Laser processing machine and method

A laser processing machine, laser processing technology, applied in metal processing, laser welding equipment, metal processing equipment and other directions, can solve the problem of unprocessable objects display and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

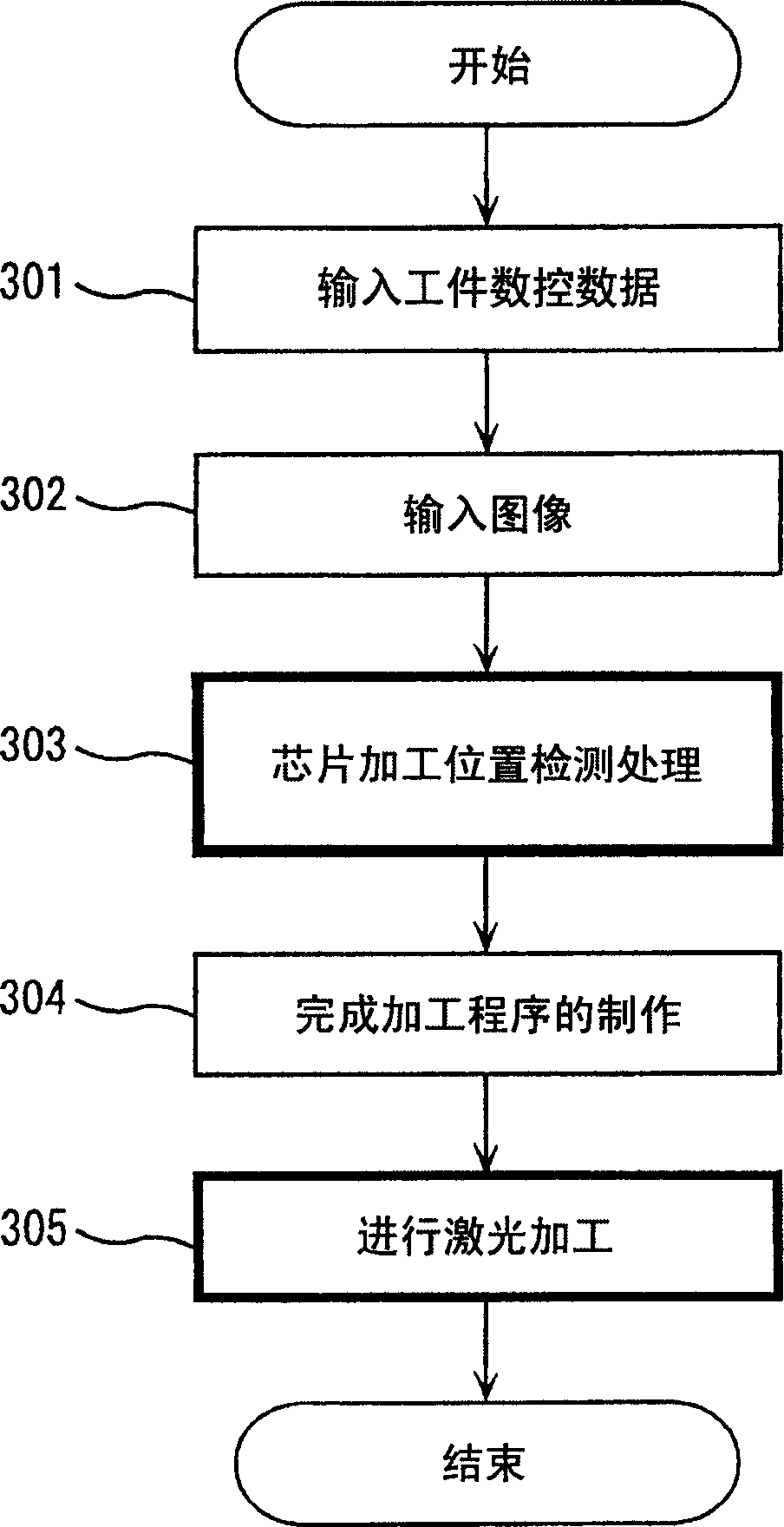

[0026] Next, embodiments of the laser processing machine and the laser processing method of the present invention will be described with reference to the drawings.

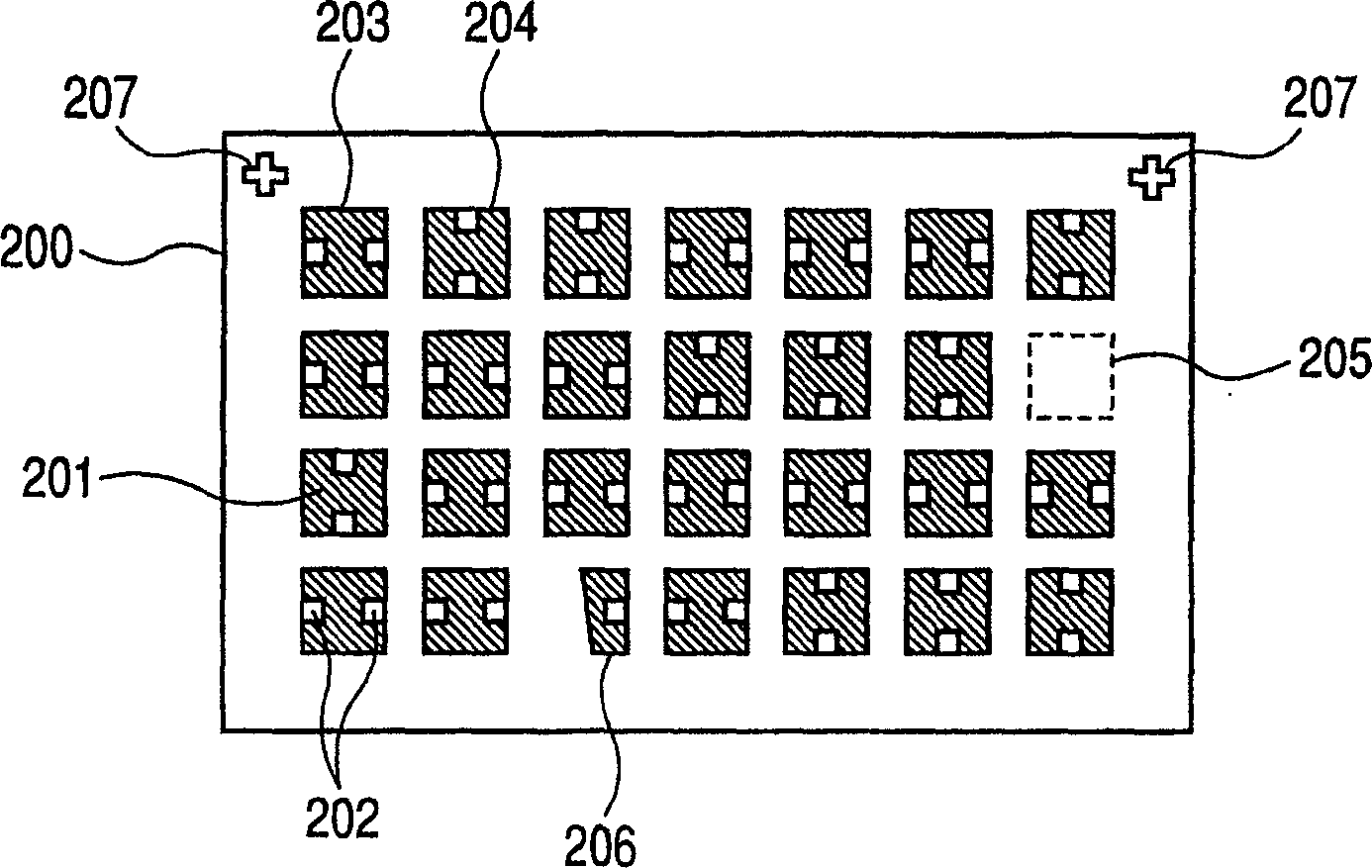

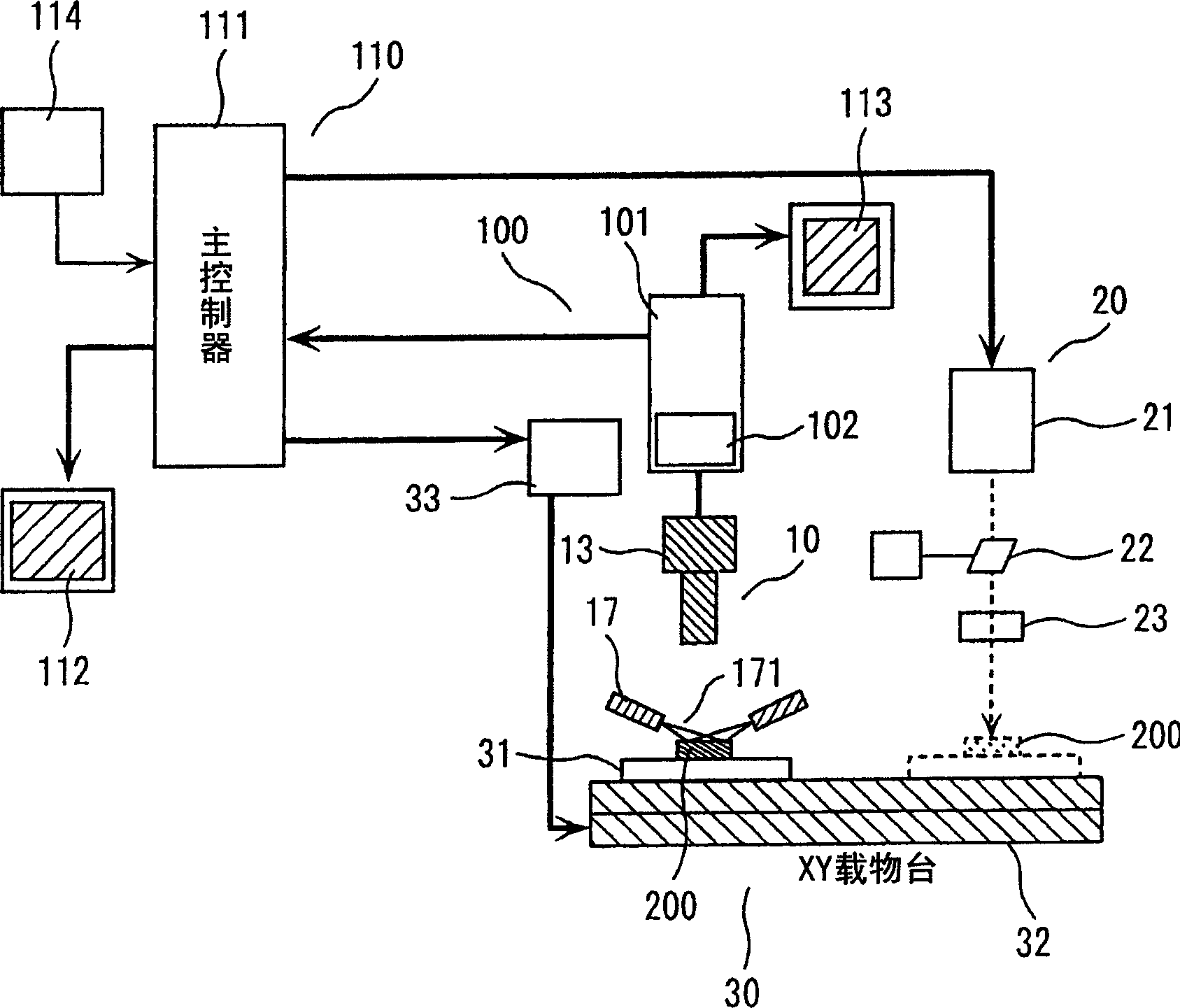

[0027] figure 1 is a diagram showing an example of a workpiece to be processed, figure 2 It is a block diagram showing an embodiment of a laser processing machine equipped with a processing position compensation mechanism according to the present invention.

[0028] First, refer to figure 1 and Figure 7 Describes the workpiece to be processed. figure 1 shows an enlarged plan view of workpiece 200, Figure 7 Shows an enlarged cross-sectional view of a part of the workpiece. The workpiece 200 is based on the reference position of the reference mark 207. For example, many tiny chip parts 201 of about 1mm square are arranged on a sheet 198 such as polyimide, and it is fixed with an adhesive or the like. It is covered with a protective film 199. Then, it is necessary to punch holes in the protective film 199 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com