Control system of thread winding machine

A technology of control system and winding machine, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., which can solve the problems of long waiting time and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

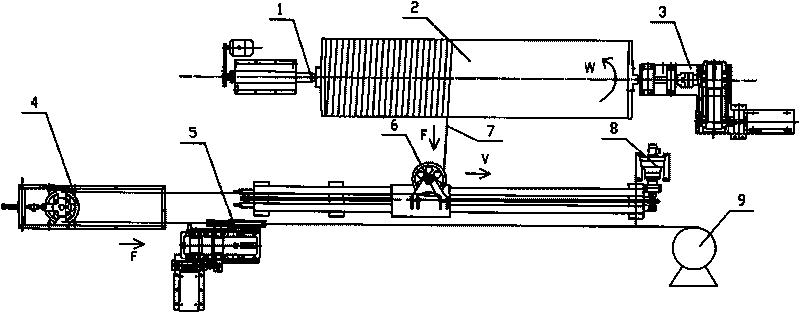

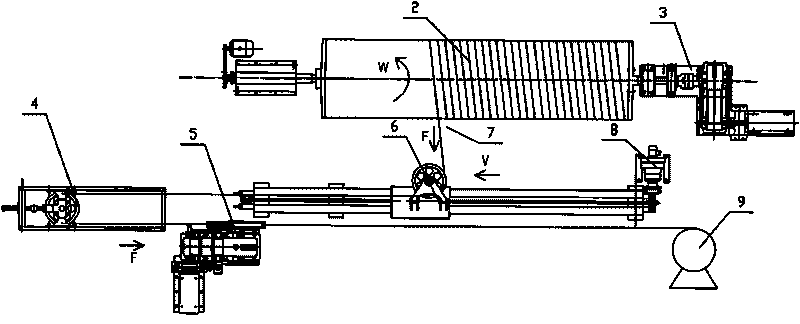

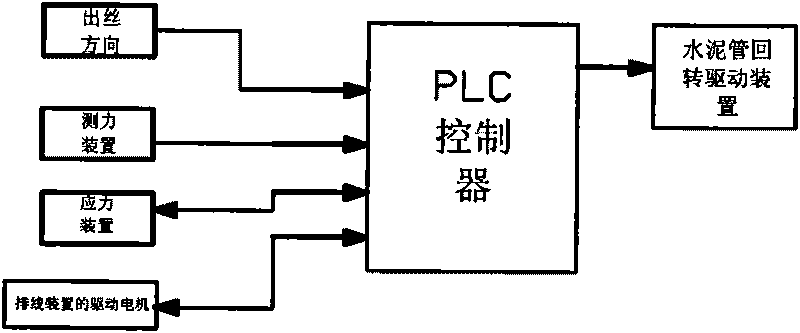

[0012] The present invention as figure 1 As shown, it includes a controller, a cement pipe rotary drive device 3, a cable arrangement, a running guide rail of the cable arrangement device, a force measuring device 4, a stress device 5 that generates a set tension on the wire 7, a cement pipe rotary drive device 3, a row The wire device, force measuring device 4, and stress device 5 are connected to the controller; the wire arrangement device includes a guide wire trolley 6 and a drive motor 8 that drives the guide wire trolley 6 to reciprocate at a fixed speed relative to the cement pipe 2, and the cement pipe 2 is covered by the cement pipe. The support device 1 is supported by the cement pipe rotary drive device 3 to drive the cement pipe 2 to run at a set speed, so that the wire 7 is wound on the cement pipe 2 at a set pitch, and the controller is equipped with an instruction stress device to change Stress is an adjustment circuit that ensures that the stress on the wire 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com