Production process of highly-compacted tricot-knitting sanded fabric

A production process, high-density warp technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as no grinding process, and achieve the effect of comfortable hand feeling, novel appearance and rough style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

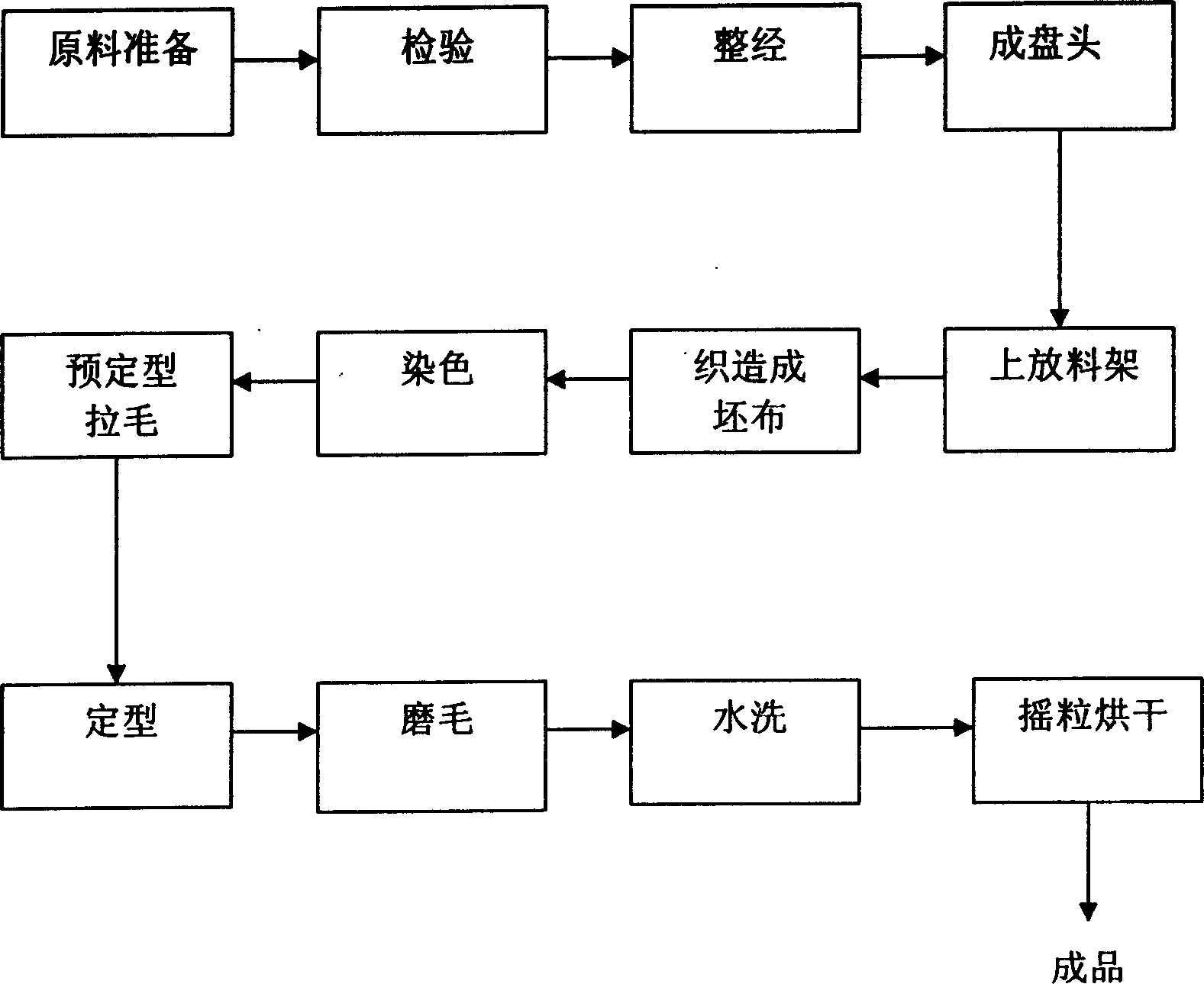

[0032] See figure 1 , The production process of the high-density warp-knitted sanded fabric of the embodiment of the present invention includes raw material preparation, inspection, warping, pan-heading, loading rack, weaving into grey cloth, dyeing, predetermined napping, shaping, sanding, washing, Foil drying.

[0033] The woven fabric of the present invention uses four combs, of which the first comb and the second comb use 30D semi-gloss polyester filaments, accounting for 7.3% of the total weight, and the third comb uses two 50D semi-gloss polyester filaments. , Accounting for 77.7% of the total weight, the fourth bar uses 40D semi-gloss polyester filament, accounting for 15% of the total weight, see figure 2 , image 3 , The first bar and the second bar go through the double strands (50D / 48F+50D / 24F), through the change of the chain (that is, the conversion on the basis of the traditional knitting 1-0 / 0-1 / / , that is, It is combined with other organizations to obtain a brand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com