Rock brittleness evaluation method based on stress strain curve and scratch test

A technology of scratch testing and evaluation method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, strength characteristics, etc., to achieve the effect of wide applicability, strong reliability and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

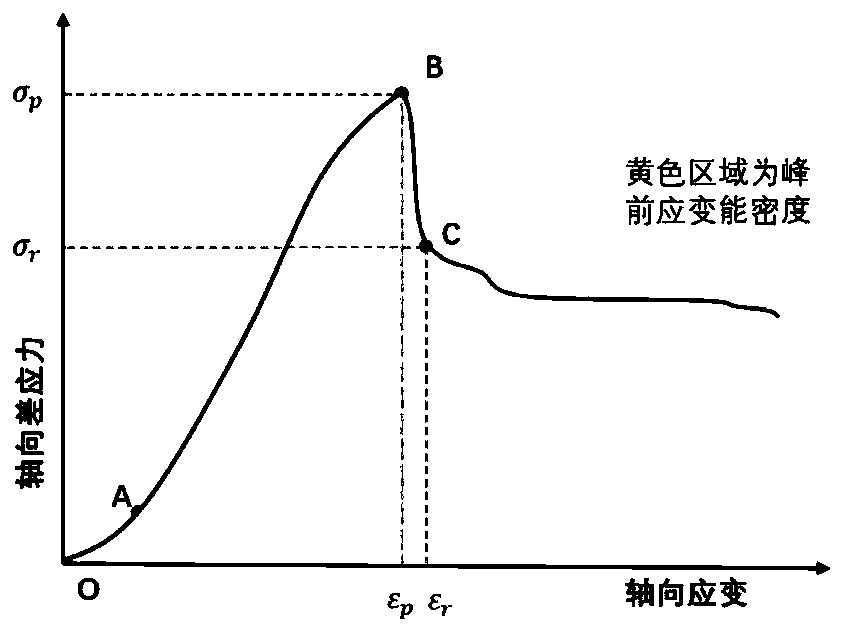

[0036] To evaluate the brittleness index of tight carbonate rocks with different buried depths, the steps of the method are as follows: figure 1 As shown, the details are as follows:

[0037] (1) Evaluate the rock from the stress environment and pore pressure of the rock: evaluate the geological environment of the tight carbonate rock: the buried depth is widely distributed, from the surface to 4000 meters underground, the rock is extremely dense, and the interior is almost Does not contain fluid;

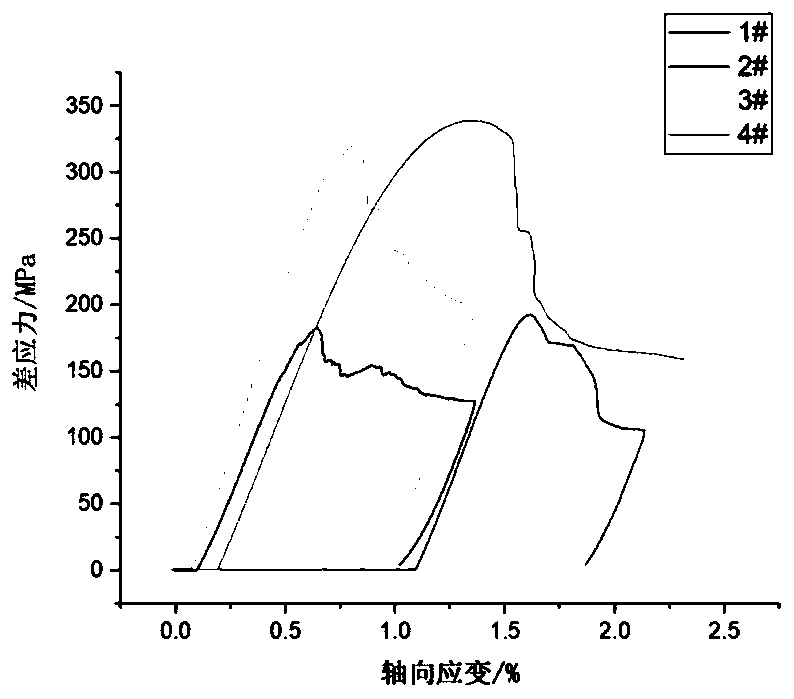

[0038] (2) Select a rock mechanics experiment that conforms to the environment of the rock sample to be tested: Since the geological environment of the rock sample is in which the main influencing factor is the in-situ stress, the conventional triaxial compression experiment is selected, the number of experiments is 4, and the confining pressure is set 10MPa, 20MPa, 30MPa and 40MPa respectively. For extremely tight reservoirs, the effective stress coefficient is taken as 0. The ...

Embodiment 2

[0052] For a low porosity and low permeability reservoir in a certain area (porosity between 10-15%, permeability 5-50*10 -3 μm 2 ) shale for brittleness index evaluation, such as figure 1 As shown, the method for calculating the brittleness index provided by the embodiments of the present invention has the following steps:

[0053] (1) Evaluation of the geological environment in which the mud shale is located: the buried depth is between 4,000 and 4,200 meters, and the rock has low porosity and low permeability. The regional pore pressure varies greatly, and the pressure coefficient varies from 1.1 to 1.5.

[0054] (2) Since the rock sample is located in the geological environment, the main influencing factors are in-situ stress and pore pressure, so the triaxial compression experiment is selected, the number of experiments is 4, the confining pressure is set to 80MPa, and the pore pressure is 45MPa, 50MPa, 55MPa respectively and 60MPa. For low porosity and low permeabilit...

Embodiment 3

[0067] To evaluate the brittleness index of tight carbonate rock, the steps of the method are as follows: figure 1 As shown, the details are as follows:

[0068] (1) Evaluate the geological environment of the carbonate rock: the carbonate rock in this section is relatively compact, and there is no fluid in the underground environment, and its buried depth is about 4000m;

[0069] (2) The condition setting of the triaxial compression test according to the rock environment: Since there is no fluid in the geological environment of the rock sample, there is no need to consider the influence of the fluid pore pressure. The main influencing factor is the in-situ stress, so the conventional Triaxial compression experiments.

[0070] In this example, the number of experiments is 1, and the confining pressure is set to 40MPa according to the buried depth of the rock. In this example, since there is no fluid, the pore pressure is zero, so the effective stress coefficient is 0. The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com