Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118 results about "Oblique illumination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oblique illumination is a contrast enhancing technique which can be realized with the use of home-made filters (patch stops) placed into the filter holder of the microscope condenser.

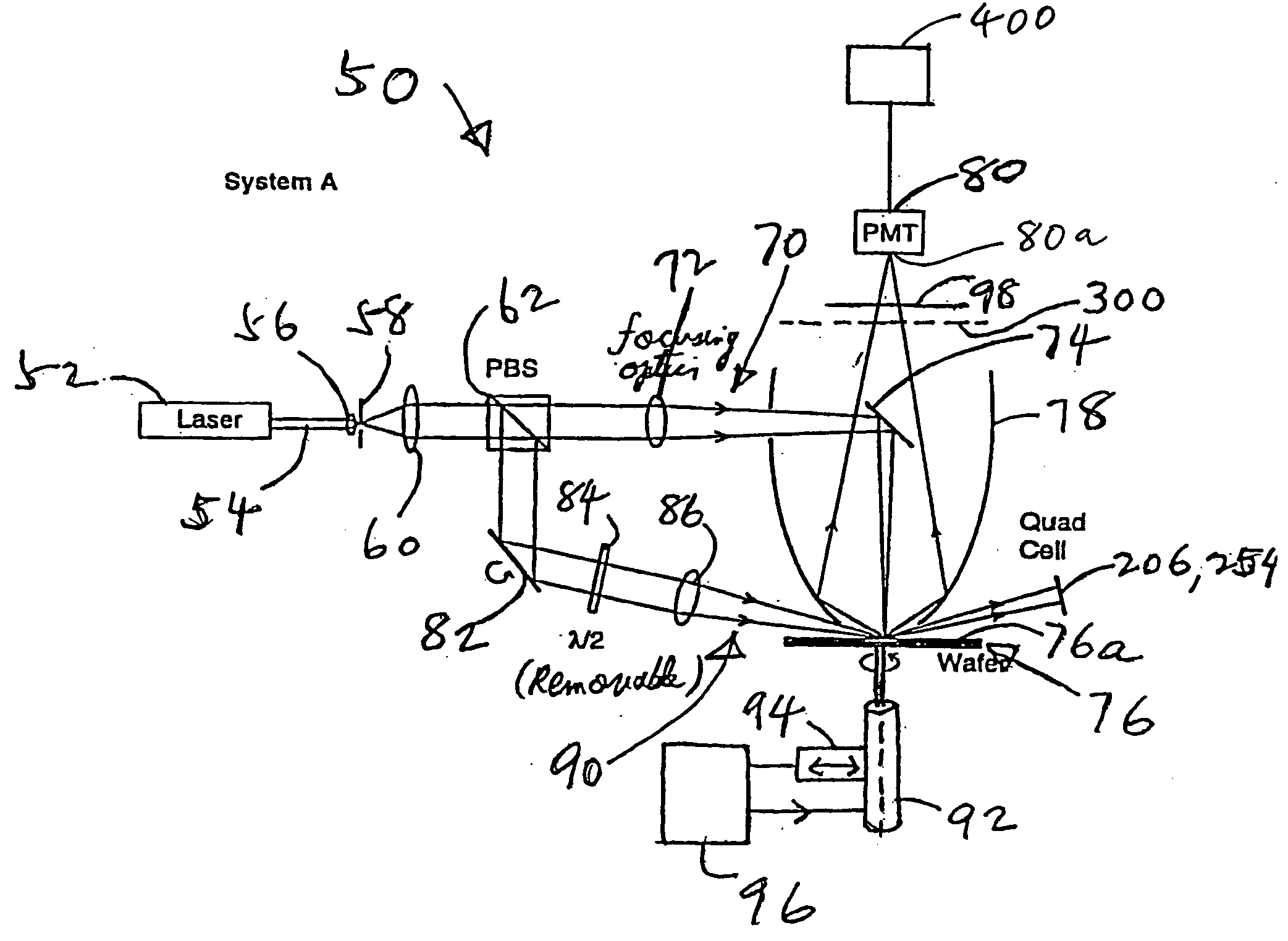

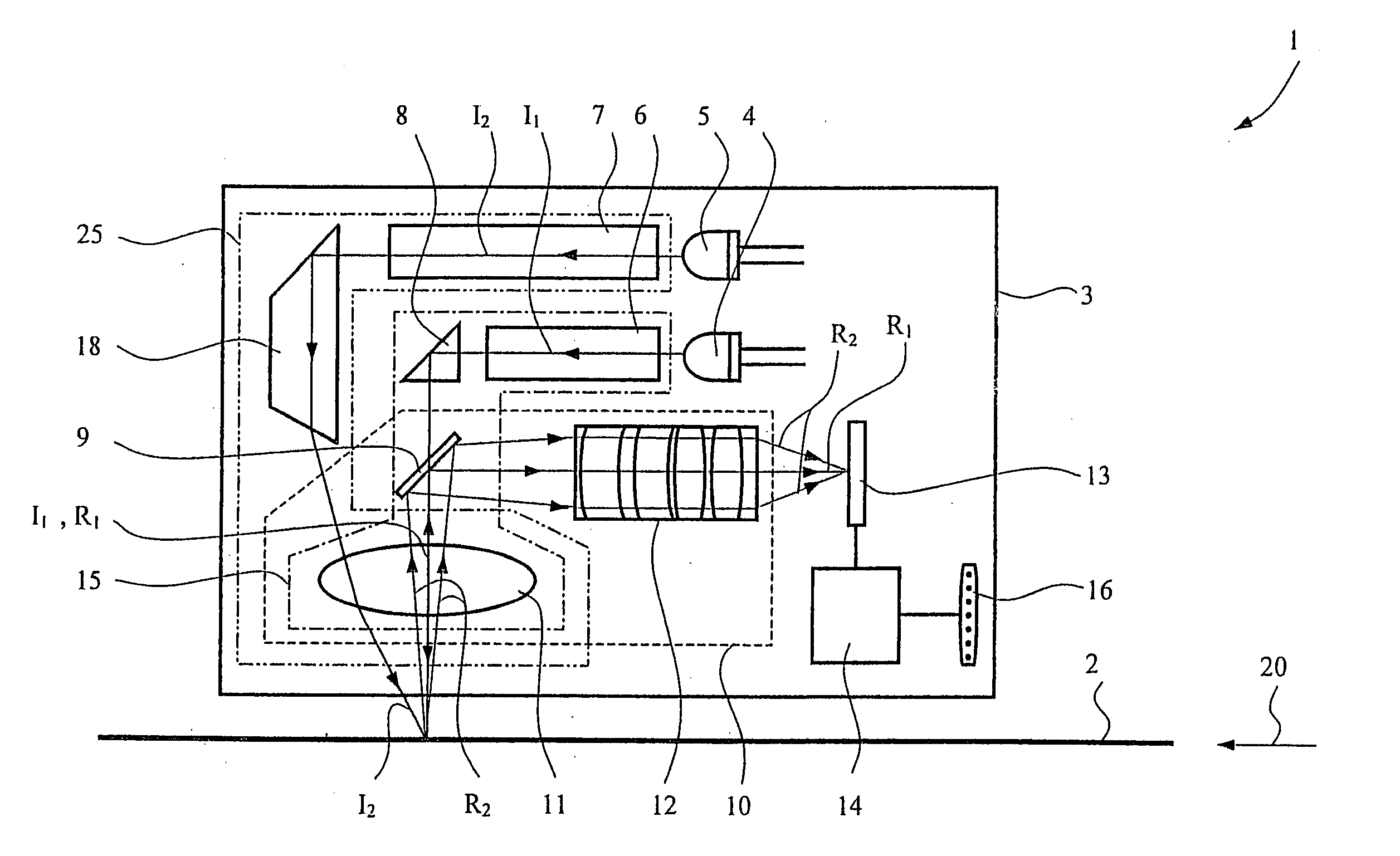

Systems and methods for multi-dimensional metrology and/or inspection of a specimen

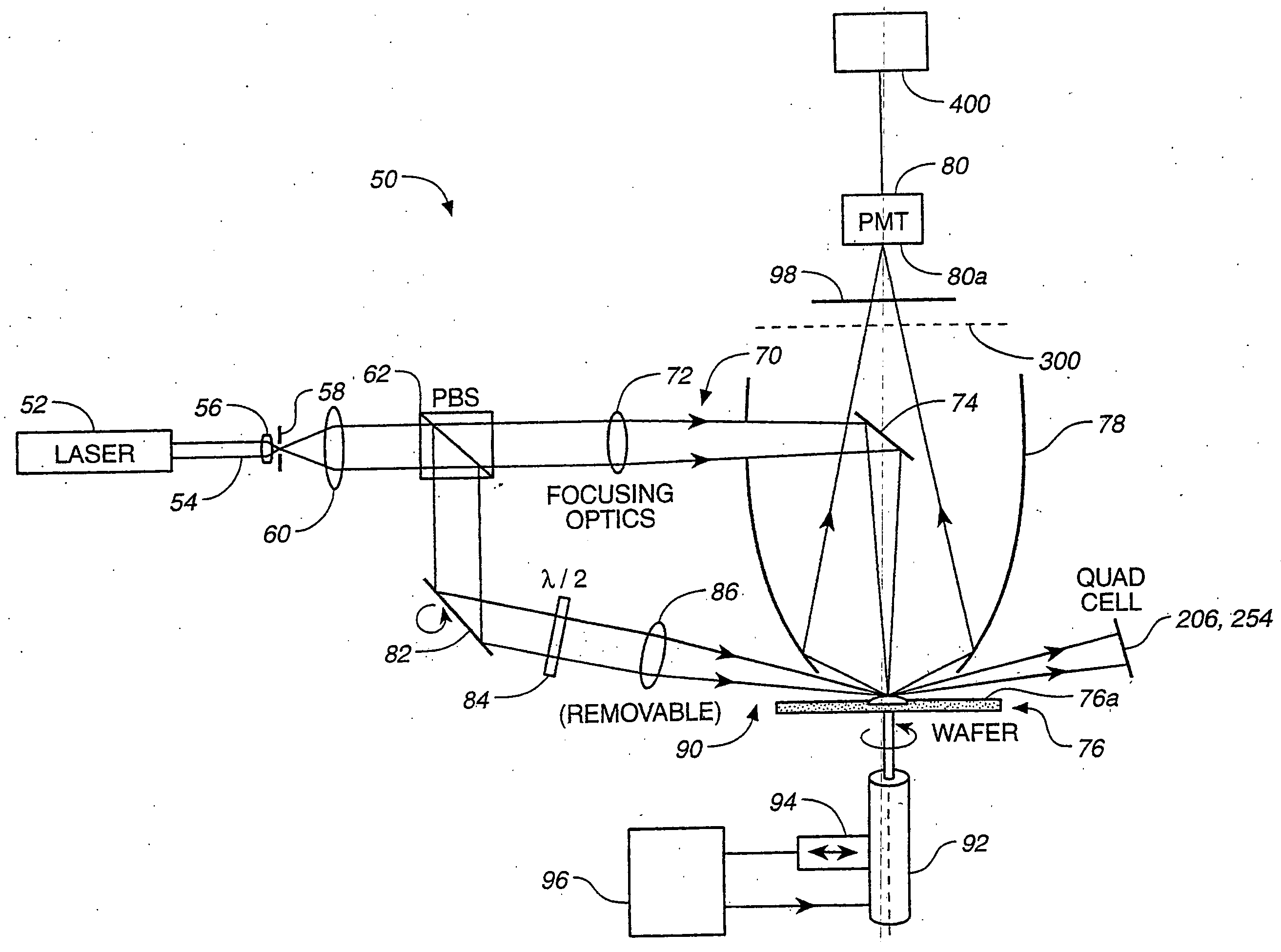

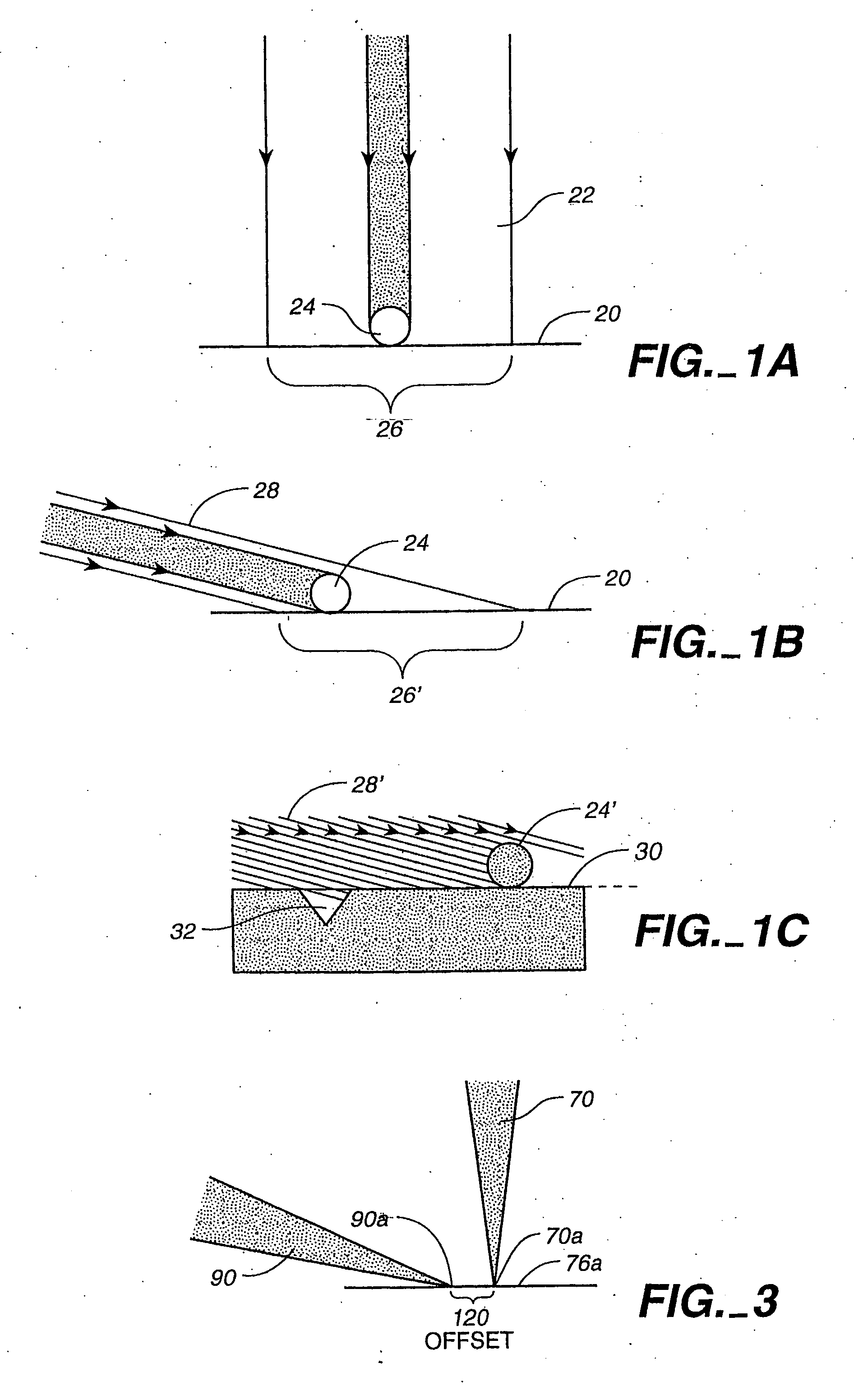

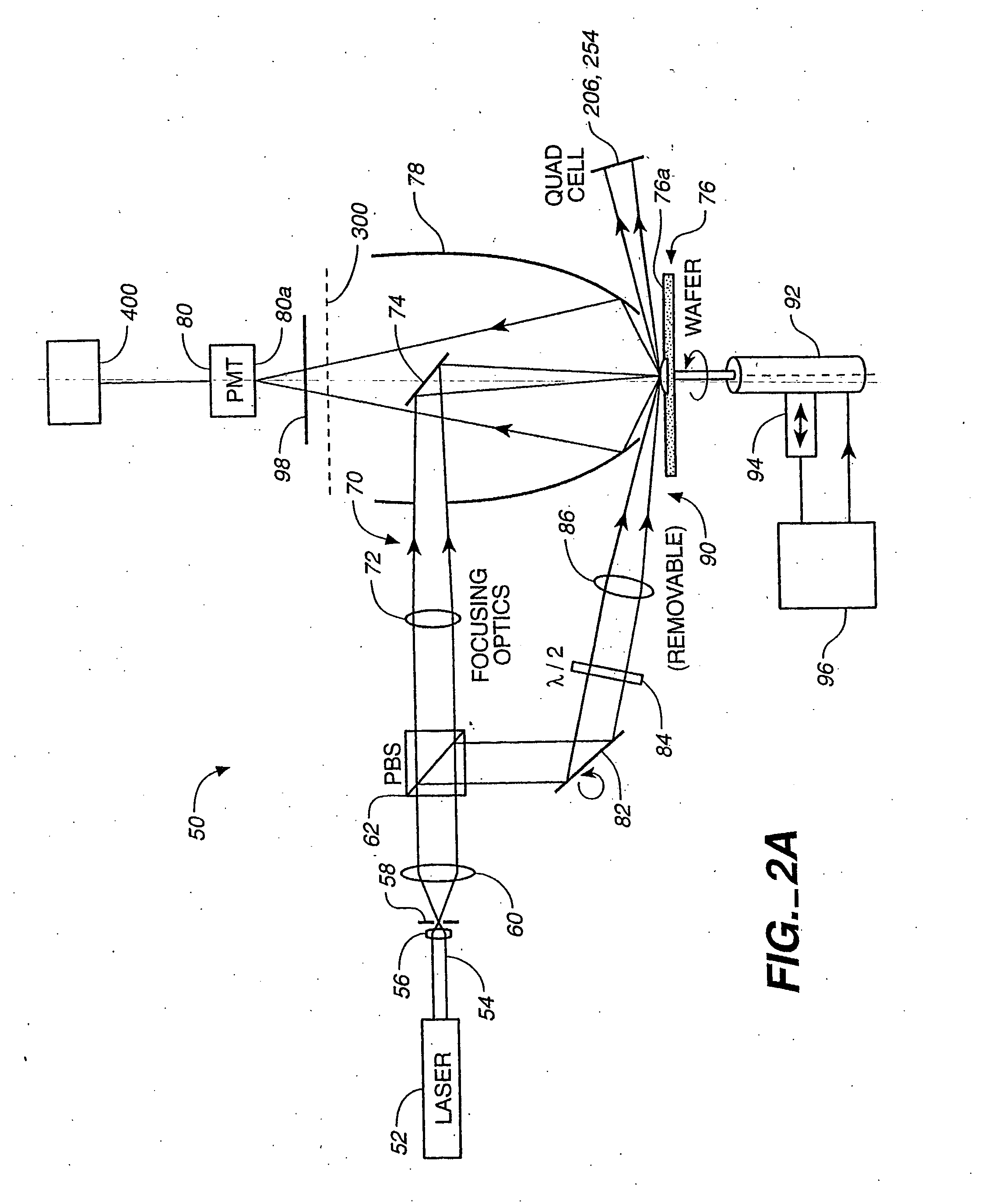

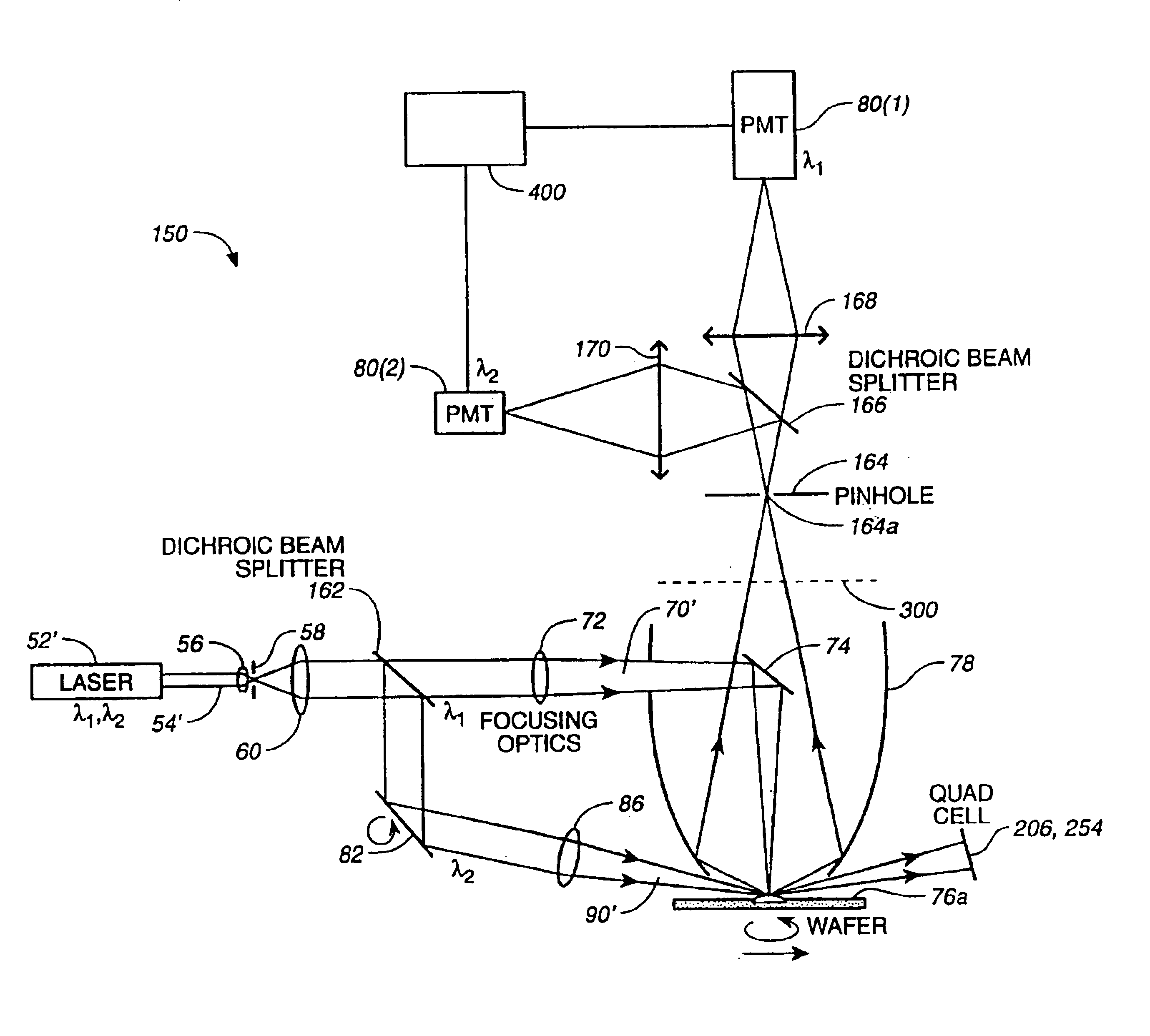

ActiveUS7126699B1Reducing albedo differenceHigh speed scanMaterial analysis by optical meansUsing optical meansMetrologyBright field image

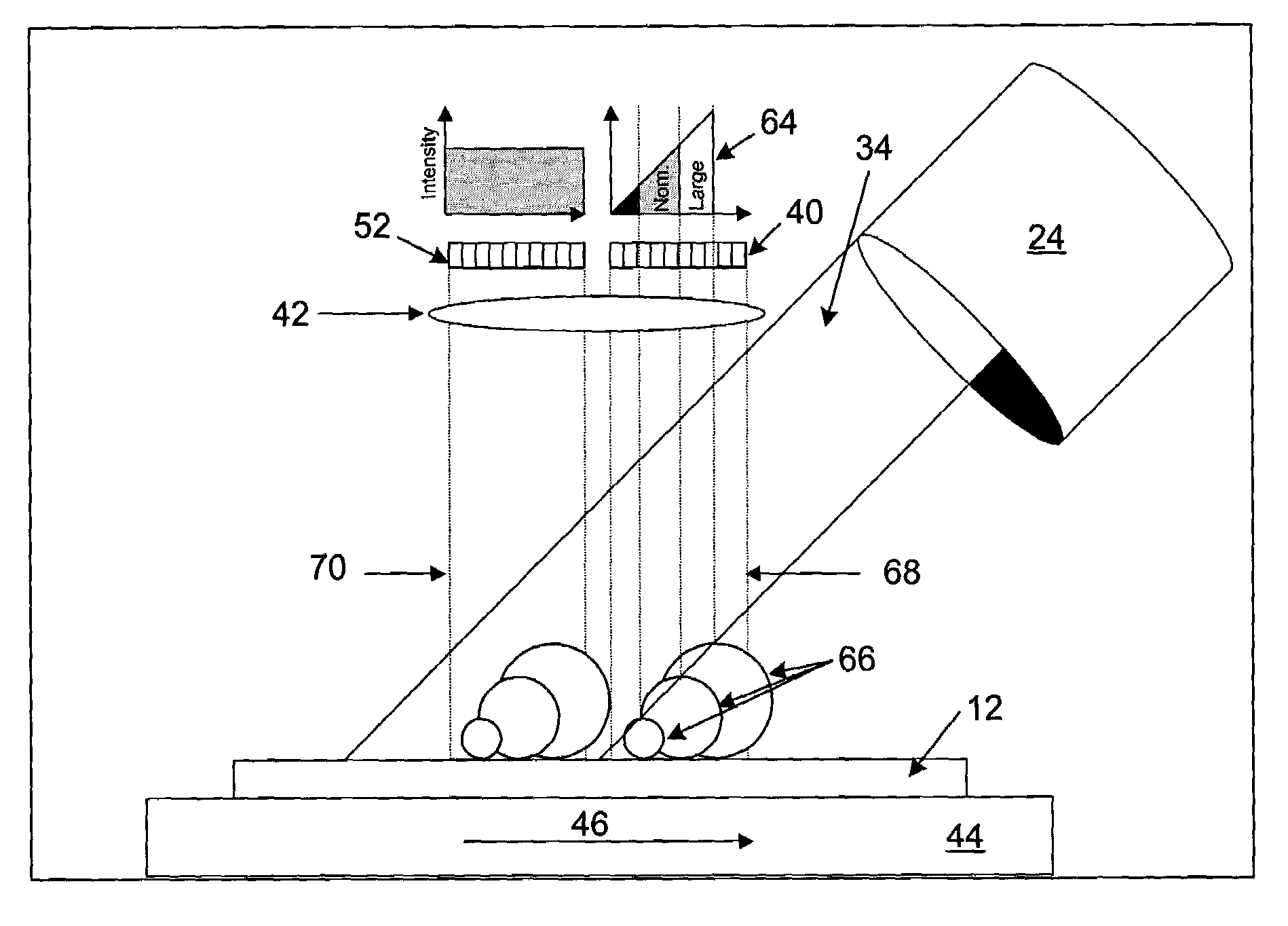

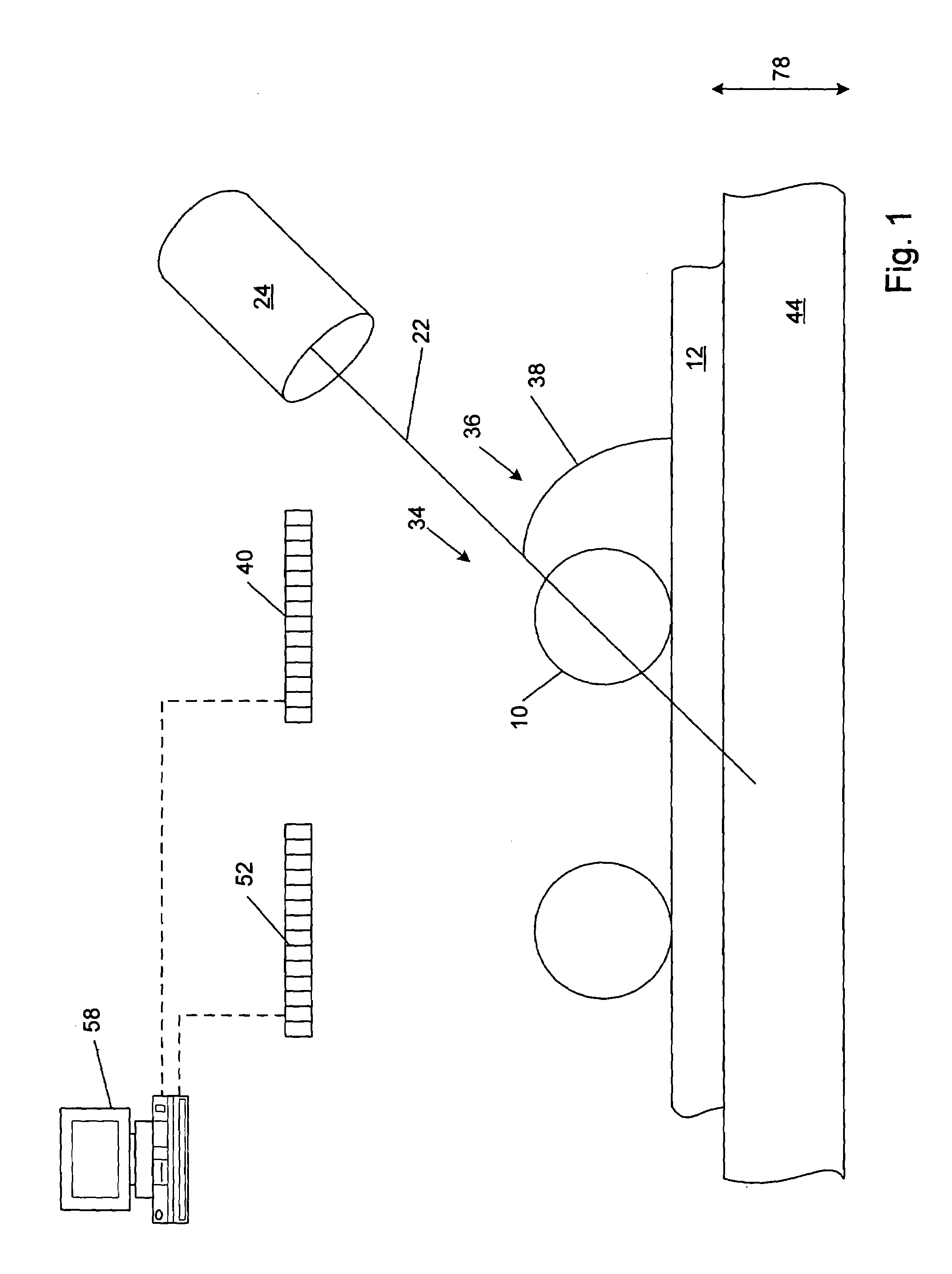

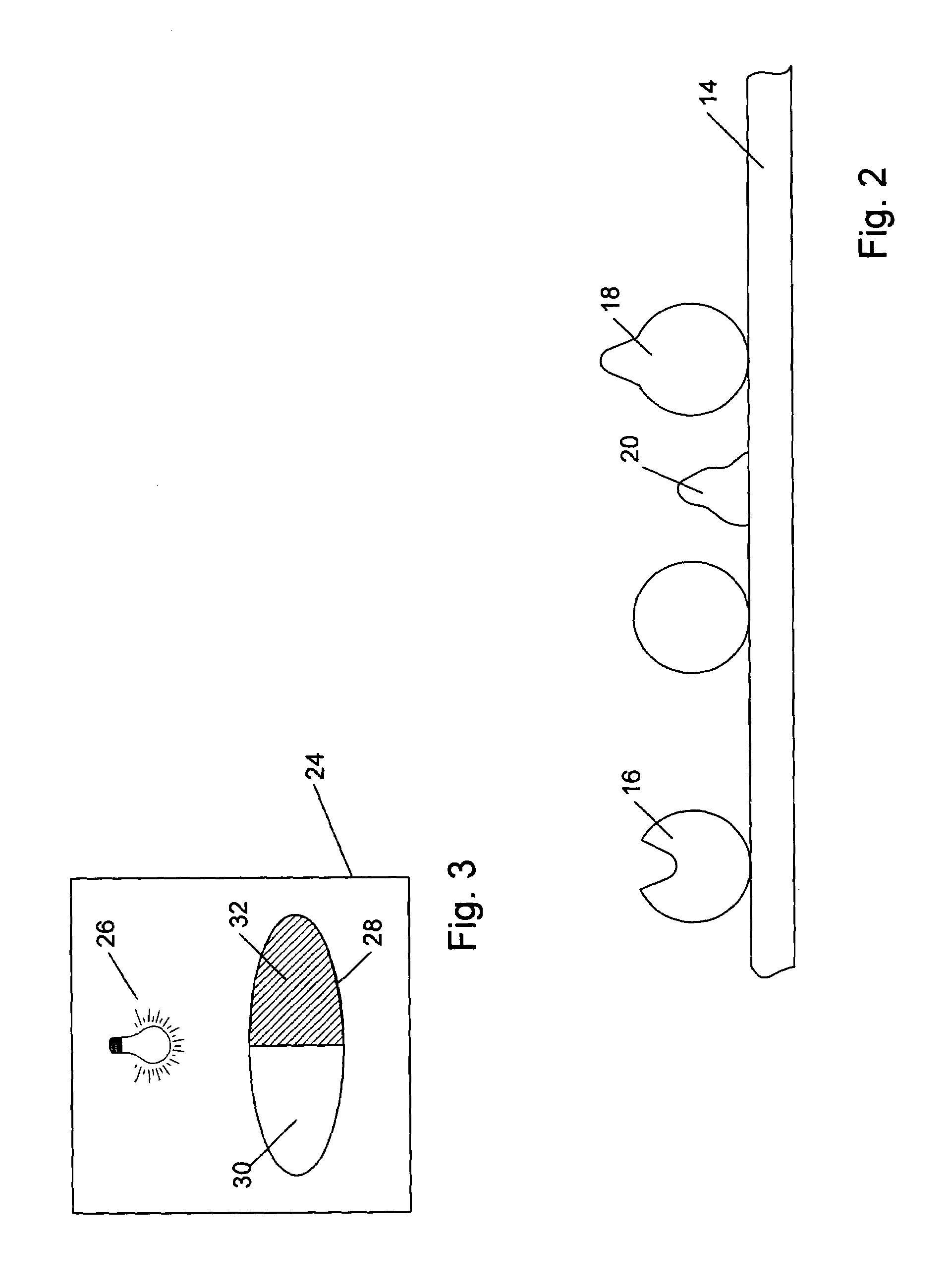

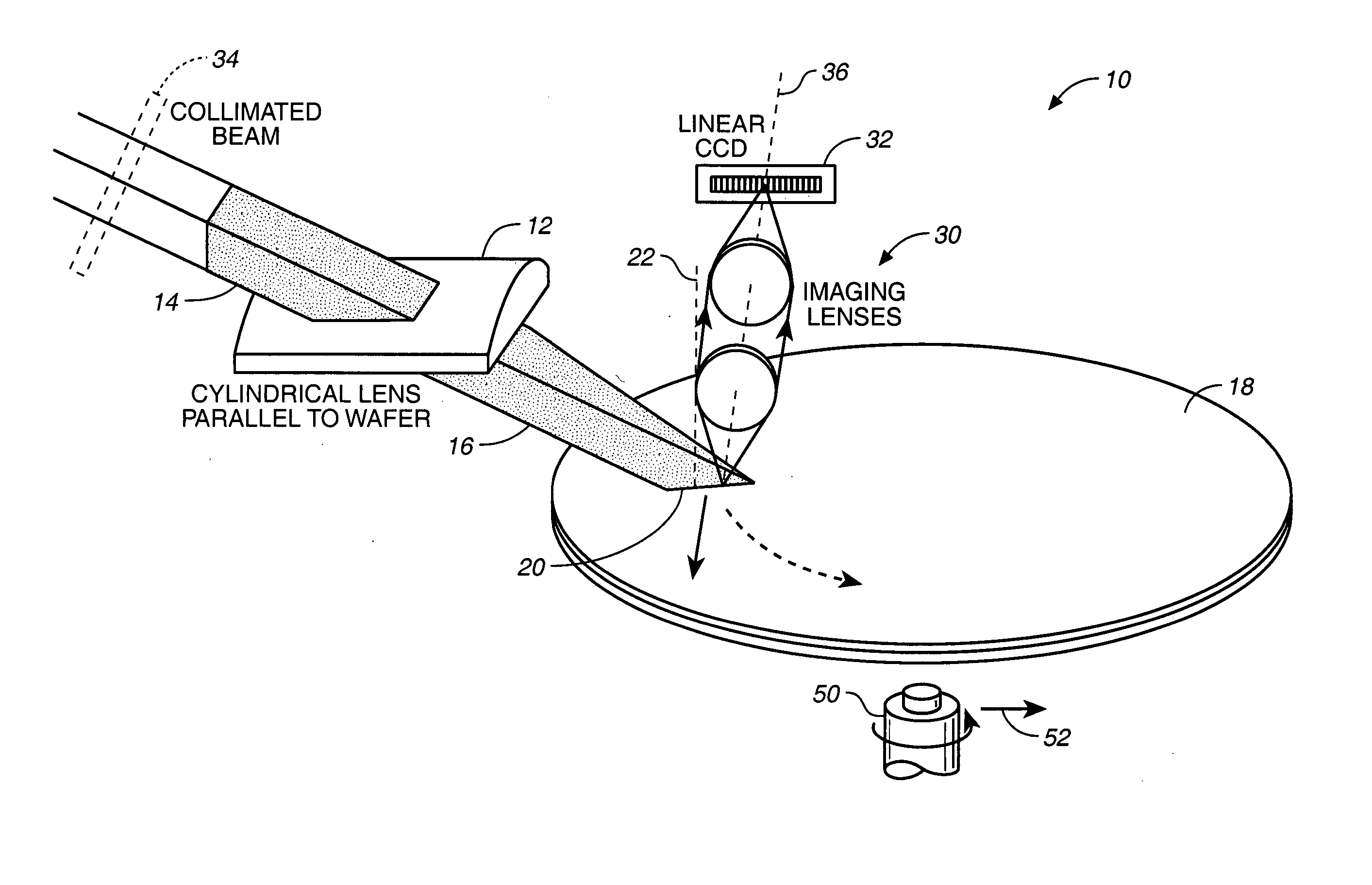

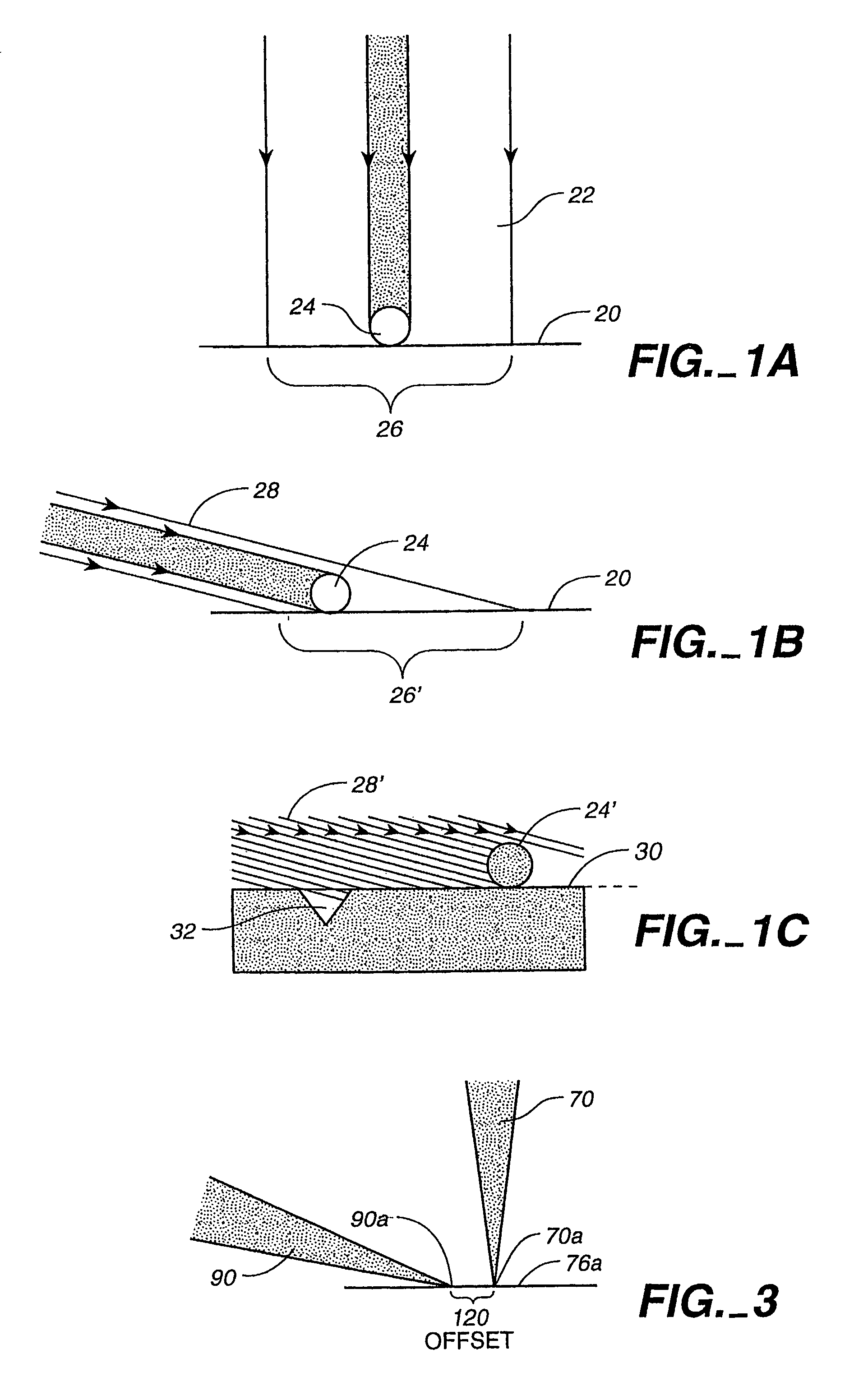

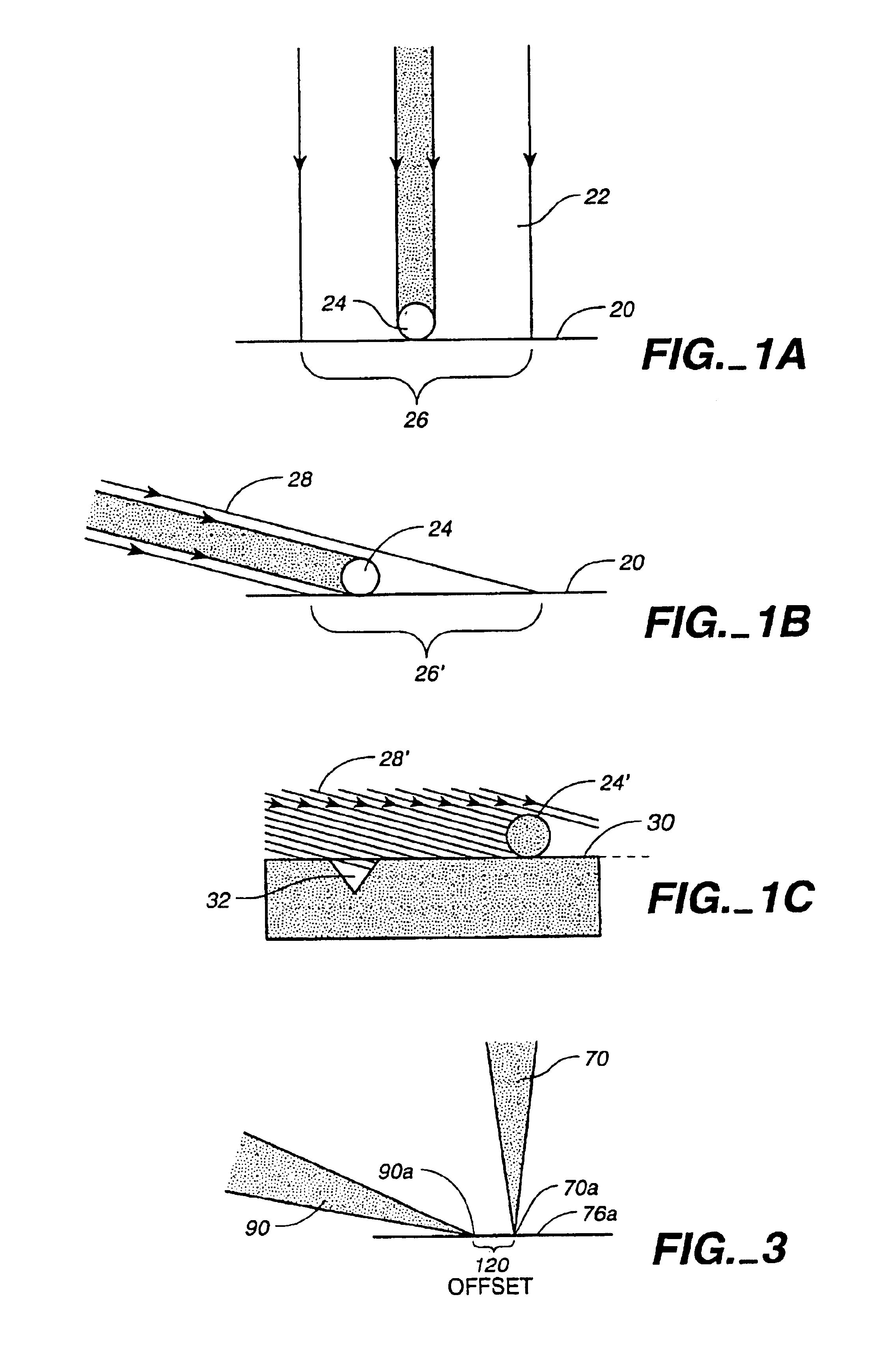

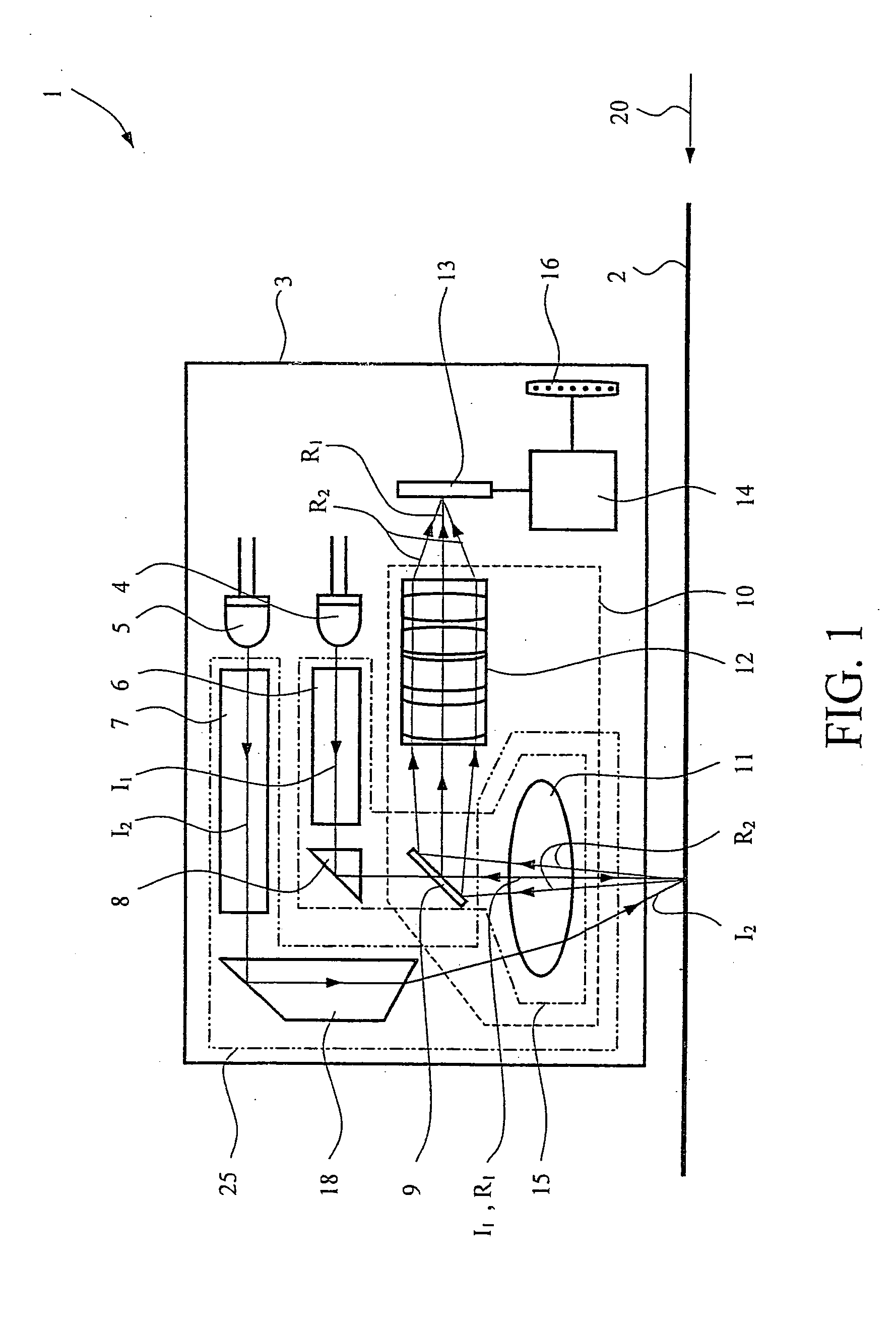

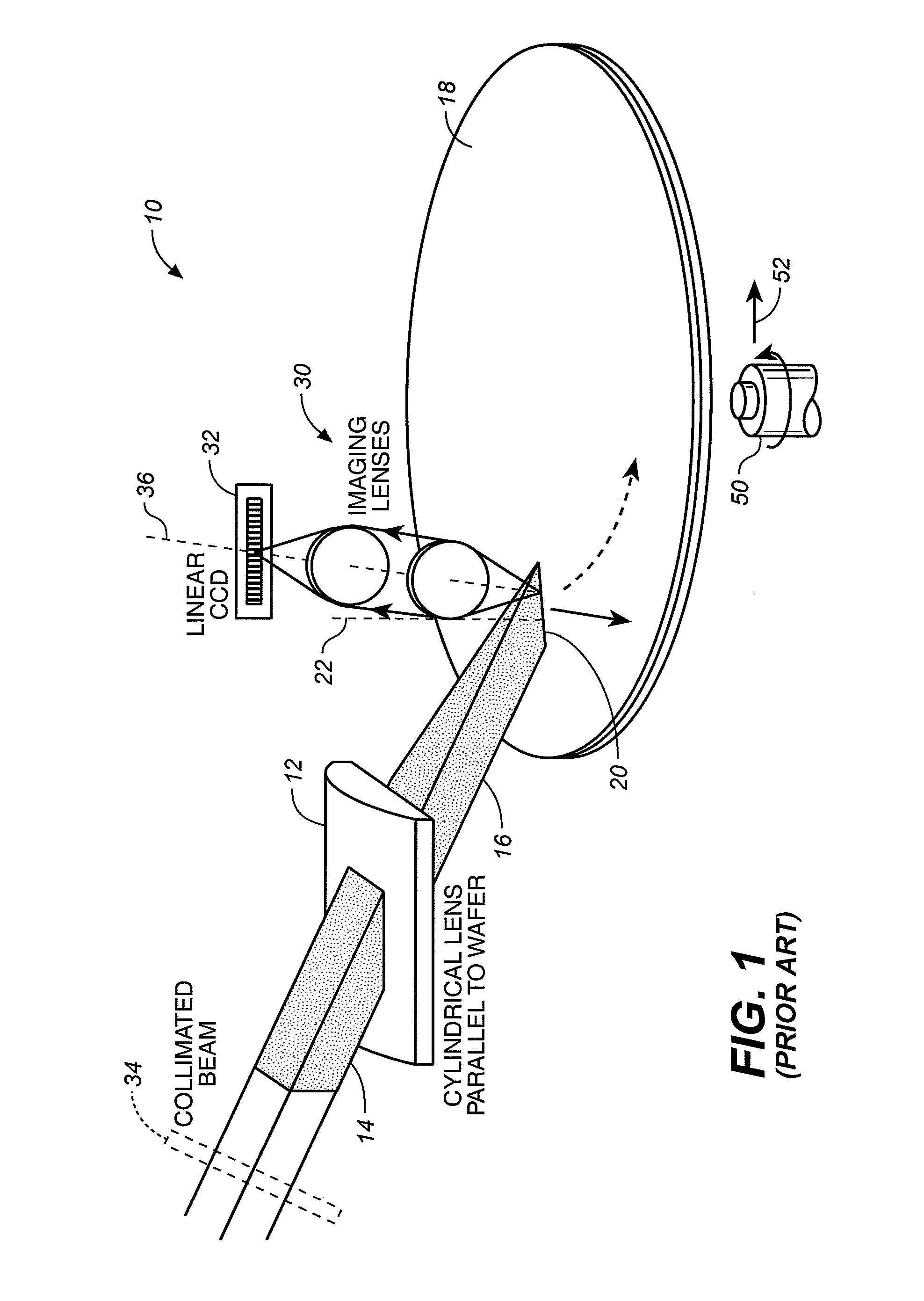

Systems and methods for multi-dimensional metrology and inspection of a specimen such as a bumped wafer are provided. One method includes scanning the specimen with partial oblique illumination to form an image of the structure, either through the normal collection angle or through an oblique collection angle. The method also includes integrating an intensity of the image and determining a height of the structure from the integrated intensity. The integrated intensity may be approximately proportional or inversely proportional to the height of the structure. In addition, the method may include scanning the specimen with bright field illumination to form a bright field image of the specimen. The method may also include determining a lateral dimension of the structure from the bright field image. Furthermore, the method may include detecting defects on the specimen from the bright field image or the obliquely-illuminated image.

Owner:KLA TENCOR TECH CORP

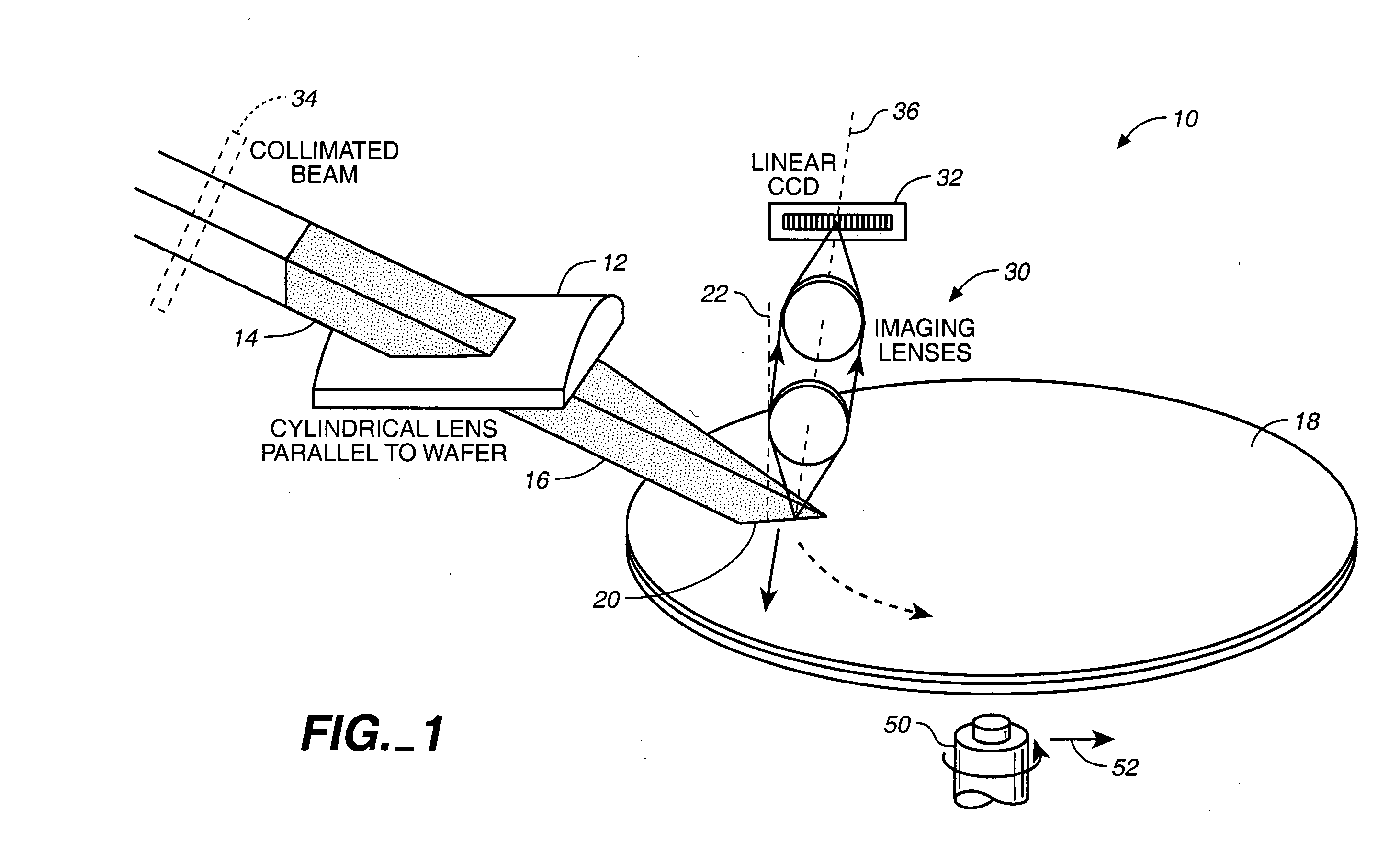

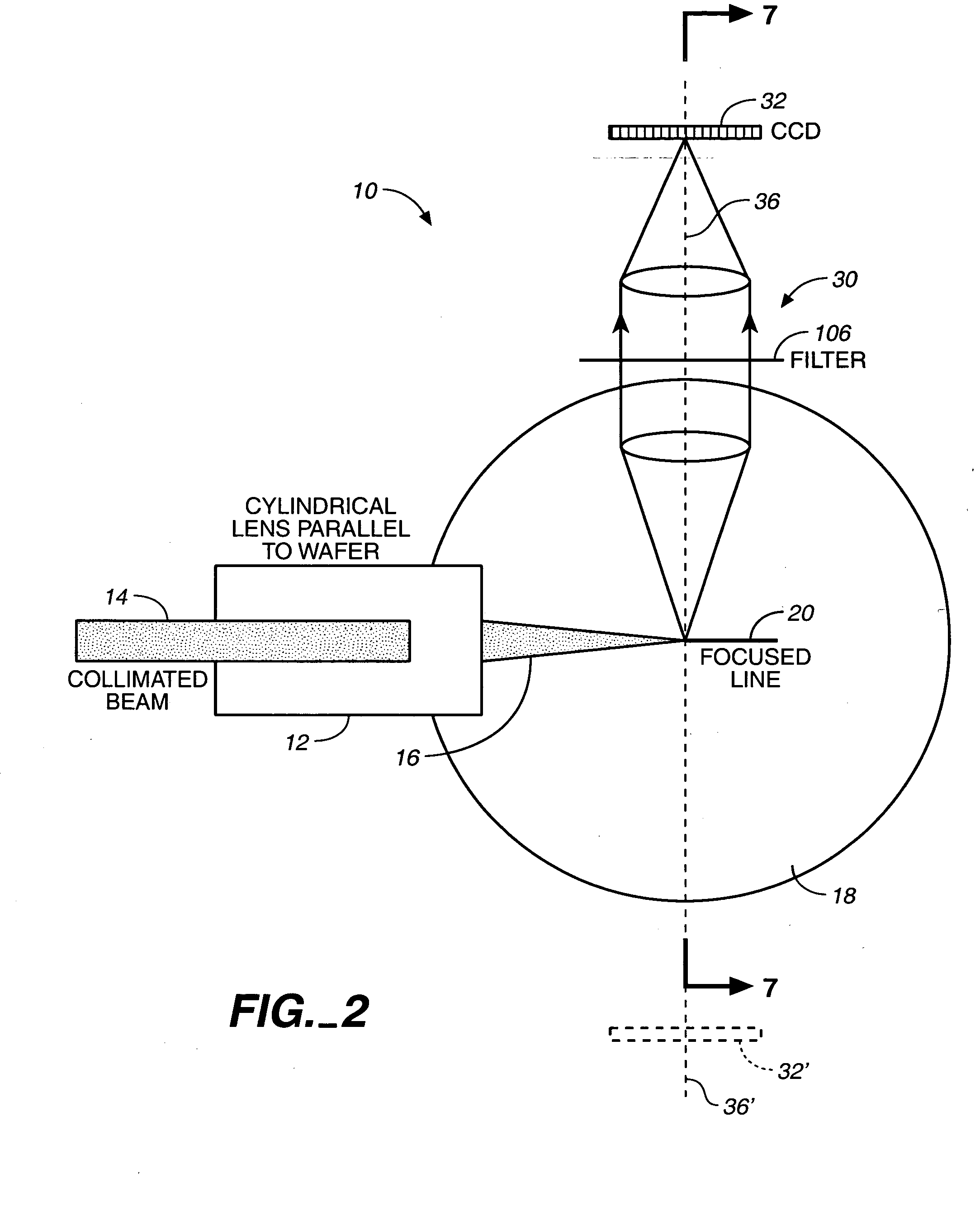

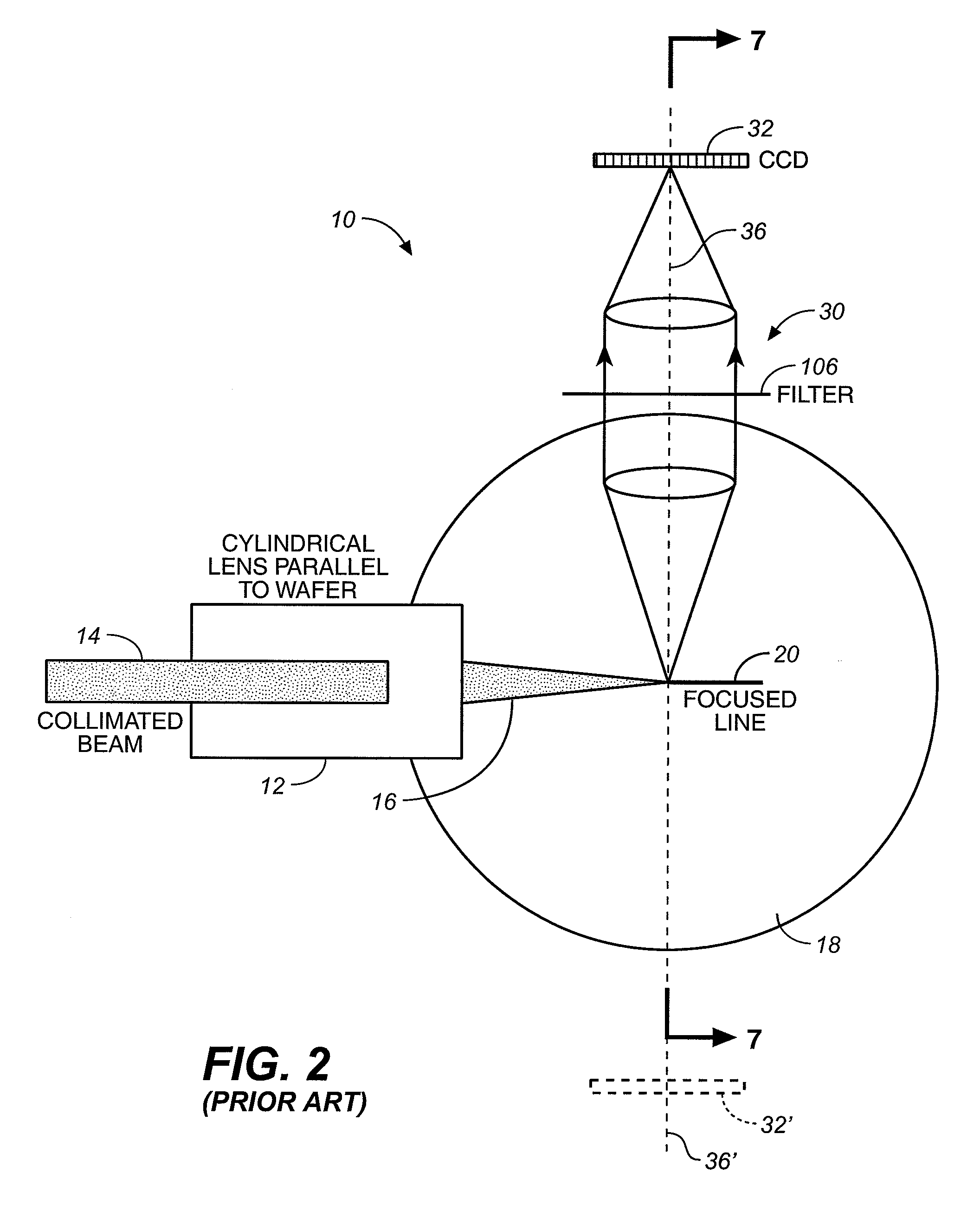

Optical system for detecting anomalies and/or features of surfaces

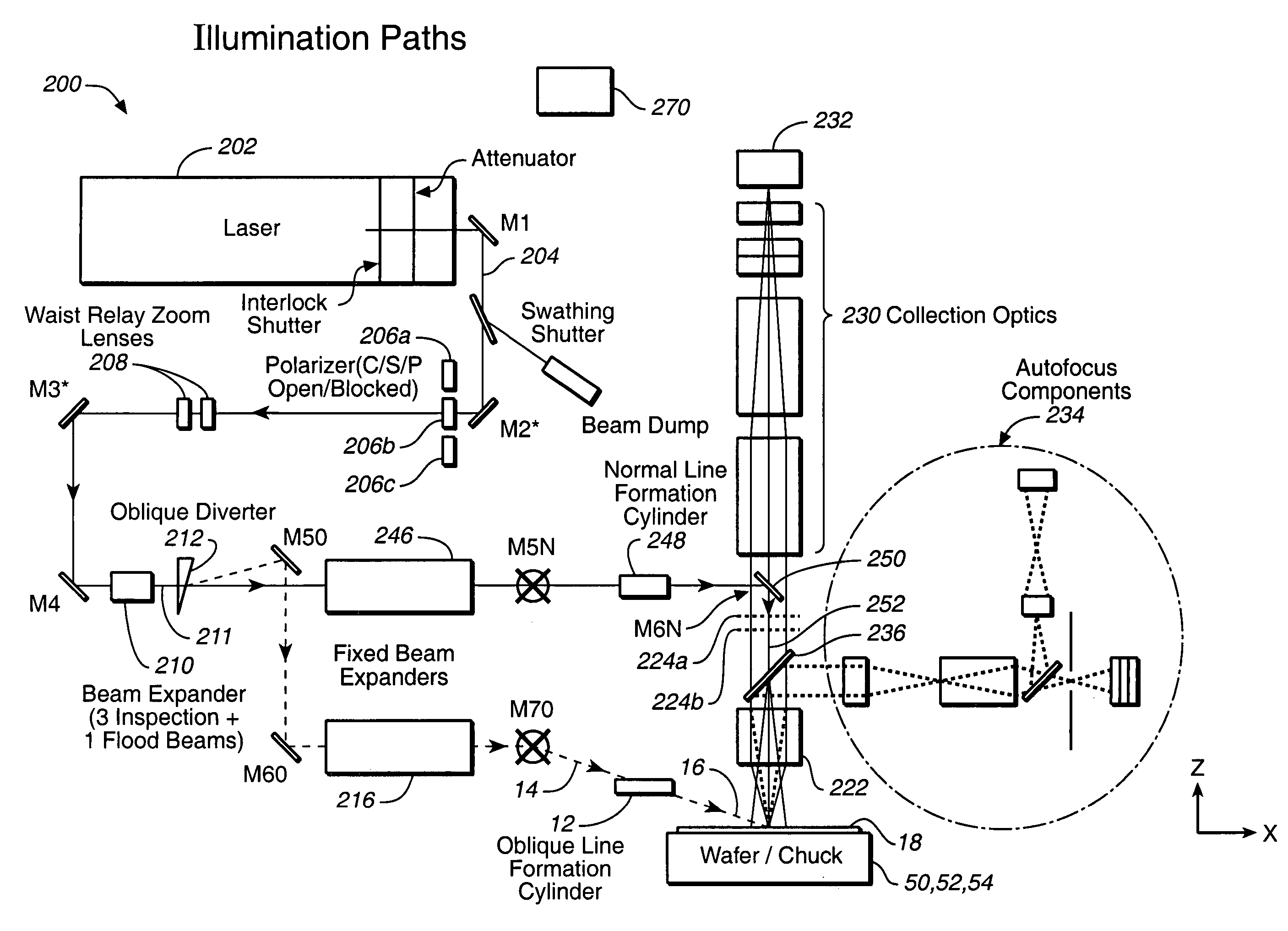

ActiveUS20050052644A1High detection sensitivityImprove throughputScattering properties measurementsOptically investigating flaws/contaminationDetector arrayRelative motion

A surface inspection of the system applies a first oblique illumination beam and may also apply a second illumination beam to illuminate a surface either sequentially or simultaneously. Radiation reflected or scattered is collected by preferably three collection channels and detected by three corresponding detector arrays, although a different number of channels and detector arrays may be used. One or both illumination beams are focused to a line on the surface to be inspected and each line is imaged onto one or more detector arrays in the up to three or more detection and collection channels. Relative motion is caused between the lines and the surface inspected in a direction perpendicular to the lines, thereby increasing throughput while retaining high resolution and sensitivity. The same detection channels may be employed by detecting scattered or reflected radiation from both illumination beams. Fourier filters may be employed to filter out diffraction at one or more different spatial frequencies.

Owner:KLA TENCOR TECH CORP

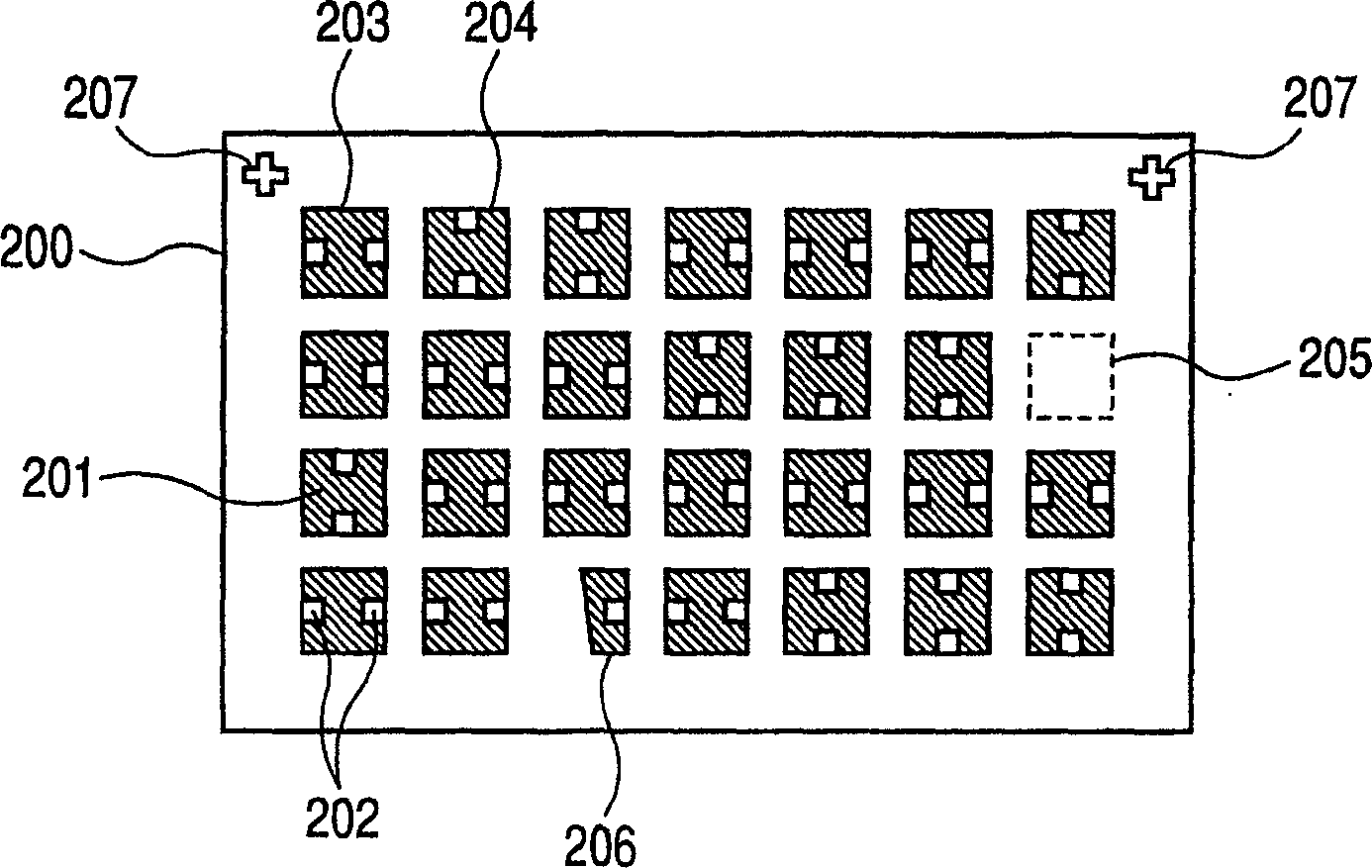

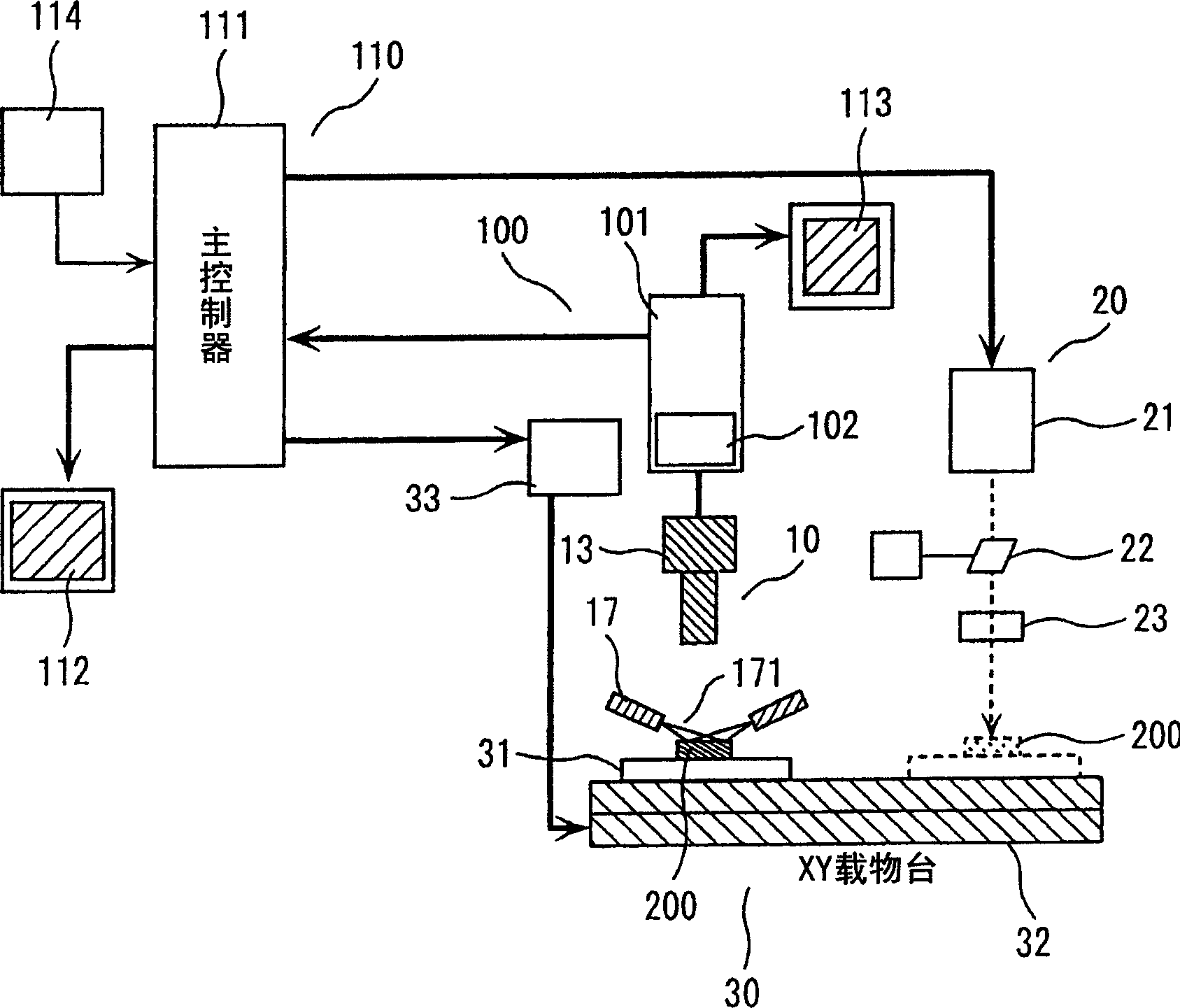

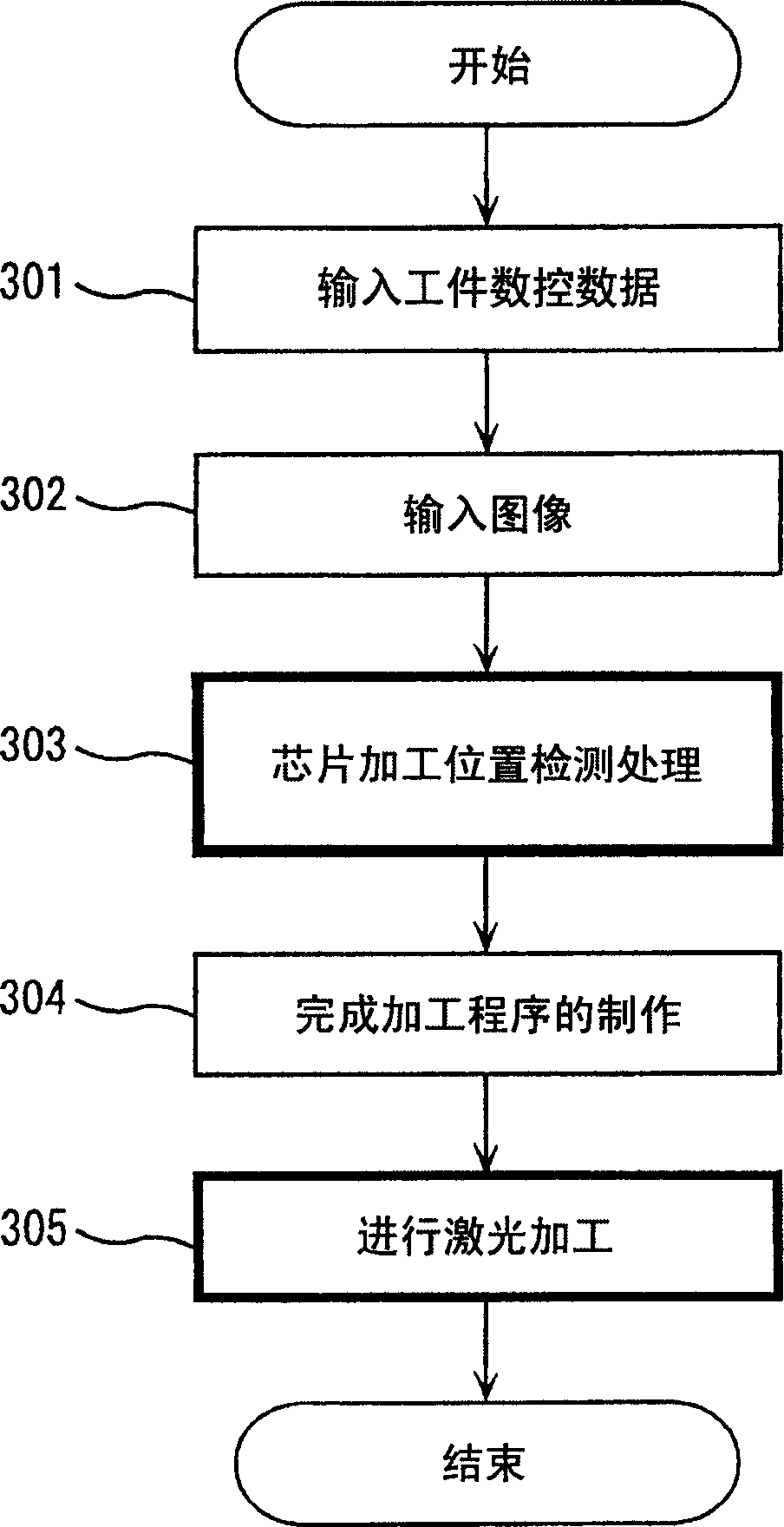

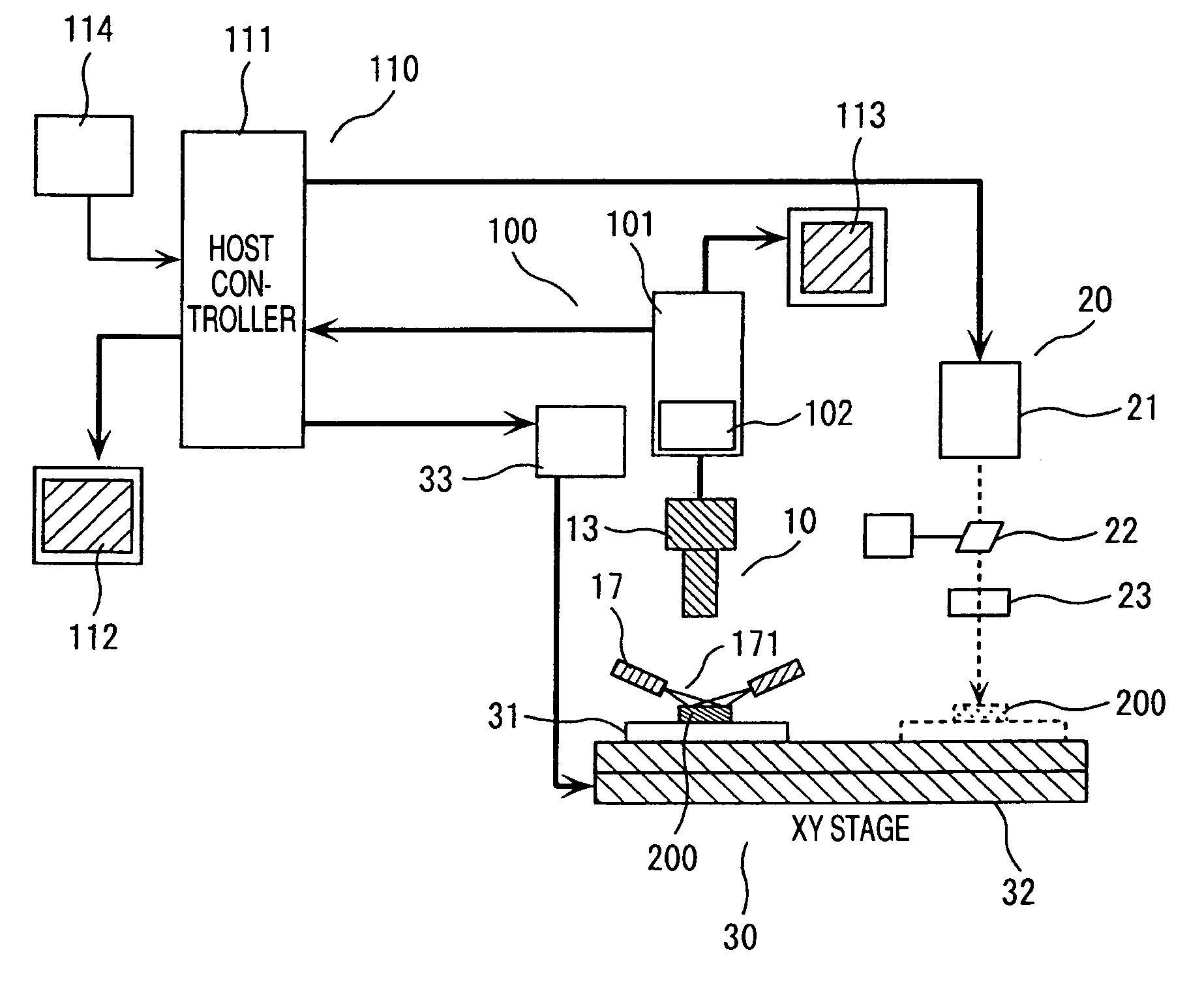

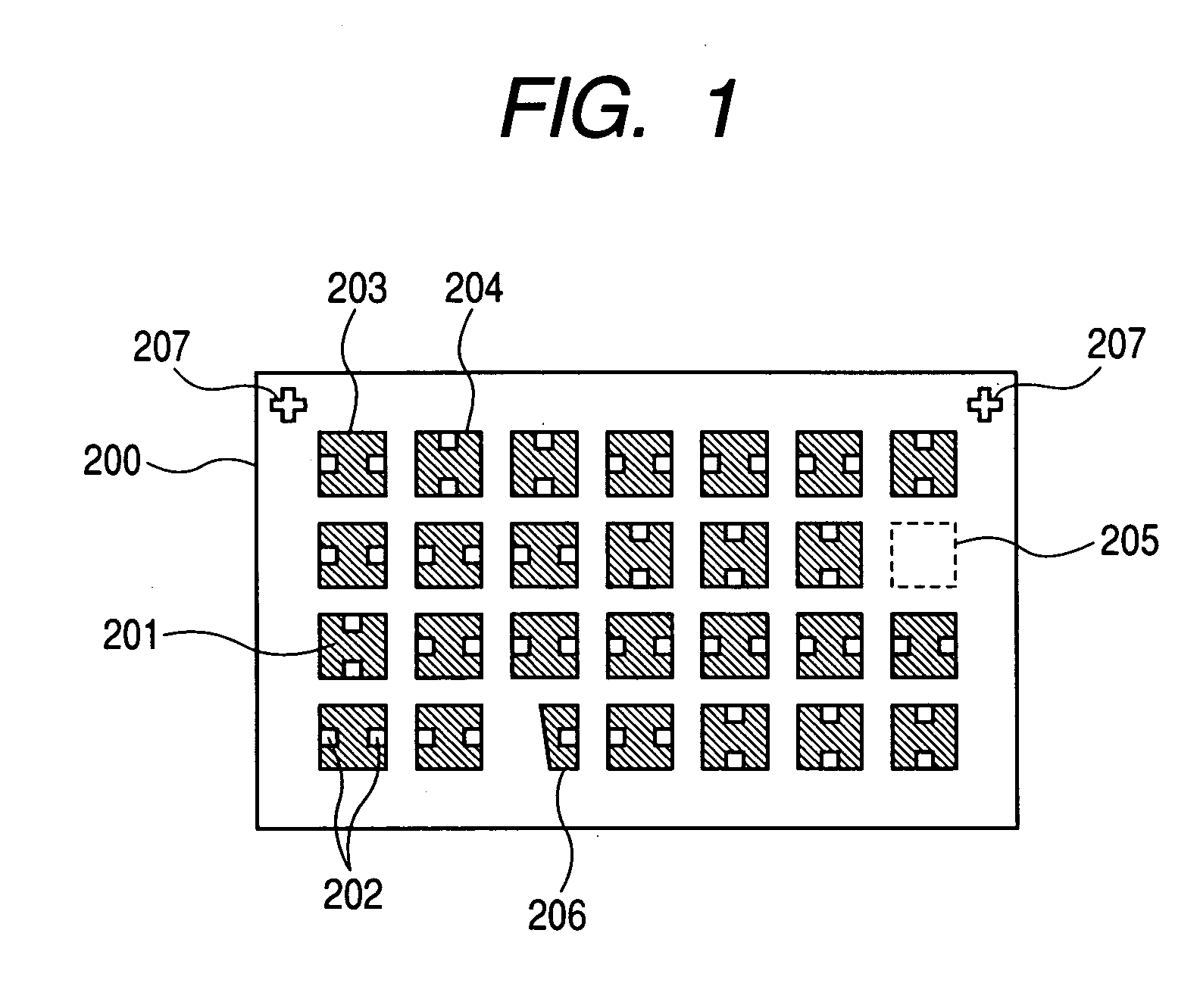

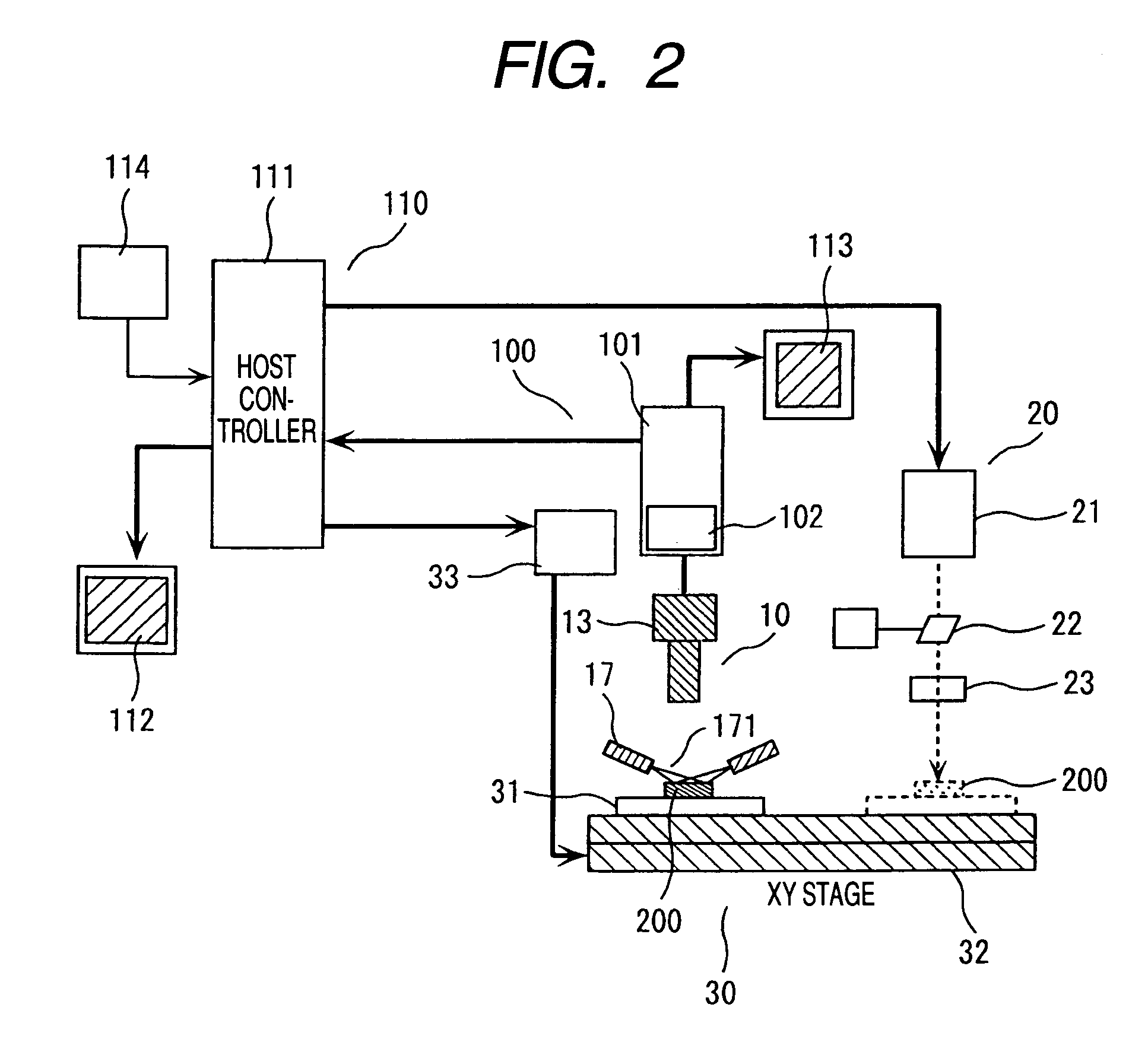

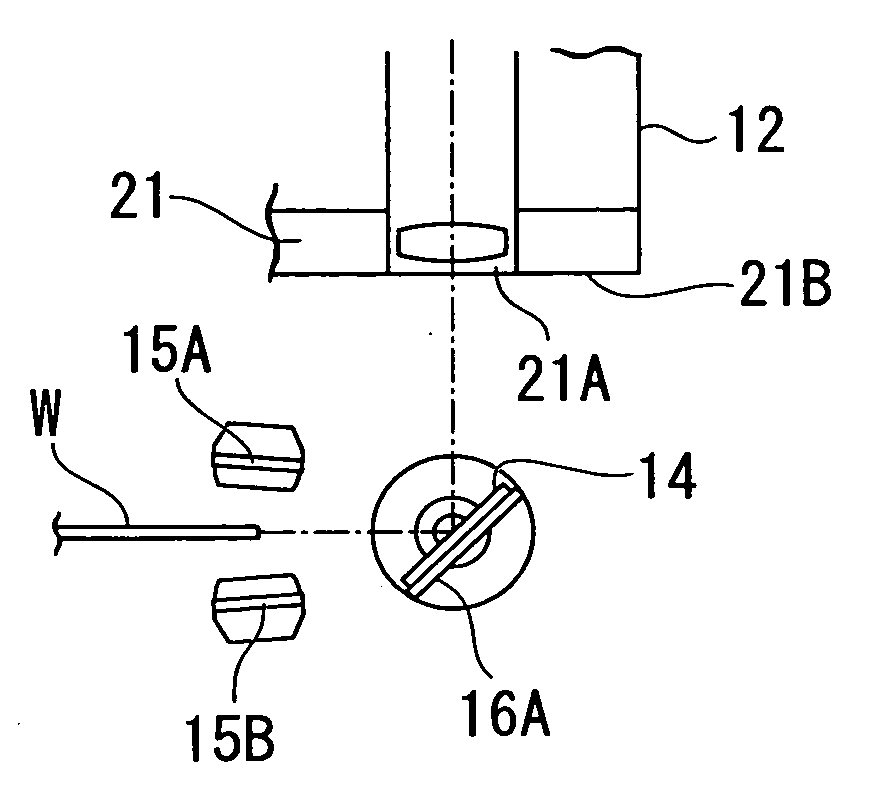

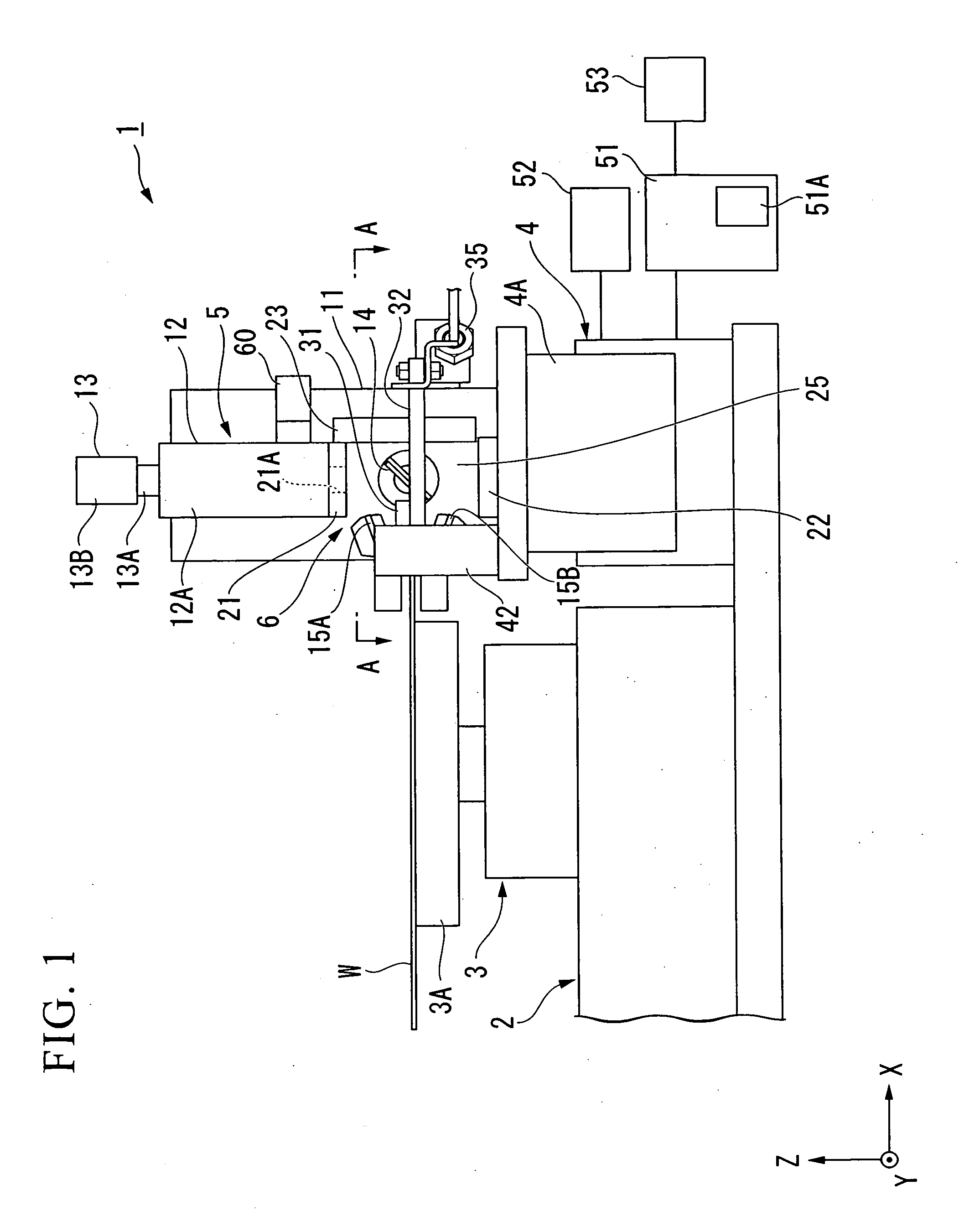

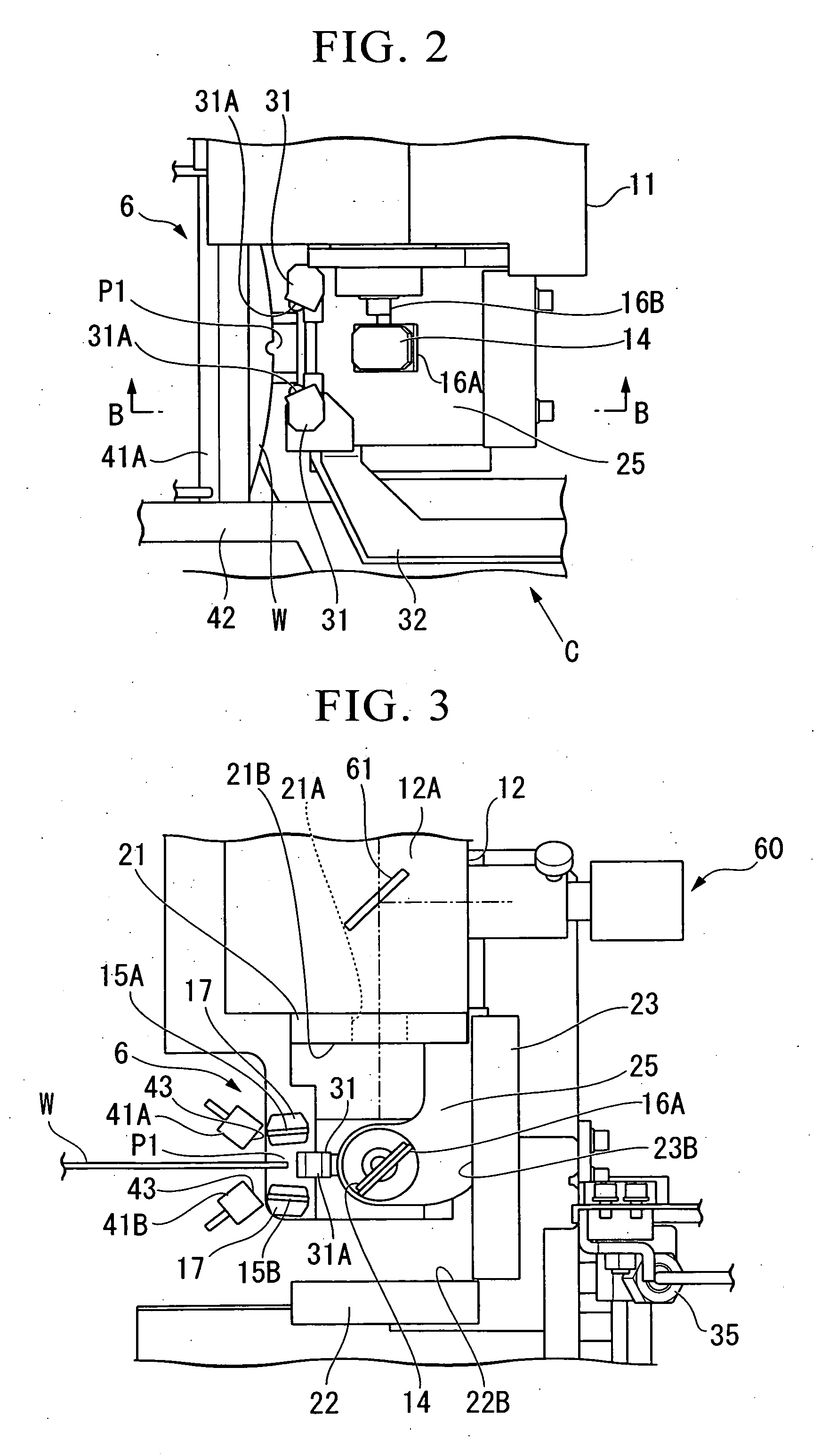

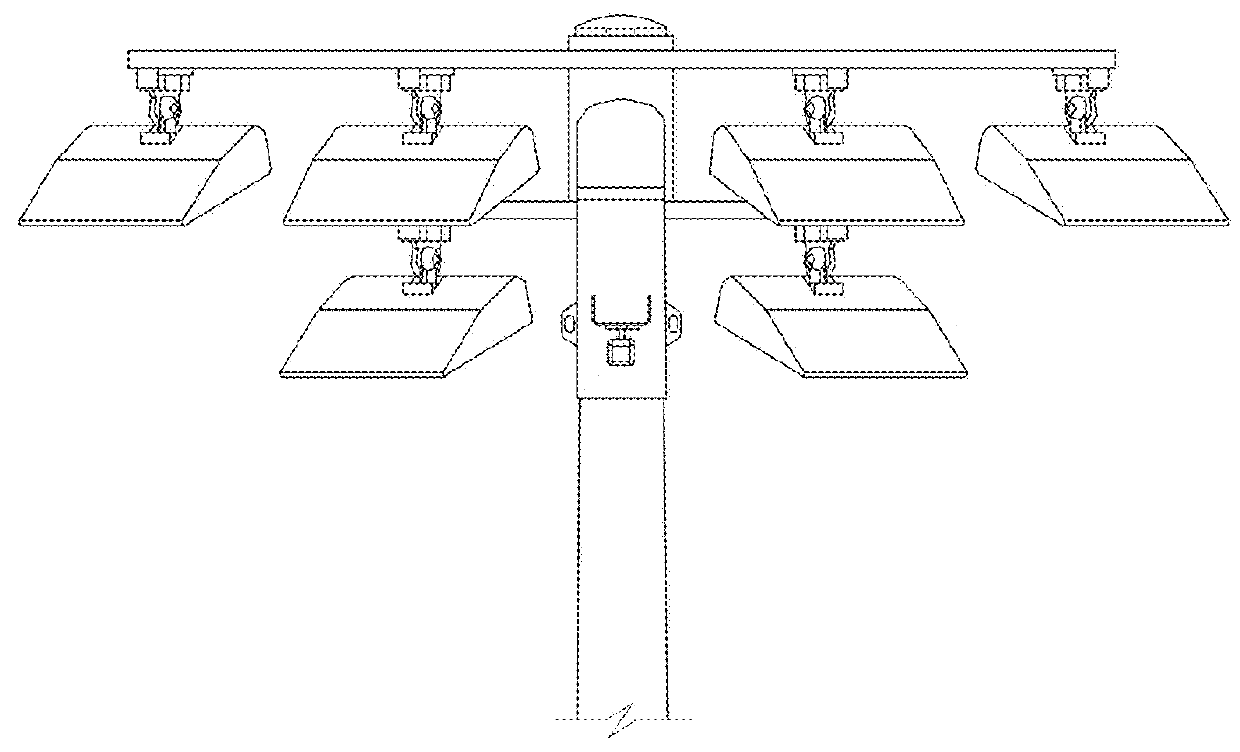

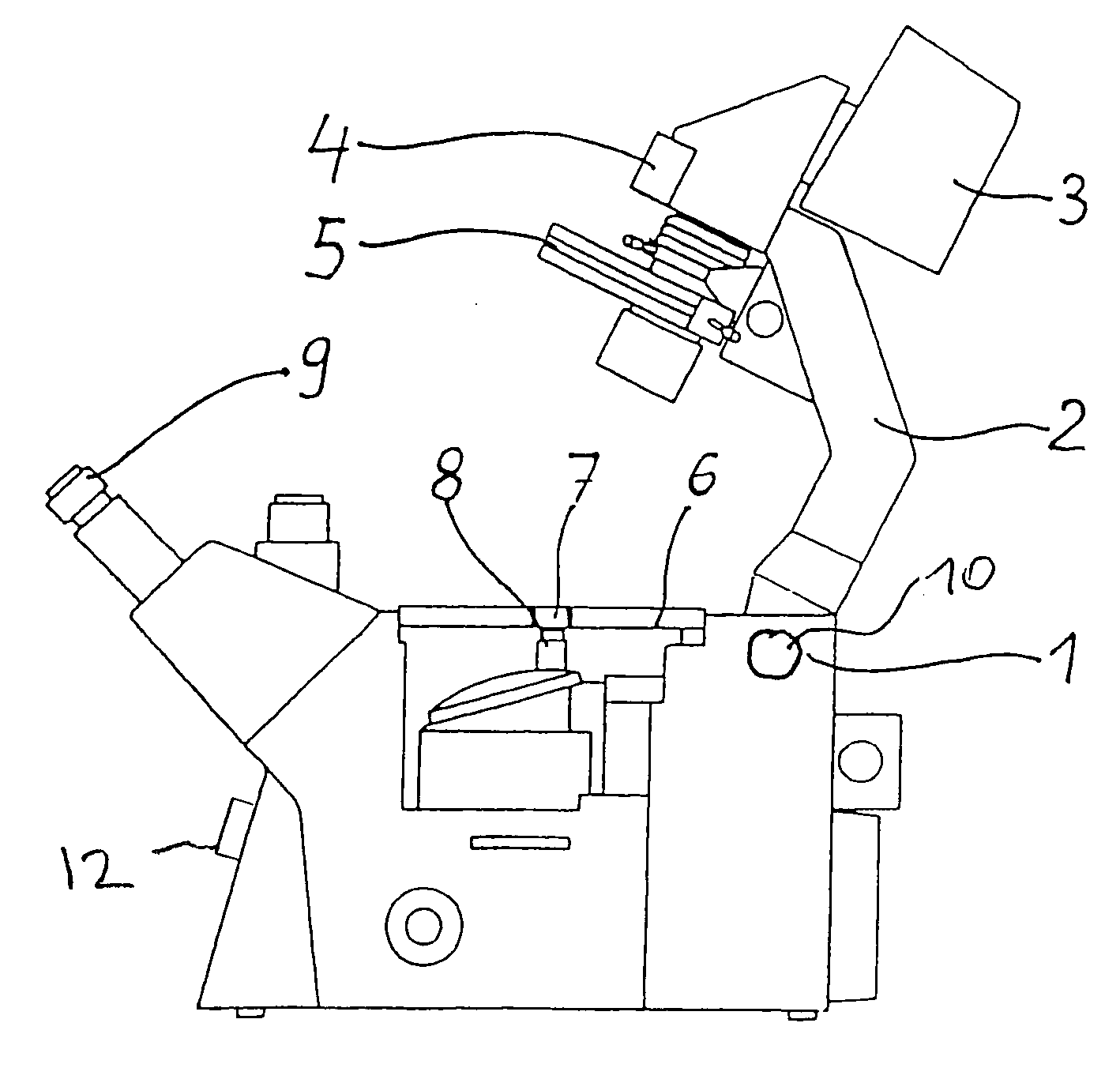

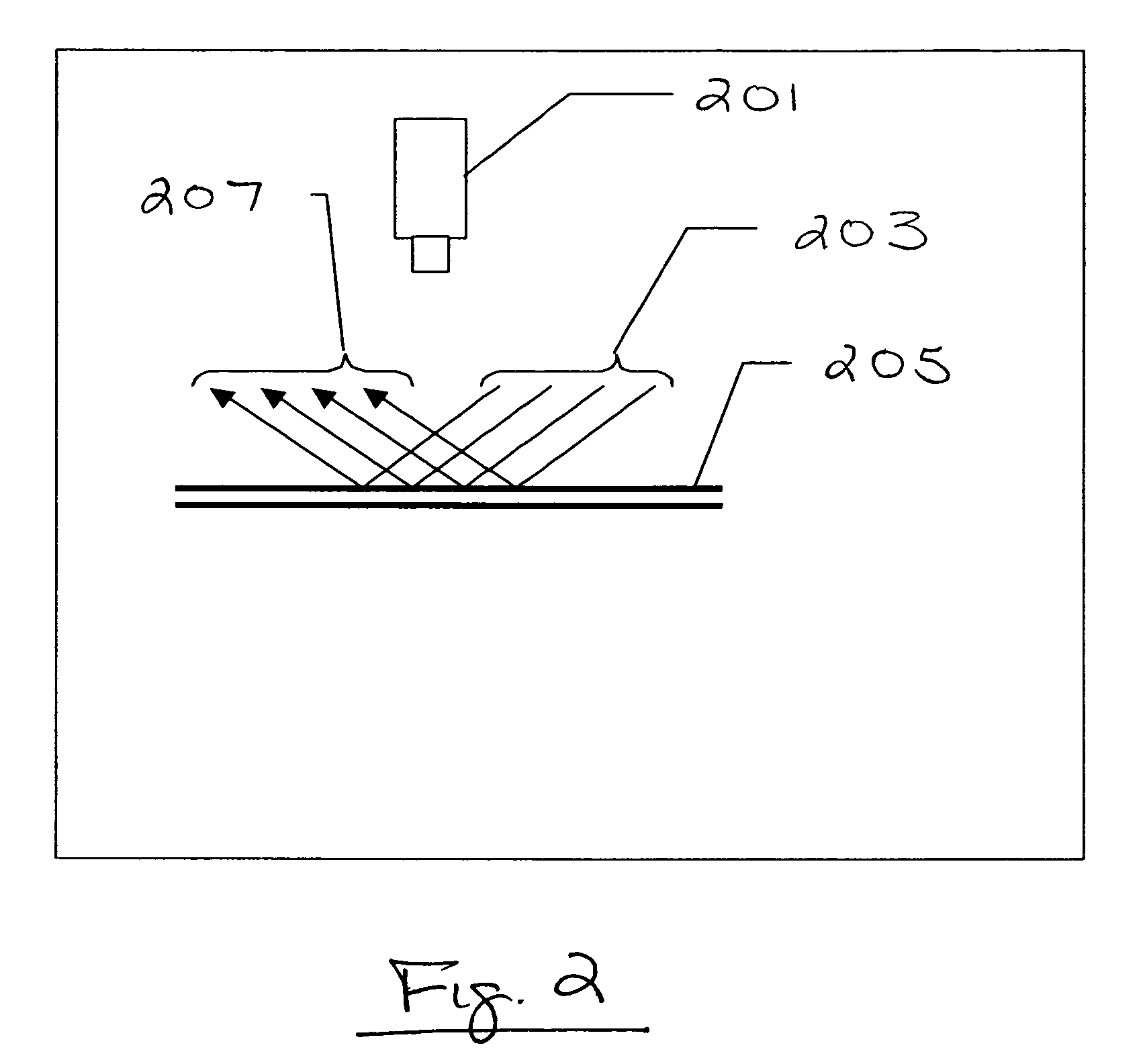

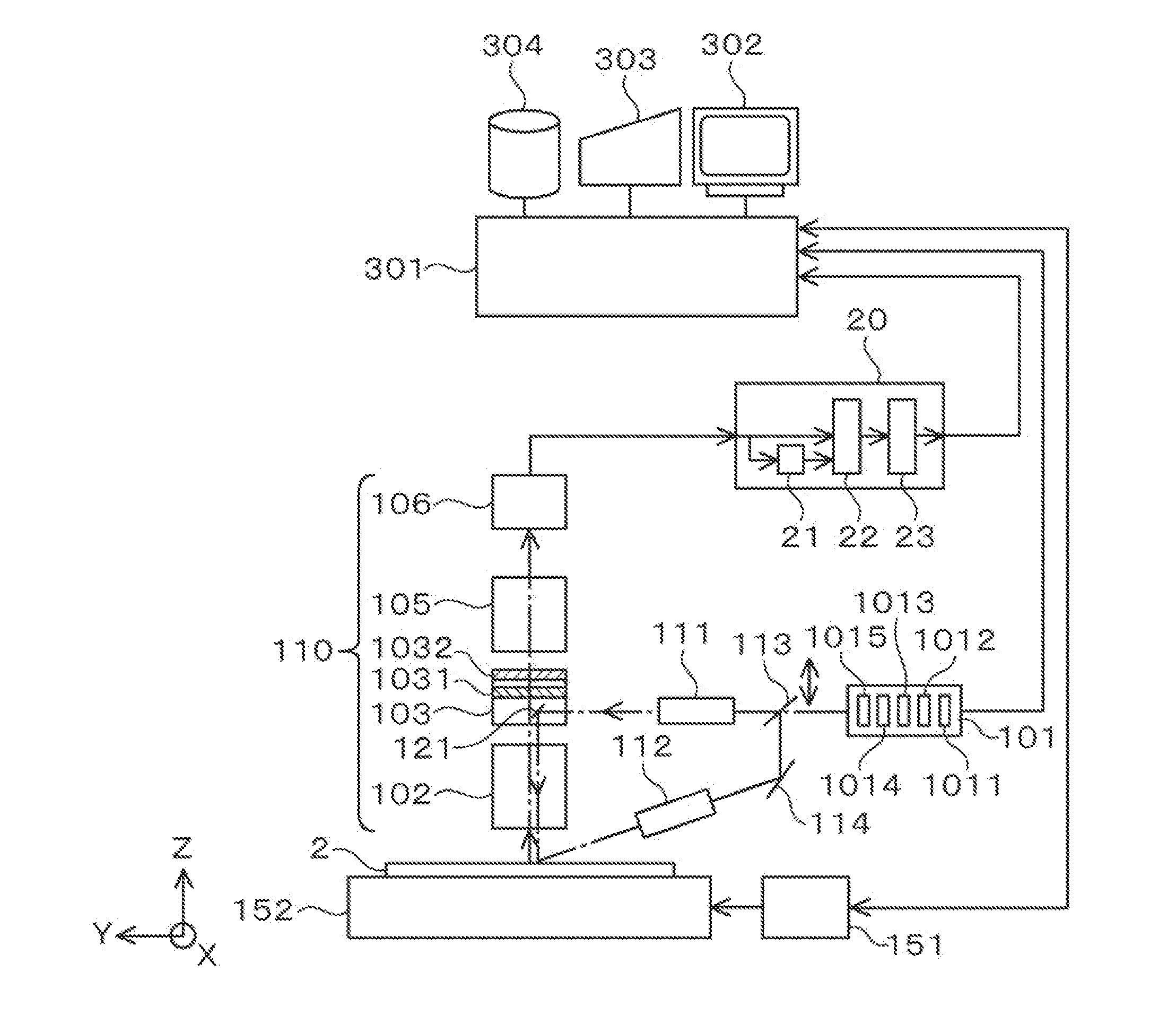

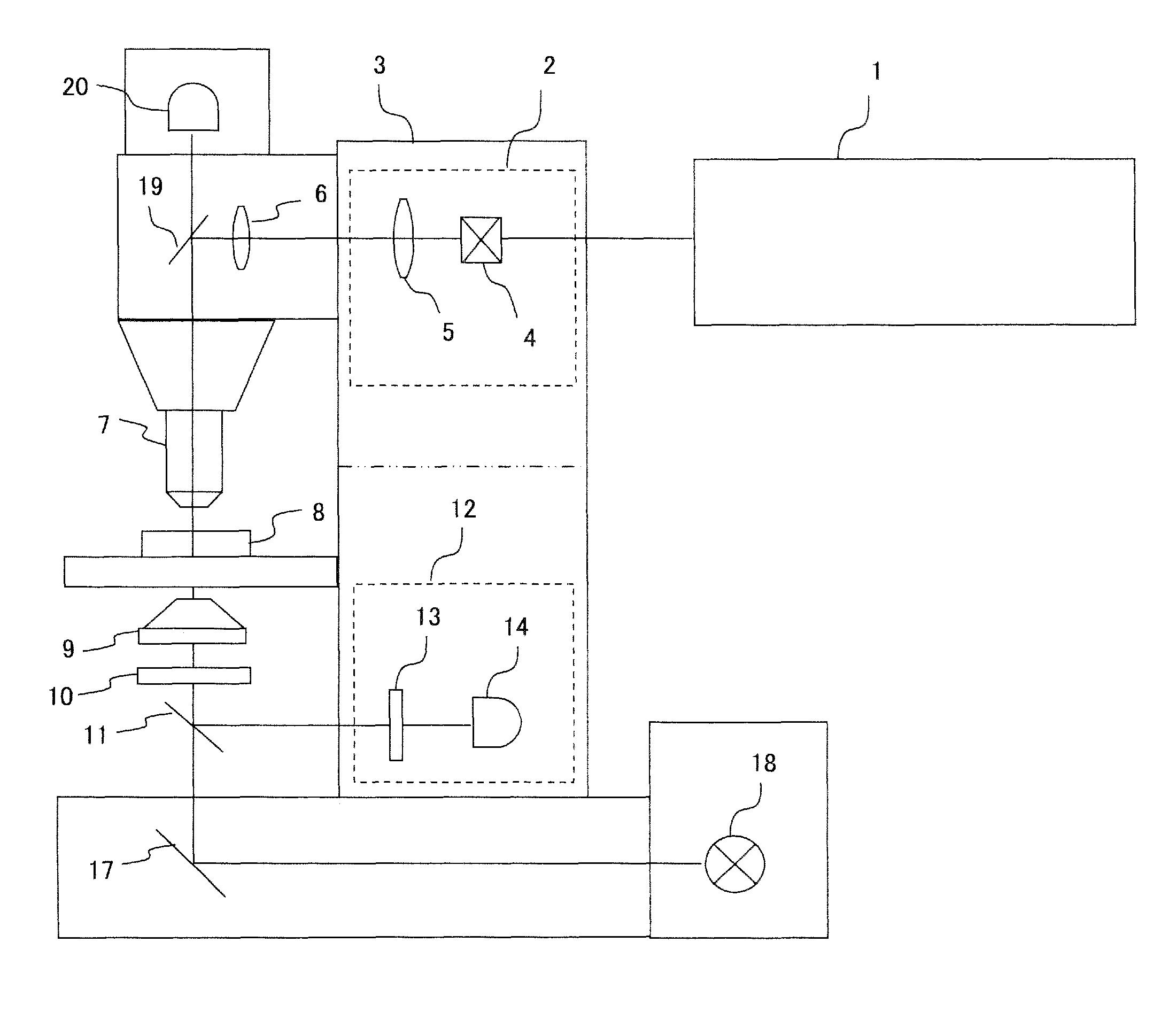

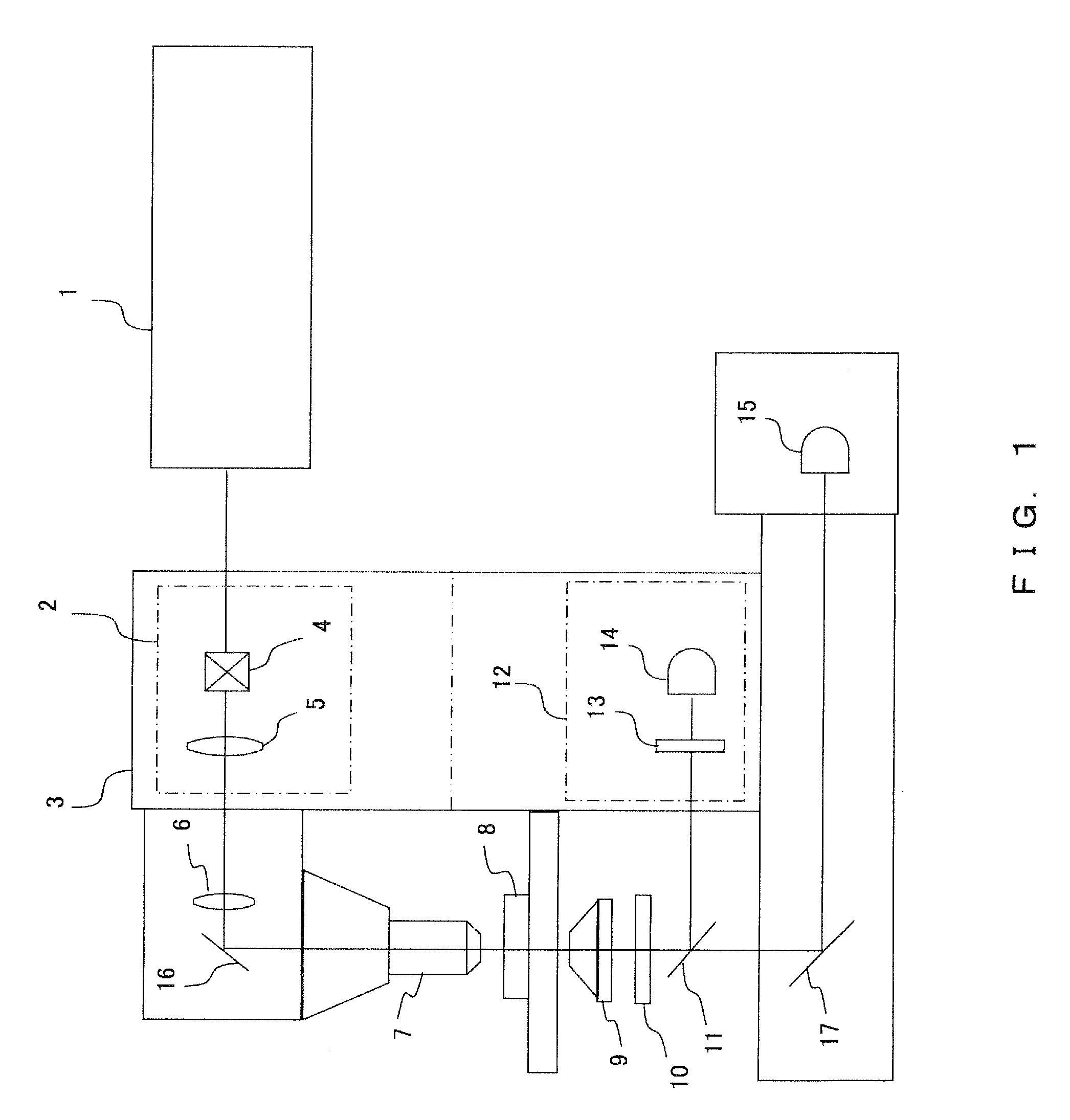

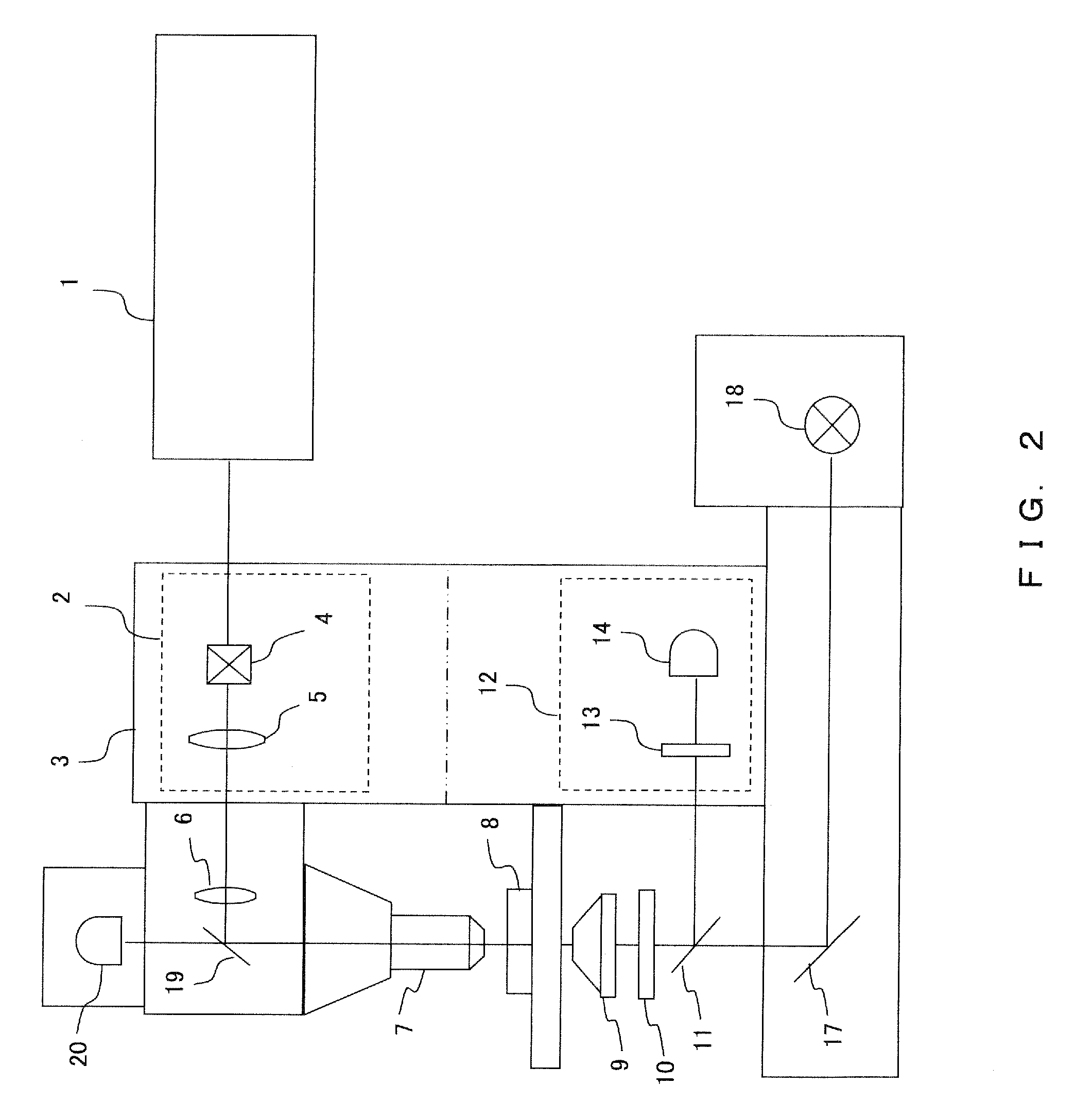

Laser processing machine and method

InactiveCN1772428AImprove efficiencyHigh precisionMetal working apparatusLaser beam welding apparatusLaser lightLaser source

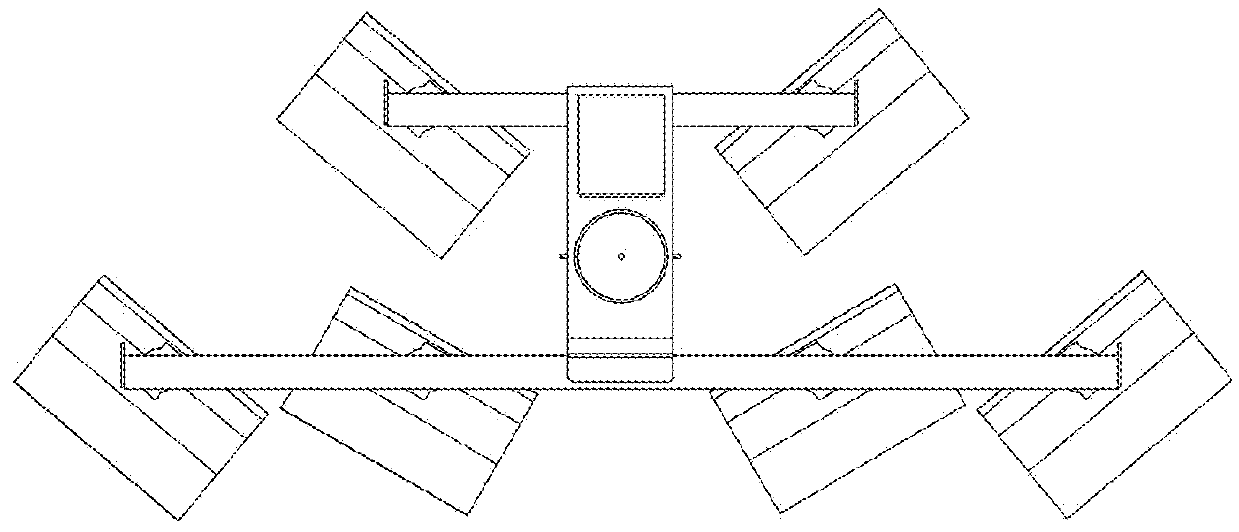

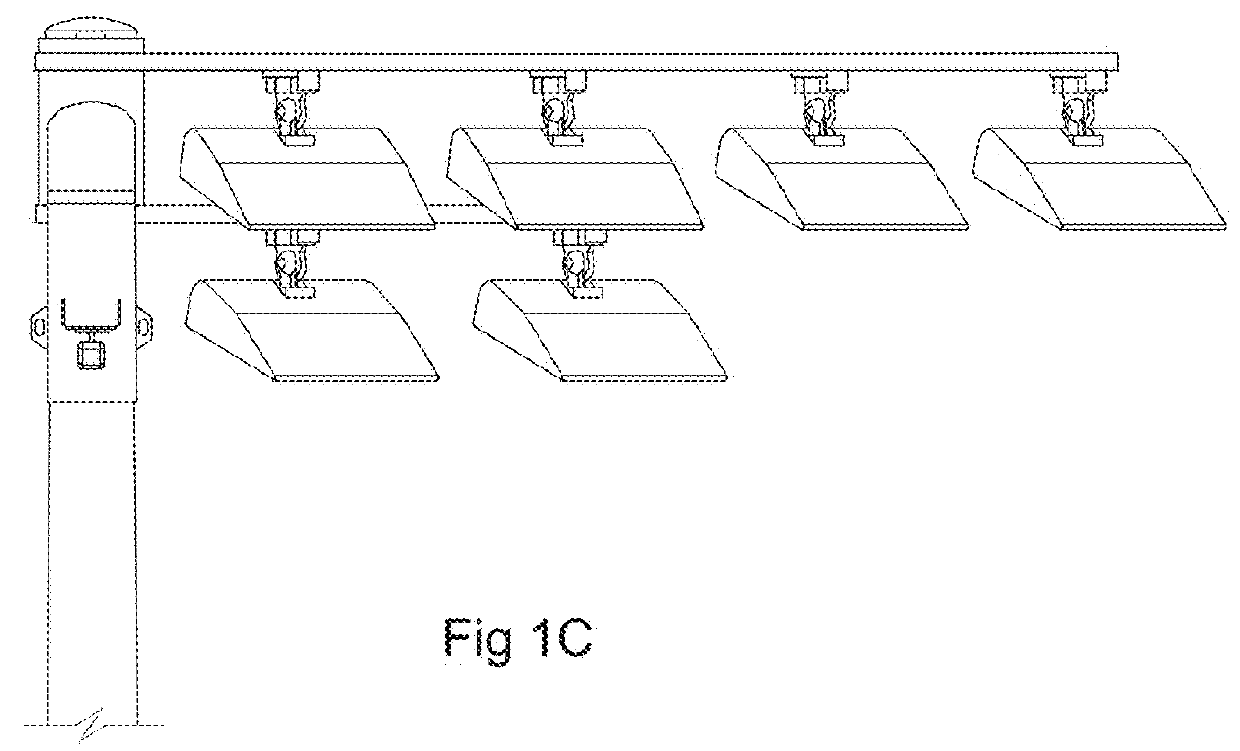

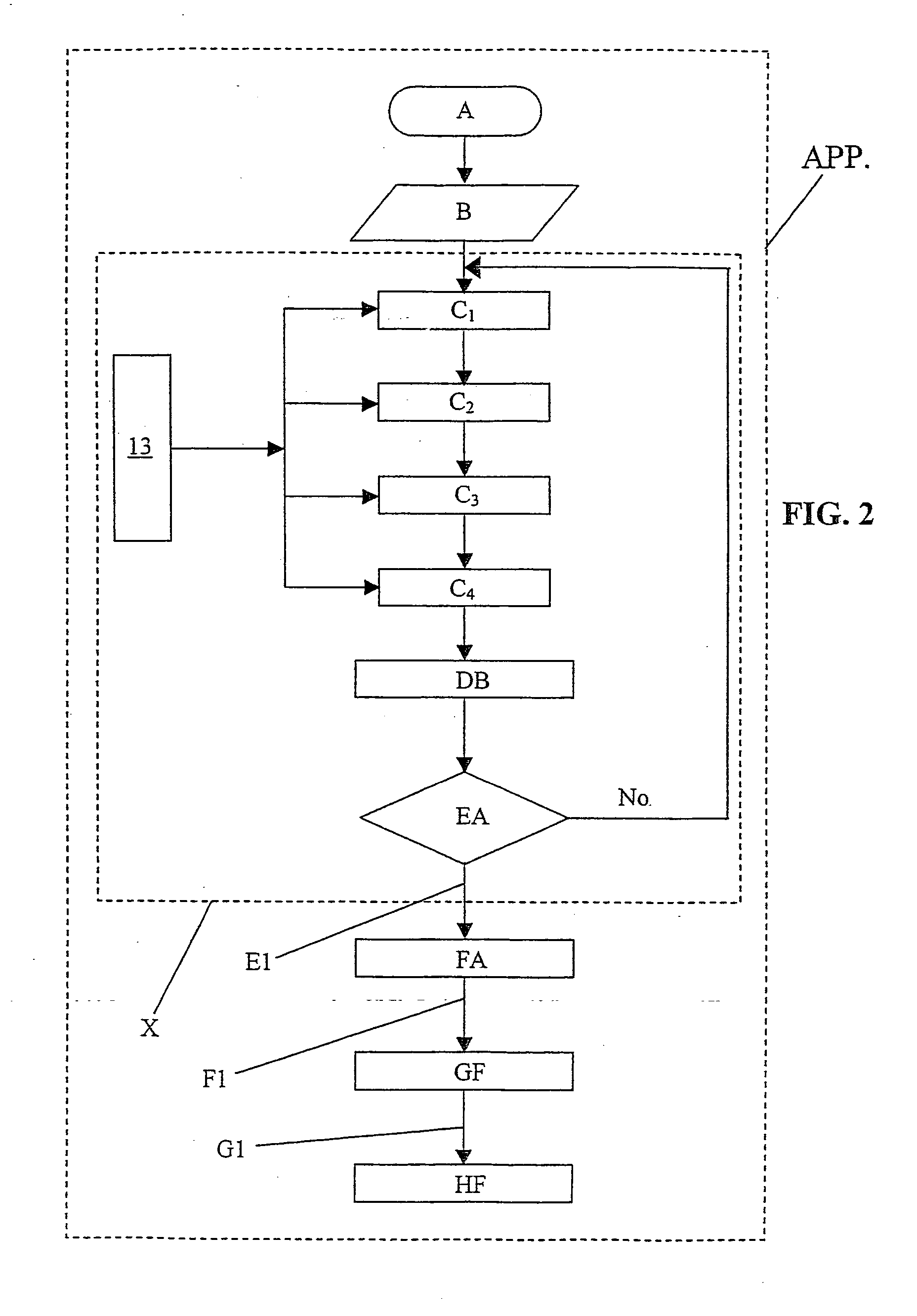

The laser processing machine of the present invention can perform high-efficiency and high-precision laser processing on workpieces where many processing objects are arranged, and deviations of the center coordinates of the processing parts within the processing tolerance or deviations of the loading positions of the processing objects occur. The laser processing machine of the present invention has: a workpiece (200) that is loaded with many processing objects; an XY stage (32) that moves in the XY direction according to the numerical control data; it is arranged on the image capturing station and has an oblique lighting optical system (17) and the image pick-up head (10) of detection optical system; Be arranged on the laser processing station, have laser source (21), obtain according to the deflection direction obtained from the image signal of each processing object obtained by the above-mentioned image pick-up head Control data, XY light deflector (22) for deflecting laser beam in XY direction and laser machining head (20) for illuminating lens (23) to incident deflected laser beam into each processing object from vertical direction.

Owner:HITACHI SEIKO LTD

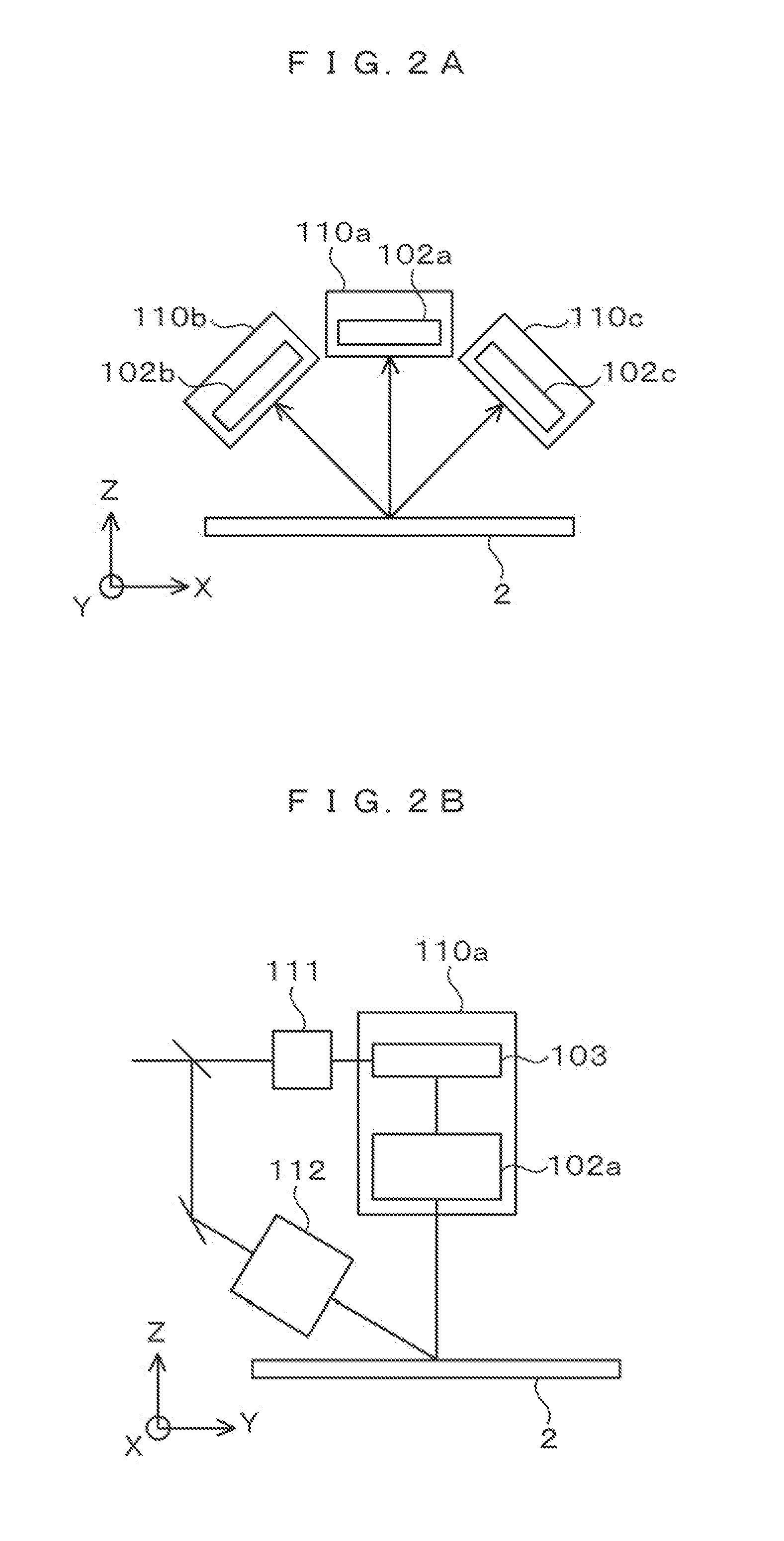

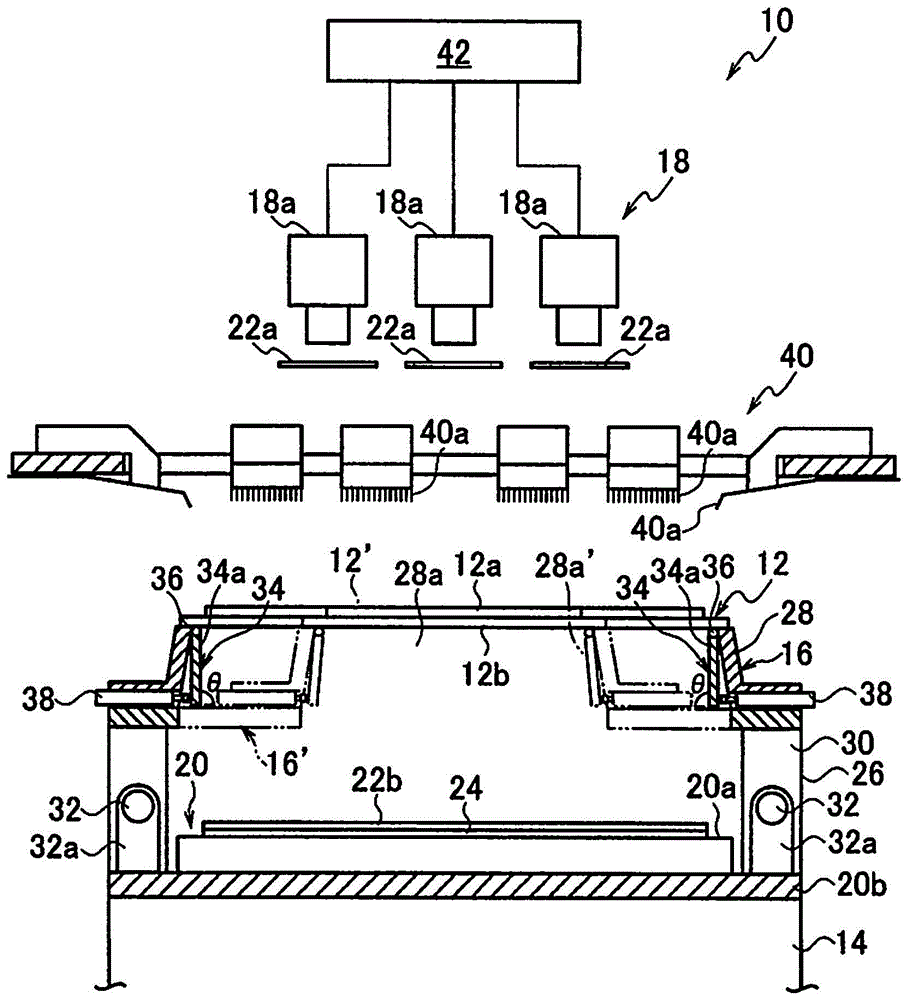

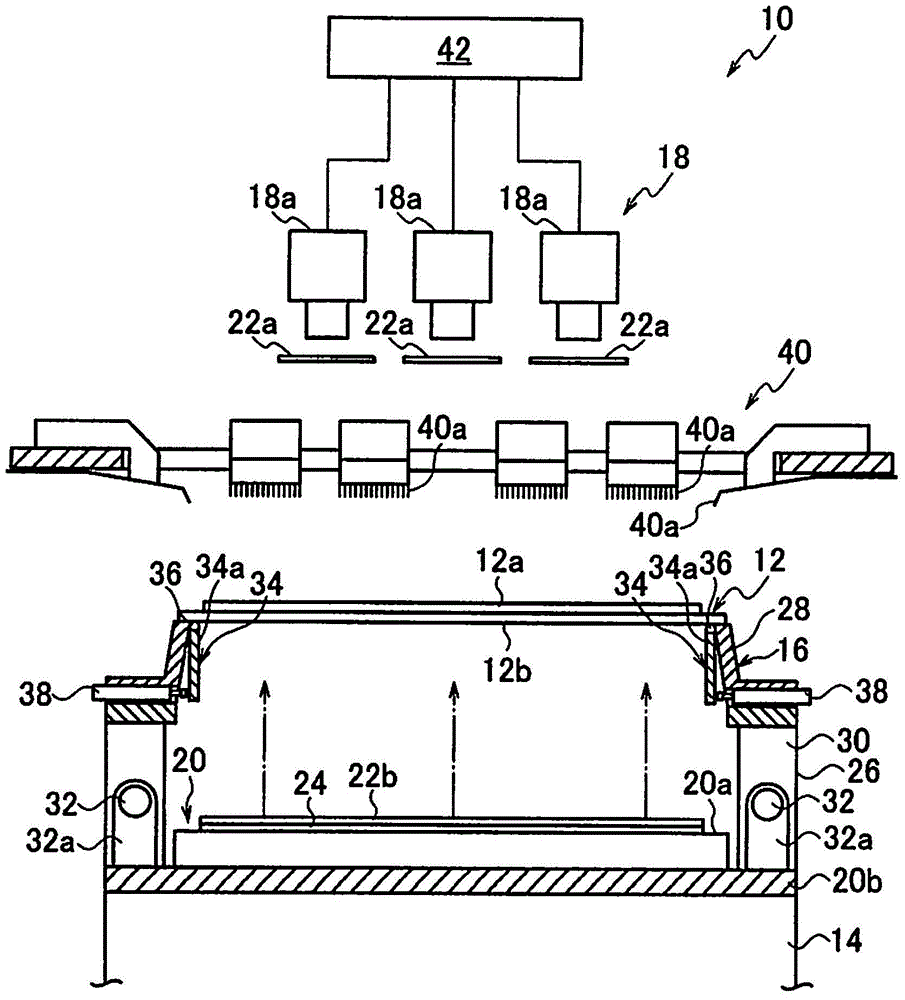

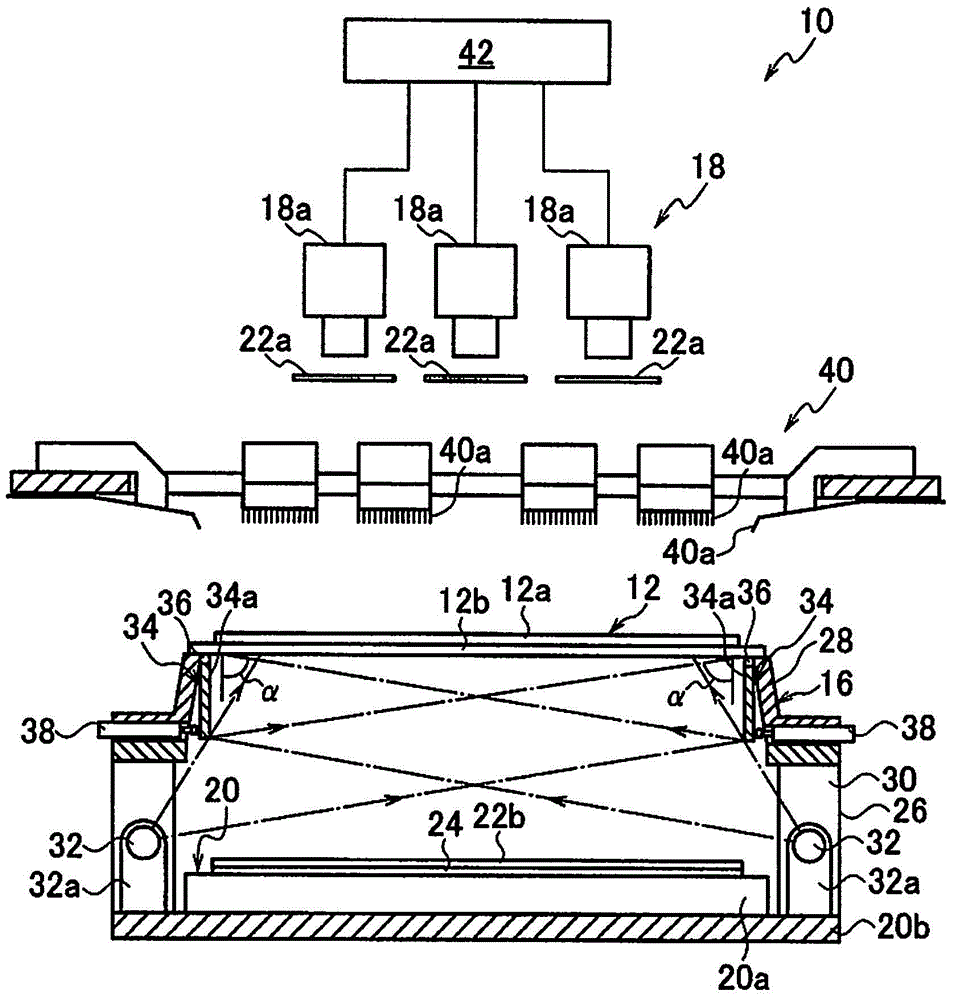

Laser processing machine and laser processing method

InactiveUS20060102608A1Efficient and high-precision processingEfficient and highly accurate laser machining of a workpieceMetal working apparatusLaser beam welding apparatusLaser lightOptoelectronics

The laser beam machine of the present invention includes: an XY stage on which to rest a workpiece with multiple machining objects arrayed on it, and which moves the workpiece in an XY direction on the basis of NC data; an image acquisition head which is provided in an image acquisition station and has oblique illumination optical system and detection optical system; and a laser machining head which is provided in a laser machining station and has a laser light source, an XY optical beam deflector for deflecting a laser beam in the XY direction on the basis of the deflection control data obtained in accordance with the image signals from each machining object that have been acquired by the image acquisition head, and an irradiation lens for admitting the above-deflected laser beam into each machining object from a substantially perpendicular direction.

Owner:HITACHI SEIKO LTD

Surface inspection apparatus and method thereof

InactiveUS6894302B2Easy to findEfficient preparationSemiconductor/solid-state device testing/measurementInvestigating moving sheetsForeign matterEpi illumination

The invention provides a surface inspection apparatus and a method for inspecting the surface of a sample that are capable of inspecting discriminatingly between the scratch of various configuration and the adhered foreign object that occur on the surface of a work target when the work target (for example, an insulating film on a semiconductor substrate) is subjected to polishing process such as CMP or grinding process in semiconductor manufacturing process or magnetic head manufacturing process. In the invention, the scratch and foreign object that occur on the polished or ground surface of the sample is epi-illuminated and slant-illuminated by use of approximately same light flux, the difference between the scattered light intensity emitted from the shallow scratch and that from the foreign object when epi-illumination is applied and slant illumination is applied to thereby discriminate between the shallow scratch and the foreign object, and the directionality of the scattered light when the epi-illumination is applied and the slant illumination is applied is detected to thereby discriminate between the linear scratch and the foreign object.

Owner:HITACHI LTD +1

Apparatus and method for inspecting defects

InactiveUS7187438B2Improve reliabilityImprove efficiencyImage analysisSemiconductor/solid-state device testing/measurementLuminous fluxUltimate tensile strength

The present invention is characterized by the following: incident illumination and oblique illumination are performed on a scratch and a foreign material, which have been made on a surface of a polished or a ground insulating layer, with substantially the same luminous flux; and on the basis of a correlation such as a ratio of intensity of scattered light generated by the shallow scratch and the foreign material between the incident illumination and the oblique illumination, the shallow scratch is discriminated from the foreign material.

Owner:HITACHI HIGH-TECH CORP +1

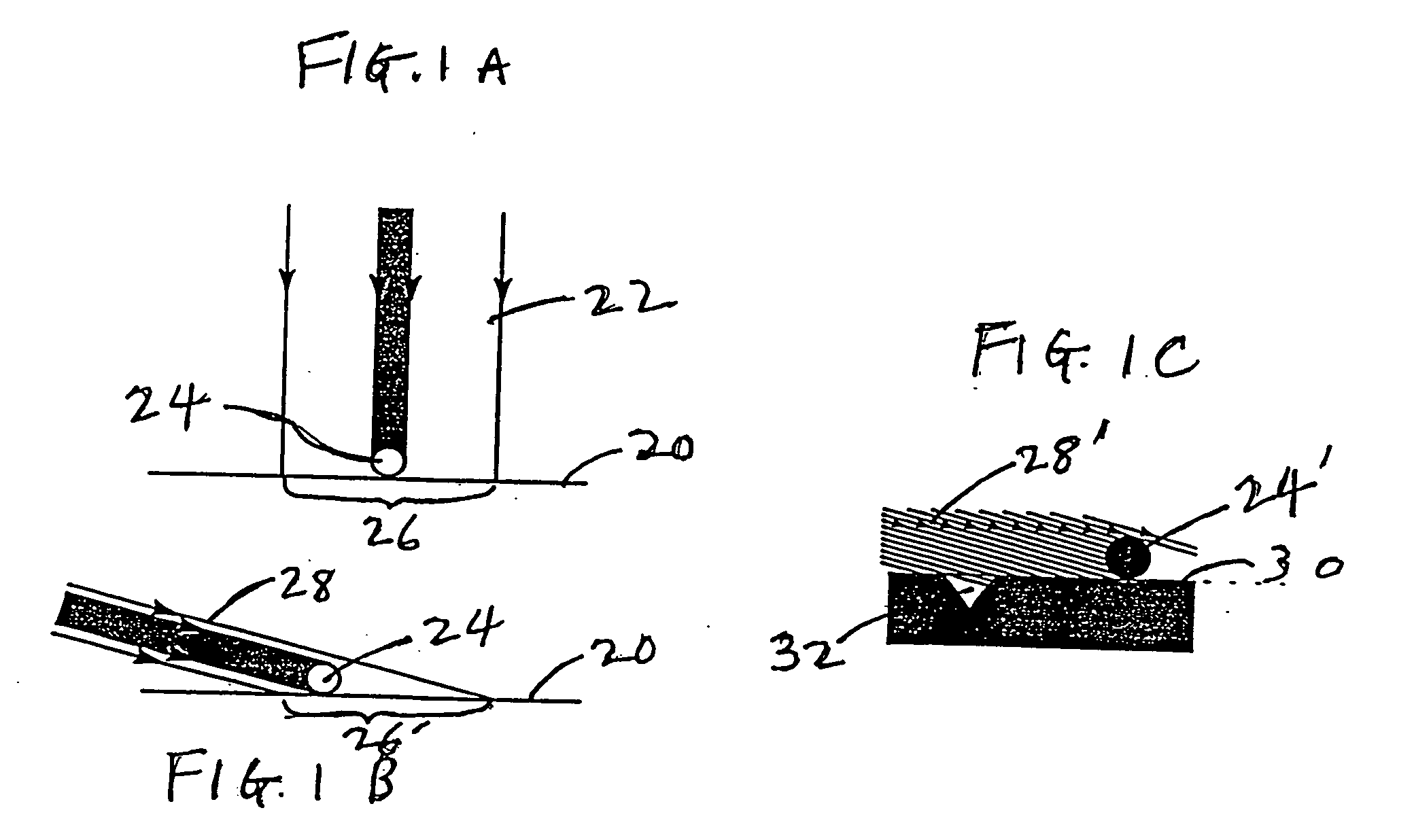

Oblique-illumination systems and methods

Oblique-illumination systems integrated with fluorescence microscopes and methods of using oblique illumination in fluorescence microscopy are disclosed. An oblique-illumination system is attached to a fluorescence microscope objective. The oblique-illumination system can be used to illuminate from any desired direction the surface of an object located at a fixed known offset away from a sample solution containing fluorescently tagged targets. Oblique illumination is used to illuminate features of the surface while epi-illumination is used to create fluorescent light emitted from the tagged targets. The combination of oblique illumination of the surface and epi-illumination of the targets enables capture of images of the surface features and the fluorescent targets so that the locations of the targets in the sample can be determined based on the locations of the surface features.

Owner:GE HEALTHCARE BIO SCI CORP

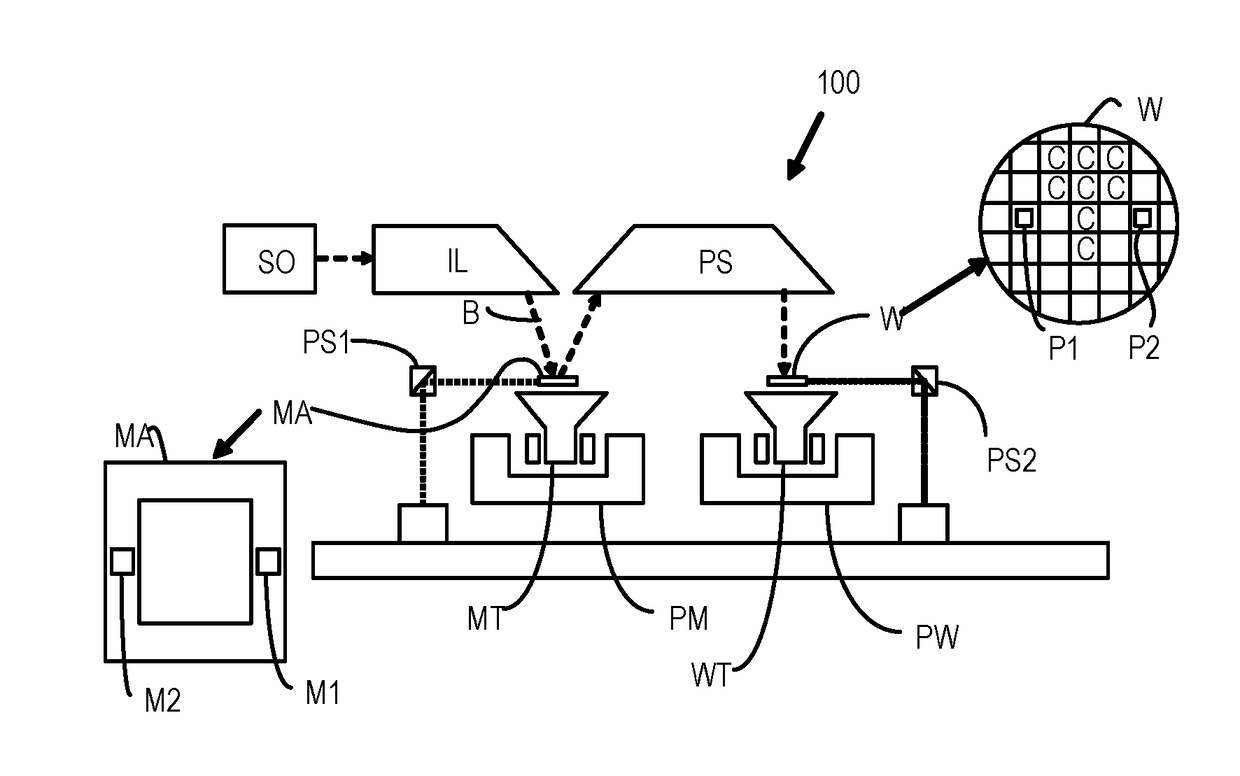

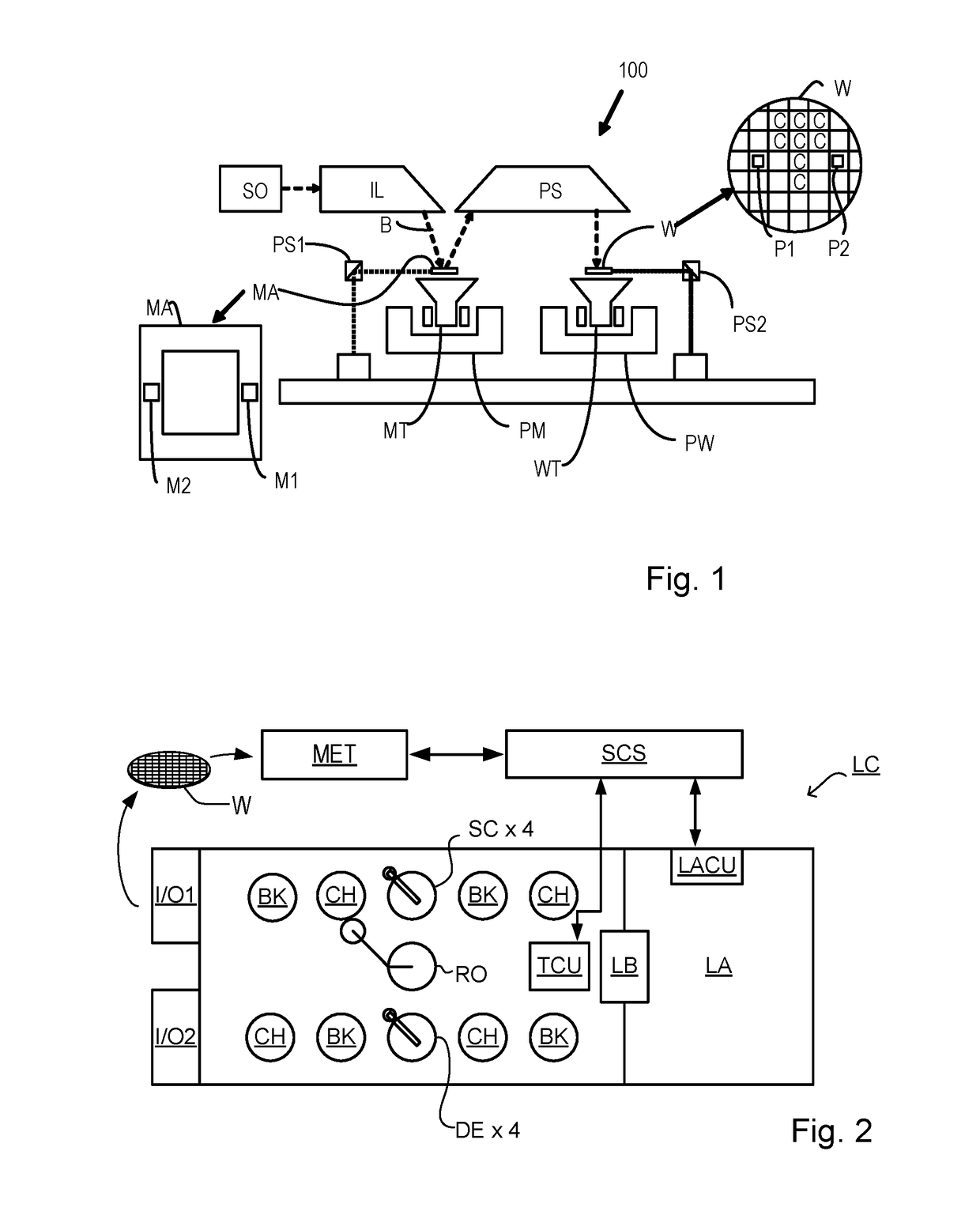

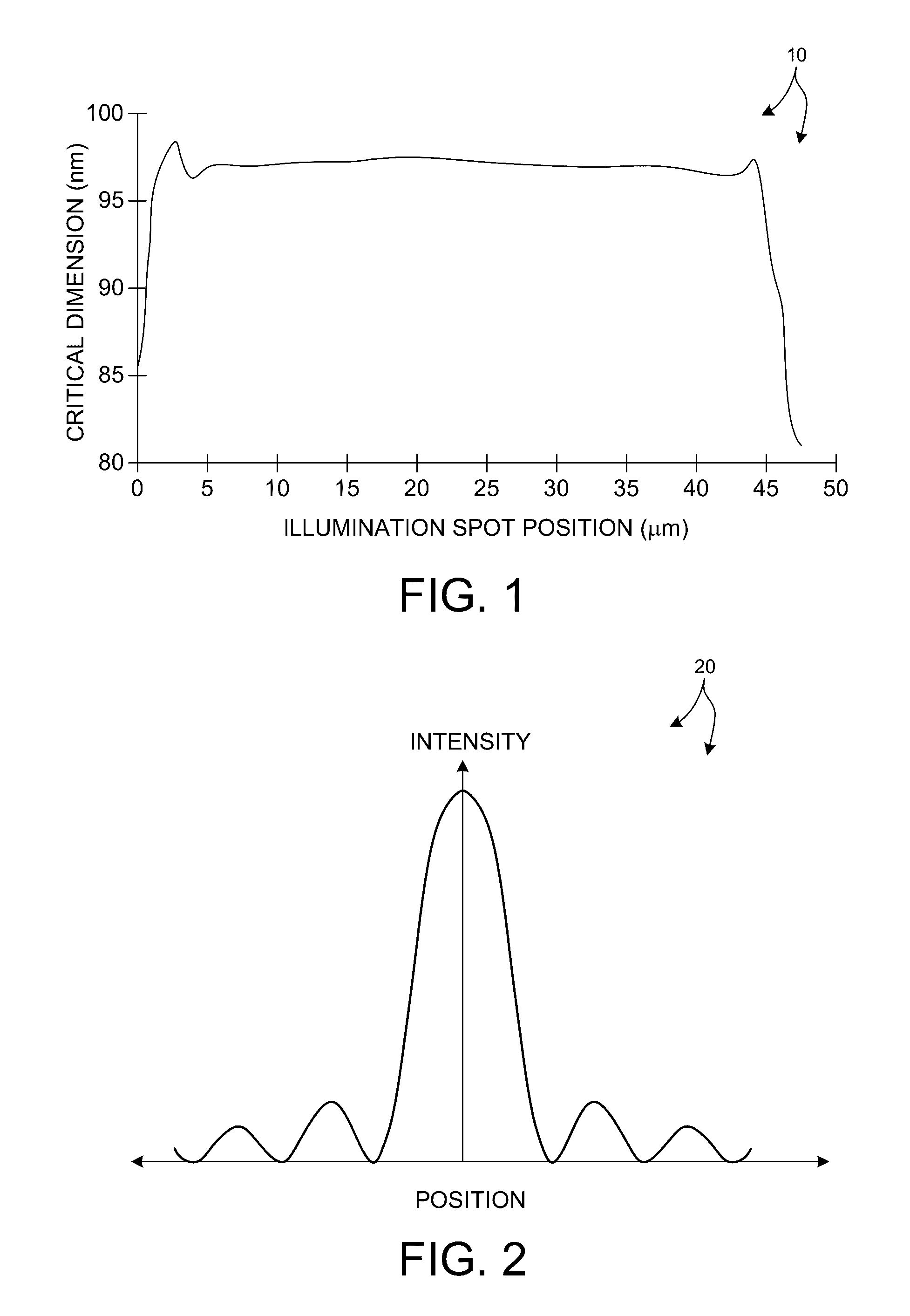

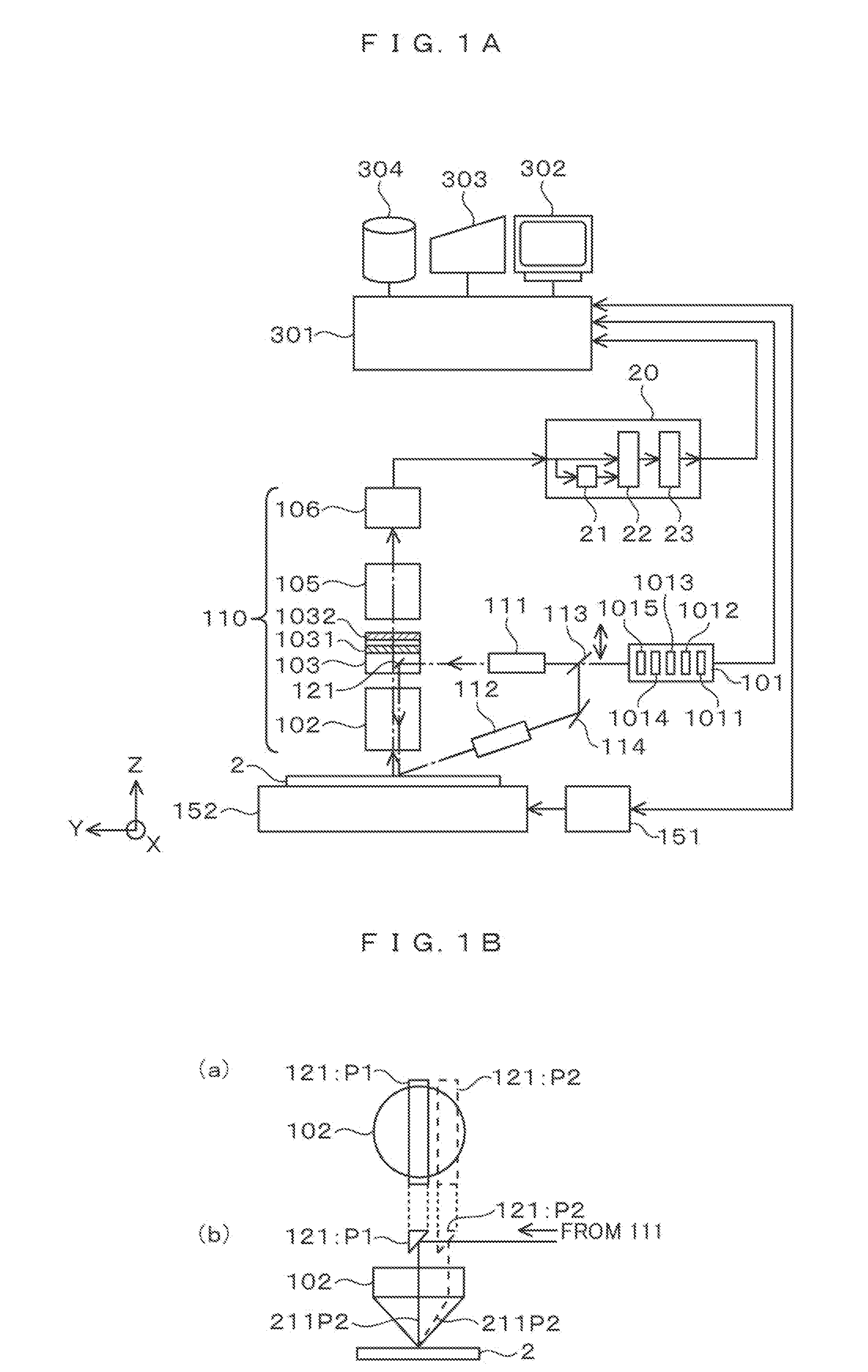

Methods and Patterning Devices and Apparatuses for Measuring Focus Performance of a Lithographic Apparatus, Device Manufacturing Method

ActiveUS20170176870A1Photomechanical exposure apparatusMicrolithography exposure apparatusMetrologyOblique angle

A lithographic apparatus (LA) prints product features and at least one focus metrology pattern (T) on a substrate. The focus metrology pattern is defined by a reflective reticle and printing is performed using EUV radiation (404) incident at an oblique angle (θ). The focus metrology pattern comprises a periodic array of groups of first features (422). A spacing (S1) between adjacent groups of first features is much greater than a dimension (CD) of the first features within each group. Due to the oblique illumination, the printed first features become distorted and / or displaced as a function of focus error. Second features 424 may be provided as a reference against which displacement of the first features may be seen. Measurement of this distortion and / or displacement may be by measuring asymmetry as a property of the printed pattern. Measurement can be done at longer wavelengths, for example in the range 350-800 nm.

Owner:ASML NETHERLANDS BV

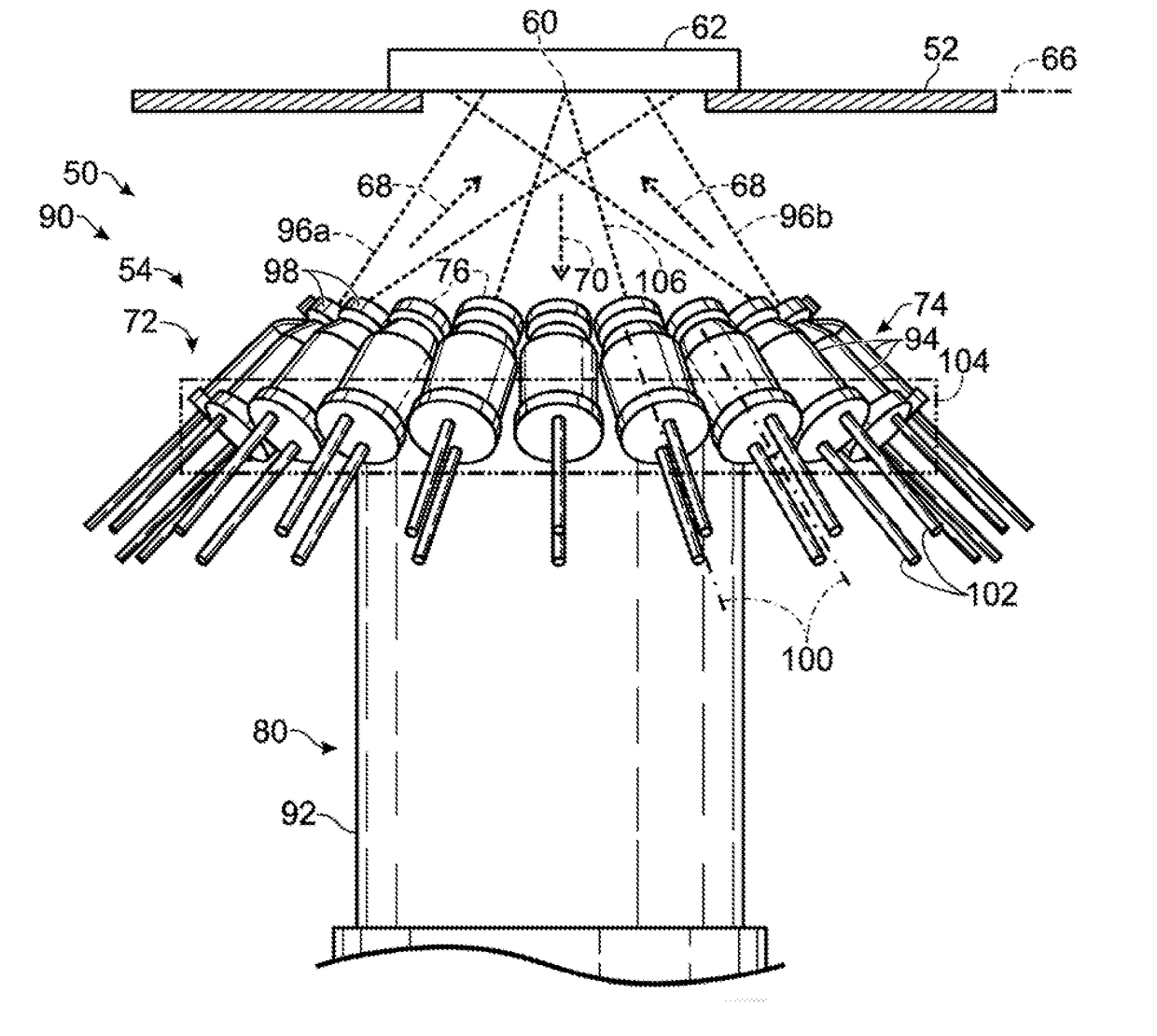

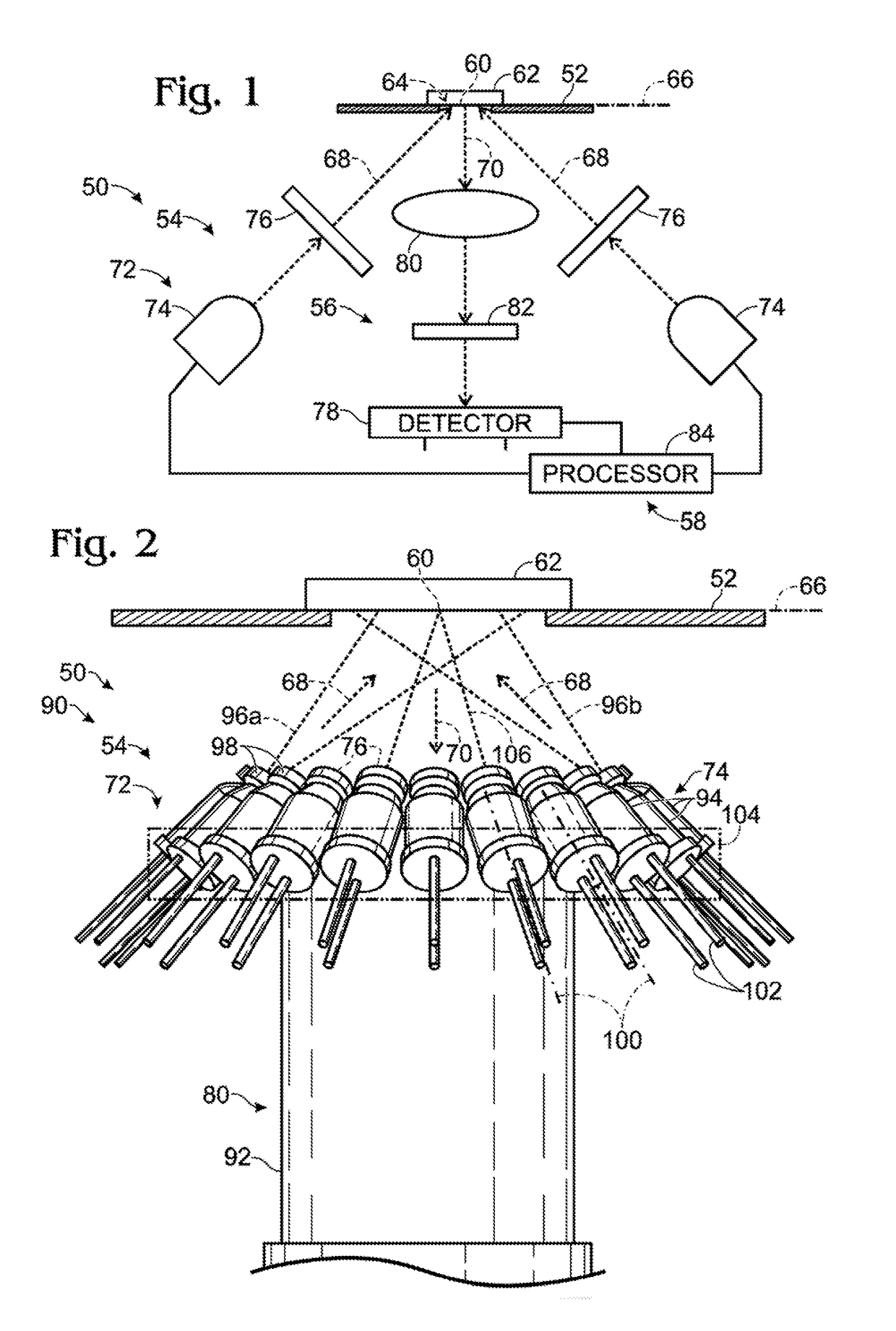

Sample inspection system

InactiveUS20050174568A1Reduce positioning errorsRadiation pyrometrySemiconductor/solid-state device testing/measurementLight beamCombined use

A curved mirrored surface is used to collect radiation scattered by a sample surface and originating from a normal illumination beam and an oblique illumination beam. The collected radiation is focused to a detector. Scattered radiation originating from the normal and oblique illumination beams may be distinguished by employing radiation at two different wavelengths, by intentionally introducing an offset between the spots illuminated by the two beams or by switching the normal and oblique illumination beams on and off alternately. Beam position error caused by change in sample height may be corrected by detecting specular reflection of an oblique illumination beam and changing the direction of illumination in response thereto. Butterfly-shaped spatial filters may be used in conjunction with curved mirror radiation collectors to restrict detection to certain azimuthal angles.

Owner:KLA TENCOR TECH CORP

Sample inspection system

InactiveUS7119897B2Reduce positioning errorsScattering properties measurementsOptically investigating flaws/contaminationCombined useVisual inspection

A curved mirrored surface is used to collect radiation scattered by a sample surface and originating from a normal illumination beam and an oblique illumination beam. The collected radiation is focused to a detector. Scattered radiation originating from the normal and oblique illumination beams may be distinguished by employing radiation at two different wavelengths, by intentionally introducing an offset between the spots illuminated by the two beams or by switching the normal and oblique illumination beams on and off alternately. Beam position error caused by change in sample height may be corrected by detecting specular reflection of an oblique illumination beam and changing the direction of illumination in response thereto. Butterfly-shaped spatial filters may be used in conjunction with curved mirror radiation collectors to restrict detection to certain azimuthal angles.

Owner:KLA TENCOR TECH CORP

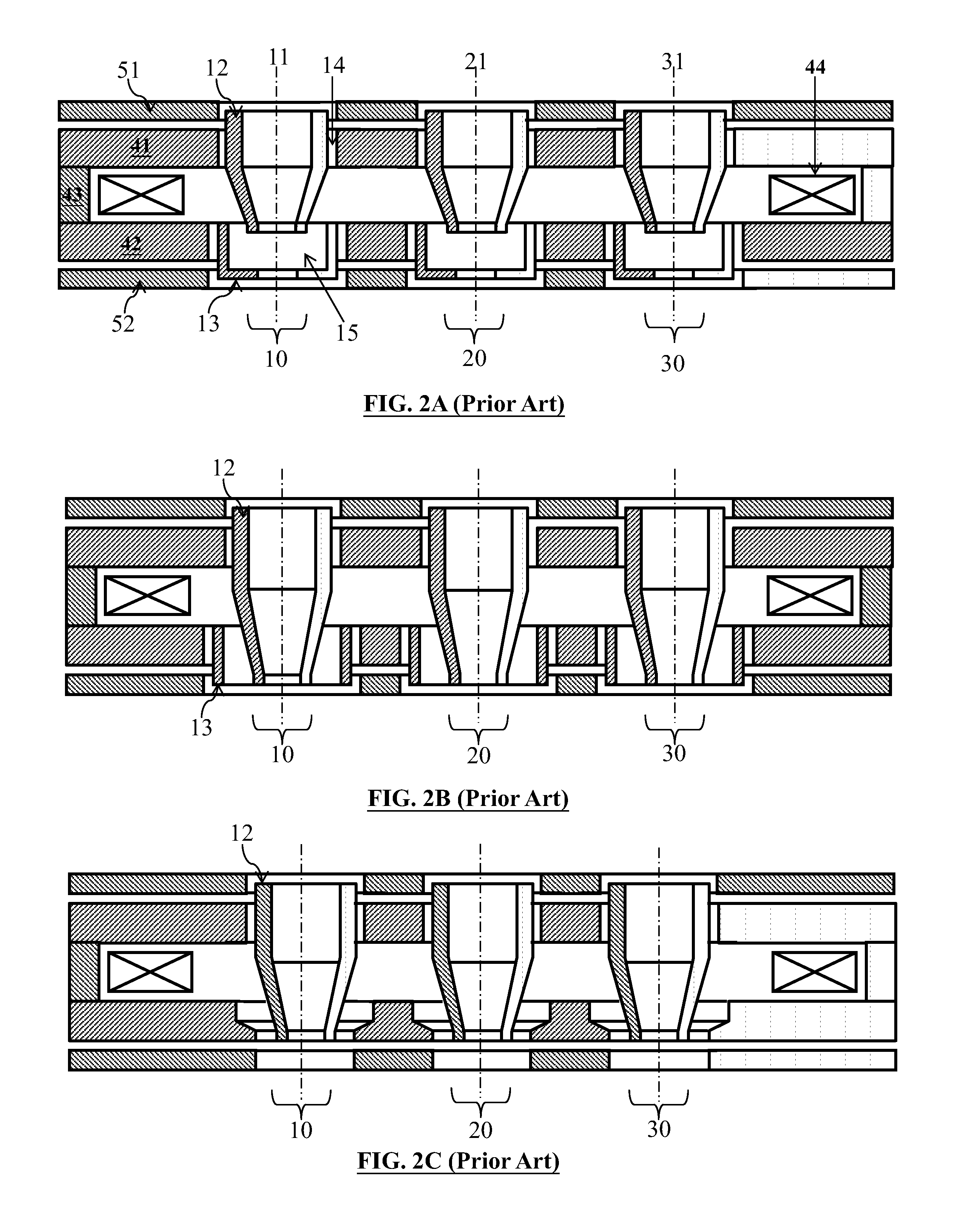

Apparatus of plural charged particle beams with multi-axis magnetic lens

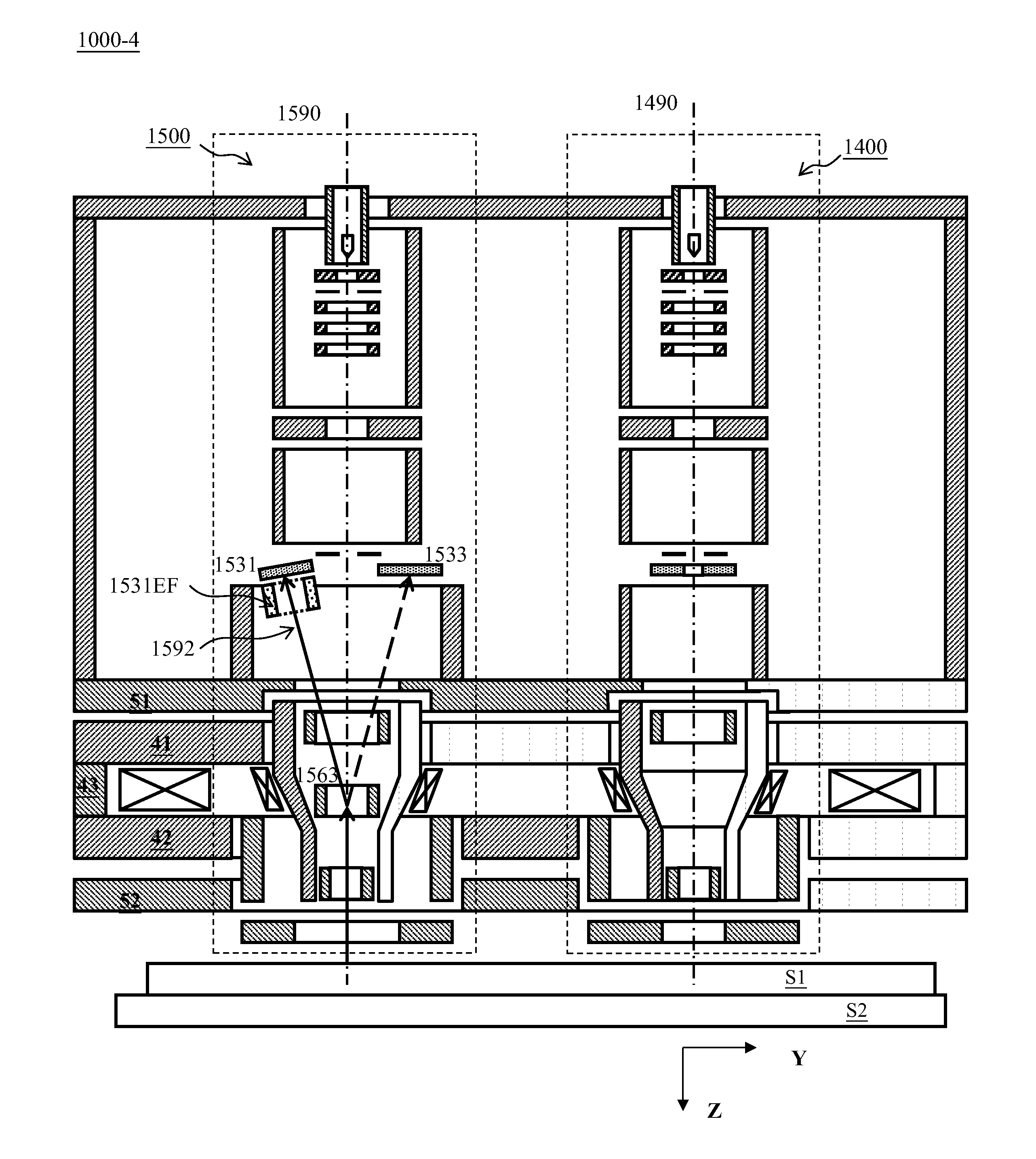

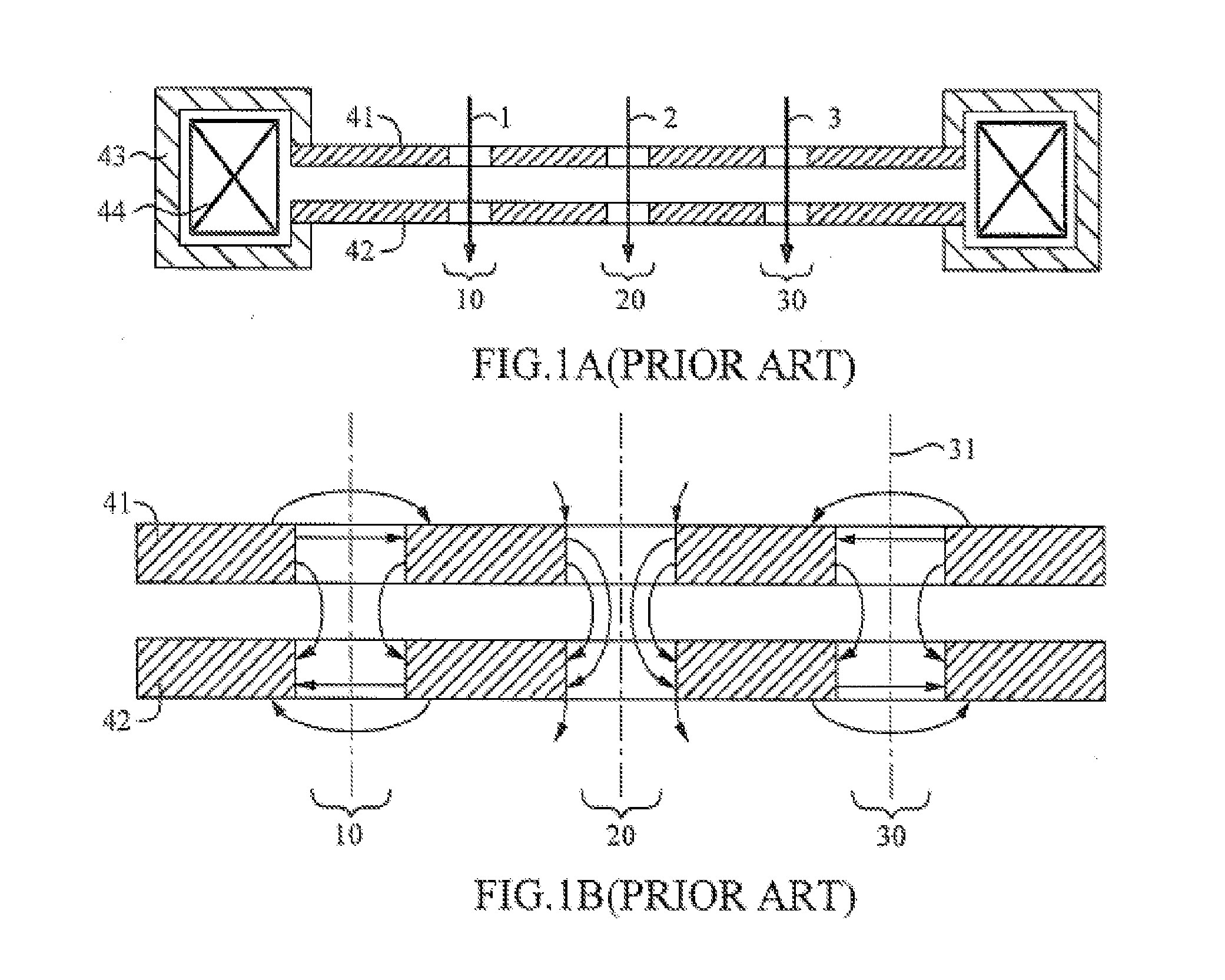

ActiveUS20150060662A1Improve throughputLow costMaterial analysis using wave/particle radiationElectric discharge tubesImage contrastImage resolution

An apparatus of plural charged particle beams with multi-axis magnetic lens is provided to perform multi-functions of observing a specimen surface, such as high-throughput inspection and high-resolution review of interested features thereof and charge-up control for enhancing image contrast and image resolution. In the apparatus, two or more sub-columns are formed and each of the sub-columns performs one of the multi-functions. Basically the sub-columns take normal illumination to get high image resolutions, but one or more may take oblique illuminations to get high image contrasts.

Owner:ASML NETHERLANDS BV

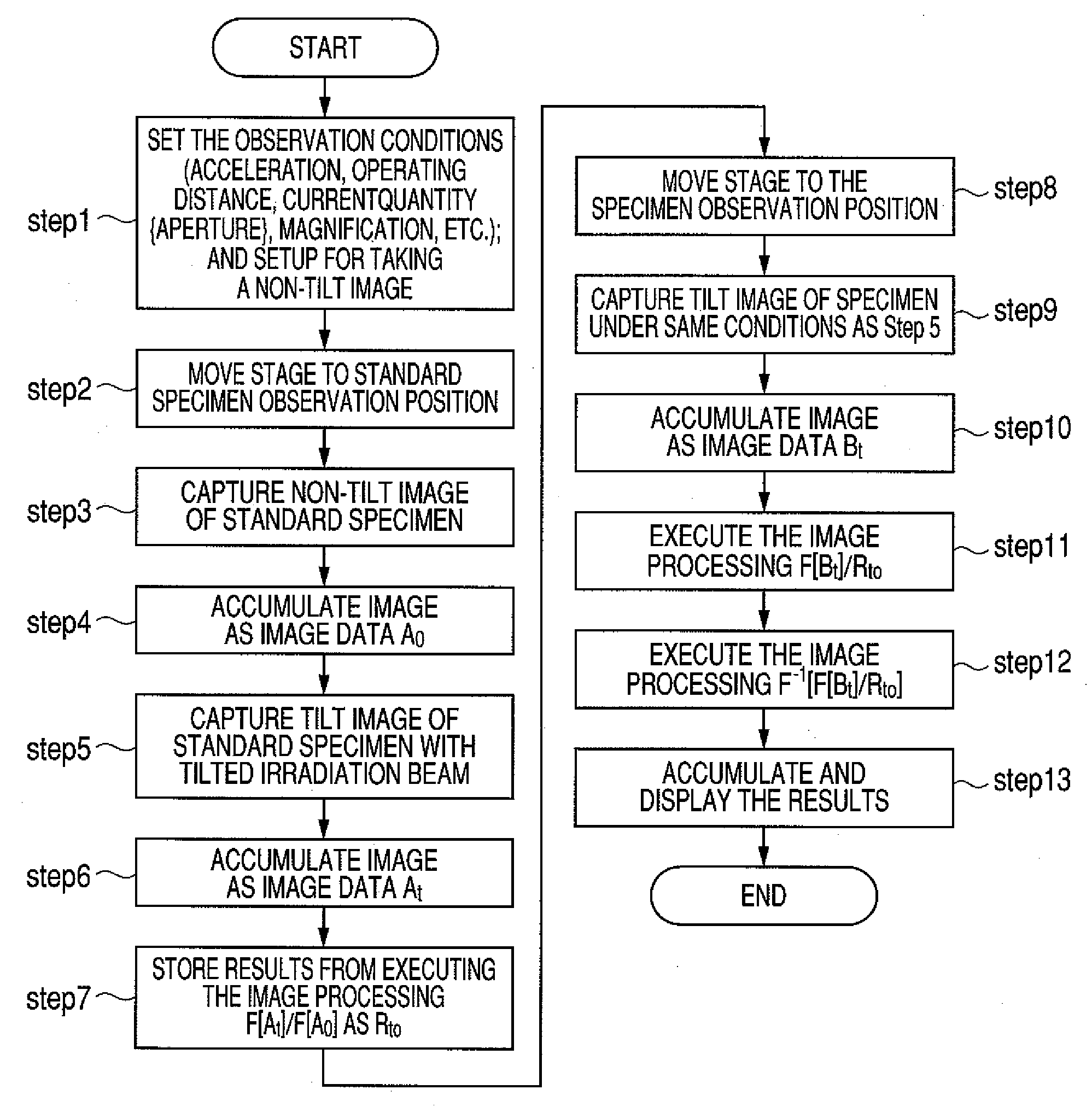

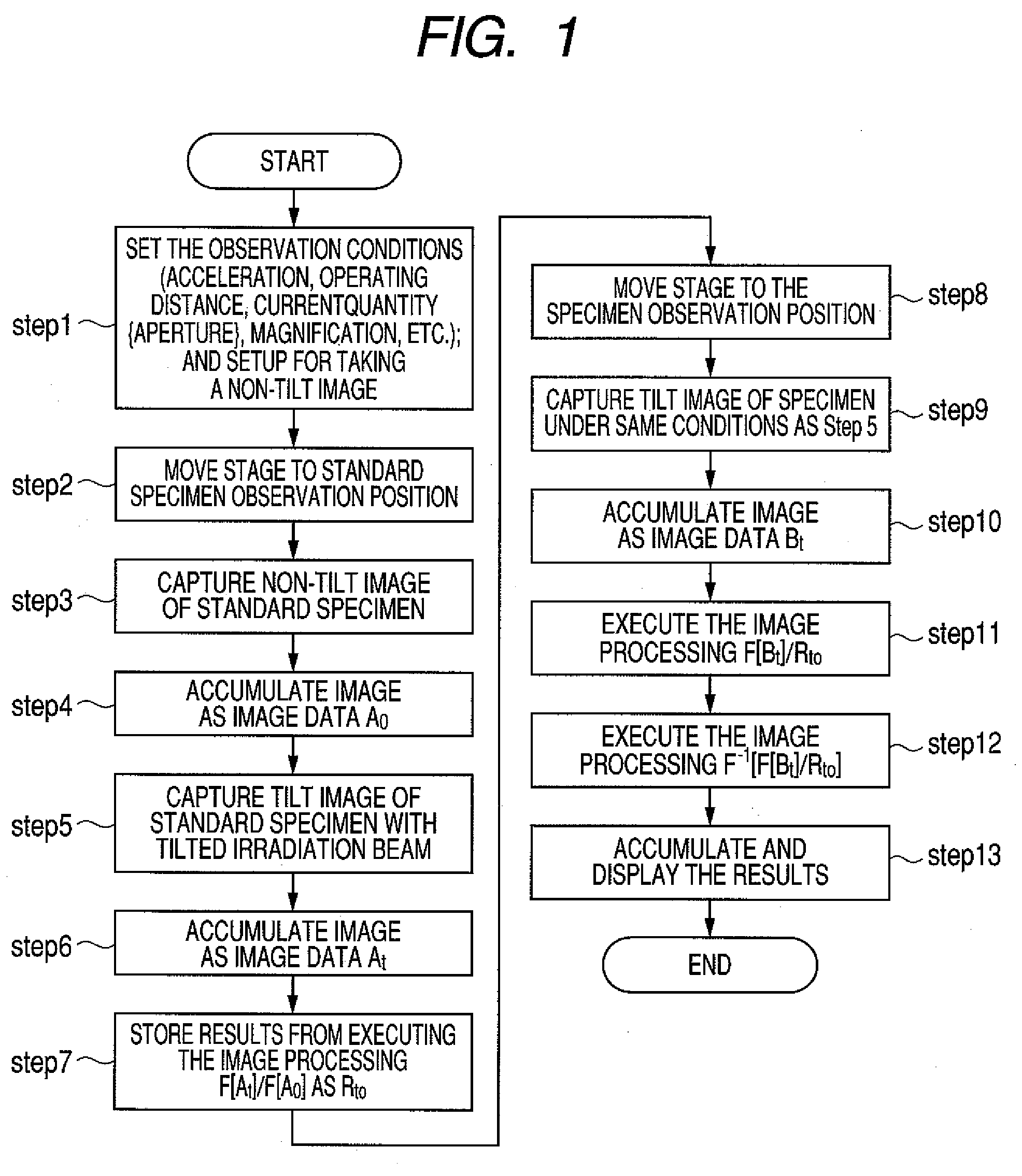

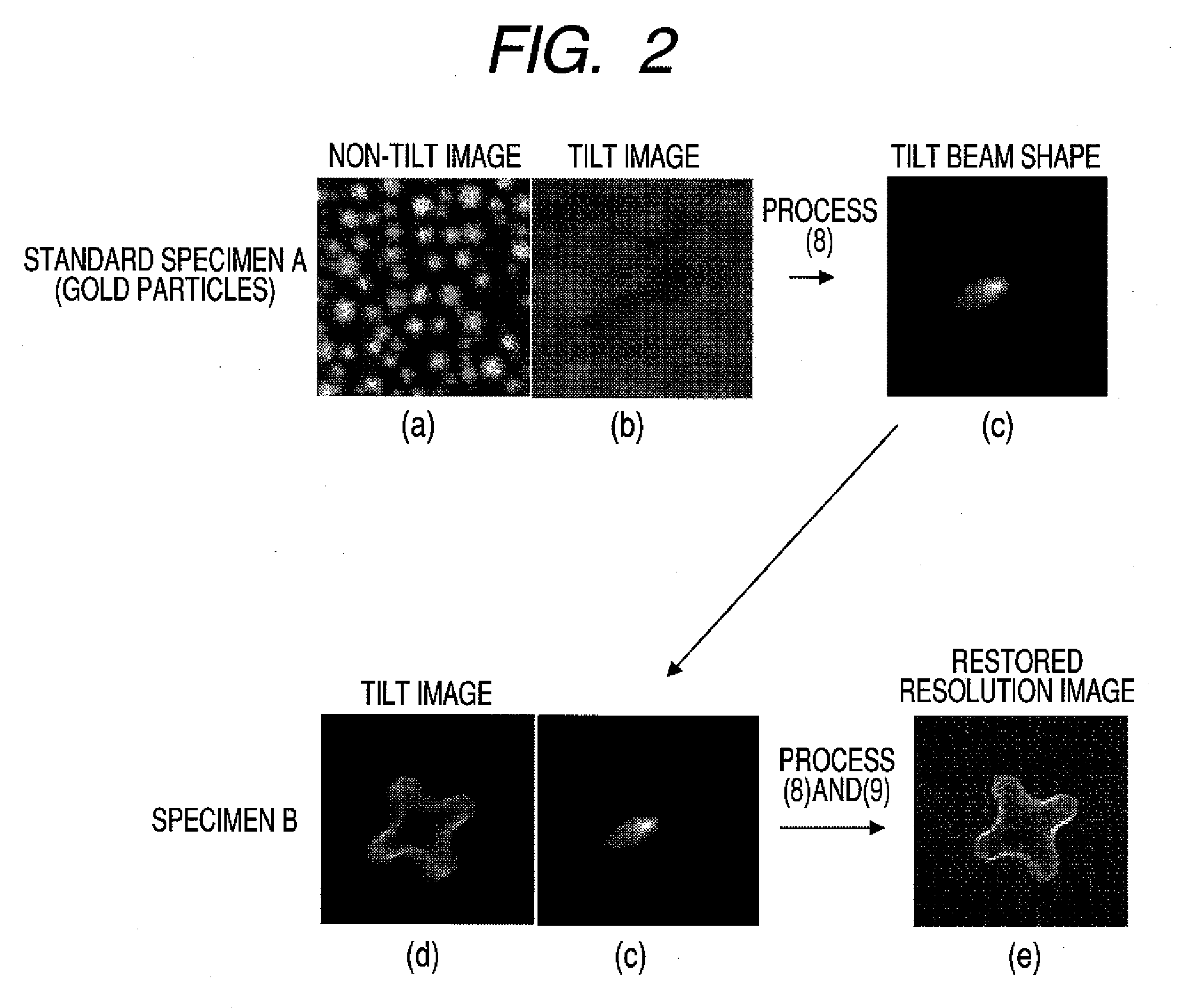

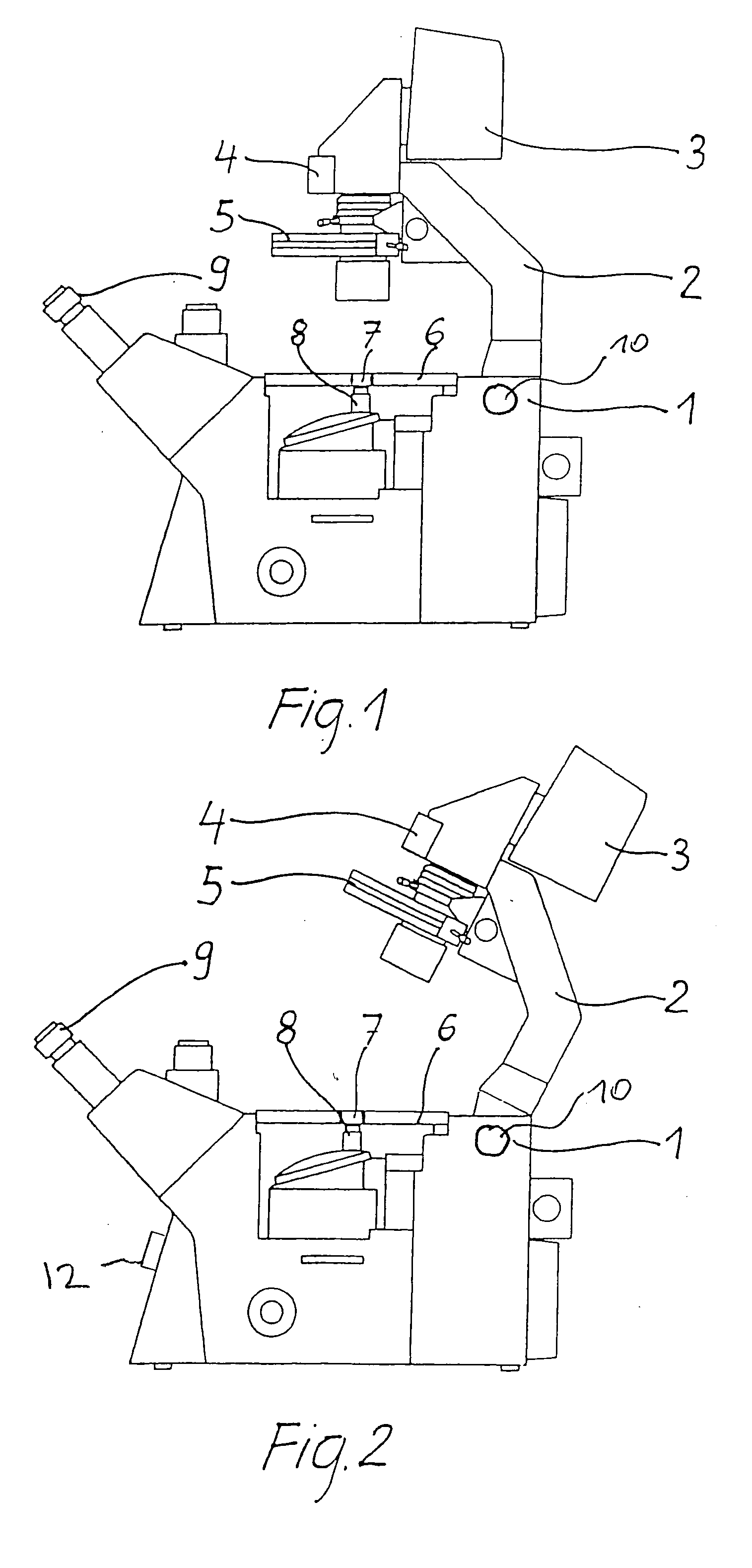

Method and Apparatus of Tilted Illumination Observation

InactiveUS20100033560A1High resolutionExtracts blurringColor television detailsClosed circuit television systemsLight beamComputer science

A tilted illumination observation method and observation device with easy adjustment, high speed, good reproducibility and low cost is provided. A high resolution tilt image of a specimen is obtained by extracting the blurring on the scanning spot occurring during beam tilt from the image (step 6) captured by the tilted beam, and the image (step 4) captured from directly above the standard specimen; and then deconvoluting (step 11, 12) the tilted image of the target specimen (step 10) using the extracted scanning spot from the oblique beam.

Owner:HITACHI HIGH-TECH CORP

Sample inspection system

InactiveUS20050099621A1Reduce positioning errorsScattering properties measurementsOptically investigating flaws/contaminationLight beamCombined use

A curved mirrored surface is used to collect radiation scattered by a sample surface and originating from a normal illumination beam and an oblique illumination beam. The collected radiation is focused to a detector. Scattered radiation originating from the normal and oblique illumination beams may be distinguished by employing radiation at two different wavelengths, by intentionally introducing an offset between the spots illuminated by the two beams or by switching the normal and oblique illumination beams on and off alternately. Beam position error caused by change in sample height may be corrected by detecting specular reflection of an oblique illumination beam and changing the direction of illumination in response thereto. Butterfly-shaped spatial filters may be used in conjunction with curved mirror radiation collectors to restrict detection to certain azimuthal angles.

Owner:KLA TENCOR TECH CORP

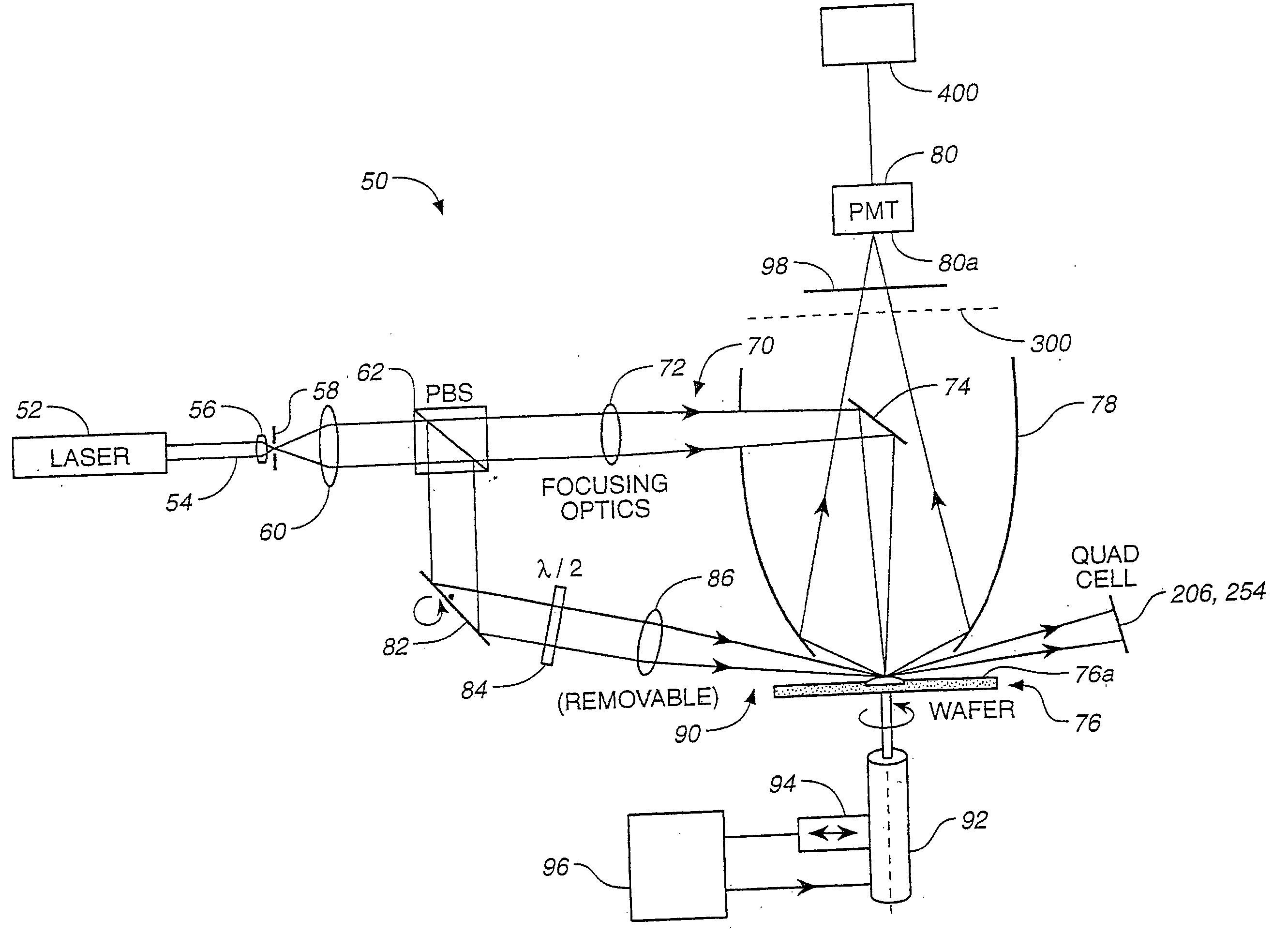

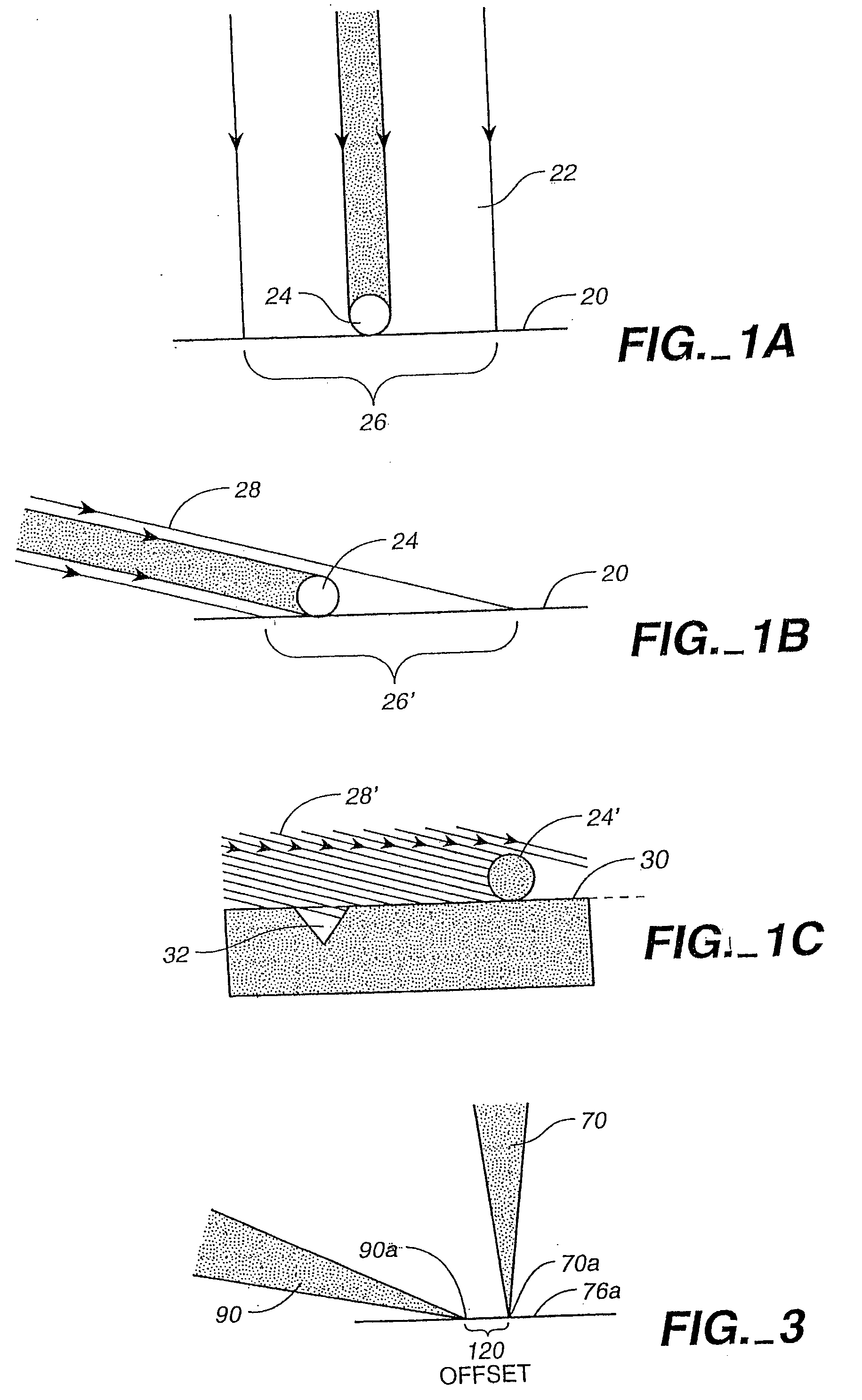

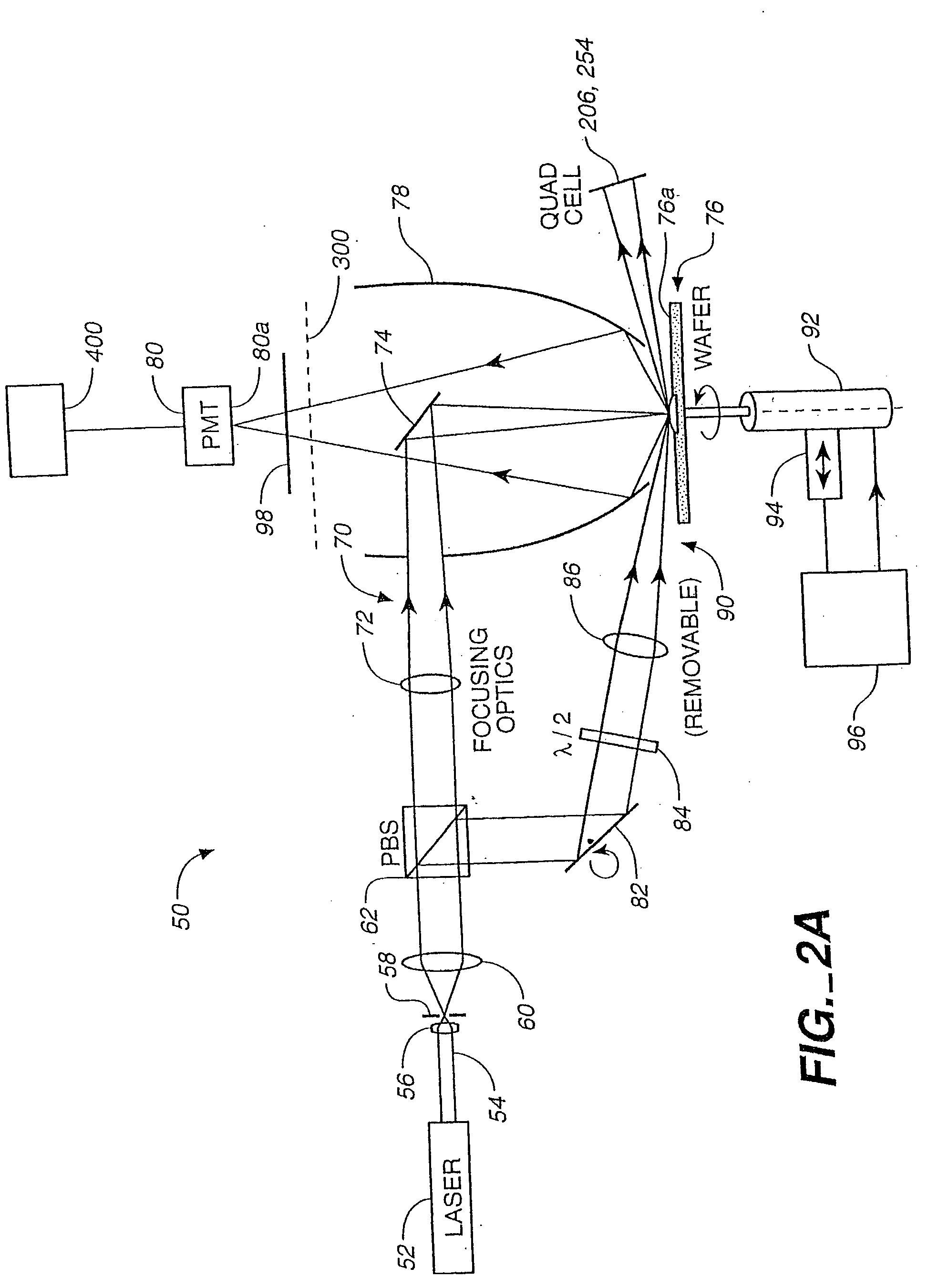

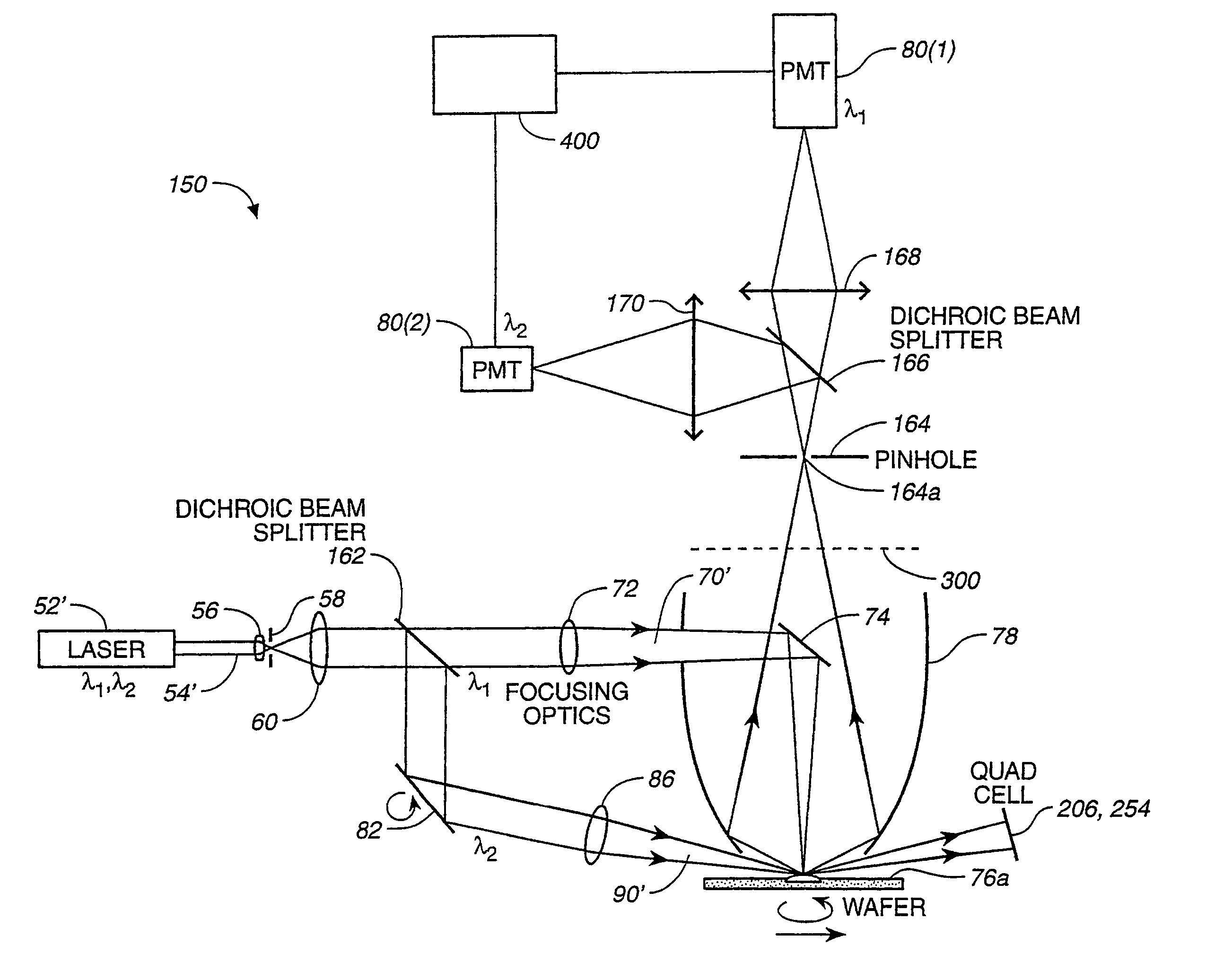

Sample inspection system

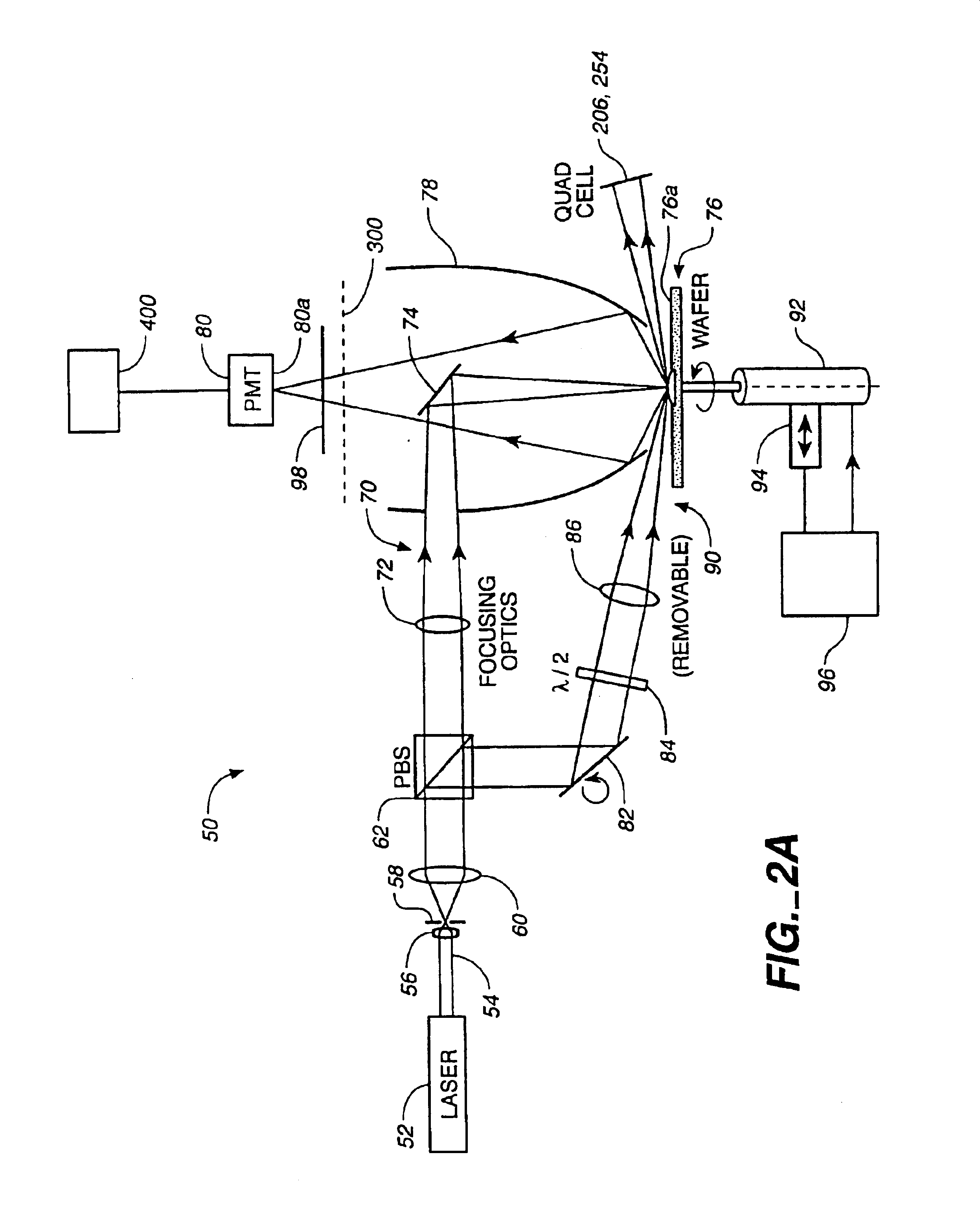

InactiveUS6891611B1Reduce positioning errorsRadiation pyrometrySemiconductor/solid-state device testing/measurementCombined useLight beam

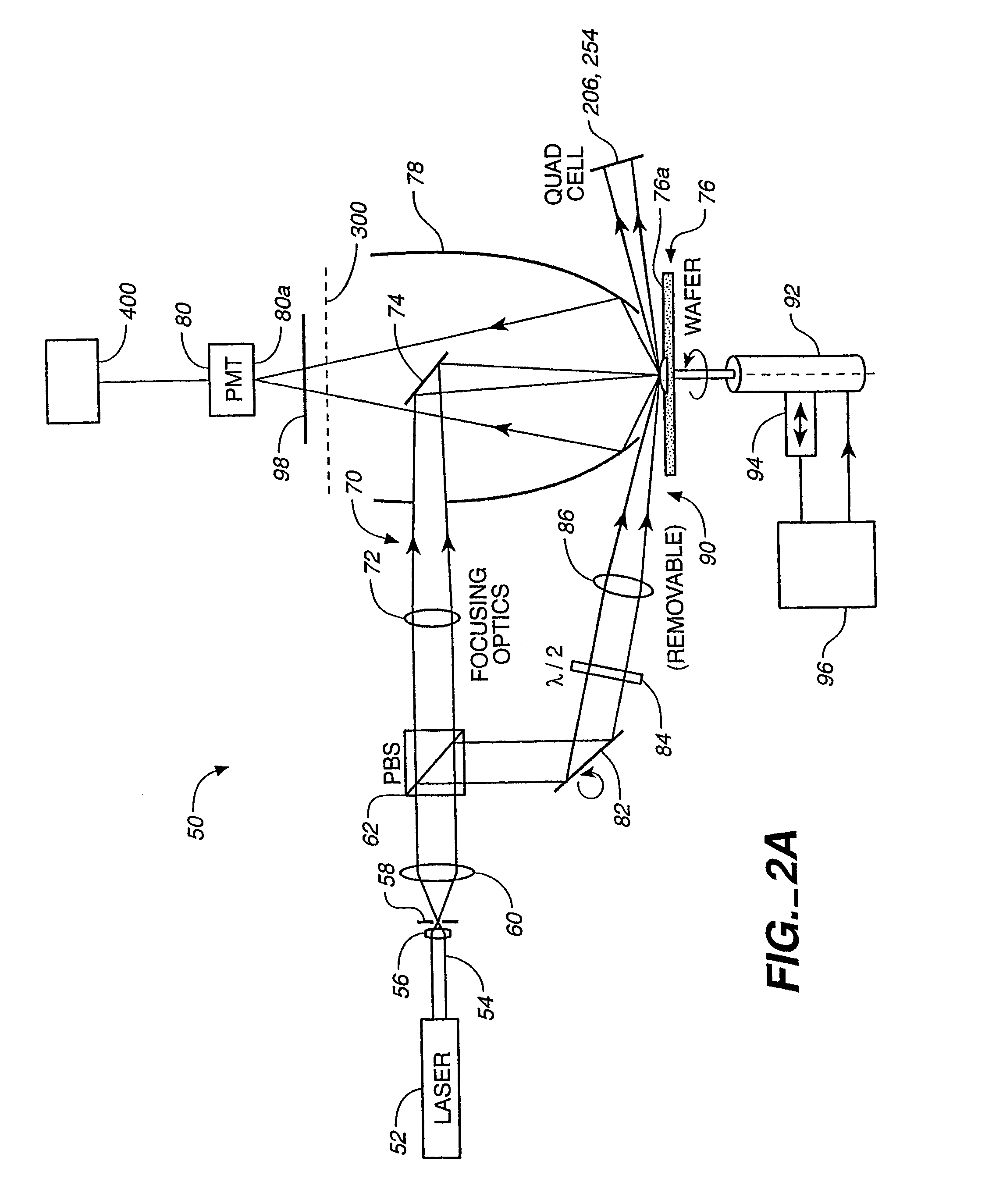

A curved mirrored surface (78) is used to collect radiation scattered by a sample surface (76a) and originating from a normal illumination beam (70) and an oblique illumination beam (90). The collected radiation is focused to a detector (80). Scattered radiation originating from the normal and oblique illumination beams may be distinguished by employing radiation at two different wavelengths, by intentionally introducing an offset between the spots illuminated by the two beams or by switching the normal and oblique illumination beams (70, 90) on and off alternately. Beam position error caused by change in sample height may be corrected by detecting specular reflection of an oblique illumination beam and changing the direction of illumination in response thereto. Butterfly-shaped spatial filters may be used in conjunction with curved mirror radiation collectors (78) to restrict detection to certain azimuthal angles.

Owner:KLA TENCOR TECH CORP

Optical Metrology With Small Illumination Spot Size

ActiveUS20160334326A1Reduce errorsPolarisation-affecting propertiesPhotomechanical apparatusSpatial light modulatorLight beam

Methods and systems are presented to reduce the illumination spot size projected onto a measurement target and associated spillover onto area surrounding a measurement target. In one aspect, a spatial light modulator (SLM) is located in the illumination path between the illumination light source and the measurement sample. The SLM is configured to modulate amplitude, phase, or both, across the path of the illumination light to reduce wavefront errors. In some embodiments, the desired state of the SLM is based on wavefront measurements performed in an optical path of the metrology system. In another aspect, an illumination aperture having an image plane tilted at an oblique angle with respect to a beam of illumination light is employed to overcome defocusing effects in metrology systems that employ oblique illumination of the measurement sample. In some embodiments, the illumination aperture, objective lens, and specimen are aligned to satisfy the Scheimpflug condition.

Owner:KLA CORP

Visual inspection apparatus

A visual inspection apparatus includes an upper illuminator, a lower illuminator, a side illuminator, and a pair of inclined illuminators, which illuminate the peripheral edge of a wafer, and illuminates the peripheral edge of the wafer brightly. A gap is formed in the upper illuminator and illumination light of an epi-illumination portion is injected through the gap. The illumination light of the epi-illumination portion is refracted and reflected by a first mirror to illuminate the peripheral edge of the wafer. The illumination position is changed by moving second mirrors together as needed. An image of the peripheral edge is acquired in an imaging portion disposed at the same axis as the epi-illumination portion.

Owner:OLYMPUS CORP

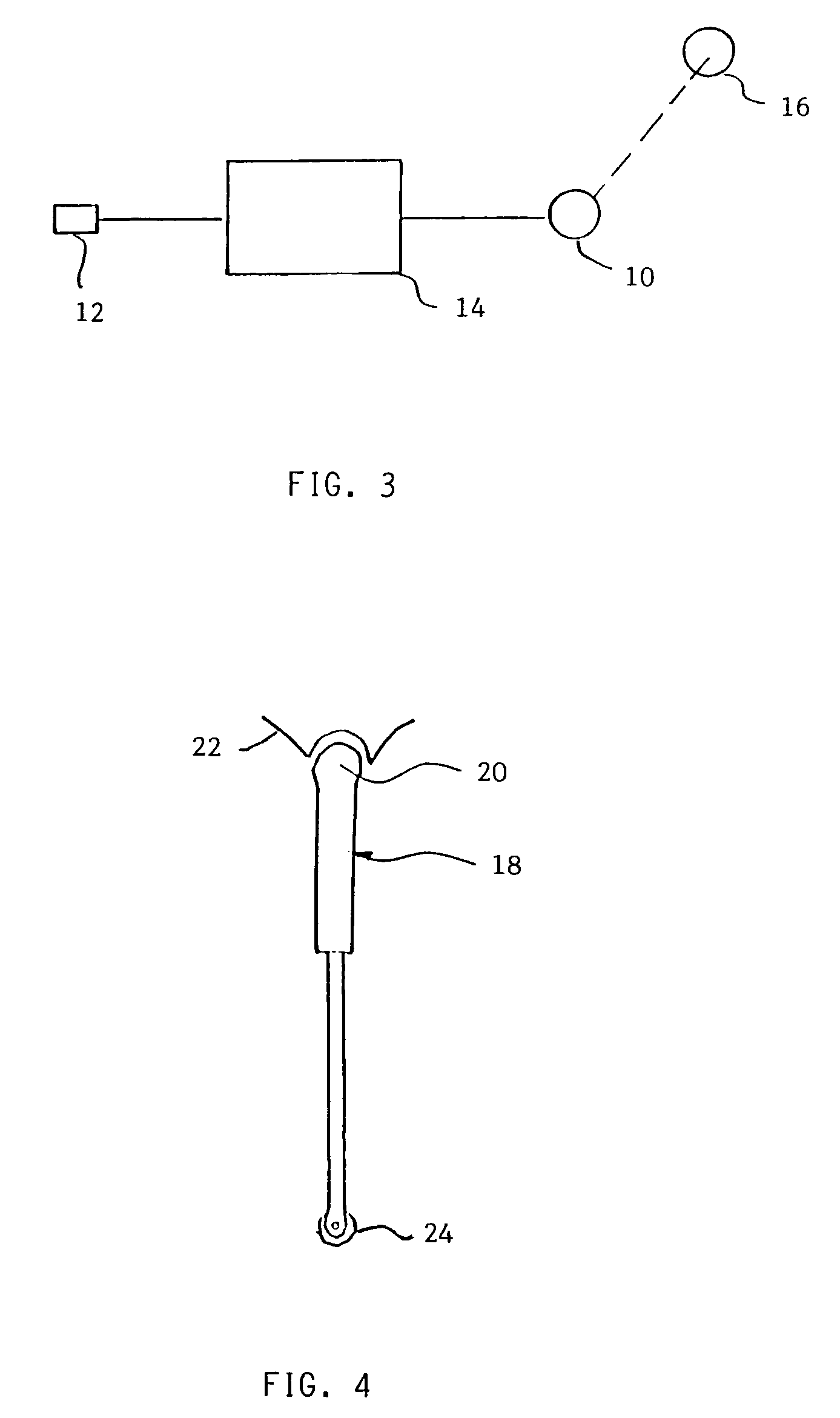

Apparatus, method, and system for tilted pole top fitter

ActiveUS9964267B1Avoid interferencePrevent unwanted uplight or localized glareMechanical apparatusLighting support devicesEffect lightLuminosity

Owner:MUSCO

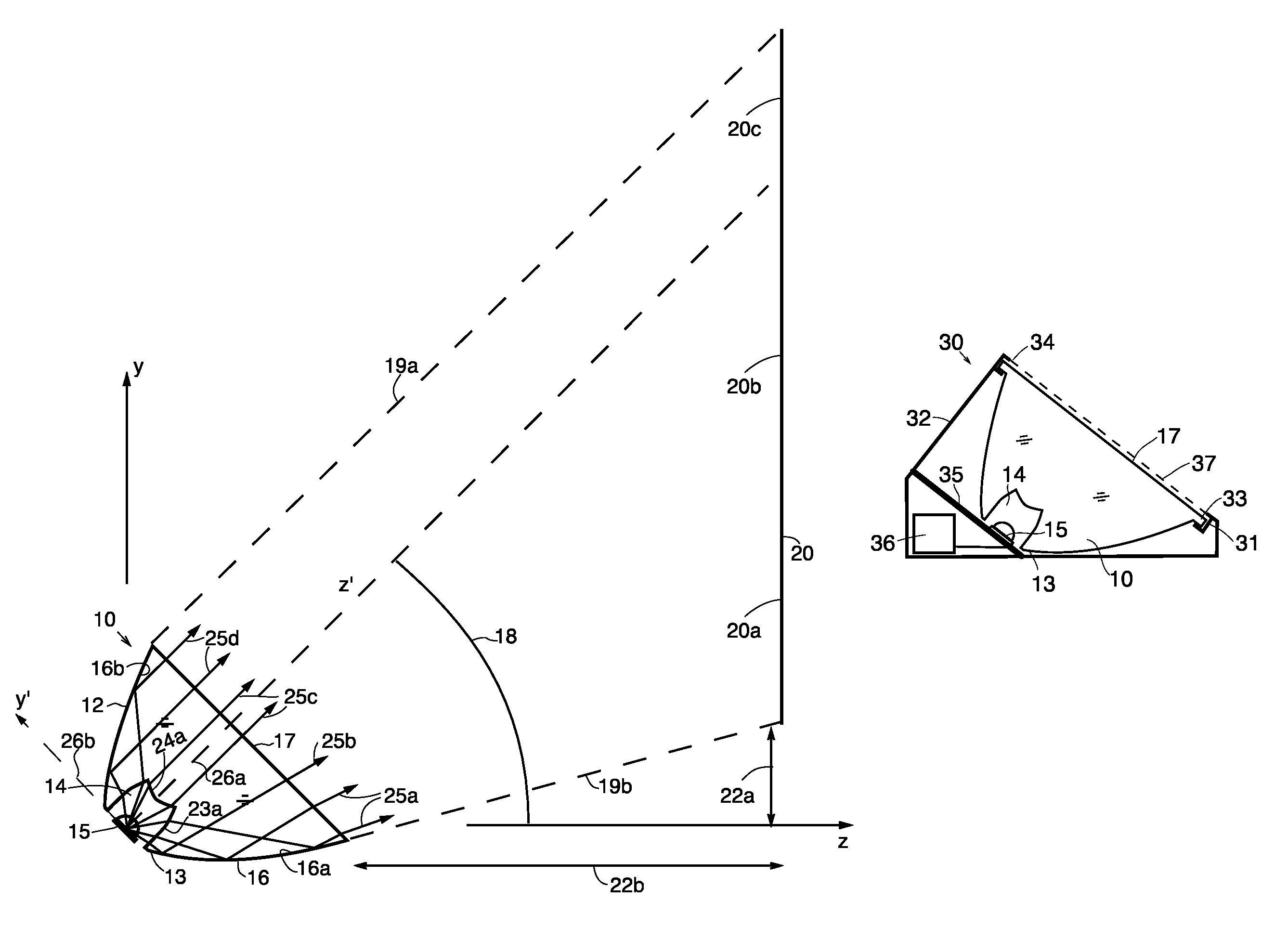

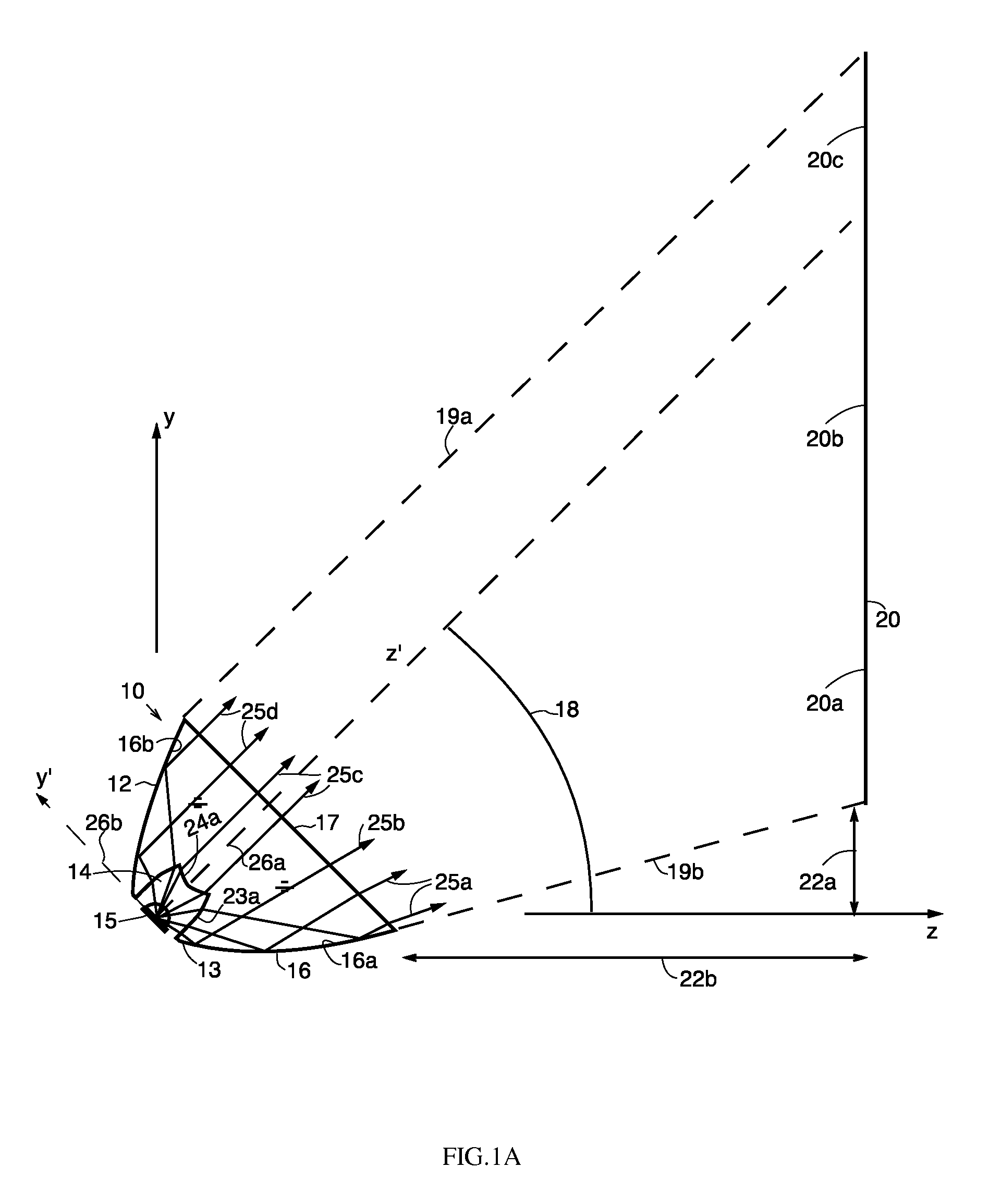

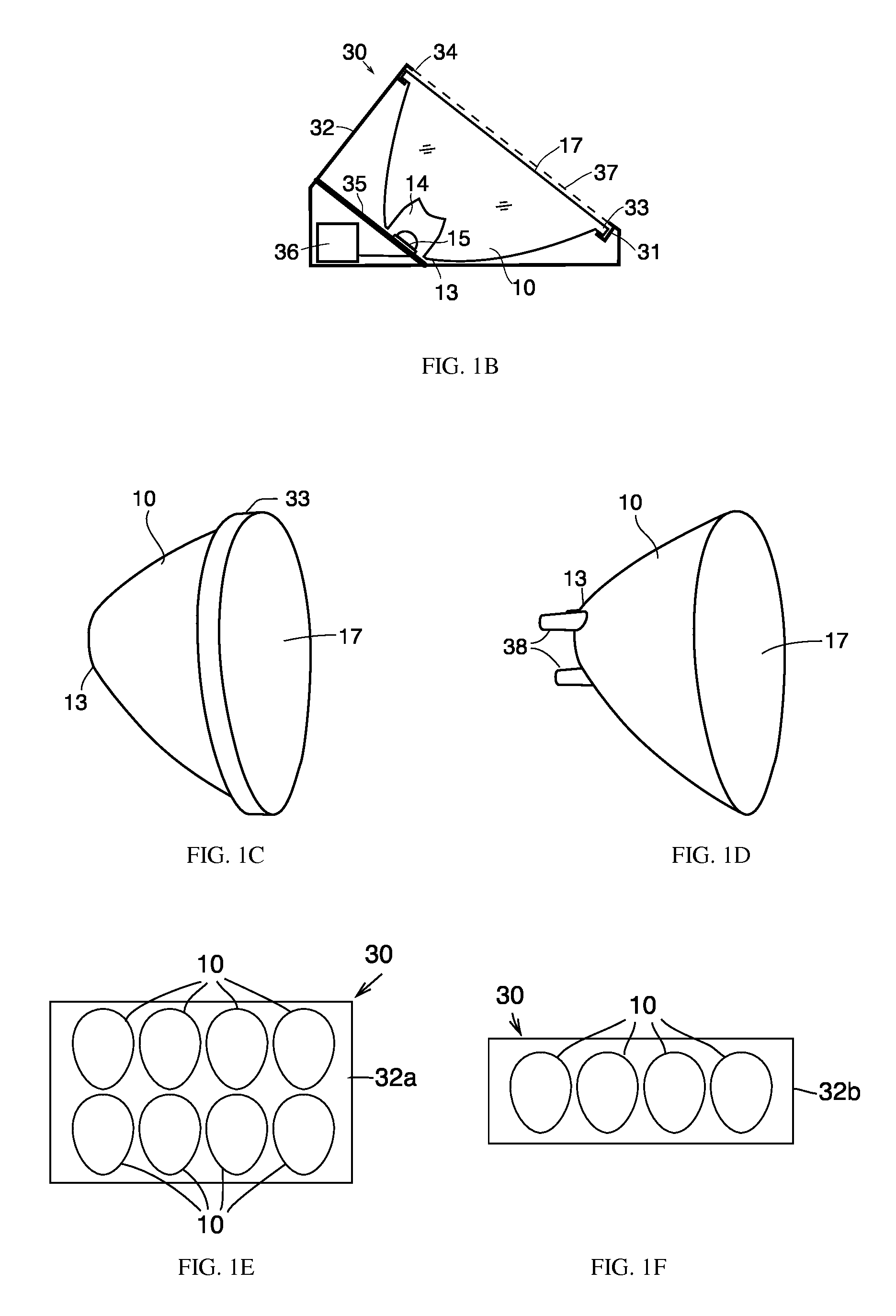

Optical element providing oblique illumination and apparatuses using same

ActiveUS9239141B1Increase illuminationExcessively uniformPlanar light sourcesMechanical apparatusTarget surfaceOptical axis

An optical element is provided having an asymmetric body, a light source, and a front face tilted at an oblique angle with respect to a target surface to provide illumination that is at least substantially uniform along the target surface's height. One or more optical elements may be in an apparatus, and multiple apparatuses may be disposed in front of one edge of a target surface to provide thereto at least substantially uniform oblique illumination. When the light source is an LED that is spectrally non-uniform at increasing angles away from its optical axis, the optical elements having such LEDs provide illumination that is spectrally non-uniform along a portion of the target surface, and additional optical elements with LED light sources are provided having a spectrum in one or more spectral ranges that compensates for such spectral non-uniformity to correct spectral non-uniformity along such portion of the target surface.

Owner:VIAVI SOLUTIONS INC

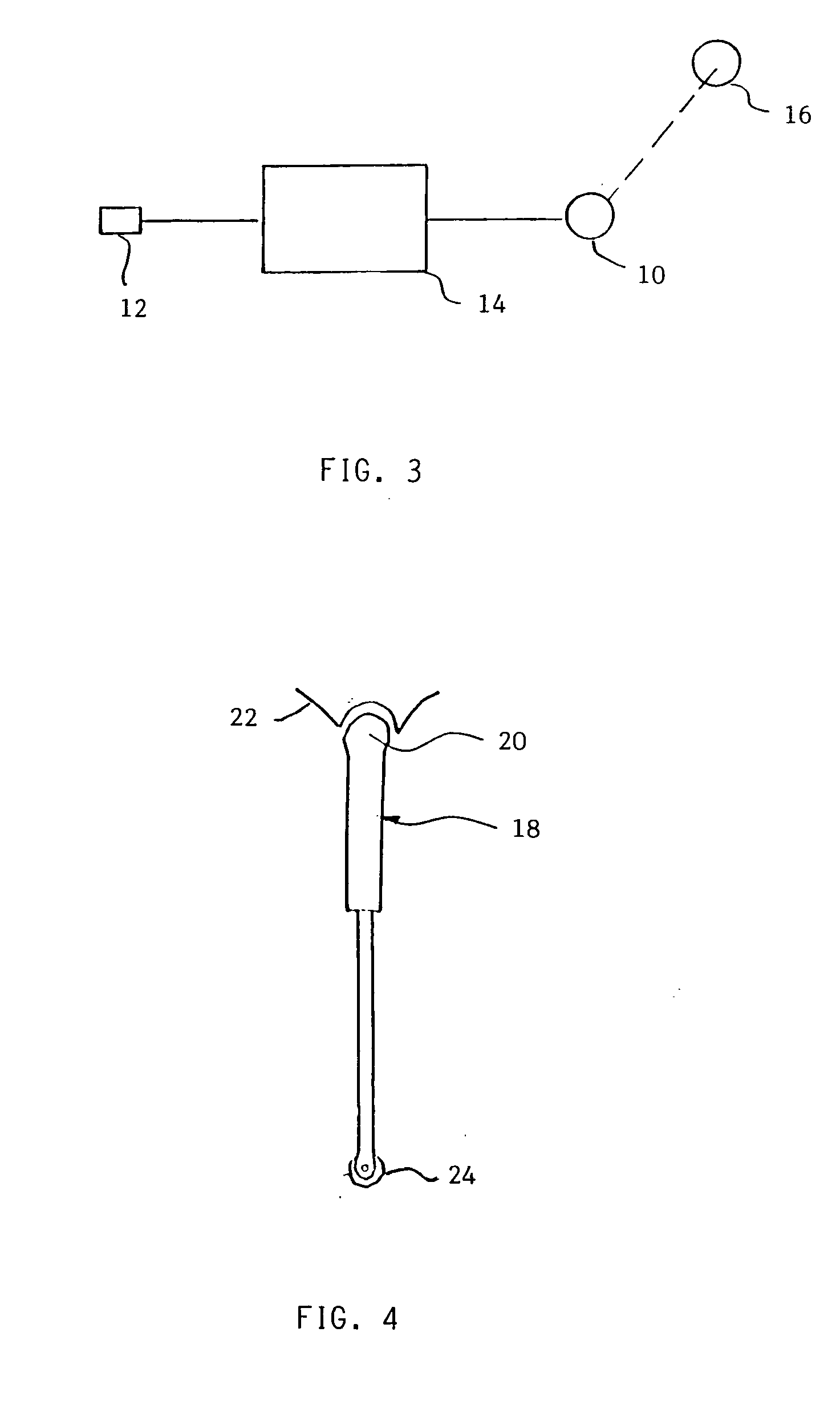

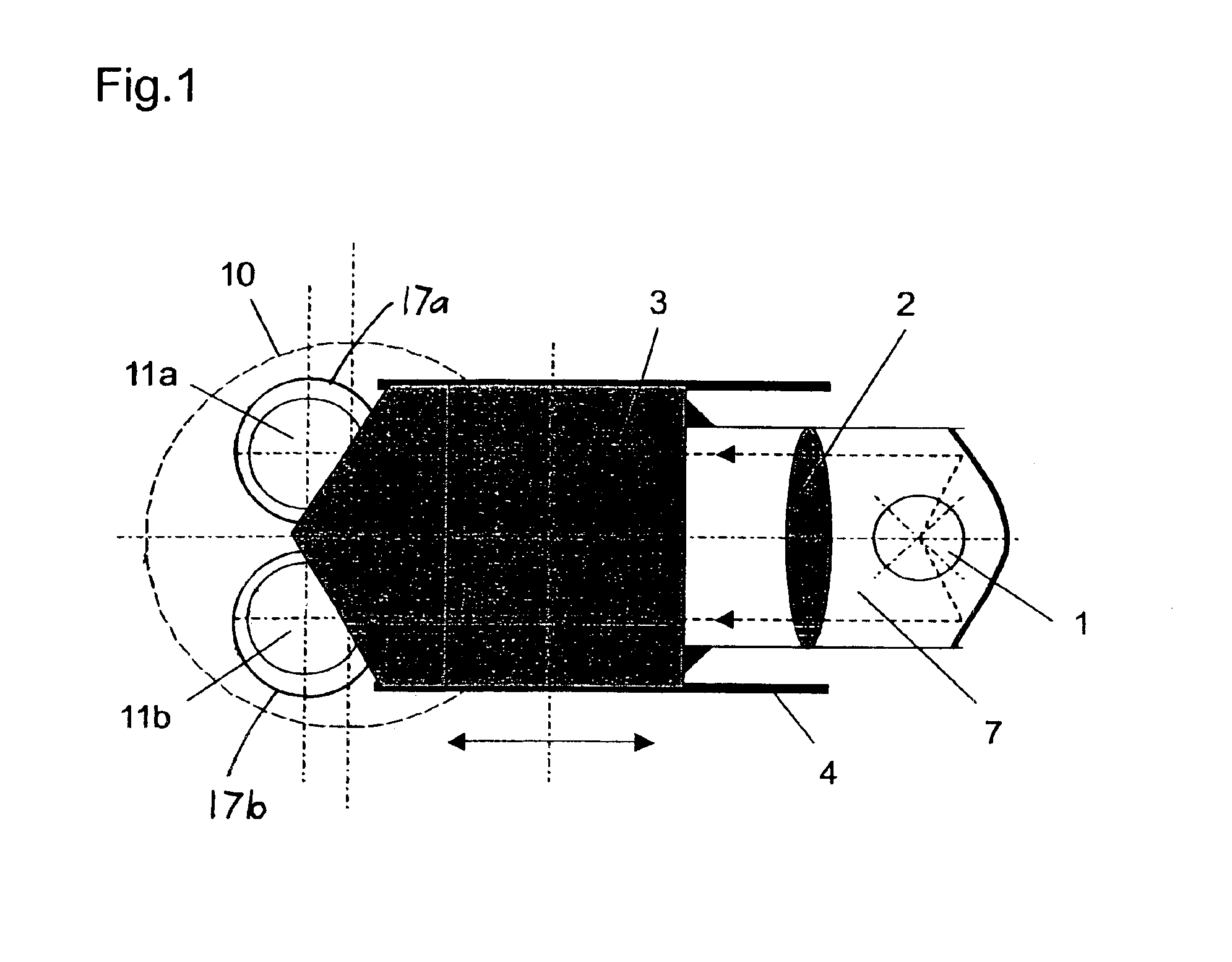

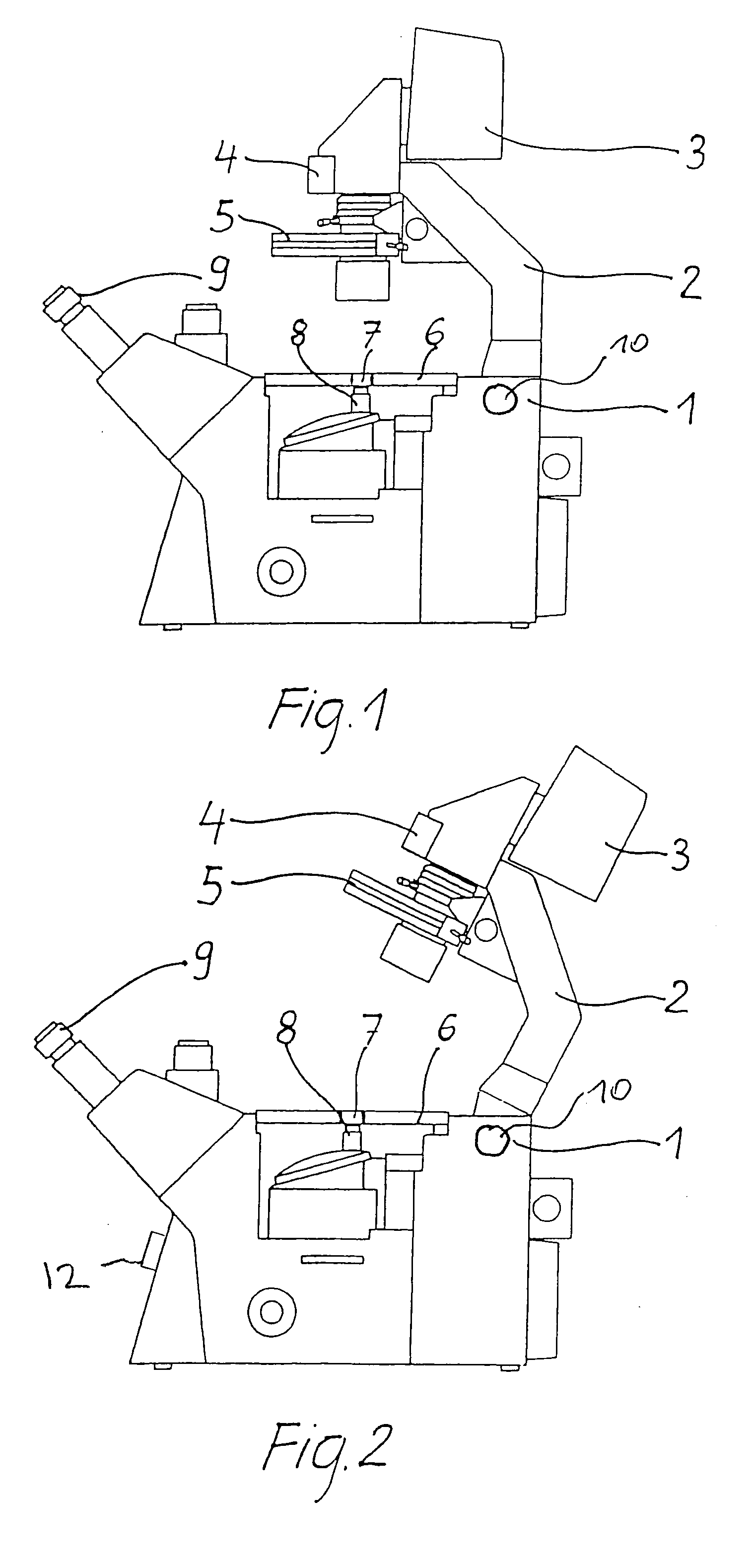

Arrangement for tilting an illumination carrier on an inverse light microscope

InactiveUS20060171024A1Easily and precisely tiltedTilt movement is dampenedMicroscopesElectric machineryOptoelectronics

An arrangement tilts the illumination carrier on light microscopes of the inverse type which include a microscope stand on which an illumination carrier having a light source is attached. The arrangement for tilting the illumination carrier (2) having a light source (3) includes an electric motor (10) with which the tilt movement of the illumination carrier (2) can be controlled in such a manner that the motor-controlled tilting of the illumination carrier (2) takes place manually utilizing an actuating element or can be triggered automatically and is stepwise adjustable. A device for damping the tilt movement is provided.

Owner:CARL ZEISS MICROSCOPY GMBH

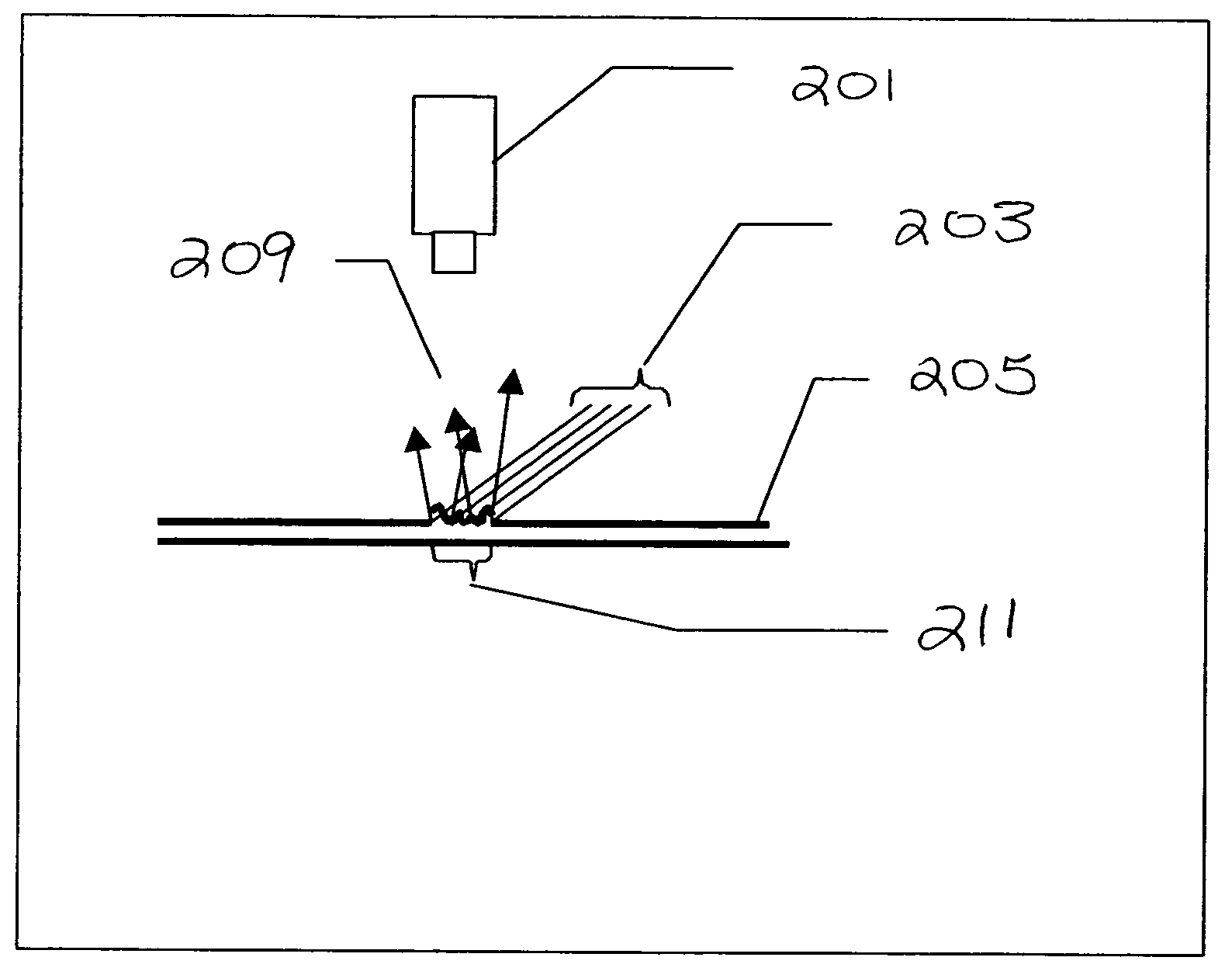

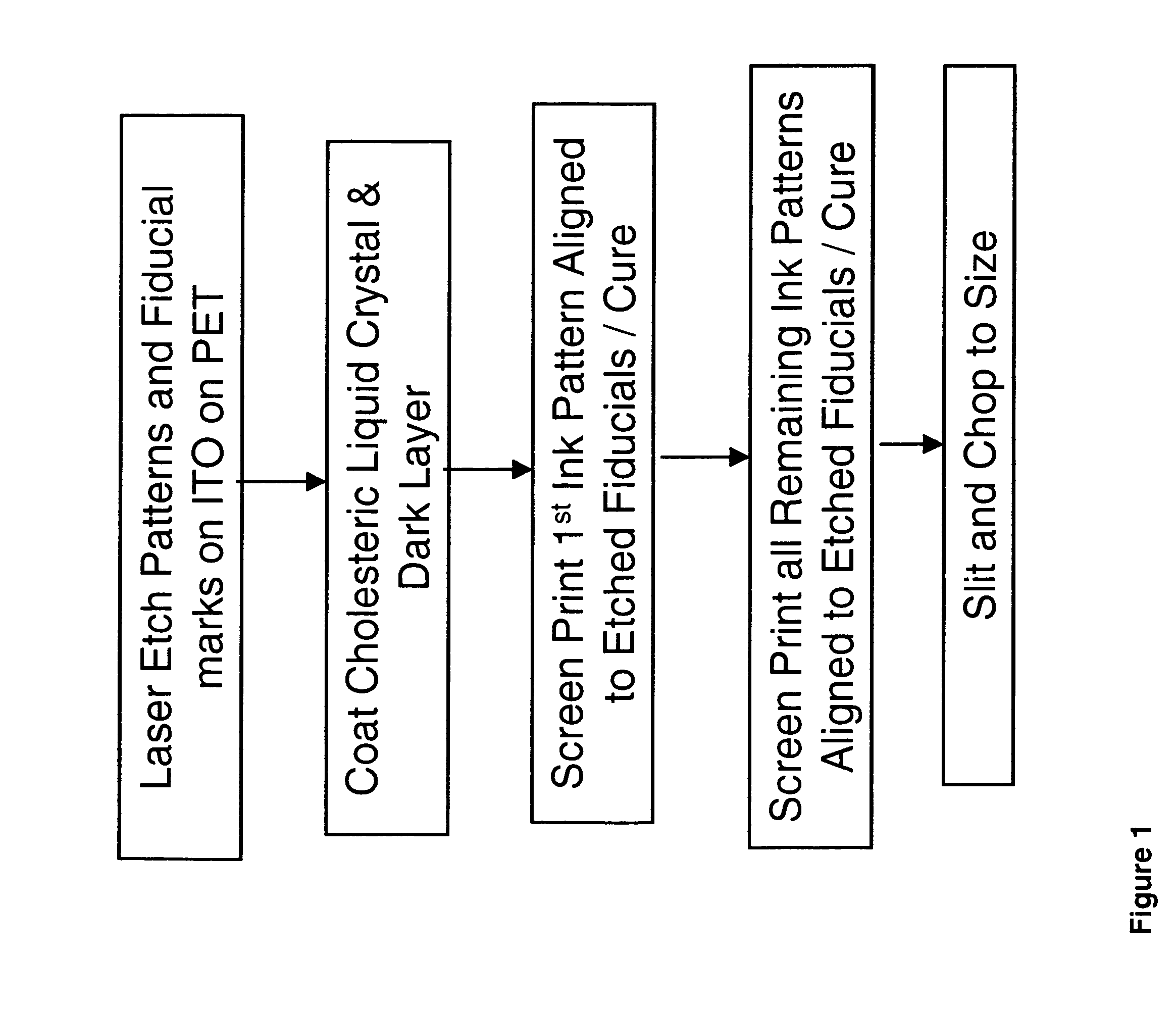

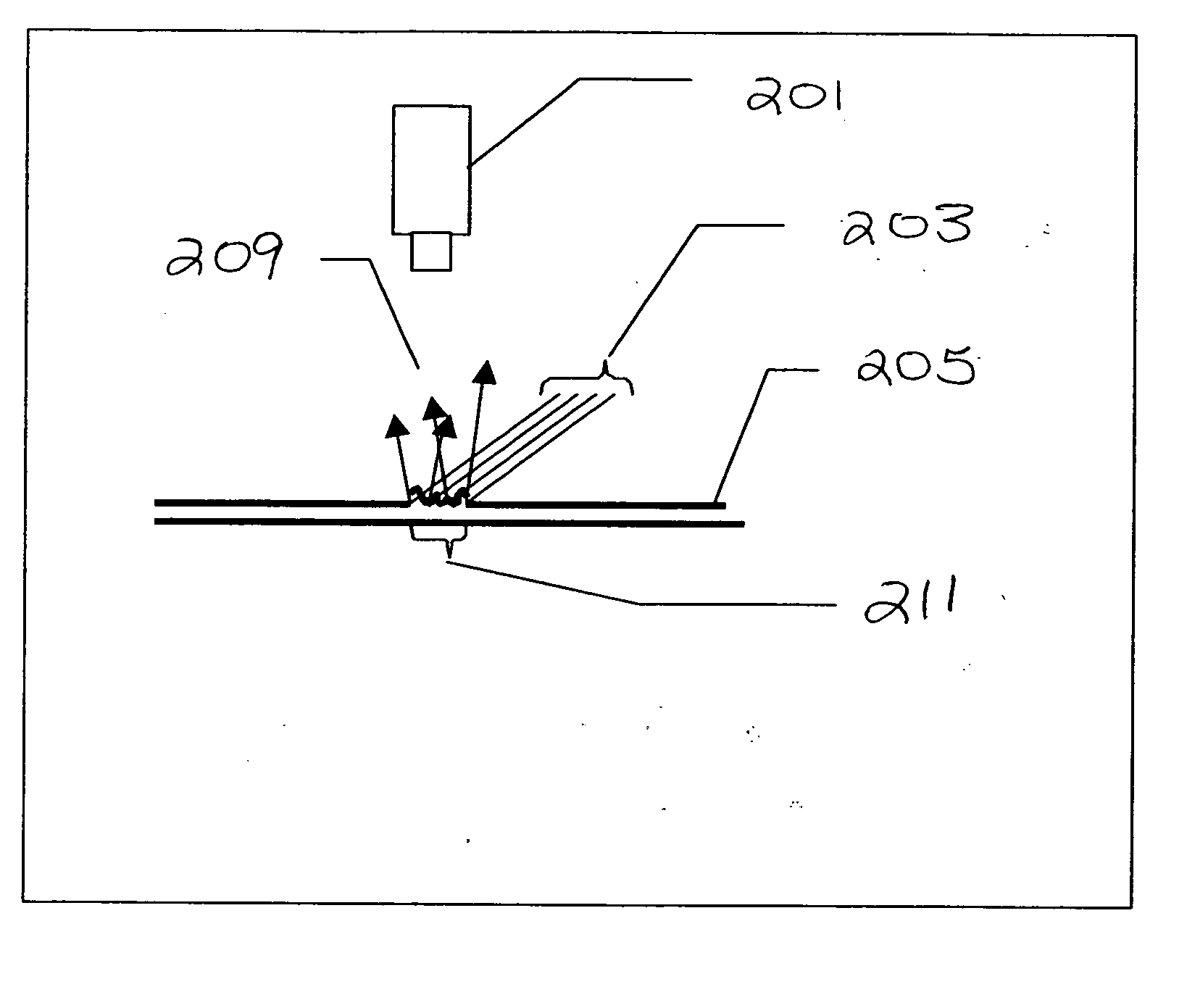

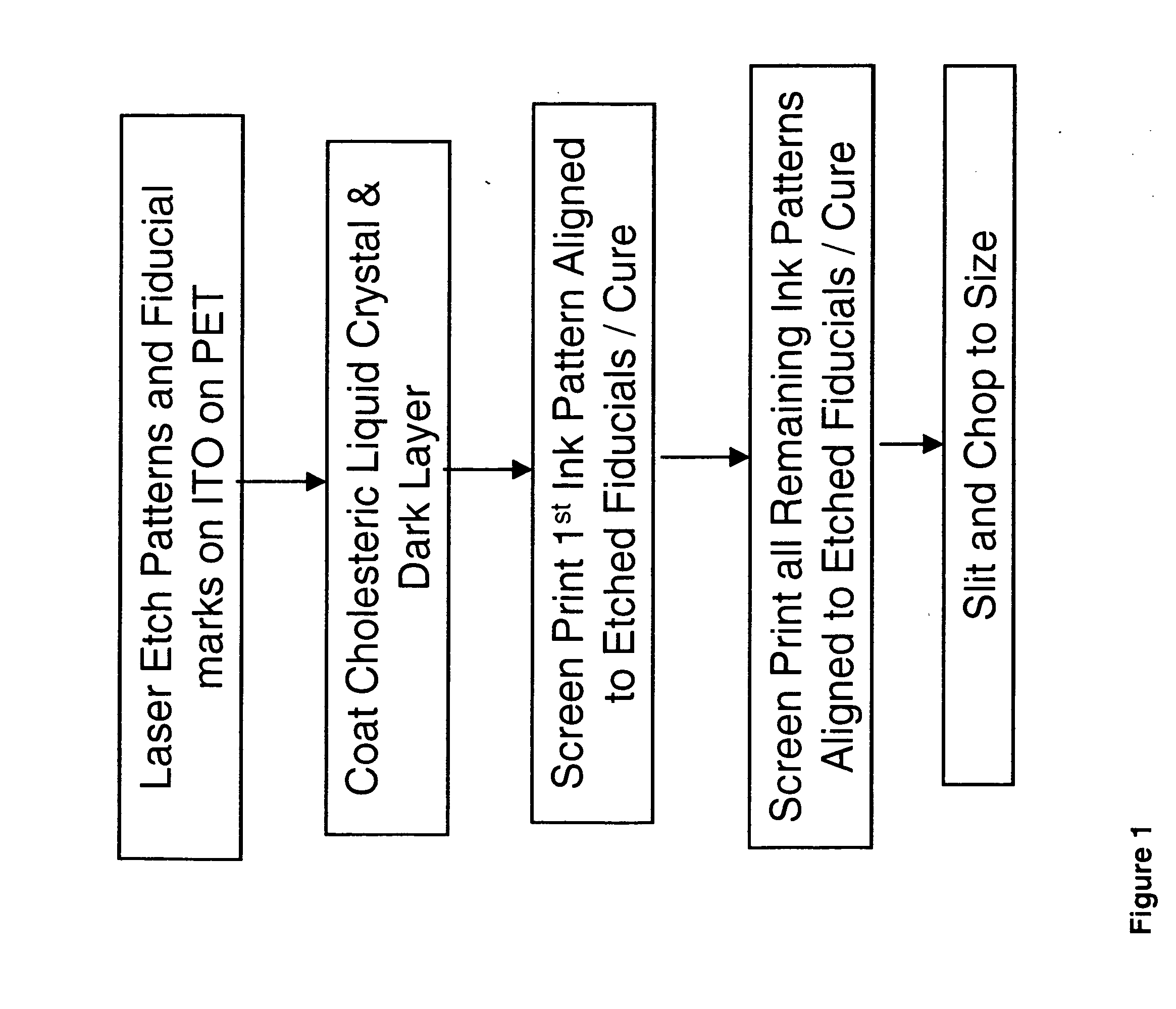

Laser etched fiducials in roll-roll display

ActiveUS7583834B2Reduce complexityRemoval costPhotomechanical apparatusSemiconductor/solid-state device manufacturingDisplay deviceEffect light

The present invention relates to a method of aligning comprising providing a support, applying a transparent layer, patterning at least the transparent layer to produce a pattern and an alignment feature capable of scattering light, illuminating the support and the transparent layer with oblique lighting, providing an analysis system capable of sensing scattered light from the alignment feature and referencing, sensing the scattered light from the alignment feature; referencing the scattered light from the alignment feature to a position on said support; and aligning a second operation to the position.

Owner:EASTMAN KODAK CO

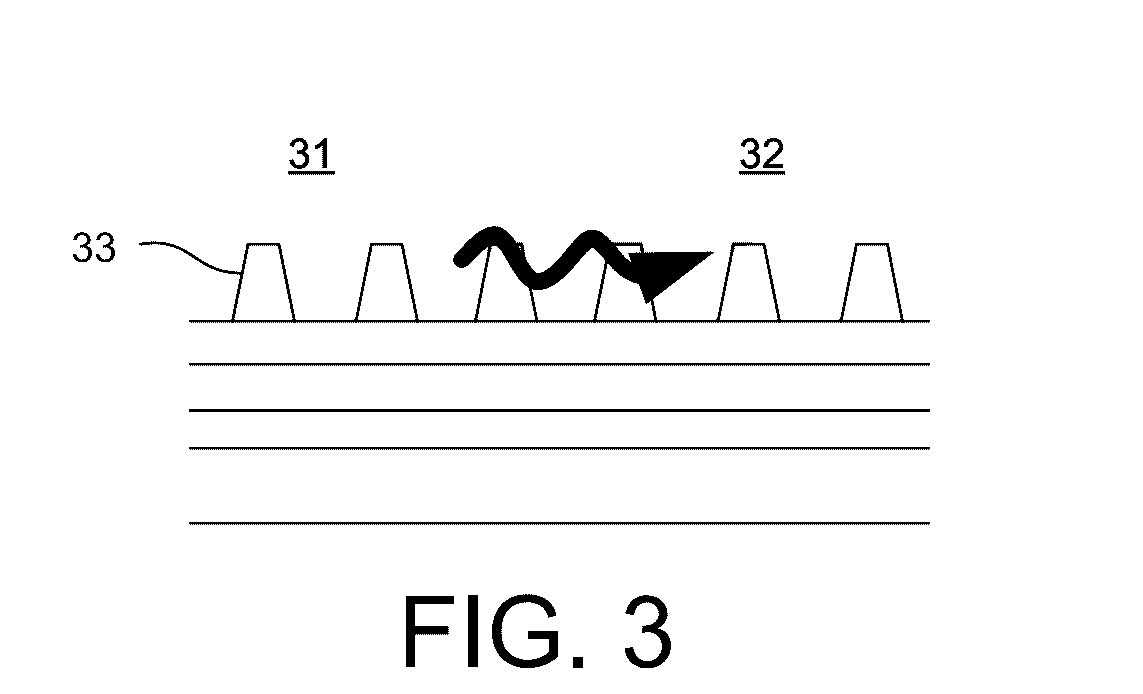

Defect Inspection Method and Defect Inspection Device

ActiveUS20150276623A1Improve efficiencyDetection is disabledPolarisation-affecting propertiesOptically investigating flaws/contaminationLength waveOptical polarization

To detect a bridge defect between lines of a line pattern formed on a sample at pitches narrower than the wavelength of inspection light, a defect inspection device is configured to comprise: a light source which emits laser; a vertical illumination unit which applies the laser to the sample from a vertical direction via an objective lens by converting the laser into linearly polarized light by using a polarization conversion unit in a state polarized in a direction orthogonal to the longitudinal direction of the line pattern; an oblique illumination unit which applies the laser to the sample from an oblique direction; a detection optical unit including an optical filter which selectively transmits a scattered light component from the defect by converting the polarization state of the reflected / scattered light; and a signal processing unit which detects the defect on the sample by processing a detection signal.

Owner:HITACHI HIGH-TECH CORP

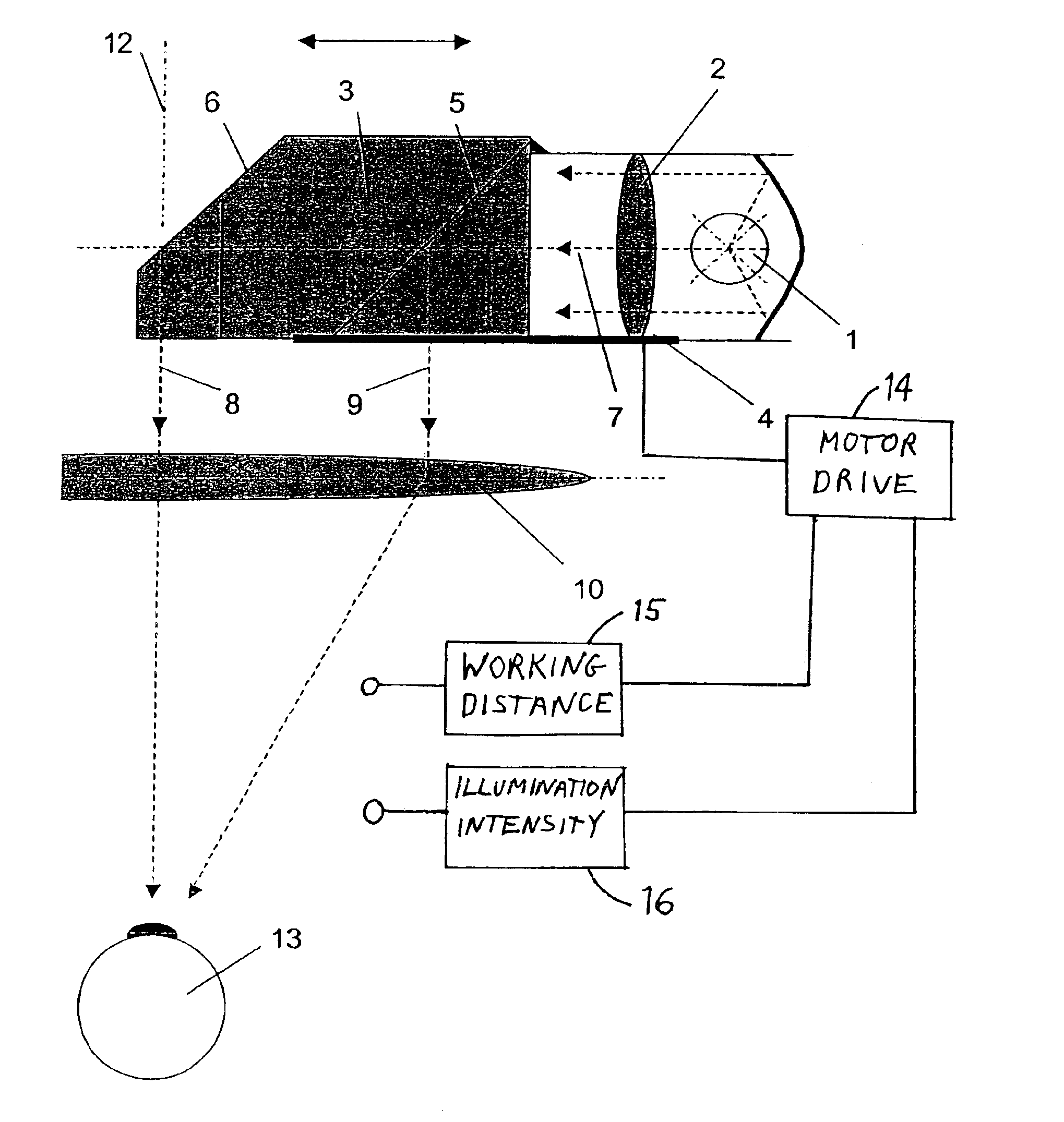

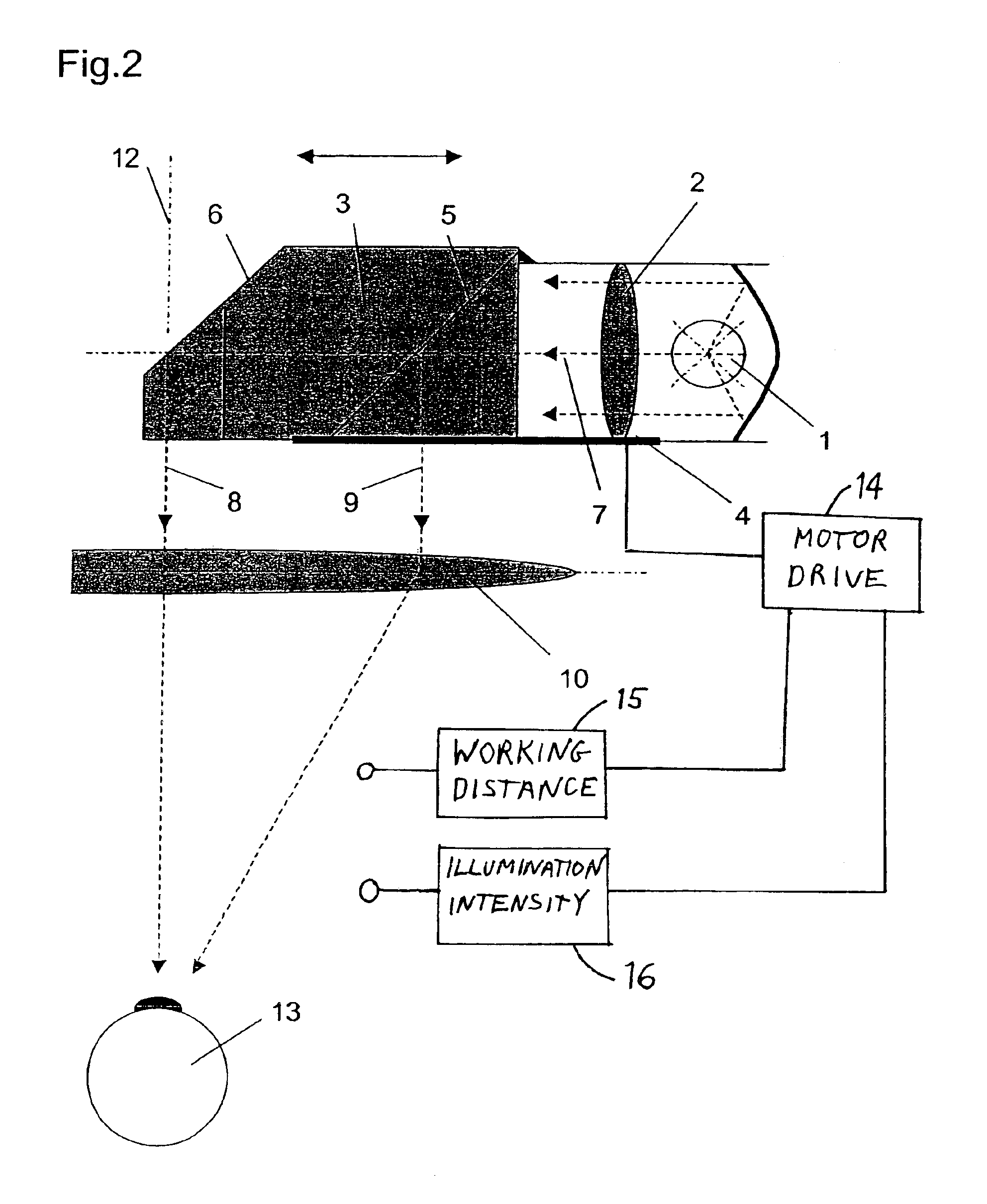

Prism construction for simultaneous zero-degree and oblique illumination of a stereoscopic surgical microscope

InactiveUS6914721B2Effective eye protectionEffective protectionPrismsEye surgeryOptical axisShortest distance

The invention concerns an apparatus for simultaneous zero-degree and oblique illumination for an optical viewing device, in particular a stereoscopic surgical microscope, which contains a shiftable prism combination (3) for deflecting a first illumination sub-beam a long distance from the optical axis (12) of the main objective in order to obtain an oblique illumination beam (9) (oblique illumination), and for deflecting a second illumination sub-beam (8) a short distance from the optical axis (12) of the main objective in order to obtain a zero-degree illumination (8).

Owner:LEICA INSTR SINGAPORE PTE

Liquid Crystal Panel Detection Device

ActiveCN104102029ARaise checkCompact structureOptically investigating flaws/contaminationNon-linear opticsLiquid-crystal displayPolarizer

Owner:NIHON MICRONICS

Sample inspection system

InactiveUS20050134841A1Reduce positioning errorsPolarisation-affecting propertiesScattering properties measurementsLight beamCombined use

A curved mirrored surface is used to collect radiation scattered by a sample surface and originating from a normal illumination beam and an oblique illumination beam. The collected radiation is focused to a detector. Scattered radiation originating from the normal and oblique illumination beams may be distinguished by employing radiation at two different wavelengths, by intentionally introducing an offset between the spots illuminated by the two beams or by switching the normal and oblique illumination beams on and off alternately. Beam position error caused by change in sample height may be corrected by detecting specular reflection of an oblique illumination beam and changing the direction of illumination in response thereto. Butterfly-shaped spatial filters may be used in conjunction with curved mirror radiation collectors to restrict detection to certain azimuthal angles.

Owner:KLA TENCOR TECH CORP

Arrangement for tilting an illumination carrier on an inverse light microscope

InactiveUS7151634B2Easily and precisely tiltedTilt movement is dampenedMicroscopesMotor controlOptoelectronics

Owner:CARL ZEISS MICROSCOPY GMBH

Laser scanning microscope having an IR partial transmission filter for realizing oblique illumination

InactiveUS7915575B2Radiation pyrometryBeam/ray focussing/reflecting arrangementsLaser scanning microscopeNonlinear optics

In a laser scanning microscope comprising an infrared pulse laser; an objective lens focusing an infrared light from the infrared pulse laser on a sample; a condenser lens disposed on an opposite side of the objective lens across the sample for collecting an observation light that is generated by a nonlinear optical effect and has a wavelength shorter than a wavelength of the infrared light; a visible light detector detecting the observation light collected by the condenser lens, an IR partial transmission filter having partially-modified transmission characteristics for the infrared light is disposed near a front focal position of the condenser lens, and an infrared light detector detecting, through the IR partial transmission filter, a transmitted light from the sample collected by the condenser lens, is provided.

Owner:EVIDENT CORP

Method and device for detecting patterns on a substrate

InactiveUS20050248767A1Increase contrastImprove measurement resultsSemiconductor/solid-state device testing/measurementCharacter and pattern recognitionLight beamEngineering

Device for detecting patterns on a travelling substrate, namely on a substrate being deposited on a sheet or on web matter, wherein the substrate is a metallized foil travelling in a travelling direction. The device comprises a housing for a first incidental beam issued from a first source of light, a second incidental beam issued from a second source of light, an optical measuring system, a photosensitive sensor respectively delivering beams reflected from the substrate and an electronic unit connected to a communication port. The optical measuring system is telecentric, the first incidental beam crosses a telecentric lighting system and the second incidental beam crosses an oblique lighting system.

Owner:BOBST SA

Optical system for detecting anomalies and/or features of surfaces

ActiveUS7365834B2High detection sensitivityImprove throughputScattering properties measurementsOptically investigating flaws/contaminationDetector arrayLight beam

A surface inspection of the system applies a first oblique illumination beam and may also apply a second illumination beam to illuminate a surface either sequentially or simultaneously. Radiation reflected or scattered is collected by preferably three collection channels and detected by three corresponding detector arrays, although a different number of channels and detector arrays may be used. One or both illumination beams are focused to a line on the surface to be inspected and each line is imaged onto one or more detector arrays in the up to three or more detection and collection channels. Relative motion is caused between the lines and the surface inspected in a direction perpendicular to the lines, thereby increasing throughput while retaining high resolution and sensitivity. The same detection channels may be employed by detecting scattered or reflected radiation from both illumination beams. Fourier filters may be employed to filter out diffraction at one or more different spatial frequencies.

Owner:KLA TENCOR TECH CORP

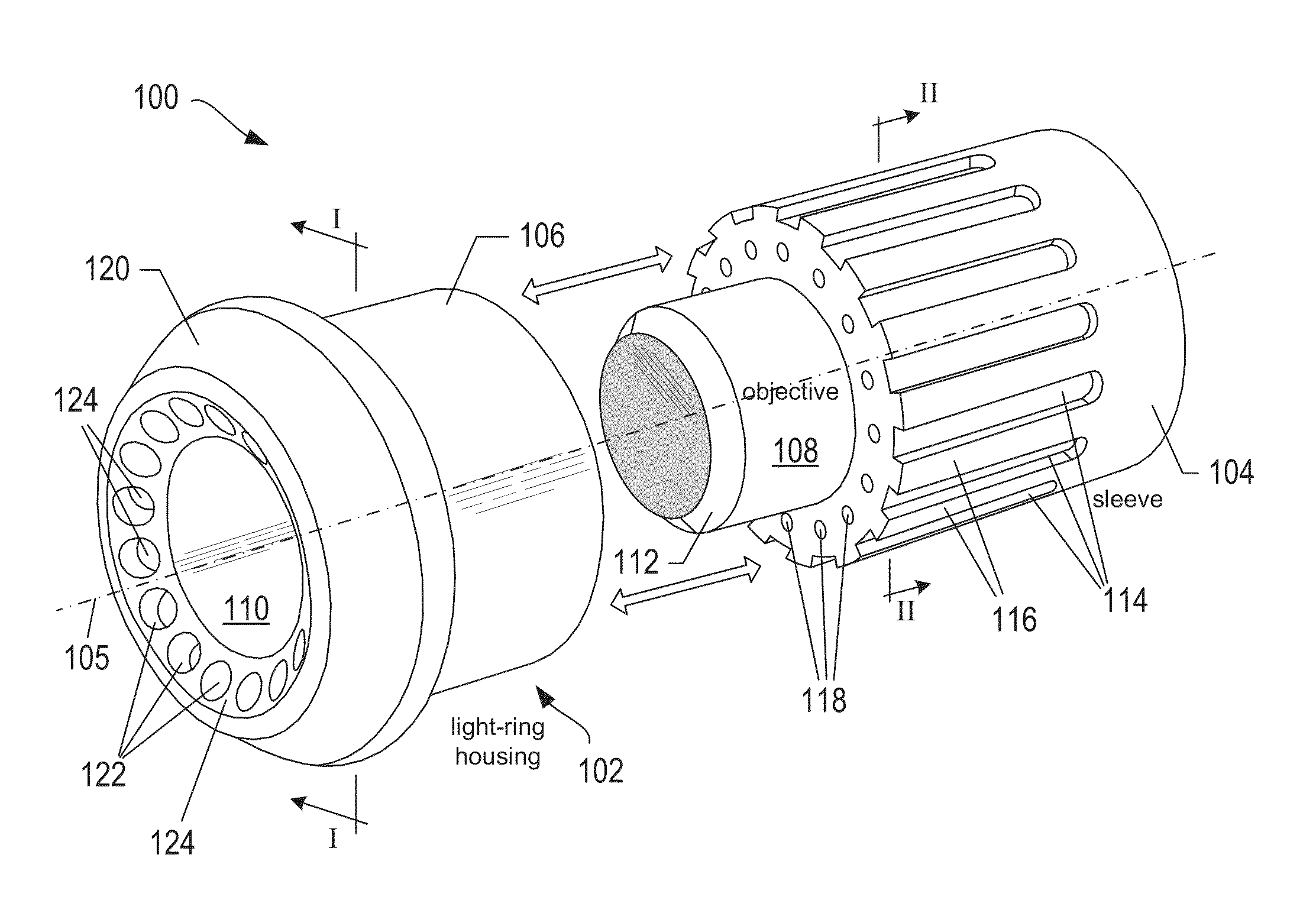

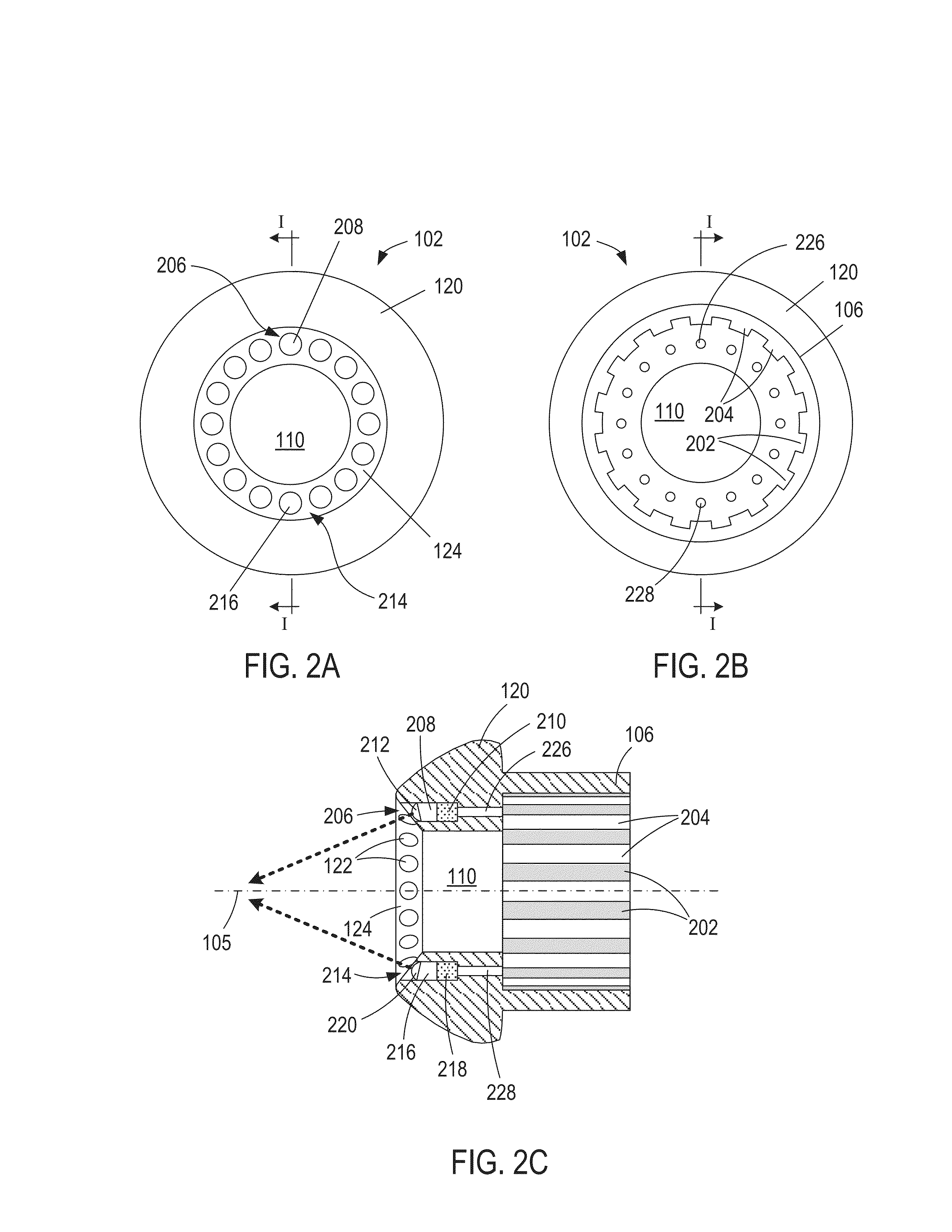

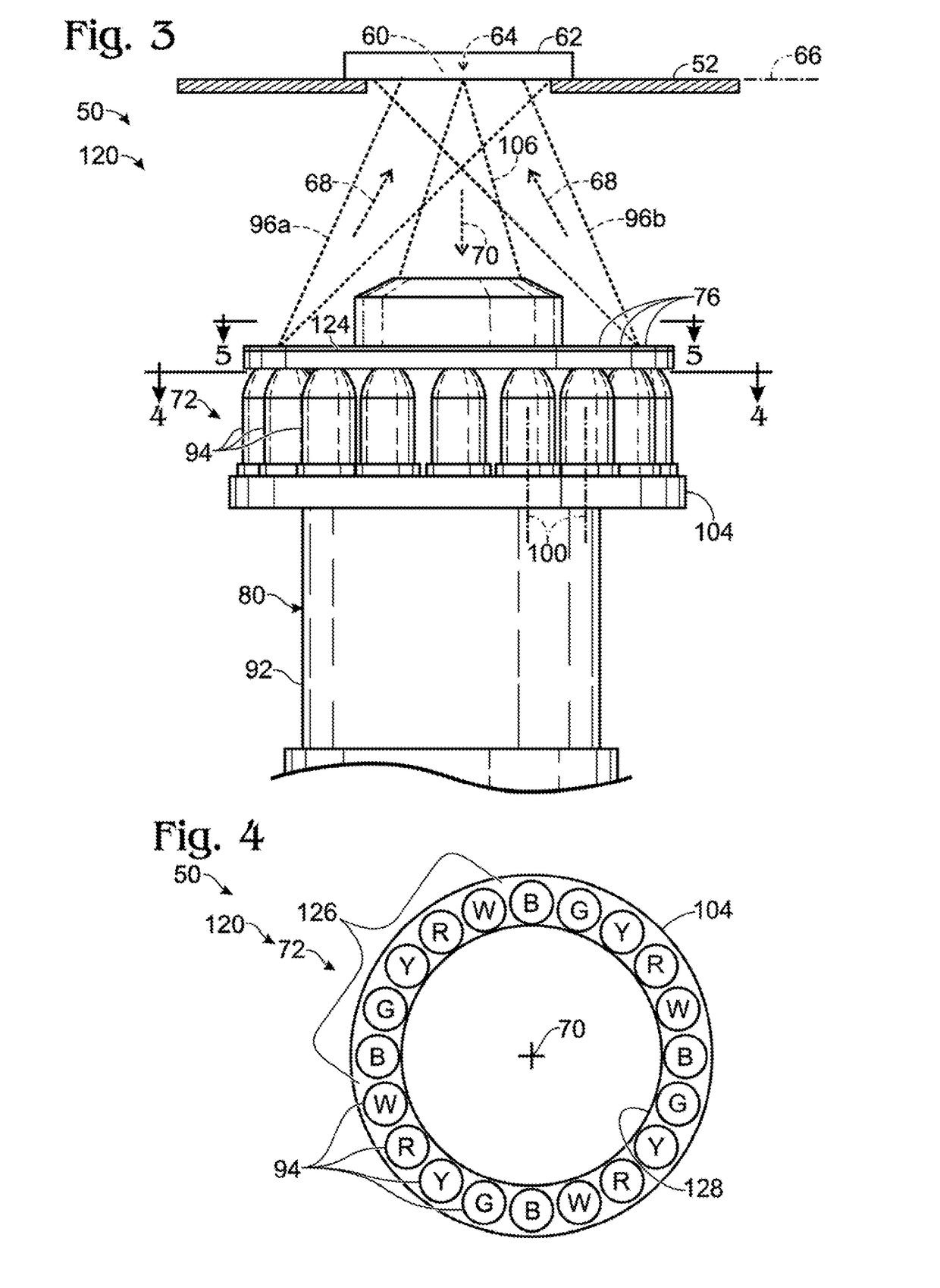

Imaging system with oblique illumination

InactiveUS20170343476A1Few moving partsCompact designMicroscopesFluorescence/phosphorescencePhotoluminescenceGlobal illumination

The present disclosure provides an imaging system, including methods and apparatus, with oblique illumination. In an exemplary method of imaging, a sample may be illuminated obliquely with excitation light generated by only a subset of a plurality of light sources mounted to an annular frame. An image may be detected, with the image formed with photoluminescence induced in the sample by the excitation light and received from a central opening of the annular frame.

Owner:MOLECULAR DEVICES

Laser etched fiducials in roll-roll display

ActiveUS20060199088A1Reduce complexityRemoval costPhotomechanical apparatusSemiconductor/solid-state device manufacturingDisplay deviceEffect light

The present invention relates to a method of aligning comprising providing a support, applying a transparent layer, patterning at least the transparent layer to produce a pattern and an alignment feature capable of scattering light, illuminating the support and the transparent layer with oblique lighting, providing an analysis system capable of sensing scattered light from the alignment feature and referencing, sensing the scattered light from the alignment feature; referencing the scattered light from the alignment feature to a position on said support; and aligning a second operation to the position.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com