Liquid Crystal Panel Detection Device

A liquid crystal panel and inspection device technology, applied in the direction of measuring devices, optics, instruments, etc., can solve the problems of insufficient reach and insufficient light irradiation of the liquid crystal panel 1, achieve compact device structure, shorten production cycle time, and shorten production cycle time the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

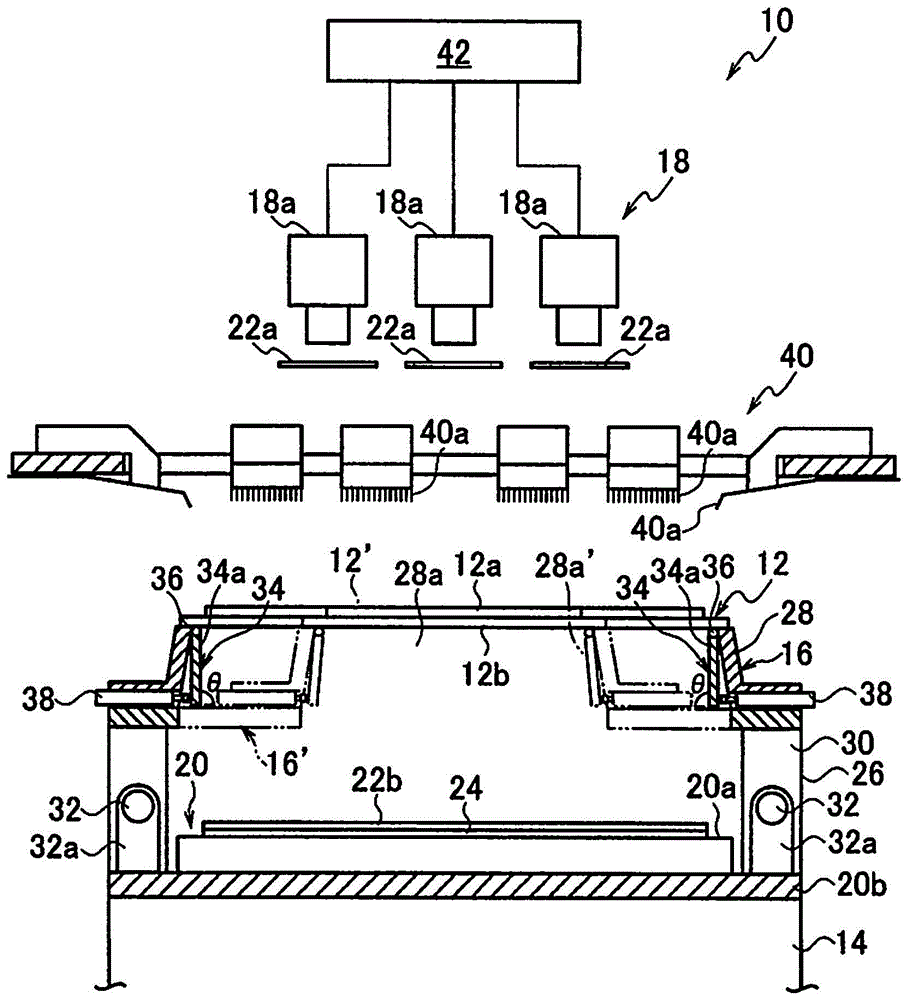

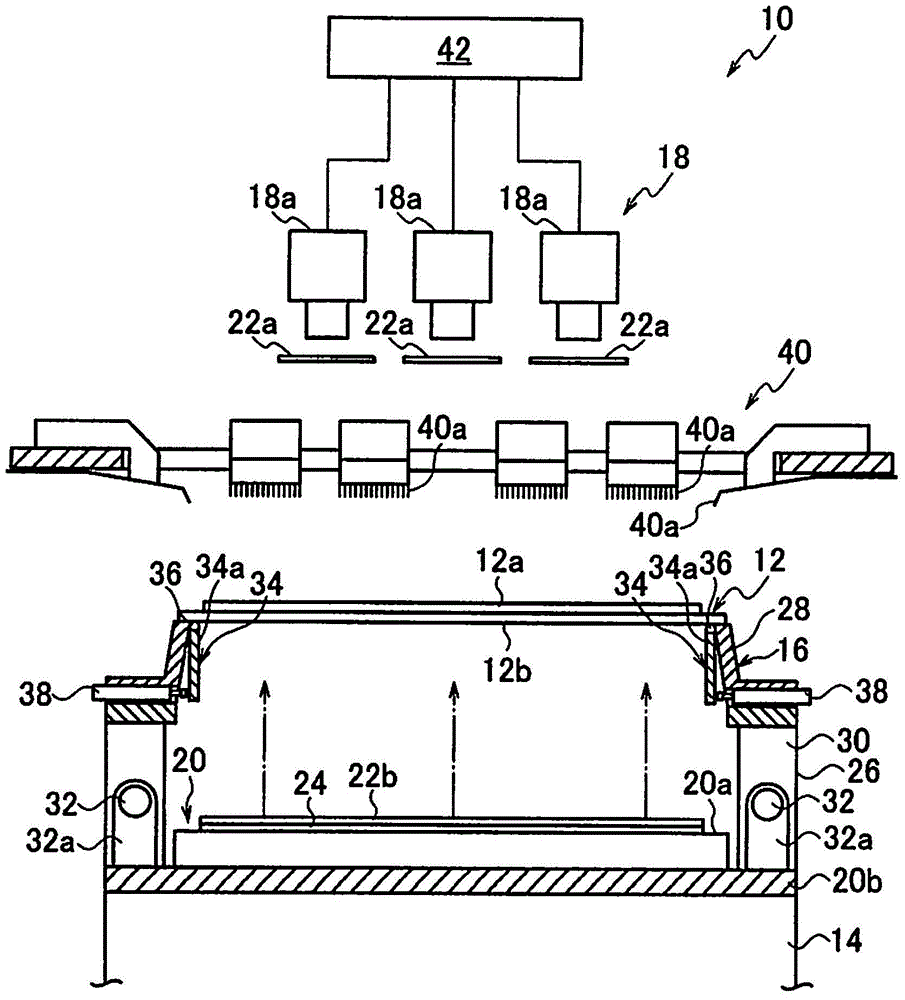

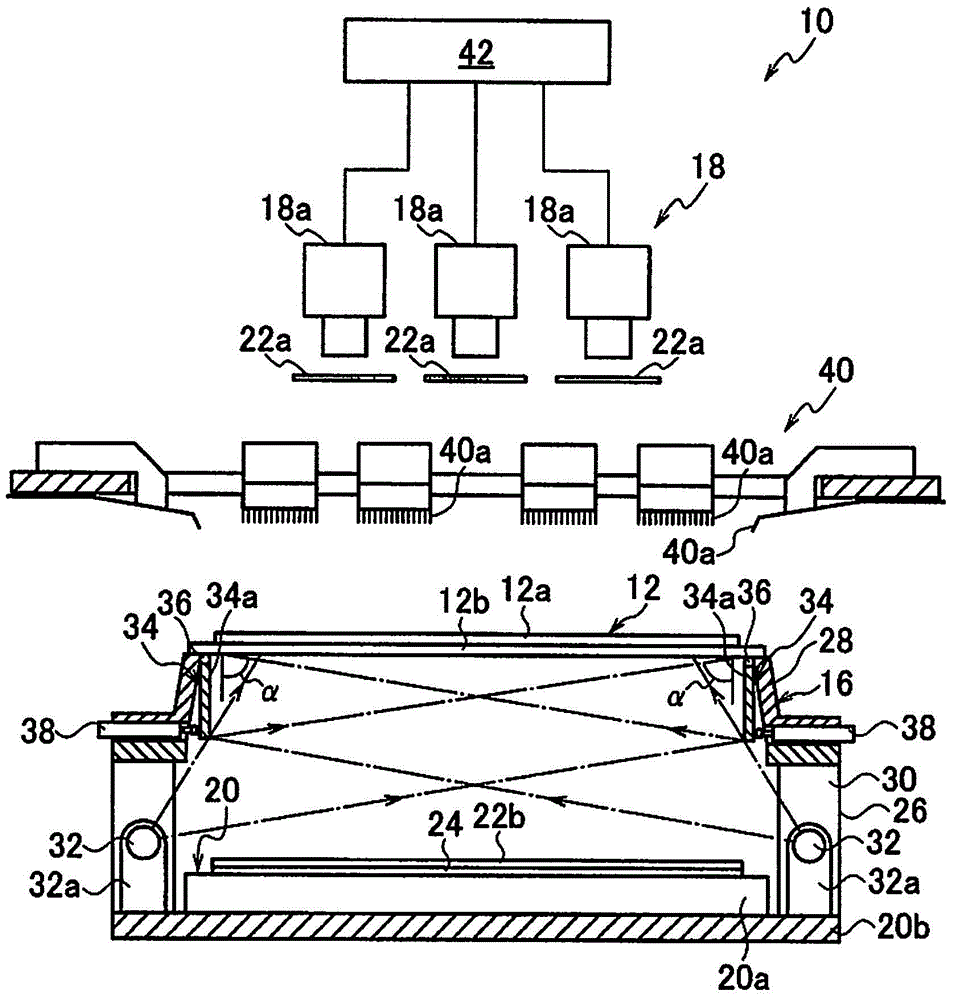

[0036] The liquid crystal panel inspection apparatus 10 of this invention is applied to the inspection of the liquid crystal panel 12 which does not have a pair of polarizing plates. The liquid crystal panel 12 has a rectangular planar shape, and conventionally known electrodes (not shown) for applying a driving voltage to each pixel of the liquid crystal panel 12 are arranged on each side of one surface (upper surface) 12 a of the liquid crystal panel 12 .

[0037] The liquid crystal panel inspection device 10 includes: a lifting table 14, which can be figure 1 The vertical direction (z-axis direction) is raised and lowered in the middle view; the worktable 16 is supported on the lifting platform and is used to hold the liquid crystal panel 12 as the object to be inspected; and the imaging unit 18 is able to An imaging means such as a CCD camera captures images of the upper surface 12 a of the liquid crystal panel 12 held on the table from above the table 16 .

[0038] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com