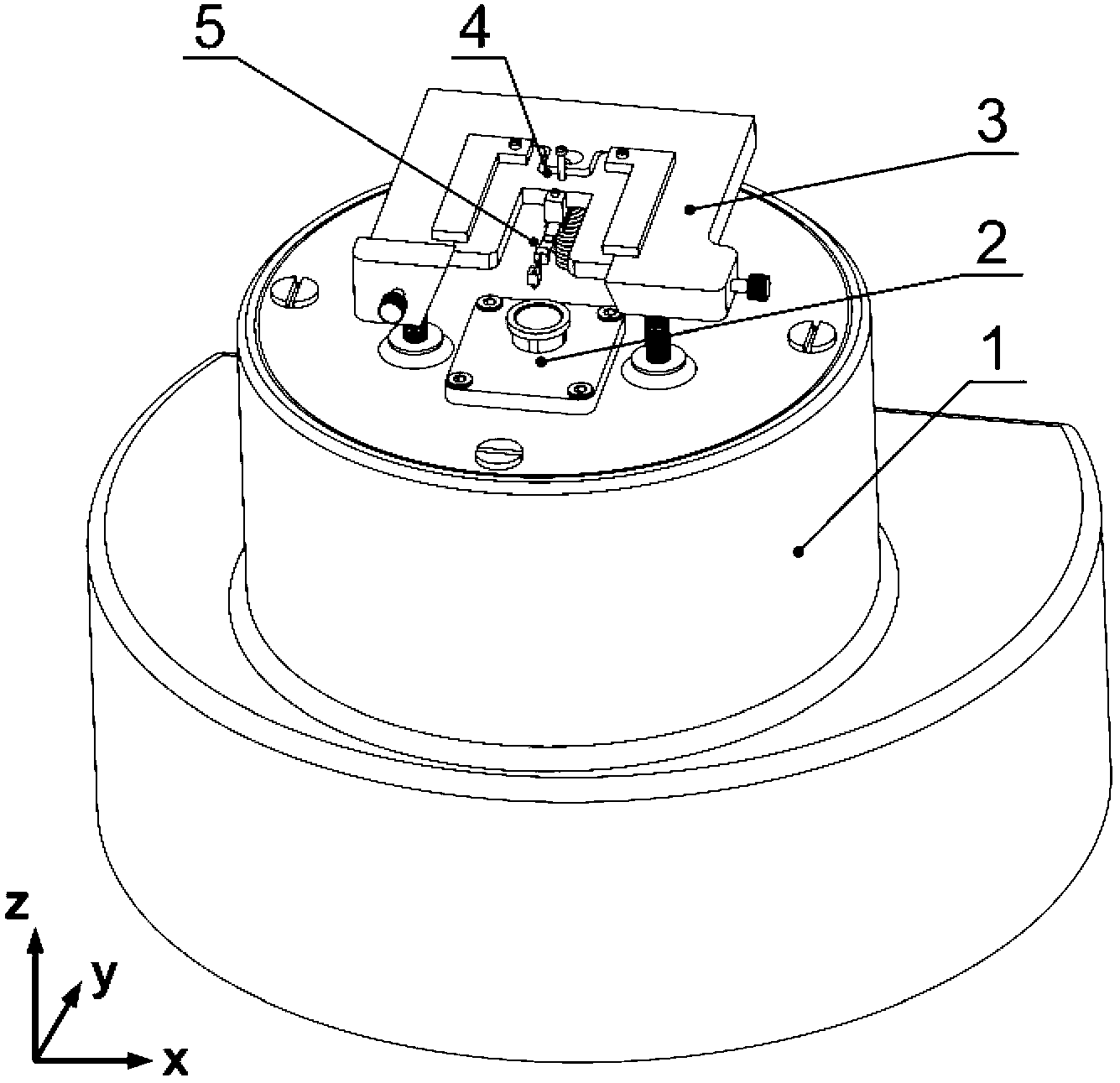

Nano cutting depth high-speed single-point scratch test device and test method thereof

ActiveCN107505248ARestore processing speedScratch at high speedIndividual particle analysisInvestigating material hardnessConvex structureEngineering

The invention discloses a nano cutting depth high-speed single-point scratch test device and a test method thereof. The device comprises a workbench, an air flotation rotary table, a test piece fixture, a test piece, a Z-direction feeding device, a nano motion platform, a force sensor and a scratch tool, wherein a micro convex structure with controllable length and height is machined in the to-be-scratched position of the test piece. The scratch speed is increased from mu m / s to m / s, and the machining speed of abrasive particles in the ultra-precise grinding process is restored really. Scratch force signals under different nano cutting depth conditions are accurately collected under the high-speed scratch condition, and the scratch force-scratch depth correspondence is explicit. The micro convex structure is constructed on the surface of the test piece, the condition that very long scratches are left on the surface of the whole wafer by a diamond needle point is avoided, abundant test data are provided in shorter scratches, the content of effective information in the unit scratch length is greatly increased, following scratch analysis and feature identification of remaining scratches are facilitated, and the integrity of the scratch tool is guaranteed.

Owner:DALIAN UNIV OF TECH

Special scratch-resistant talcum powder for polypropylene and preparation method thereof

ActiveCN102127261ALow oil absorptionHigh oil absorption valuePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsCouplingBiological activation

The invention relates totalcum powder and preparation method thereof, in particular to special scratch-resistant talcum powder for polypropylene and a preparation method thereof. The talcum powder comprises the following components in parts by weight: 0.1-0.5 part of titanate coupling agent, 0.1-0.5 part of silane coupling agent, 97-99 parts of superfine talcum powder and 0.1-0.5 part of high molecular weight siloxane copolymer. The invention has the following advantages and effects: the activation rate of the talcum powder provided by the invention is more than 99.0%, the oil adsorption value is less than 1.5mL / 100g, the product purity is high and the particle size is 1-50mu m. Through the inspections of the professional inspection institution, the scratch resistance of the polypropylene car bumper special material prepared from the talcum powder which is provided the invention satisfies the grade A of the multi-finger scratch test and the Delta L in the Erichsen cross test is less than 1.5.

Owner:LIAONING JINGHUA NEW MATERIAL CO LTD

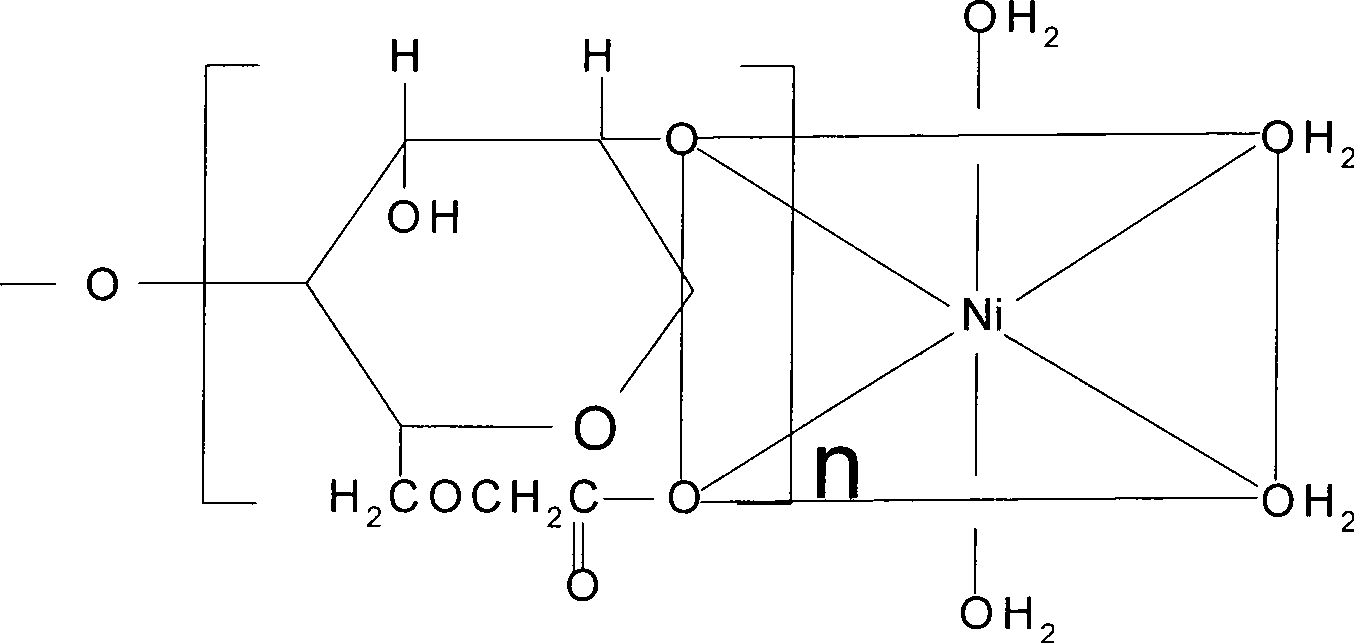

Palladium-free activation process for plastic substrate surface of nickel adsorbed sodium carboxymethylcellulose by chelating function

InactiveCN101381865AWide variety of sourcesLow priceLiquid/solution decomposition chemical coatingScanning electron microscopeBiological activation

The invention provides a method for non-precious metal Pd-free plastic matrix surface activation using sodium carboxymethyl cellulose to chelae and absorb nickel, which comprises the processing steps of pretreatment of the surface of the plastic matrix to be plated, preparation of an activating and film forming liquid, treatment of activation and film forming, treatment of reduction, and chemical nickel plating; and a metal organic complex solution consisting of divalent ion water soluble salt containing nickel uses a strong reducing agent to directly reduce the active metal-nickel and deposit on the matrix, then the chemical nickel plating is carried out. The result of the configuration of a nickel plating layer by a scanning electron microscope and a metaloscope shows that the plating layer is combined compactly, and particles are evenly distributed; and scratch tests show that the bonding force of the plating layer is good. The method has simple process, convenient operation, wide sources and low price of sodium carboxymethyl cellulose used, low cost and reduced precious metal pollution due to replacement of expensive Pd by nickel, can be suitable for most of plastics due to low activation temperature, and has high practical value and application prospect.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

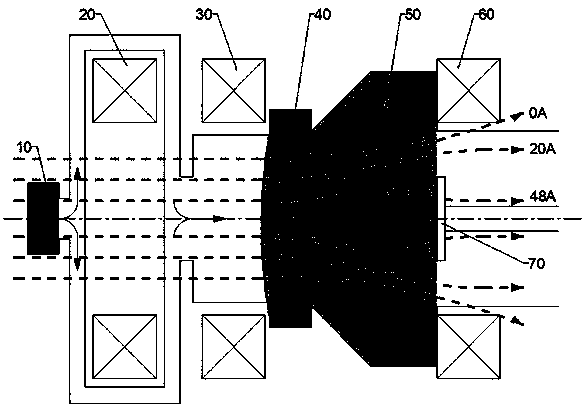

Method for controlling growth of graphene nanocrystalline carbon film by adjusting irradiation density of ECR ions

ActiveCN110396661AImprove mechanical propertiesImprove featuresVacuum evaporation coatingSputtering coatingCarbon filmMaterials science

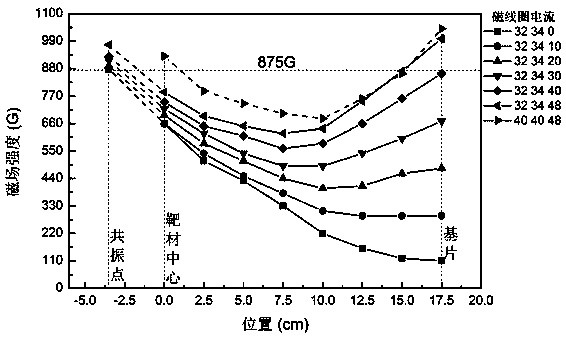

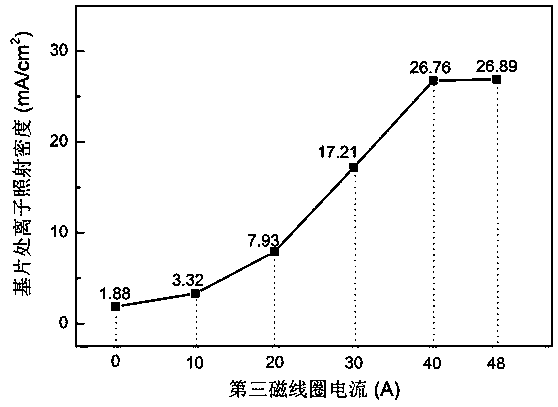

The invention provides a method for controlling the growth of graphene nanocrystalline carbon film by adjusting the irradiation density of ECR ions. According to the method, an ECR plasma sputtering system is utilized, the current of a third magnetic coil is adjusted to be changed within the range of 0-48A, argon ions are restrained by adopting a transition magnetic field mode, and a certain working pressure and microwave power are combined, so that the ion irradiation density in the preparation process of the carbon film is further changed. Nano-indentation and nano-scratching tests are carried out on the carbon films prepared under different ion irradiation densities, and when the current of the third magnetic coil varied from 0 A to 48 A, the ion irradiation density can vary from 1.88 mA / cm<2> to 26.89 mA / cm<2>, therefore, the graphene nanocystalline carbon film influenced by the ion irradiation densities within the range has the average size of the graphene nanocystalline from 0.66nm to 1.19 nm, the hardness from 6.45 GPa to 14.53 GPa, the elastic modulus from 116.30 GPa to 179.28 GPa, the friction coefficient from 0.07 to 0.38, and the scratch depth from 2.78 nm to 6.36 nm, and and has better mechanical and tribological properties.

Owner:SHENZHEN UNIV

PMMA/ASA alloy material with high heat resistance and high black brightness and preparation method and application of PMMA/ASA alloy material

ActiveCN111690222AImprove scratch resistanceNo decrease in surface glossRadiatorsAcrylonitrilePolymethyl methacrylate

The invention discloses a PMMA / ASA alloy material with high heat resistance and high black brightness and a preparation method and application thereof. The PMMA / ASA alloy material is prepared from thefollowing components in parts by weight: polymethyl methacrylate (PMMA) resin, acrylonitrile-styrene-acrylate copolymer (ASA rubber powder), a heat-resisting agent, an antioxidant, a light stabilizer, an anti-scraping agent and a coloring agent. According to the PMMA / ASA alloy material prepared through the method, HDT can reach 95 DEG C or above and is improved by 20 DEG C or above compared withmature materials on the market, the surface gloss is basically not reduced, the blackness L value is 22.5, and the effect of piano black can be achieved. Meanwhile, the scratch resistance is also obviously improved, and a five-finger scratch test and a surface wear resistance test can be passed.

Owner:DONGGUAN HONOUR E P

Scratch-resistant polyamide composition and preparation method thereof

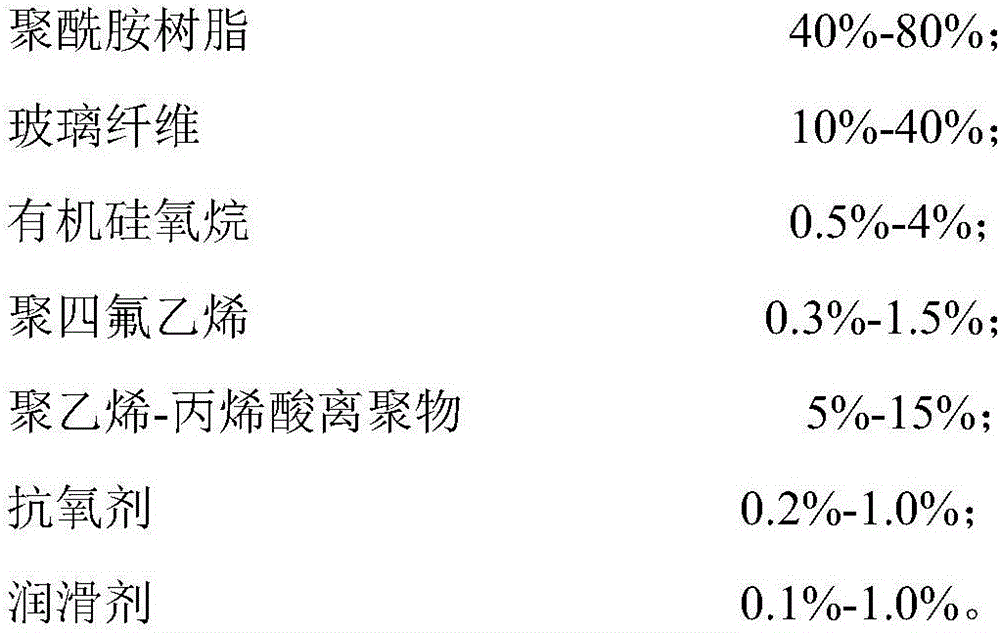

The invention discloses a scratch-resistant polyamide composition and a preparation method thereof. The scratch-resistant polyamide composition is prepared from the following raw materials in percentage by mass: 40-80% of a polyamide resin, 10-40% of a glass fiber, 0.5-4% of organo-siloxane, 0.3-1.5% of polytetrafluoroethylene, 5-15% of a polyethylene-crylic acid ionomer, 0.2-1.0% of an antioxidant and 0.1-1.0% of a lubricant. The invention further discloses a preparation method of the scratch-resistant polyamide composition. The scratch-resistant polyamide composition disclosed by the invention is good in scraping resistance, mechanical property and coloring property, no conspicuous scratch marks are caused in five-finger scratch tests, and components and elements made of the composition are not easily scratched in long-term use.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

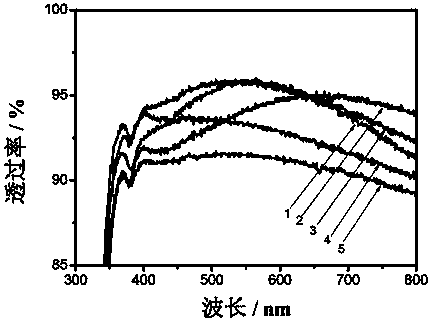

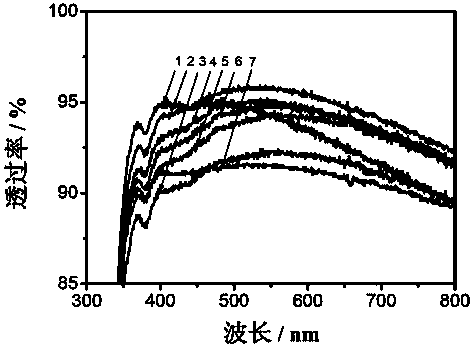

Super-hydrophilic antireflection coating preparation method and super-hydrophilic antireflection coating

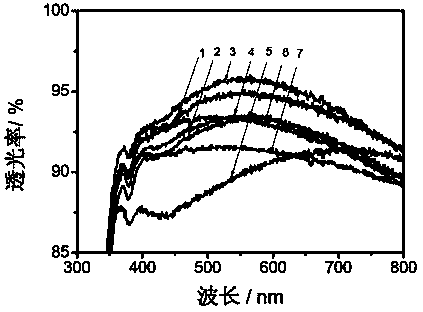

The present invention relates to a high strength super-hydrophilic antireflection coating preparation method and a high strength super-hydrophilic antireflection coating prepared through the method. According to the present invention, an acid catalysis sol-gel (sol-gel) method is adopted to prepare the high strength super-hydrophilic antireflection coating, wherein the super-hydrophilic antireflection coating integrates advantages of low reflectivity, high light transmittance, good hydrophilicity and the like of silica films; a SiO2 solid sphere type nanoparticle layer forms the rough structure of the coating surface, and the coating has characteristics of antireflection and super-hydrophilicity, wherein the particle size of the SiO2 solid sphere type nanoparticle is 3-4 nm; and the glass plate coated with the high strength super-hydrophilic antireflection coating can bear the 6H pencil scratch test, light transmittance of the glass plate coated with the high strength super-hydrophilic antireflection coating can be increased to 95.9% from 91.6%, and a contact angle of water on the surface of glass coated with the coating is 0 DEG.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

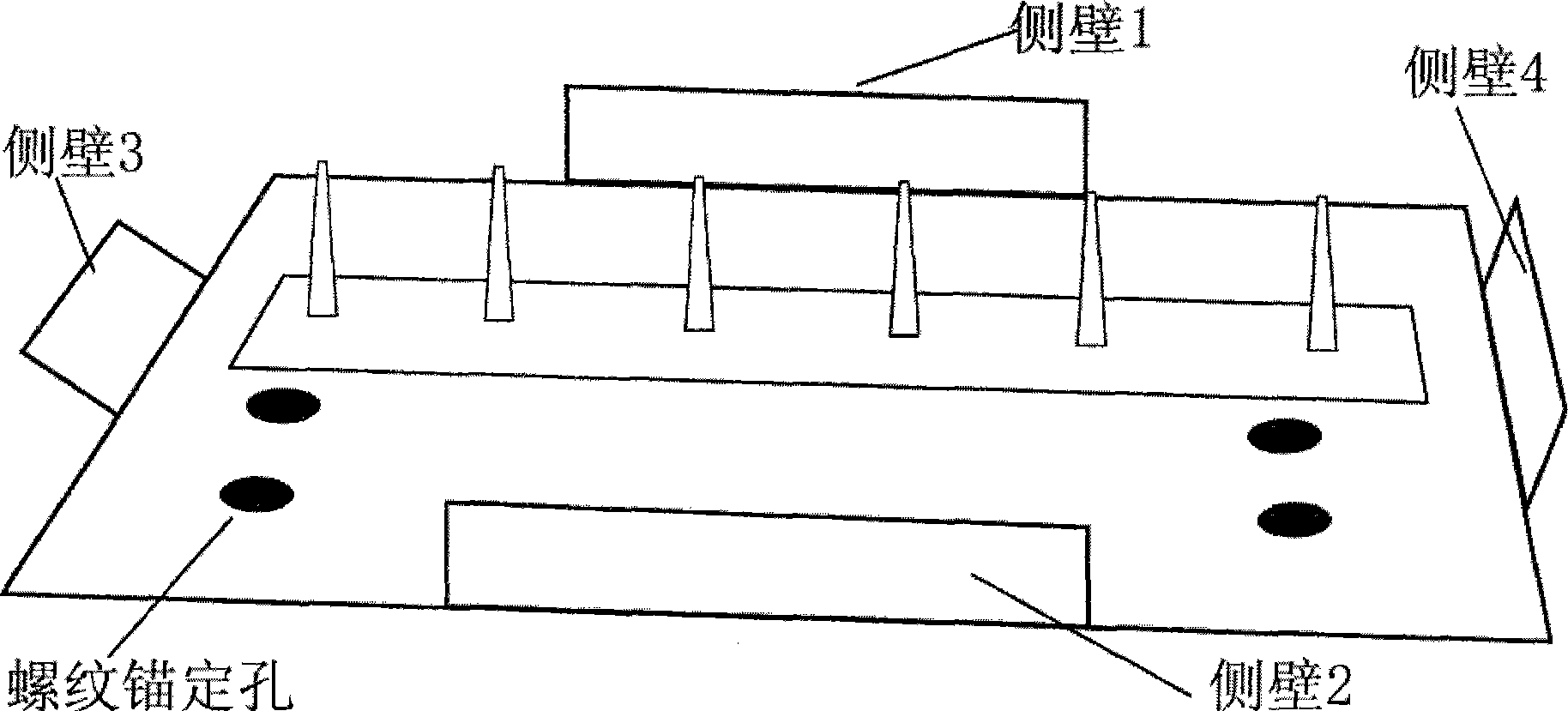

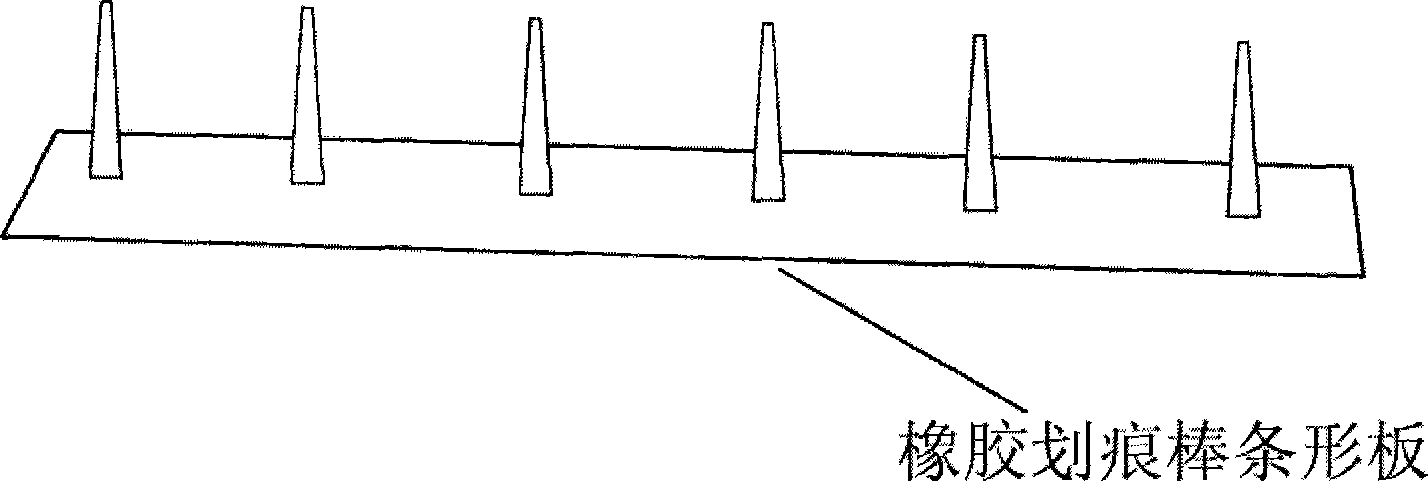

Scuffing experimental device for cell migration research and high throughput medicament sifting motion

InactiveCN101508954AReduce mistakesReliable resultsBioreactor/fermenter combinationsBiological substance pretreatmentsHigh-Throughput Screening MethodsAlcohol

The invention relates to a simple and rapid scratching test device, which is applicable to the cell migration research and the high throughput drug screening taking the cell migration as a target spot. The scratching test device is provided with a demountable rubber scratching head, takes a cell culture plate containing a plurality of pores (6, 12, 24, 96, 384 pore plates and the like) as an experimental object, can be precisely sheathed on the cell culture plate and only needs to be lightly pushed to generate the neat and uniform scratch and the scratching position is fixed, thus being convenient for taking pictures and subsequent statistical analysis. The scratching test device is also applicable to an automation working platform of a high throughput screening system and used for rapid screening the medicine taking the cell migration as the target spot. In addition, the scratching test device can be repeatedly used and the rubber scratching head has the demountable function and can be used after being sprayed by alcohol and irradiated by ultraviolet. The invention provides a simple and rapid method for the scratching test, which has great market prospect.

Owner:NANKAI UNIV

Coatings, methods for producing the same, and the use thereof

Transparent coatings with a thickness of at least 30 μm, a relative elastic resilience to DIN 55676 of at least 70%, and a scratch resistance corresponding to a score of not more than 2 in the steel wool scratch test to DIN 1041 after 10 double strokes; process for producing them, and their use.

Owner:BASF COATINGS GMBH

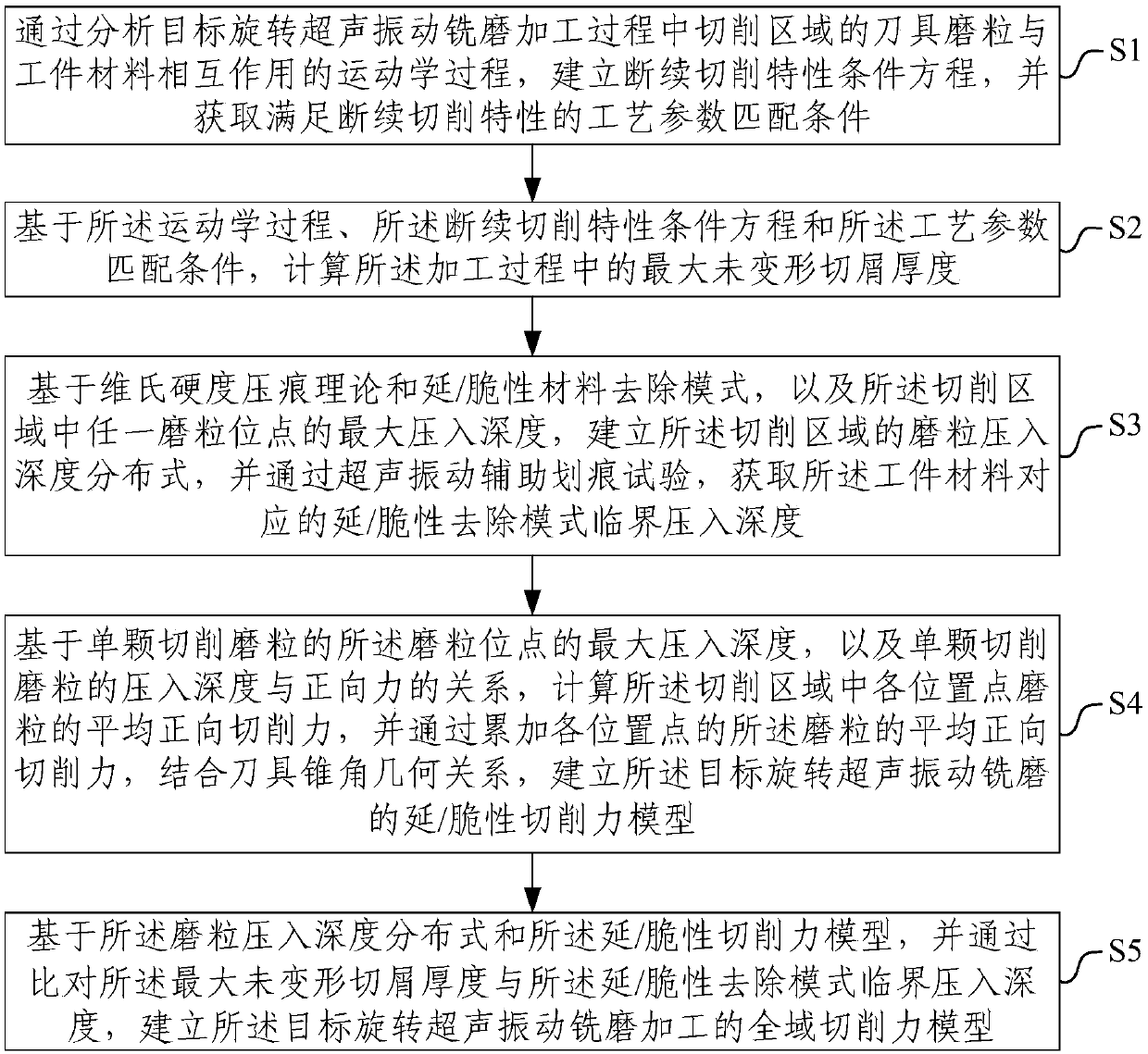

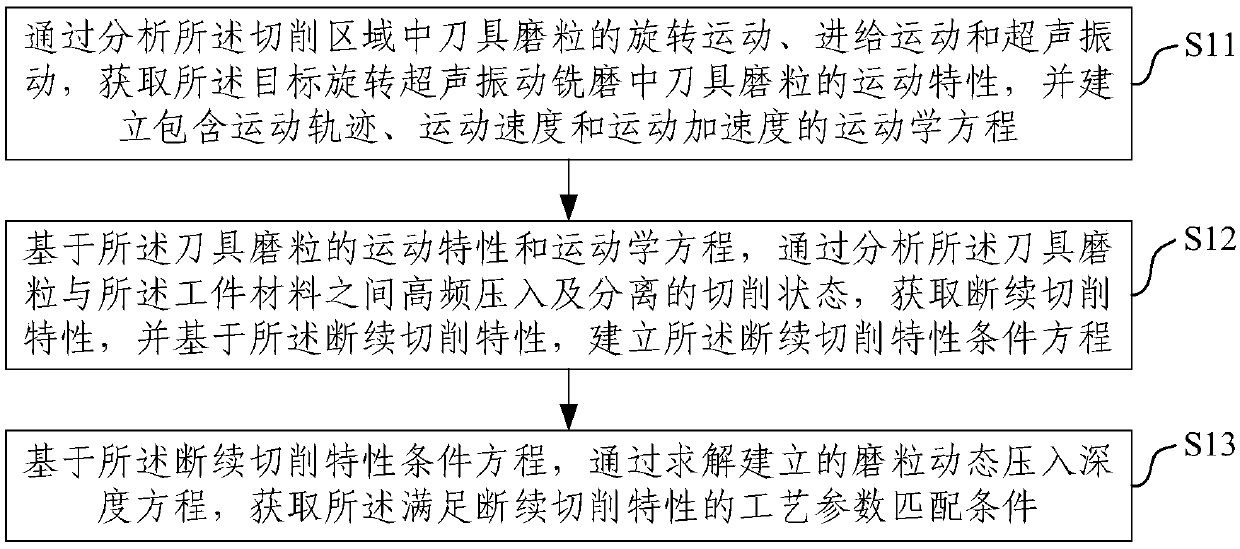

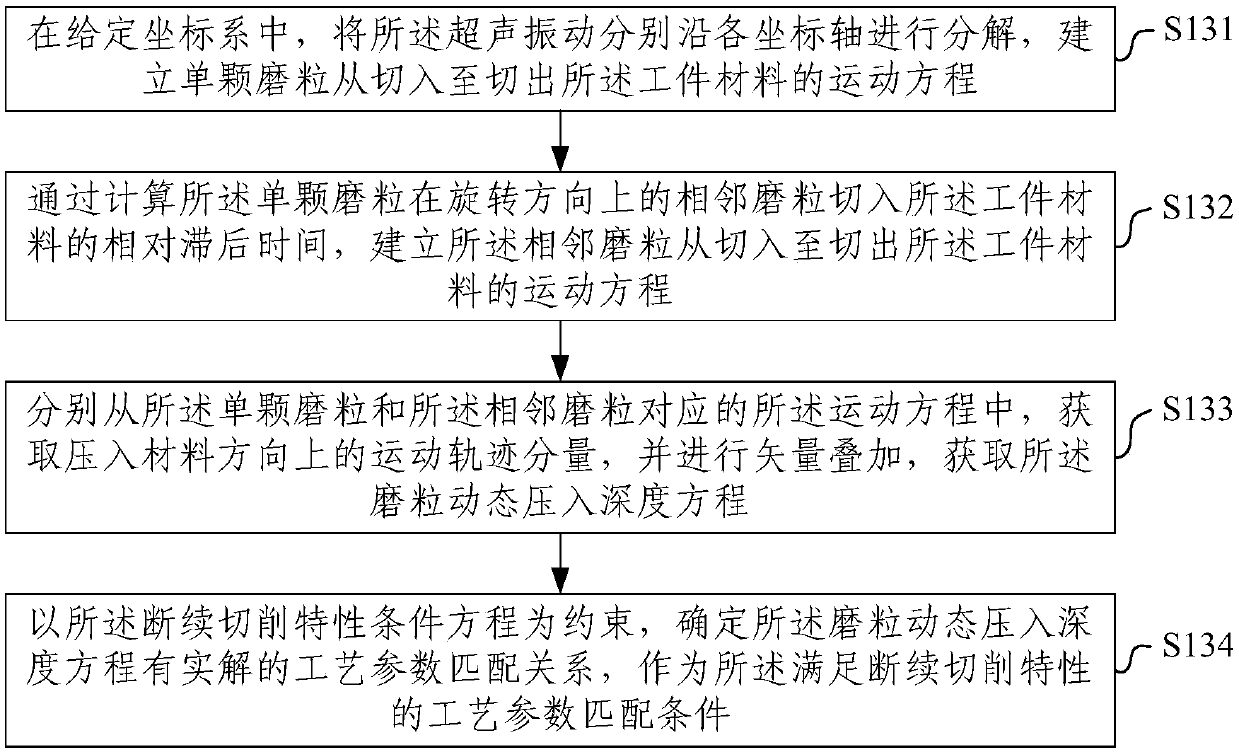

Method and device of full-domain cutting force modeling in rotary ultrasonic vibration milling

The invention provides a method and a device of full-domain cutting force model in rotary ultrasonic vibration milling. By carrying out the kinematics analysis between a tool abrasive grain and a workpiece material interaction in the machining process, a technology parameter matching relation meeting the vibration separation of a cutting area is obtained, and a condition equation of an intermittent cutting characteristic is established; and according to an ultrasonic vibration auxiliary scratch test, critical press-in depth of ductility or brittleness removal mode changing of a material is obtained, the abrasive particle press-in depth distribution relation of the cutting area is established, the abrasive grain loads of different positions of the cutting area are accumulated, and ductilityor brittleness cutting force model is obtained correspondingly, the models are fused according to the critical press-in depth and the maximum cutting thickness, and the rotary ultrasonic vibration machining whole-domain cutting force model is obtained. According to the device, the rotary ultrasonic vibration machining characteristic and a removing mechanism can be more comprehensively reflected,so that the cutting force prediction and the technology optimization of the actual machining can be effectively guided.

Owner:BEIHANG UNIV

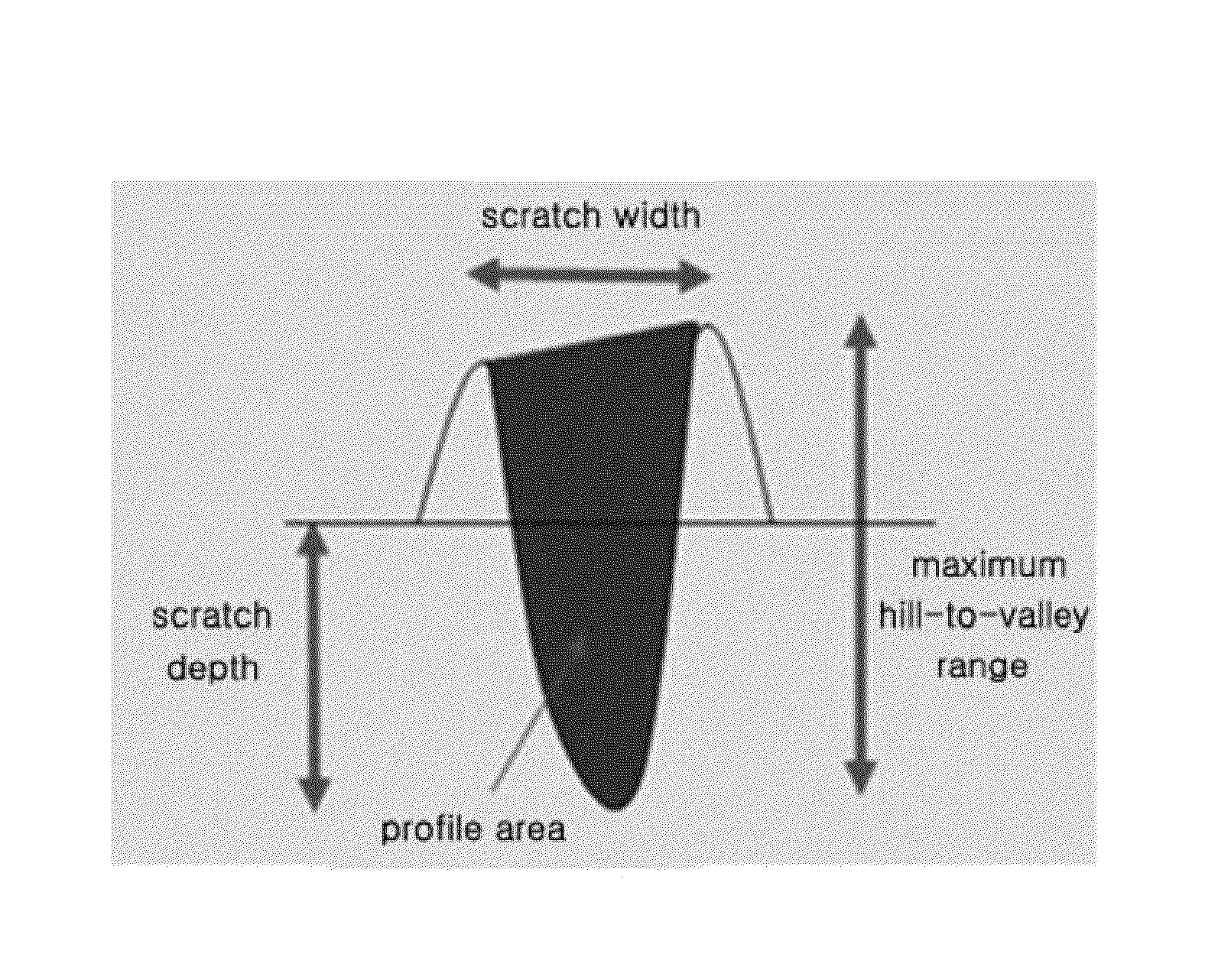

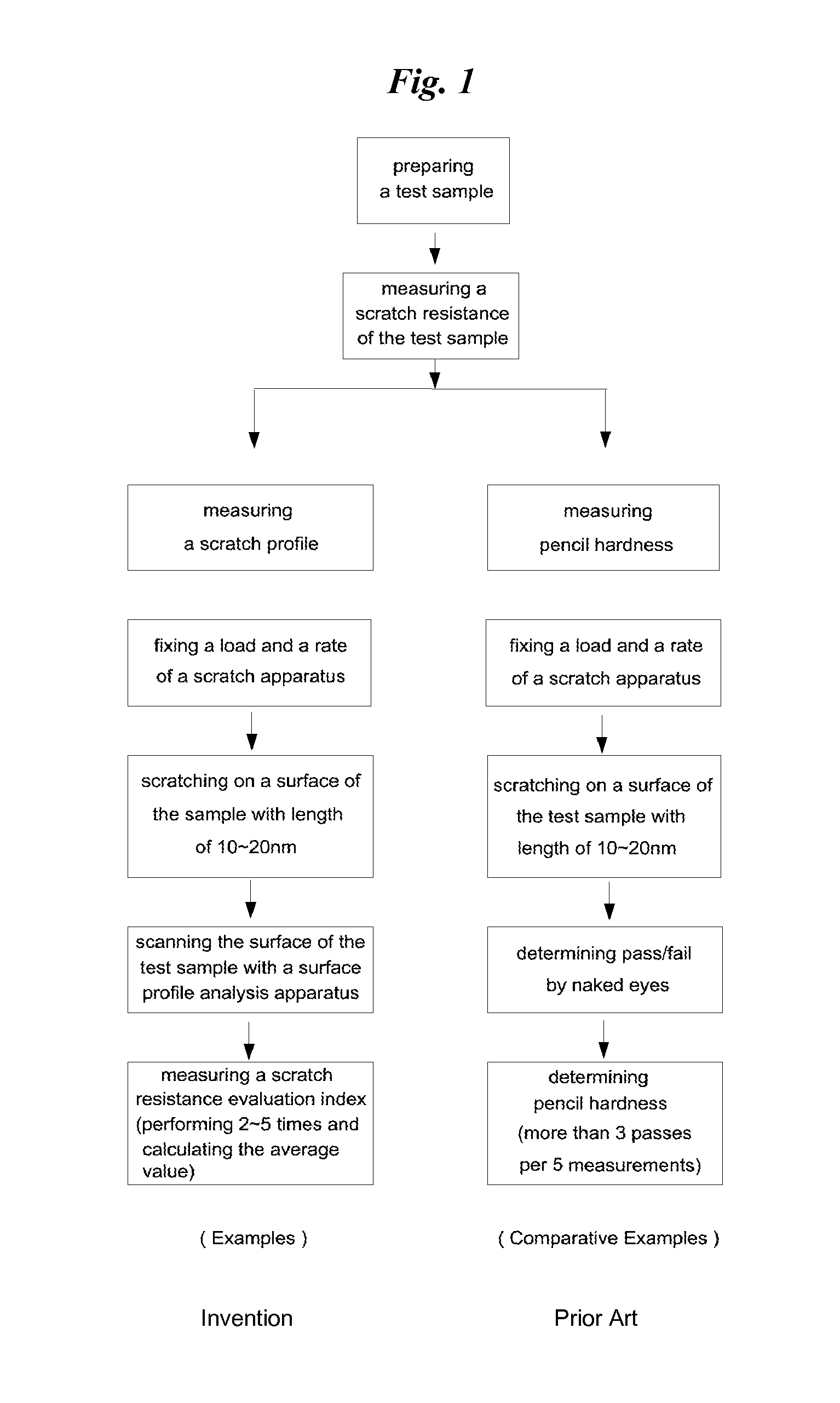

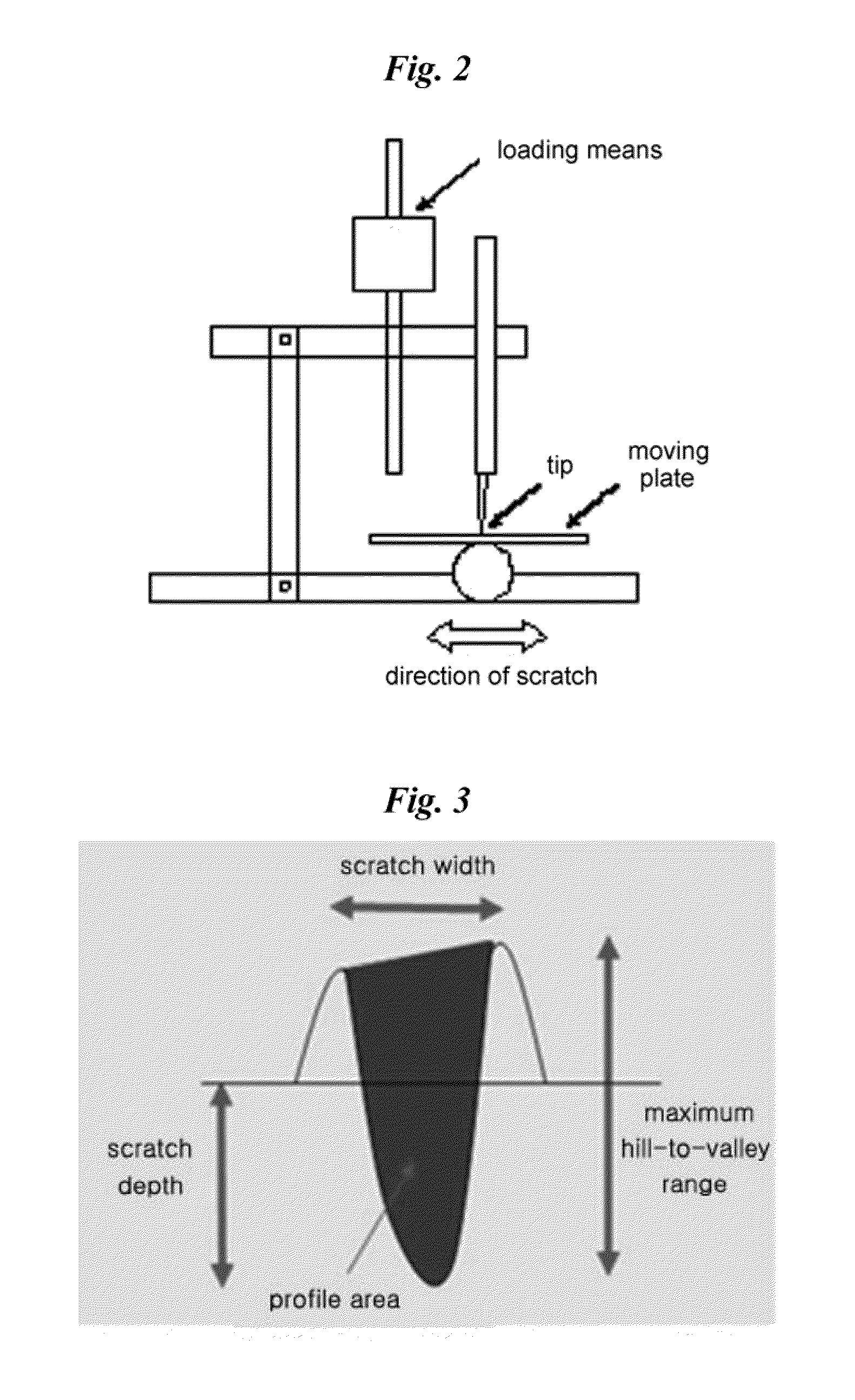

Method for Evaluating Scratch Resistance of Plastic Resins

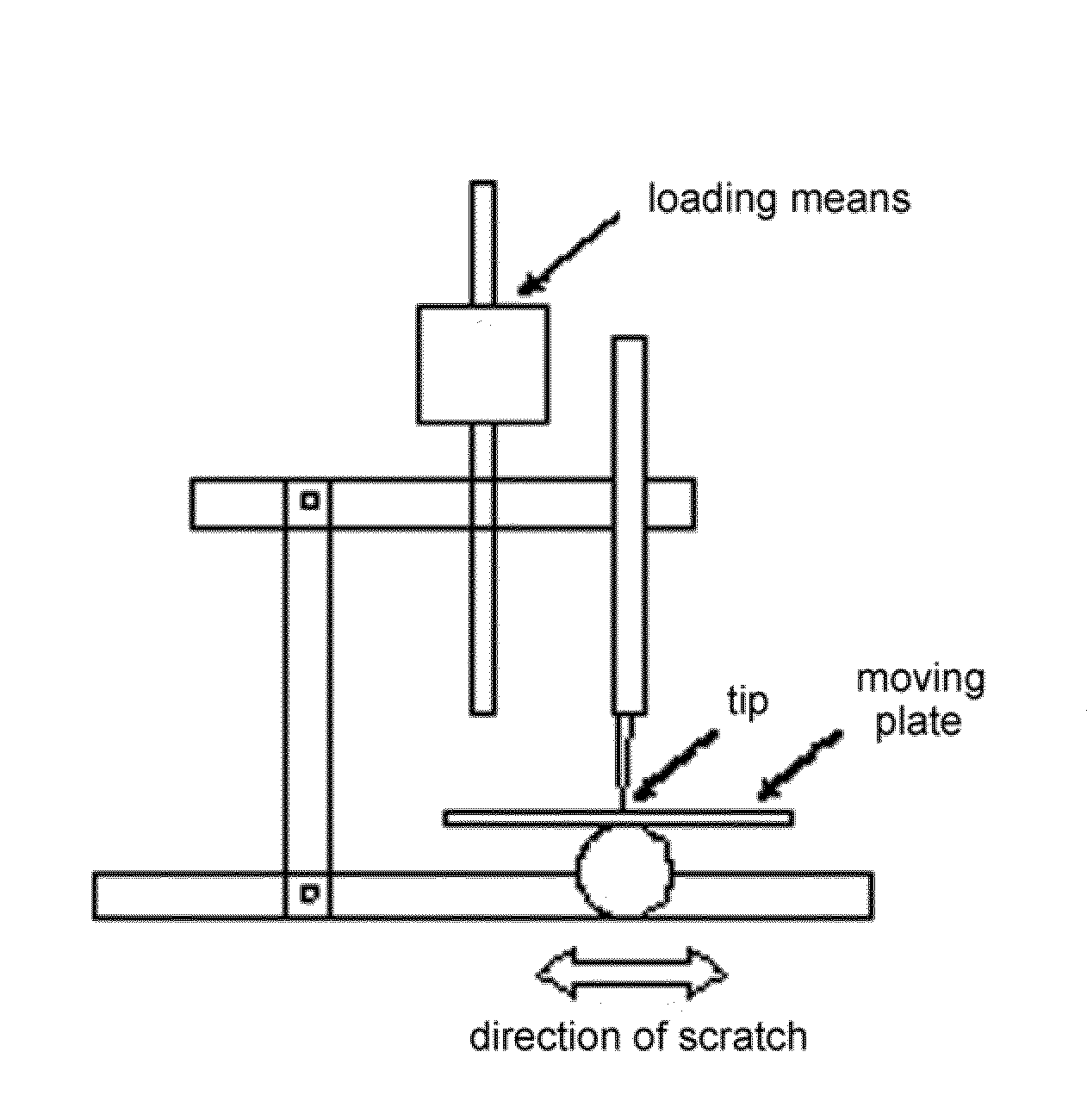

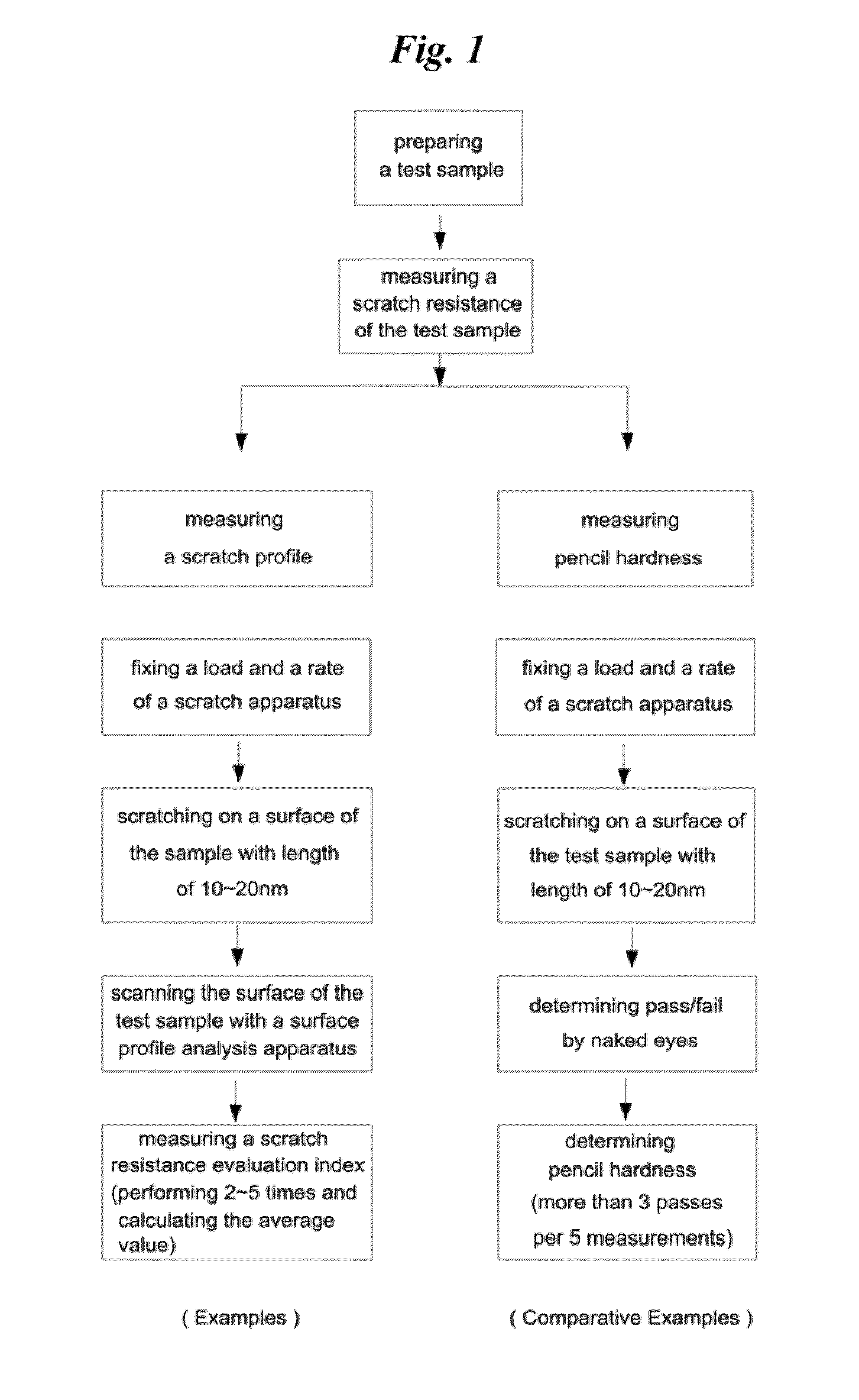

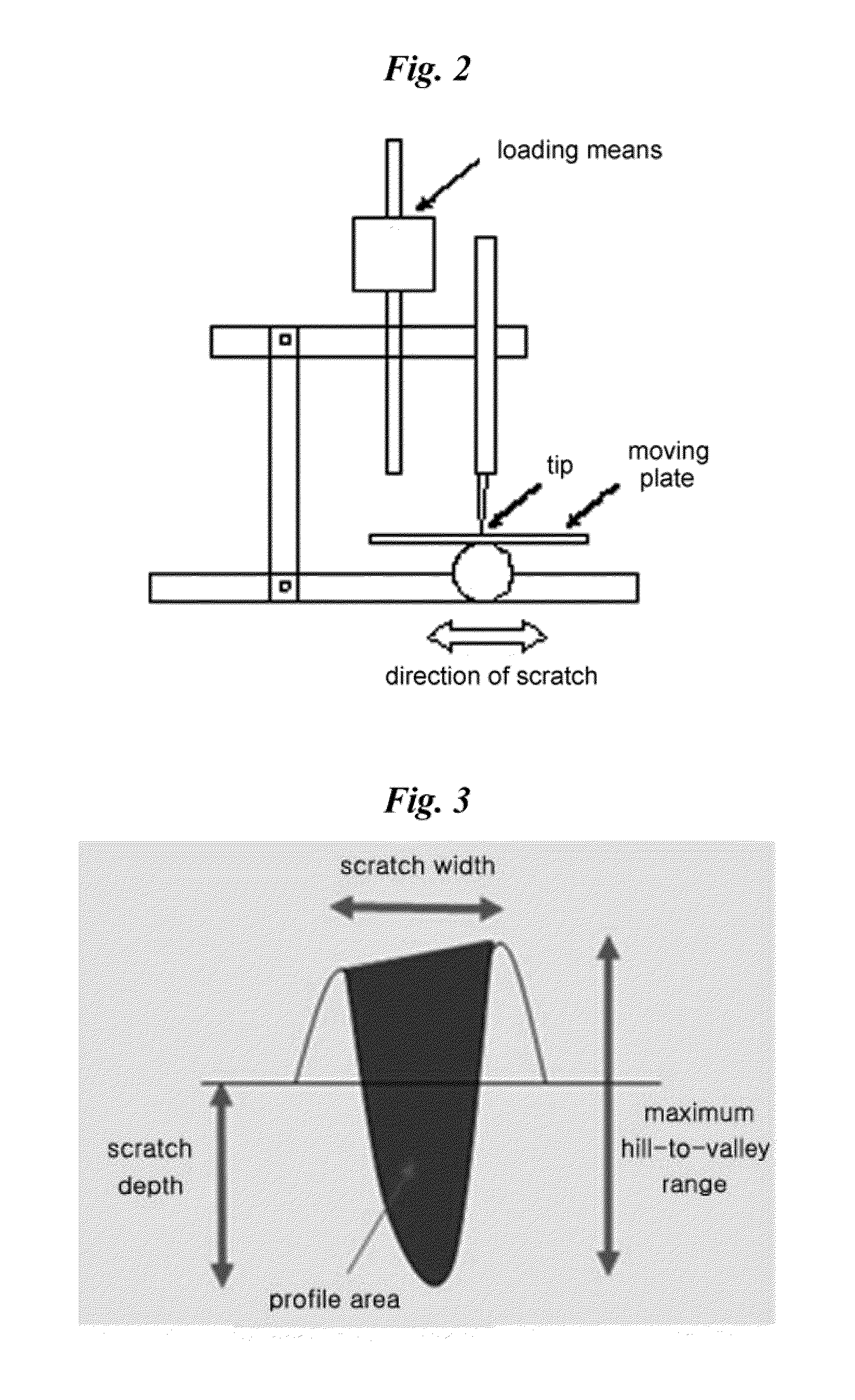

ActiveUS20090293585A1Improve reliabilityGood reproducibilityUsing mechanical meansInvestigating material hardnessTest sampleProfile analysis

Disclosed herein is a method for evaluating scratch resistance of a plastic resin comprising scratching a surface of a test sample of plastic resin using a scratch apparatus to form a scratch of the surface having a scratch profile; scanning the scratched test sample with a surface profile analysis apparatus to measure the scratch profile; and creating a scratch resistance evaluation index based on the measured scratch profile to evaluate the scratch resistance of the test sample. The method has good reliability and reproducibility, reduces measurement time and errors caused by measurers and measuring conditions, provides easy measurement and can be widely applied to all plastic resins.

Owner:LOTTE ADVANCED MATERIALS CO LTD

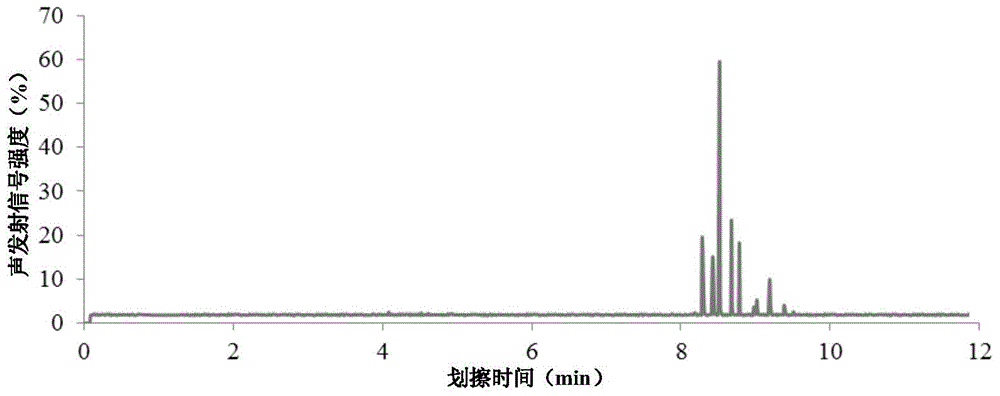

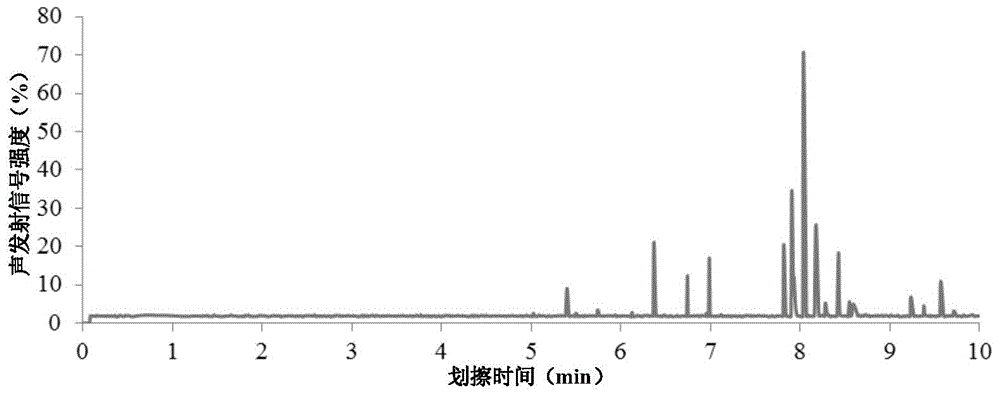

Abrasive particle shear fatigue test equipment

InactiveCN104483210ARealize quantitative comparisonMaterial strength using steady shearing forcesAcoustic emissionShear capacity

The invention discloses abrasive particle shear fatigue test equipment. The abrasive particle impact fatigue test equipment comprises abrasive particles fixedly connected with a tool head, a scratched test piece, a base system, an ultrasonic vibration system, a force measuring system and an acoustic emission system, wherein the ultrasonic vibration system is mounted on and connected with the base system; the tool head is fixedly connected with the ultrasonic vibration system; the acoustic emission system is mounted on and connected with the tool head; the force measuring system is mounted on and connected with the base system; the scratched test piece is fixedly connected with the force measuring system; the relative position between the scratched test piece and the abrasive particles is adjusted through the base system; the shear sliding between the abrasive particles and the scratched test piece is realized by the ultrasonic vibration system; the force measuring system is used for detecting dynamic force change between the abrasive particles and the scratched test piece; the acoustic emission system is used for carrying out acoustic emission of signals when the abrasive particles reach the fatigue rupture condition during the shear sliding process between the abrasive materials and the scratched test piece. The abrasive particle impact fatigue test equipment disclosed by the invention can quantize and compare the shear resistance of different abrasive particle materials, and meanwhile, provides the shear resistance time data, so as to achieve the theoretical guiding significance in the aspects of abrasive material manufacture, abrasive tool design and the like.

Owner:HUAQIAO UNIVERSITY

Coatings, methods for producing the same, and the use thereof

InactiveUS20050233147A1Improve adhesionHigh glossMaterial nanotechnologyMolten spray coatingSteel woolEngineering

Transparent coatings with a thickness of at least 30 μm, a relative elastic resilience to DIN 55676 of at least 70%, and a scratch resistance corresponding to a score of not more than 2 in the steel wool scratch test to DIN 1041 after 10 double strokes; process for producing them, and their use.

Owner:BASF COATINGS GMBH

Method for evaluating scratch resistance of plastic resins

ActiveUS8266944B2Good reproducibility and reliabilityReduce errorsUsing mechanical meansInvestigating material hardnessTest sampleProfile analysis

Disclosed herein is a method for evaluating scratch resistance of a plastic resin comprising scratching a surface of a test sample of plastic resin using a scratch apparatus to form a scratch of the surface having a scratch profile; scanning the scratched test sample with a surface profile analysis apparatus to measure the scratch profile; and creating a scratch resistance evaluation index based on the measured scratch profile to evaluate the scratch resistance of the test sample. The method has good reliability and reproducibility, reduces measurement time and errors caused by measurers and measuring conditions, provides easy measurement and can be widely applied to all plastic resins.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Salt mist scratch test device

ActiveCN102680381ASimple structureScratch operation is simple and convenientWeather/light/corrosion resistanceVertical planeEngineering

The invention discloses a salt mist scratch test device which is used for scratching a sample by using a cutter. The salt mist scratch test device comprises a base platform, a sample holding device arranged on the base platform and used for holding a sample, a cutter holding device used for holding the cutter, a cutter installing frame arranged on the base platform, a first driving mechanism used for driving the cutter installing frame to translate relative to the base platform along the horizontal direction and a second driving mechanism used for driving the cutter holding device to rotate in a vertical plane relative to the cutter installing frame, wherein the cutter holding device is arranged on the cutter installing frame, and the cutter installing frame can be vertically adjusted so that the cutter is vertically arranged relative to the sample. The salt mist scratch test device is simple in structure, convenient and simple in scratching and capable of meeting the scratching requirement of salt mist tests, effectively improving the testing efficiency and quality and avoiding hurting an operator in a scratching process.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

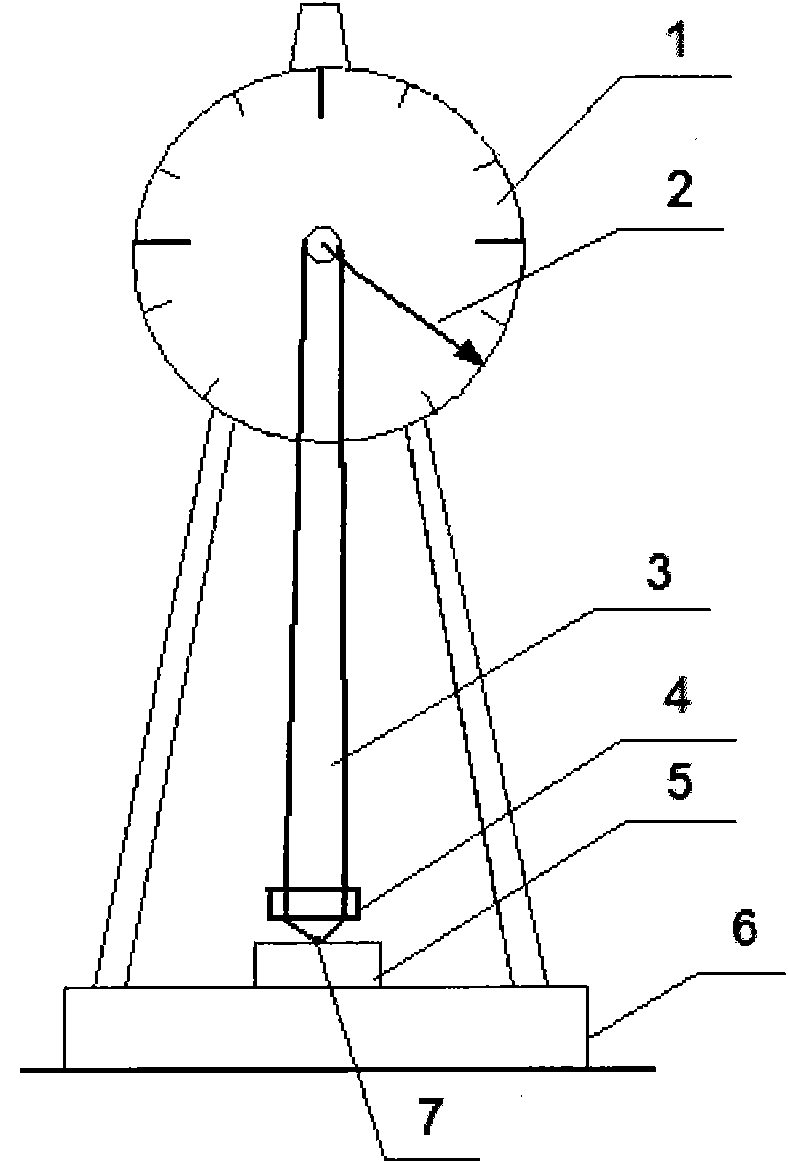

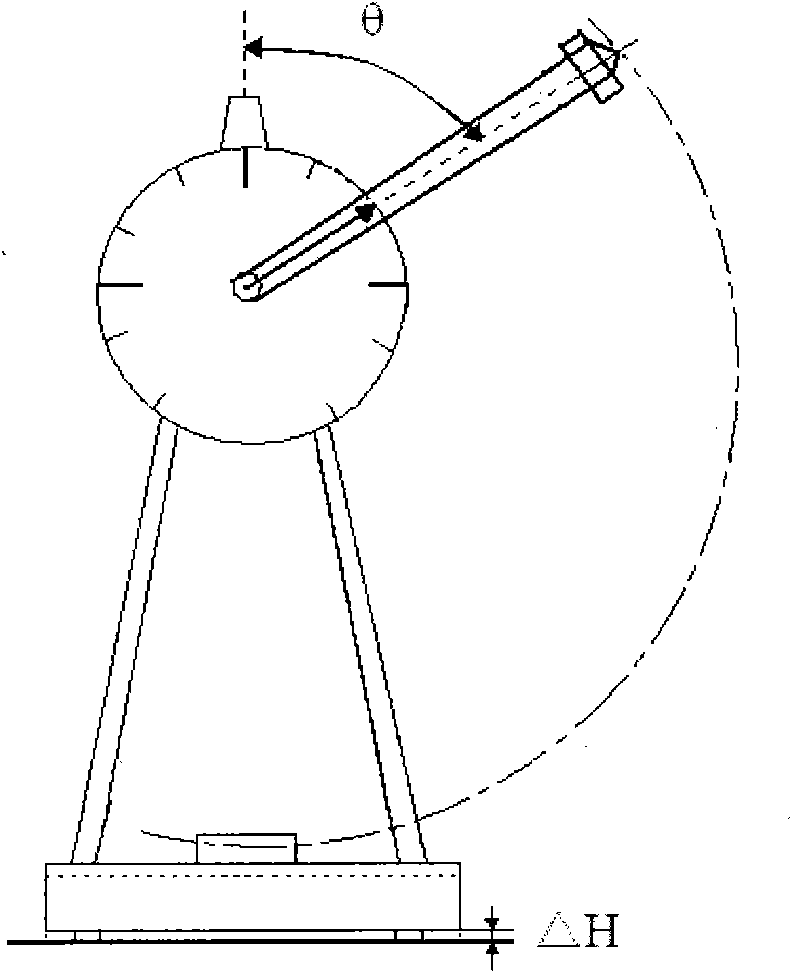

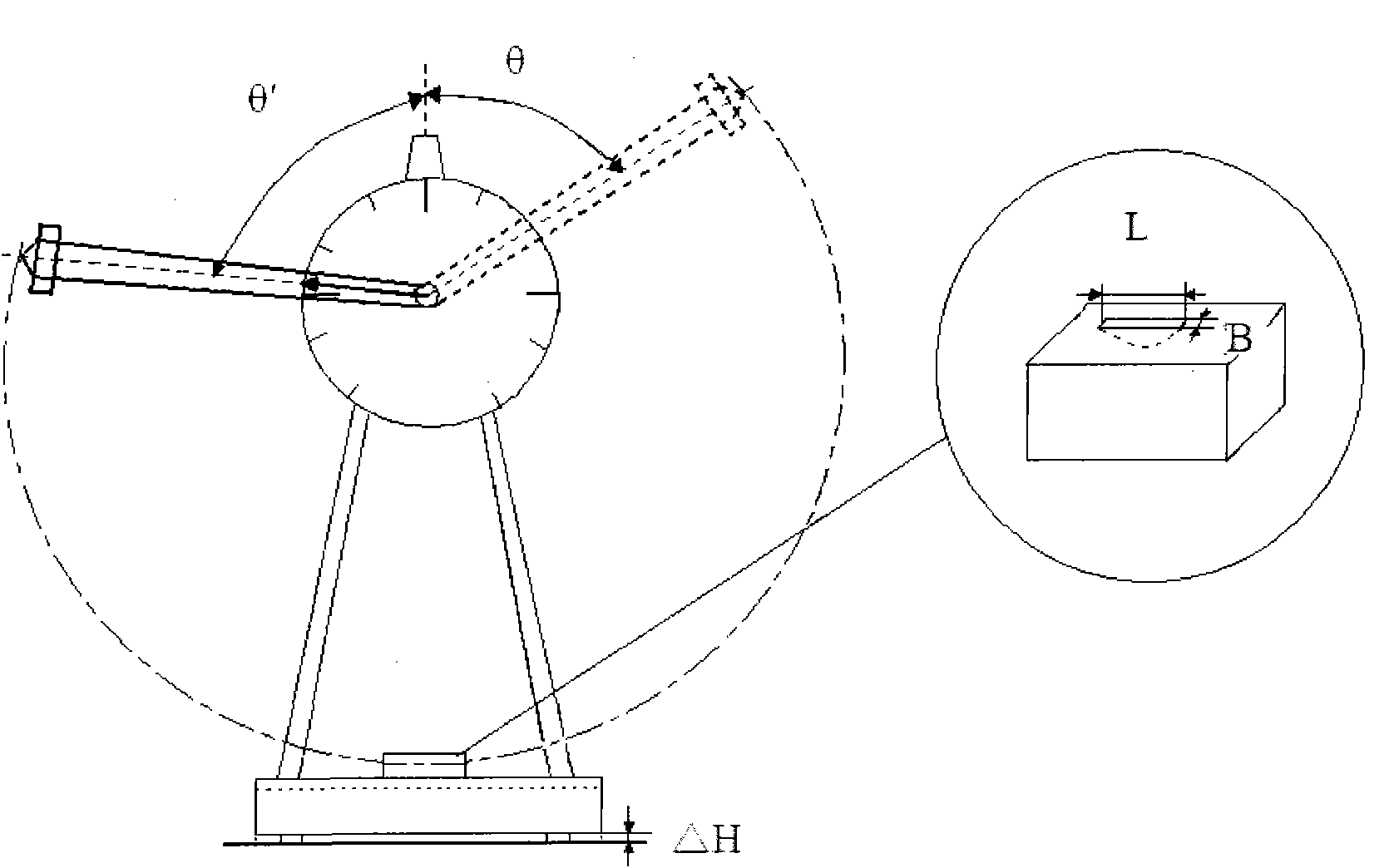

Suspended rotary rapid positioning in-situ indentation/deepened arc indentation testing device

PendingCN107132139AQuick focusSimple structureInvestigating material hardnessMicro nanoElectric machine

The invention relates to a suspended rotary rapid positioning in-situ indentation / deepened arc indentation testing device and belongs to the field of mechanical and electronic integrated precise instruments. The device comprises a suspended rotary rapid positioning module, a deepened arc indentation testing module, a micro-nano indentation module and an in-situ observation module, wherein the micro-nano indentation module and the in-situ observation module are integrated on the suspended rotary rapid positioning module; the deepened arc indentation testing module is composed of an indentation tester and a test piece supporting platform together; and the test piece supporting platform is composed of two parts, namely a shear-type electric lifting table and an electric rotating platform. The device disclosed by the invention has the advantages that the device is novel in structure, has motor-driven rapid feed ability and micro-nano-level piezoelectric micro actuating ability, and can be used for accurately testing the hardness, elasticity modulus, scratching resistance and other mechanical property performances of the test materials. The loading displacement resolution reaches a micro-nano level, and the loading force resolution reaches a micro-Newton level. The effective test means is provided for mechanical behaviors and service behaviors of the materials.

Owner:JILIN UNIV

Full-strain measurement type in-situ nanometer impress/scratch testing device

ActiveCN102928308ARealize the scoring functionRealize in situ observationInvestigating material hardnessDiffractometerX-ray

The invention relates to a full-strain measurement type in-situ nanometer impress / scratch testing device, belonging to the field of an electric integrated precise scientific instrument. The full-strain measurement type in-situ nanometer impress / scratch testing device comprises a macro-adjustment mechanism, a precise pressing unit, a load and displacement signal detecting unit, and a scratch driving unit; the macro-adjustment mechanism is mounted on a base; the precise pressing unit is connected with an x direction sliding table of the macro-adjustment mechanism through a transition connection board; the load and displacement signal detecting unit comprises two groups of eight strain sheets; the strain sheets are respectively mounted on a flexible hinge and an x direction flexible hinge for detecting a load of the precise pressing unit in an embedded manner; and the scratch driving unit is connected with the base through a screw. Signal detection is carried out by using the internal strain sheets, so that the entire testing device has the advantages of compact structure and small size; and the entire testing device is conveniently mounted on carrier tables, such as a scanning electron microscope (SEM) or an X-ray diffraction meter, so that the in-situ impress and scratch test of the material can be realized. Therefore, the full-strain measurement type in-situ nanometer impress / scratch testing device provides technical support for researching a damage mechanism of the material.

Owner:中机试验装备股份有限公司

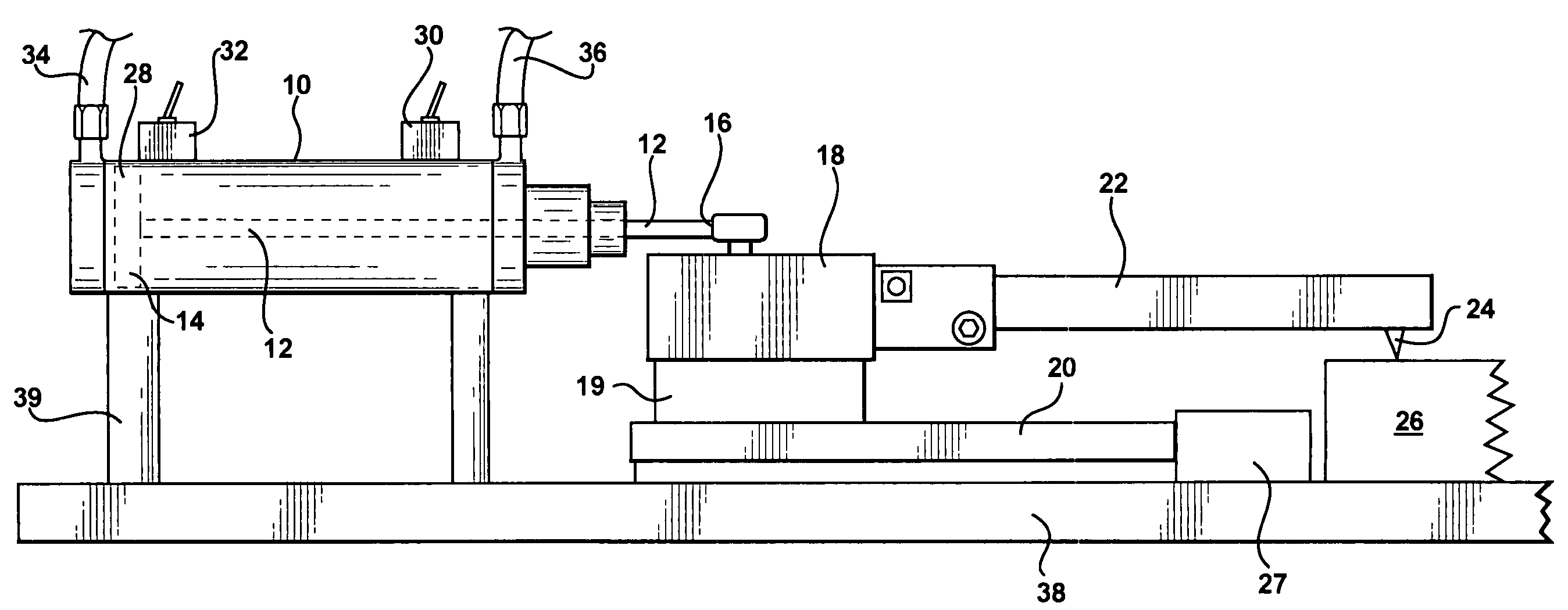

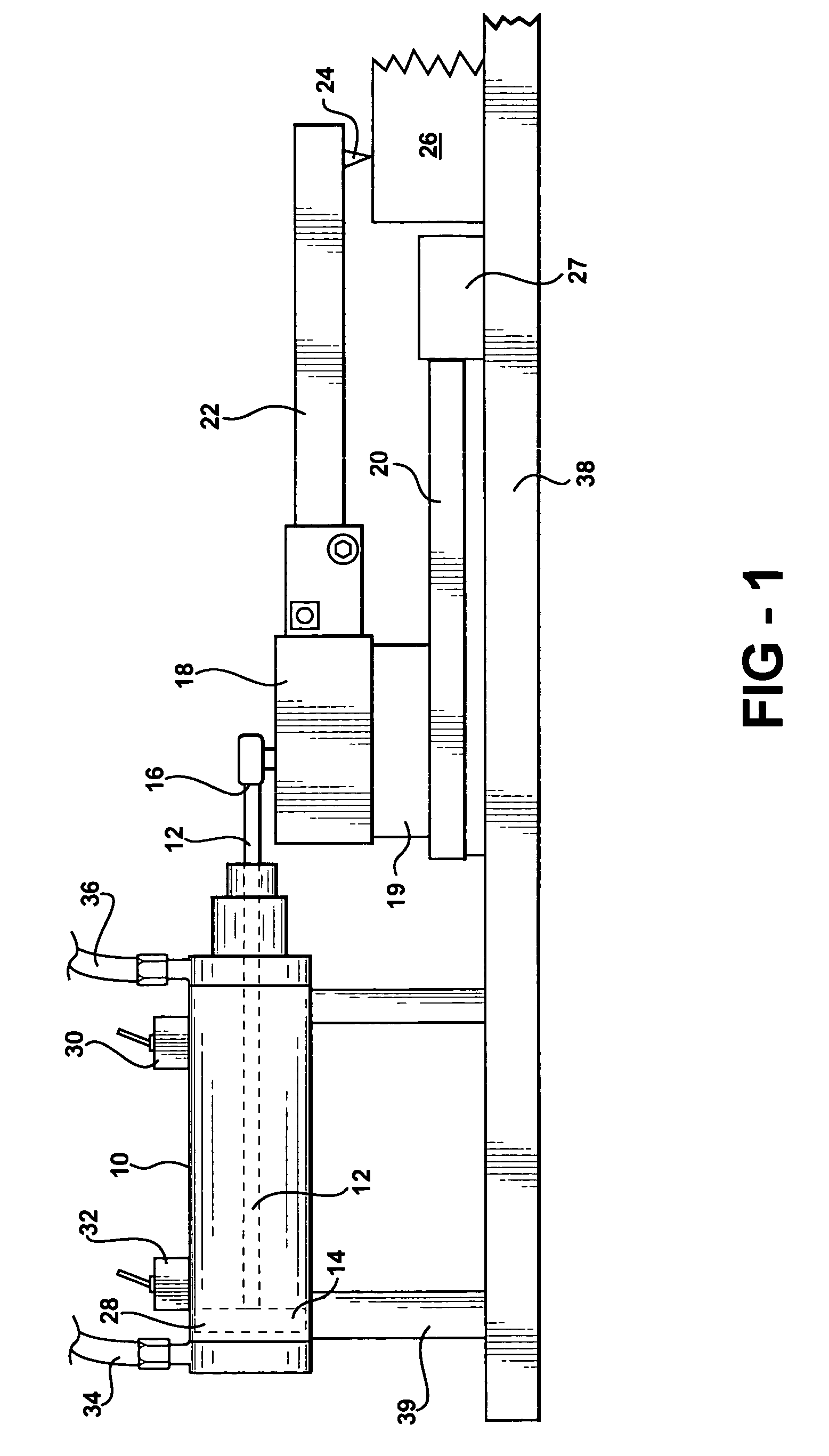

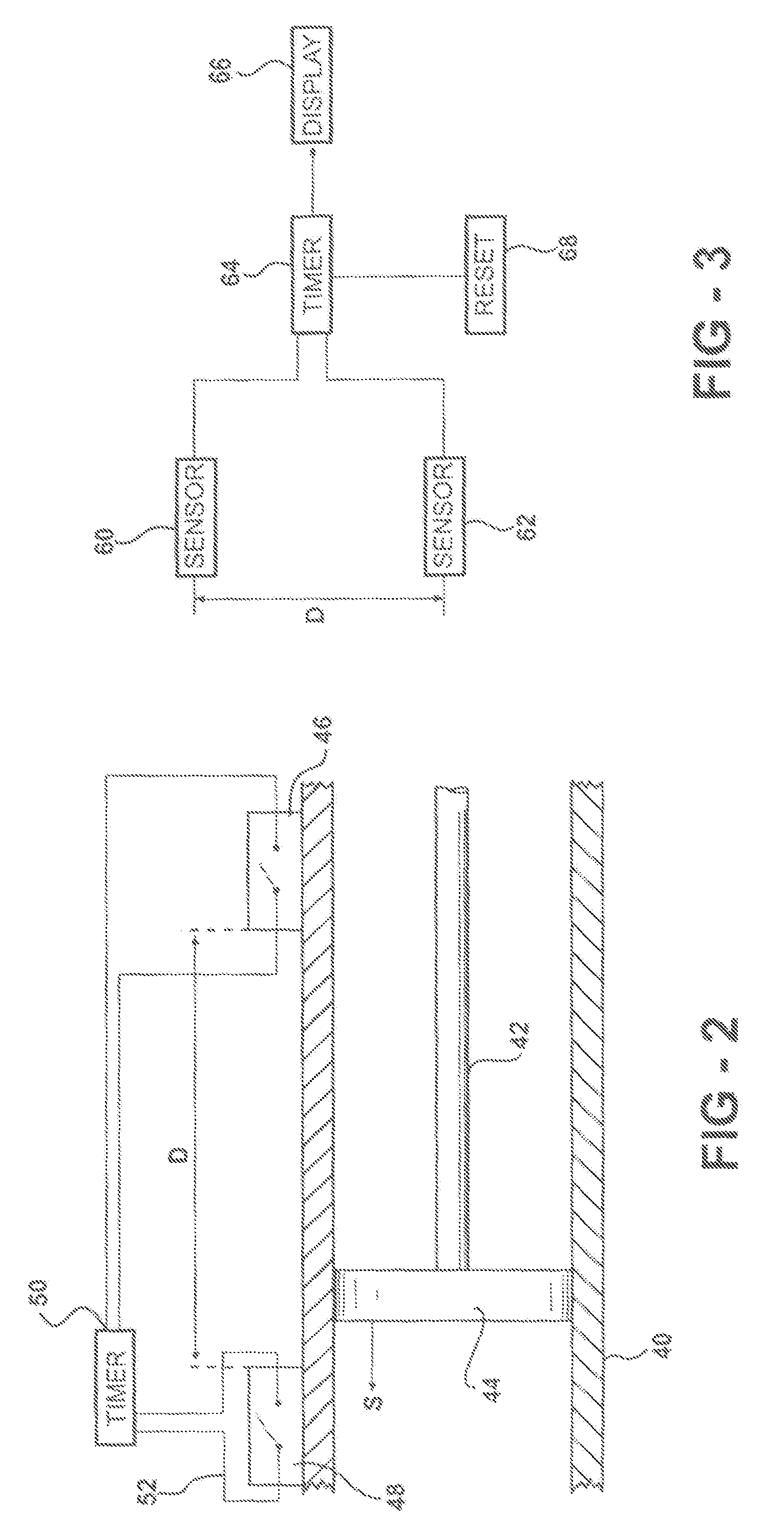

Automatic speed calculation for scratch machine

InactiveUS7275423B2Accurately determineMeasurement/indication equipmentsUsing mechanical meansEngineeringReed switch

An improved surface testing apparatus, such as a scratch test apparatus, allows accurate determination of the test speed, for example using one or more magnetic sensors. An example scratch test apparatus comprises an arm assembly, and an attached blade moving over the surface during the scratch test. A pair of spaced apart reed switches are provided proximate to the arm assembly, the reed switches being successively actuated by a magnetic portion of the arm asssembly as it moves during the scratch test.

Owner:TOYOTA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com