Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2116results about "Brake types" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

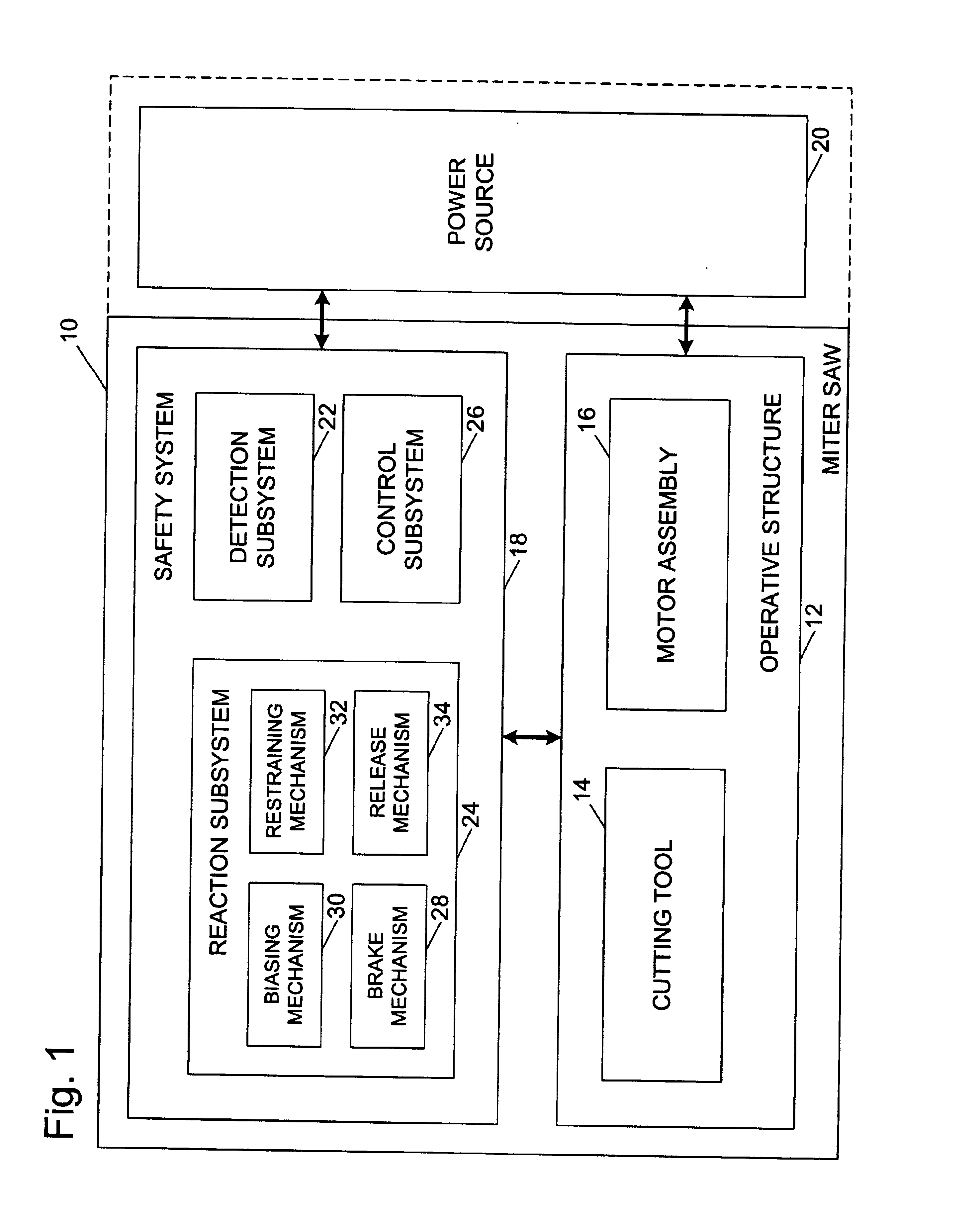

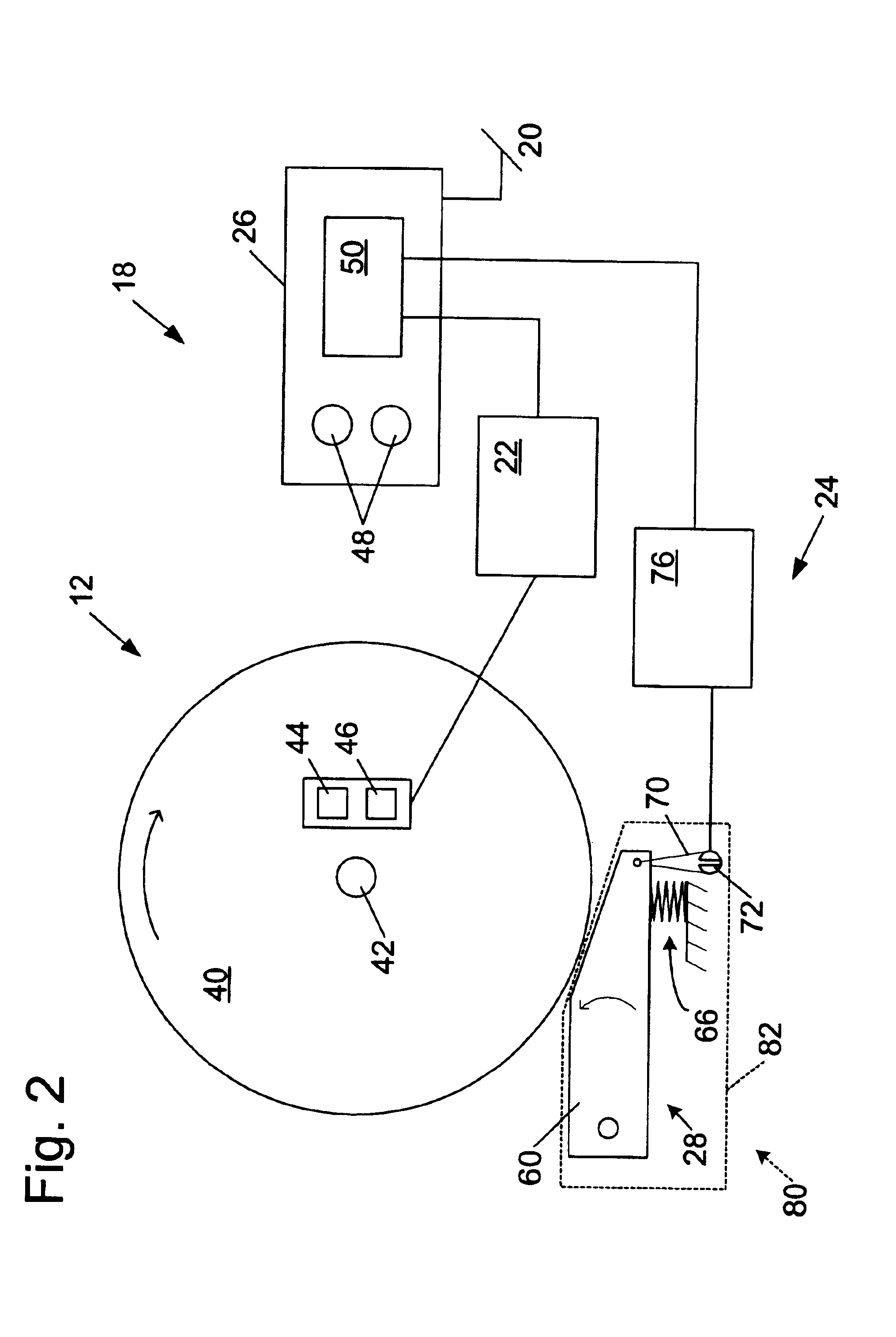

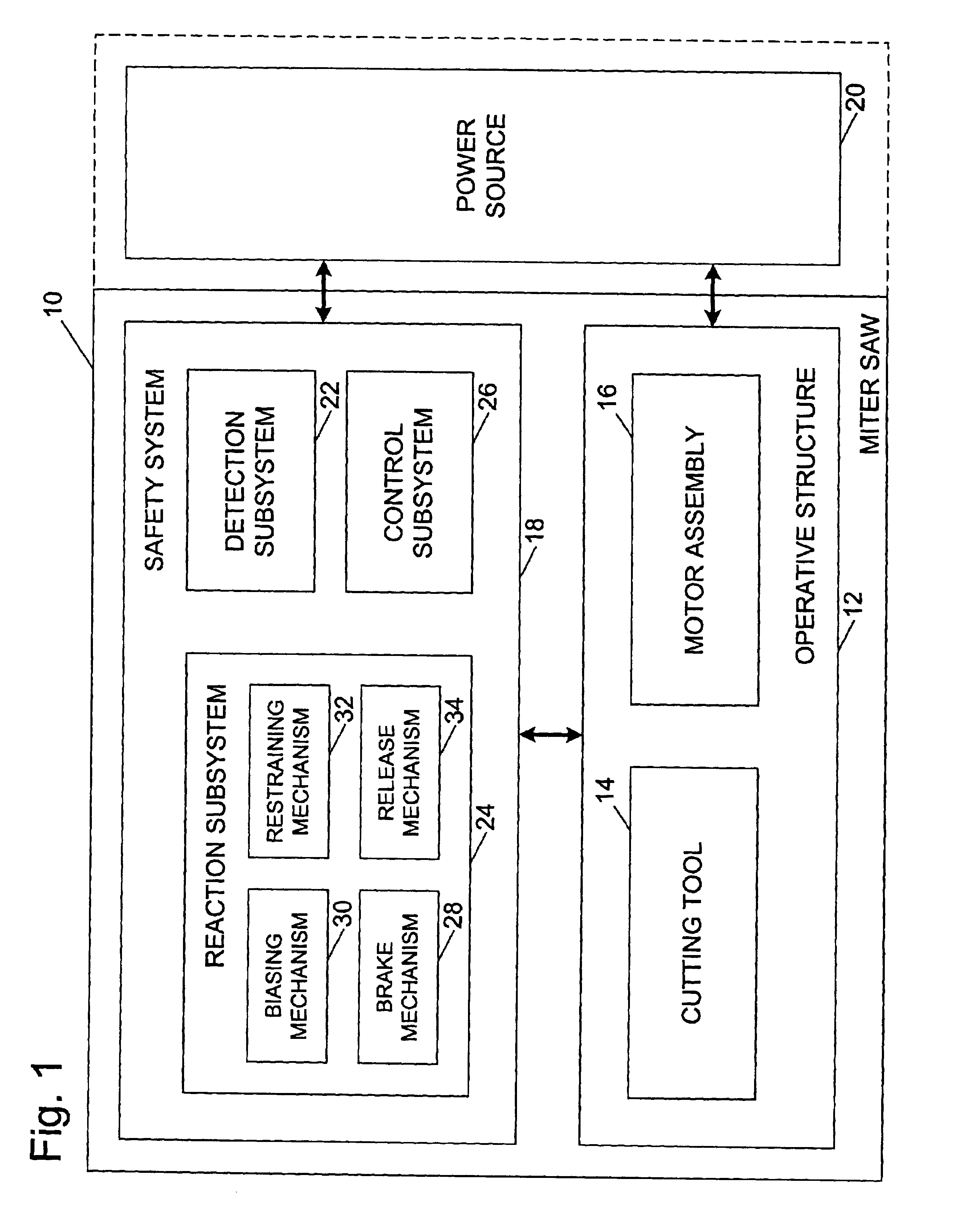

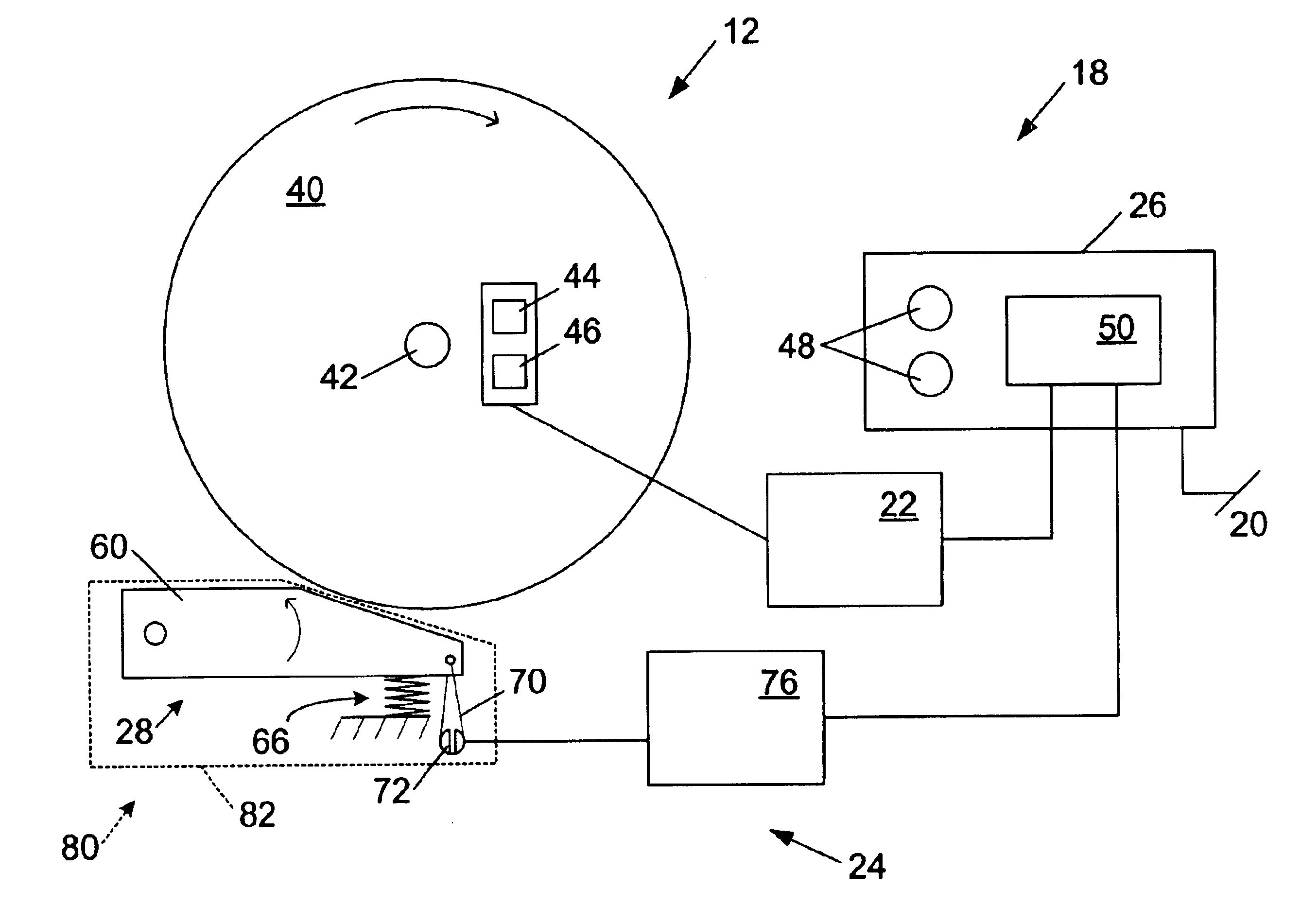

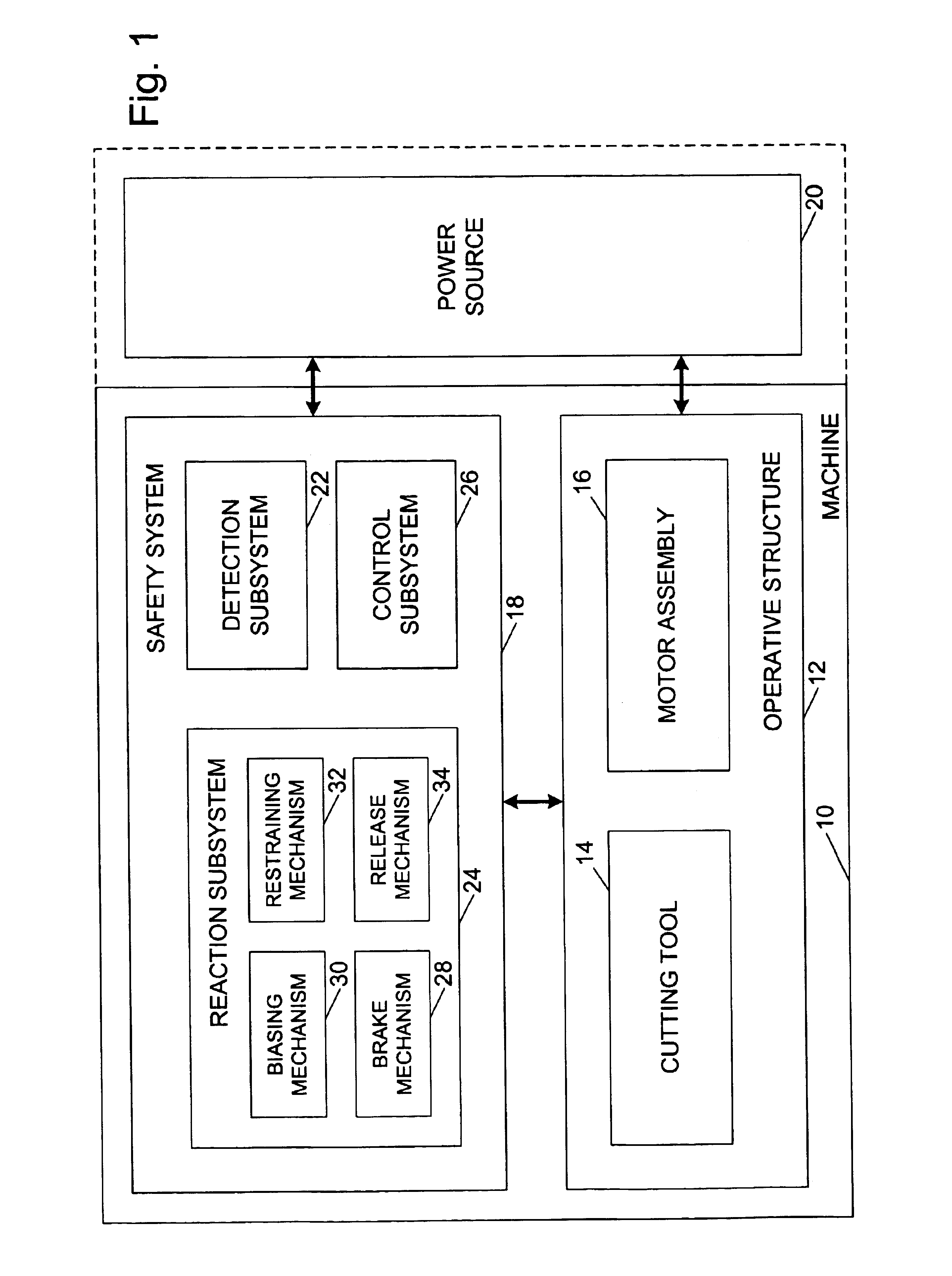

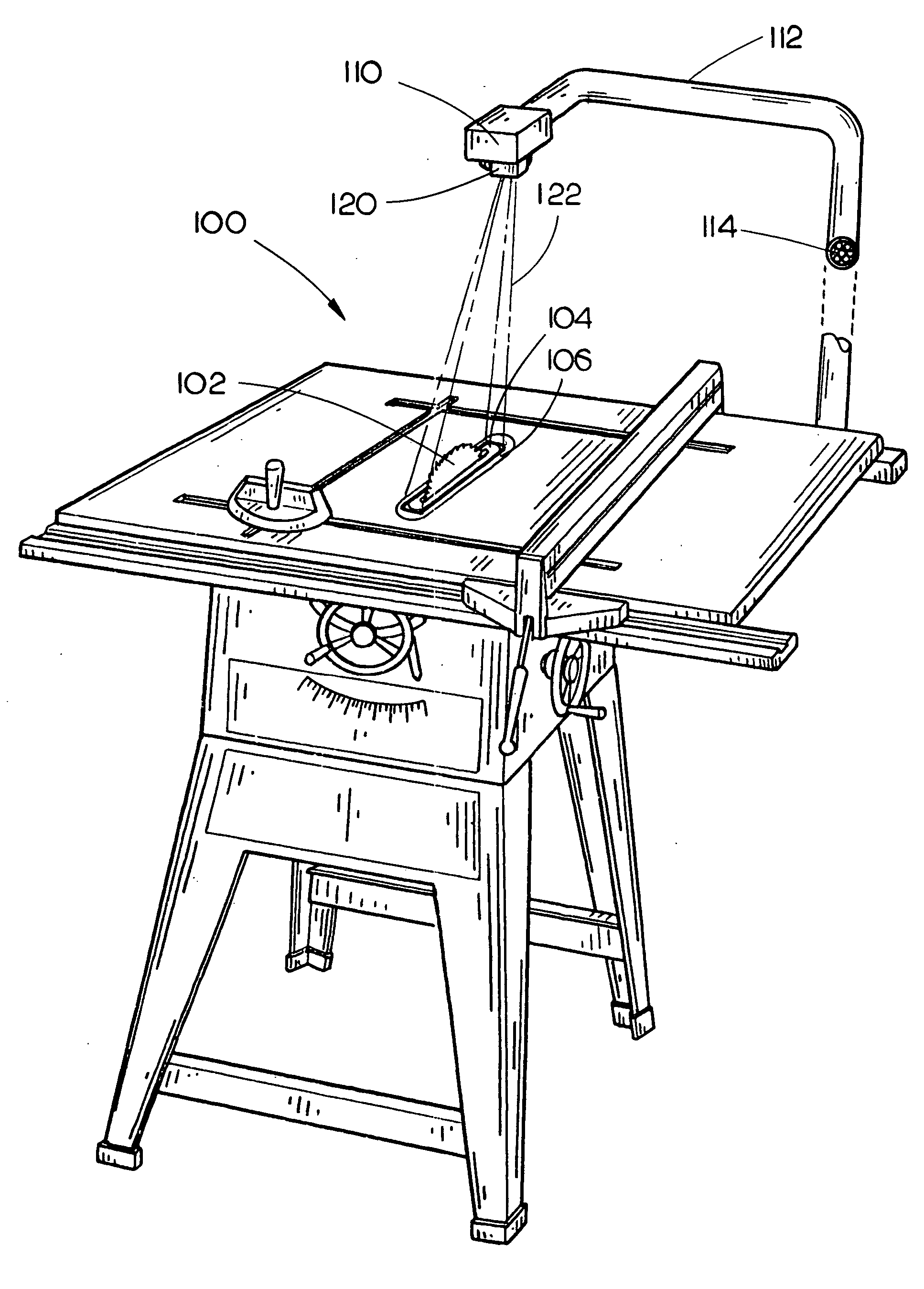

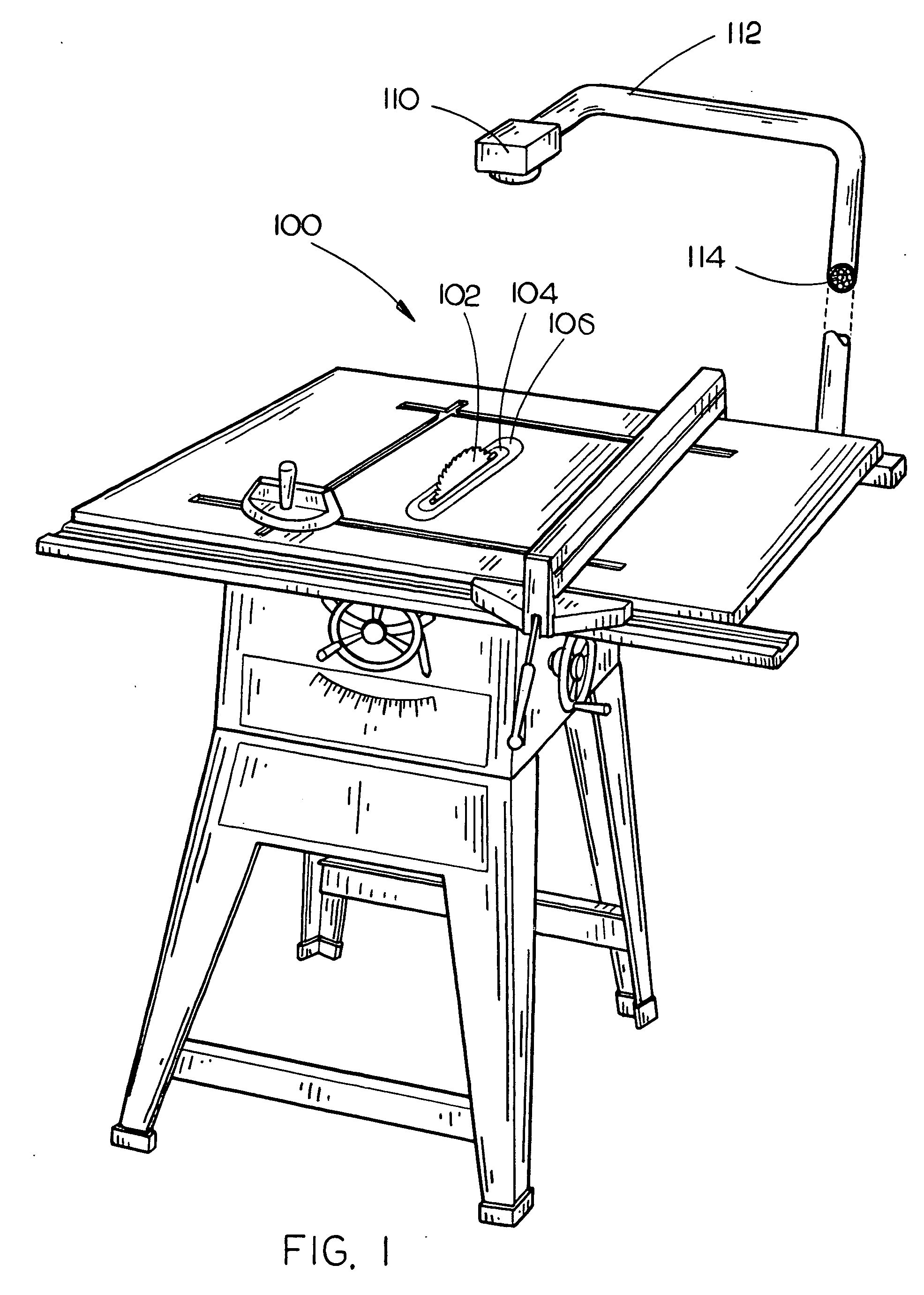

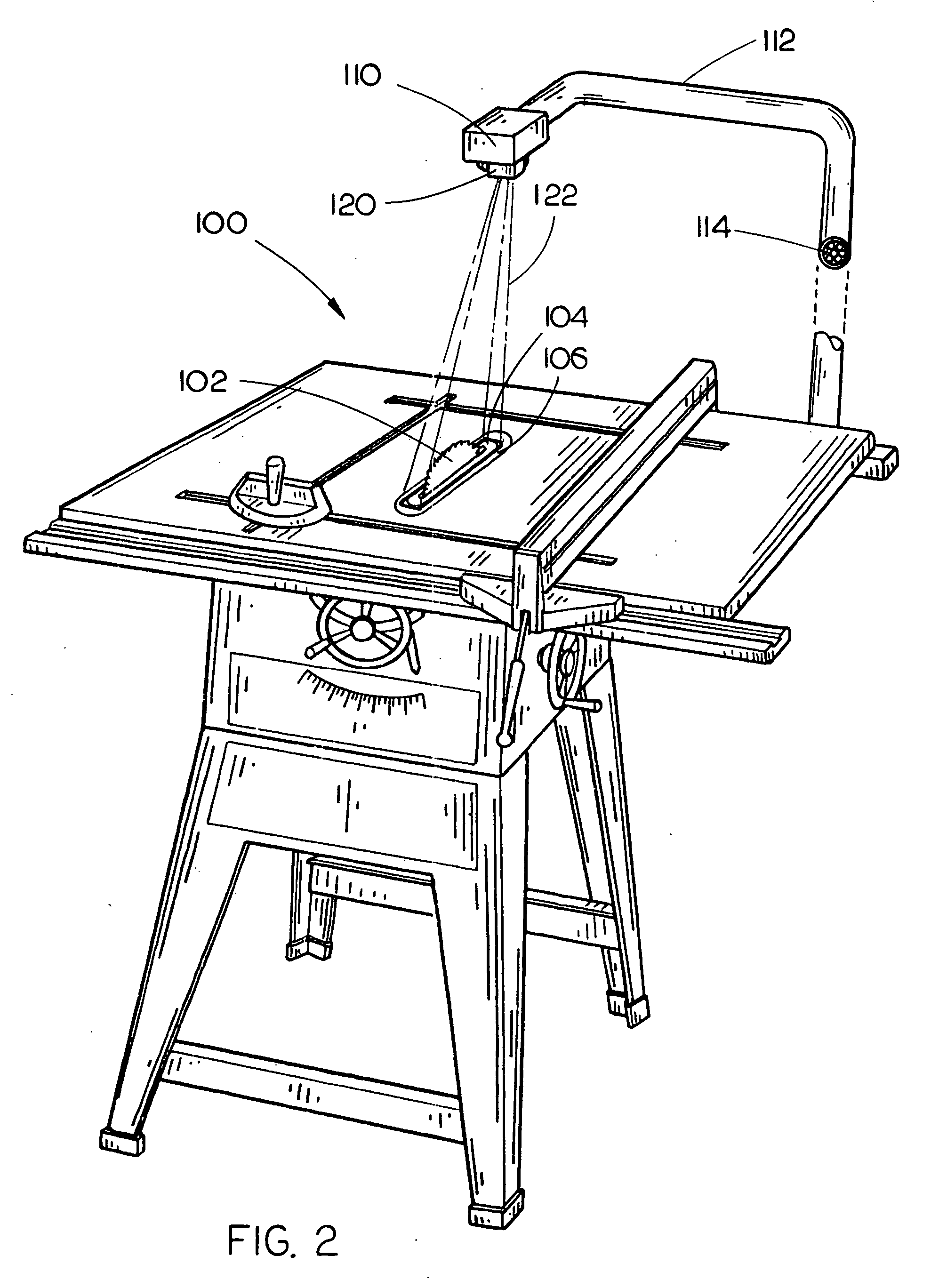

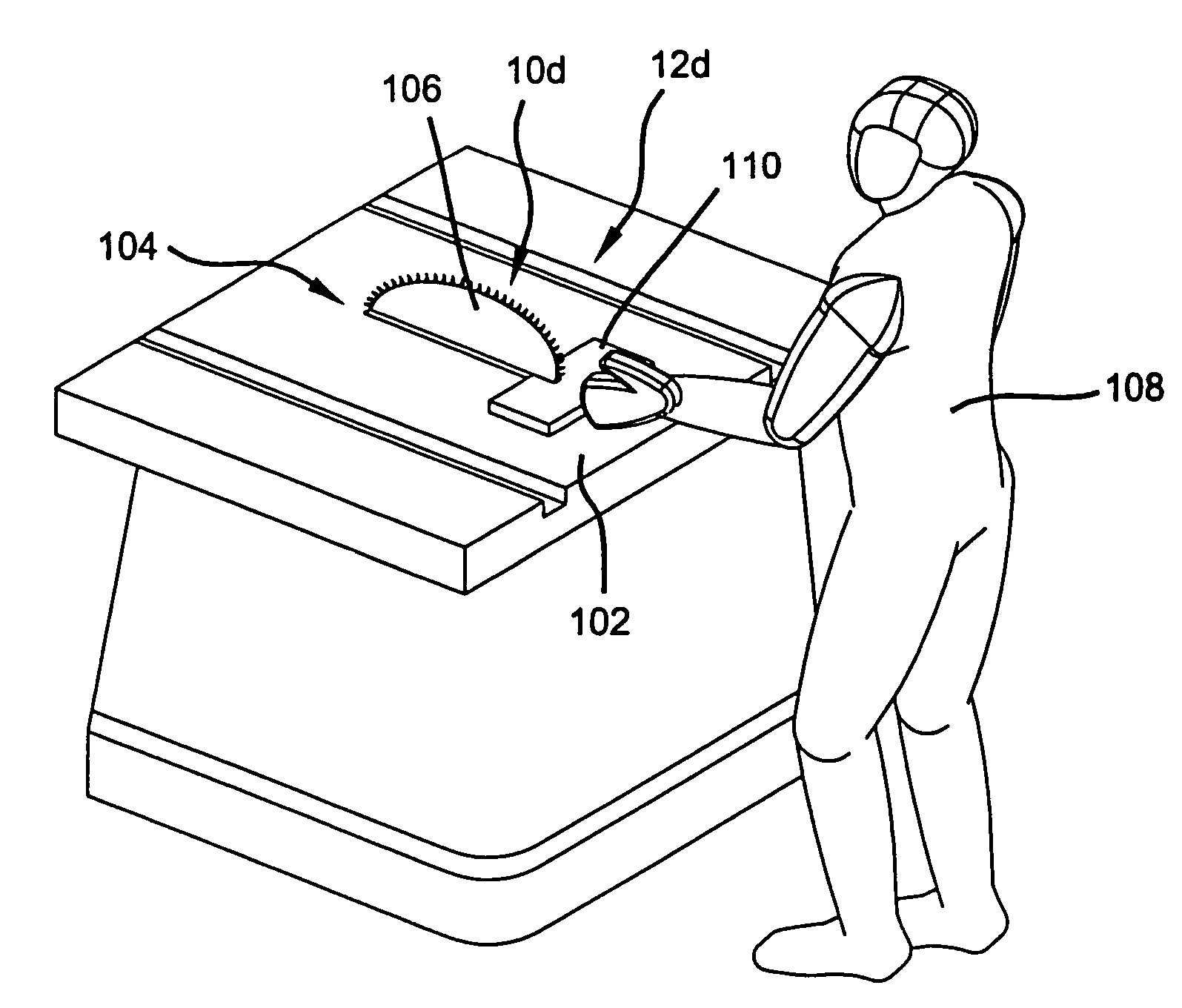

Miter saw with improved safety system

InactiveUS6826988B2Increase opportunitiesLimit and even prevent injuryEmergency protective circuit arrangementsEngineering safety devicesEngineeringWoodworking machine

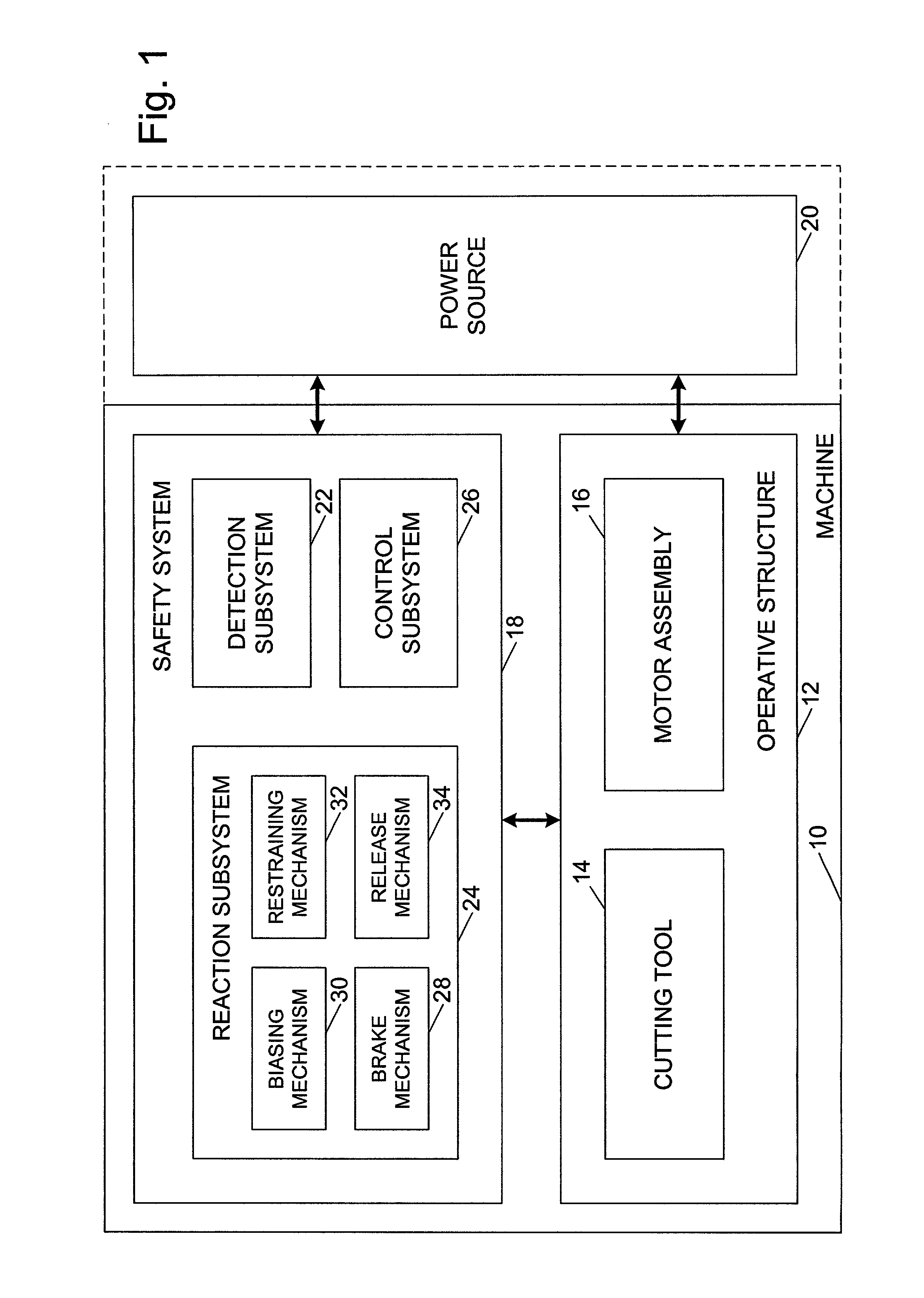

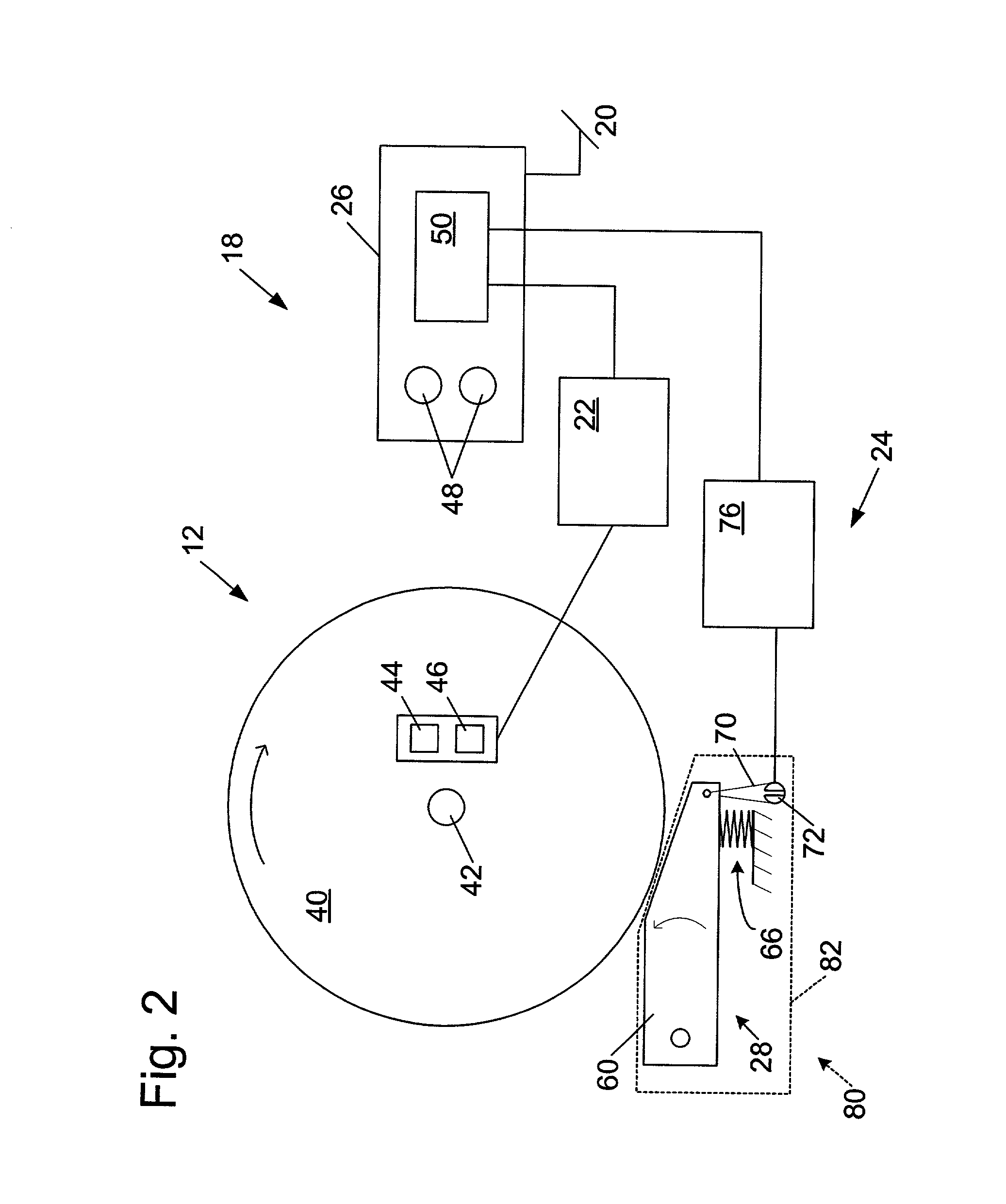

A woodworking machine is disclosed having a base, a blade, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating and / or to stop movement of the blade toward the cutting zone.

Owner:SAWSTOP HLDG LLC

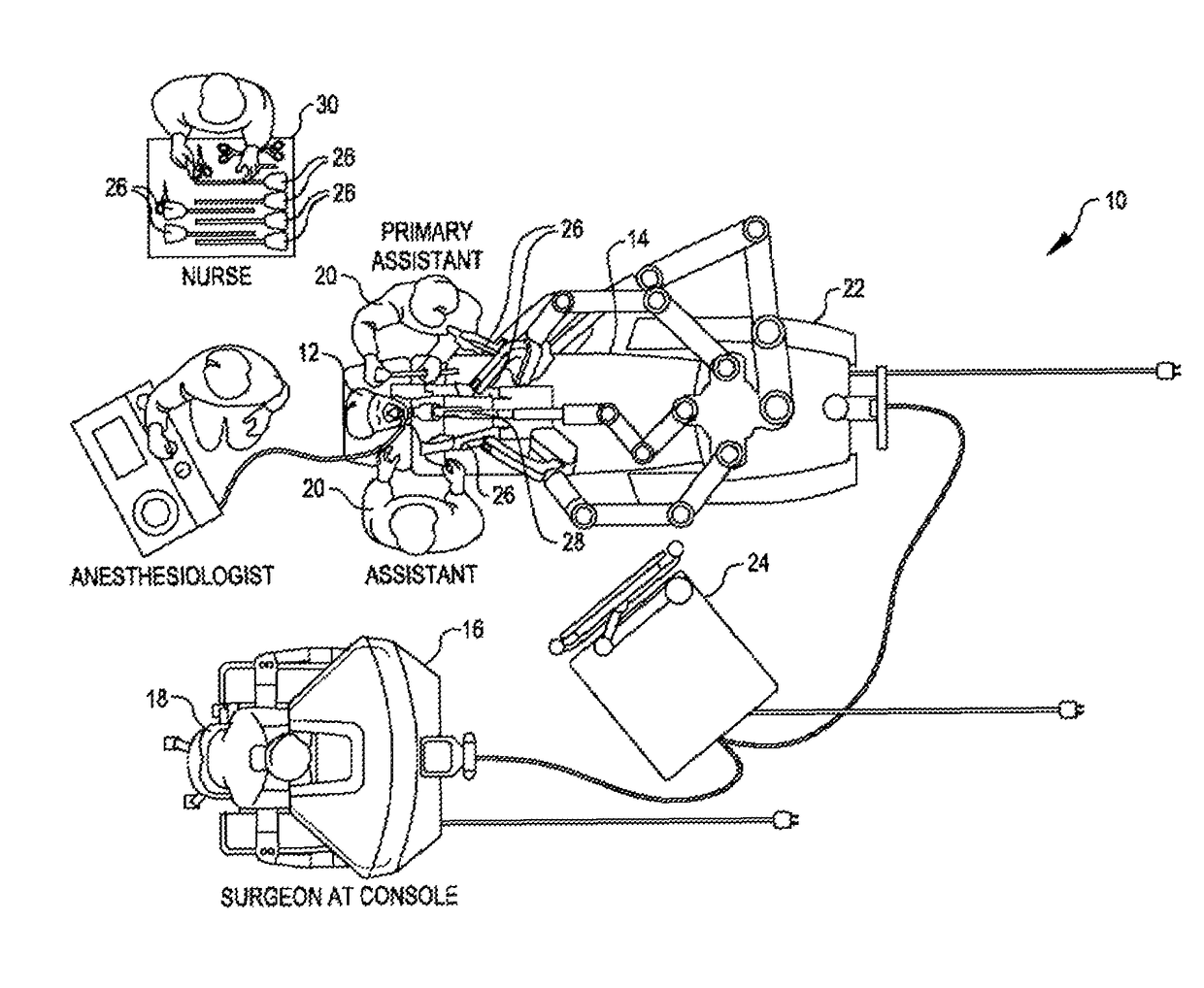

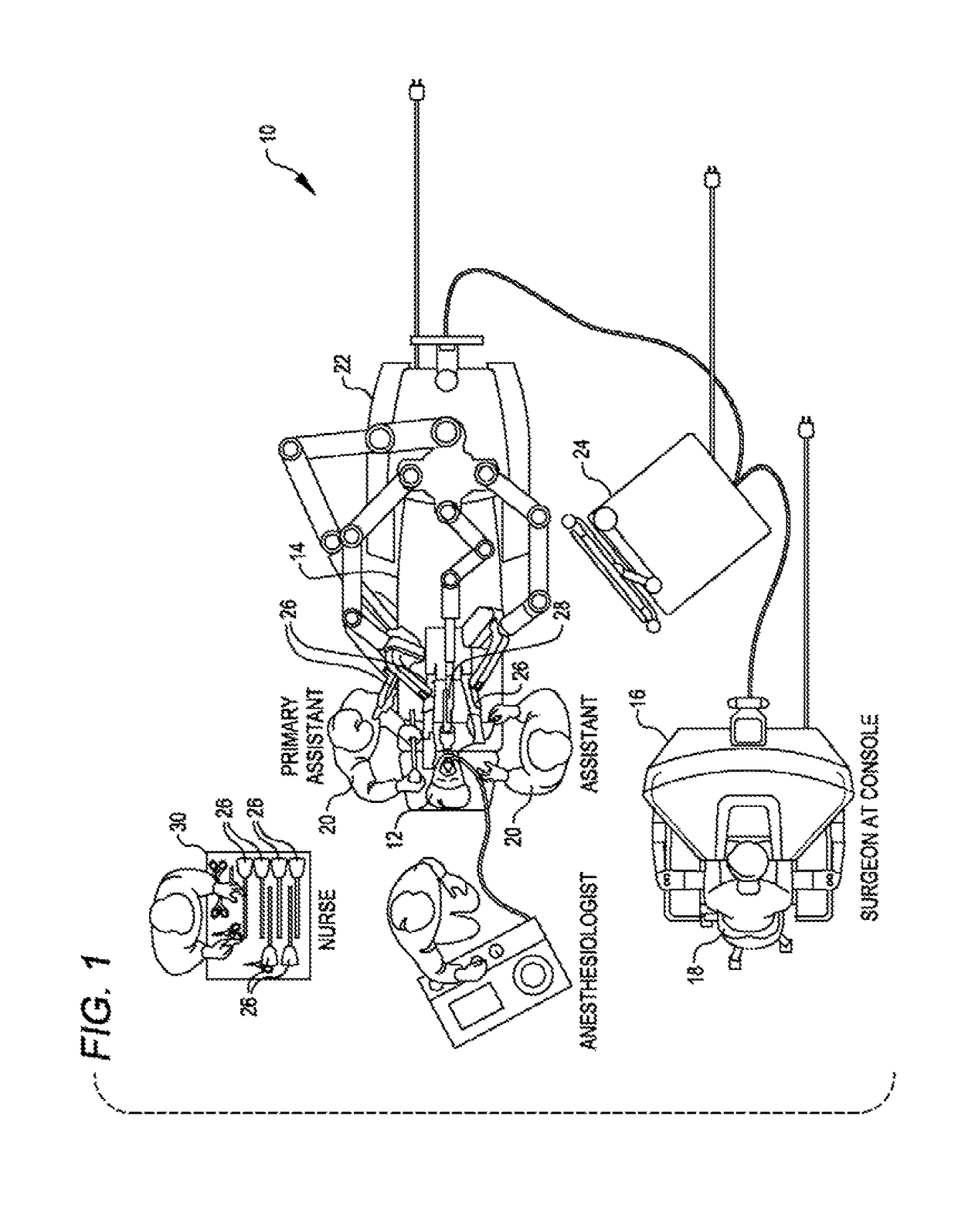

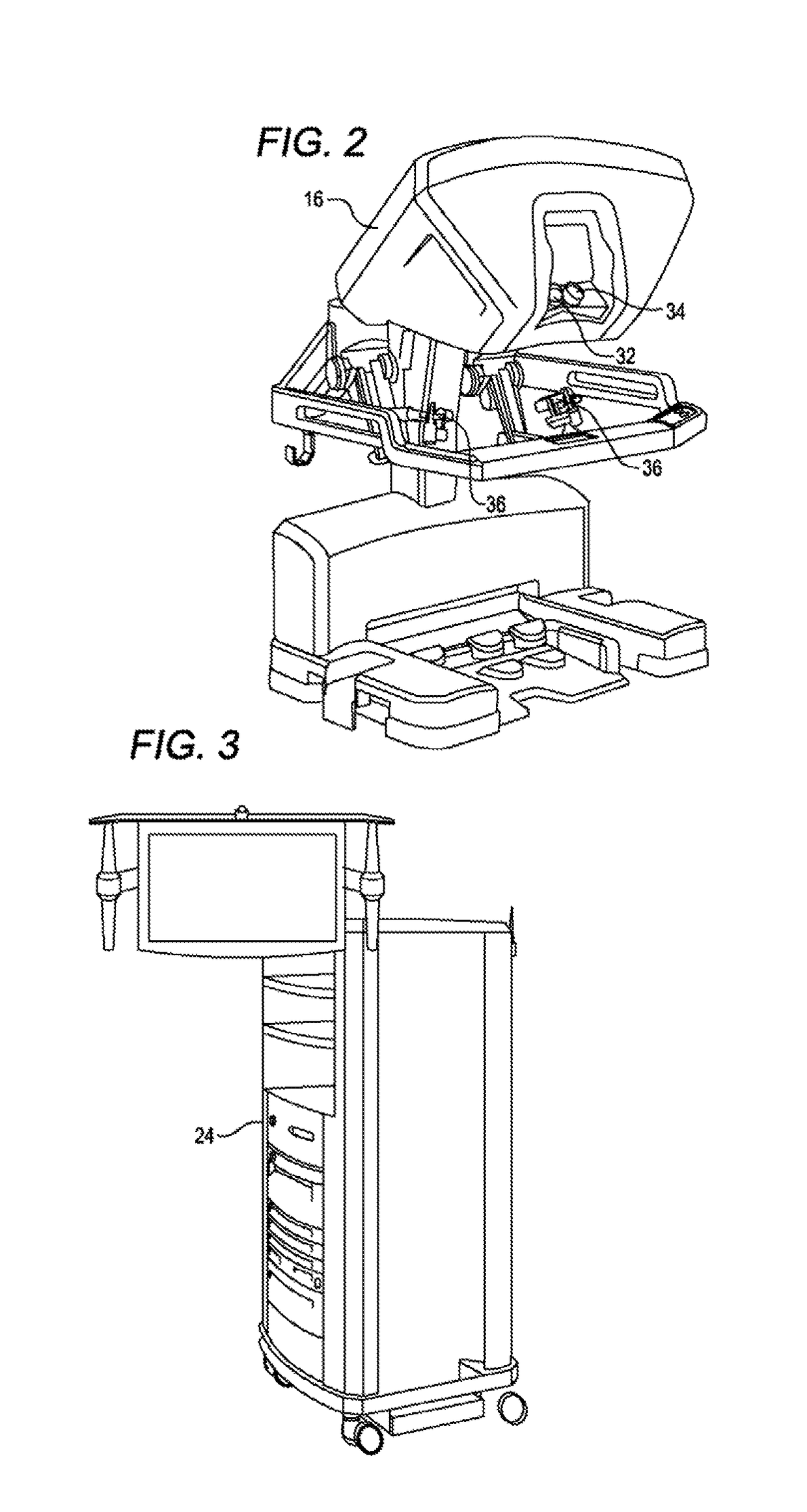

Control input accuracy for teleoperated surgical instrument

A surgical system having a patient side cart having at least one telesurgically operated instrument, the at least one telesurgically operated instrument comprising a surgical end effector having a plurality of effector components. A transmission is coupled to a motor. The drive train includes at least a first effector drive train and a second effector drivetrain. A controller comprises at least one processor for controlling the transmission. The controller is performs a method by locking an output gear of the second effector drivetrain rotating a camshaft to shift coupling of the motor from the first effector drivetrain to the second effector drivetrain; determining that the output gear is aligned by driving the locked output gear using a first torque; determining that the output gear is properly braked by driving the locked output gear using a second torque; disengaging the lock from the output gear; and driving the second effector drivetrain using the motor.

Owner:INTUITIVE SURGICAL OPERATIONS INC

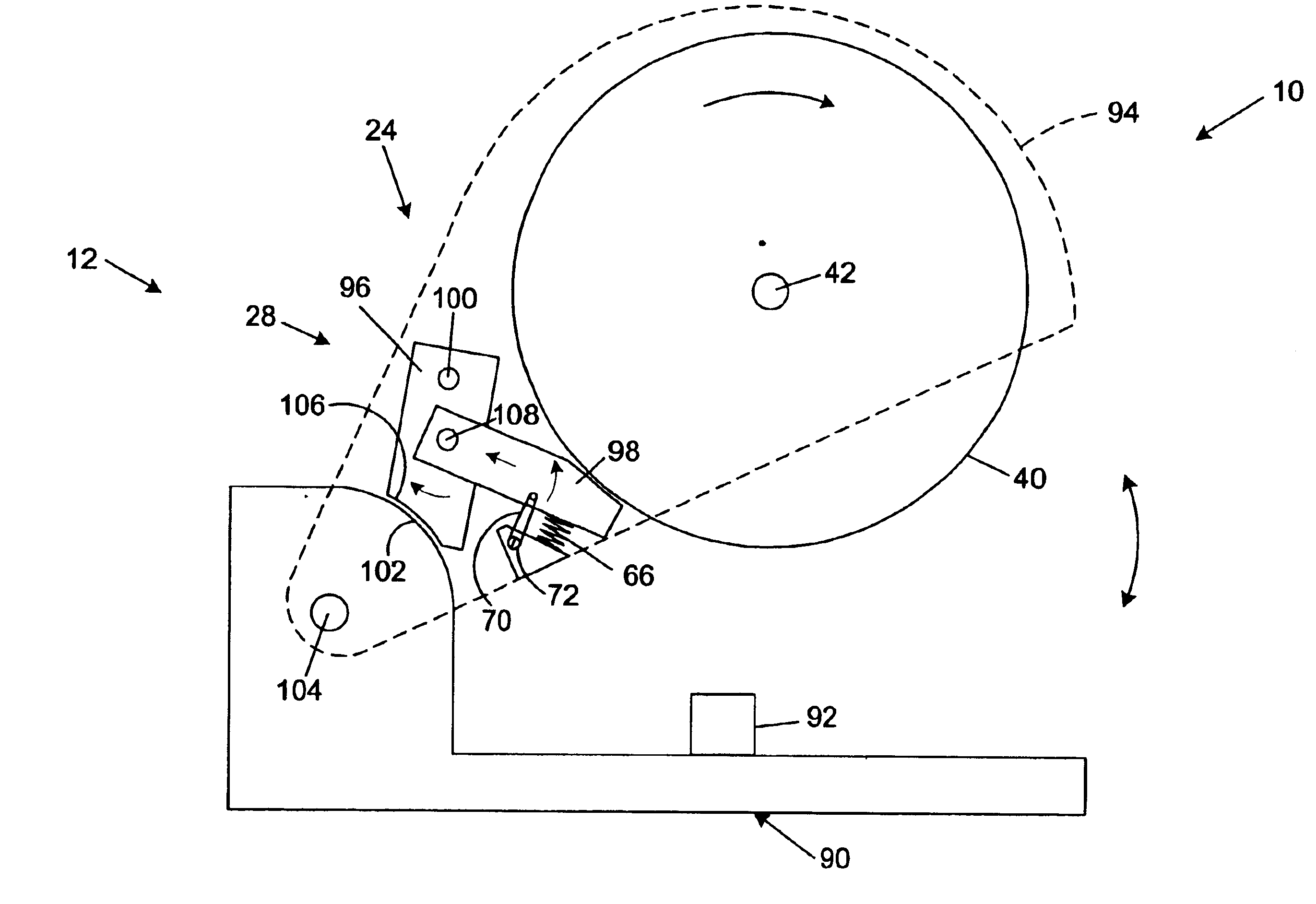

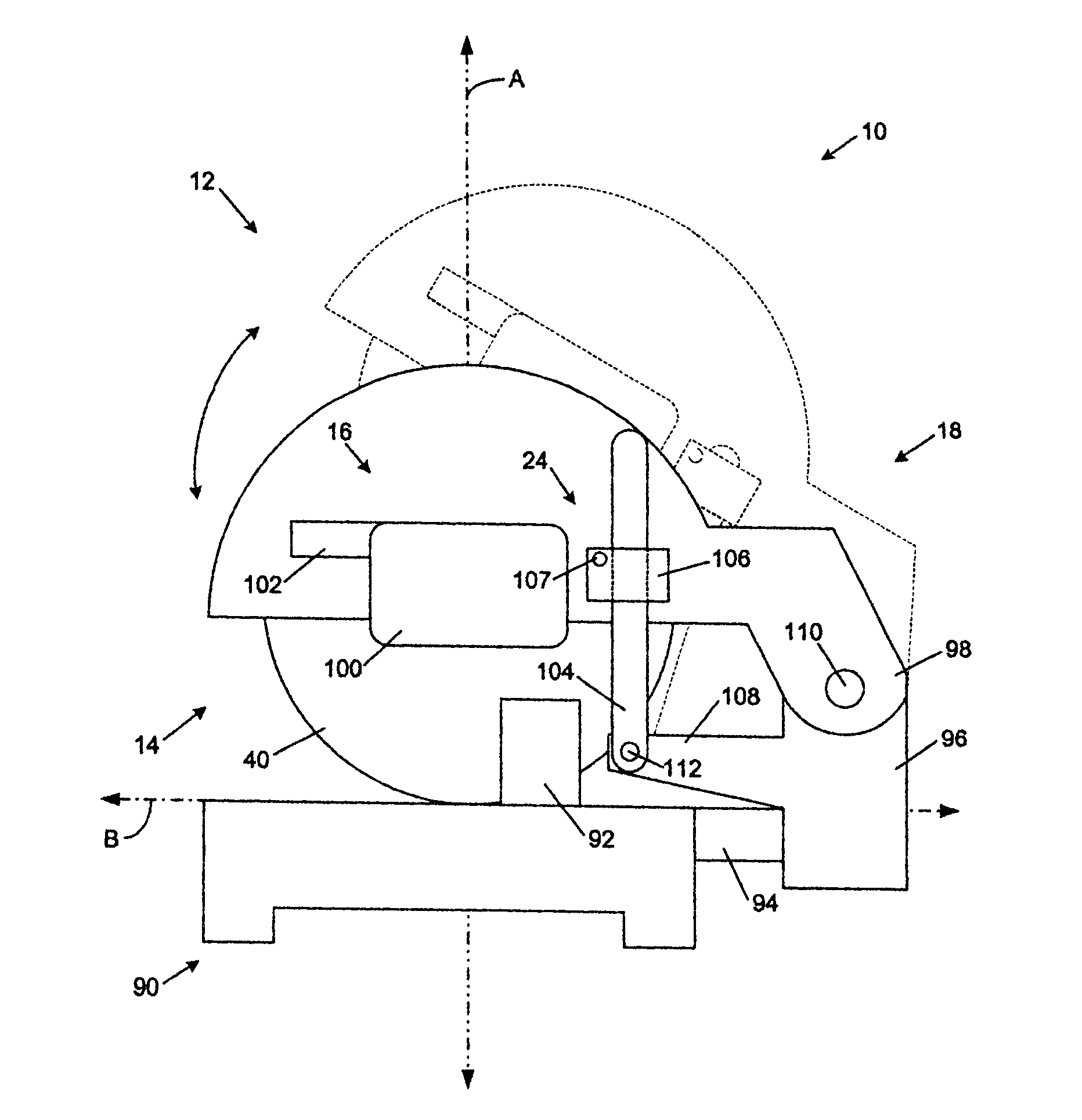

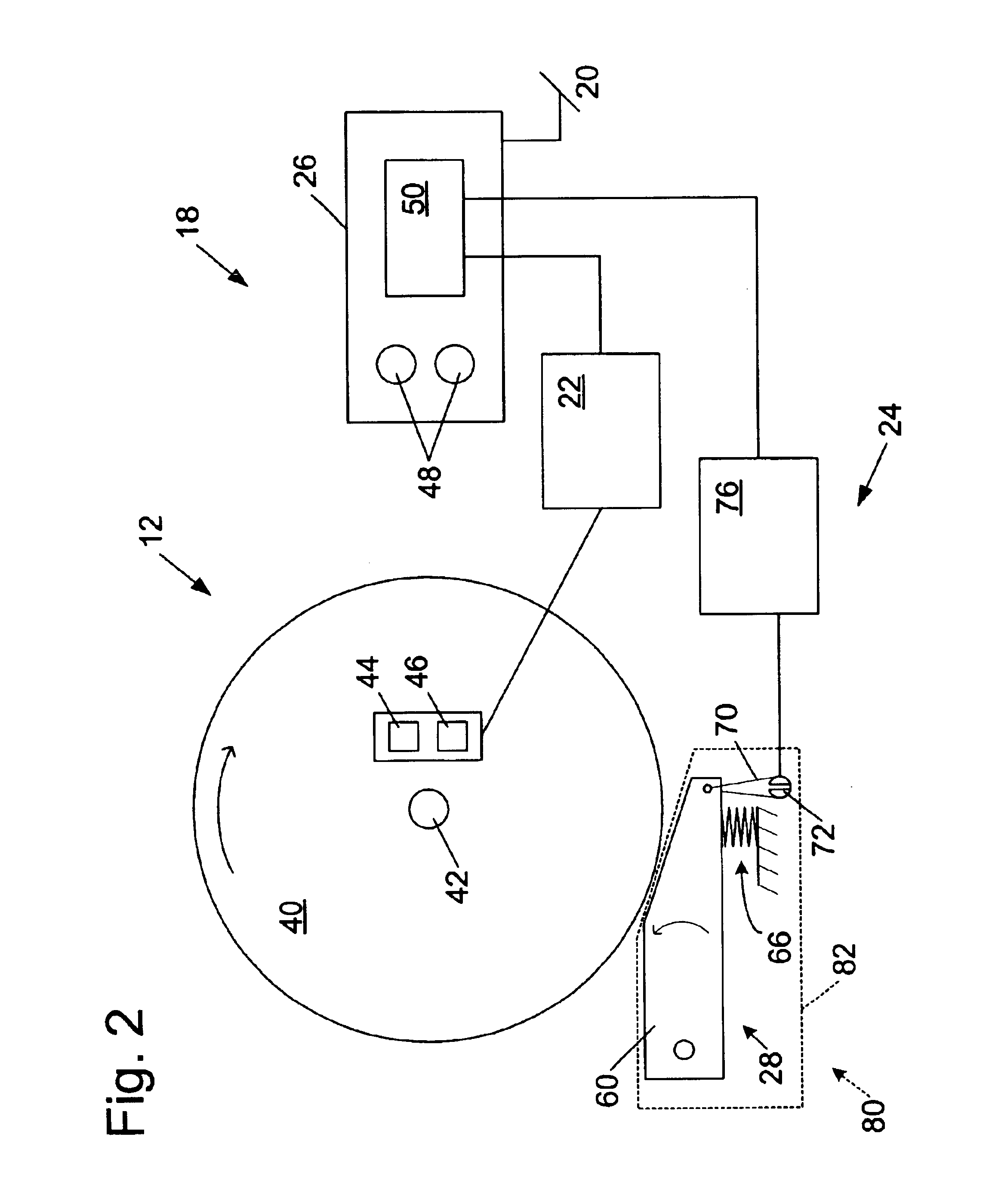

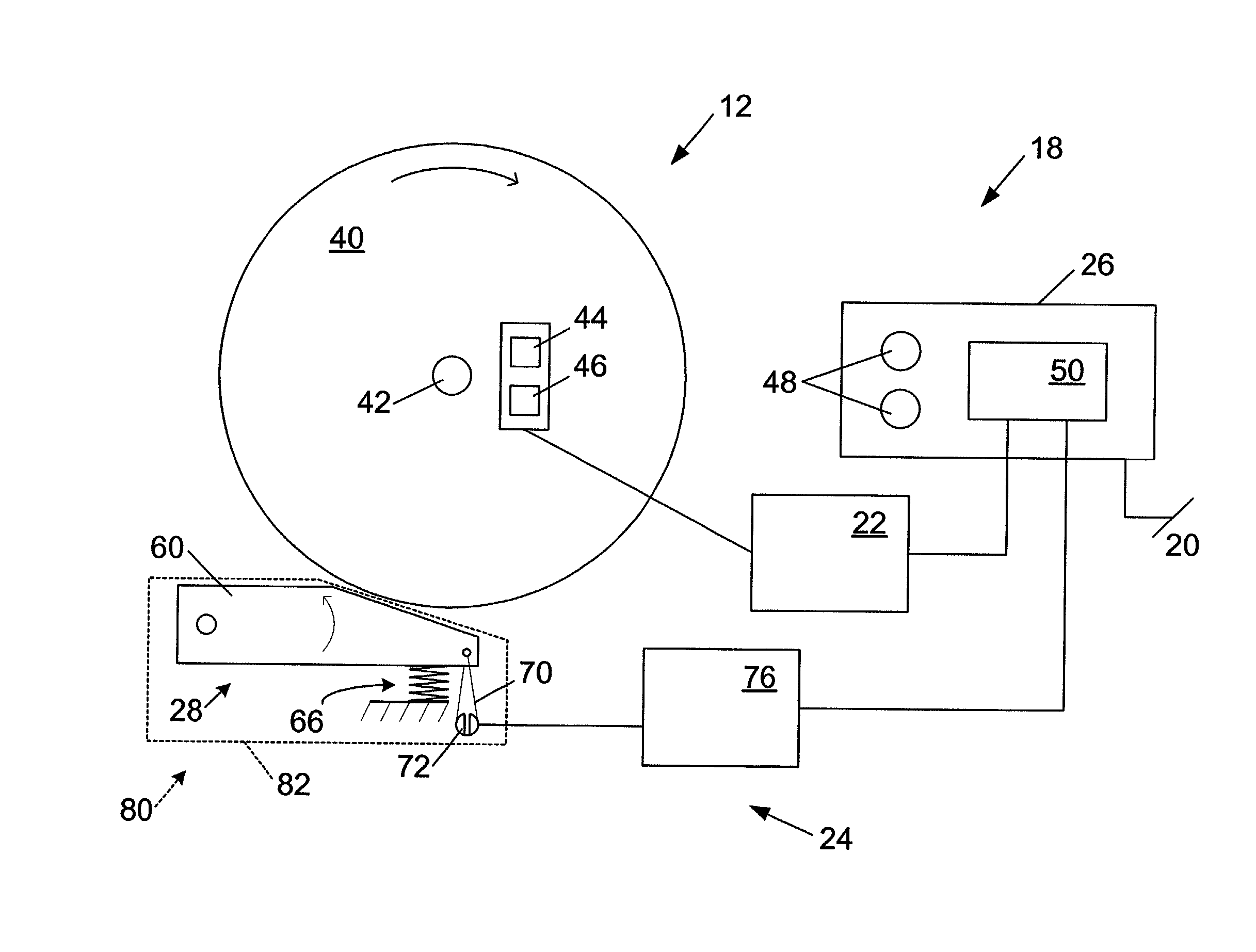

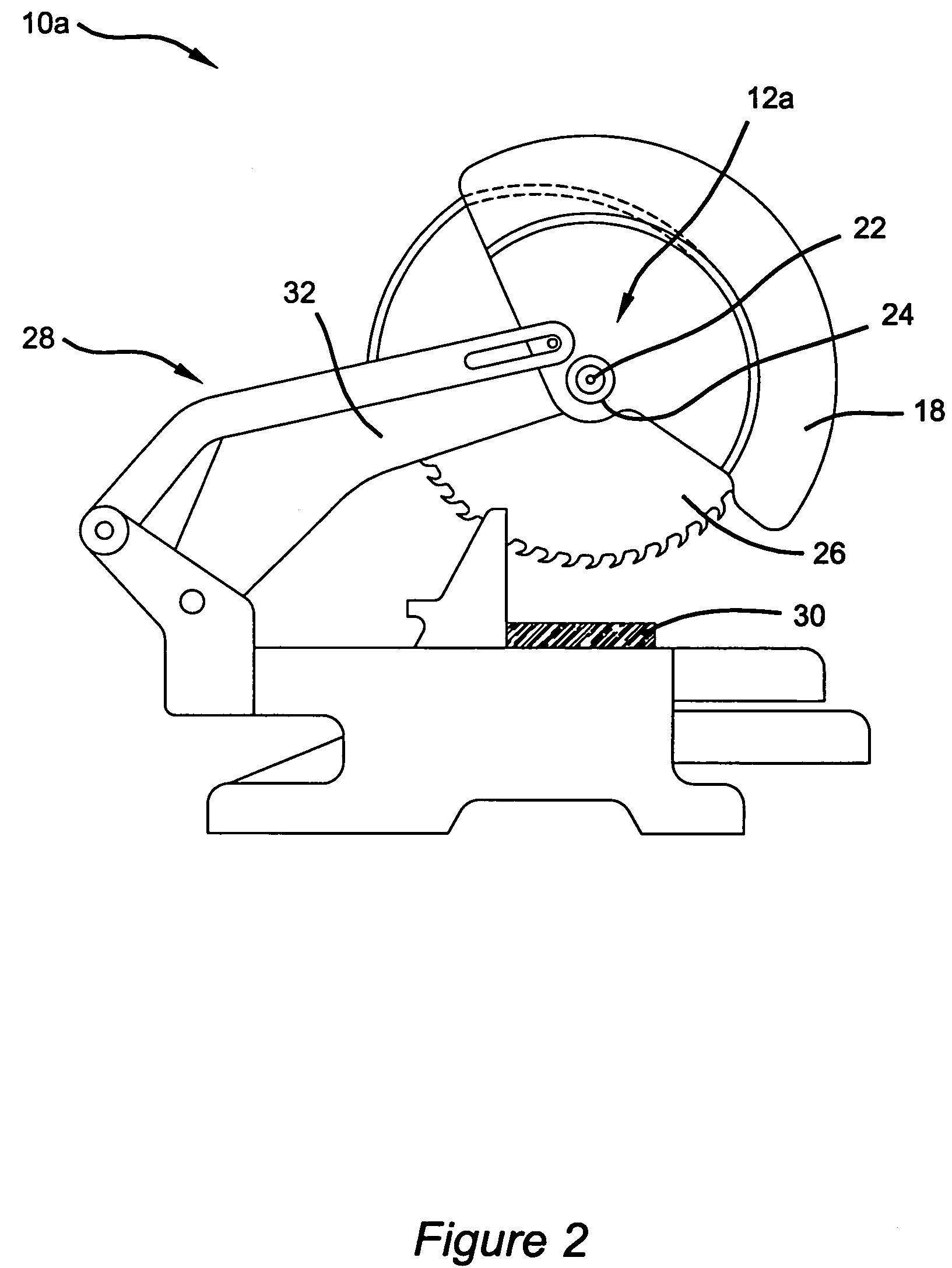

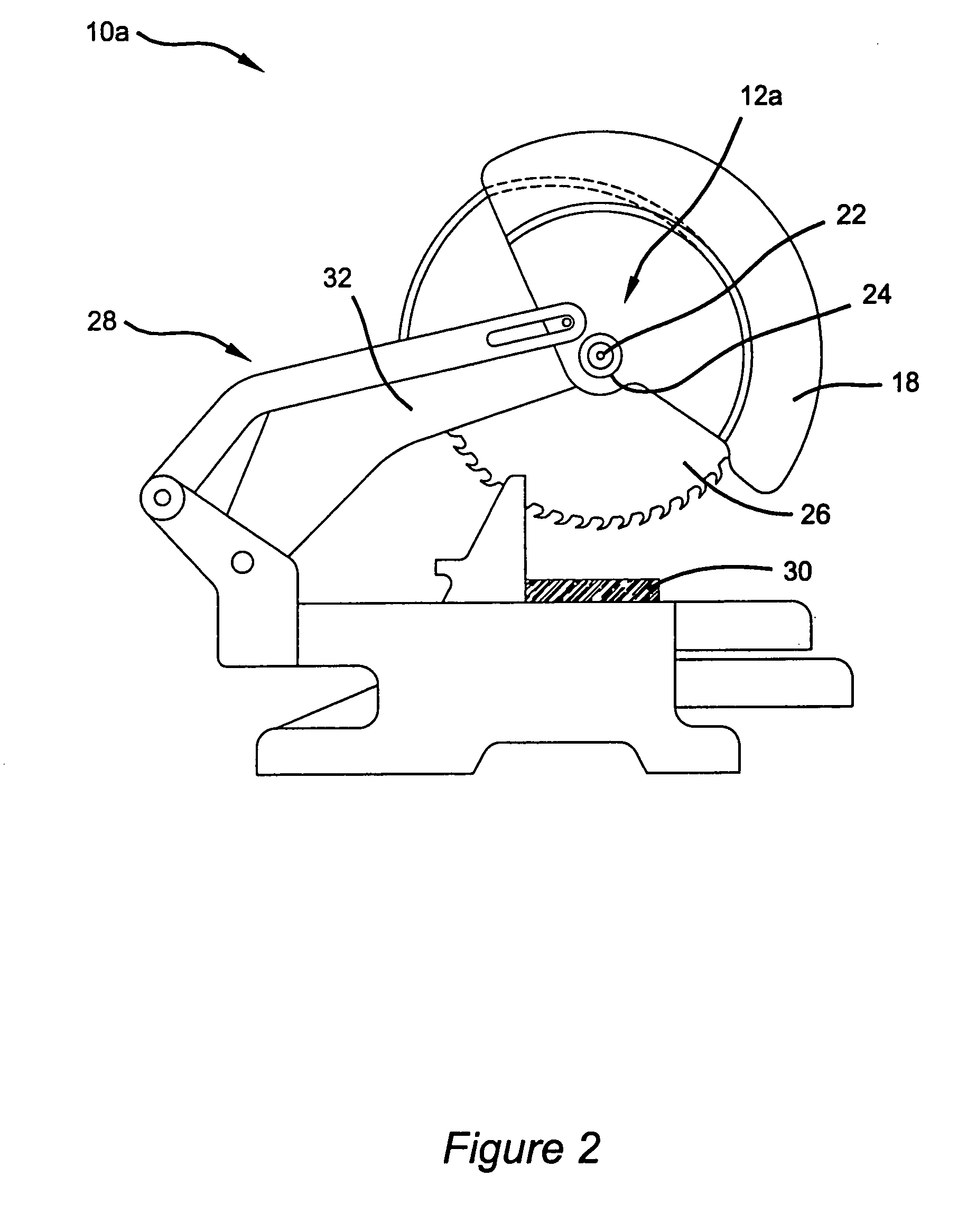

Miter saw with improved safety system

InactiveUS6880440B2Limit and even prevent injuryImprove the security systemEmergency protective circuit arrangementsEngineering safety devicesEngineeringMechanical engineering

A miter saw having a base and an arm that pivots toward the base is disclosed. A blade is supported by the arm, and is designed to cut workpieces resting on the base when the arm and blade pivot downward. The saw includes a detection system configured to detect one or more dangerous conditions between a person and the blade, such as when a person accidentally touches the spinning blade, and the saw includes a reaction system to stop the downward movement of the blade and arm when the dangerous condition is detected.

Owner:SAWSTOP HLDG LLC

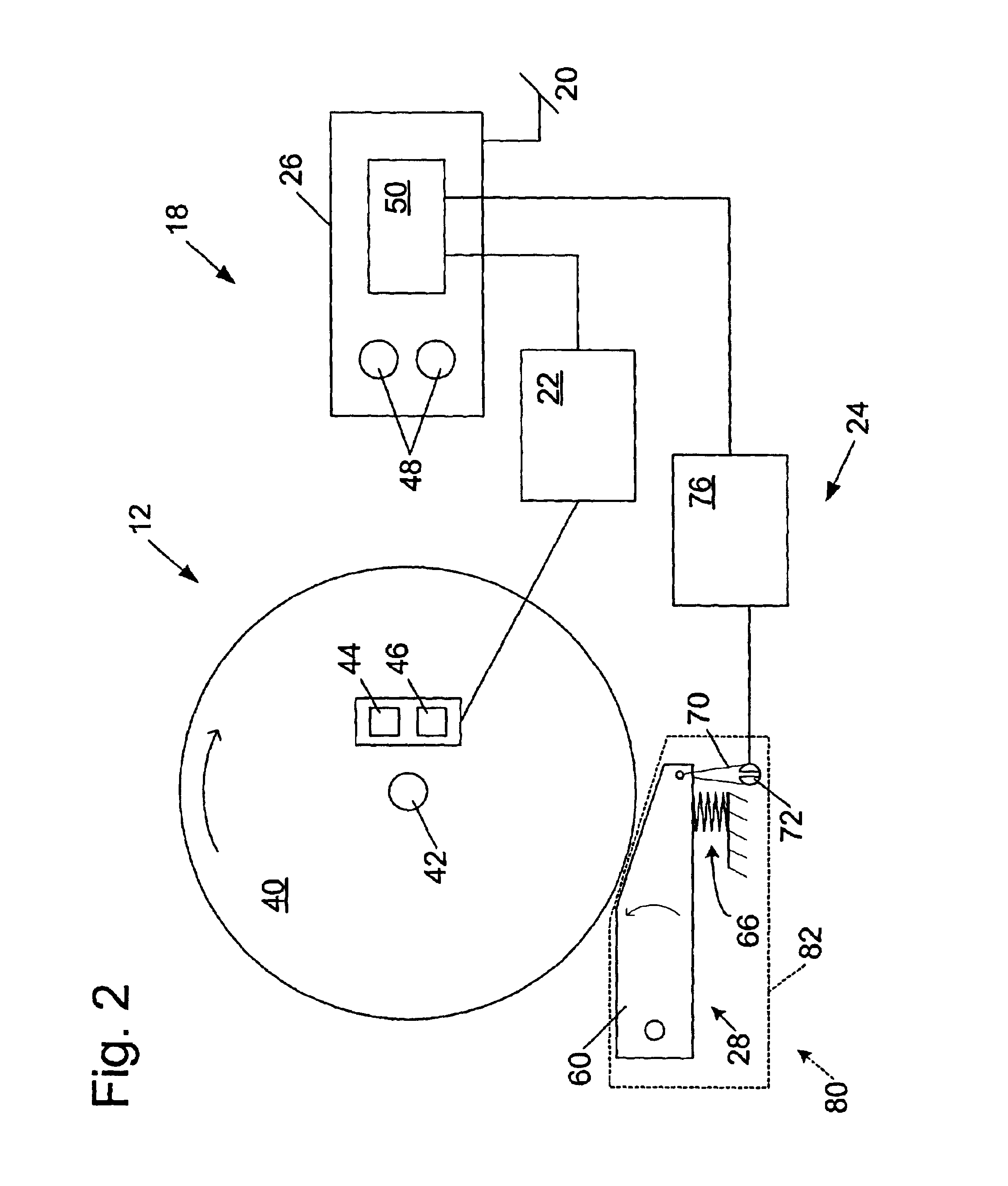

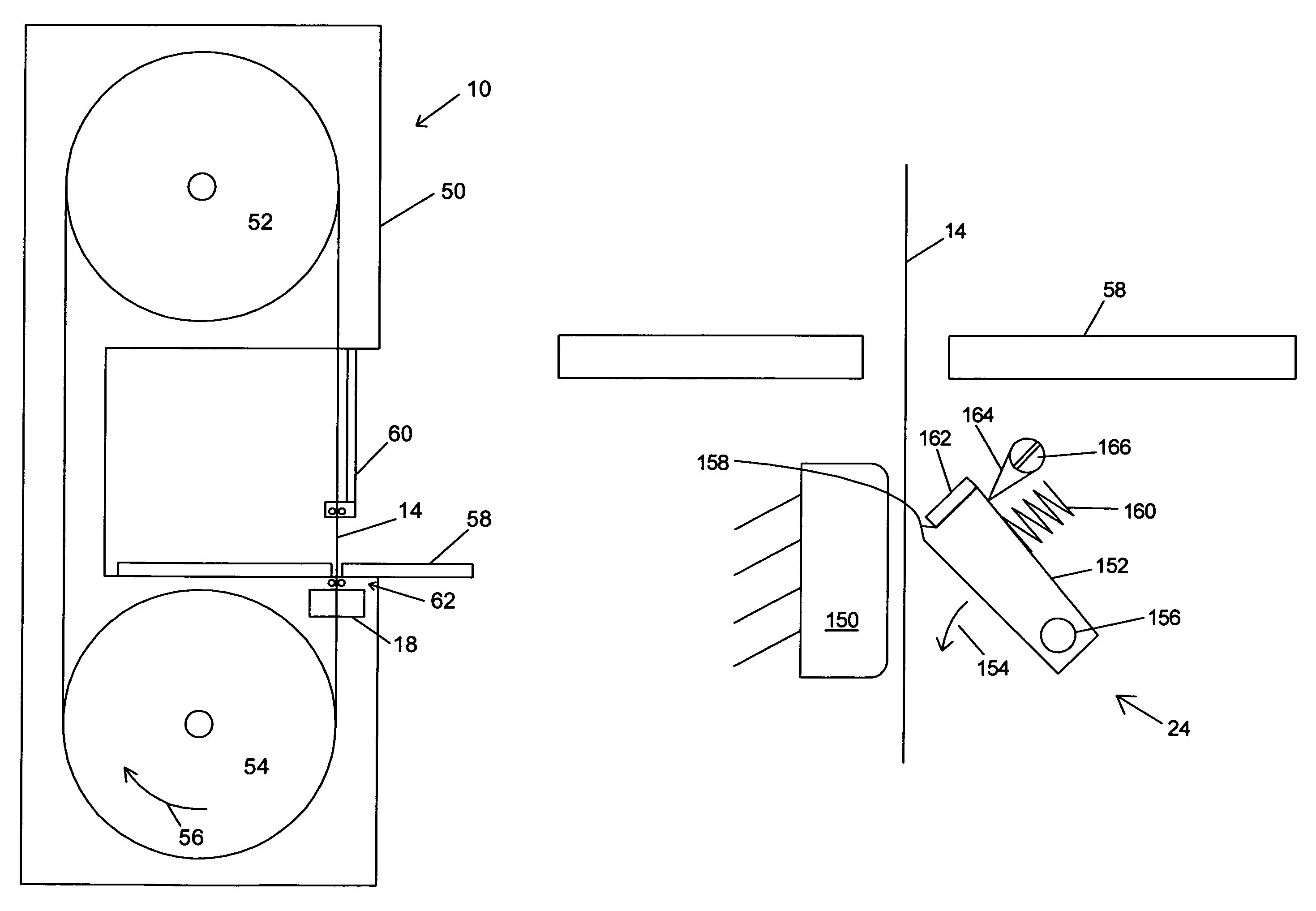

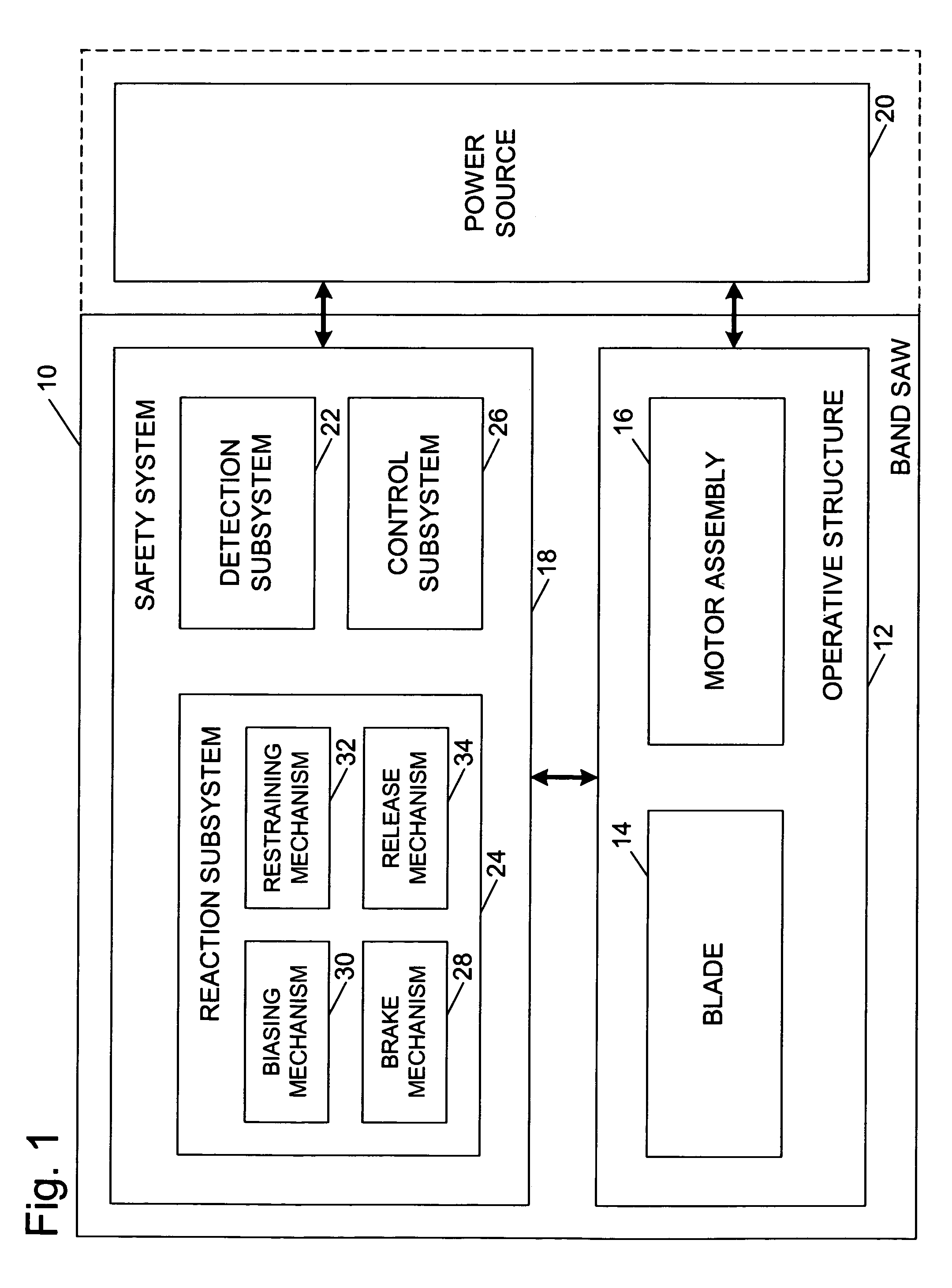

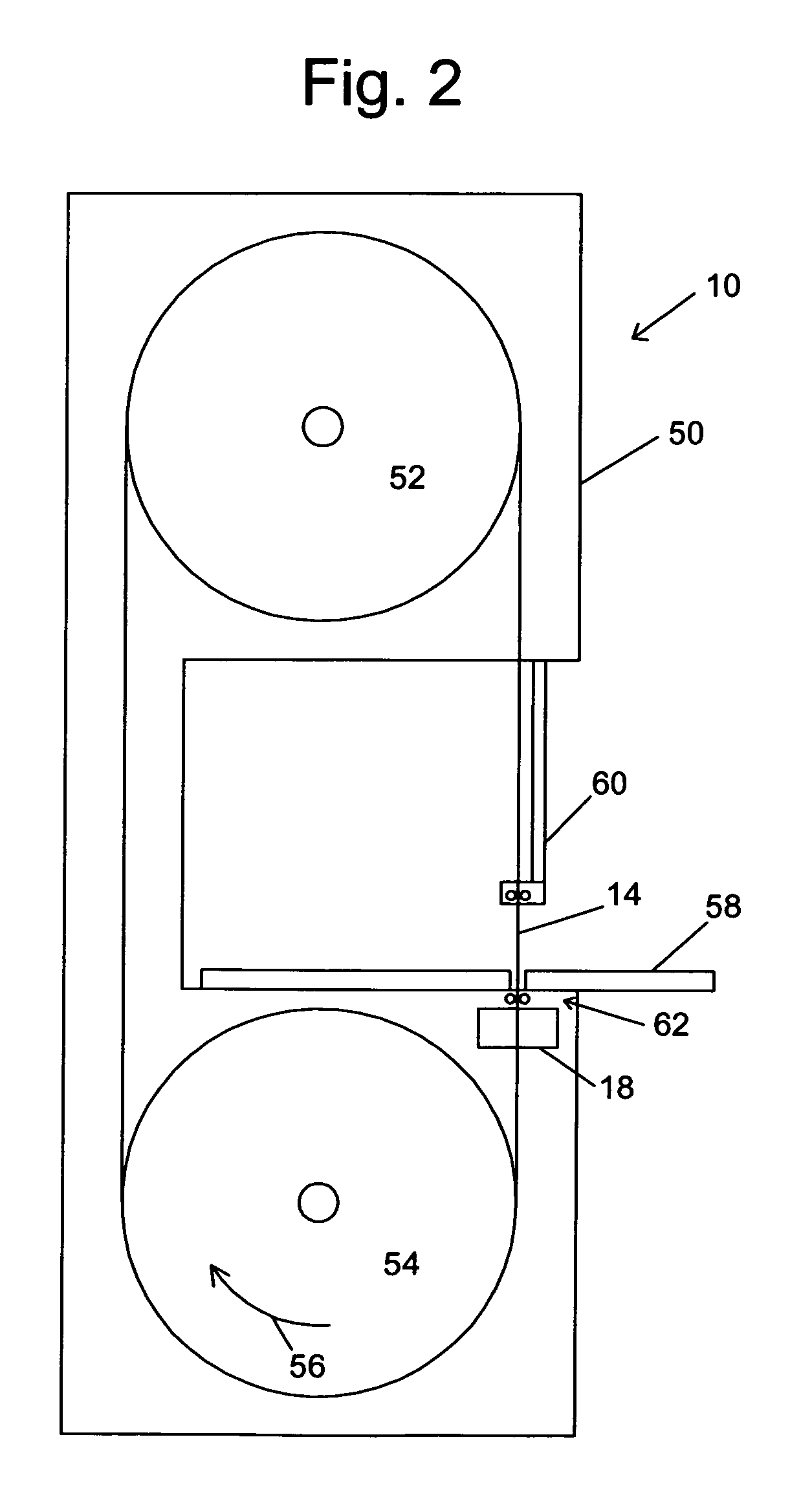

Safety systems for band saws

Owner:SAWSTOP HLDG LLC

Safety systems for power equipment

A saw with a safety system is disclosed. The safety system includes a detection system adapted to detect contact between a person and a blade while the blade is moving. The safety system further includes a brake system adapted to engage the blade and to stop the blade when the detection system detects contact between the person and the blade.

Owner:SAWSTOP HLDG LLC

Detection system for power equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

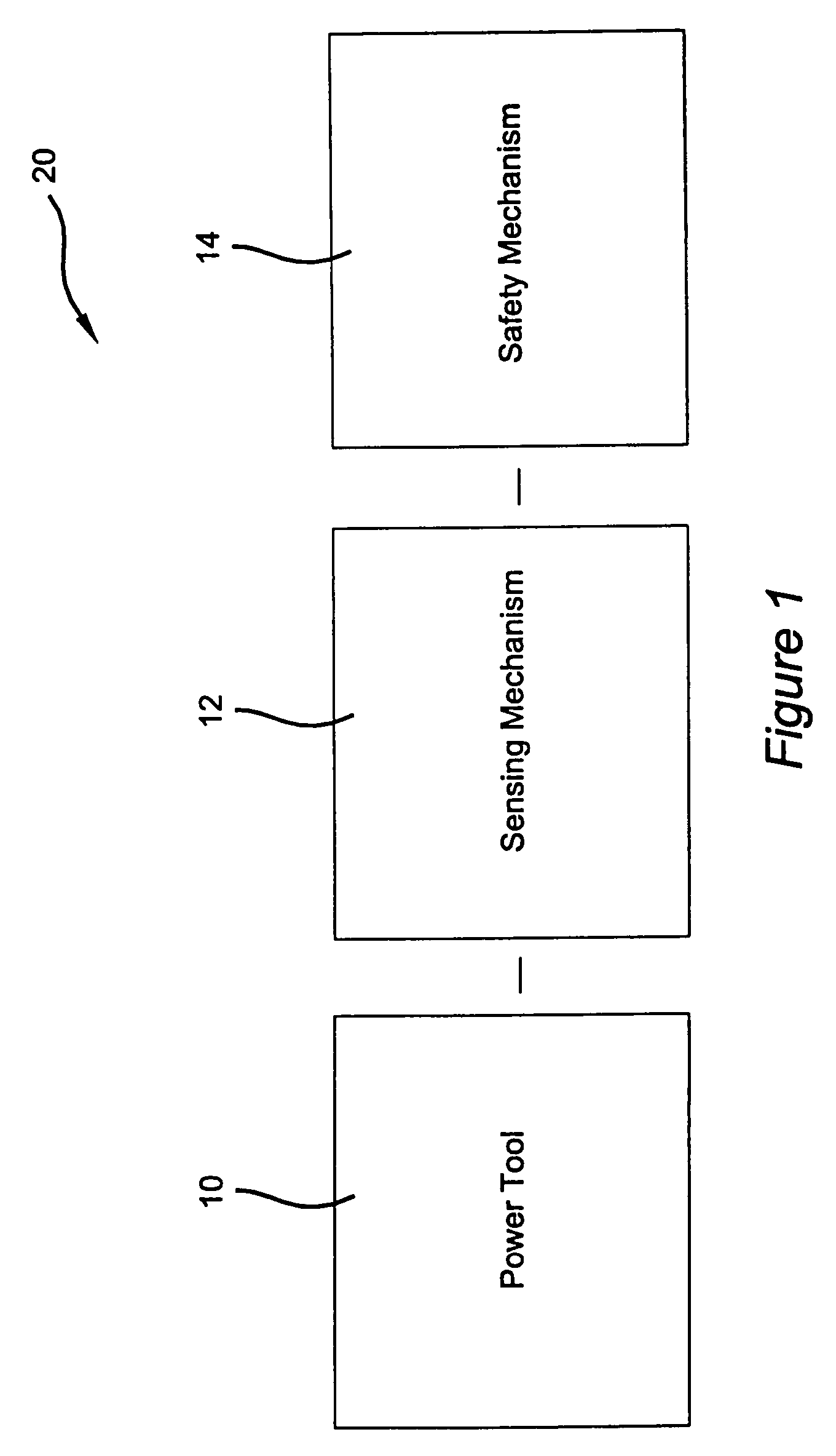

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

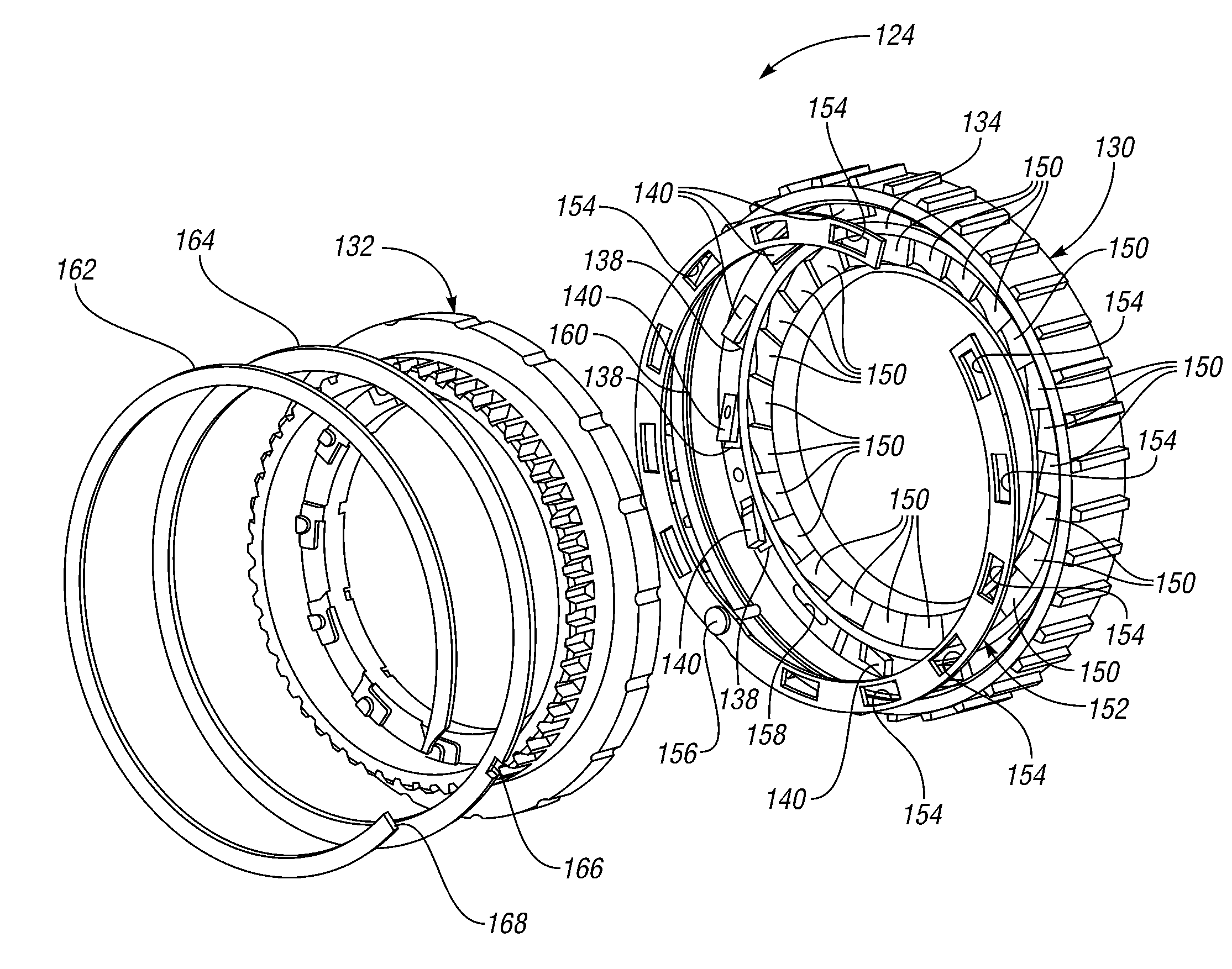

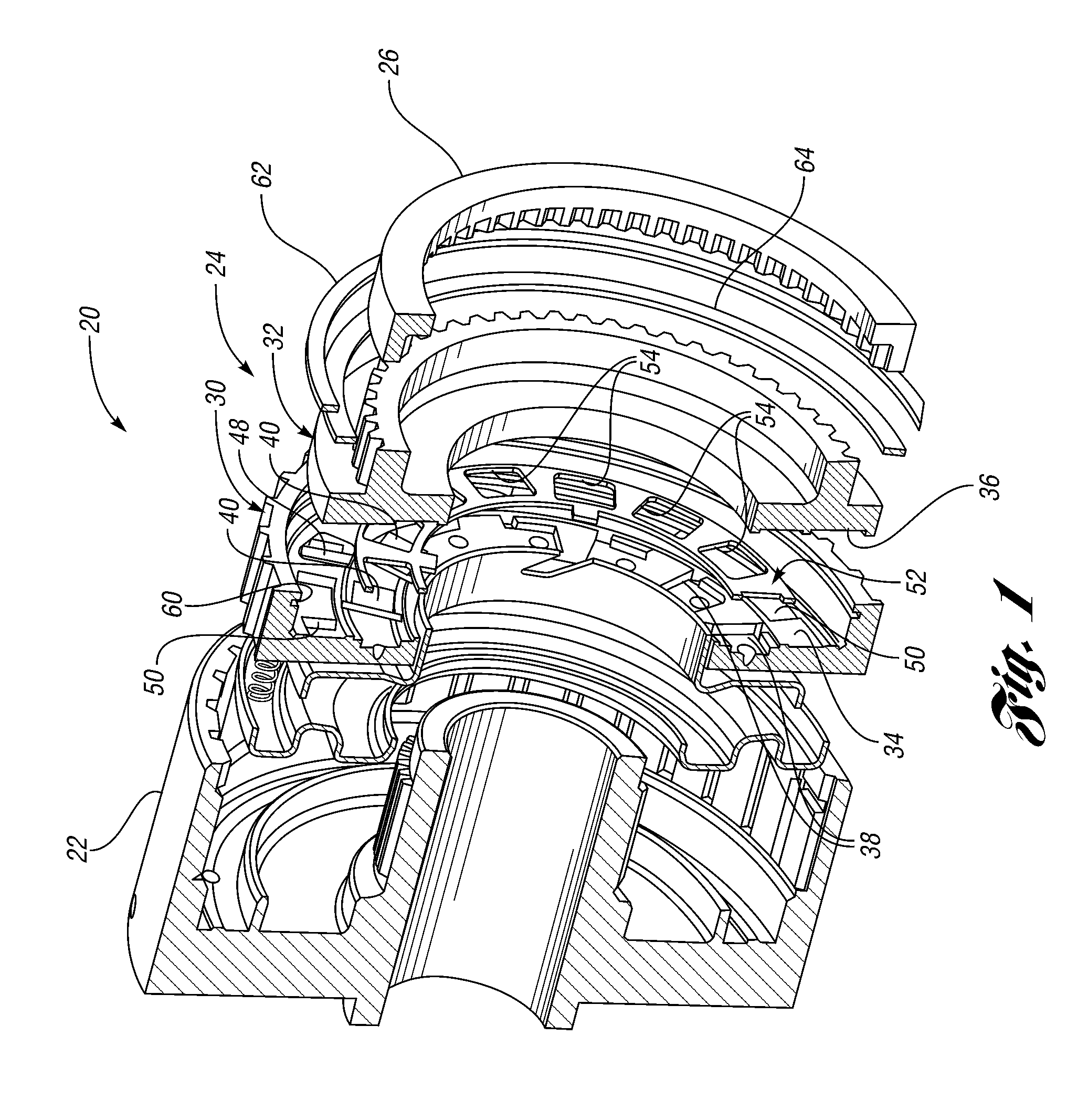

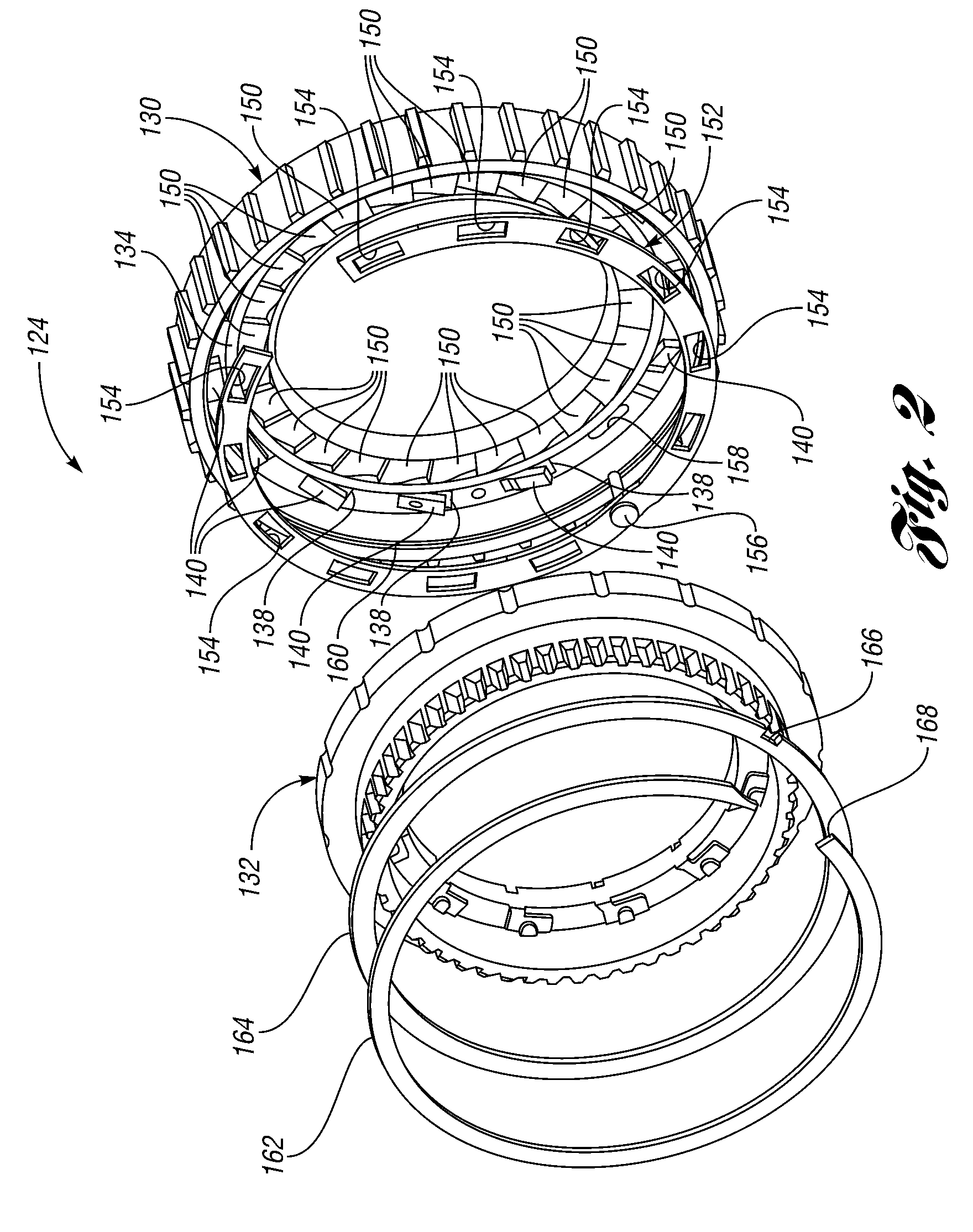

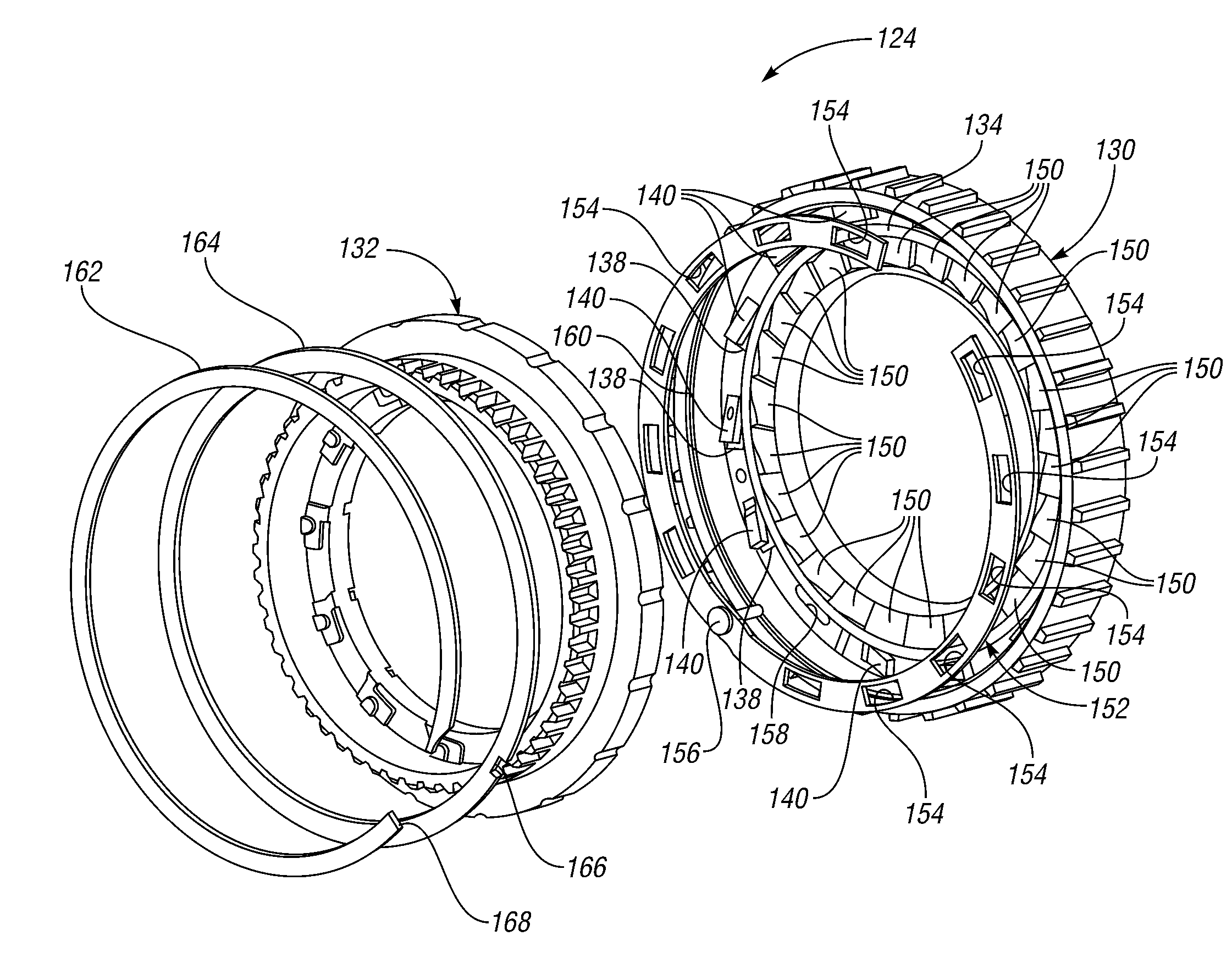

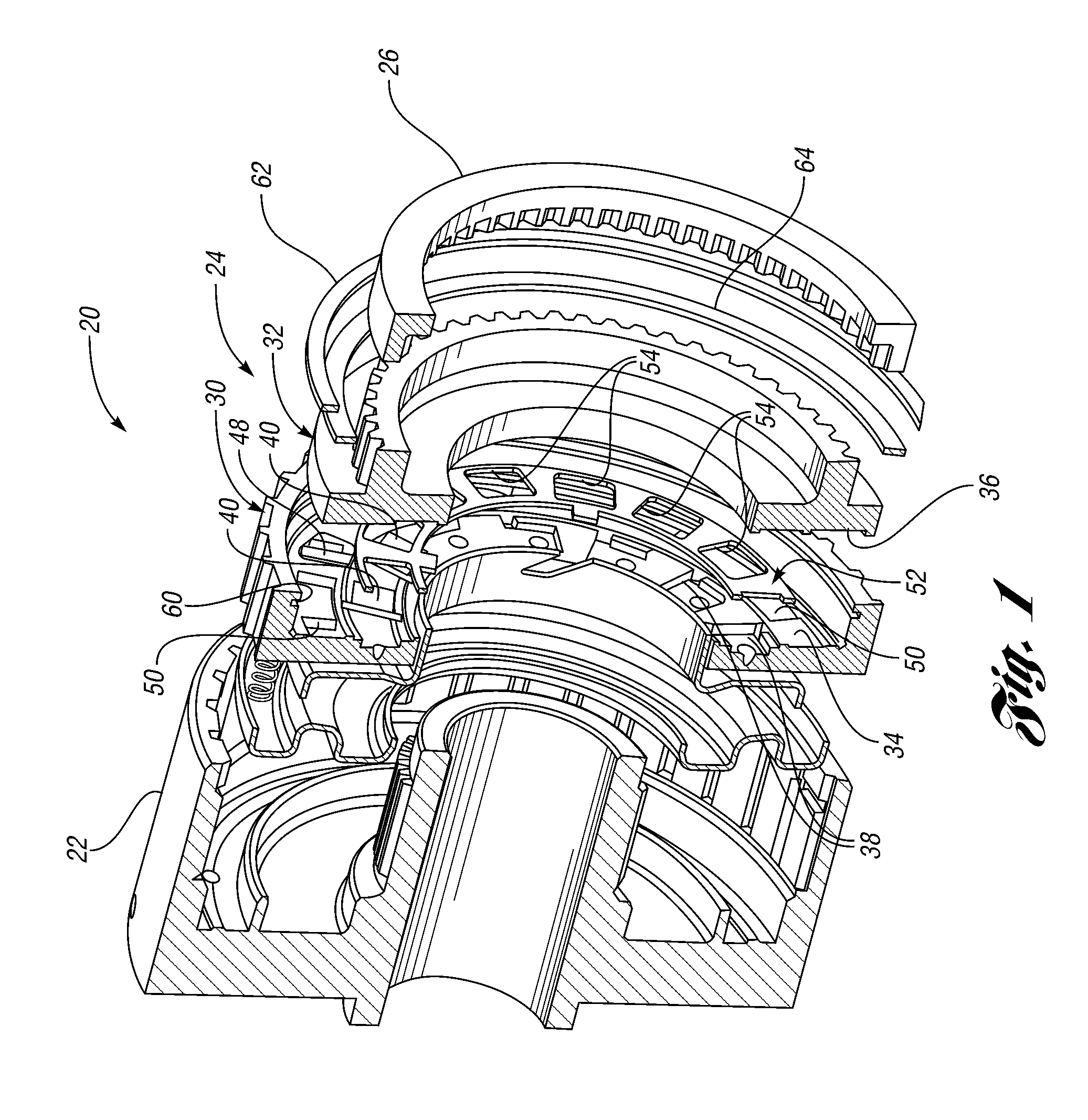

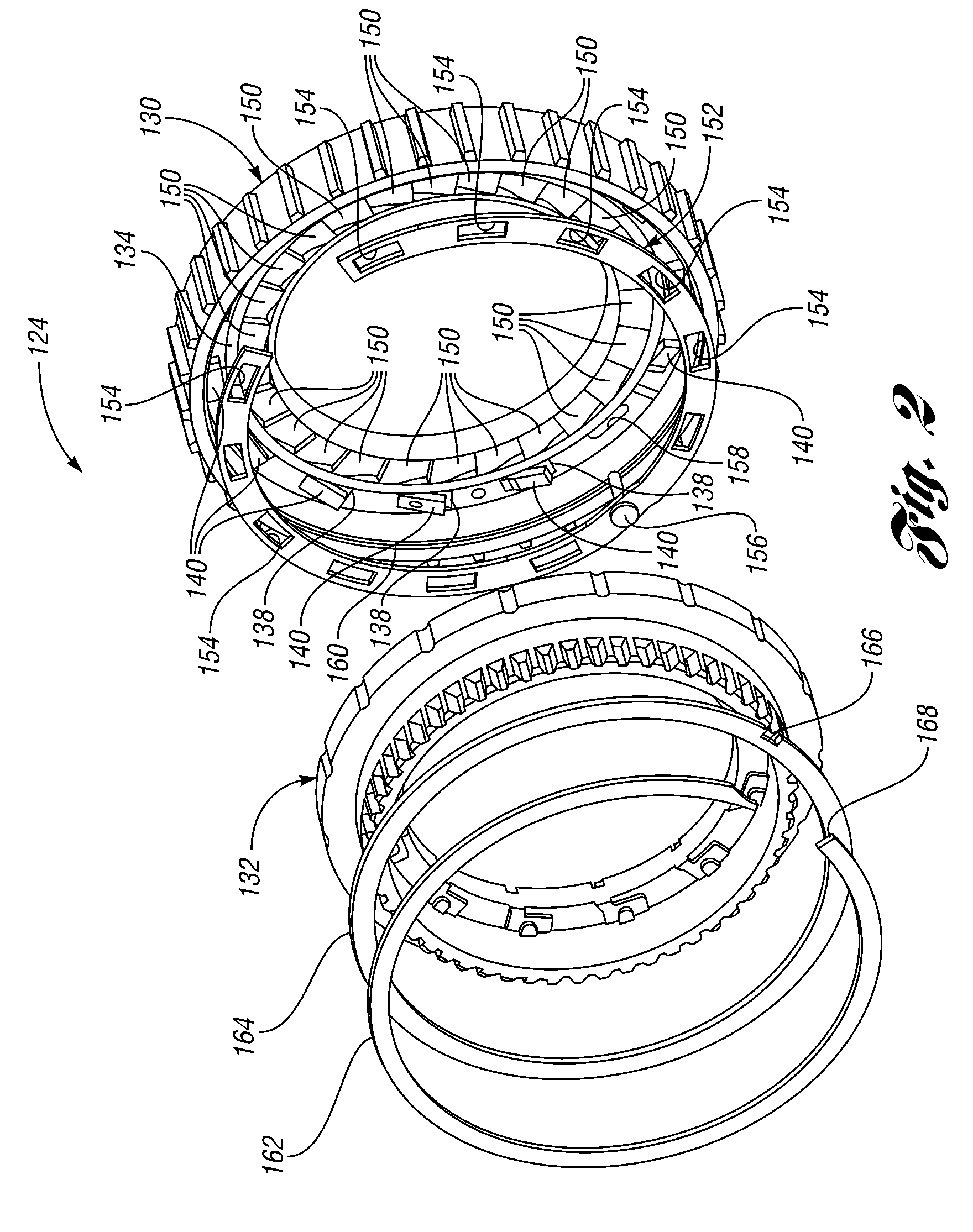

Overrunning Coupling Assembly

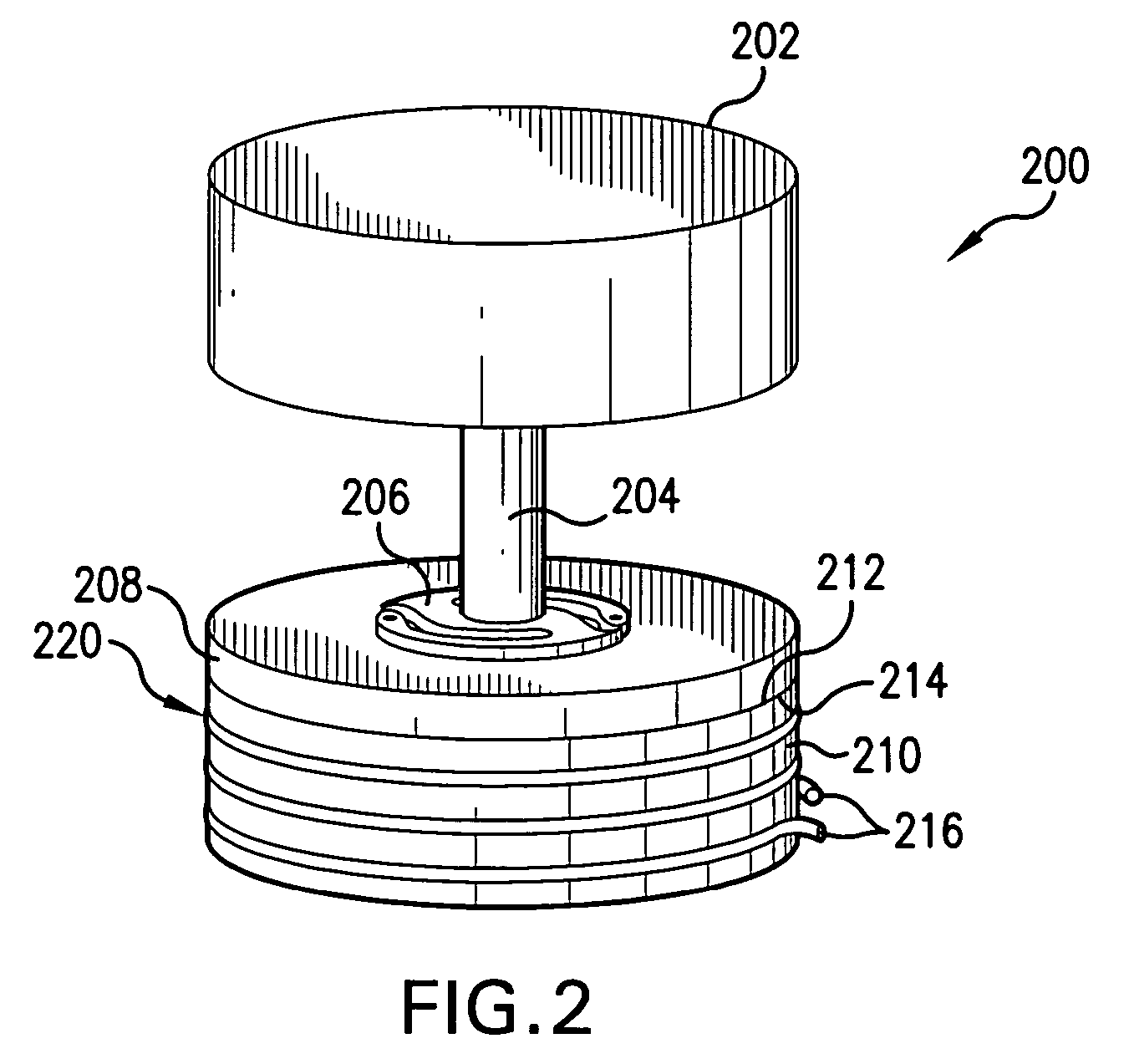

ActiveUS20090159391A1Improved overrunningEasy to assembleFriction clutchesInterengaging clutchesCouplingControl theory

An overrunning coupling assembly includes a control element mounted for controlled shifting movement between coupling faces of annular coupling members relative to a first set of pockets in the first member. The control element is operable for controlling position of only reverse struts in the first set of pockets without controlling the position of forward struts in a second set of pockets in the coupling face of the second member. The control element allows at least one of the reverse struts to engage at least one of a set of locking formations on the coupling face of the second coupling member in a first position of the control element. The control element maintains the reverse struts in their pockets in a second position of the control element.

Owner:MEANS IND INC

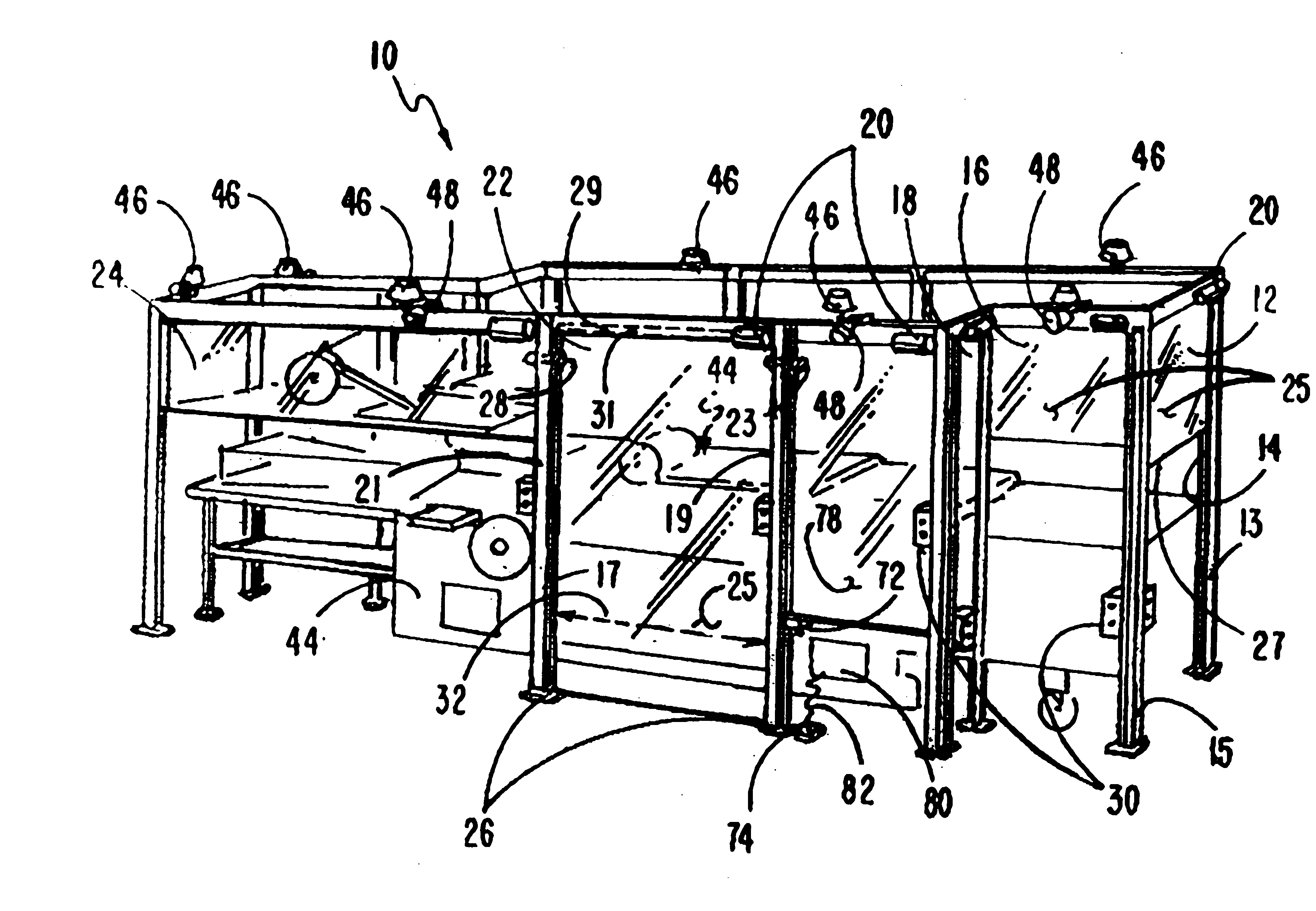

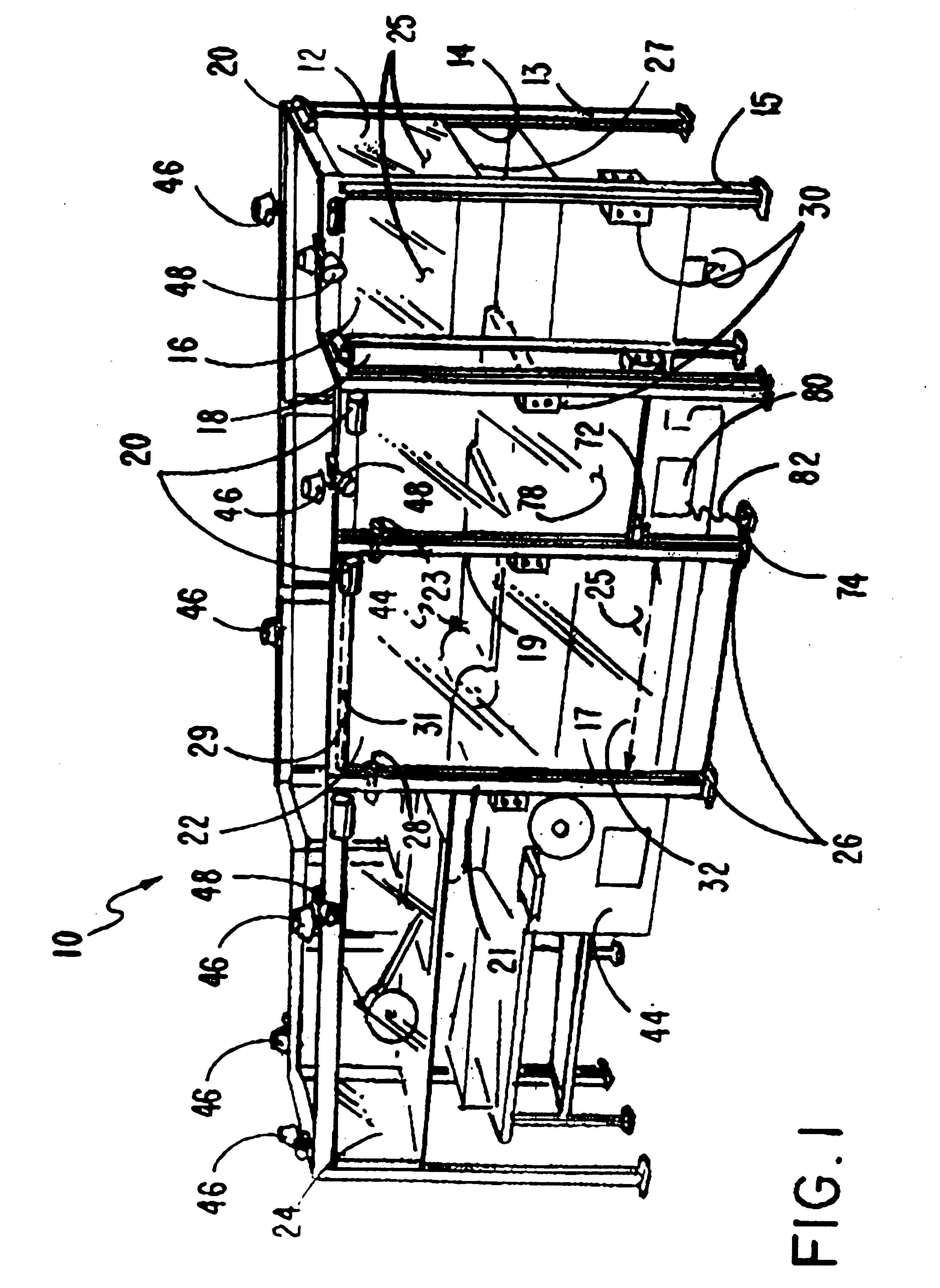

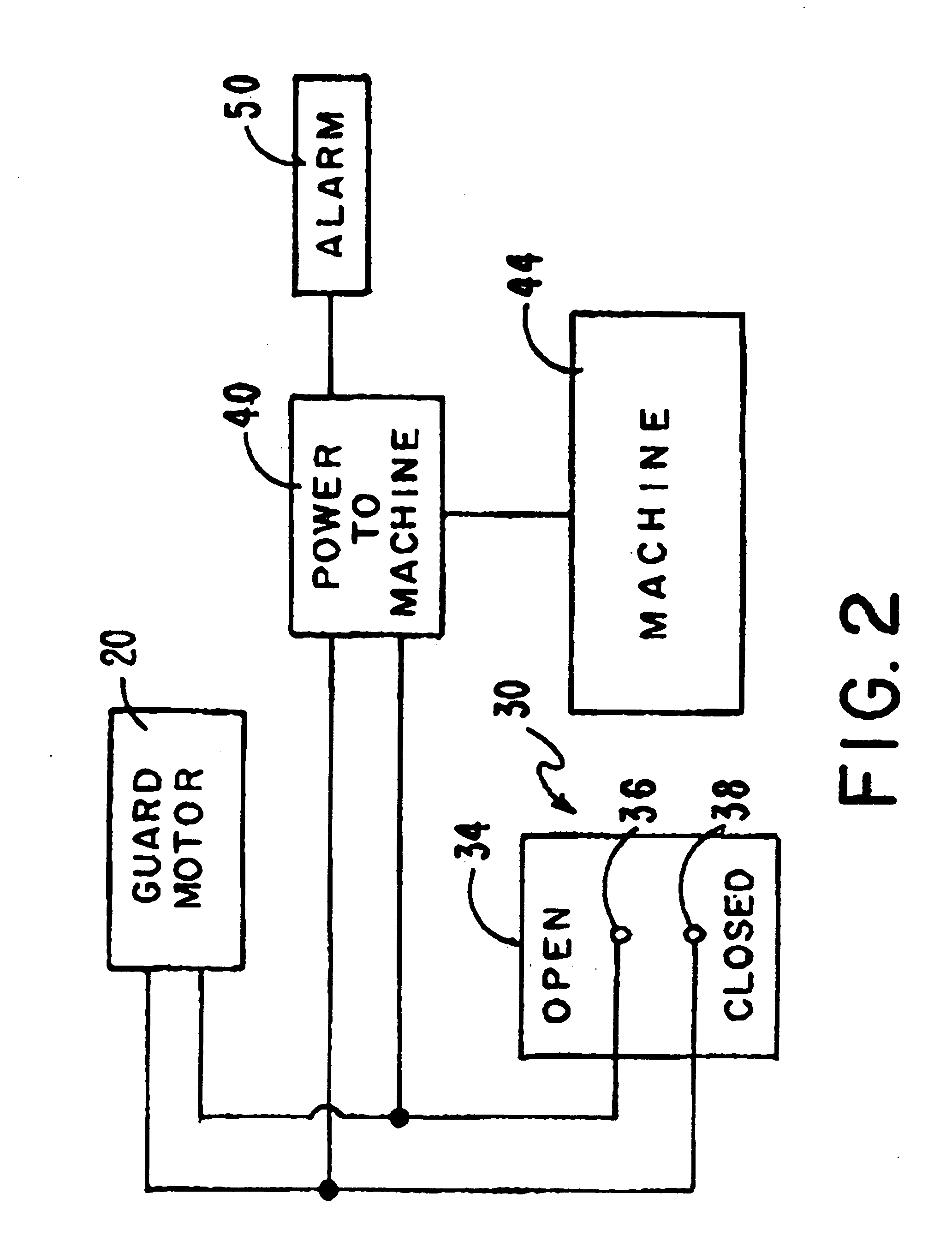

Machine safety guard

InactiveUS6325195B1Easy to operateProvide securityYielding couplingShutters/ movable grillesUnit systemEngineering

A machine safety guard unit system having a flexible panel moved upwards and downwards between track members with the system positioned between the operative parts of a machine and a machine operator, such panel when closed protecting the machine operator and when moved upwards into its open mode, allowing access to the machine and preventing the machine from operating. In some embodiments more than one of such units can be disposed around a machine with alarm means; and in yet other embodiments, with interengagement means connecting such units.

Owner:RITE HITE HLDG CORP

Controllable or selectable bi-directional overrunning coupling assembly

An overrunning coupling assembly includes a control element mounted for controlled shifting movement between coupling faces of annular coupling members relative to a first set of pockets in the first member. The control element is operable for controlling position of only reverse struts in the first set of pockets without controlling the position of forward struts in a second set of pockets in the coupling face of the second member. The control element allows at least one of the reverse struts to engage at least one of a set of locking formations on the coupling face of the second coupling member in a first position of the control element. The control element maintains the reverse struts in their pockets in a second position of the control element.

Owner:MEANS IND INC

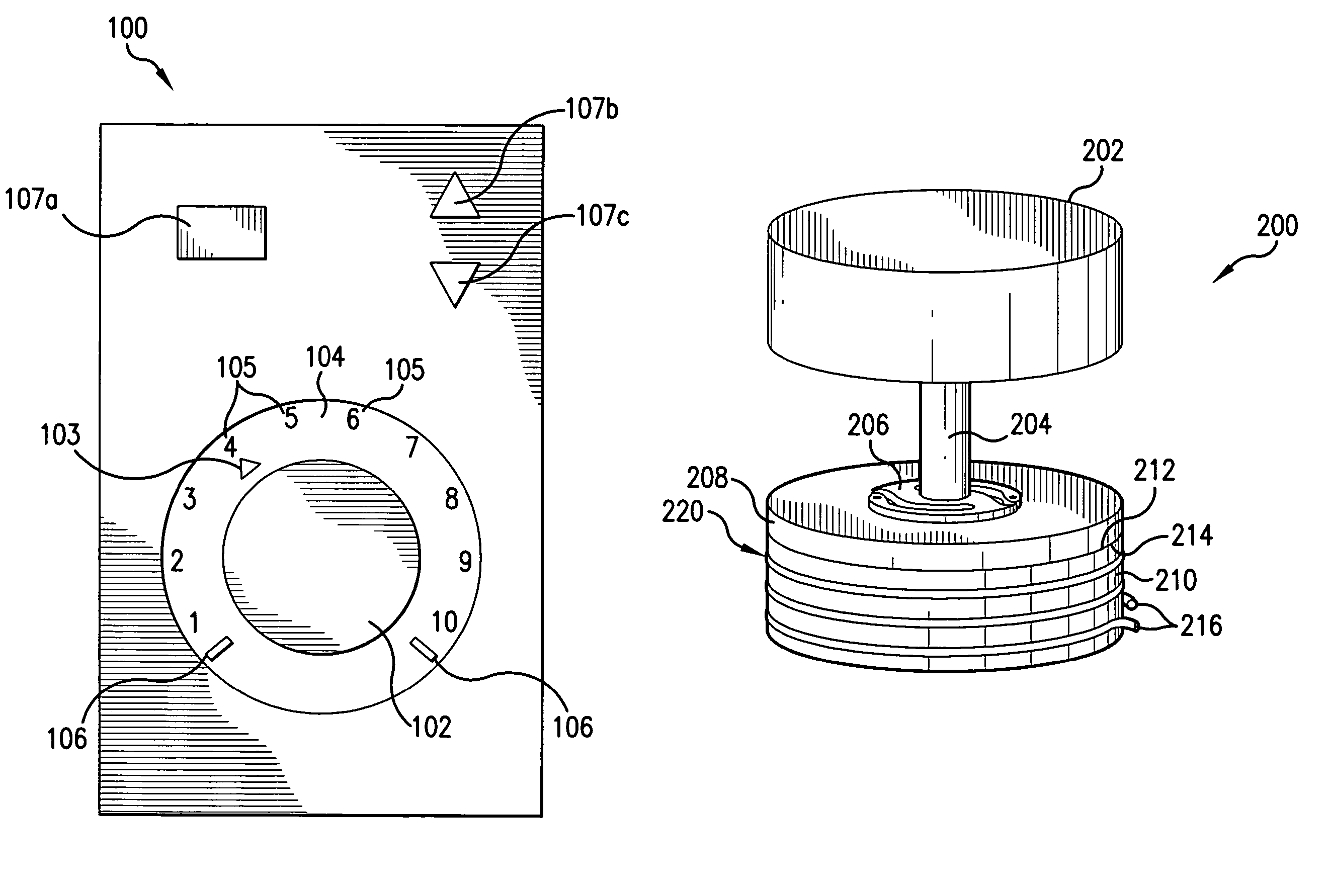

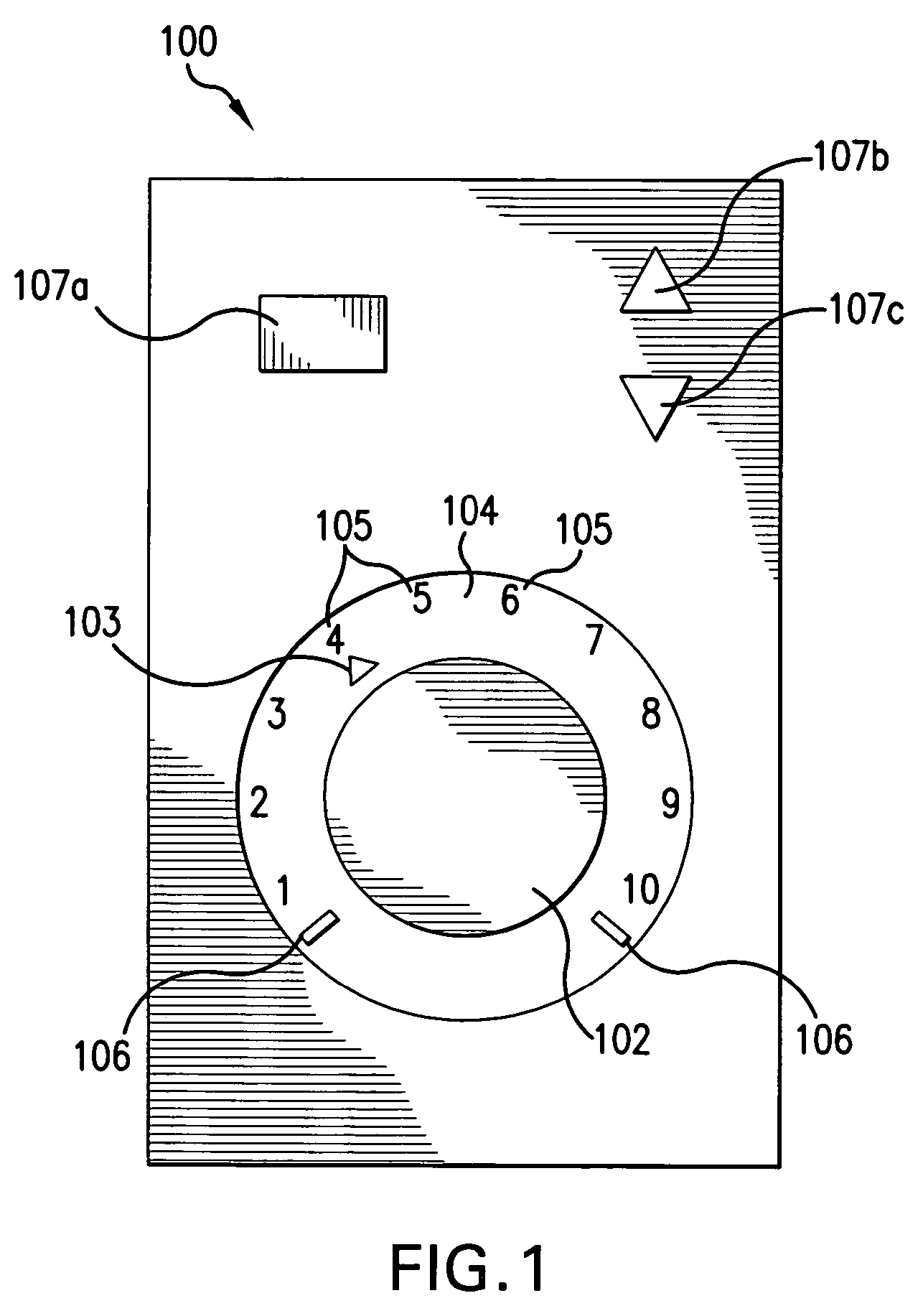

Systems and methods for providing a haptic device

ActiveUS8002089B2Degree of rotationControlling membersDynamo-electric brakes/clutchesEngineeringActuator

Systems and methods for providing a haptic device are described. In one described system, a first brake surface of a first element contacts a second brake surface of a second element. At least one actuator is configured to exert a force on at least one of the first and second elements. A flexure is coupled to at least one of the first element, the second element, a housing, a manipulandum, and a shaft coupled to the manipulandum. The flexure provides a degree of rotational flexibility to the manipulandum when the at least one actuator exerts the force. The described system may include a processor in communication with the at least one actuator for providing the haptic effects.

Owner:IMMERSION CORPORATION

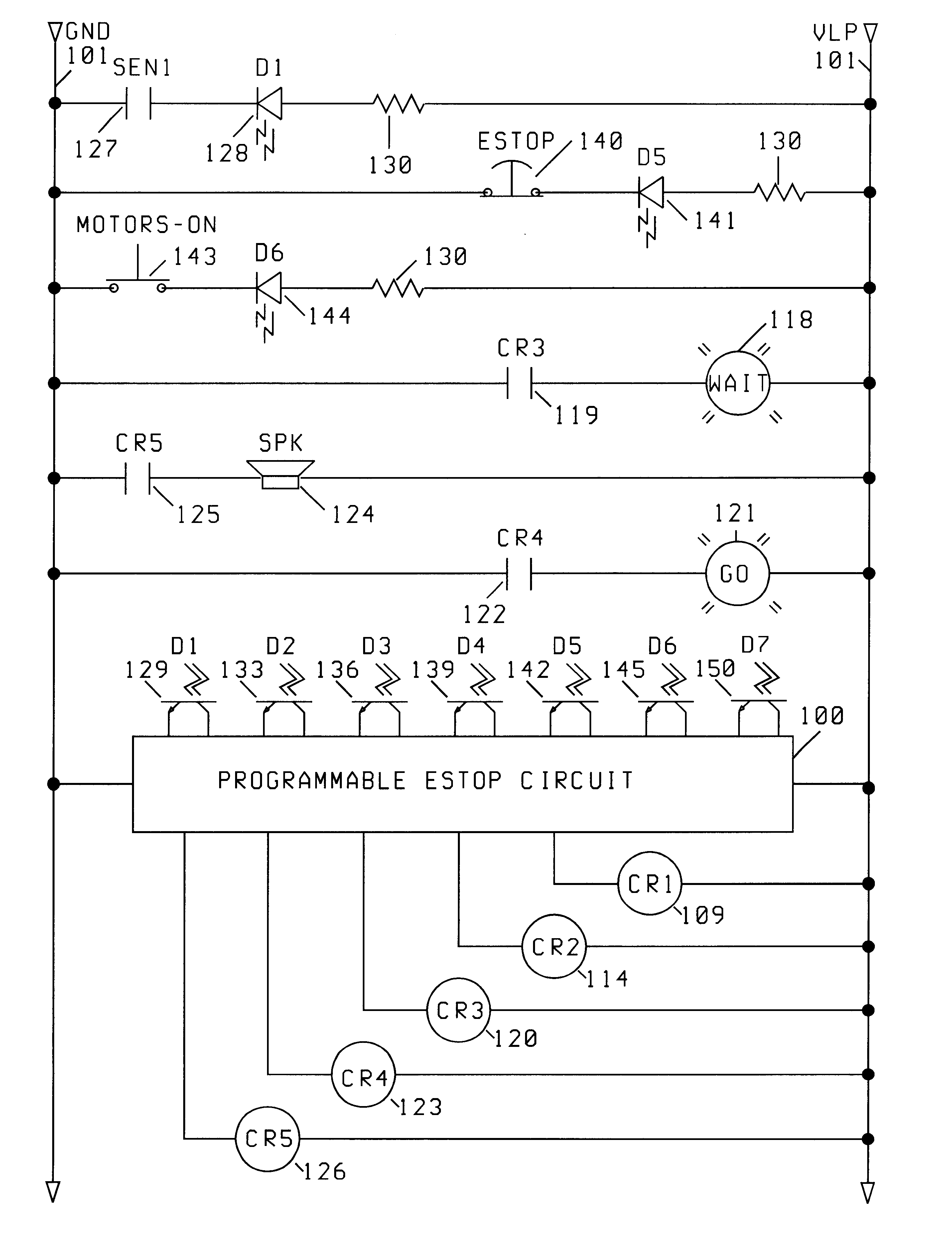

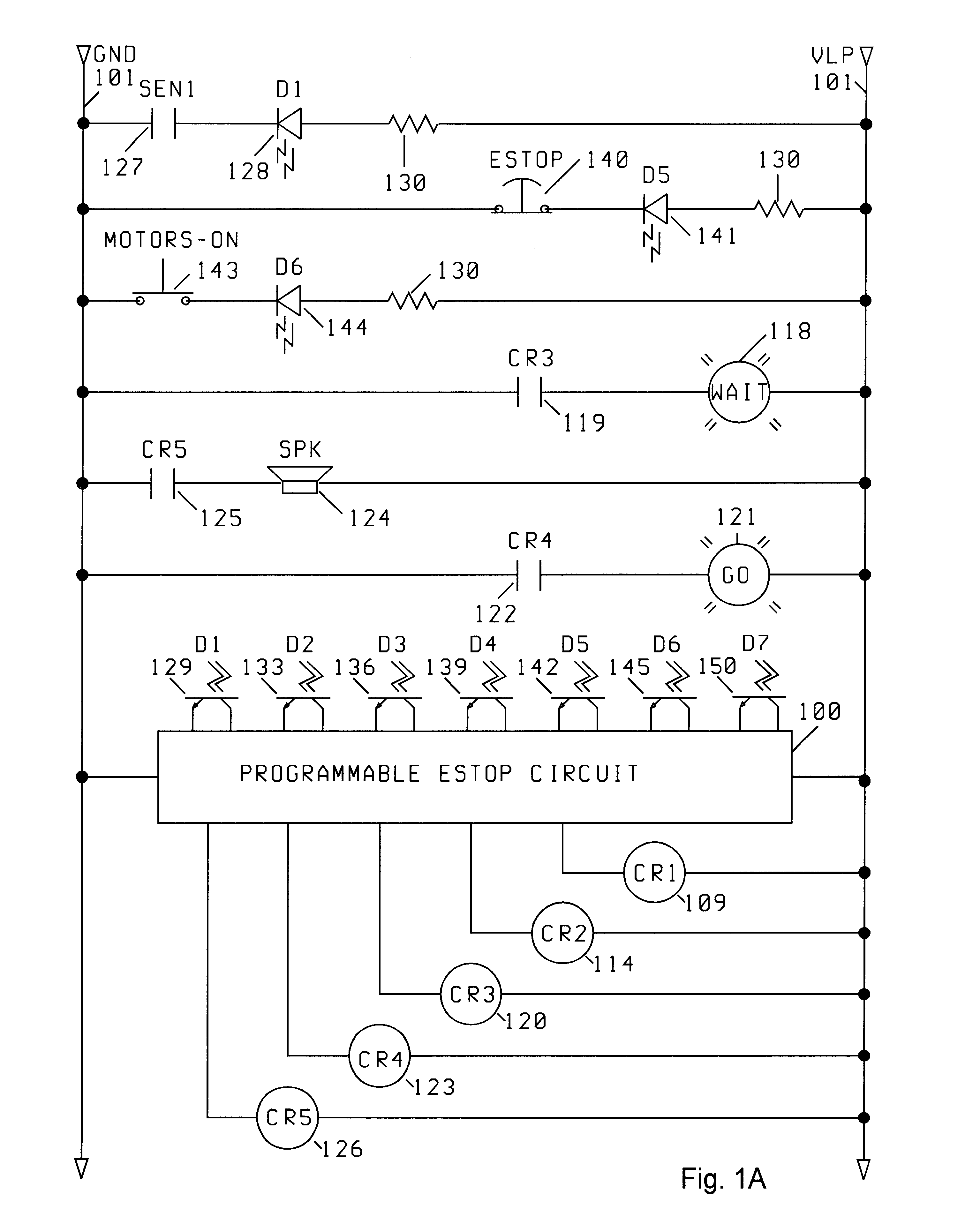

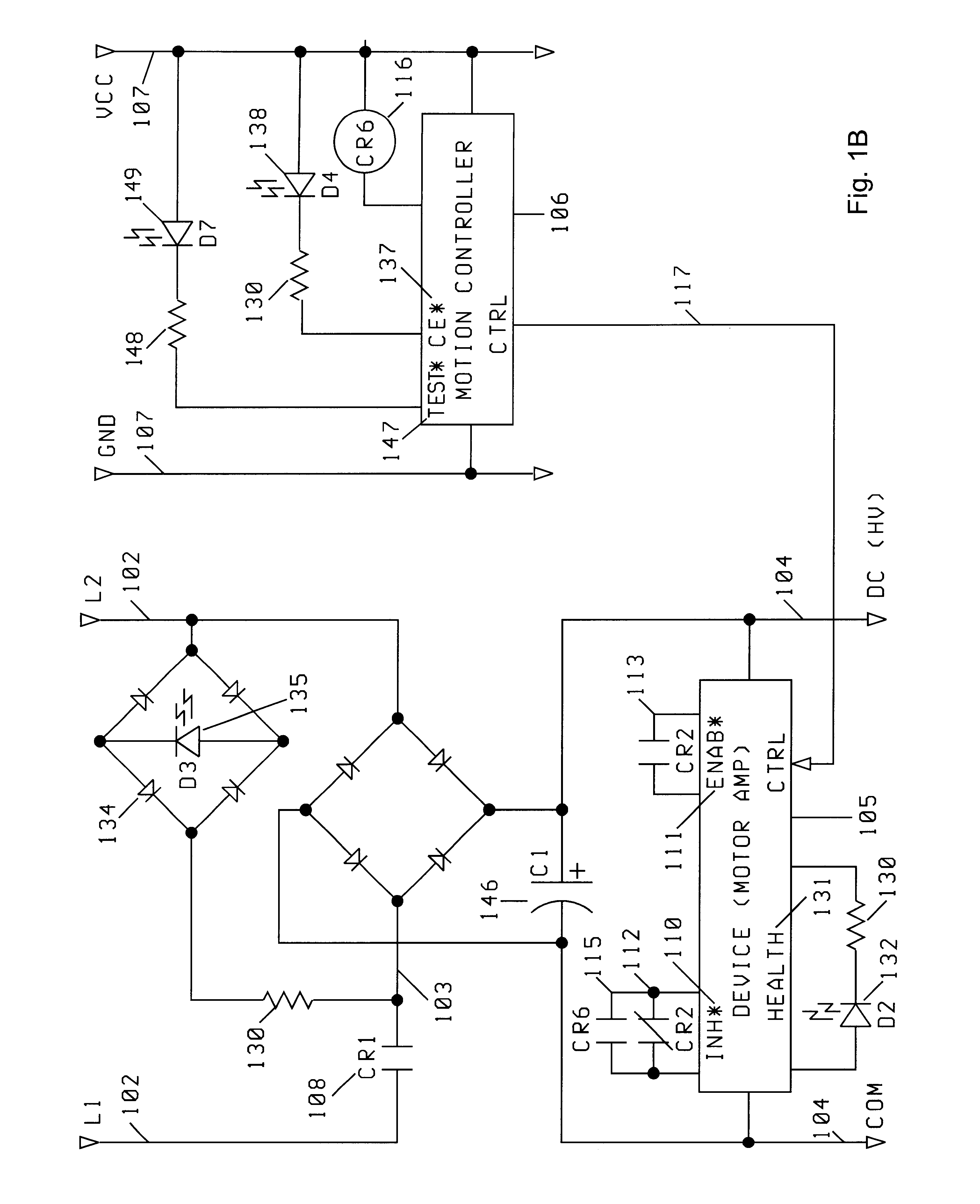

Programmable emergency-stop circuit with testing

InactiveUS6734581B1Safely incorporatedReduce sensitivityBatteries circuit arrangementsEmergency protective circuit arrangementsTest inputKill switch

The invention includes a programmable emergency-stop circuit apparatus and method that provides advanced function not found in other systems. The circuit centralizes the control of high voltage motor power into one place, by providing connections for, in its minimum configuration, several different kill switches, a motors-on button, and an AC motor power relay coil. In the present invention, kill switches, test inputs, emergency-stop and motors-on buttons, computer ready and watchdog signals are all conveniently connected in one location, alongside the AC motor power relay coil driver. Programmable options exist for testing kill inputs online, while the emergency stop is energized.

Owner:EIGENPOINT

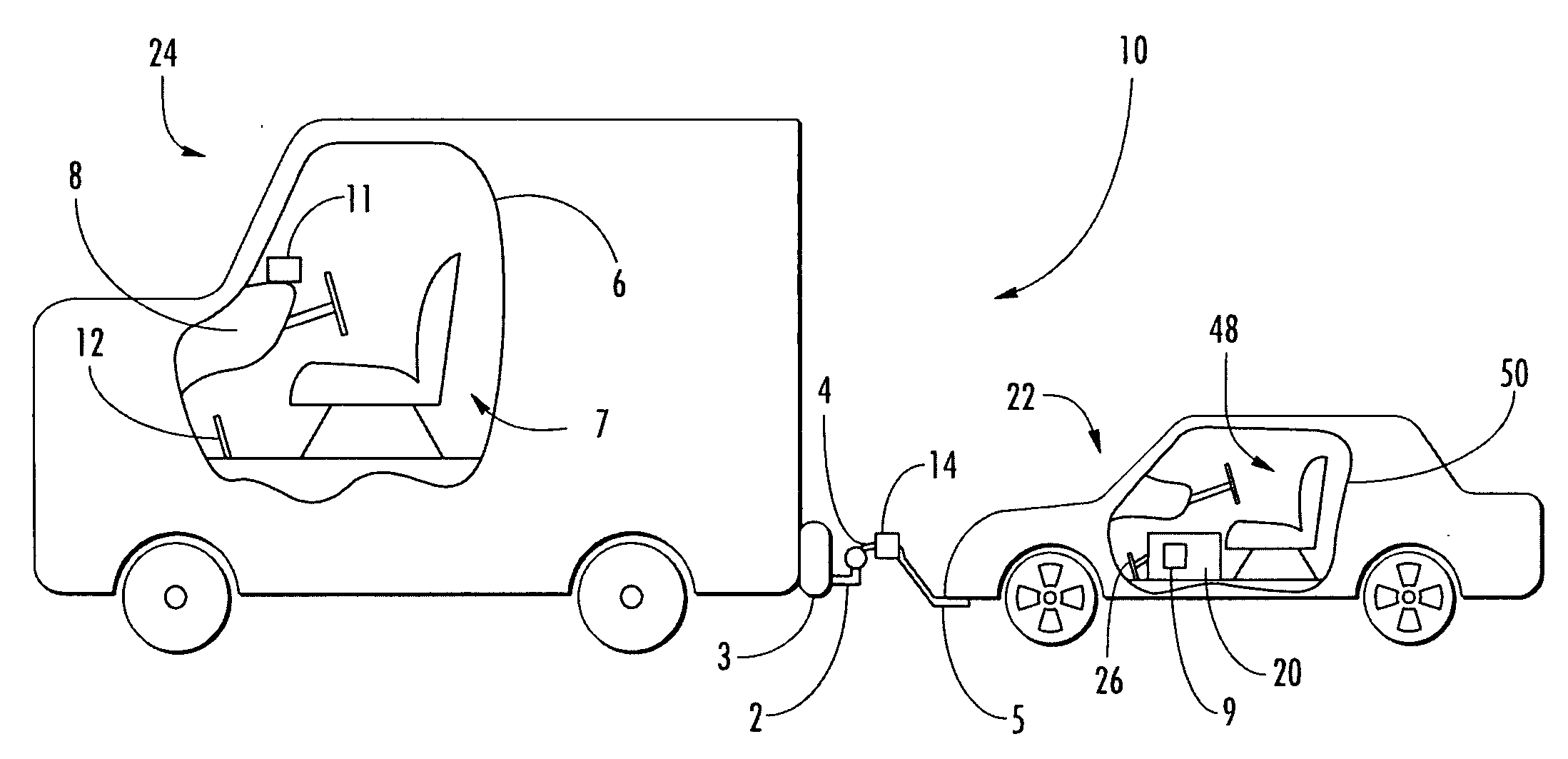

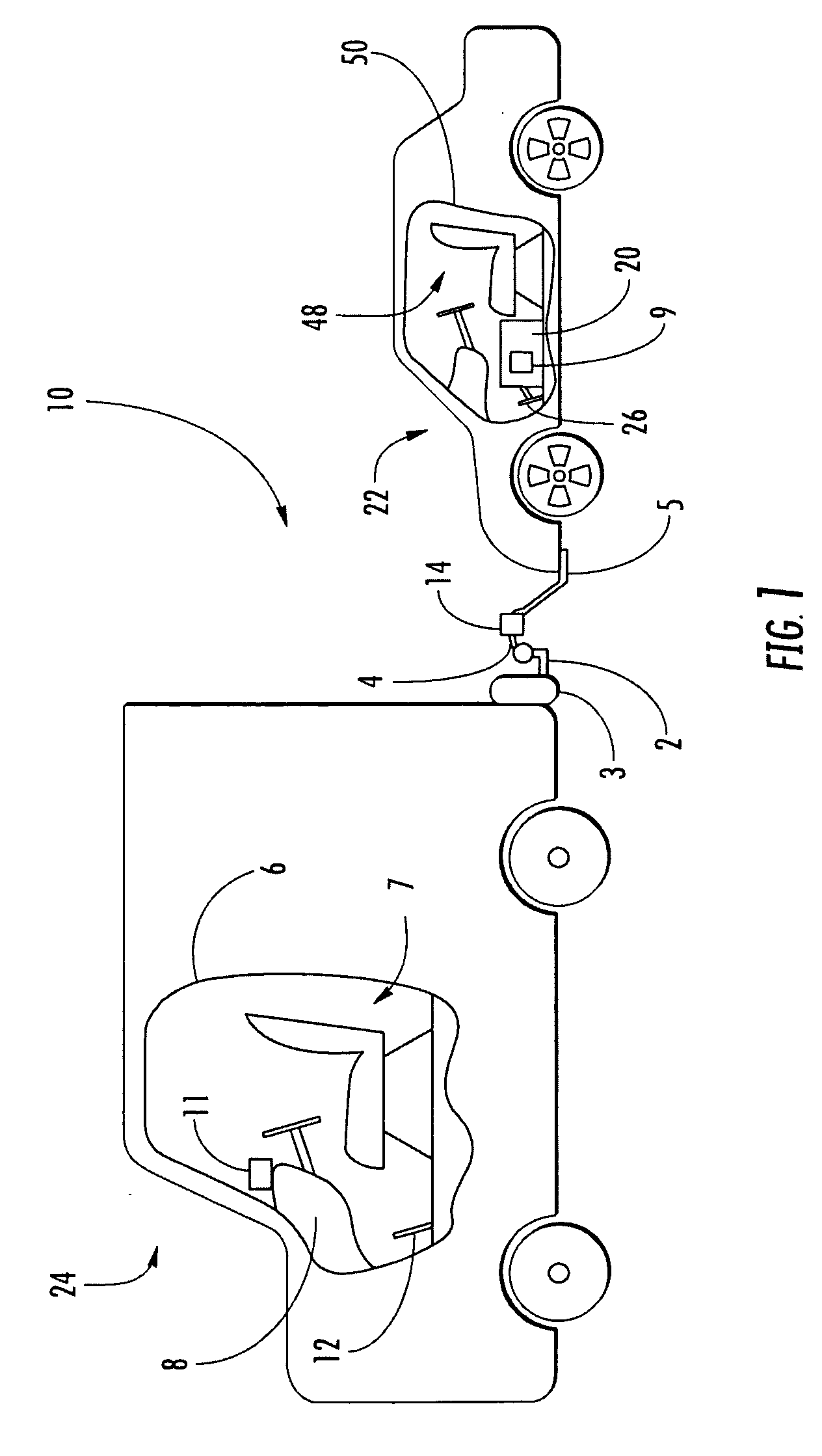

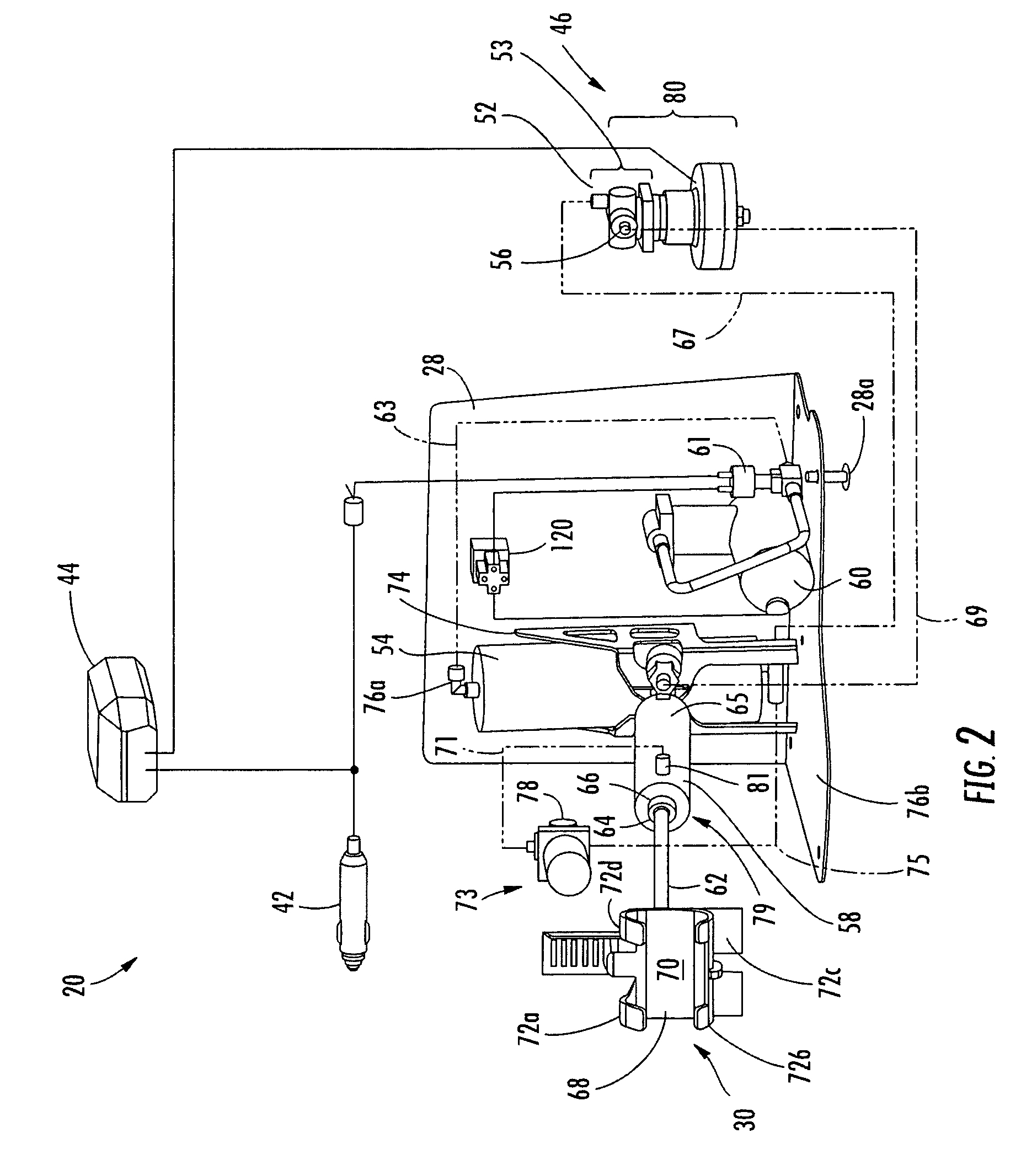

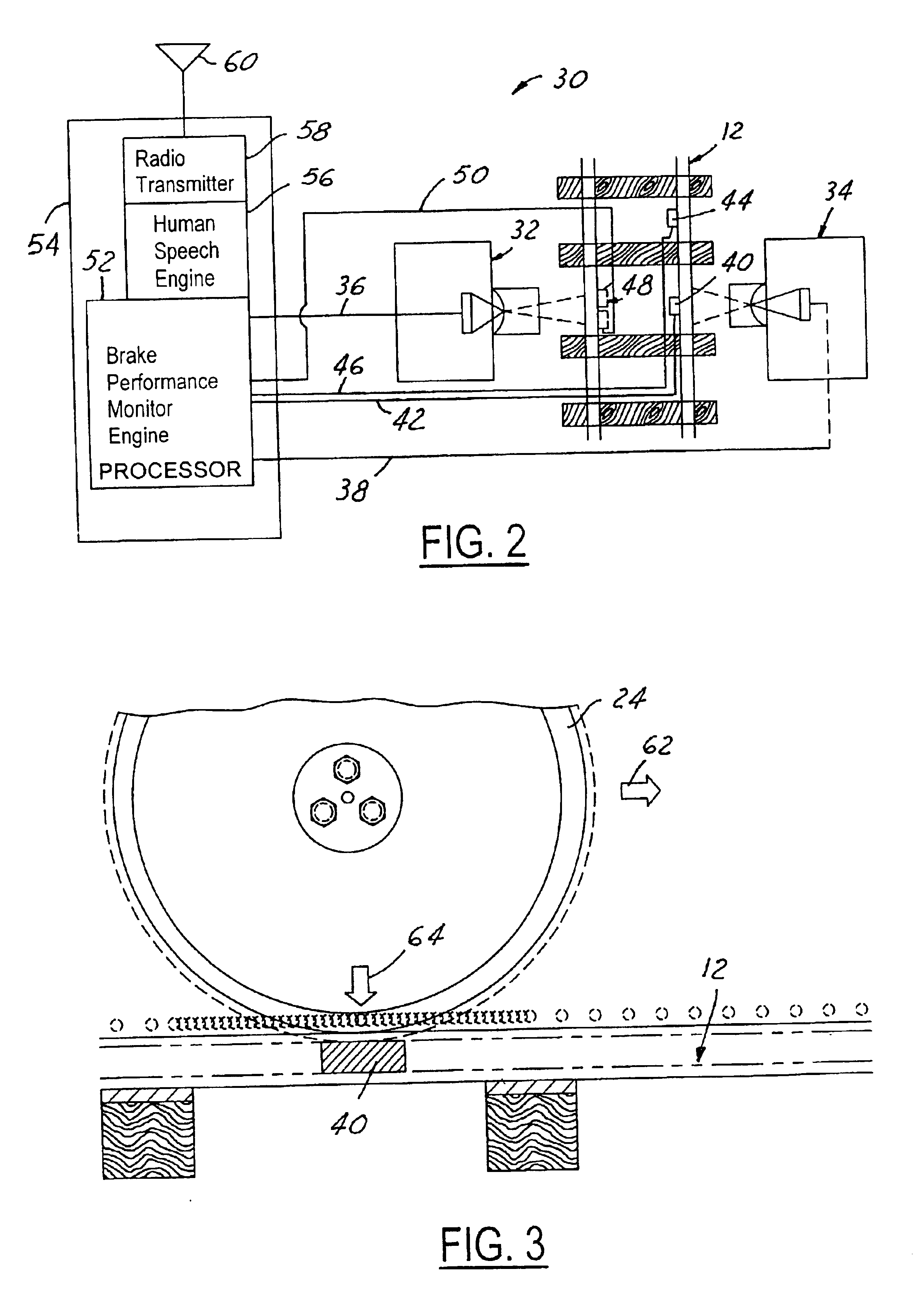

Brake monitoring system

InactiveUS20080257656A1Variably controlEasy to assembleAutomatic initiationsBrake typesDisplay deviceMonitoring system

A brake monitoring system is disclosed. The monitoring system includes a primary braking system located in a towing vehicle. A towed vehicle is releasably attached to the towing vehicle. A towed vehicle braking system is mounted in the towed vehicle. An auxiliary braking device is configured to activate the towed vehicle braking system and to sense at least one parameter of the auxiliary braking device or of the towed vehicle braking system. A transmitter is in communication with the auxiliary braking device. The transmitter is configured to send a signal about the parameter. A receiver is located in the towing vehicle. The receiver is configured to receive the signal from the transmitter. A display is located in the towing vehicle and is in communication with the receiver. The display is configured to display a message to a towing vehicle occupant about the parameter.

Owner:EDWARDS JERRY A

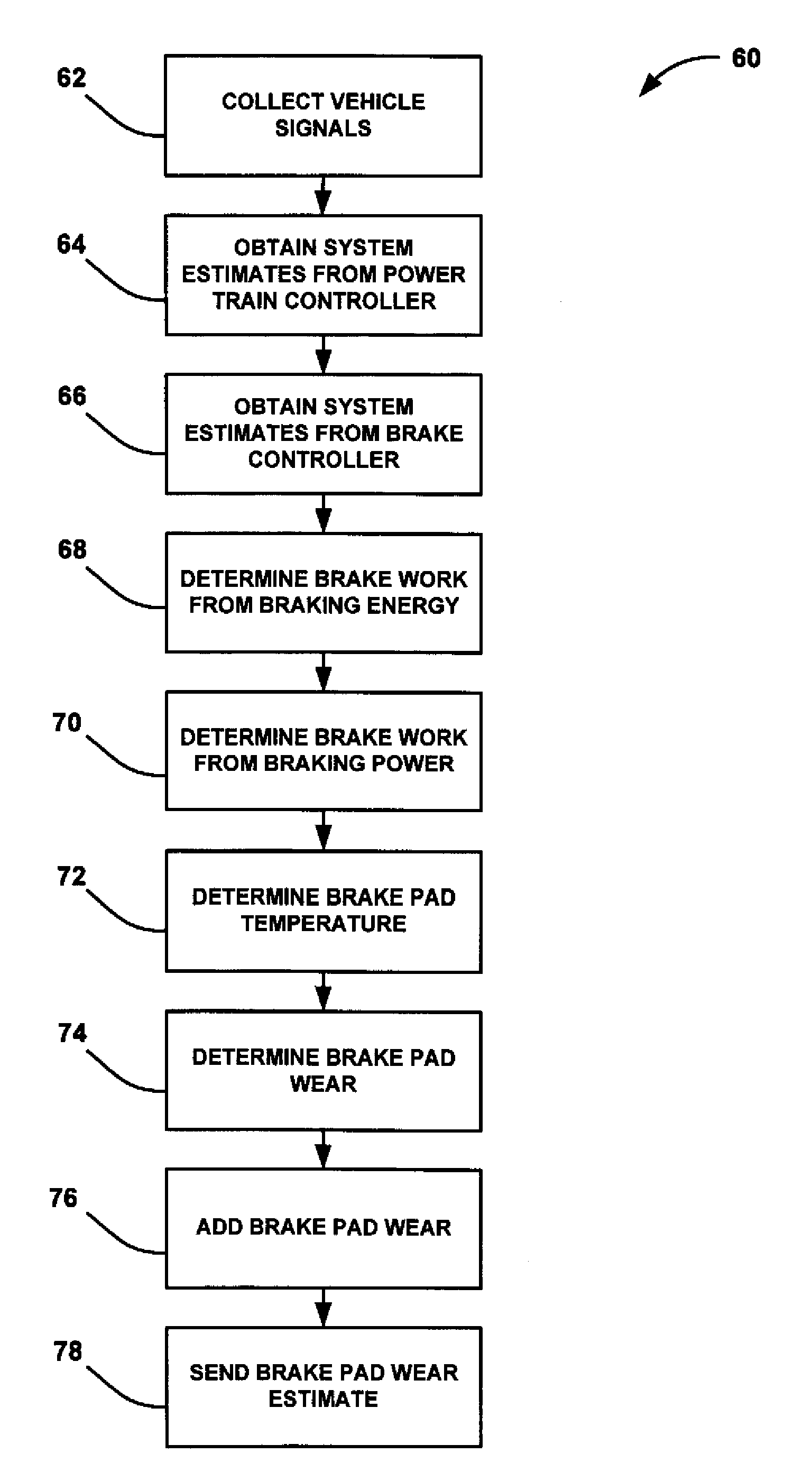

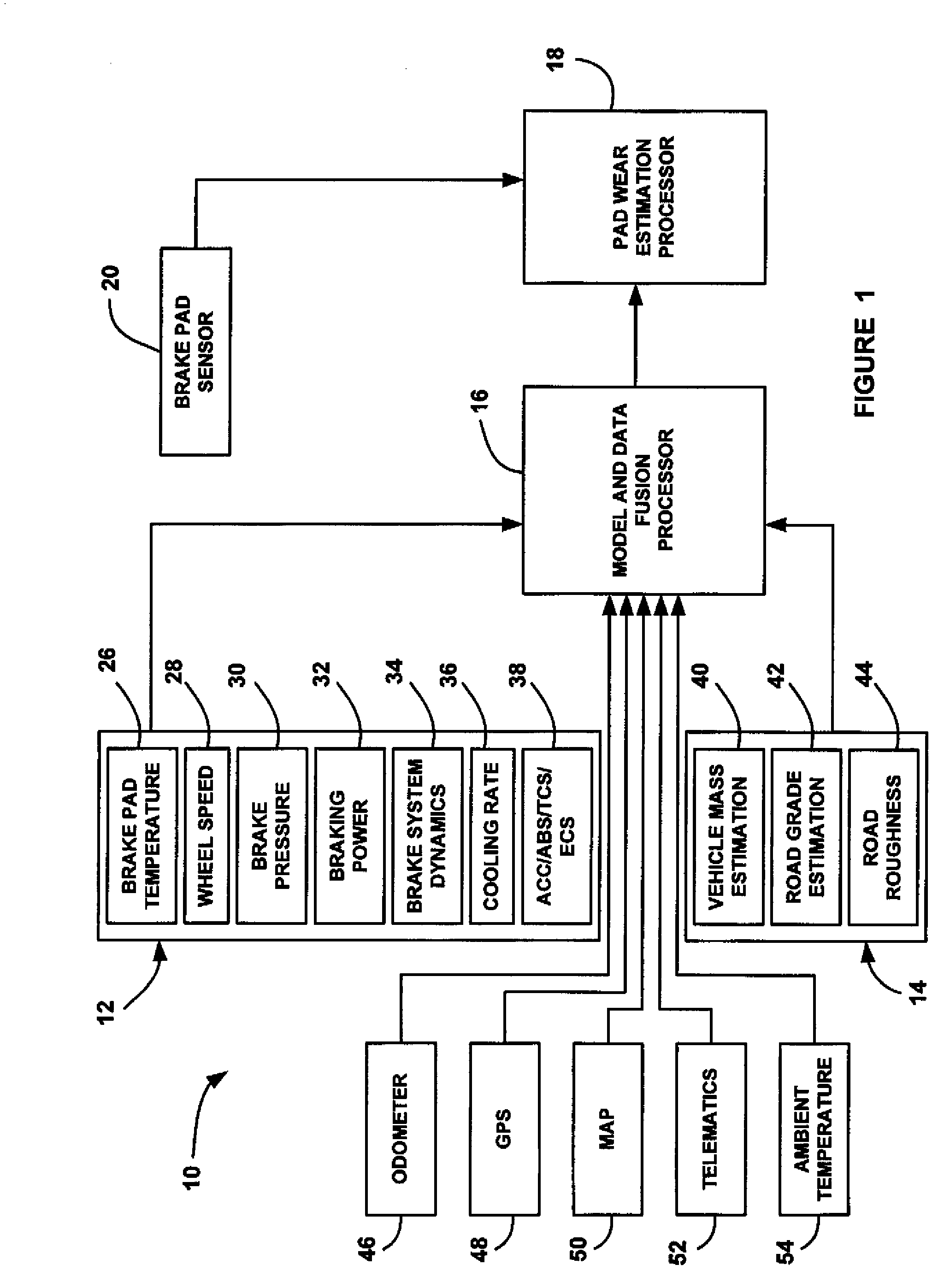

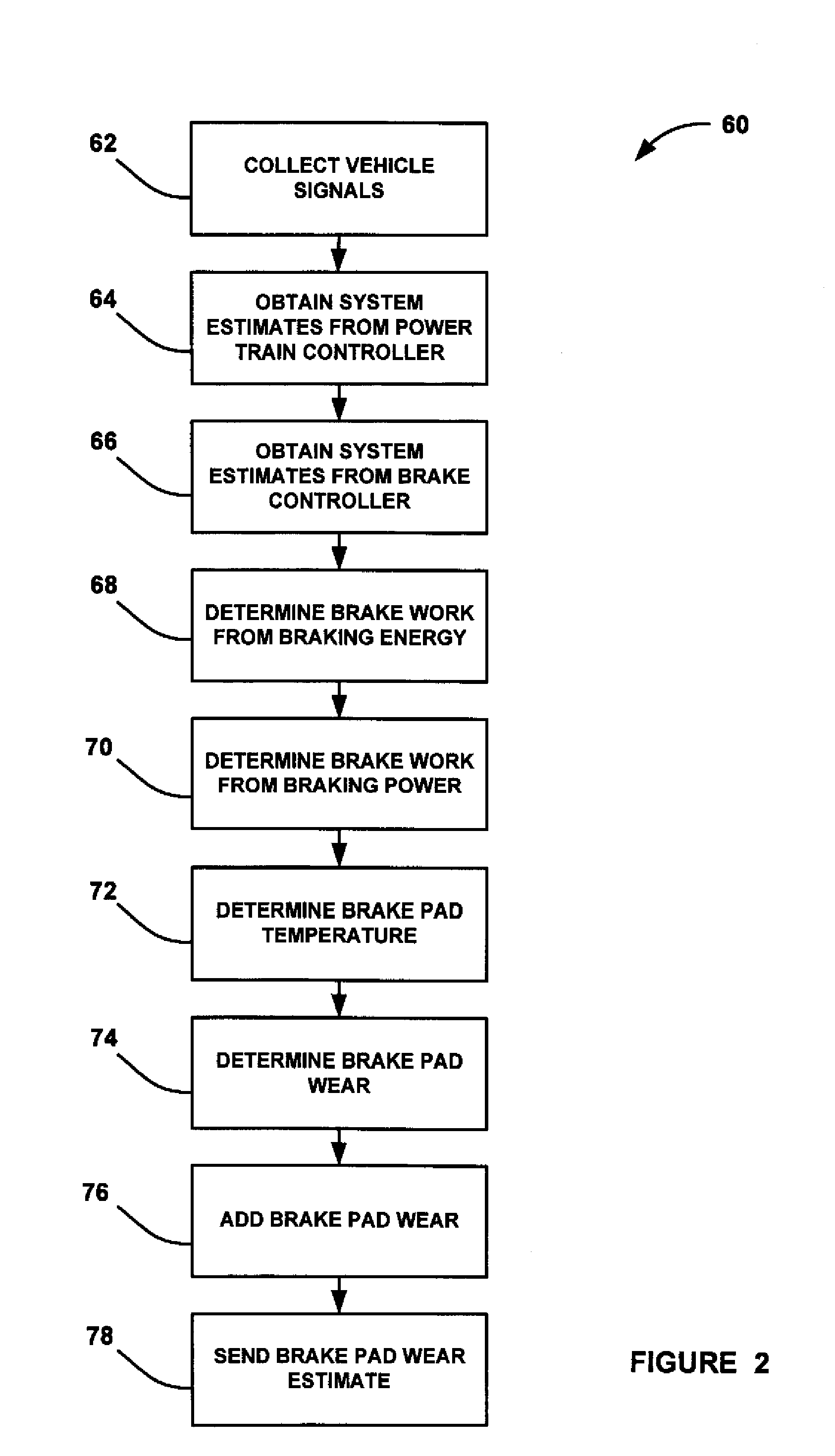

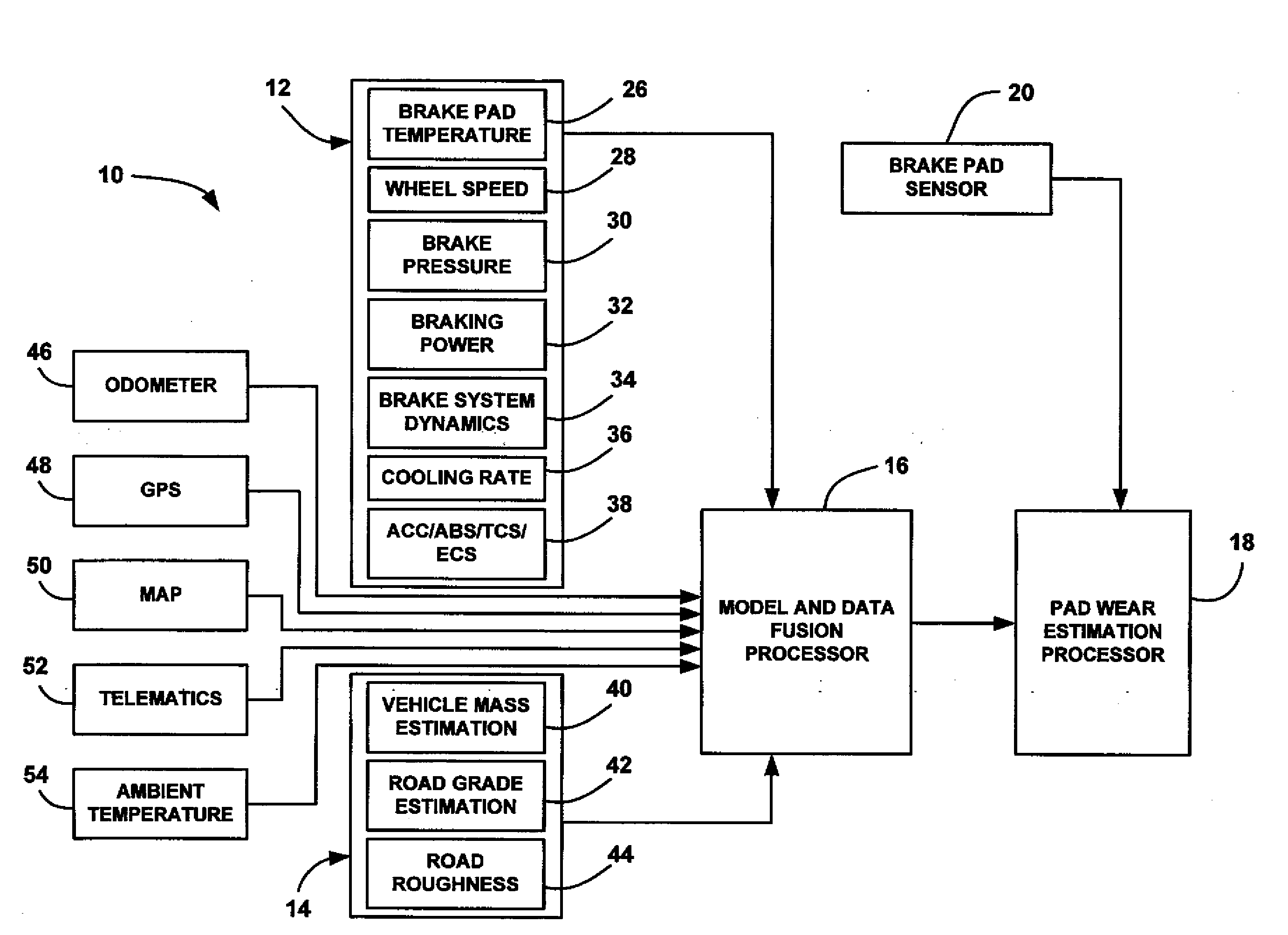

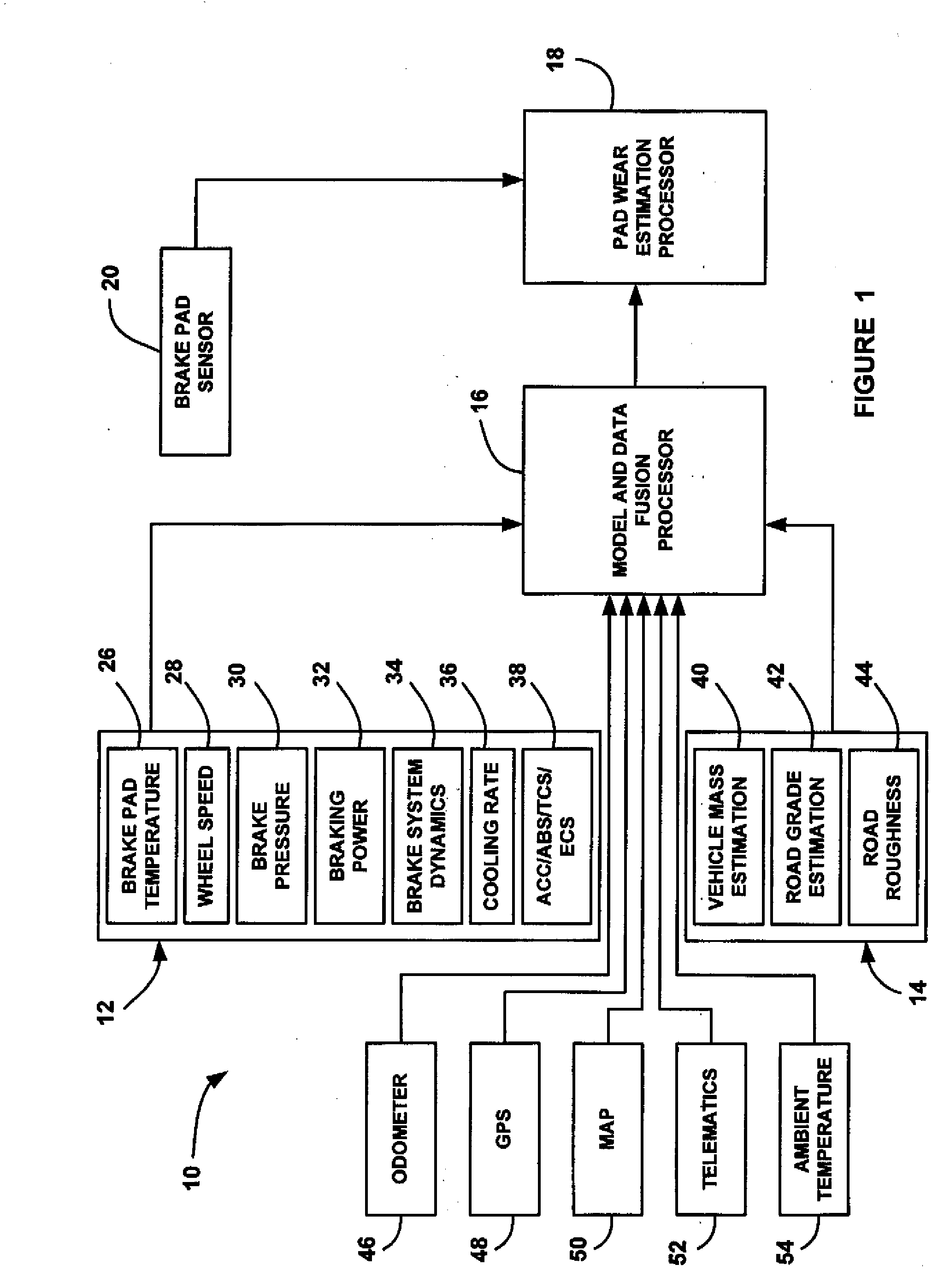

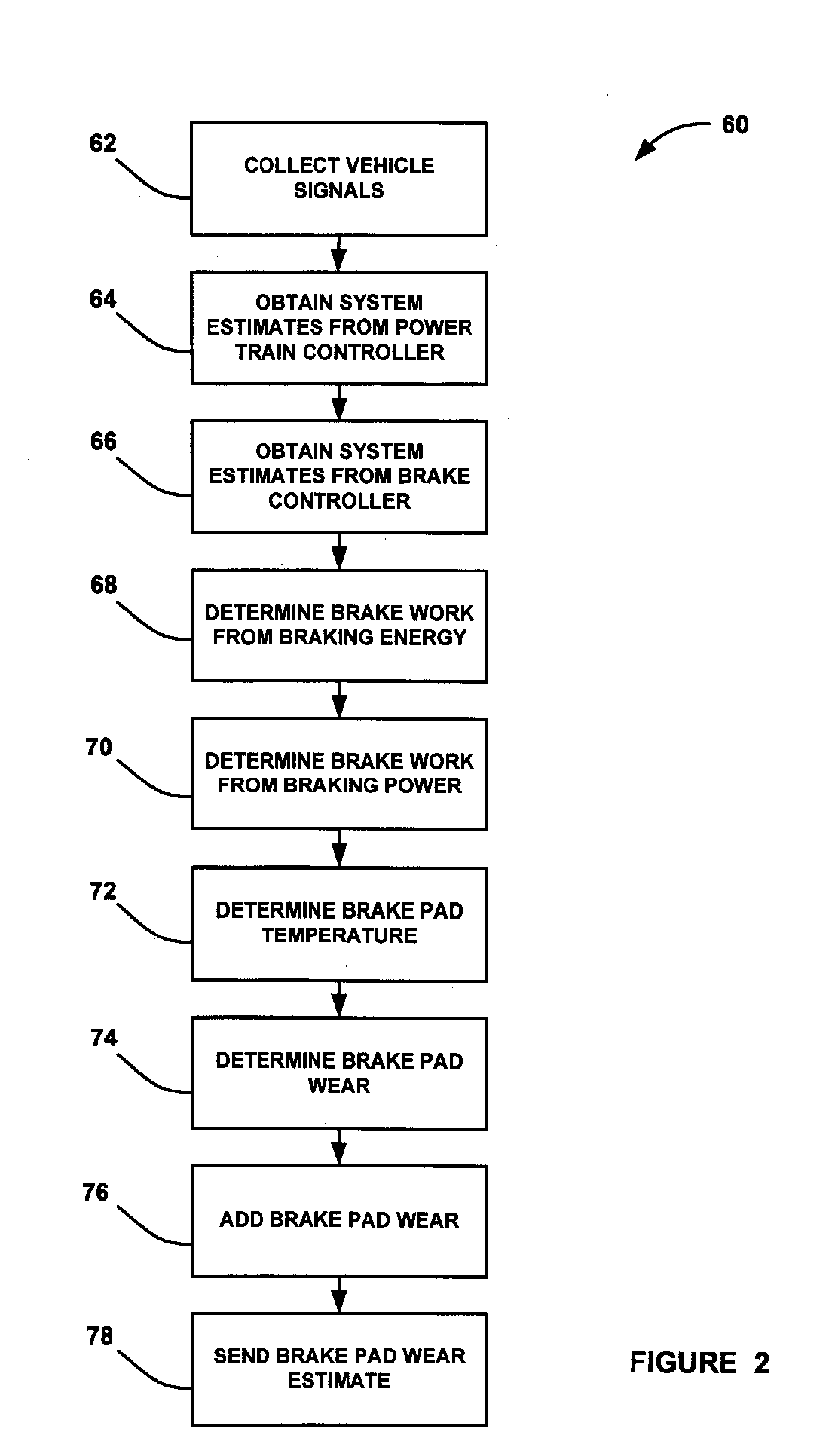

Brake pad prognosis system

A method for providing an estimate of brake pad thickness. The method employs fusion of sensors, if used, and driver brake modeling to predict the vehicle brake pad life. An algorithm is employed that uses various inputs, such as brake pad friction material properties, brake pad cooling rate, brake temperature, vehicle mass, road grade, weight distribution, brake pressure, brake energy, braking power, etc. to provide the estimation. The method calculates brake work using total work minus losses, such as aerodynamic drag resistance, engine braking and / or braking power as braking torque times velocity divided by rolling resistance to determine the brake rotor and lining temperature. The method then uses the brake temperature to determine the brake pad wear, where the wear is accumulated for each braking event. A brake pad sensor can be included to provide one or more indications of brake pad thickness from which the estimation can be revised.

Owner:GM GLOBAL TECH OPERATIONS LLC

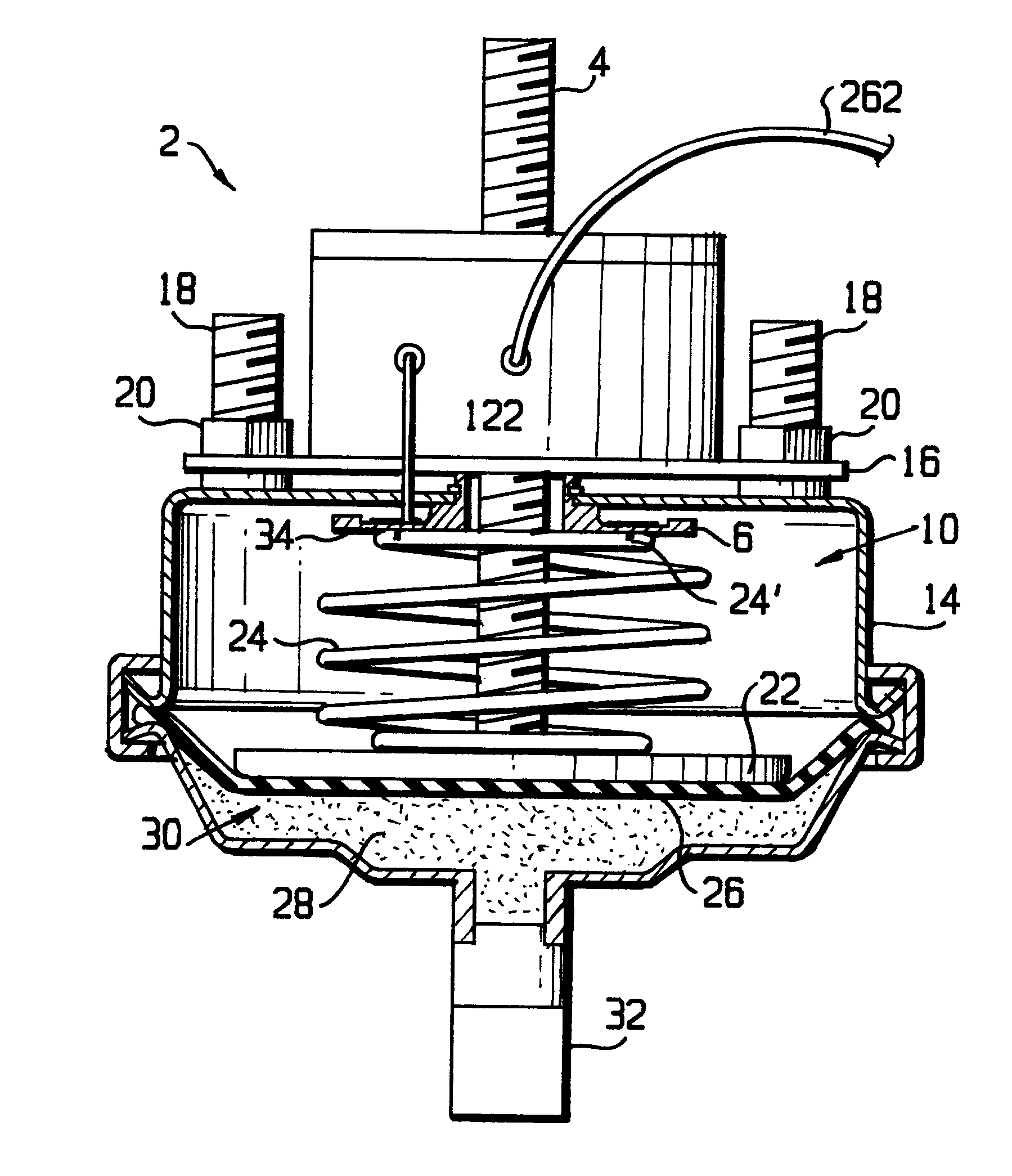

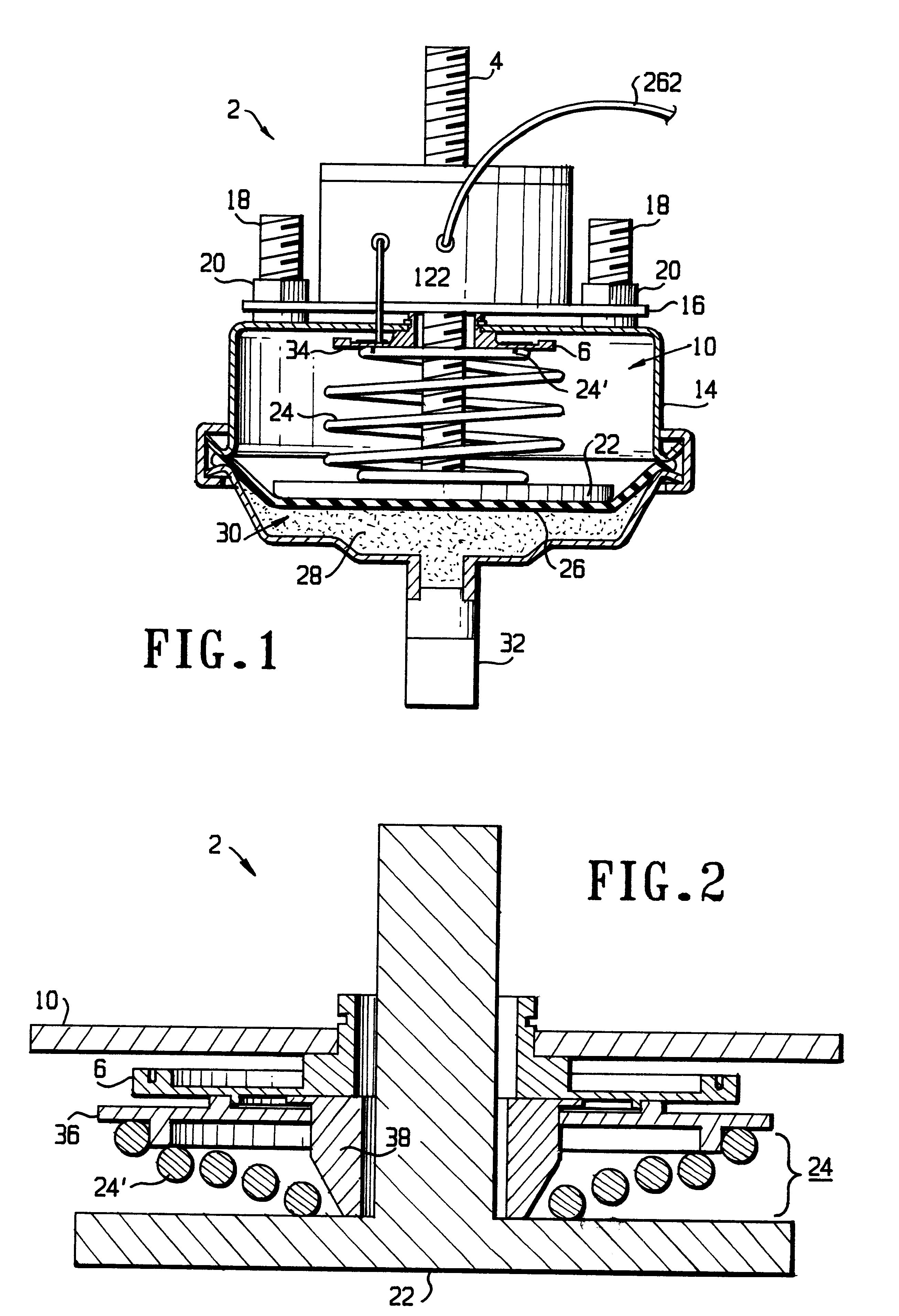

Vehicular sensors

A brake stroke sensor and an steering sensor are individually and collectively provided. A brake stroke sensor includes a force-receiving plate, a second plate movable relative to the force-receiving plate, a spring disposed between the plates and operatively connected to the pushrod, a strain gauge bridge mounted on the force-receiving plate and a microcontroller capable of converting the strain gauge bridge signal into digital data. A steering sensor includes a mechanical interface operatively connected to a nonmoving member and a moving member, an encoder capable of transforming the rotational motion of the mechanical interface into an electrical signal, and a microcontroller capable of calculating, from the electrical signal, a count indicative of the relative positions of the members. A combined brake stroke and steering sensor may include individual and common elements of both the brake stroke and steering sensors described above. The brake stroke, steering sensor and combined brake stroke and steering sensor may utilize a modem for transmitting data to a system controller over an electrical bus.

Owner:CALSPAN CORP

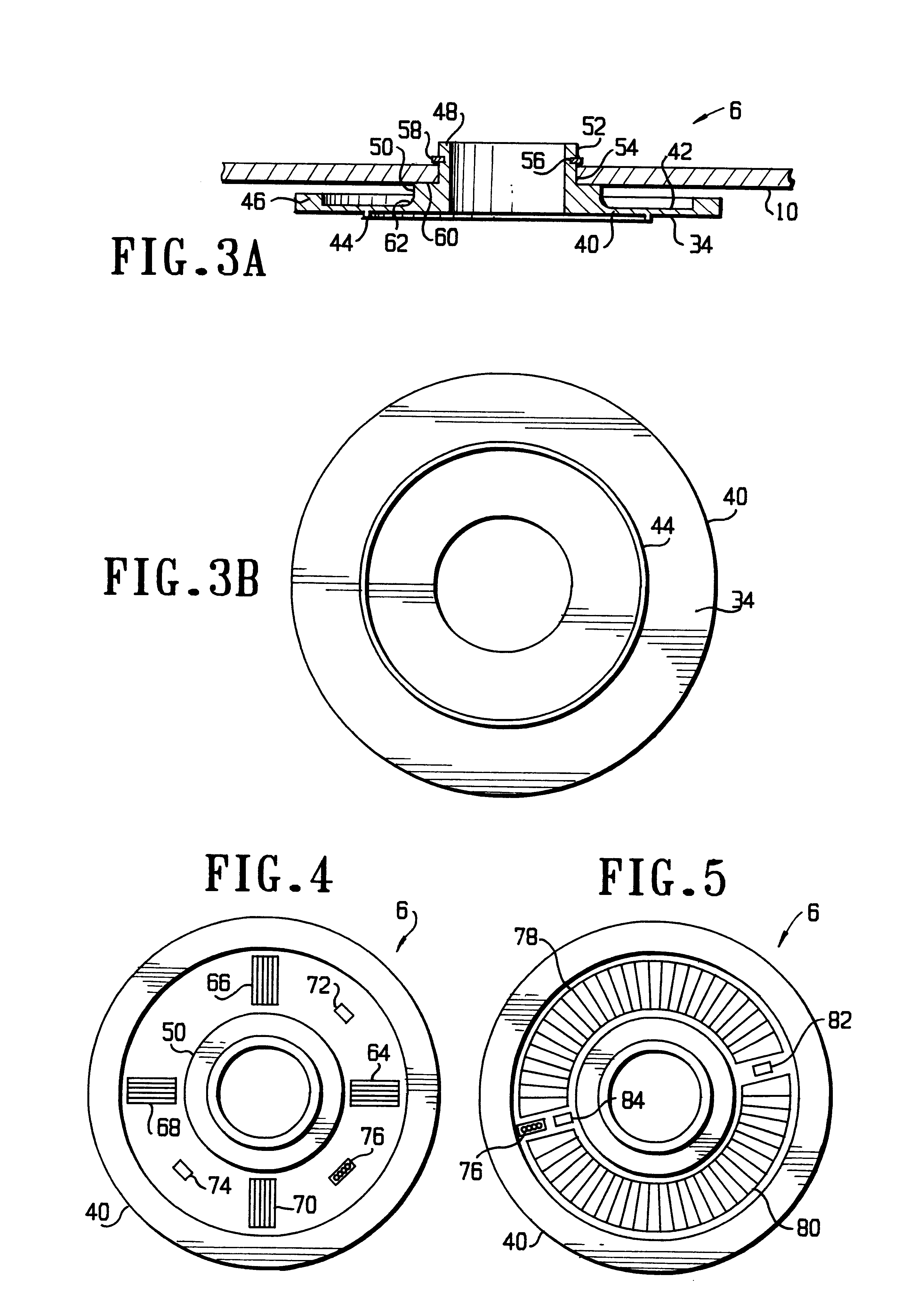

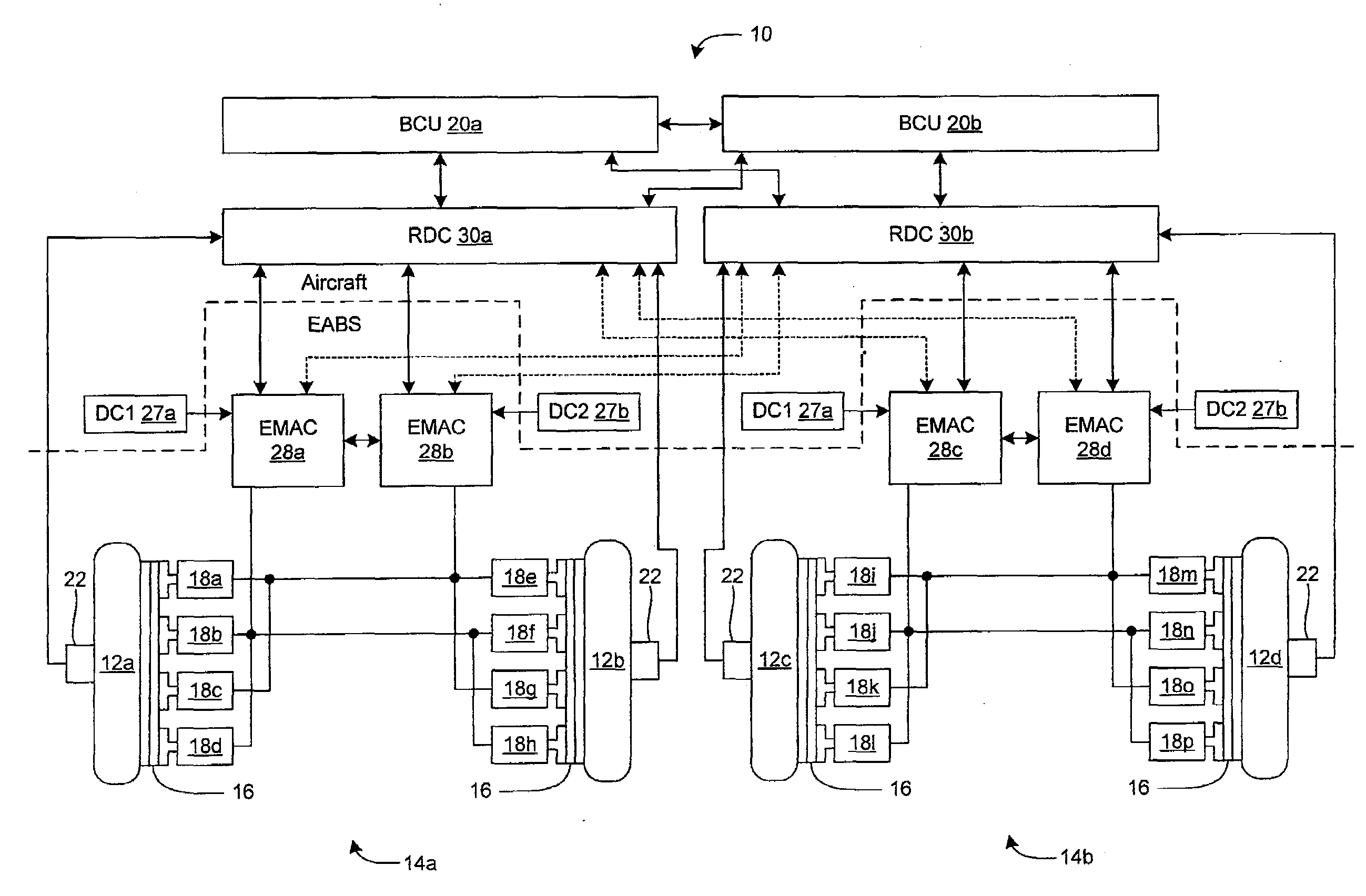

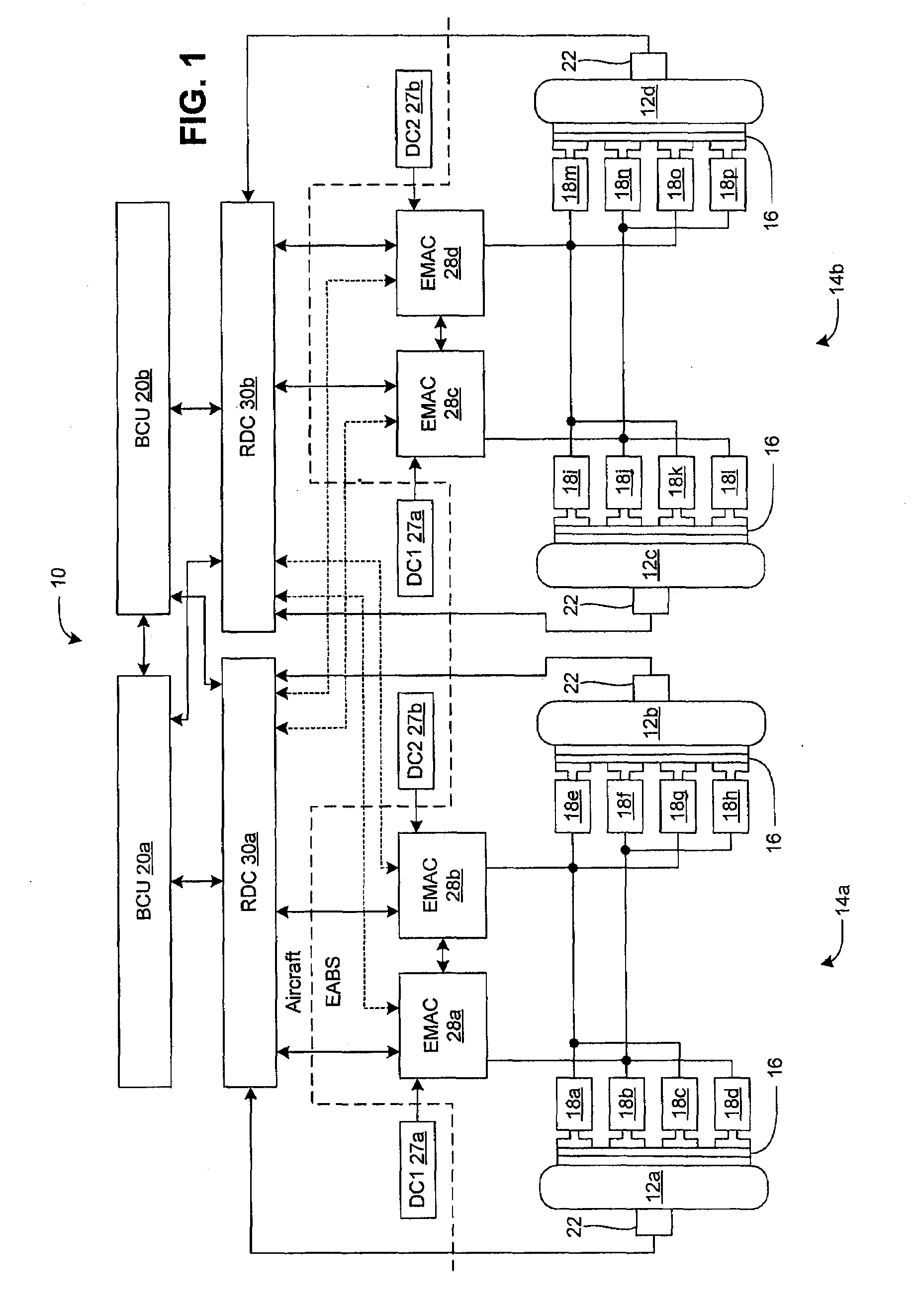

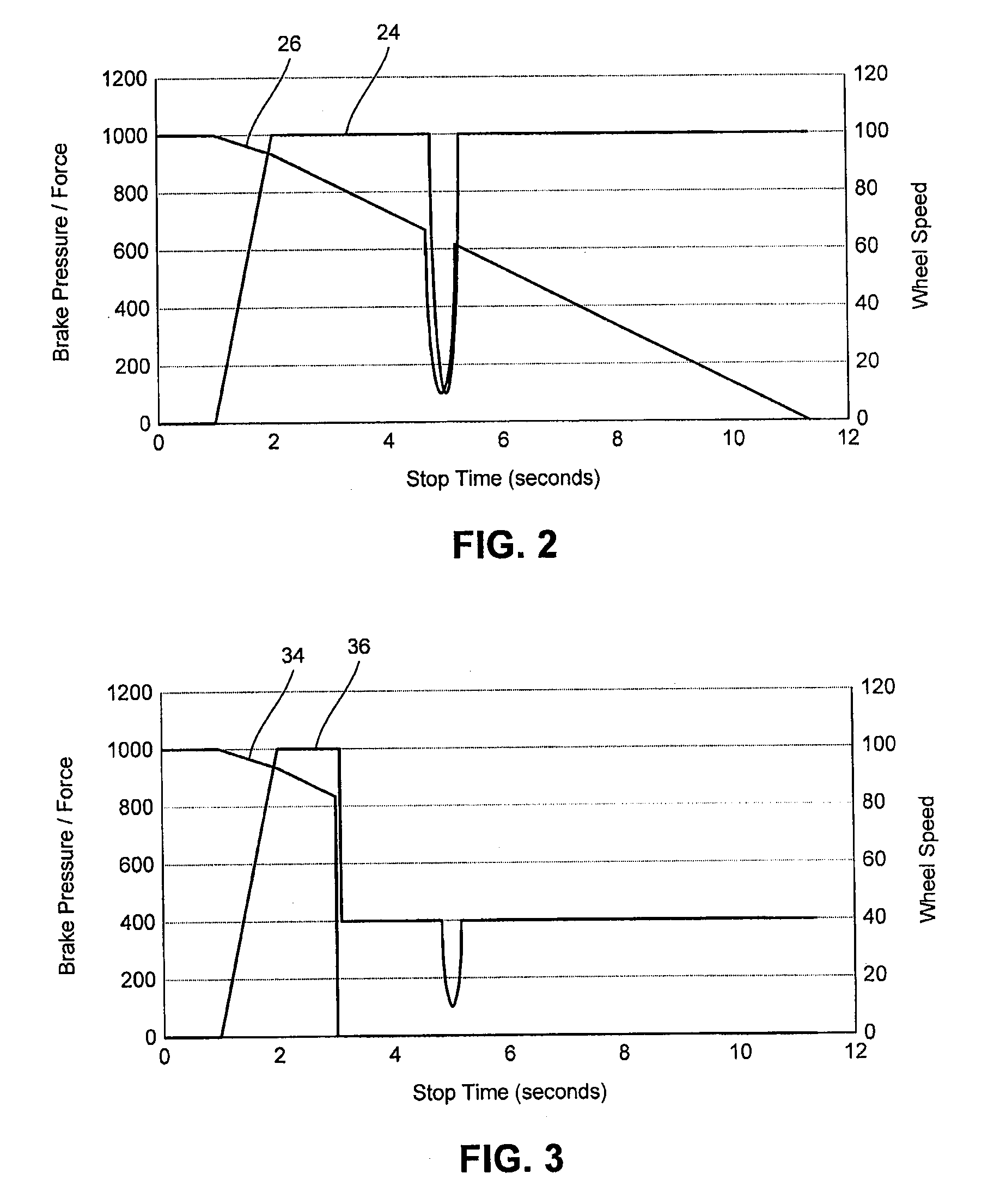

Aircraft brake control system and method

InactiveUS20090276133A1Broaden applicationBraking force can be appliedDigital data processing detailsBrake control systemsControl systemControl signal

A method includes receiving an input brake command that indicates a desired amount of braking for a vehicle. A brake control signal is then derived from the input brake command to facilitate applying a braking force to a wheel of the vehicle, and the braking force facilitates achieving the desired amount of braking for the vehicle. The method further comprises determining that data from a sensor associated with the wheel is unavailable, and then modifying the brake control signal in response to determining that the data is unavailable. The modification may be based on sensor data or controller output associated with a second wheel where data is available. Such modification facilitates the desired amount of braking for the vehicle.

Owner:THE BF GOODRICH CO

System and method for rapidly stopping a spinning table saw blade

A system for stopping a spinning table saw blade is comprised of a pin assembly disposed adjacent to a saw blade assembly for stopping a spinning saw blade. A receiving block is disposed on a side of the saw blade opposing the pin assembly for receiving the tip of the pin assembly. A driving assembly is coupled to the pin assembly for driving the pin assembly into the spinning saw blade into the receiving block. Finally, a sensing assembly is coupled to at least one of the saw blade assembly and the driving assembly for sensing encroachment of a user's hand in a pre-defined zone. In use, upon sensing a user's hand the sensing assembly signals the driving assembly to stop the spinning saw blade by driving the pin assembly through the saw blade and into the receiving block.

Owner:CHANG TYPE INDAL

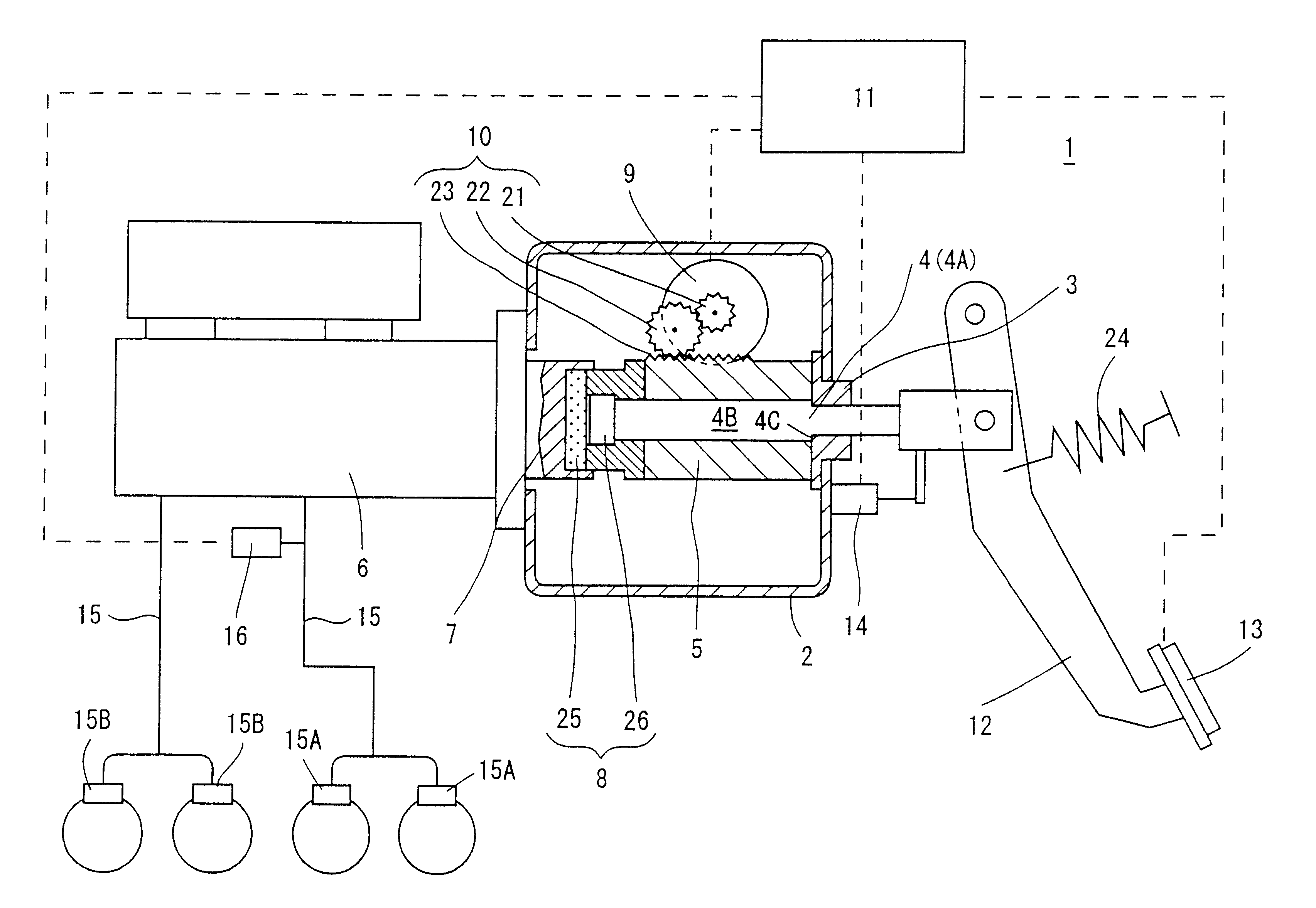

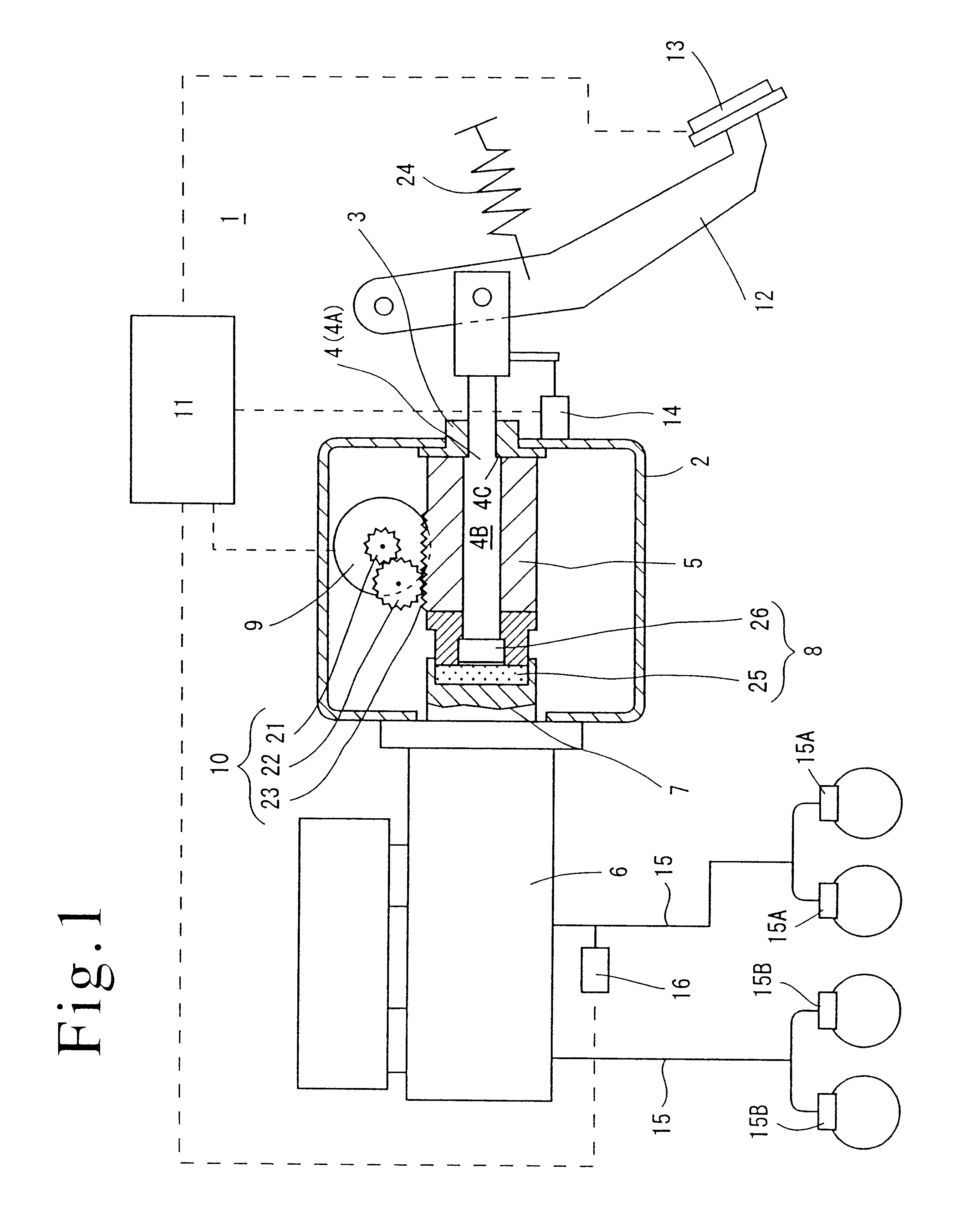

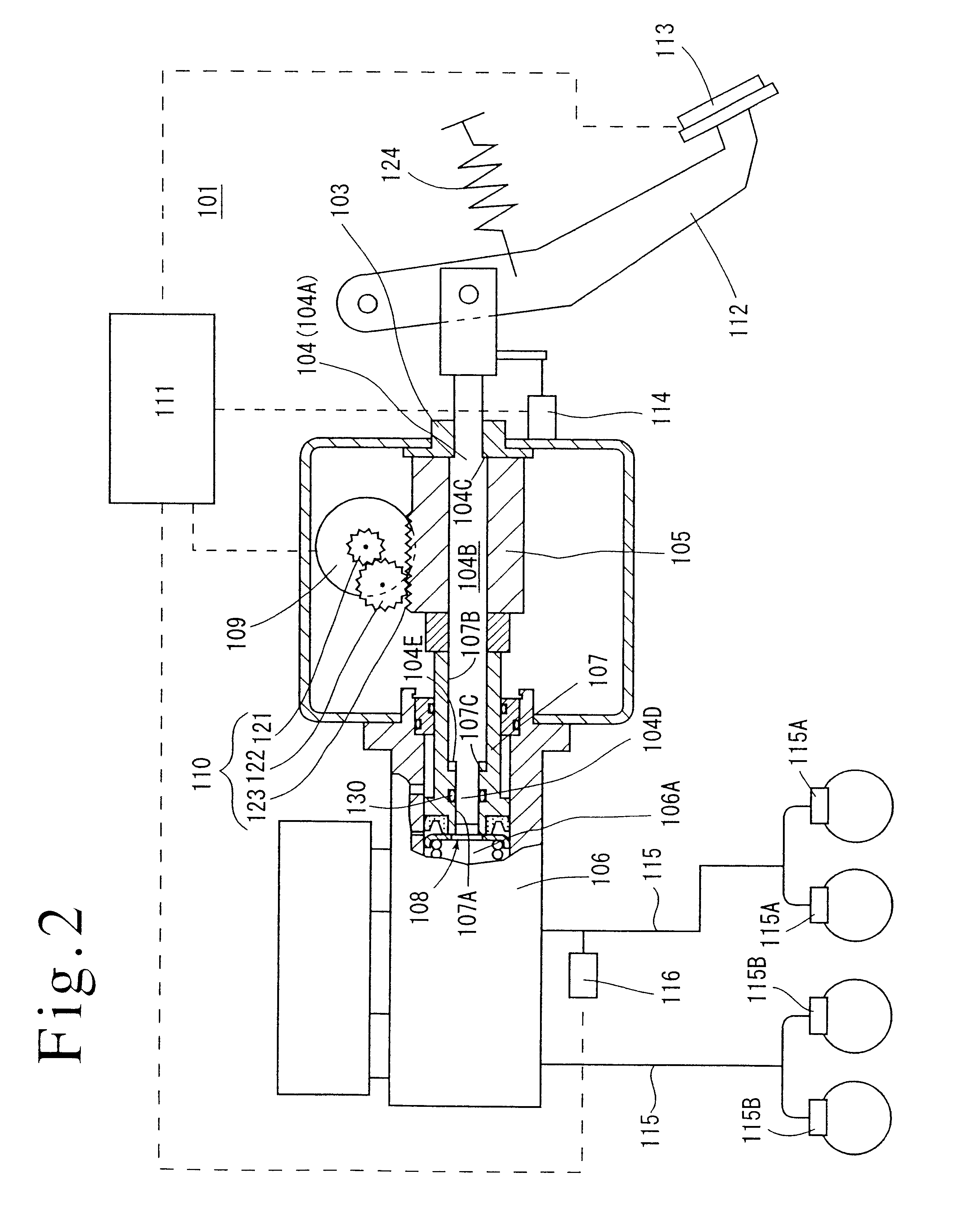

Electrically driven brake booster

InactiveUS6634724B2Reduce weightEasy constructionServomotor componentsRotary clutchesLinear motionMaster cylinder

An electrically driven brake booster (1) includes an input member (4) disposed in operative association with a brake pedal (12), an output member (5) disposed in operative association with the master cylinder (6), and drive transmitting device (10) for translating a rotating motion of a motor (9) into a linear motion to be transmitted to the output member (5). The drive transmitting device (10) comprises a rack (23) formed on the output member (5), and pinions (21, 22) disposed in operative association with the motor (9) and in meshing engagement with the rack (23). Also, reaction transmitting device (8) which transmits a brake reaction to the input member (4) and the output member (5) at a given proportion is provided. In comparison to conventional drive transmitting device, the drive transmitting device (10) of the present invention has a simple construction, a reduced weight and a better transmission efficiency. The provision of reaction transmitting device allows a correct brake control to be achieved on the basis of a brake reaction.

Owner:DIESEL KIKI CO LTD

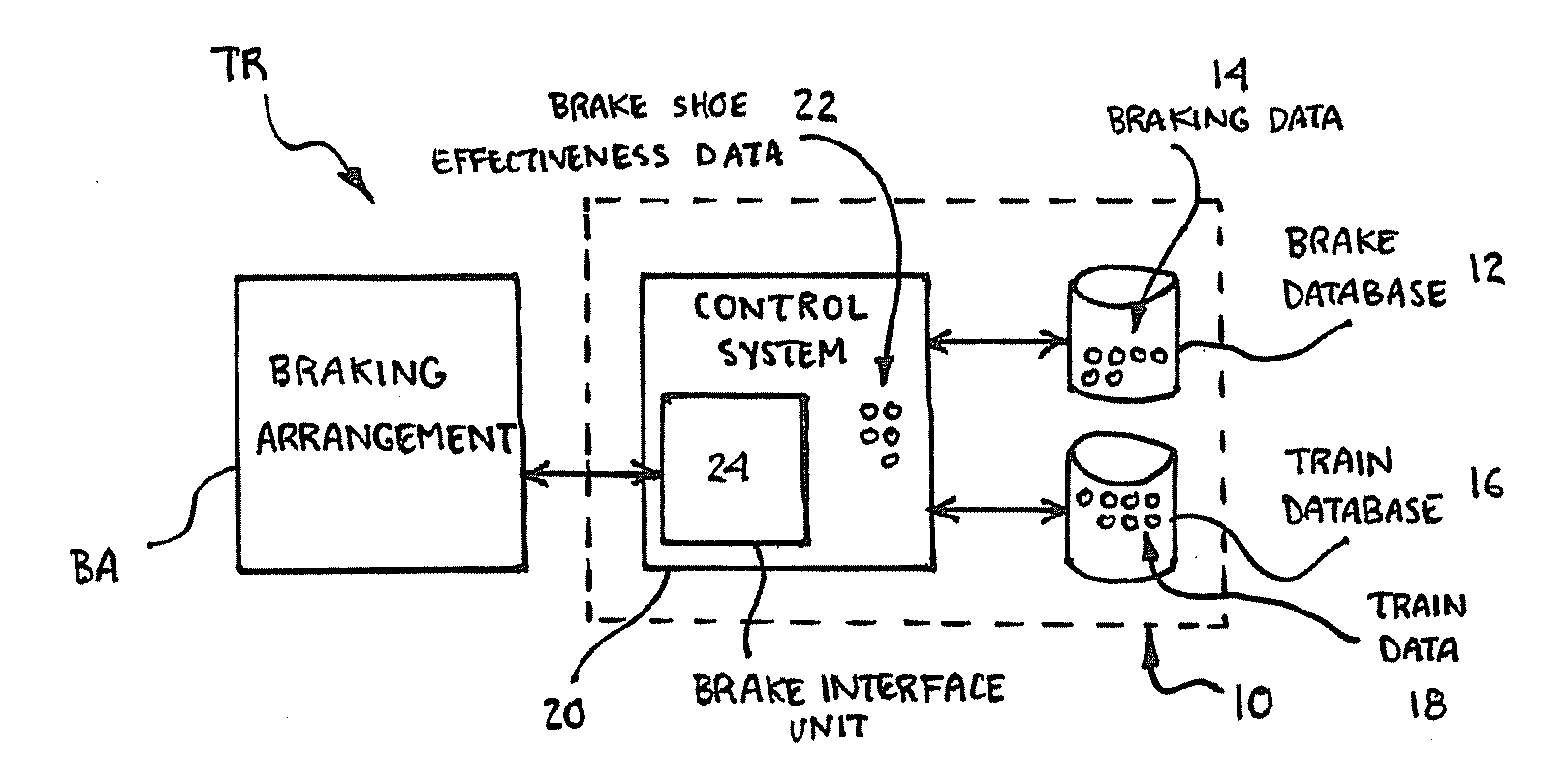

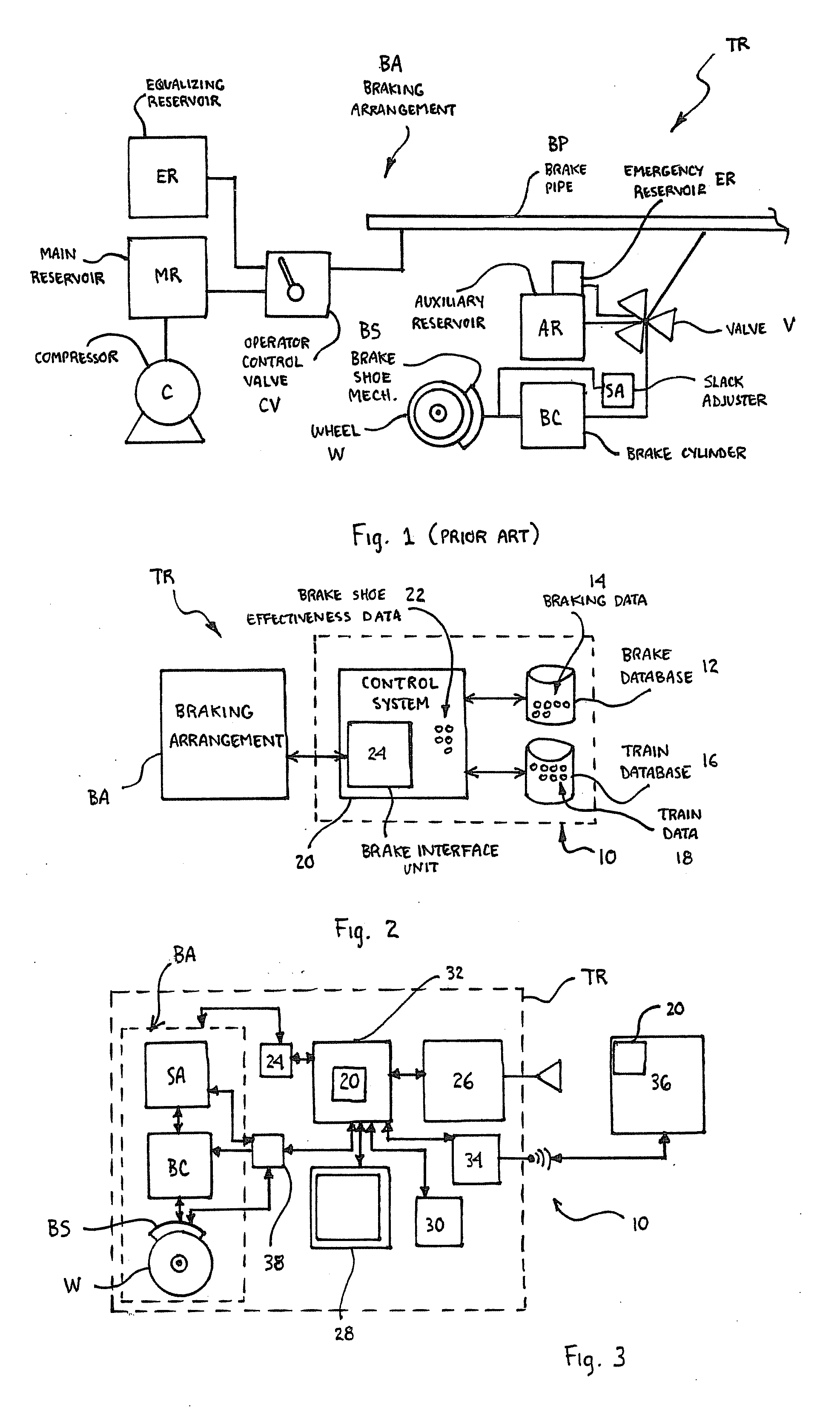

Method and System for Determining Brake Shoe Effectiveness

A system for determining brake shoe effectiveness of a braking arrangement of a train during operation of the train including at least one brake database including braking data and at least one train database including train data. A control system is in communication with the at least one brake database and the at least one train database, and the control system dynamically determines brake shoe effectiveness data based upon the braking data and the train data, where the brake shoe effectiveness data includes the ability of the braking arrangement to retard the train to a specified level.

Owner:WABTEC HLDG CORP

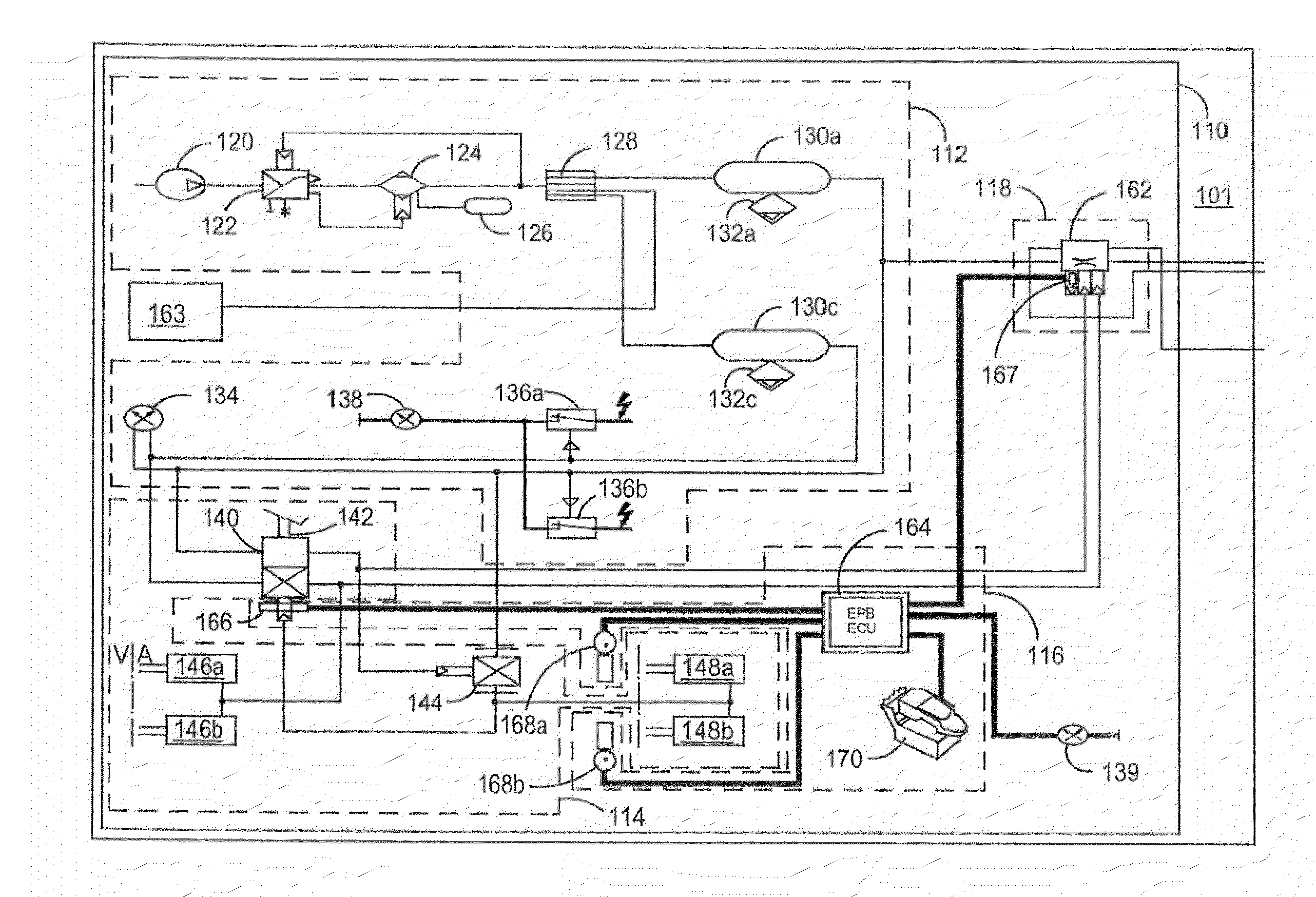

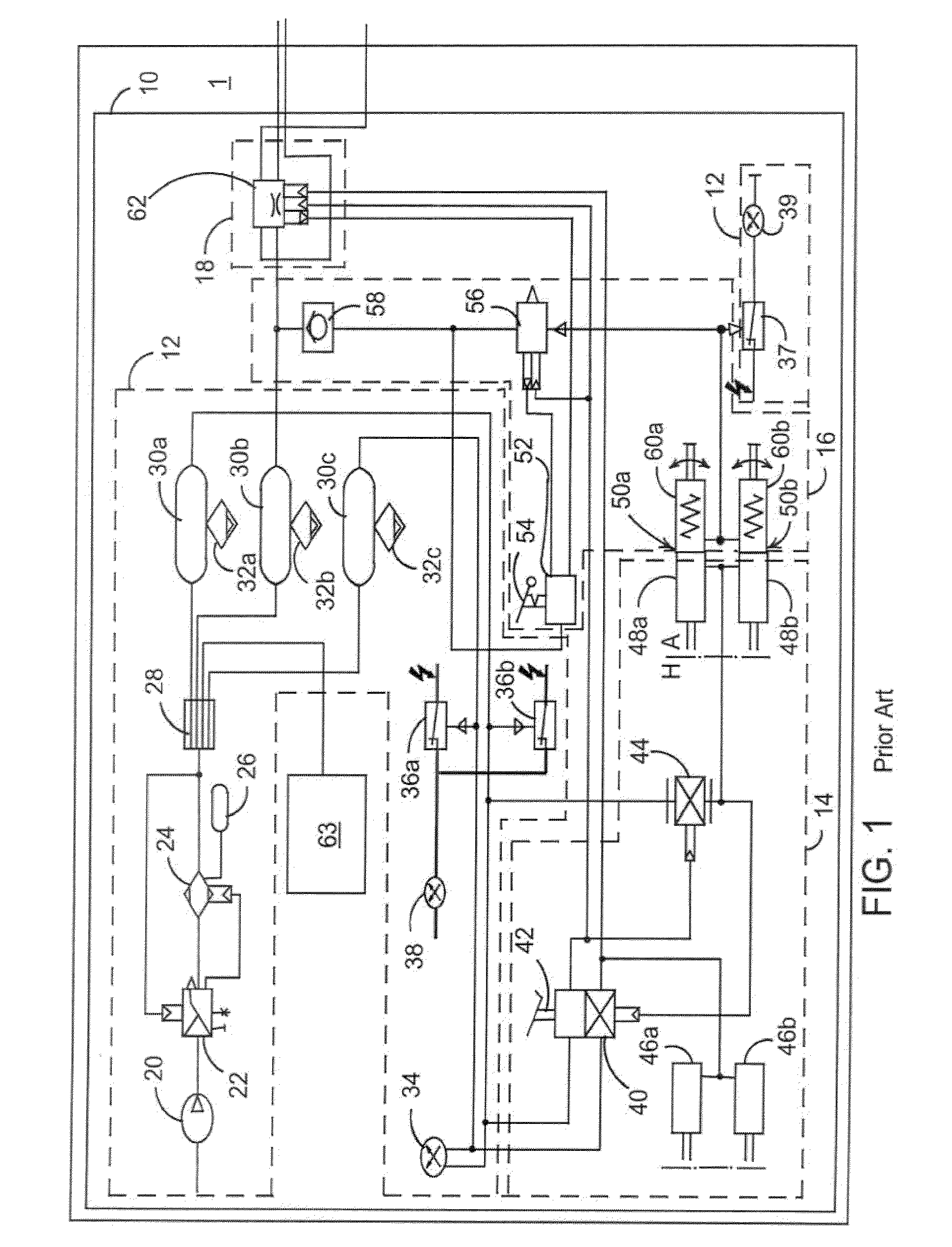

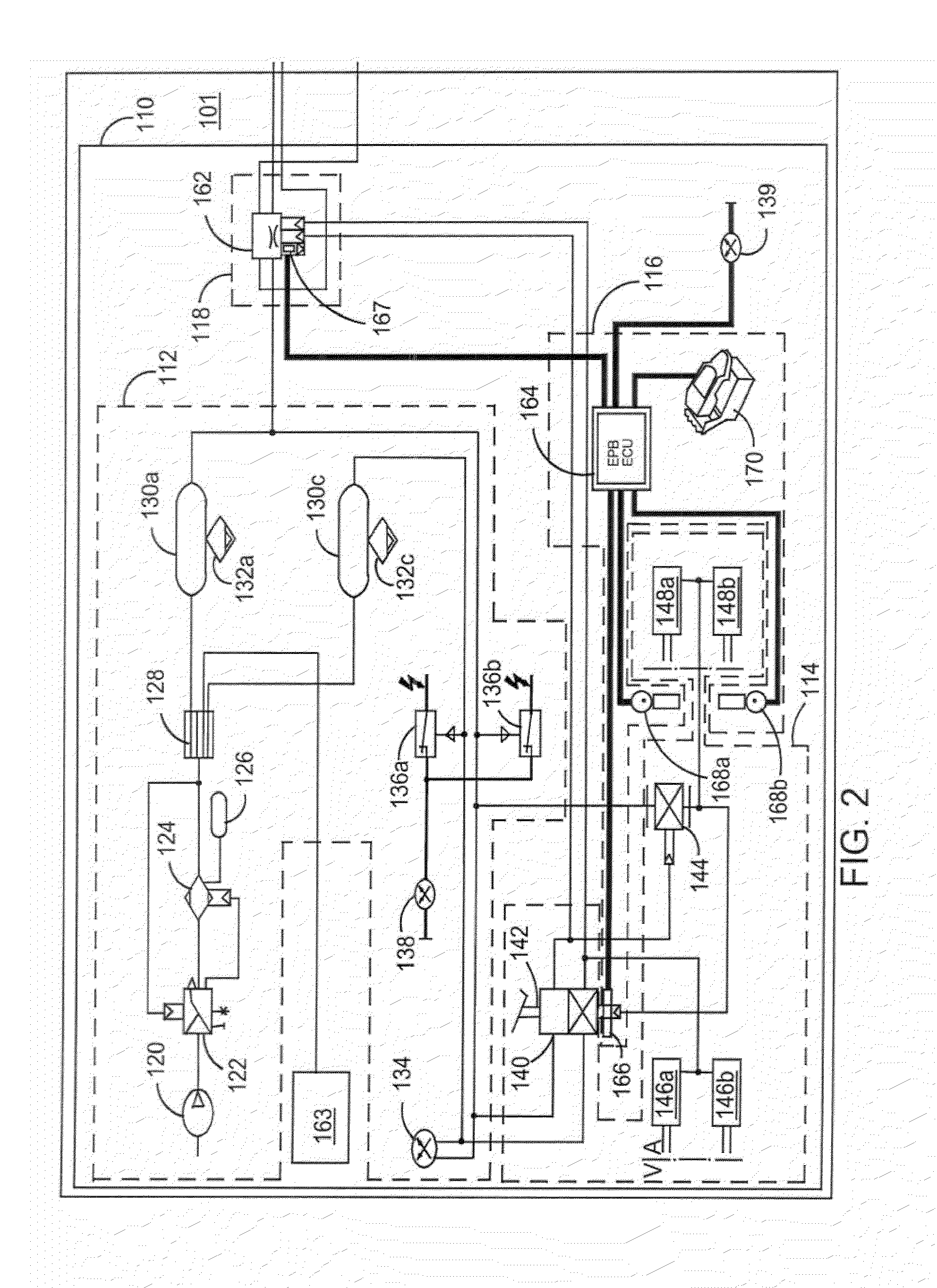

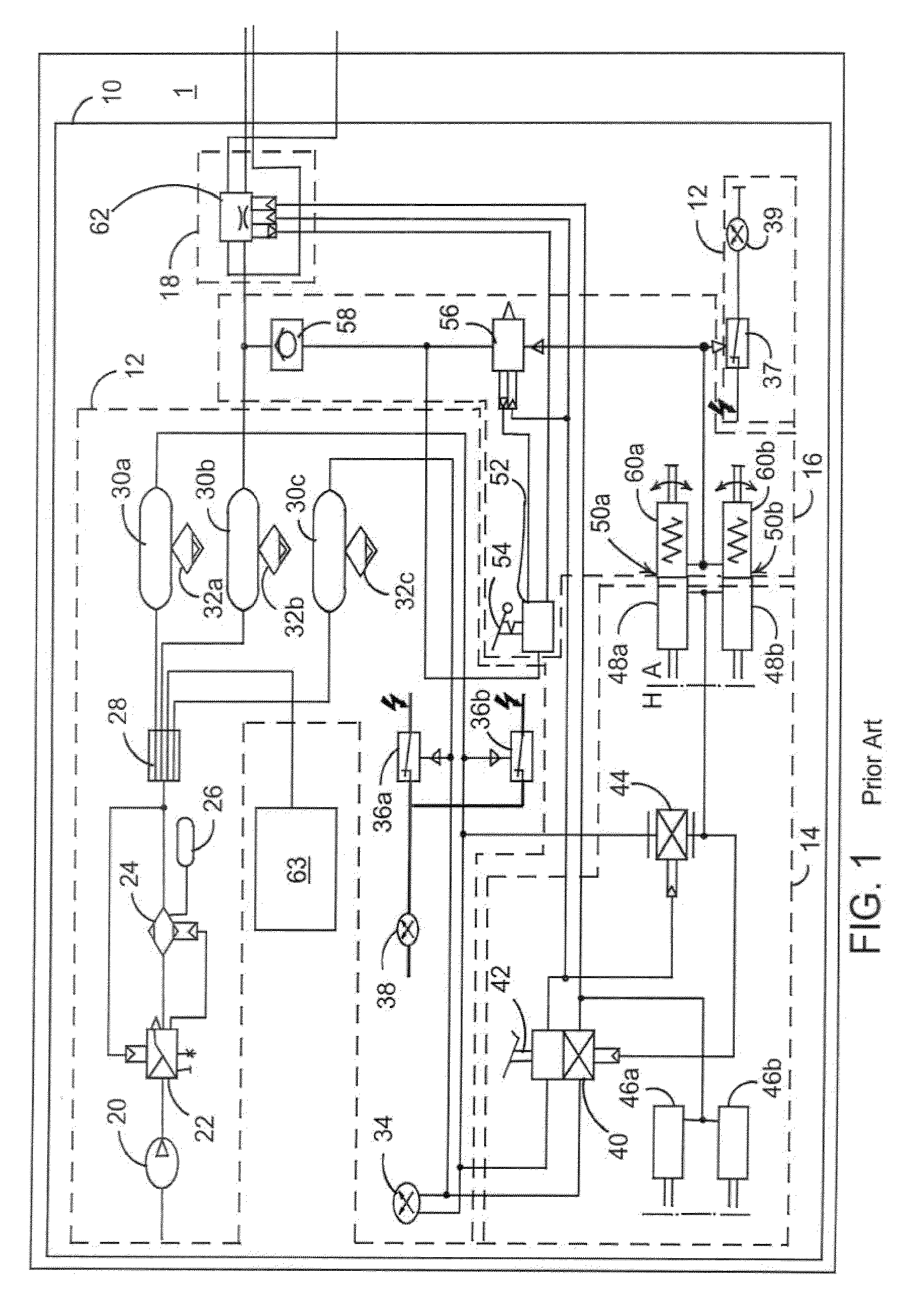

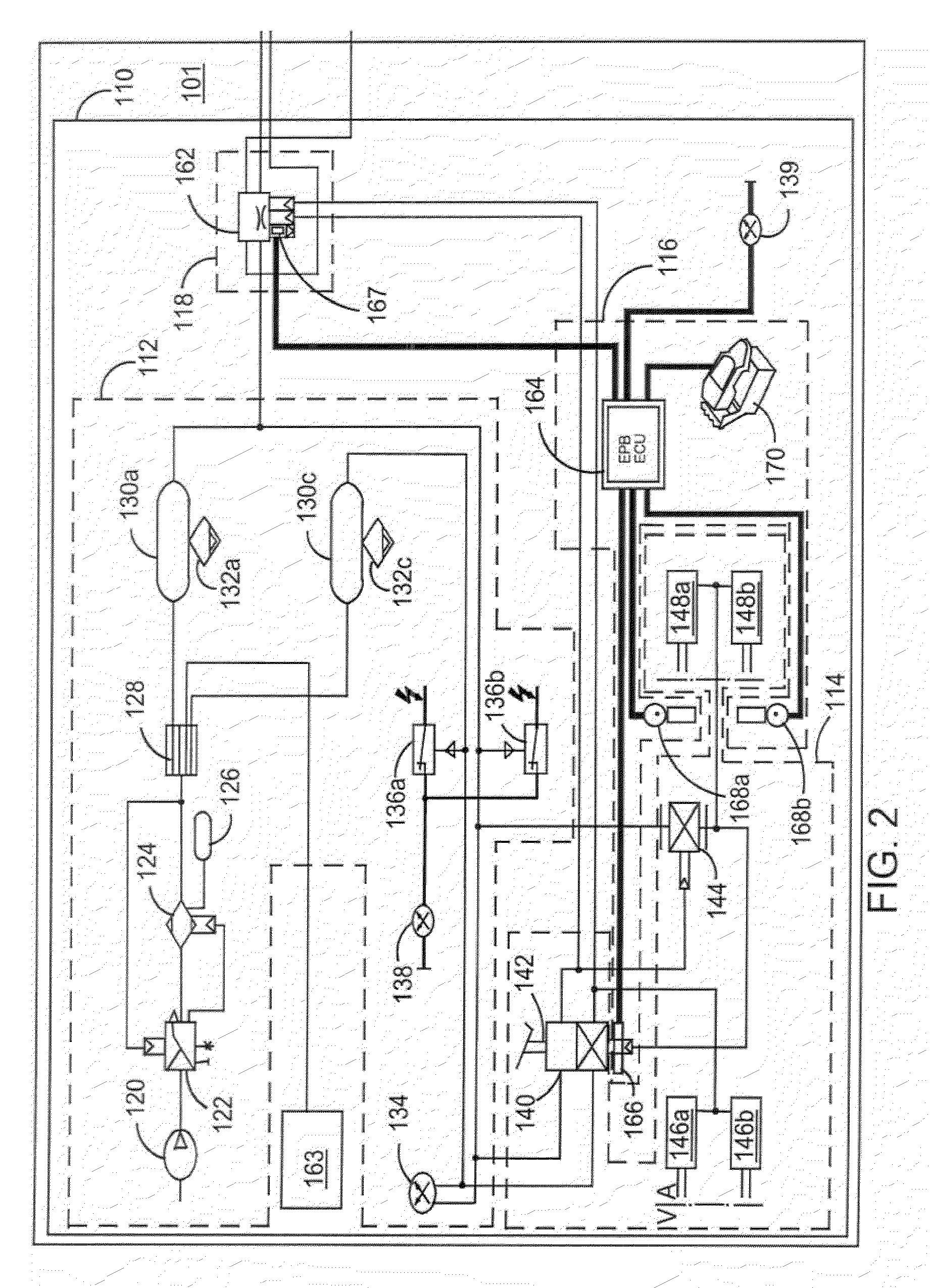

Brake system and method

ActiveUS20090195058A1Solve insufficient braking forceBraking action transmissionAutomatic initiationsActuatorParking brake

An electromechanical parking brake system for a heavy vehicle braked by air-actuated service brakes includes an EPB-ECU and a first electromechanical parking brake actuator controlled by the EPB-ECU. The electromechanical parking brake system further includes a redundant sub-system for applying a second parking brake in an event of a failure in the EPB-ECU or the first electromechanical parking brake actuator.

Owner:MERITOR HEAVY VEHICLE BRAKING SYST (UK) LTD

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

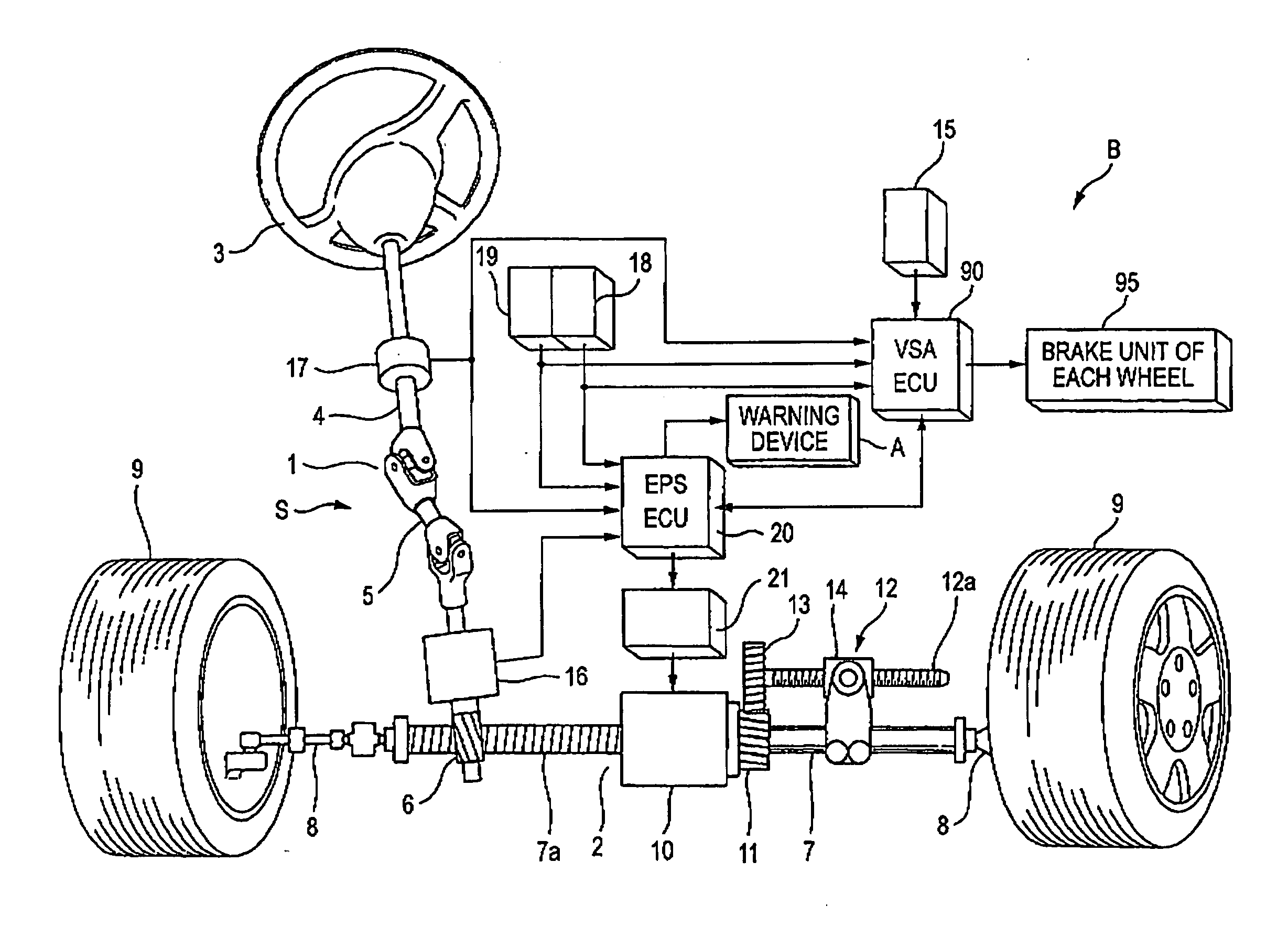

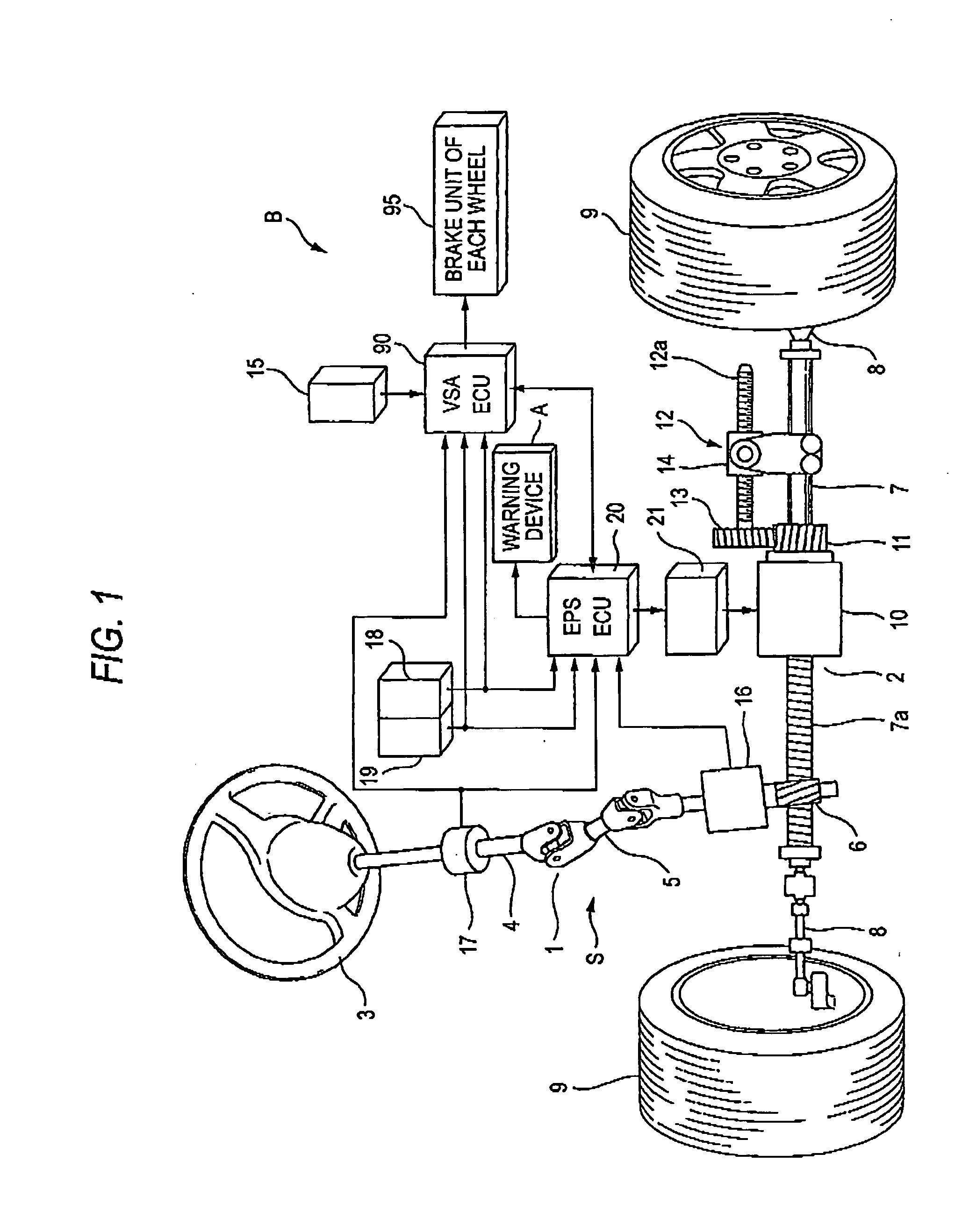

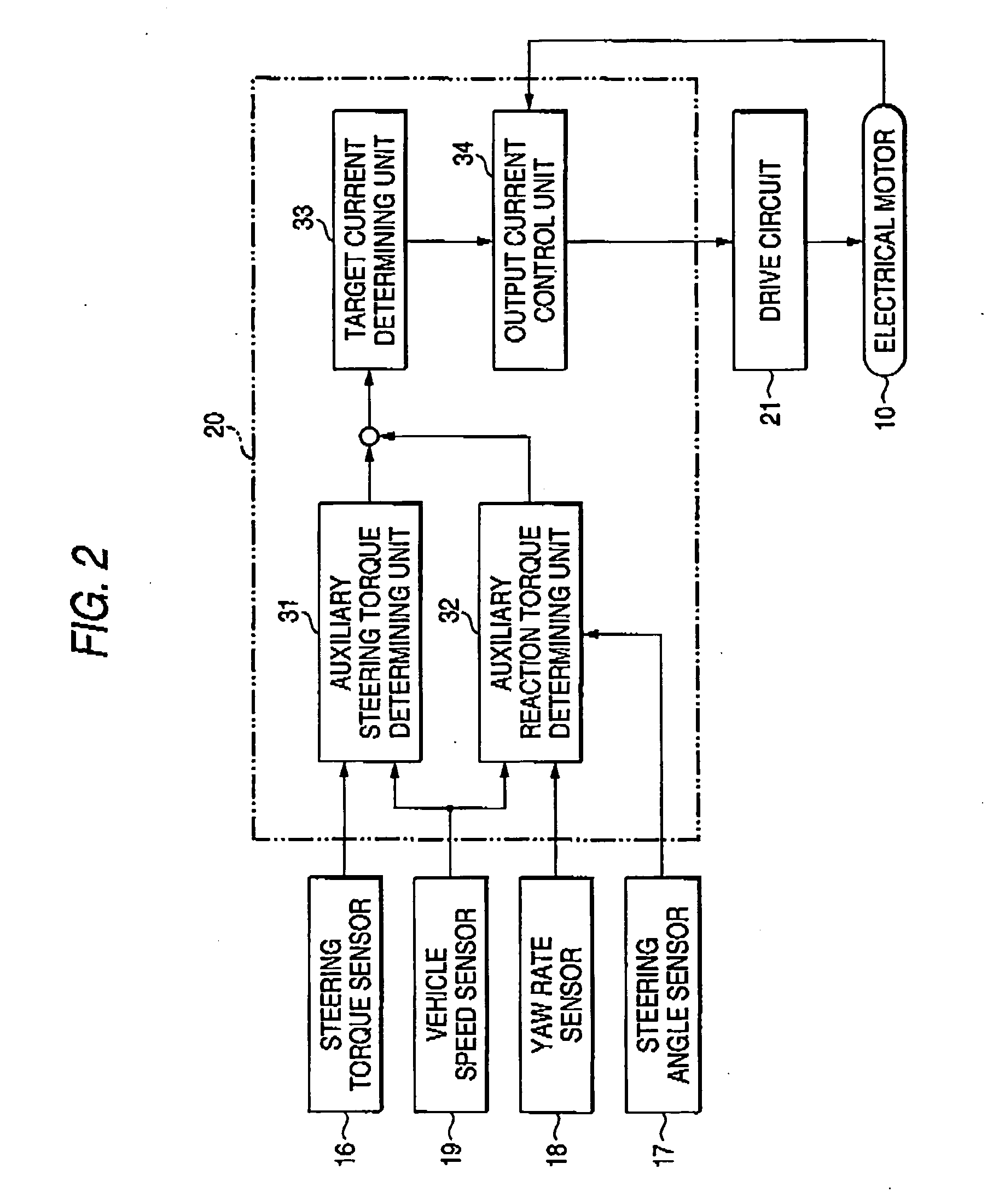

Understeer suppressing apparatus for vehicle

InactiveUS20060208564A1Improve understeer stateDegree of understeer is rather increasedBrake system interactionsDigital data processing detailsElectric power steeringLow speed

An understeer suppressing apparatus for a vehicle includes an electric power steering device S for suppressing steering when the vehicle is in the understeer state, an alarm device A for informing a driver that the vehicle is in the understeer state, and a braking force distribution device B for generating moment of the vehicle by applying braking forces different from each other to the left and right wheels. As the degree of understeer is increased, the electric power steering device S, the alarm device A, and the braking force distribution device B are operated in this order.

Owner:HONDA MOTOR CO LTD

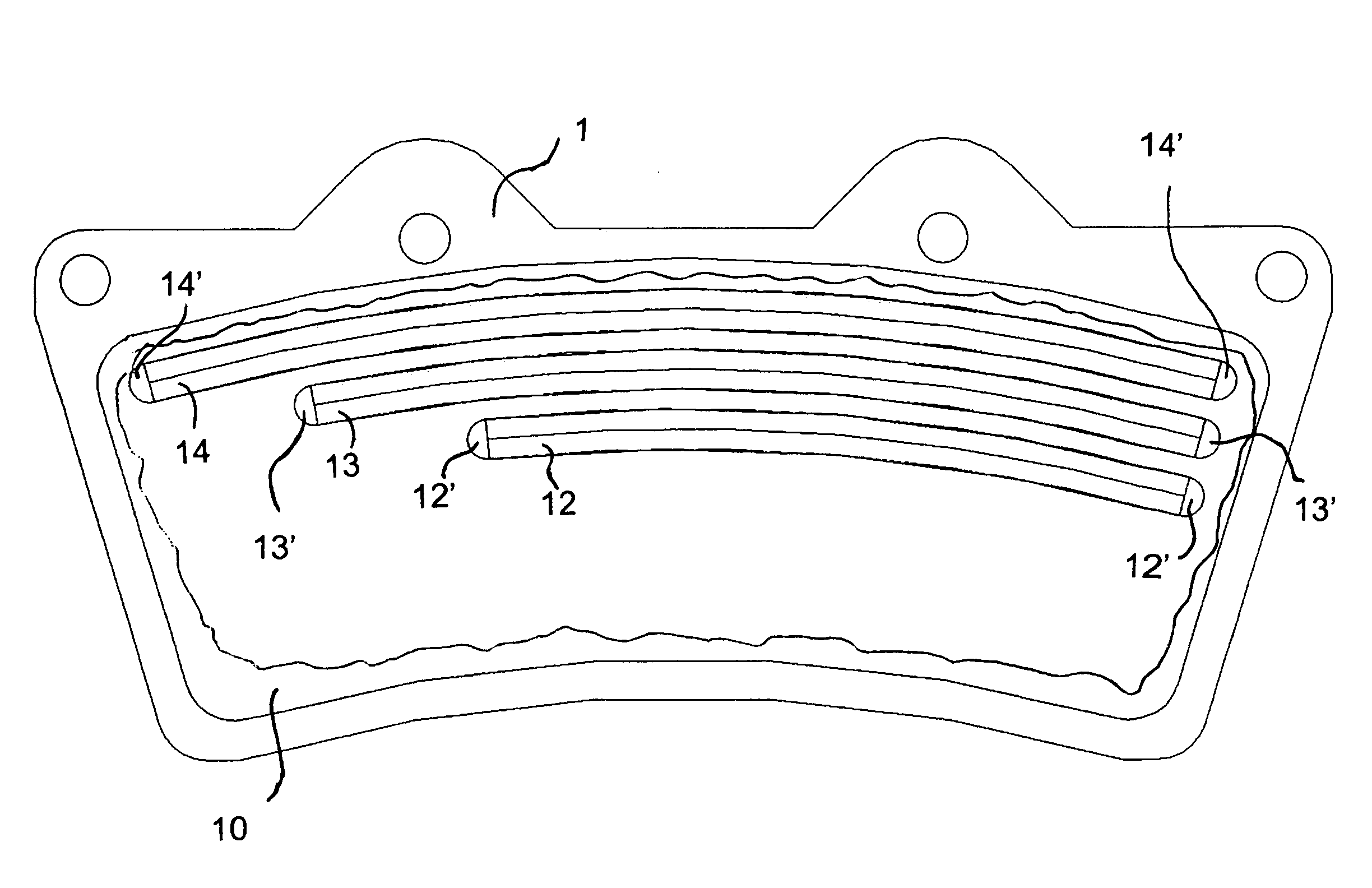

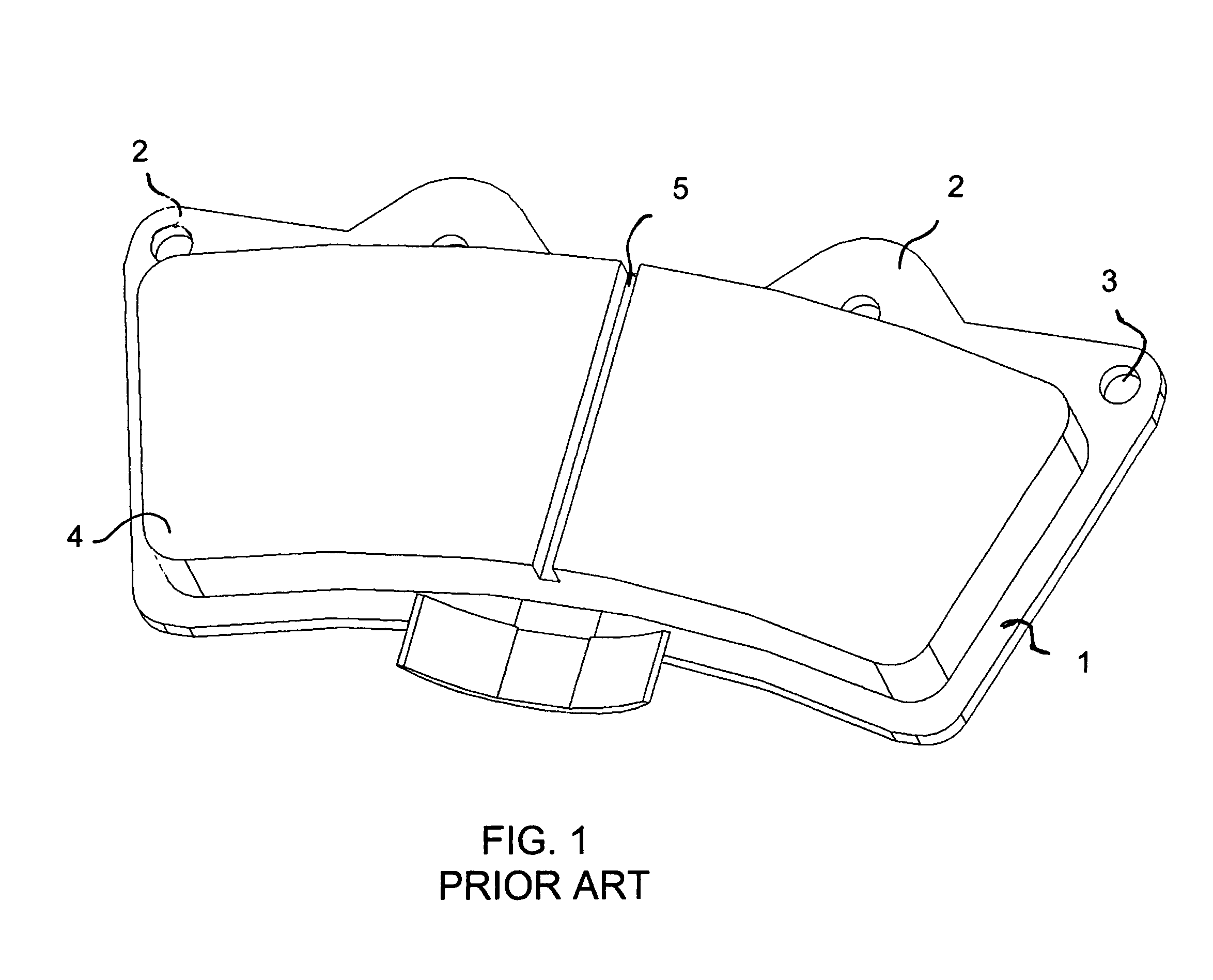

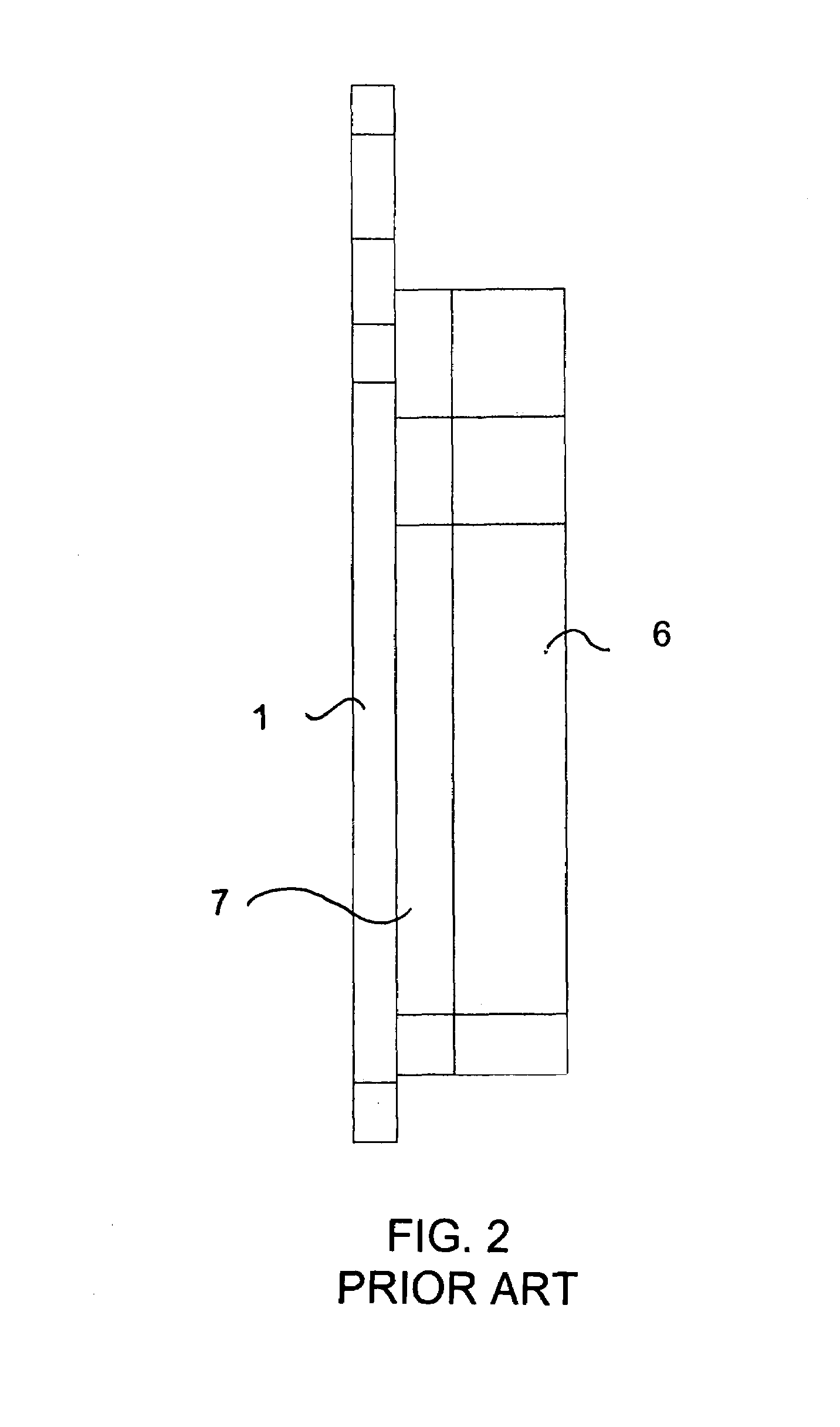

Brake pad with wear indicator

InactiveUS7424936B2Simple and reliable and effectiveBrake typesFriction liningMechanical engineeringBrake pad

A brake pad includes a backing plate and a friction material layer attached to the backing plate. At least one inner layer is disposed within the friction material layer. The inner layer has a color different than the friction material layer.

Owner:MCCLELLAN WILLIAM THOMAS

Brake Pad Prognosis System

A method for providing an estimate of brake pad thickness. The method employs fusion of sensors, if used, and driver brake modeling to predict the vehicle brake pad life. An algorithm is employed that uses various inputs, such as brake pad friction material properties, brake pad cooling rate, brake temperature, vehicle mass, road grade, weight distribution, brake pressure, brake energy, braking power, etc. to provide the estimation. The method calculates brake work using total work minus losses, such as aerodynamic drag resistance, engine braking and / or braking power as braking torque times velocity divided by rolling resistance to determine the brake rotor and lining temperature. The method then uses the brake temperature to determine the brake pad wear, where the wear is accumulated for each braking event. A brake pad sensor can be included to provide one or more indications of brake pad thickness from which the estimation can be revised.

Owner:GM GLOBAL TECH OPERATIONS LLC

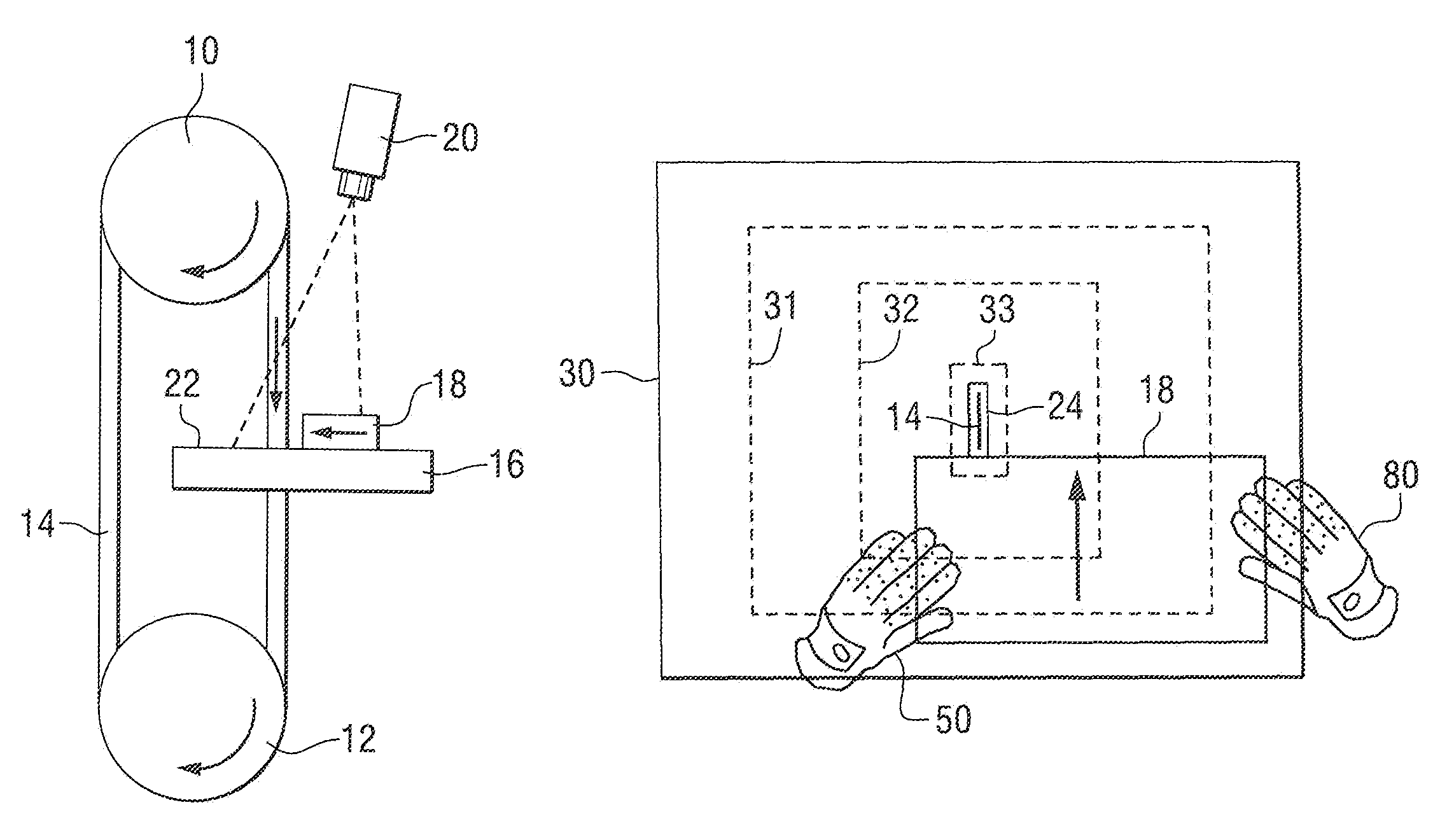

Method for sensing the presence of a human body part within a region of a machine tool

A detection system senses the location of a preselected color within one or more monitored zones of a machine tool. If the operator of a machine tool wears a red glove, the system detects the location of the color red and defines various monitored zones through the use of synchronization signals and a time circuit. The system can take action based on the location of the particular monitored zones in which the red glove is sensed. These actions can include the sounding of a horn, the lighting of a light, or the deactivation of the machine tool.

Owner:BRUNSWICK CORPORATION

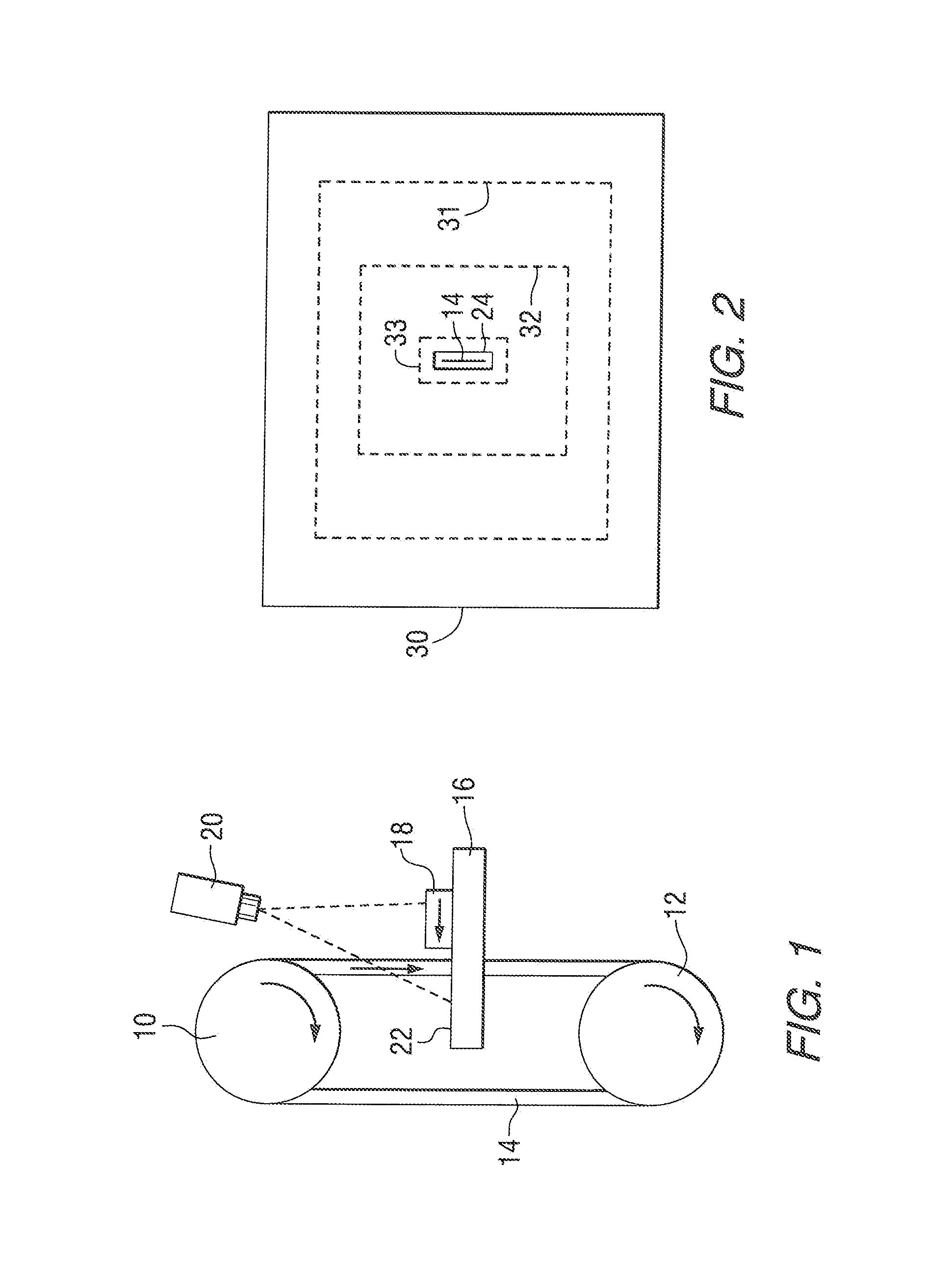

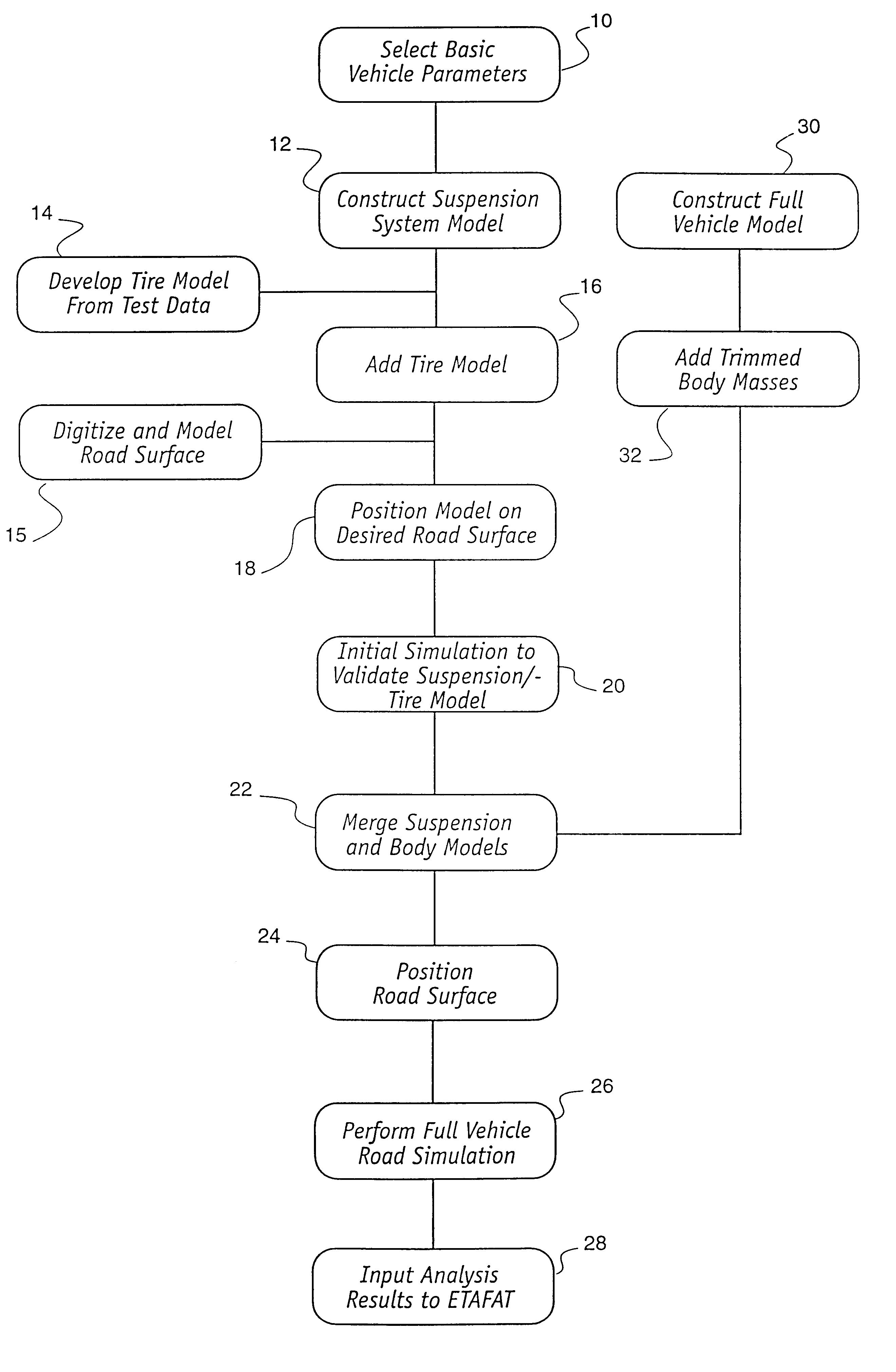

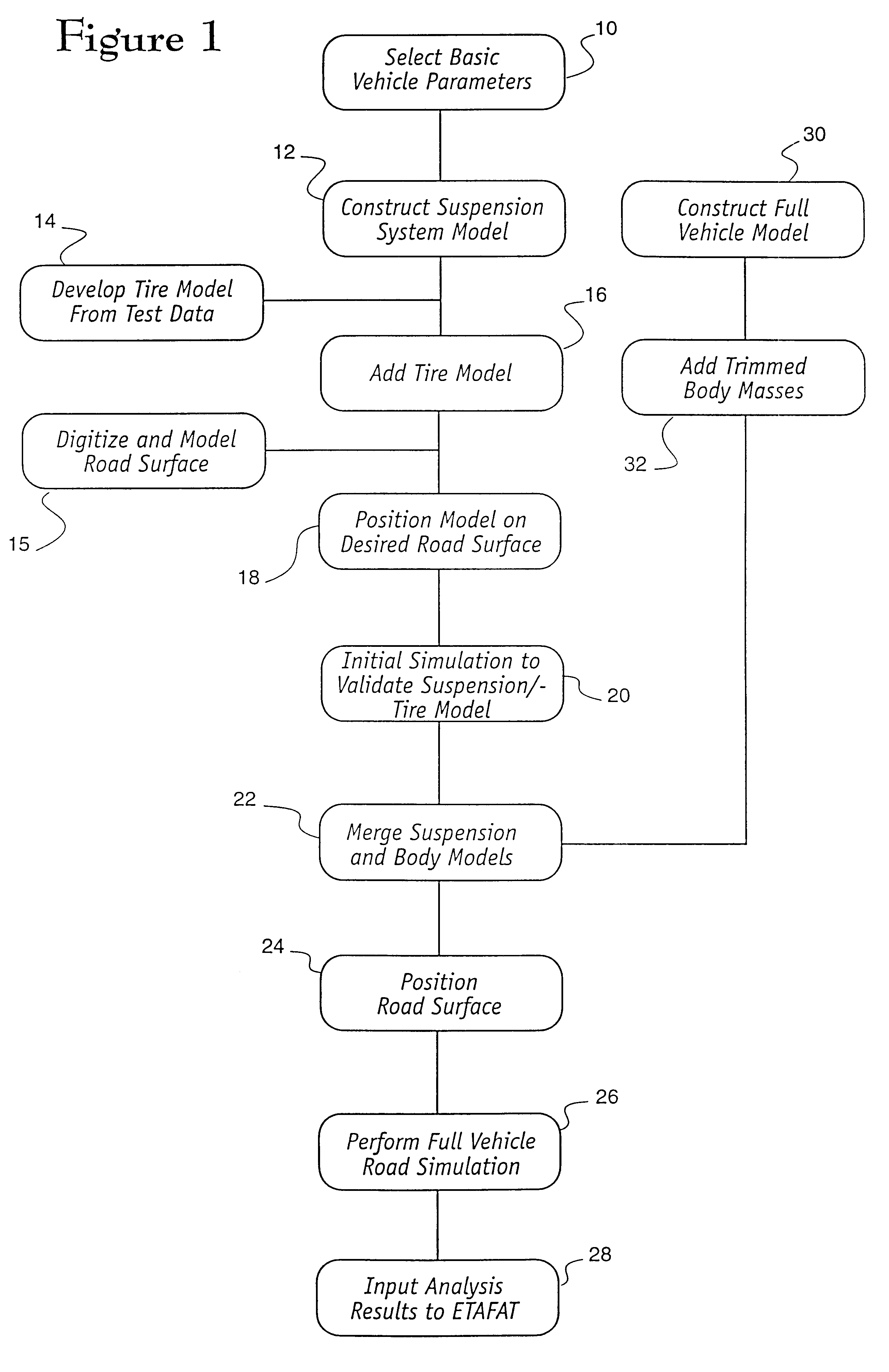

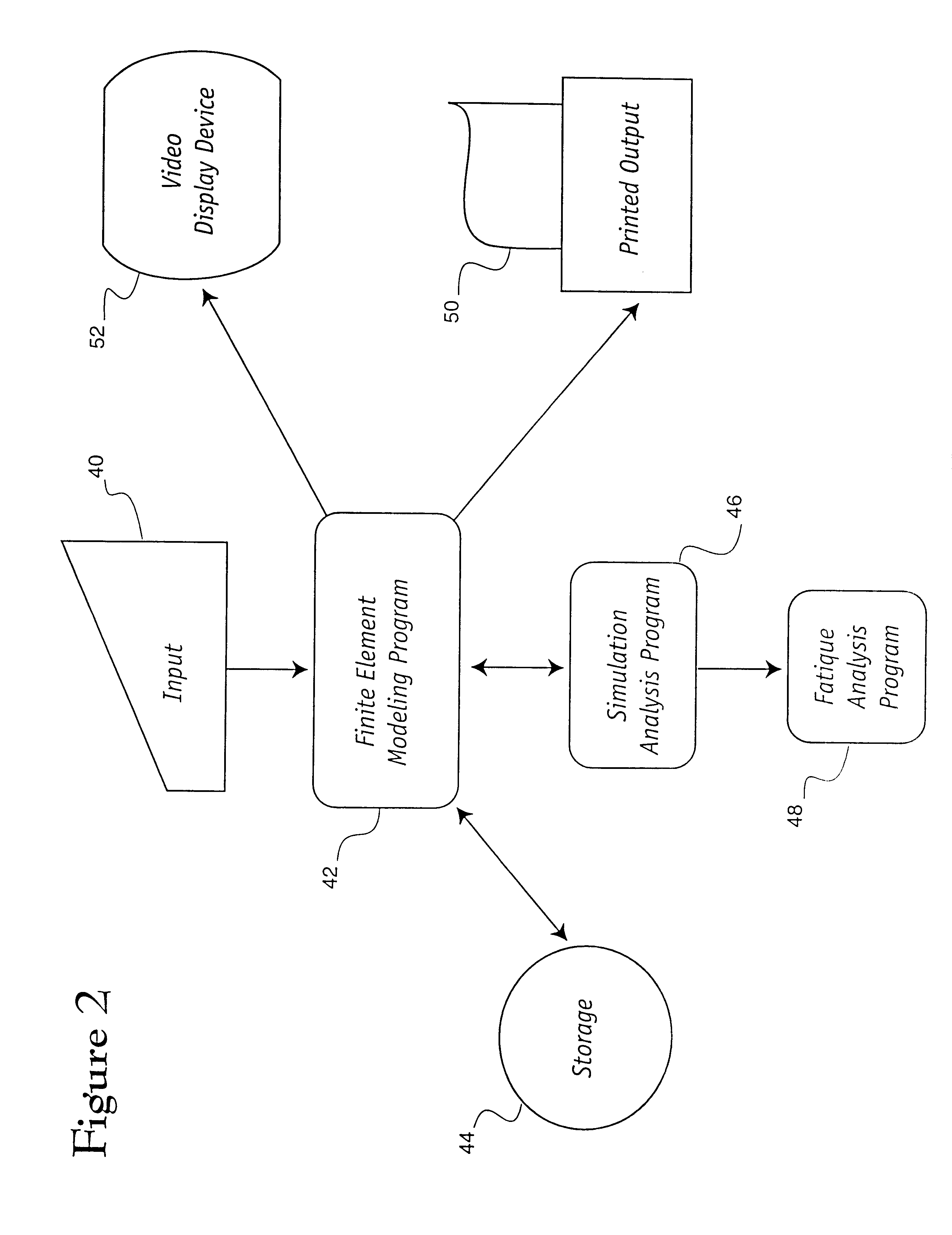

Method and system for simulating vehicle and roadway interaction

The present invention is directed to a system and method for simulating the interaction of a simulated vehicle with one or more simulated road surfaces. A computer modelling program is used to create a computer-based road surface model and a computer-based vehicle model. The computer-based vehicle model may include a body model, a chassis model, a suspension model, a wheel model and a tire model. A computer simulation engine program is operative with the computer-based road surface and vehicle models to selectively simulate the interaction therebetween and provide simulation data relative thereto. The simulation data may be used to identify high stress areas or low durability areas of the vehicle or to compute vehicle suspension parameters.

Owner:ENG TECH ASSOC

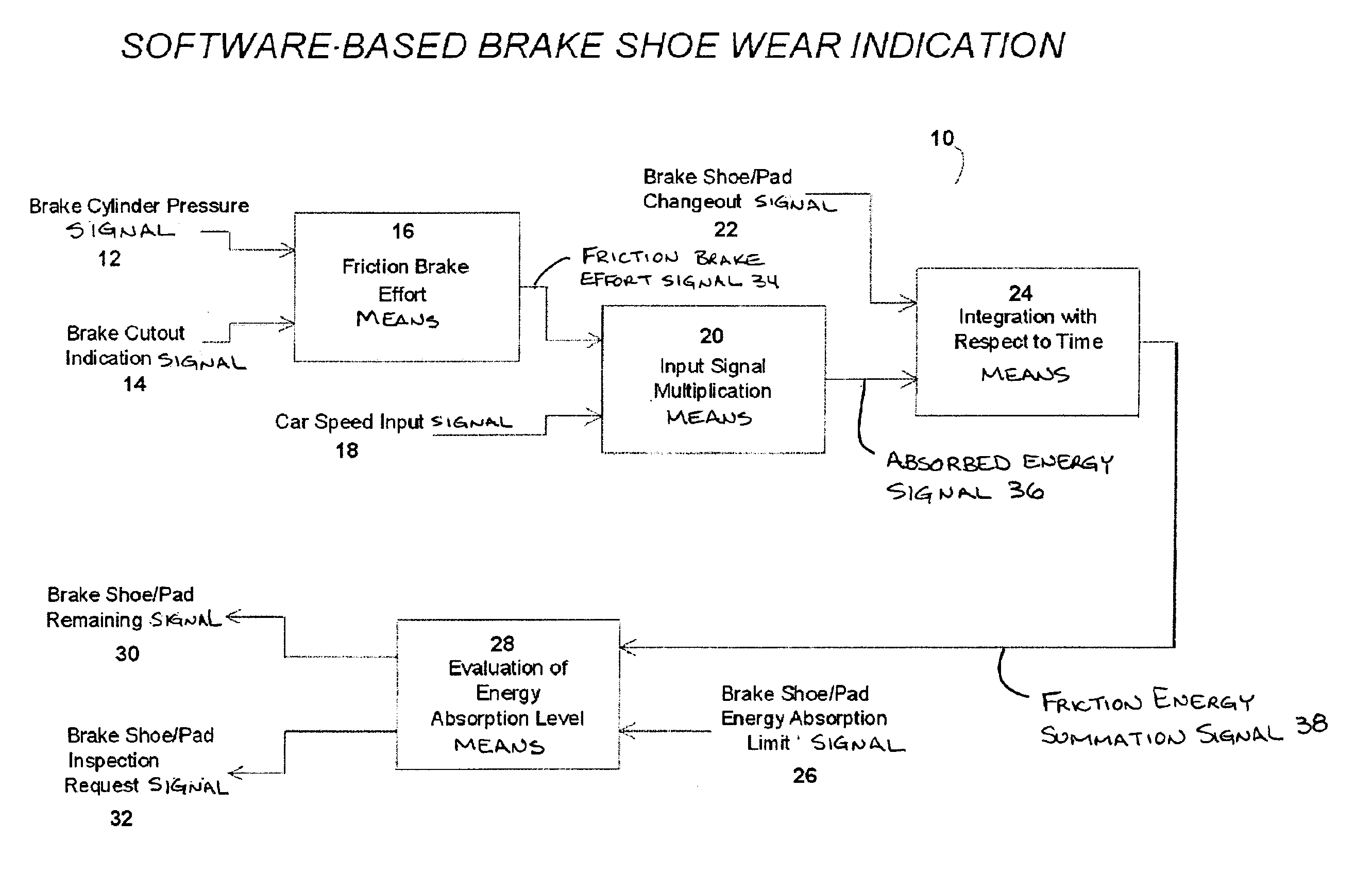

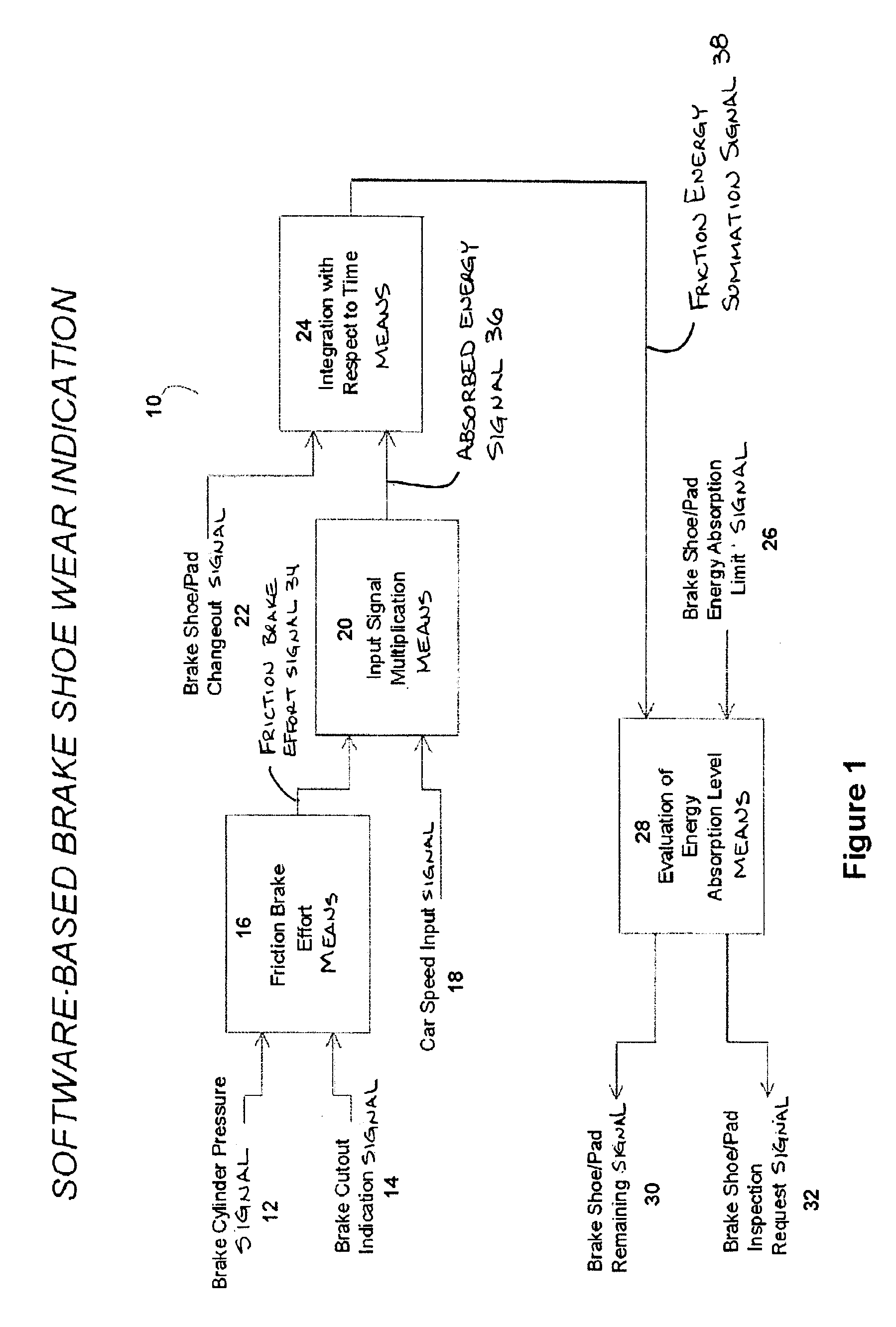

Software based brake shoe wear determination

InactiveUS6847869B2Reduce harmReduce amount of friction brake effort suppliedVehicle testingRegistering/indicating working of vehiclesEngineeringEnergy supply

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

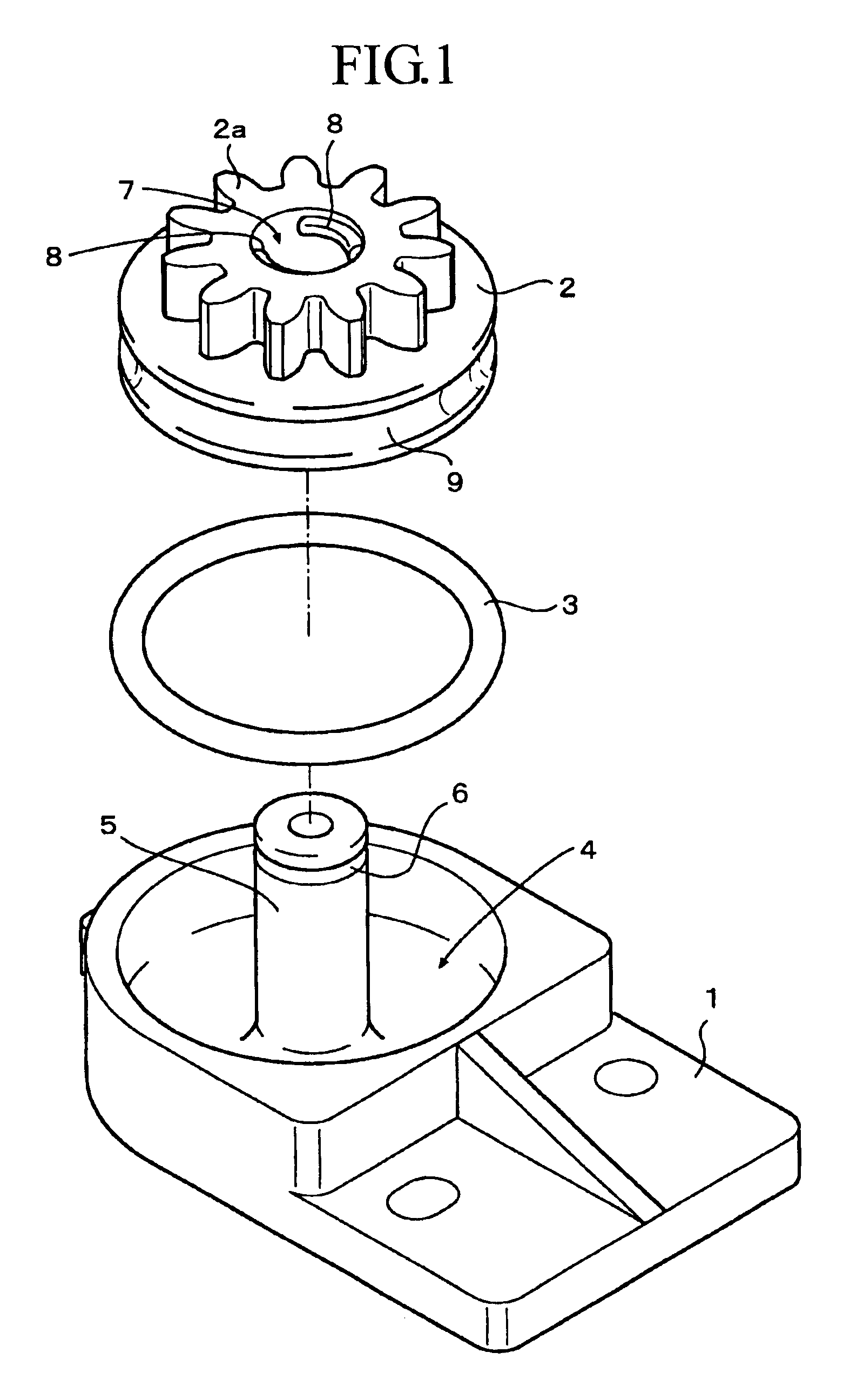

Rotary damper

InactiveUS6840353B2Small in friction coefficientSpringsAutomatic initiationsHOLDING CHAMBERBrake force

A rotary damper includes a housing (1) that has a holding chamber (4), a rotor (2) integral with a gear (2a) disposed rotatably in the holding chamber (4) of the housing (1), and a braking member (3) for controlling the rotation of the rotor (2). The braking member (3) is interposed between the outer periphery of the rotor (2) and the inner periphery the holding chamber (4). A supporting shaft (5) is erected on the bottom part of the holding chamber (4) of the housing (1). A through-hole (7) is bored in the rotor for permitting insertion therein of the supporting shaft (5) in the axial direction of the rotor (2). The rotor (2) is supported through the supporting shaft (5) and the through-hole (7). With this configuration, a stabilized braking force is constantly provided because the rotor (2) does not incline it is being rotated.

Owner:PIOLAX CO LTD

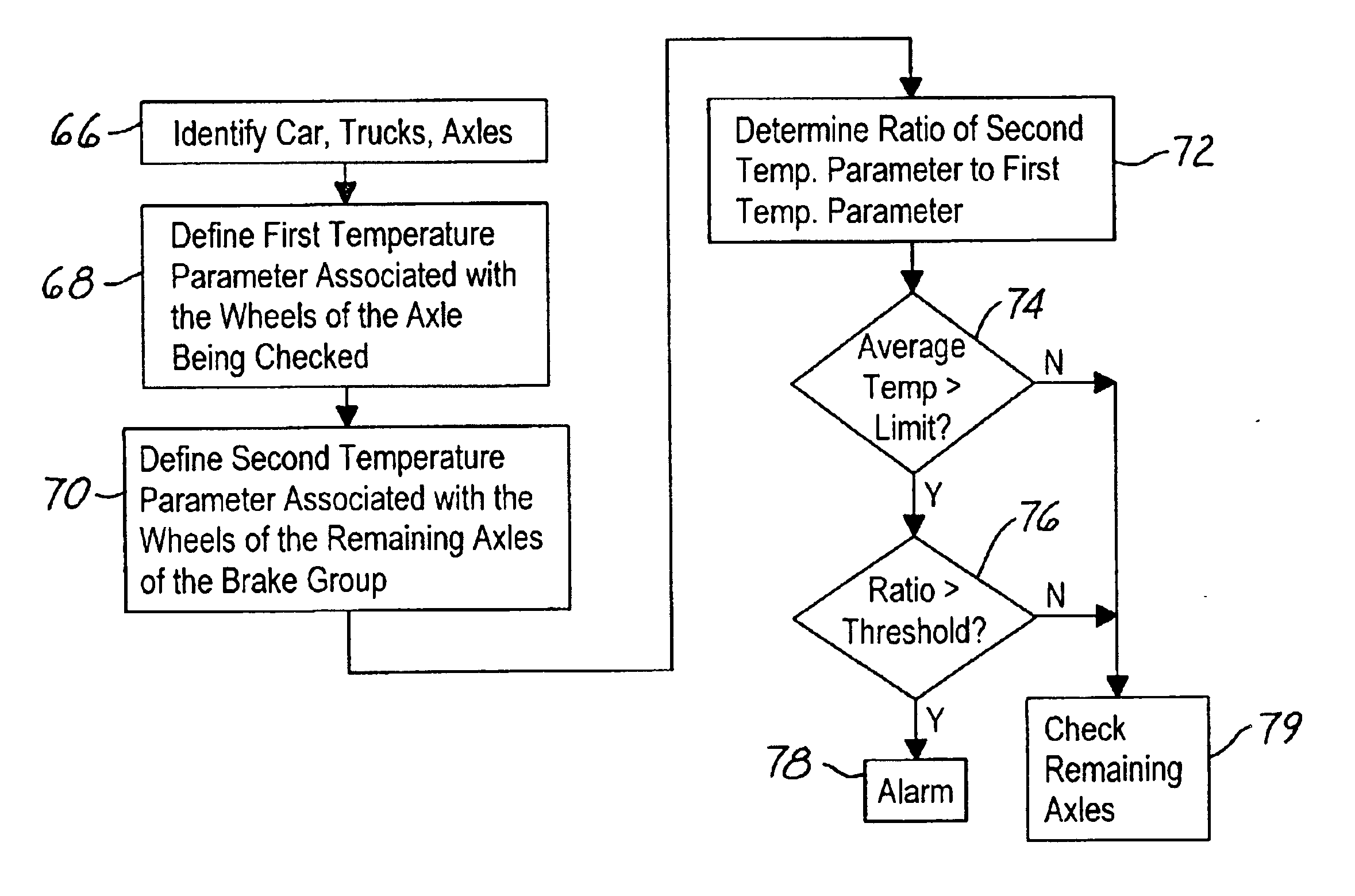

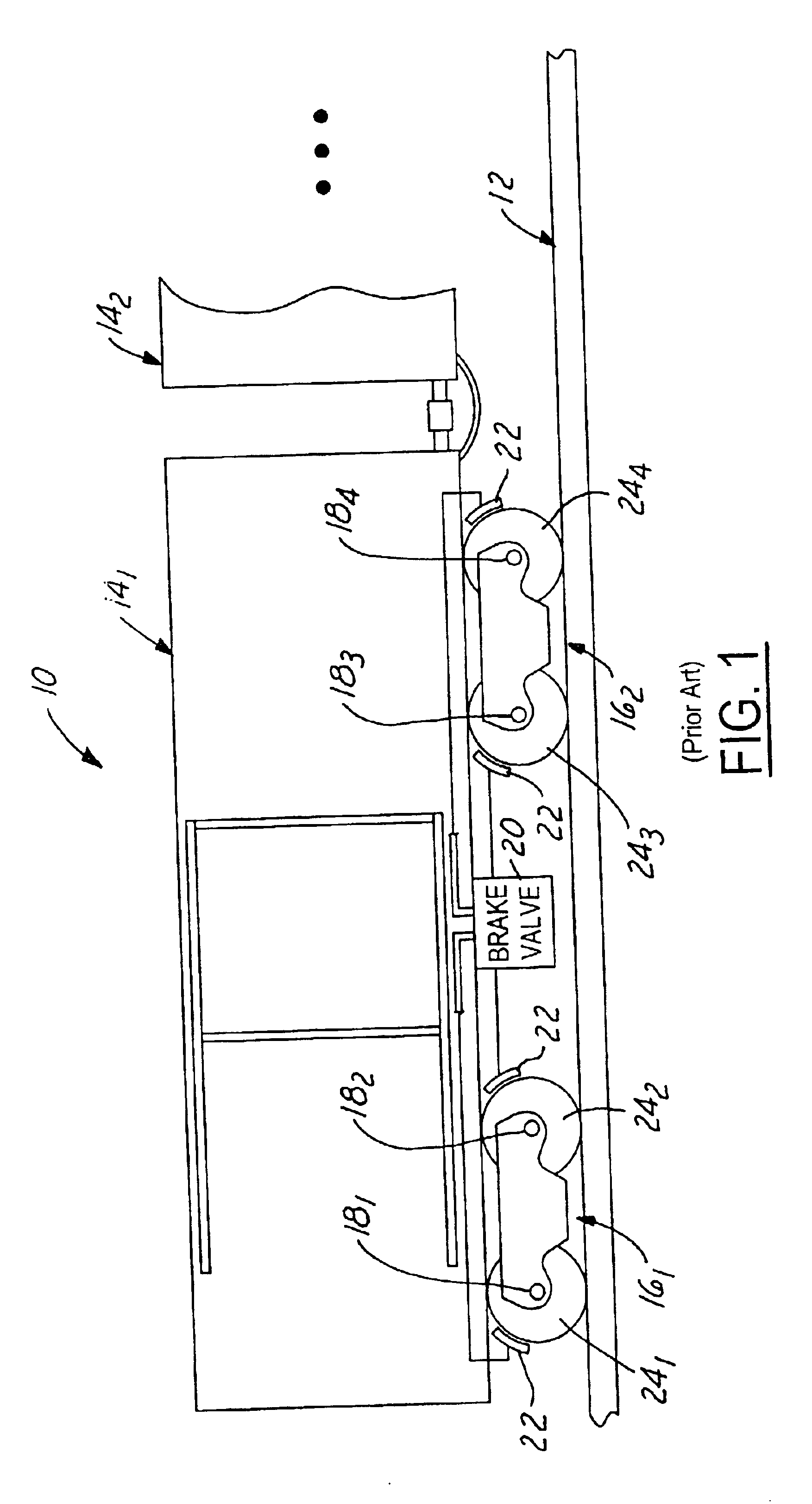

Method and apparatus for monitoring wheel/brake performance

A sliding wheel detector apparatus automatically detects a sliding wheel condition of a wheel of a passing train. The apparatus includes means for parsing the cars (and trucks thereof) and segregating the same into brake valve groupings. The apparatus also includes means for determining a ratio between a wheel being evaluated and the rest of the wheels in a brake valve group. A sliding wheel will be much cooler than a properly braking wheel, and a ratio threshold is selected to detect this difference in temperature and produce an alarm.

Owner:NORFOLK SOUTHERN

Brake system and method

ActiveUS20090198427A1Solve insufficient braking forceAnalogue computers for trafficBraking action transmissionVolume estimationWeight estimation

A system configured to estimate a change in temperature of a brake component of a vehicle brake during a braking operation. The system includes a weight estimation module for estimating a weight of a vehicle to which a brake is fitted, a volume estimation module for estimating a volume of a brake component, a temperature model module for calculating a change in temperature during brake application based on a relationship between the weight of the vehicle as estimated by the weight estimation module, the volume of the brake component as estimated by the volume estimation module, the deceleration of the vehicle, and further constants of the vehicle and / or the brake.

Owner:MERITOR HEAVY VEHICLE BRAKING SYST (UK) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com