Cold forging processing method of hardened and tempered structural steel

A processing method and technology of structural steel, applied in the field of steel cold forging, can solve problems such as incomplete metal streamlines, poor mechanical properties of parts, and influence on use safety, and achieve the effects of reducing dependence, improving fatigue strength, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

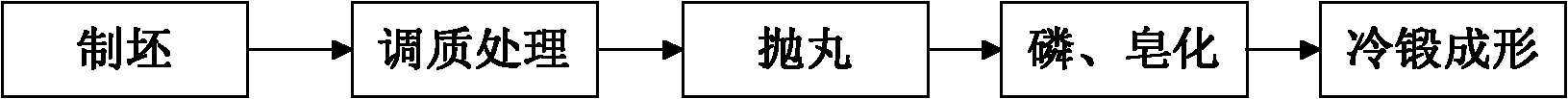

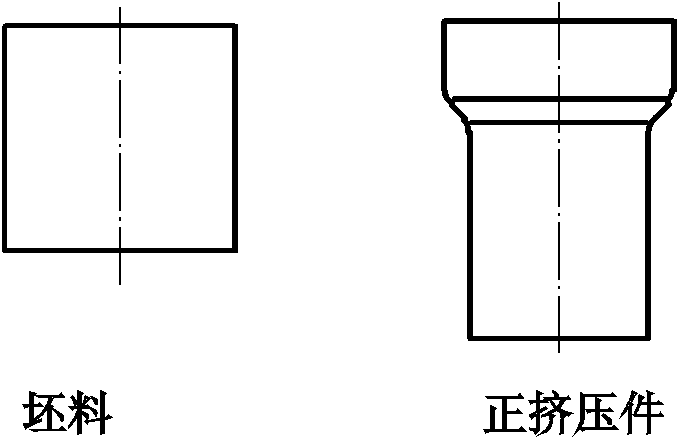

[0028] Taking the forming process of positive extrusion parts as an example, the process flow is:

[0029] 1. For billet making, choose a hot-rolled round bar with a diameter of φ30.0mm, the material grade is 40Cr, and cut it by sawing, and the cutting length is controlled at 29.9-30.1mm.

[0030] 2. Quenching and tempering. According to the performance requirements of forged extrusion parts, the quenching and tempering process is as follows: heating to 850°C for quenching, then tempering at 580°C, holding for 2 hours and then leaving the furnace for air cooling.

[0031] 3. Conventional shot blasting process.

[0032] 4. Conventional phosphorus saponification process.

[0033] 5. Cold forging is formed by cold extrusion through a positive extrusion die. The diameter of the extruded part is φ20.0 mm, and the degree of deformation is about 55.6%.

[0034] The metal streamlines of the obtained positive extrusion are continuously distributed, and there is no defect of center bu...

Embodiment 2

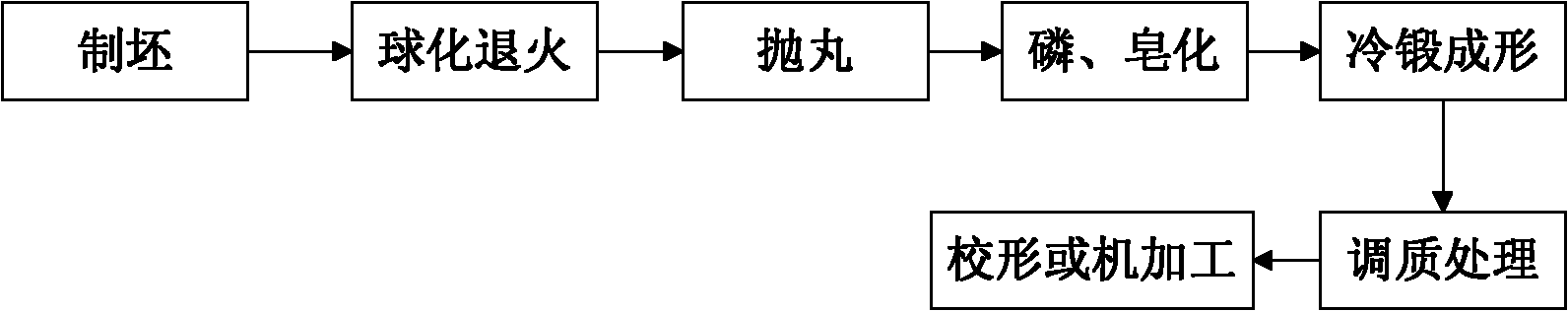

[0036] Taking the forming process of reverse extrusion parts as an example, the process flow is as follows:

[0037] 1. For billet making, choose a hot-rolled round bar with a diameter of φ25.0mm, the material grade is 40Cr, and cut it by sawing, and the cutting length is controlled at 24.9-25.1mm.

[0038] 2. Quenching and tempering. According to the performance requirements of forged extrusions, the quenching and tempering process is as follows: heating to 850°C for quenching, and then tempering at 630°C. After holding for 2 hours, it is out of the furnace and air-cooled.

[0039] 3. Conventional shot blasting process.

[0040] 4. Conventional phosphorus saponification process.

[0041] 5. Cold forging is formed by cold extrusion through a reverse extrusion die. The diameter of the inner hole of the reverse extrusion is φ15.8 mm, the bottom thickness is 10.0 mm, and the degree of deformation is about 40.0%.

[0042] The metal streamlines of the obtained back-extruded part ...

Embodiment 3

[0044] Take the forming process of an automobile hub locking sleeve as an example. The automotive hub locking sleeve is a functional element used to lock the connection between the hub and the axle. The locking force to be borne reaches 100kN, so there are certain requirements for its strength, that is, small End surface hardness should be in the range of 25HRC ~ 29.5HRC.

[0045] The technological process of the present embodiment is:

[0046] 1. Billet, because there is no pipe material that meets the size specifications, choose a hot-rolled round bar with a diameter of φ50.0mm, the material grade is 20MnMoB, and preformed by sawing, upsetting, reverse extrusion, and thinning and stretching After the process, a tube blank with an inner diameter of φ47.0 mm and an outer diameter of φ57.0 mm is obtained.

[0047] 2. Quenching and tempering. Since the locking sleeve needs to bear a certain locking force when used, there are certain requirements for the hardness of the end face...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com