Method for designing crack propagation characteristic simulator of centrifugal impeller central hole

A technology of centrifugal impeller and crack growth, which is applied in computer-aided design, design optimization/simulation, calculation, etc., and can solve problems such as inability to carry out fatigue crack growth tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

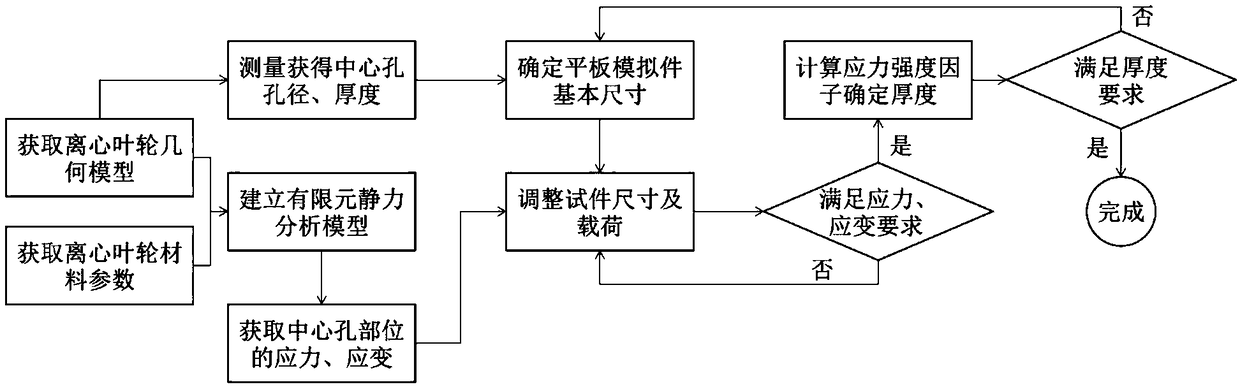

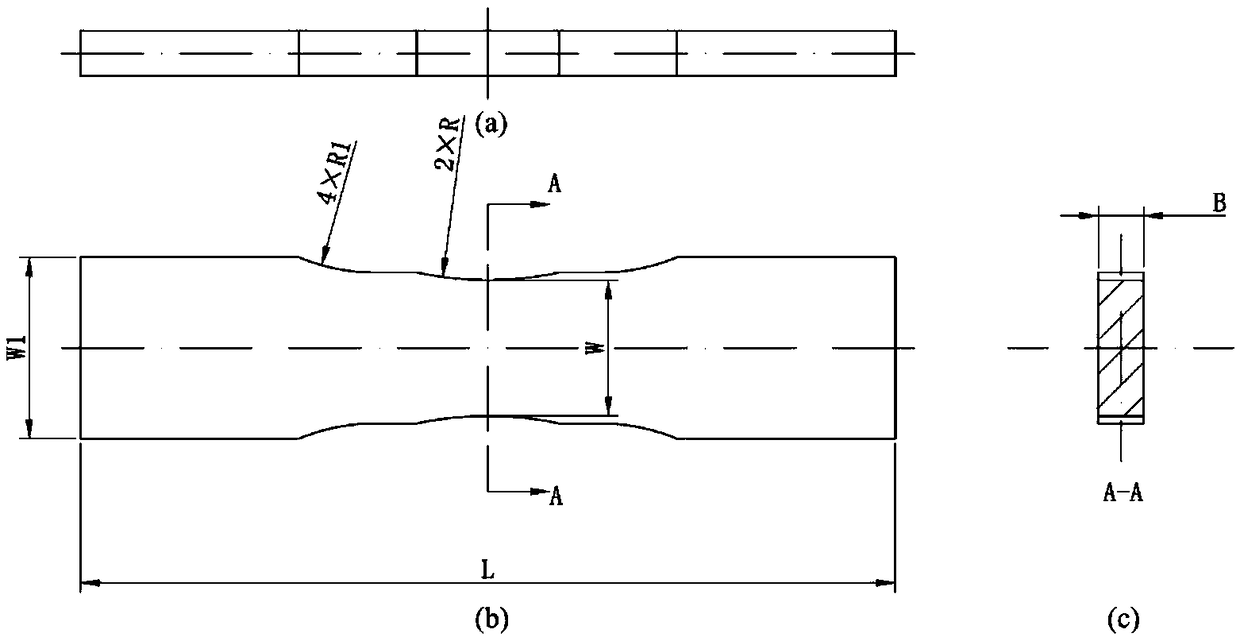

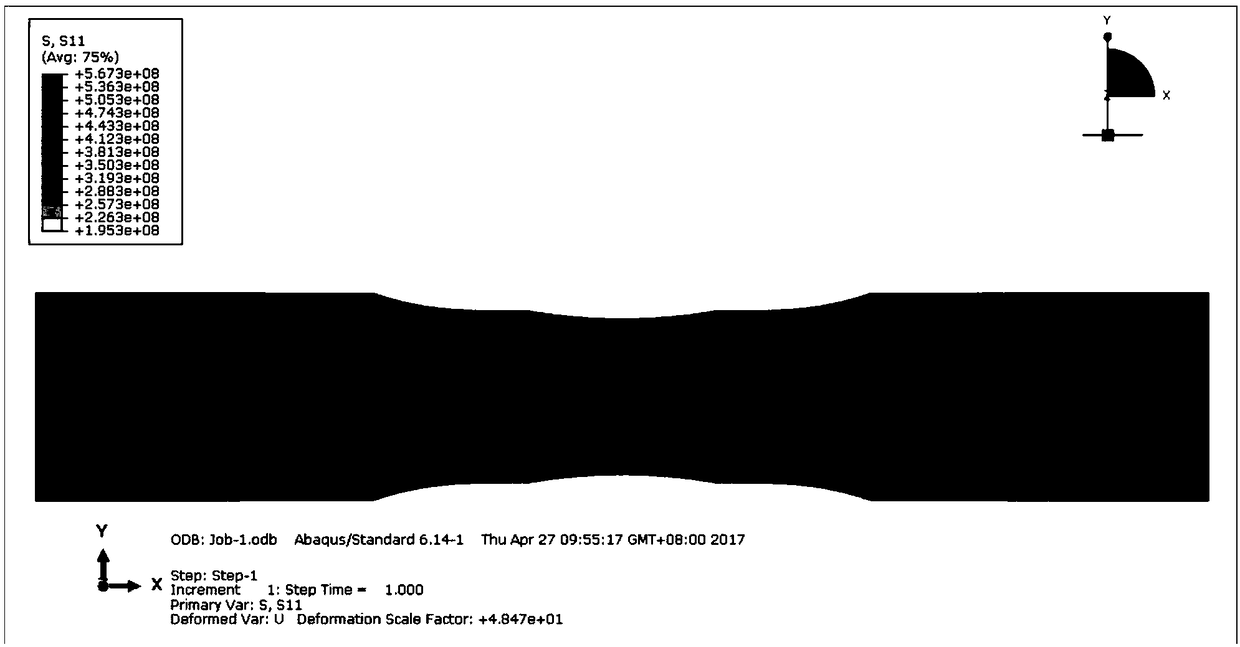

[0029] Embodiment 1, the present invention realizes steps as follows:

[0030] The first step is to obtain the geometric model of the centrifugal impeller, and measure the diameter and thickness of the central hole structure of the centrifugal impeller. The geometric model refers to the three-dimensional geometric model of the centrifugal impeller designed according to actual engineering requirements by means of computer-aided design software; the aperture refers to the diameter of the penetrating circular hole at the center of the centrifugal impeller; the thickness refers to the diameter of the circular hole in the center of the centrifugal impeller. radial thickness. For example, the diameter of the central hole structure of a certain centrifugal impeller is 54mm and the thickness is 48mm.

[0031] The second step is to obtain the working conditions of the centrifugal impeller and the material performance parameters under the working conditions. The operating conditions i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com