High-sinking-resistance transparent primer and preparation method thereof

A transparent primer and performance technology, which is applied in the coating of substrates and the coating of solid wood substrates, can solve the problem of restricting the application of deep wood grain and deep conduit wood, compressing the profit space of solid wood furniture, affecting the adhesion of primer and topcoat. Focus on problems such as high fullness, short grinding time and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

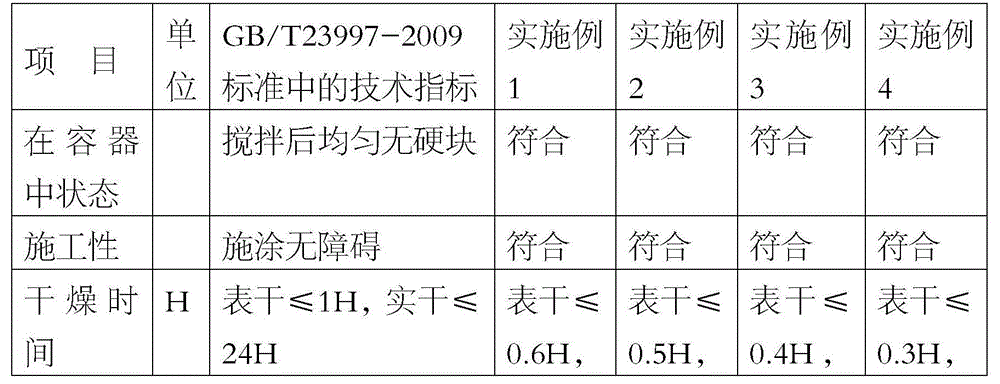

Examples

Embodiment 1

[0034] 1. Preparation method of main paint

[0035] The main paint is prepared by the following steps:

[0036] (1) Mix butyl acetate, propylene glycol methyl ether acetate, and divalent ester according to the mass ratio of 10:9:4 to form an environmentally friendly mixed solvent;

[0037] (2) Dibutyltin dilaurate and butyl acetate are mixed according to the mass ratio of 1:1.5 to form a drier;

[0038] (3) After mixing 70 parts of short oil alkyd resin, 10 parts of castor oil modified alkyd resin, 0.1 part of wetting and dispersing agent, and 10 parts of environmentally friendly mixed solvent, disperse at 600 rpm for 8 minutes while dispersing While adding 5 parts of zinc stearate and 0.5 parts of anti-settling agent, disperse at a speed of 1200 rpm for 10 minutes until the fineness is ≤40um, then add 1 part of defoamer and 0.5 parts of leveling agent while dispersing, and dry 0.3 parts of solvent, 2.6 parts of environmentally friendly mixed solvent, disperse at 800 rpm for...

Embodiment 2

[0048] Embodiment 2 (preferred embodiment)

[0049] 1. Preparation method of main paint

[0050] The main paint is prepared by the following steps:

[0051] (1) Mix butyl acetate, propylene glycol methyl ether acetate, and divalent ester according to the mass ratio of 10:9:4 to form an environmentally friendly mixed solvent;

[0052] (2) Dibutyltin dilaurate and butyl acetate are mixed according to the mass ratio of 1:1 to form a drier;

[0053] (3) After mixing 55 parts of short oil alkyd resin, 10 parts of castor oil modified alkyd resin, 0.5 parts of wetting and dispersing agent, and 8 parts of environmentally friendly mixed solvent, disperse at 700 rpm for 9 minutes while dispersing While adding 5 parts of zinc stearate, 15 parts of talcum powder, and 1 part of anti-settling agent, disperse at 1350 rpm for 13 minutes until the fineness is ≤40um, then add 0.6 parts of defoamer and leveling agent while dispersing 0.5 parts, 0.2 parts of drier, 4.2 parts of environmentally...

Embodiment 3

[0079] 1. Preparation method of main paint

[0080] The main paint is prepared by the following steps:

[0081] (1) Mix butyl acetate, propylene glycol methyl ether acetate, and divalent ester according to the mass ratio of 10:9:4 to form an environmentally friendly mixed solvent;

[0082] (2) Dibutyltin dilaurate and butyl acetate are mixed according to the mass ratio of 1:1.2 to form a drier;

[0083] (3) After mixing 55 parts of short oil alkyd resin, 15 parts of castor oil modified alkyd resin, 0.3 parts of wetting and dispersing agent, and 5 parts of environmentally friendly mixed solvent, disperse at 800 rpm for 10 minutes while dispersing While adding 3 parts of zinc stearate, 15 parts of talc powder, and 1 part of anti-settling agent, disperse at a speed of 1500 rpm for 15 minutes until the fineness is ≤40um, then add 0.5 parts of defoamer and leveling agent while dispersing 0.3 parts, 0.1 parts of drier, 4.8 parts of environmentally friendly mixed solvent, disperse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com