Multi-step forming reamer

A multi-step, stepped technology, applied in reamers, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in ensuring the surface quality and machining accuracy of stepped holes, unfavorable machining accuracy and surface quality, and poor surface quality of stepped holes. , to reduce the risk of knife breakage, improve the surface quality, and achieve the effect of reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

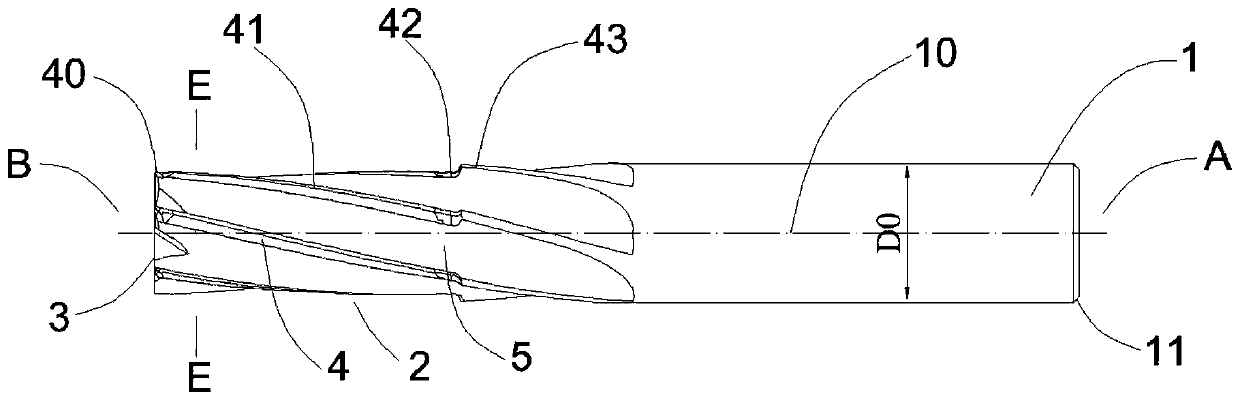

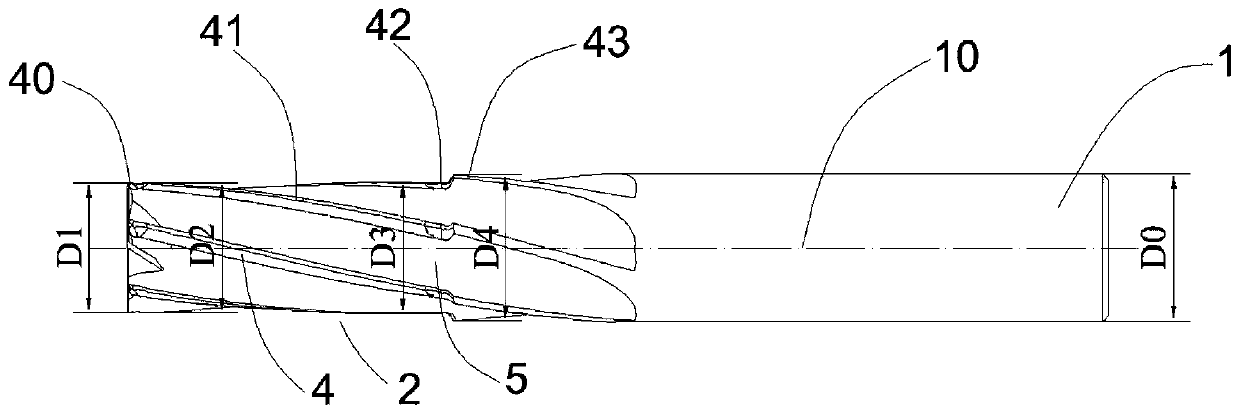

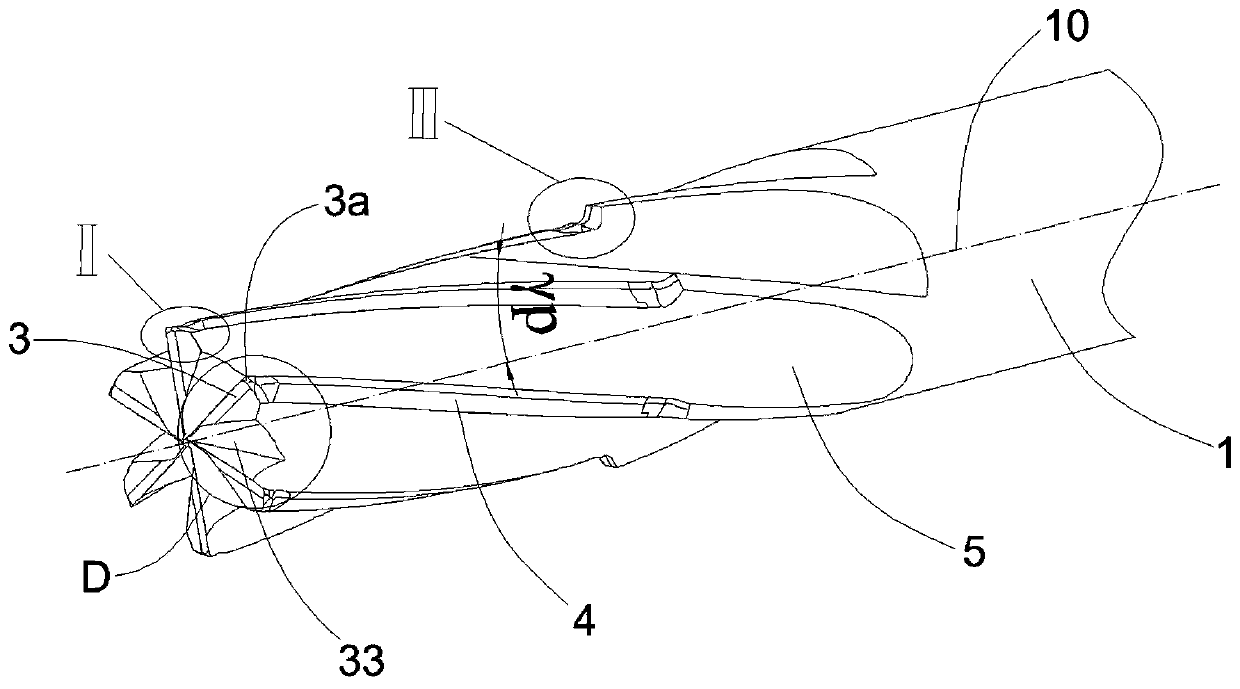

[0050] Such as figure 1As shown, a multi-step forming reamer corresponding to a preferred embodiment of the present invention includes a cylindrical shank 1 and a cutter body 2 connected to the shank 1 , and the shank 1 starts from the first end along the axis 10 A extends to the second end B, and the cutter body 2 is located at the second end B, which is arranged coaxially with the handle 1 . The multi-step forming reamer is preferably made of cemented carbide.

[0051] The shank 1 is used for clamping and fixing the reamer, and the end surface close to the first end A is provided with a shank chamfer 11, which can prevent the inner wall of the collet from being worn when the tool is clamped and affect the clamping accuracy, and its diameter is D0 .

[0052] The cutter body 2 includes a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com