A Design Method of Crack Propagation Characteristic Simulation Parts of Centrifugal Impeller Boss

A centrifugal impeller and crack growth technology, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve problems such as inability to perform fatigue crack growth tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

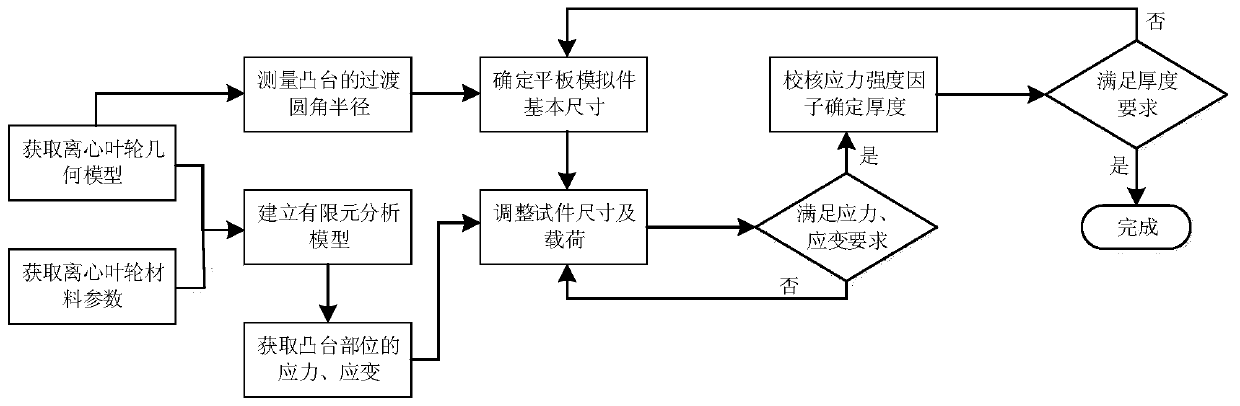

[0035] In Embodiment 1, the implementation steps of the present invention are as follows:

[0036] The first step is to obtain the geometric model of the centrifugal impeller, and measure the transition fillet radius of the centrifugal impeller boss and the radial length of the boss. The geometric model refers to the three-dimensional geometric model of the centrifugal impeller designed according to actual engineering requirements with the aid of computer-aided design software; the transition fillet radius refers to the radius of the transition fillet between the boss and the impeller; the boss radial Length refers to the radial length of the centrifugal impeller boss. For example, the transition fillet radius of a centrifugal impeller boss is 20mm, and the radial length is 4mm.

[0037] The second step is to obtain the operating conditions of the centrifugal impeller and the material performance parameters under the operating conditions. The operating conditions include the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com