Medium and low sintering temperature stable ceramic capacitor material and preparation method thereof

A temperature-stable, low-temperature sintering technology, applied in the field of ceramic compositions, can solve problems such as increasing the manufacturing cost of capacitors, and achieve the effects of wide sintering temperature, easy control of sintering process and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

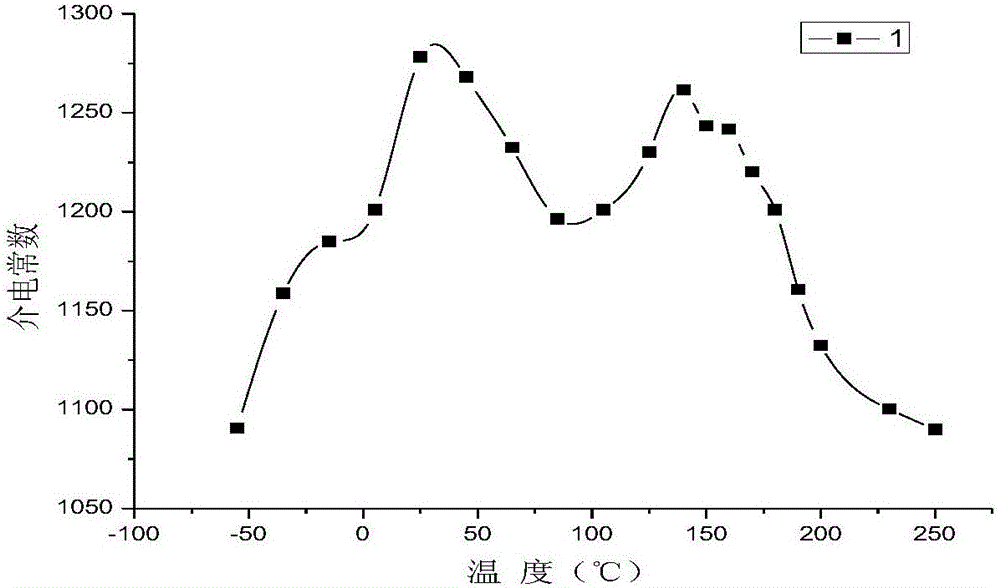

Embodiment 1

[0039] (1) Mix the raw materials evenly according to the raw material composition and mass percentage content of the sintering aid: 16% Bi 2 o 3 , 14%K 2 CO 3 , 12% ZnO, 18% CaF 2 , 18%P 2 o 5 , 22% CaO;

[0040] The mixed raw materials were put into deionized water ball mill for 10 hours, dried at 70°C, calcined at 1150°C, kept for 9 hours at a heating rate of 8°C / min, and naturally cooled to obtain a sintering aid;

[0041] (2) According to the raw material composition and mass percentage content of metal oxide, the raw materials are evenly mixed: 18%Nb2 o 5 , 20% MgO, 22% WO 3 , 17% CaTiO 3 , 23% CuO;

[0042] Add deionized water to the mixed raw materials, ball mill for 9 hours, and dry at a temperature of 70°C to obtain ceramic powder of metal oxides;

[0043] (3) According to the BaTiO 3 On the basis of adding 3% mass percentage of sintering aid and 7% metal oxide stoichiometric ratio for secondary batching, uniform mixing, adding deionized water ball mill for...

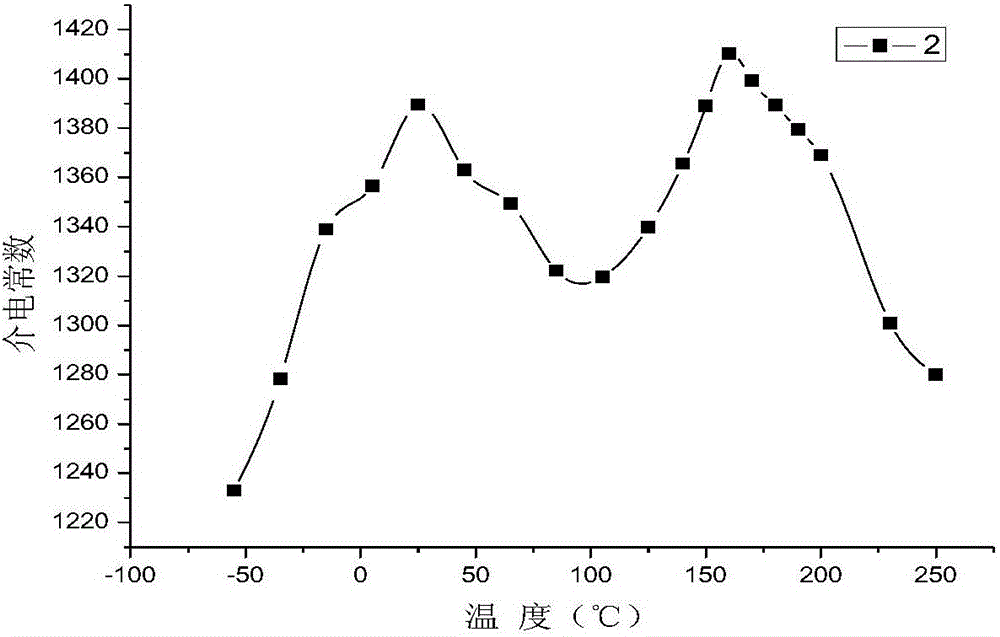

Embodiment 2

[0050] (1) Mix the raw materials uniformly according to the raw material composition and mass percentage content of the sintering aid: 8% Bi 2 o 3 , 22%K 2 CO 3 , 4% ZnO, 26% CaF 2 , 10%P 2 o 5 , 30% CaO;

[0051] The mixed raw materials were put into deionized water ball mill for 10 hours, dried at 70°C, calcined at 1150°C, kept for 9 hours at a heating rate of 8°C / min, and naturally cooled to obtain a sintering aid;

[0052] (2) Mix the raw materials evenly according to the raw material composition and mass percentage content of the metal oxide: 2% Nb 2 o 5 , 28% MgO, 30% WO 3 , 9% CaTiO 3 , 31% CuO;

[0053] Add deionized water to the mixed raw materials, ball mill for 9 hours, and dry at a temperature of 70°C to obtain ceramic powder of metal oxides;

[0054] (3) According to the BaTiO 3 On the basis of adding sintering aids with a mass percentage content of 1.5% and a stoichiometric ratio of 8.5% metal oxides for secondary batching, uniform mixing, adding deio...

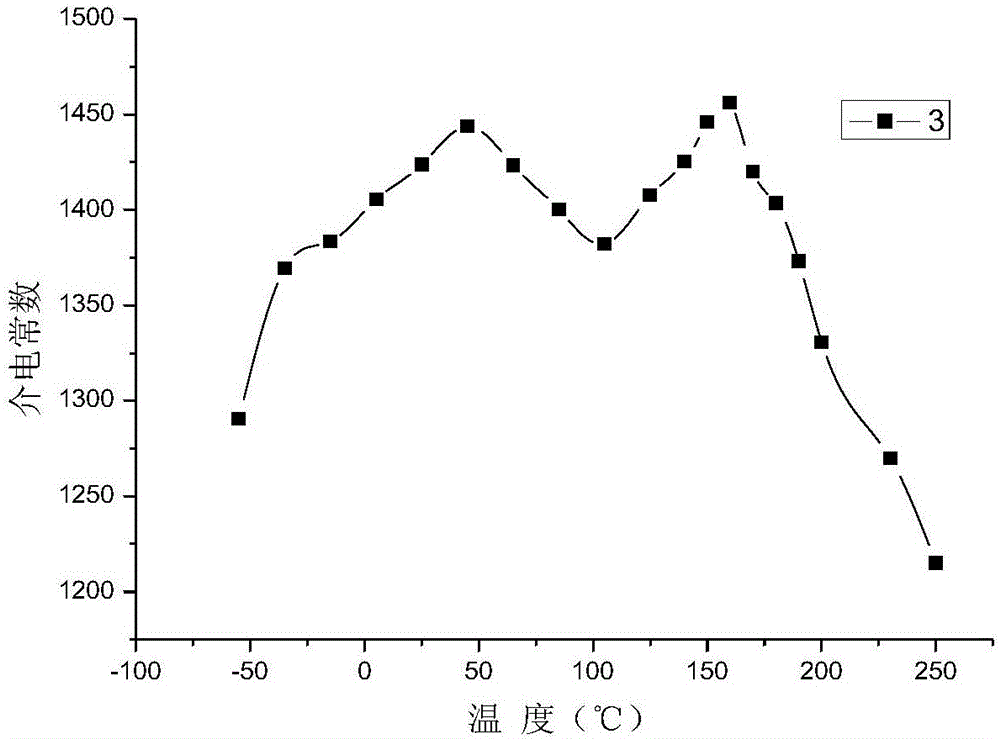

Embodiment 3

[0061] (1) Mix the raw materials evenly according to the raw material composition and mass percentage content of the sintering aid: 10% Bi 2 o 3 , 20%K 2 CO 3 , 18% ZnO, 12% CaF 2 , 12%P 2 o 5 , 28% CaO;

[0062] The mixed raw materials were put into deionized water ball mill for 10 hours, dried at 70°C, calcined at 1150°C, kept for 9 hours at a heating rate of 8°C / min, and naturally cooled to obtain a sintering aid;

[0063] (2) Mix the raw materials evenly according to the raw material composition and mass percentage content of the metal oxide: 20% Nb 2 o 5 , 14% MgO, 16% WO 3 , 23% CaTiO 3 , 27% CuO;

[0064] Add deionized water to the mixed raw materials, ball mill for 9 hours, and dry at a temperature of 70°C to obtain ceramic powder of metal oxides;

[0065] (3) According to the BaTiO 3 On the basis of adding 2% mass percentage of sintering aid and 8% metal oxide stoichiometric ratio for secondary batching, uniform mixing, adding deionized water ball mill for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com