Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Wide firing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clear glaze and method for manufacturing same

InactiveCN101182238AWide firing temperatureNot prone to chromatic aberrationPotassium feldsparCalcite

The invention discloses a transparent glaze and a preparation method thereof. The weight percentages of ach component of the transparent glaze are 10 percent to 35 percent of potassium feldspar powder, 8 percent to 25 percent of calcite, 8 percent to 10 percent of kaolin, 2 percent to 5 percent of quartz, 9 percent to 15 percent of calcined kaolin, 5 percent to 8 percent of burning talc, 3 percent to 5 percent of alumina, 1 percent to 3 percent of barium carbonate, 3 percent to 10 percent of transparent of fusion cake, 0.15 percent to 0.35 percent of methyl, 0.2 percent to 0.4 percent of tripolyphosphate and 15 percent to 30 percent of water. The weight percentage of the glaze material fineness is that the 250 meshes sieve residue is less than 0.15 percent. The technical process of the manufacturing method is as follows: the raw material enters the factory for testing, proportioning, ball milling, detecting, removing iron, sieving and storing in a storehouse for using. The sintering temperature of ball milled glaze slurry is 1200 DEG C to 1210 DEG C, and the sintering period is 50min to 65min. The application range of the invention is wide; the performance of the glaze material is good; the glaze surface is smooth and is not easy for producing chromatic aberration; the cost can be reduced by about 35 percent.

Owner:霍炳祥

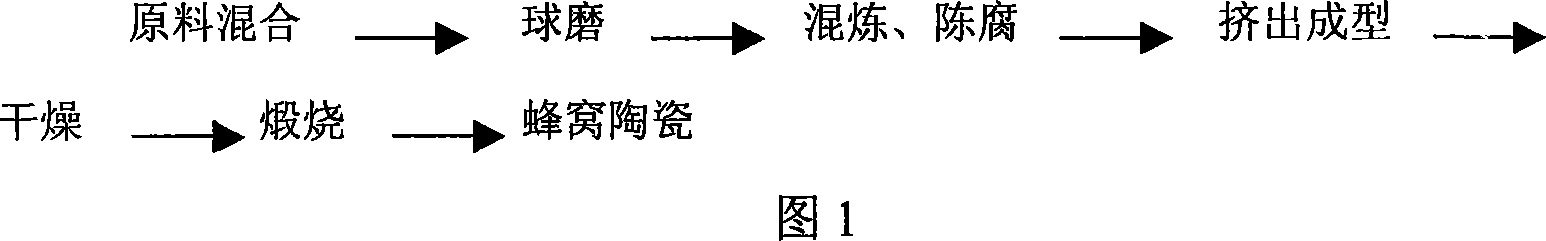

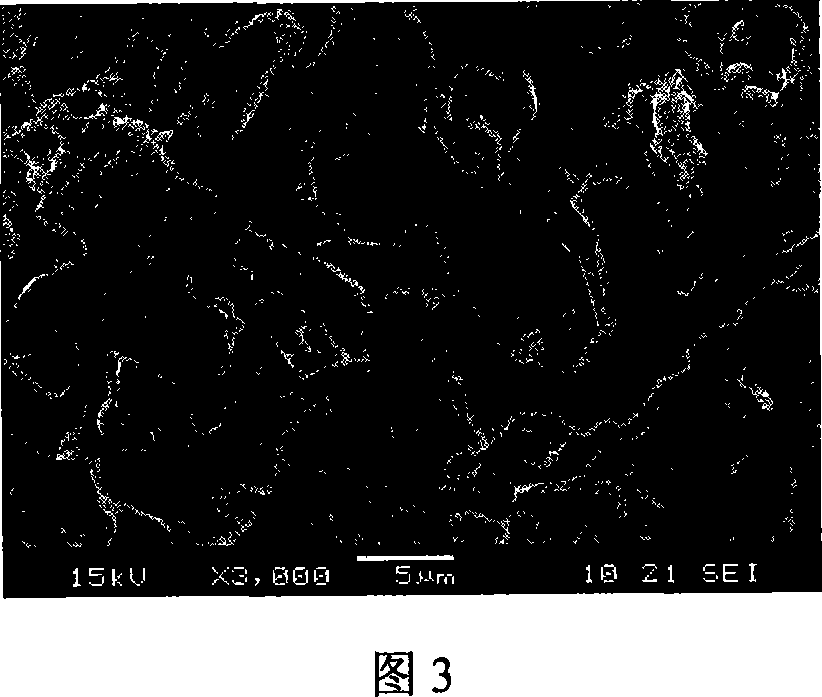

Multi-phase functional ceramic honeycomb support and preparation method thereof

ActiveCN101062868AThe preparation method is simple and controllableLow costCatalyst carriersCeramicwareRare earthSilicon dioxide

The invention discloses a preparing method of polyphase functionality honeycomb ceramic supporting body, which comprises the following steps: choosing titanium white, silica dioxide and aluminum oxide as main raw material; doping rare earth; adding right amount magnesium oxide accelerating burnt agent and additive; mixed-refining; squeezing; forming; drying; calcining for 2-3 h under 1200-1500 deg. c; generating the product with aluminium titanate and red schorl as principal crystalline phase. This product possesses shockproof, corrosion resistant, high intensity and good association with coated carrier, which can be used to the carrier of car exhaust gas cleansing activator and carrier reactor of photocatalyzer.

Owner:SHANDONG GEMSKY ENVIRONMENTAL PROTECTION TECH CO LTD

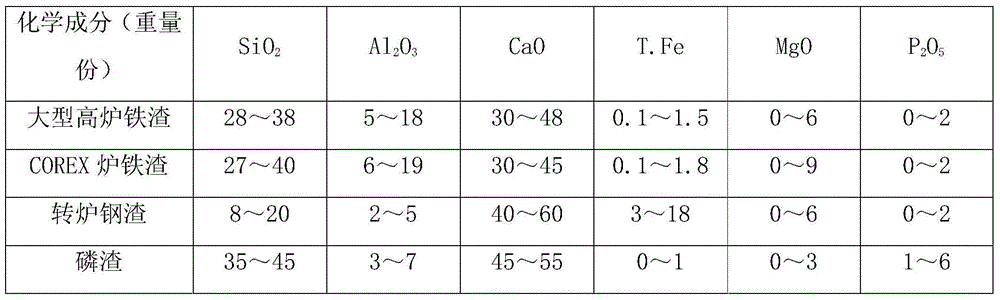

Method for preparing frits for ceramic glazes from high temperature liquid industrial slag

The invention relates to a method for preparing frits for ceramic glazes from high temperature liquid industrial slag. The high temperature liquid industrial slag is adopted as a raw material, and high temperature heat energy and chemical components of the slag are used for directly preparing frits for ceramic glazes. The method comprises the following steps that 1, 20-90 parts, by weight, of the high temperature liquid industrial slag is added into a high temperature furnace, 10-95 parts, by weight, of a hardening and tempering material is added, heating is performed under the temperature of 1300-1600 DEG C, and the hardening and tempering material is molten and sufficiently mixed with the slag to form a clear and homogenous melt; 2, the melt is discharged from the high temperature furnace and is subjected to water quenching to form frit particles, and the frit particles are dried, smashed and screened to obtain the frits for ceramic glazes. The production technology is simple, the frit quality is excellent, and raw materials and energy needed by production of frits for ceramic glazes are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Red stoneware mineral aggregate lightweight porous ceramsite and preparation method thereof

InactiveCN106866175AHigh porosityFine poresSustainable biological treatmentCeramicwareApparent densityPorosity

The invention discloses a method for preparing lightweight porous ceramsite. Red stoneware mineral aggregate is used as a main raw material, a fixed amount of pore forming agent and fluxing agent is added, and the lightweight porous ceramsite is prepared by crushing, sieving, burdening, mixing, forming, rotting, drying, preheating and high temperature sintering. The lightweight porous ceramsite comprises the following materials in parts by weight: 78-86 parts of red stoneware mineral aggregate, 12-16 parts of pore forming agent and 2-6 parts of fluxing agent, wherein there are 20 parts of 80-300-mesh red stoneware mineral aggregate, 25 parts of 20-80-mesh red stoneware mineral aggregate and 55 parts of 5-20 mesh red stoneware mineral aggregate. The ceramsite prepared by the method disclosed by the invention has the advantages of lower apparent density, higher porosity, higher strength, higher adsorbability, simple preparation process and the like, and can be used as living water purification filtering material, a filtering material of biological aerated filters, an aquaculture water purification filtering material, building material filler, etc.

Owner:洛阳逸人紫砂有限公司

Sintering flux for solid waste sintered porous heat insulation sheets, and preparation method and application thereof

ActiveCN104774029AWide firing rangeImprove physical and mechanical propertiesSolid waste disposalCeramicwareToxic industrial wasteIndustrial waste

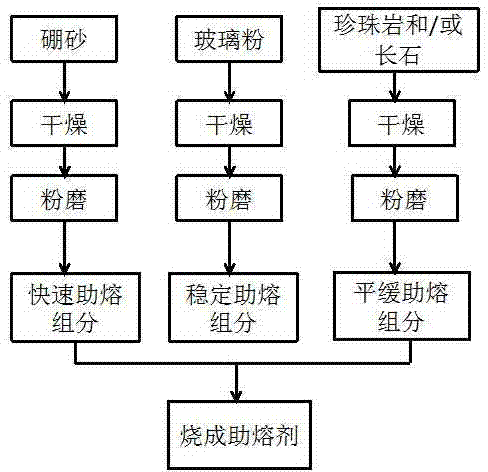

The invention relates to a sintering flux for solid waste sintered porous heat insulation sheets, and a preparation method and an application thereof. The sintering flux comprises a rapid fluxing component, a stable fluxing component and a mild fluxing component; a mass ratio of the rapid fluxing component to the stable fluxing component is 0.5-2:1, and a mass ratio of the mild fluxing component to the stable fluxing component is 0.5-2:1; and the rapid fluxing component is borax, the stable fluxing component is glass powder, and the mild fluxing component is one or two of perlite and feldspar. The invention also provides the preparation method and the application of the sintering flux for solid waste sintered porous heat insulation sheets. The flux is added in the sintering process of the sintering flux for solid waste sintered porous heat insulation sheets to decrease the sintering temperature by 50-150DEG C, a large amount of waste mine tailings and industrial waste residues are used, and the utilization rate reaches 80%, so environment protection is facilitated, resources are saved, and waste discharge is reduced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Zirconium oxide fire-resistant material and preparation process thereof

The invention relates to a fire-resistant material, and particularly relates to a zirconium oxide fire-resistant material and a preparation process thereof. The zirconium oxide fire-resistant material provided by the invention has good heat shock stability because electric-smelting monoclinic zirconium oxide has better fracture toughness and strength, and can further play a stabilizing role on the electric-smelting monoclinic zirconium oxide, improve the heat expansion coefficient of the electric-smelting monoclinic zirconium oxide, enhance the toughness of the electric-smelting monoclinic zirconium oxide, outstandingly enhance the heat shock stability of a product and reduce the firing temperature of the electric-smelting monoclinic zirconium oxide through the addition of yttrium oxide or yttrium nitrate and barium oxide or barium carbonate or barium phosphate, thereby reducing the energy consumption and enlarging the firing range. The preparation process of the zirconium oxide fire-resistant material, which is provided by the invention, has the advantage that the fire-resistant material has the characteristic of crack-growth stability because a pre-burned material has very excellent heat shock property and compactness by being subjected to activated treatment at a temperature lower than burning temperature, and the compactness, heat shock property and the mechanical property of the fire-resistant material are enhanced.

Owner:ZHEJIANG IRON LION HIGH TEMPERATURE MATERIALS CO LTD

Fancy glaze and method for manufacturing same

The invention discloses a fancy glaze and a preparation method thereof. The weight percentages of each component of the fancy glaze are 18 percent to 38 percent of potassium feldspar, 10 percent to 23 percent of calcite, 4 percent to 7 percent of talc, 3 percent to 7 percent of quartz, 4 percent to 10 percent of zirconium silicate, 2 percent to 5 percent of zinc oxide, 5 percent to 10 percent of alumina, 3 percent to 6 percent of barium carbonate, 6 percent to 10 percent of black mud, 0 percent to 0.3 percent of tripolyphosphate, 6 percent to 20 percent of water, 0 percent to 10 percent of squeegee oil and 0 percent to 10 percent of printing paste. The weight percentage of the glaze material fineness is that the 250 meshes sieve residue is 100 percent. The technical process of the method of manufacturing the fancy glaze is as follows: the raw material enters the factory for testing, proportioning, ball milling, detecting, removing iron, sieving and storing in a storehouse for using. The sintering temperature is 1195 DEG C to 1210 DEG C, and the sintering period is 50min to 65min. The application range of the invention is wide; the glaze surface is smooth; the sintering temperature range is wide; the chromatic aberration can not be produced easily; the finished product rate is high; the cost can be reduced by about 40 percent.

Owner:清远市欧雅陶瓷有限公司

Enamel coating with function of resisting sulfuric acid and hydrochloric acid dew point corrosion and preparation technology thereof

ActiveCN108409138AThe preparation process is non-toxicNo pollution in the processMetallic materialsBoron trioxide

The invention relates to the field of inorganic protection coatings, and particularly provides an enamel coating with the function of resisting sulfuric acid and hydrochloric acid dew point corrosionand a preparation technology thereof. The enamel coating can serve as Q235 steel, BTC1 steel, 304 stainless steel and other metal material parts. Micron oxide particles are uniformly dispersed and distributed in an enamel glaze substrate parent phase, wherein enamel glaze is formed by mixing and melting the analytical pure raw materials (such as: silicon dioxide, aluminum sesquioxide, diboron trioxide, sodium oxide, potassium oxide, nickel oxide, cobalt oxide and calcium fluoride) at the high temperature and water quenching, and the micron oxide particles are one or arbitrary combination of analytical pure aluminum sesquioxide, silicon dioxide, titanium dioxide and zirconium dioxide. The enamel coating is prepared from the raw materials which can be purchased in the market directly, and the preparation technology is free of toxicity and pollution in the process, and conforms to the energy-saving and environment-friendly development trend. The enamel coating is compact and free of pores, has higher strength, fracture toughness, good binding force with a steel substrate and a matched coefficient of thermal expansion.

Owner:NORTHEASTERN UNIV

Anti-static ceramic

The invention is an antistatic ceramic, which is made of the following raw materials in parts by weight: silicon nitride 60-75, kaolin 10-16, aluminum oxide 2-8, silicon dioxide 2-5, tin oxide 3‑9, zirconia 1‑5, molybdenum disilicide 1‑3, antimony powder 10‑15, titanium dioxide 1‑3, conductive graphite 5‑6, silicon carbide 1‑5, boron carbide 1‑2, aluminum nitride 1 ‑2, thorium oxide 2‑4, appropriate amount of deionized water. The ceramic prepared by the present invention has certain electrical and thermal conductivity, prevents the generation of static electricity, prevents frictional overheating, prolongs the service time of pipelines and channels, and the ceramic of the present invention also has certain corrosion resistance and oxidation resistance, and has Good toughness.

Owner:苏州志英明建信息科技有限公司

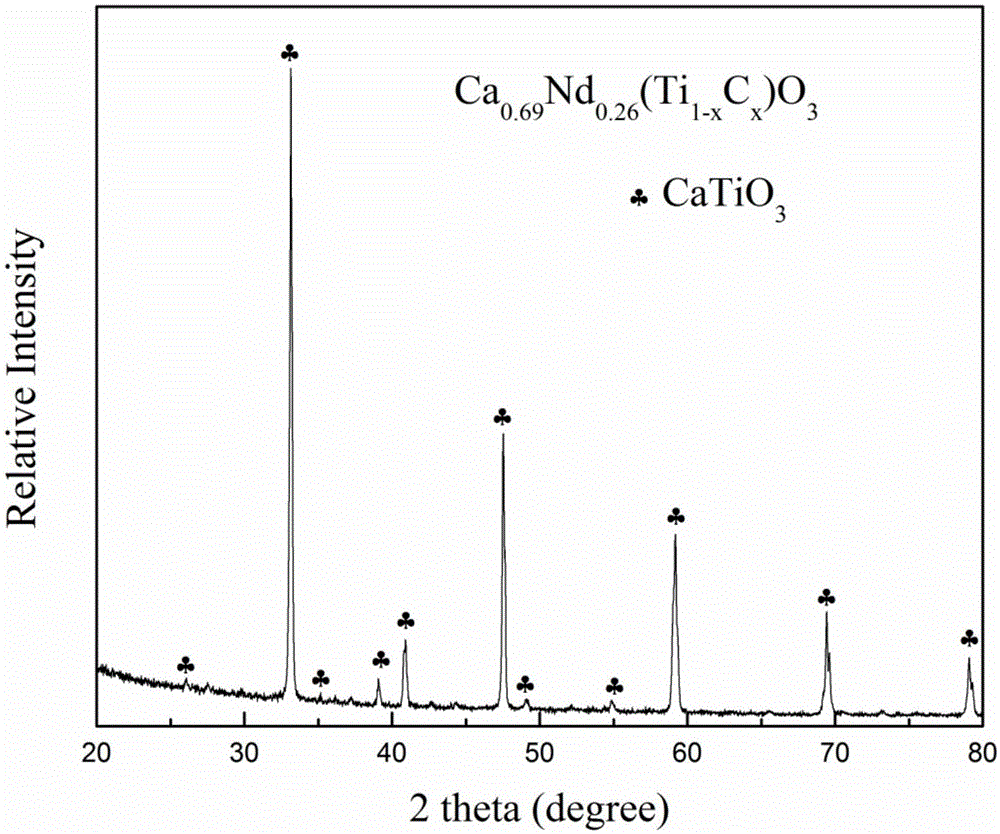

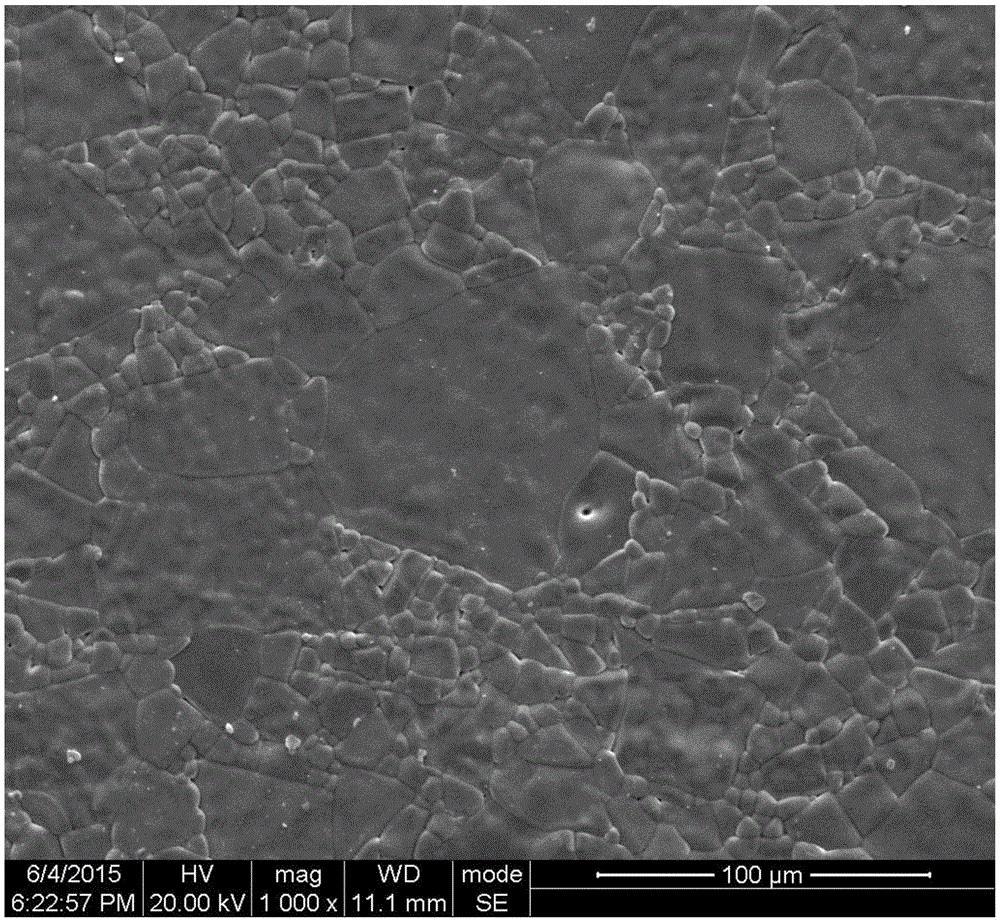

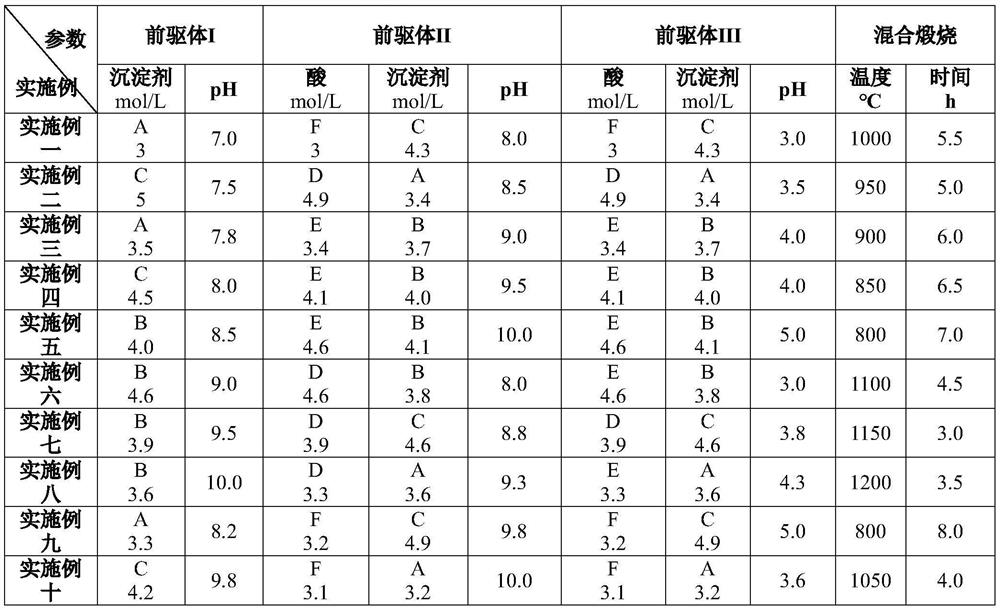

Ca-Nd-Ti microwave dielectric ceramic material and preparation method thereof

The invention provides a Ca-Nd-Ti microwave dielectric ceramic material and a preparation method thereof. The general chemical formula of the material is Ca0.61Nd0.26(Ti1-xCx)O3 and C=MN, wherein x is larger than or equal to 0.15 and smaller than or equal to 0.2, and the aim of controlling the microwave performance of a system is achieved through B-site substitution; M represents Nb with valence state higher than tetravalence, N represents one or more of elements with valence state lower than tetravalence and ionic radius similar to that of Ti, and simultaneous substitution or independent substitution is achieved for M and N. The preparation method includes the steps of determining weight percentage contents of all components according to the general chemical formula, conducting ball-milling and mixing, conducting presintering at a temperature of 1050 DEG C to 1150 DEG C, and conducting sintering at a temperature of 1350 DEG C to 1450 DEG C to obtain the material. The dielectric constant, ranging from 70 to 100, of the obtained material and the frequency temperature coefficient of the material can be adjusted, and meanwhile the excellent Q*f value is kept between 9000 GHz and 16000 GHz; Pb, Cd and other volatile or heavy metal are not contained in the formula, performance is greatly improved compared with other systems, raw materials are sufficiently supplied in domestic, price is lower than that of other systems, and it is made possible that high-performance microwave ceramic is low in cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Creamy white frit and preparation method thereof

The invention relates to a creamy white frit, belonging to the technical field of ceramic. The creamy white frit comprises the components in parts by weight: 5-15 parts of potash feldspar, 15-25 parts of quartz, 15-25 parts of soda feldspar, 5-15 parts of dolomite, 1-3 parts of fine particle calcium carbonate, 8-15 parts of zinc oxide, 10-15 parts of zirconium silicate, 1-5 parts of potassium carbonate, 0.5-1.5 parts of sodium fluosilicate, 2-10 parts of boric acid, 0.5-2 parts of barium carbonate, and 1-5 parts of aluminum oxide. The preparation method of the creamy white frit comprises the steps of: mixing and stirring uniformly the components, melting in a 1500-1600 DEG C high-temperature frit furnace for 1.5-2.0 hours, and carrying out water quenching on the molten liquid with cold water to obtain the creamy white frit. The obtained frit has good fluidity, relatively low viscosity, good glossiness, higher flatness, and wider firing temperature; and the product quality is improved greatly and the product yield is increased.

Owner:刘锐浩

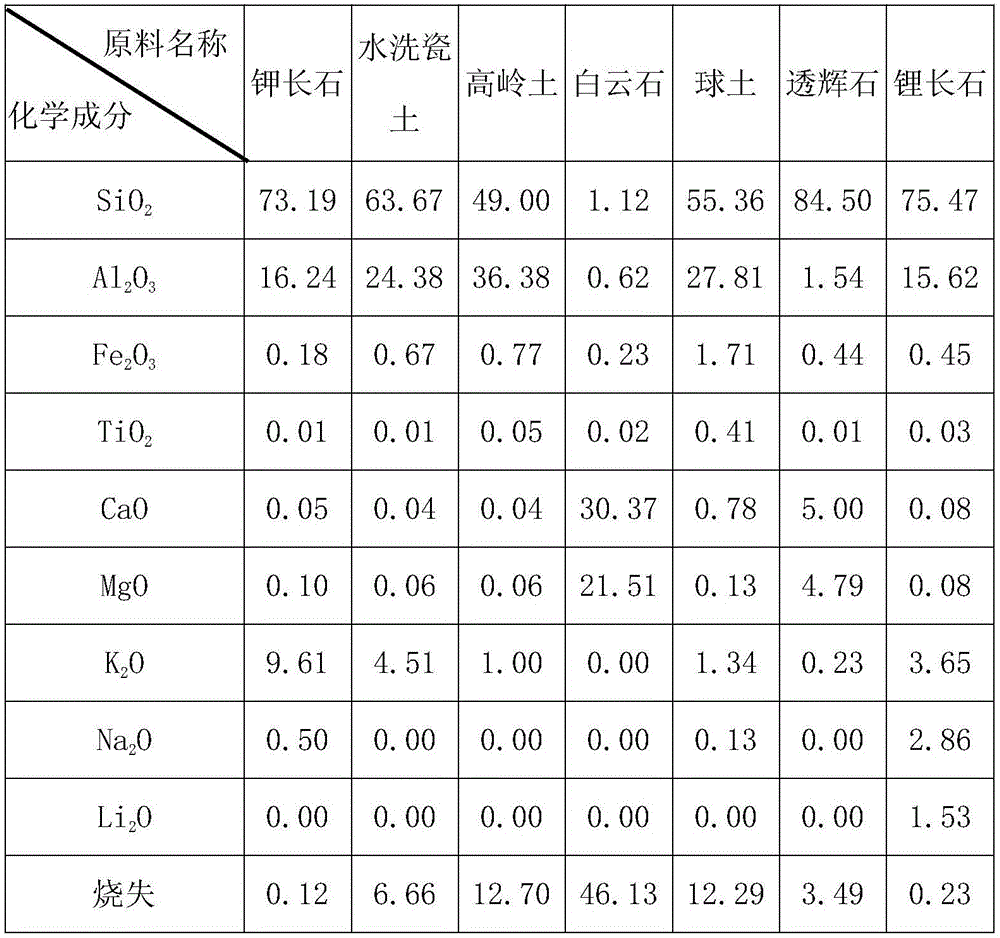

Slurry for craft ceramic and composition for preparation of slurry

The invention discloses a slurry for craft ceramic and a composition for preparation of the slurry. The composition comprises the following matters in parts by weight: 40 to 60 parts of washed clay, 5 to 10 parts of kaolin, 3 to 8 parts of ball clay, 3 to 5 parts of potassium feldspar, 3 to 5 parts of lithium feldspar, 10 to 15 parts of dolomite, 8 to 15 parts of diopside and 0.01 to 0.03 part of cobalt blue. The slurry prepared from the composition provided by the invention has the advantages of low sintering temperature, short sintering time, low energy consumption, and high product strength and whiteness.

Owner:福建科福材料有限公司

High-temperature glisten glaze and preparation method thereof

The invention discloses a high-temperature glisten glaze and a preparation method thereof. The glaze comprises, by mass, 1-16% of Al2O3, 50-75% of SiO2, 0.5-5% of CaO, 0-2% of MgO, 2-9% of K2O, 0-2% of Na2O, 2-16% of ZnO, 0-2% of PbO, 3-9% of ZrO2, 3-10% of CeO2 and 0.5-8% of B2O3. The glisten glaze is wide in application range, good in firing performance and high in stability and glisten strength; and the preparation method is reasonable and simple in technology.

Owner:威远县大禾陶瓷原料有限公司

Milky white clinker for glaze and preparation method for clinker

The invention relates to milky white clinker for glaze, and belongs to the technical field of ceramic. The clinker comprises the following components in part by weight: 5 to 15 parts of potassium feldspar, 15 to 25 parts of quartz, 15 to 25 parts of albite, 5 to 15 parts of dolomite, 1 to 3 parts of light calcium carbonate, 8 to 15 parts of zinc oxide, 10 to 15 parts of zirconium silicate, 1 to 5 parts of potassium carbonate, 2 to 10 parts of borax, 0.5 to 2 parts of barium carbonate and 1 to 5 parts of alumina. A preparation method comprises the following steps of: mixing and uniformly stirring the components, melting in a high temperature clinker furnace at the temperature of between 1,500 and 1,600 DEG C for 1.5 to 2.0 hours, and performing water quenching on the melted liquid by using cold water to obtain the milky white clinker for the glaze. The clinker for the glaze has high liquidity, relatively low viscosity, high gloss, relatively high flatness and a wide firing temperature range, the quality of a product is greatly improved, and the yield of the product is improved.

Owner:刘锐浩

Transparent clinker and preparation method thereof

The invention relates to a transparent clinker, and belongs to the technical field of ceramic. The transparent clinker comprises the following components in part by weight: 25-35 parts of quartz, 30-40 parts of potash spar, 8-15 parts of calcite, 3-8 parts of raw talc, 5-10 parts of zinc oxide, 5-10 parts of boric acid, 0.5-2.0 parts of kaolin, 3-5 parts of barium carbonate, 0-3 parts of red lead and 0.5-2 parts of zirconium silicate. The preparation method of the transparent clinker comprises the following steps of: uniformly mixing and stirring the components; melting in a high-temperature clinker furnace of 1,500-1,550 DEG C for 1.5-2.0 hours; and water-quenching molten liquid with cold water to obtain the transparent clinker. The clinker has the advantages of high flatness, high glossiness, good three-dimensional effect and wider firing temperature, and can be widely applied to building ceramic.

Owner:黄喜波

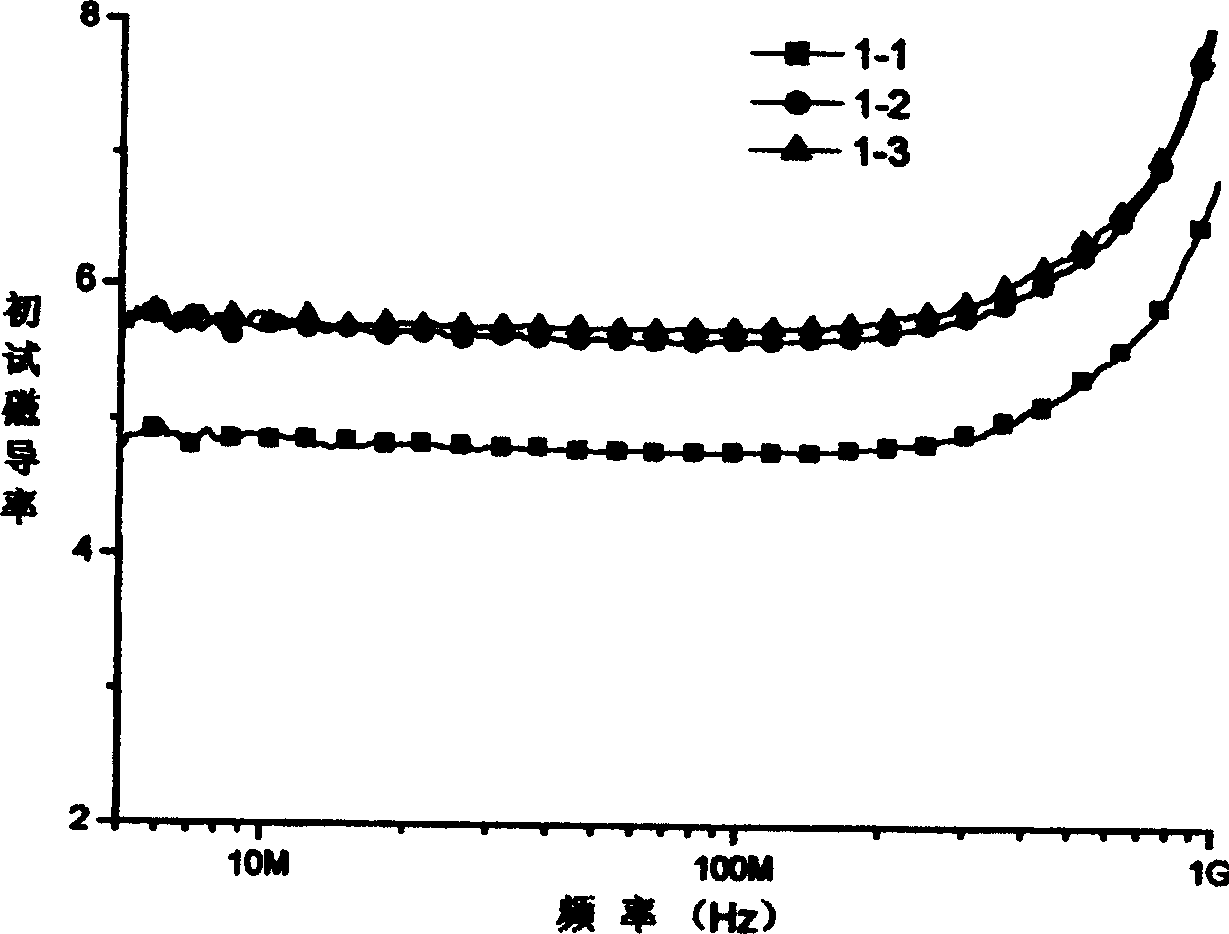

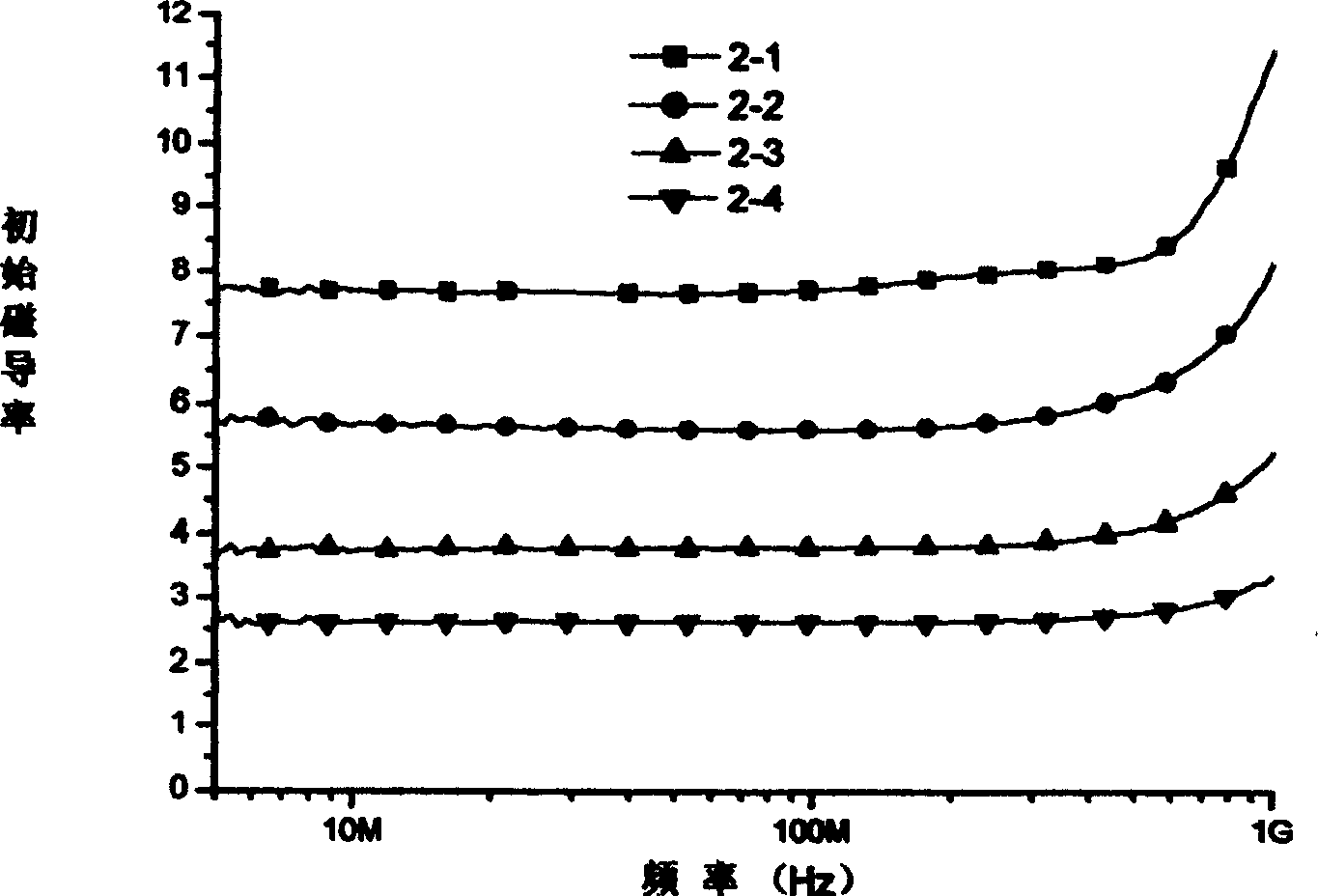

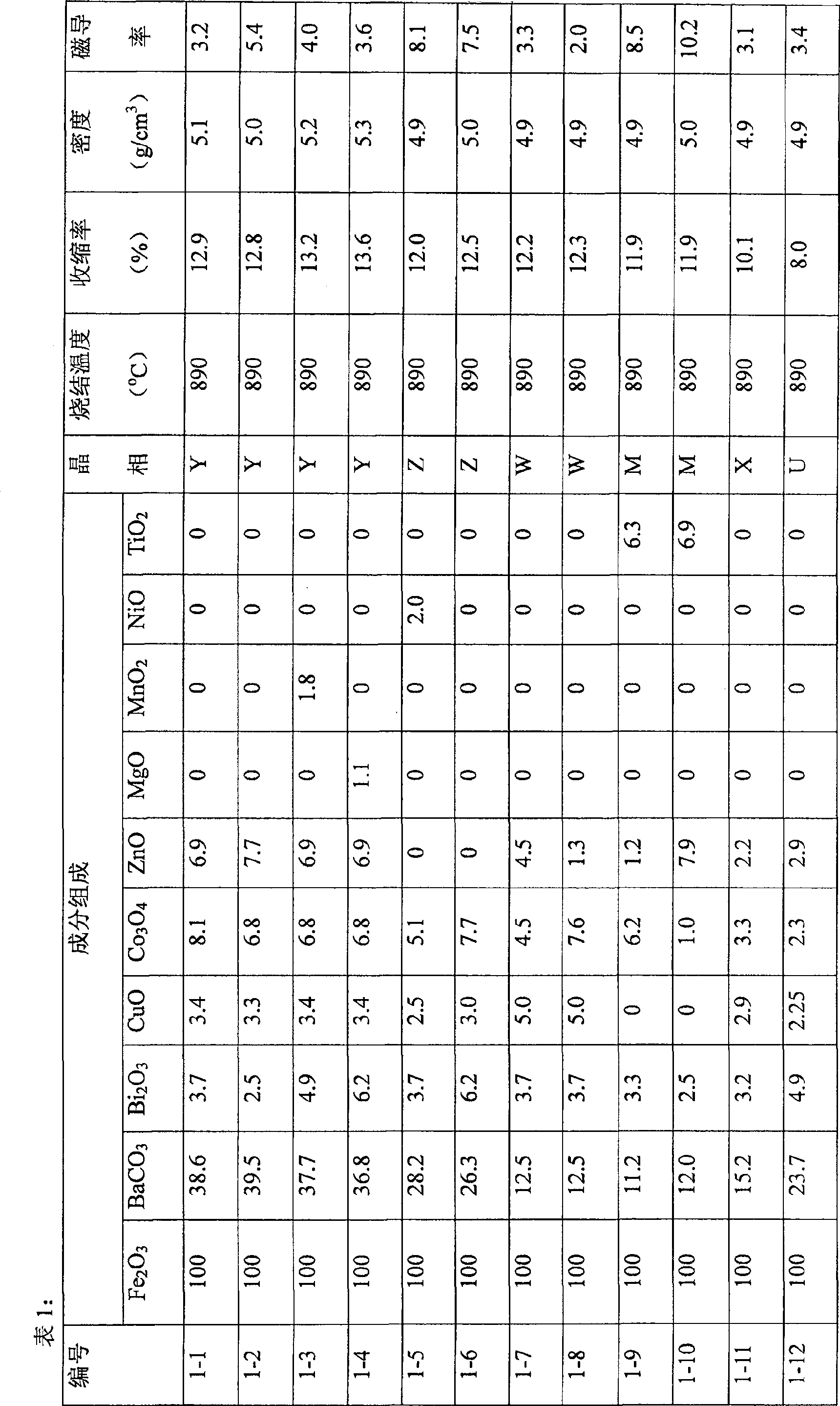

Low temperature sintered very high frequency laminated sheet type electrical inductance, sheet type magnetic beal material and its preparation method

InactiveCN1191594CLower sintering temperatureRecipe adjustableInorganic material magnetismInductances/transformers/magnets manufactureHigh densityMagnetic bead

The VHF slice type inductance and the slice type bead material are obtained by sintering the admixture of BaSrPbZnCoCu and the sintering supporting agent being mixed according to certain weight percentage rate. Fe2O3, BaCO3, SrCO3, PbO, Co3O4 etc. are used as the main materials to prepare BaSrPbZnCoCu. The composite sintering supporting agent is prepared from Bi2O3+Al2O3+PbO+B2O3+SiO2+CaF2+LiF. The material possesses the properties of magnetic permeability 2-40, cut-off frequency 800 MHz to more than 1.8 GHz, the variety rate of specific temperature less than 10 to the power -6 / deg.C and resistivity larger than 10 to the power 9 ohm.cm. The invention realizes the low temperature sintering, providing the features of high density, the even size of crystal grain and the stable performance.

Owner:TSINGHUA UNIV

Powder blue glaze and its production method

The invention relates to a powder green glaze material, which is a slurry obtained by mixing the powder green glaze raw materials according to the formula, and then through ball milling, sieving, and iron removal processes, including powder after dehydration and drying. A proper amount of talc, chromium oxide and other raw materials are introduced into the formula, which solves the problems of over-burning, foaming and "smoking" in the process of high-temperature melting of traditional blue-glazed ceramics. The glaze is green, smooth, delicate, gorgeous and pure in color. The quality is as clean as jade; the invention also discloses a method of using the powder green glaze to manufacture ceramic products at the same time. The powder green glaze ceramic products produced by the method have high yield, good density and strong acid and alkali corrosion resistance.

Owner:汤秋影

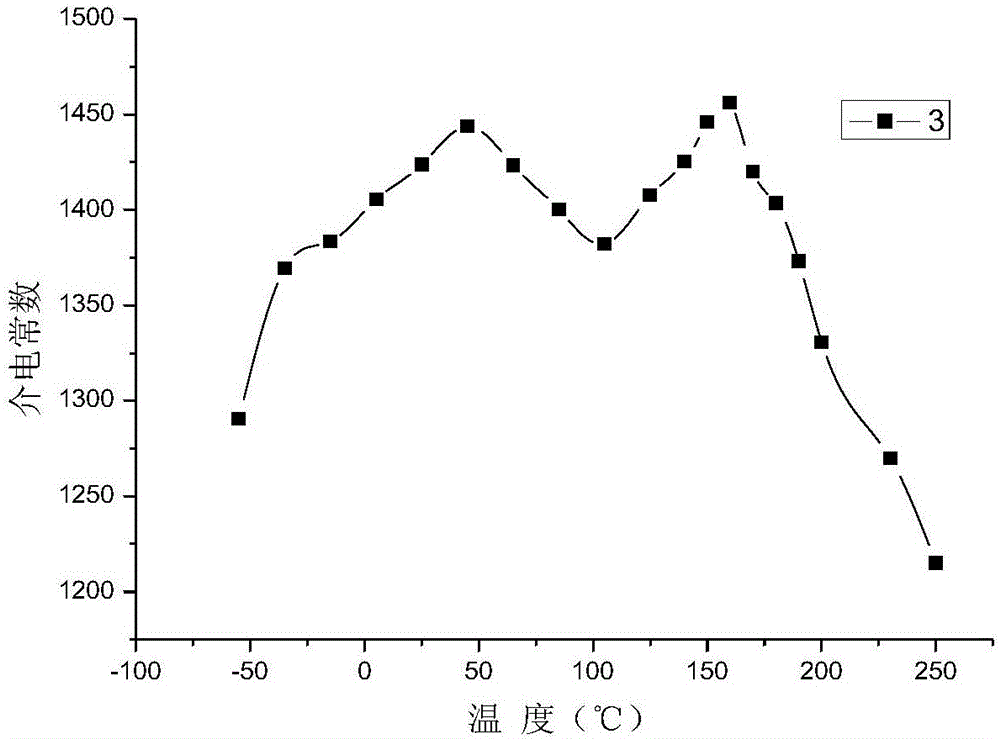

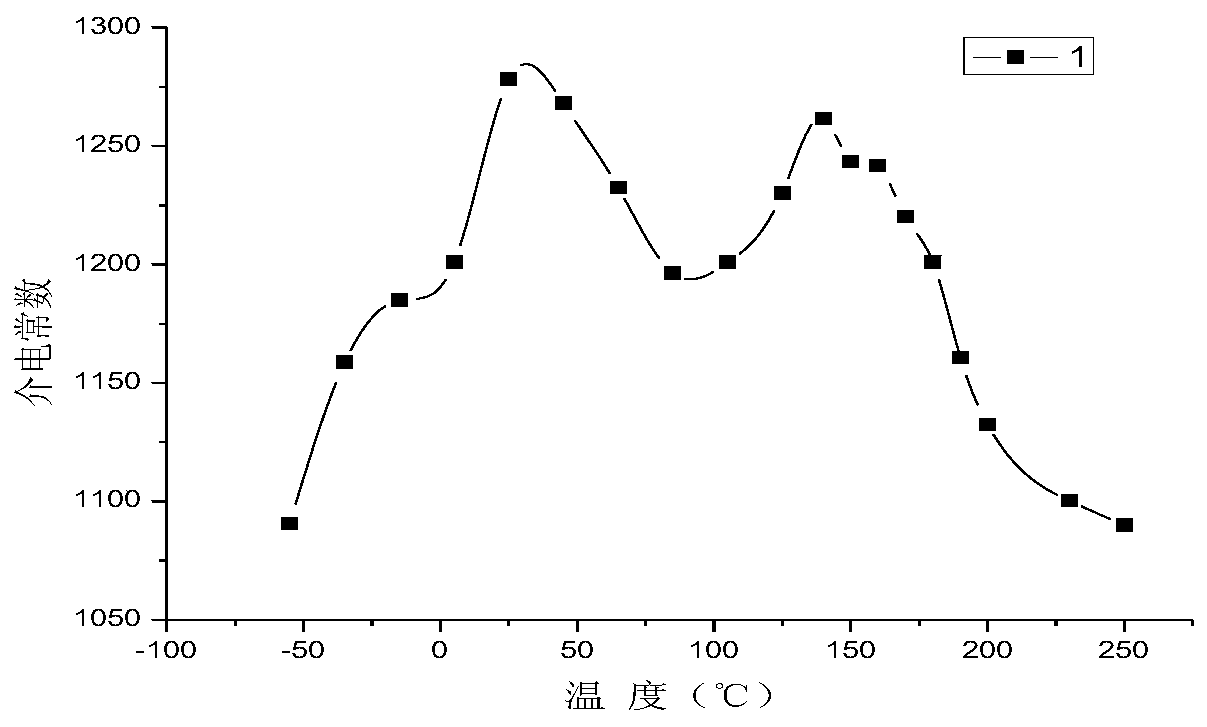

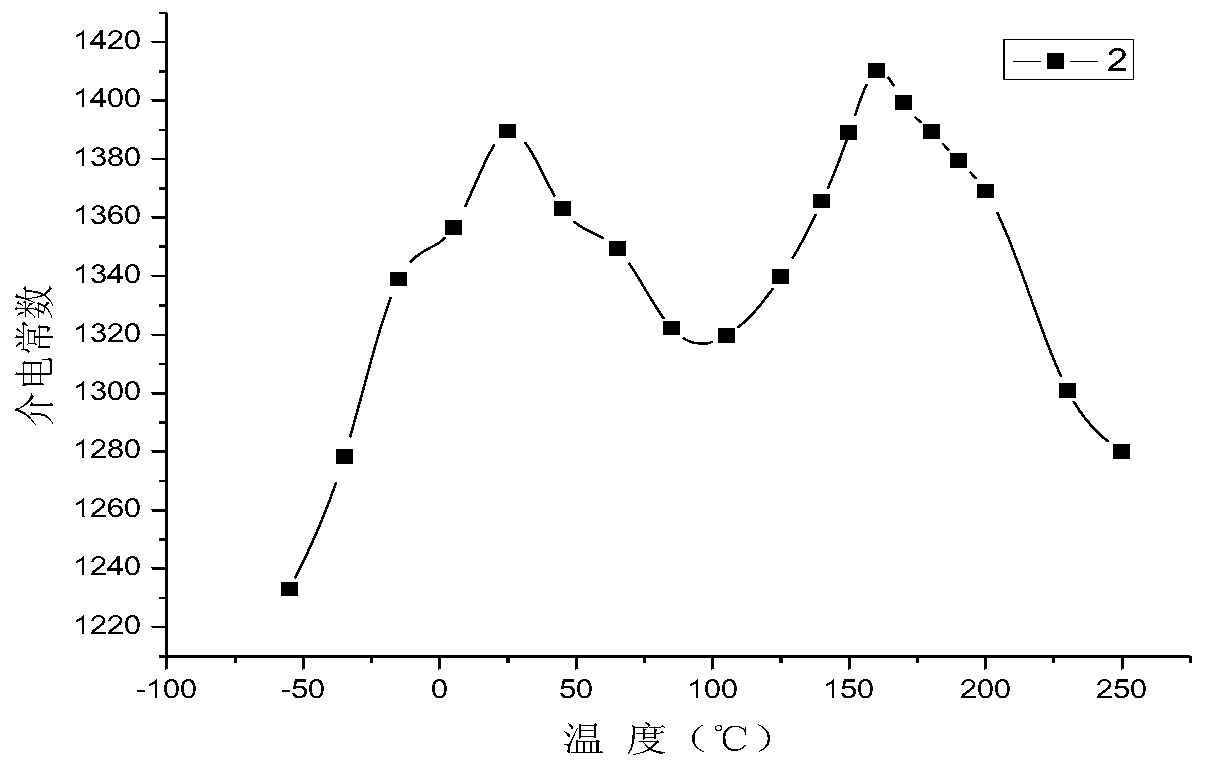

Medium and low sintering temperature stable ceramic capacitor material and preparation method thereof

InactiveCN106747416AUltra high temperature stabilityExcellent dielectric propertiesDielectric lossCeramic capacitor

Owner:TIANJIN UNIV

Milky white frit for glaze and preparation method for milky white frit for glaze

The invention relates to milky white frit for glaze and belongs to the technical field of ceramics. The milky white frit comprises the following components in part by weight: 5 to 15 parts of potash feldspar, 15 to 25 parts of quartz, 15 to 25 parts of soda feldspar, 5 to 15 parts of dolomite, 1 to 3 parts of calcium carbonate, 8 to 15 parts of zinc oxide, 10 to 15 parts of zirconium silicate, 1 to 5 parts of potassium carbonate, 2 to 10 parts of boric acid, 0.5 to 2 parts of barium carbonate, and 1 to 5 parts of aluminum oxide. A preparation method comprises the following steps of: uniformly mixing and stirring the components, melting in a high-temperature frit furnace at the temperature of between 1,500 and 1,600 DEG C for 1.5 to 2.0 hours, and performing water quenching on the melted liquid by using cold water to obtain the milky white frit. The frit for the glaze is high in mobility, low in viscosity, high in glossiness and flatness, and wide in firing temperature range; and quality and yield of a product is improved, and the yield of the product is greatly improved.

Owner:刘锐浩

Acid corrosion-resistant enamel coating on weather-resistant structural steel surface and preparation method thereof

The invention discloses an acid-corrosion-resistant enamel coating on the surface of weather-resistant structural steel and a preparation method thereof. The preparation method of the acid-corrosion-resistant enamel coating on the surface of weather-resistant structural steel of the present invention comprises: a) melting enamel glaze, b) preparing enamel glaze powder, c) alkaline degreasing treatment of weather-resistant structural steel, d) enamel coating Spraying and firing at high temperature, wherein, the enamel glaze material has two kinds, which are enamel enamel A and enamel enamel B respectively. The acid-corrosion-resistant enamel coating on the surface of the weather-resistant structural steel obtained by the preparation method of the invention has the advantages of excellent acid-corrosion resistance, especially sulfuric acid resistance, high bonding strength, and long service life. In addition, the preparation method of the present invention is simple, adopts two kinds of glazes to be melted separately, and the surface of the weather-resistant structural steel is treated with alkaline degreasing, which improves production efficiency, saves energy consumption, reduces the production cost of enamel coating, and is suitable for large-scale popularization and application. .

Owner:宁波硕强环保新材料有限公司

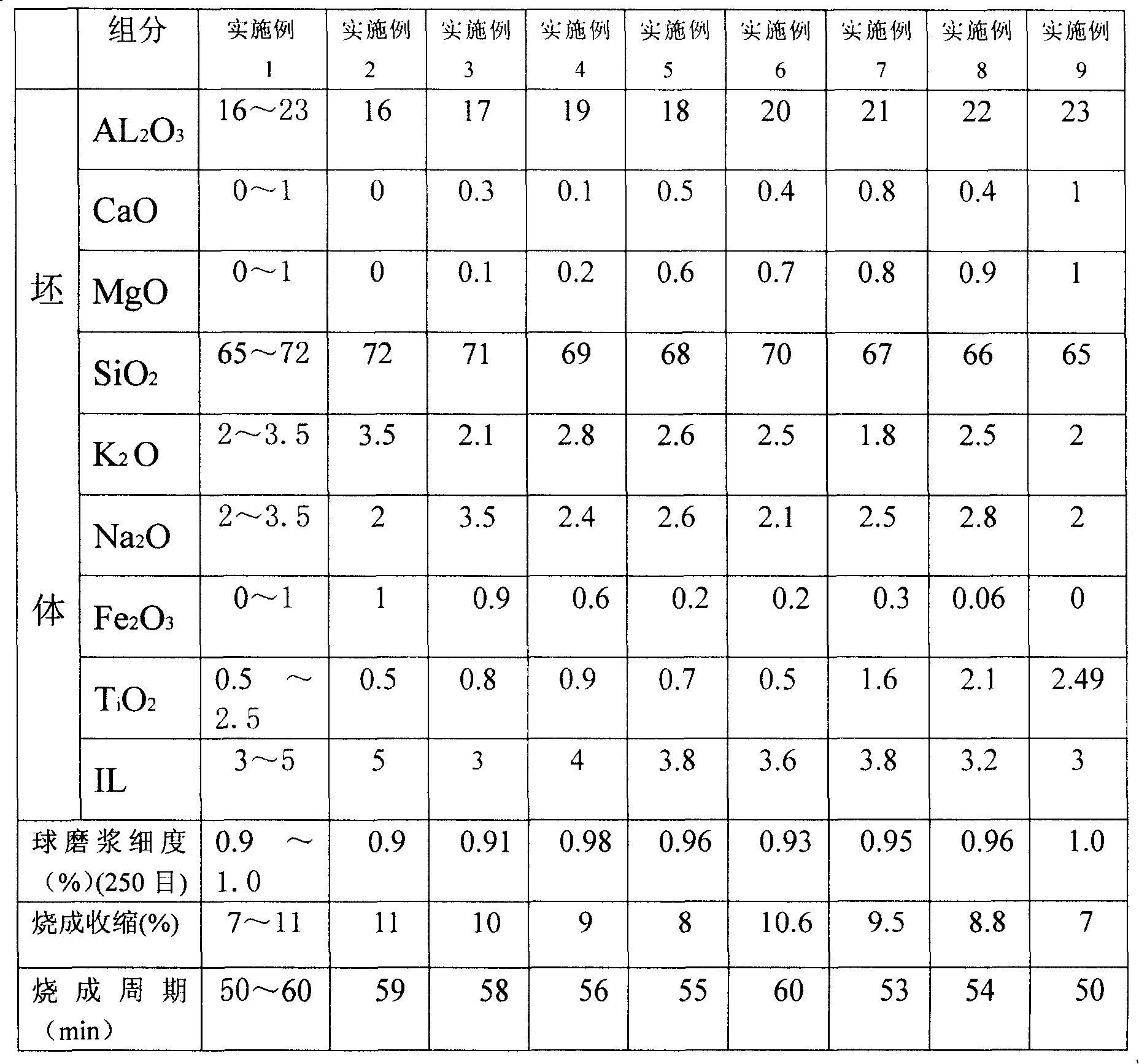

Novel pseudo-classic brick and method for manufacturing same

The invention discloses a new antique brick and the manufacturing method; wherein, weight percentage of chemical component for main raw material is as follows: 16 to 23% Al2O3, less than 2% CaO and MgO, 65 to 7% SiO2, 4 to 7% K2O and Na2O, less than 1% Fe2O3, less than 0.5 to 2.5% TiO2, and 3 to 5% IL; the manufacturing method comprises the following steps: entry of raw material to the factory -> checking -> preparation -> ball milling-> testing -> pulp discharging -> powder making -> mixing for dry mixing machine -> sieving and warehousing -> ready for use; weight percentage of fineness for ball milling slurry is 250 meshes sieve residue: 0.9 to 1.0%; 7 to 11% of calcining shrinkage; 50 to 60min calcining cycle, 1200 to 1210 DEG C of temperature: 1.70 to 1.70g / cm<3> of ball milling slurry weight for mixture making; 16 to 23S of flow velocity for ball milling slurry for mixture making; 5.8 to 6.2% of powder lot moisture. The invention has the advantages of rational process and good qualitative sense of products.

Owner:霍炳祥

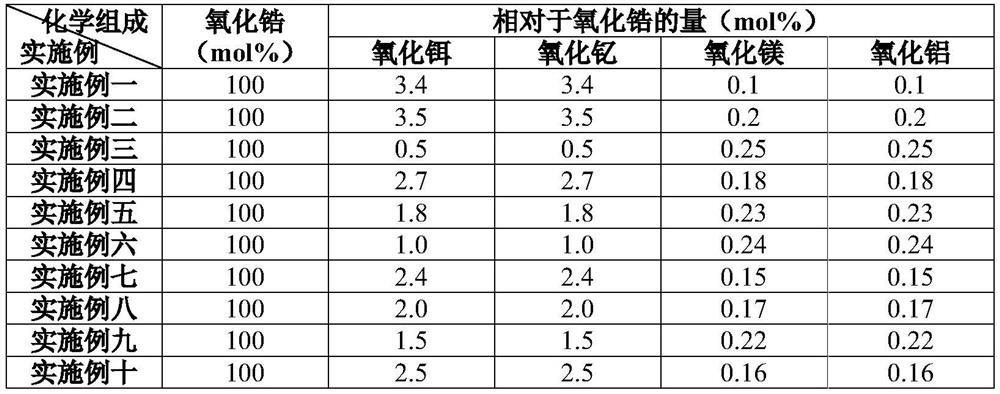

A kind of high-strength pink zirconia ceramic powder and its preparation method and application

The invention discloses a high-strength pink zirconia ceramic powder, the chemical composition of which is zirconia and an added oxide; the content of the added oxide is 0.5-4.0 mol% of erbium oxide, yttrium oxide 0.5-4.0 mol%, magnesium oxide 0.1-0.3 mol%, aluminum oxide 0.1-0.3 mol%. In addition, the preparation method and application of the above-mentioned high-strength pink zirconia ceramic powder are also disclosed. The powder raw material with stable composition and excellent performance obtained by optimizing the composition of the formula in the present invention is conducive to obtaining pink aesthetic ceramic products with high strength, good toughness, good color development, high moisturization and few surface defects, so that it can be well It can fully meet the stringent processing requirements in practical applications, and is conducive to broadening its application fields, with significant economic benefits and broad application prospects.

Owner:江西德锆美瓷有限公司

ca‑nd‑ti microwave dielectric ceramic material and preparation method thereof

The present invention provides a high quality factor microwave dielectric ceramic material substituted by B position and its preparation method. The B position is substituted to achieve the purpose of controlling the microwave properties of the system; M represents Nb whose valence is higher than tetravalent, N represents one or several other elements whose valence is lower than tetravalent and the ionic radius is similar to Ti, and M and N are simultaneously Substituted or replaced alone; the preparation method is to determine the respective mass percentages according to the general chemical formula, mix by ball milling, pre-calcine at 1050-1150°C, and then sinter at 1350-1450°C; the dielectric constant of the prepared material ( 70~100) and frequency temperature coefficient are adjustable while maintaining excellent Q×f value (9000GHz~16000GHz), the formula does not contain volatile or heavy metals such as Pb and Cd, and the performance is greatly improved compared with other systems. Raw materials The domestic supply is sufficient, and the price is relatively low compared to other systems, which makes it possible to reduce the cost of high-performance microwave ceramics.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Multi-phase functional ceramic honeycomb support and preparation method thereof

ActiveCN100445237CThe preparation method is simple and controllableLow costCatalyst carriersCeramicwareRare earthSilicon dioxide

The invention relates to a multi-phase functional honeycomb ceramic support body and a preparation method thereof. Using titanium dioxide, silica, and alumina as the main raw materials, through rare earth doping, adding an appropriate amount of burning accelerator magnesium oxide and additives, kneading and extrusion molding, drying, and calcining at 1200 to 1350°C for 2 to In 3 hours, a ceramic honeycomb carrier with aluminum titanate and rutile as the main crystal phases was generated. The honeycomb ceramic prepared by the invention has a thermal expansion coefficient of 3.6 to 7.5×10-6 / ℃ between 50 and 1000°C, is resistant to thermal shock, acid and alkali corrosion, has high strength, shows solid acidity, and is well combined with the carrier coating. This honeycomb ceramic can be used in a variety of applications, and is especially suitable for industrial flue gas integrated denitration catalyst supports, vehicle exhaust gas purification catalyst carriers, and photocatalyst carrier reactors.

Owner:SHANDONG GEMSKY ENVIRONMENTAL PROTECTION TECH CO LTD

Acid-corrosion-resistant enamel coating layer on surface of weather-resistant structural steel and preparation method of acid-corrosion-resistant enamel coating layer

The invention discloses an acid-corrosion-resistant enamel coating layer on the surface of weather-resistant structural steel and a preparation method of the acid-corrosion-resistant enamel coating layer. The preparation method of the acid-corrosion-resistant enamel coating layer on the surface of the weather-resistant structural steel comprises the steps: a) melting enamel glazes, b) preparing enamel glaze powder, c) performing alkaline degreasing treatment on the weather-resistant structural steel, and d) performing spraying and high-temperature firing on the enamel coating layer, wherein the enamel glazes comprise two kinds, namely an enamel enamel A and an enamel enamel B. The acid-corrosion-resistant enamel coating layer on the surface of the weather-resistant structural steel, whichis obtained by adopting the preparation method disclosed by the invention, has the advantages of excellent acid corrosion resistance, particularly sulfuric acid corrosion resistance, high bonding strength, long service life and the like. In addition, the preparation method is simple, the two glazes are adopted for separate melting, the surface of the weather-resistant structural steel is subjectedto alkaline degreasing treatment, the production efficiency is improved, energy consumption is reduced, the production cost of the enamel coating layer is reduced, and the preparation method is suitable for large-scale application and popularization.

Owner:宁波硕强环保新材料有限公司

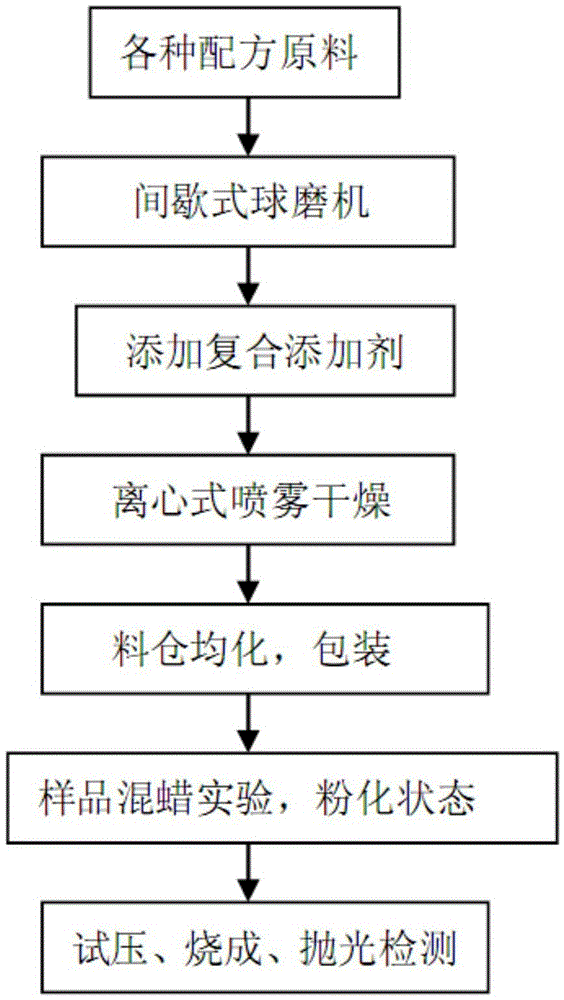

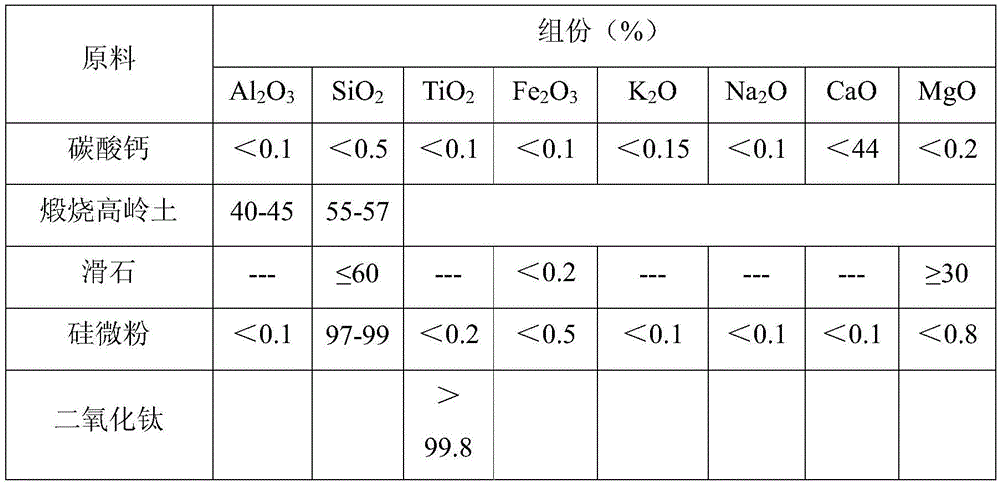

A kind of preparation method of aluminum oxide granulation powder special for hot-pressed water valve sheet

The invention discloses a preparation method of aluminum oxide granulation powder specially used for hot-pressed water valve sheets, and belongs to the technical field of new materials. This method uses optimized special alumina powder as the main raw material, and uses a unique ball milling process to control the particle size gradation of the mud; using compound additives to modify the surface of the granulated powder to achieve wet spraying, the granular granulated powder can reach a similar level during use. The effect of dry grinding granulated powder (micro powder). The prepared alumina granulated powder is suitable for hot die-casting equipment of various manufacturers in the market, and the fired products have high precision, no deformation and good polishing effect.

Owner:JINGANG NEW MATERIALS

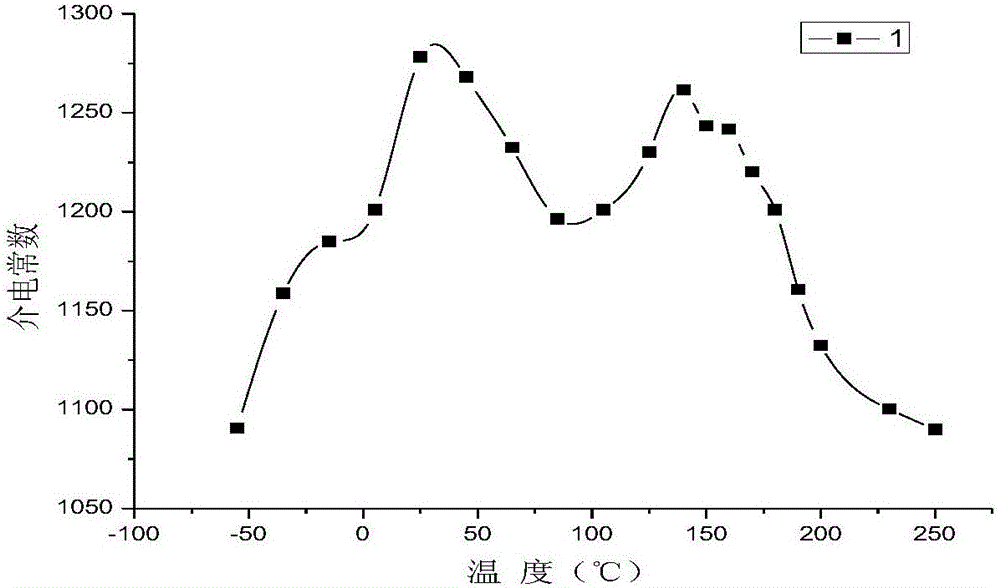

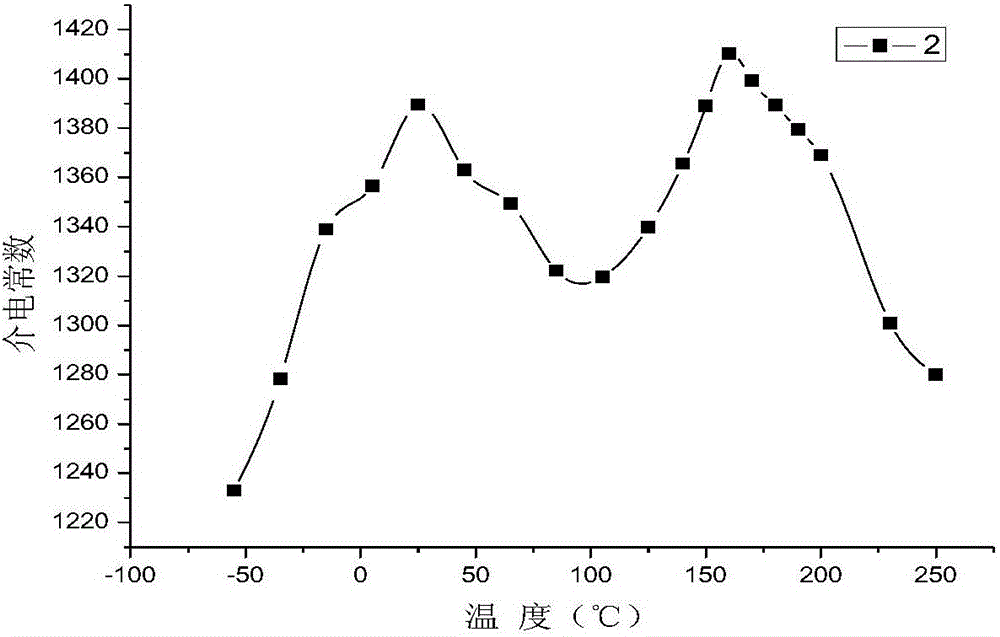

Medium and low temperature sintering temperature stable ceramic capacitor material and preparation method thereof

InactiveCN106747416BUltra high temperature stabilityExcellent dielectric propertiesDielectric lossWorking temperature

The invention discloses a medium and low sintering temperature stable ceramic capacitor material and a preparation method. The material comprises BaTiO3 as a main material, together with 1-7% of mass of sintering assistant and 0.5-9.5% of mass of metal oxide. The sintering assistant comprises the following raw materials by mass percentage: 1-26% of Bi2O3, 1-24% of K2CO3, 1.2-22% of ZnO, 1.5-28% of CaF2, 2-28% of P2O5 and 3.5-32% of CaO, and the metal oxide comprises the following raw materials by mass percentage: 1-28% of Nb2O5, 0.2-30% of MgO, 0.5-32% of WO3, 0.3-27% of CaTiO3 and 0.1-33% of CuO. The material has a wide sintering temperature (850-1050 DEG C), and is low in dielectric loss, high in dielectric constant, stable in performance, high in mechanical strength, high in reliability, good in uniformity and environment-friendly; a working temperature zone is from -55 DEG C to +250 DEG C; and the material meets severe environment requirements.

Owner:TIANJIN UNIV

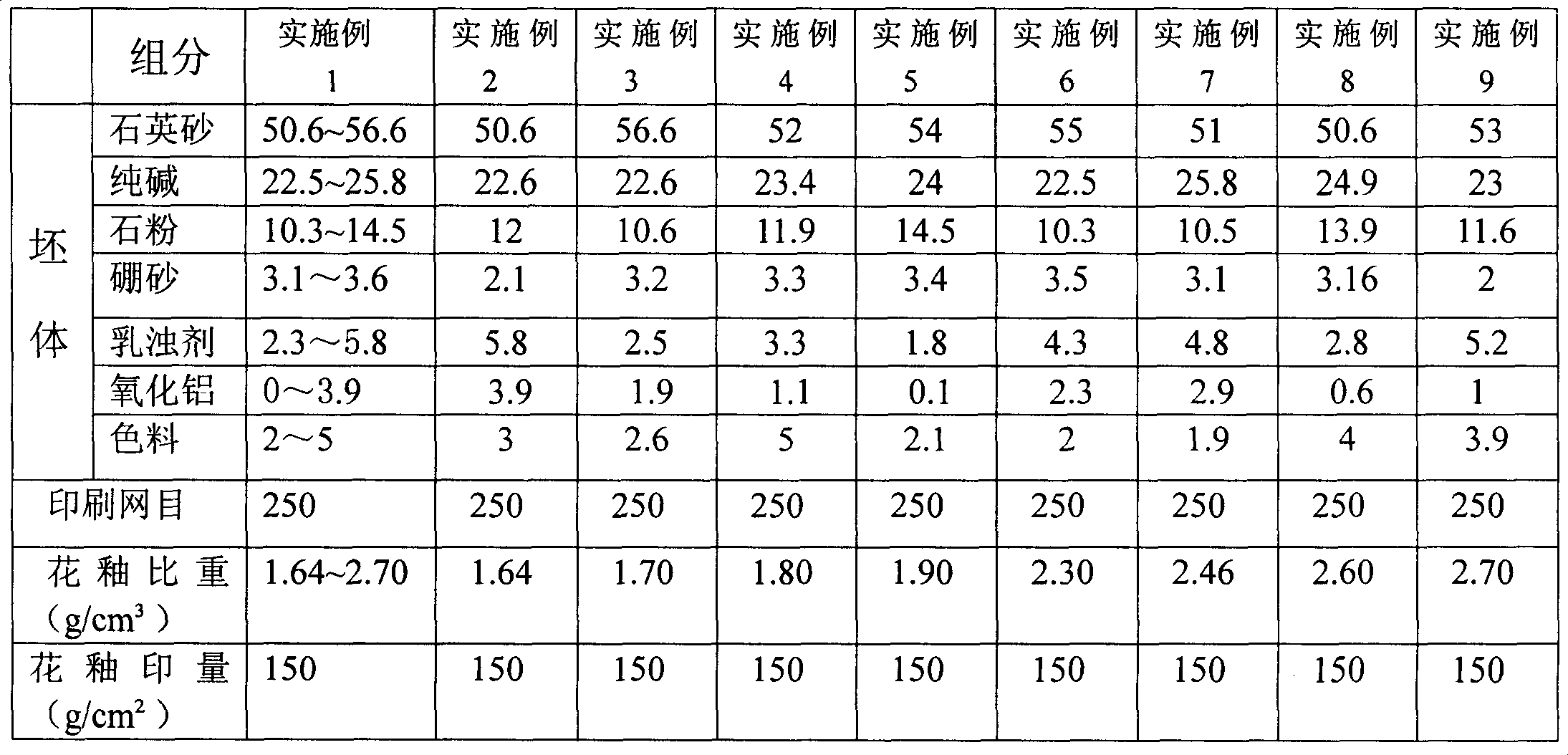

Glass waist-line, flower piece and producing method

This invention relates to a glass corbel and flower piece. According to weight, the key components are: quartz sand 50.6 to 56.6%, sodium carbonate 22.5 to 25.8%, mountain meal 10.3 to 14.5%, borax 3.1 to 3.6%, opacifier 2.3 to 5.8%, alumina 0 to 3.9%, toner 0 to 1.3%; this invention also discloses the manufacturing method. The production process: pattern design ->film out->drying->hunk glass cutting->snippet glass cutting-> printing bottom white-> printing bottom closing glue->incising->planking->burning->edging->sorting->casing; the printing mesh is 250; flower glaze specific gravity is 1.64 to 2.70g / cm3; flower glaze printing quantity: 150g / cm2; this invention can reduce cost about 20%.

Owner:霍镰泉

Low-temperature sintering hexagonal crystal series soft magnet ferrite

InactiveCN100533611CImprove performancePerformance variesInorganic material magnetismElectricity priceSoft magnet

The invention belongs to the metal material field, in particular to a hexagonal soft magnetic ferrite material that can be sintered at a low temperature directly. The invention is characterized in that the invention adopts Bi2O3 as one of the constituent, and replaces Ba2+ with Bi3+, and divalent metal Me2+ with Fe3+ to balance the overall electricity price. The crystal phase of the hexagonal soft magnetic ferrite material is Y-type hexagonal ferrite, and the molecular formula is Ba2-xBixMe2+xFe12-xO22, 0 H01F 1 / 34 C04B 35 / 26 C04B 35 / 64 1 4 1 2007 / 6 / 14 101106004 2008 / 1 / 16 000000000 University of Science and Technology Beijing Beijing 100083 Bai Yang Qiao Lijie Xu Fang luzhong qiang 11207 The Patent Agency of Beijing University of Science and Technology No.30 Xueyuan Road, Beijing 100083

Owner:UNIV OF SCI & TECH BEIJING

High-temperature glisten glaze and preparation method thereof

The invention discloses a high-temperature glisten glaze and a preparation method thereof. The glaze comprises, by mass, 1-16% of Al2O3, 50-75% of SiO2, 0.5-5% of CaO, 0-2% of MgO, 2-9% of K2O, 0-2% of Na2O, 2-16% of ZnO, 0-2% of PbO, 3-9% of ZrO2, 3-10% of CeO2 and 0.5-8% of B2O3. The glisten glaze is wide in application range, good in firing performance and high in stability and glisten strength; and the preparation method is reasonable and simple in technology.

Owner:威远县大禾陶瓷原料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com