Test method for evaluating initial wear resistance of austenite high manganese steel under high impact load

A technology of impact load and lower austenite, which is applied in the field of wear resistance evaluation of metal materials, can solve the problems that the influence of initial wear resistance is not considered, and it cannot be used to evaluate the initial wear resistance of austenitic high manganese steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

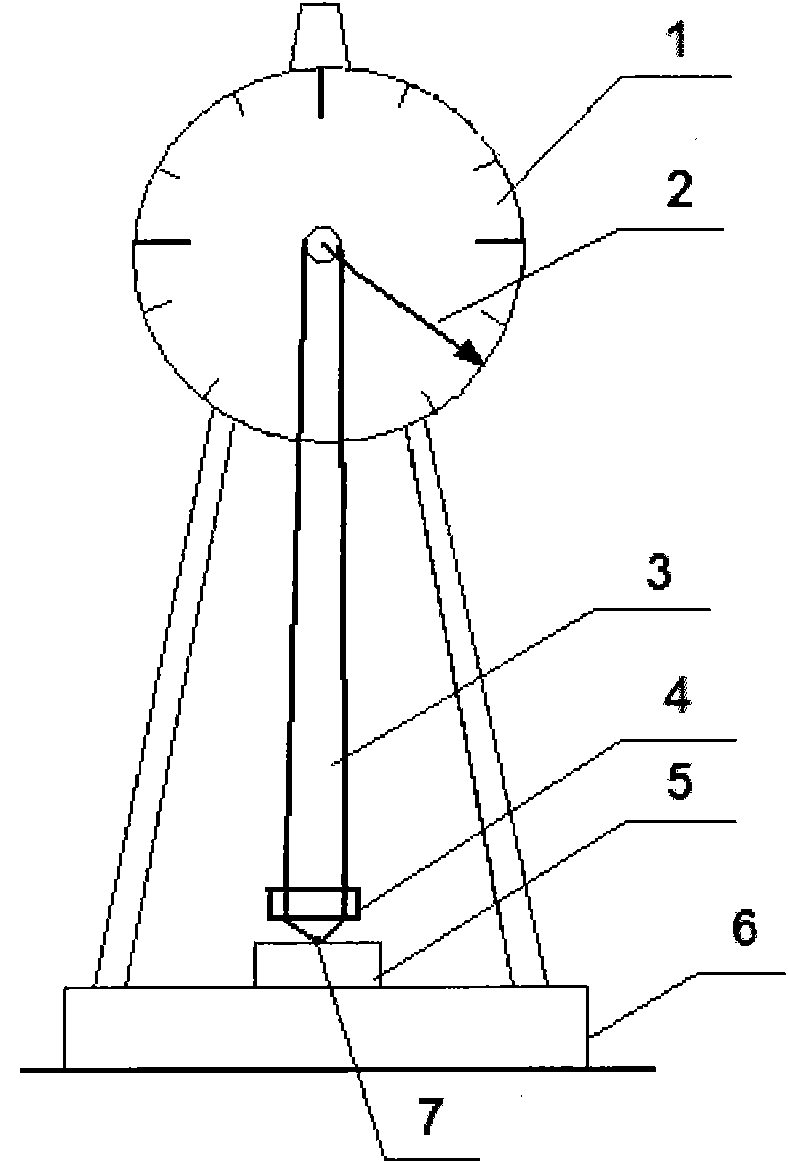

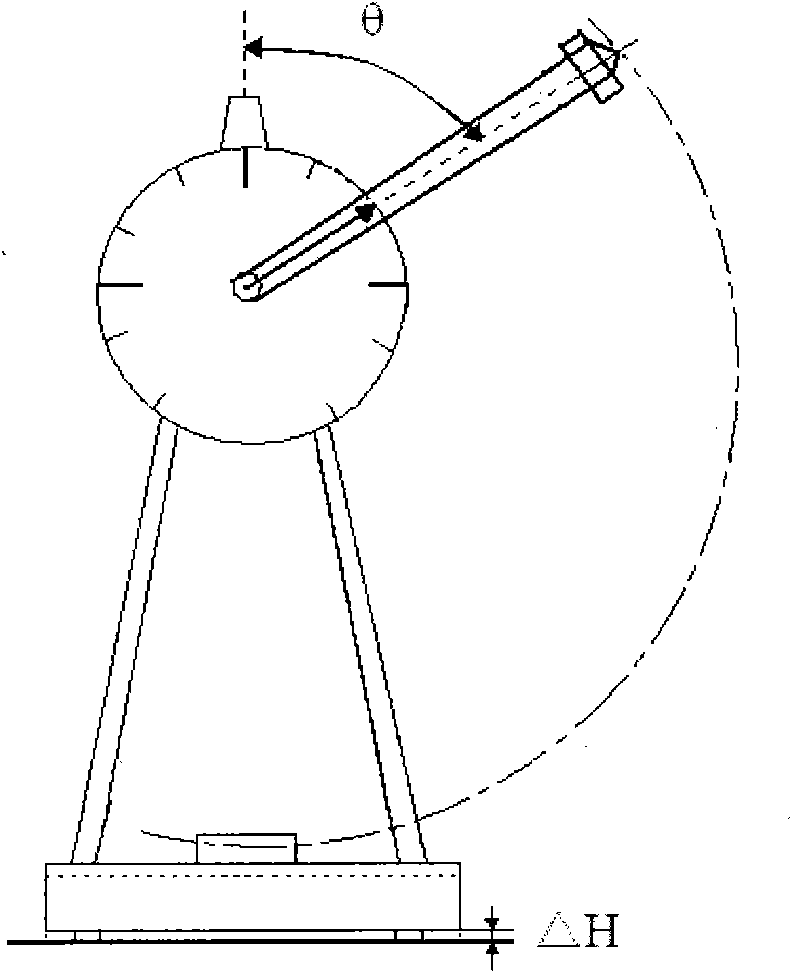

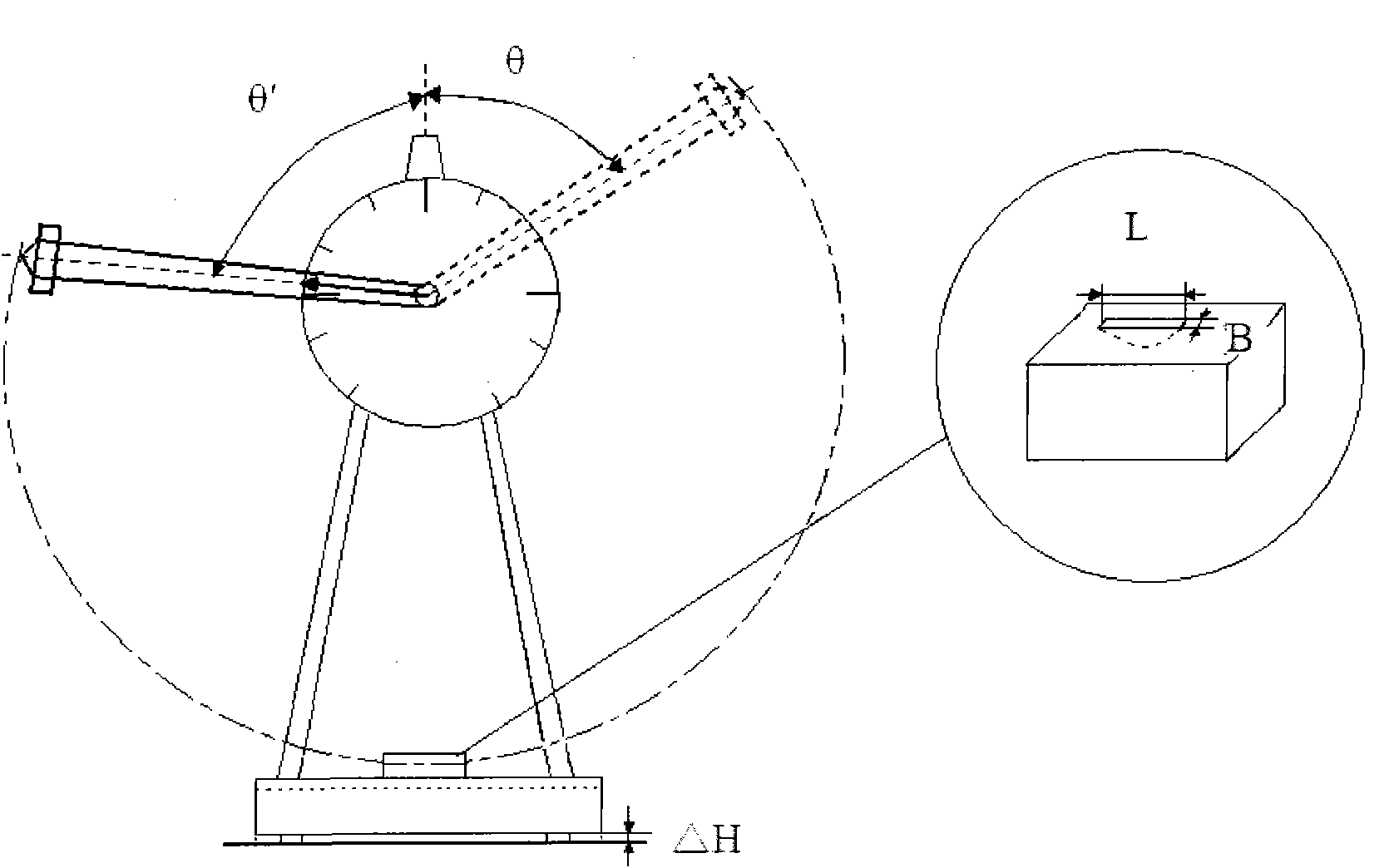

Method used

Image

Examples

Embodiment 1

[0024] The high manganese steel samples after aging treatment by different processes were subjected to a single pendulum impact scratch test under the conditions of an initial pendulum angle θ of 50° and a table lift ΔH of 60 μm. The test results are shown in Table 1:

[0025] Table 1

[0026]

[0027] It can be seen that the specific energy consumption value of the austenitic high manganese steel sample is the largest after aging at 600 ℃ for 1 hour.

Embodiment 2

[0029] The high-manganese steel samples after aging treatment by different processes were subjected to a single pendulum impact scratch test under the conditions of an initial pendulum angle θ of 50° and a table lift ΔH of 100 μm. The test results are shown in Table 2:

[0030] Table 2

[0031]

[0032] It can be seen that the specific energy consumption value of the austenitic high manganese steel sample is the largest after aging at 600 ℃ for 1 hour.

Embodiment 3

[0034] The high-manganese steel samples after aging treatment by different processes were subjected to a single pendulum impact scratch test under the conditions of an initial pendulum angle θ of 60° and a table lift ΔH of 40 μm. The test results are shown in Table 3:

[0035] table 3

[0036]

[0037] It can be seen that the specific energy consumption value of the austenitic high manganese steel sample is the largest after aging at 600 ℃ for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com