Sintering flux for solid waste sintered porous heat insulation sheets, and preparation method and application thereof

A technology for solid waste and insulation boards, which is applied in the field of sintering flux and preparation of solid waste sintered porous insulation boards, which can solve the problems of reasonable compatibility of fluxes and high firing temperature without consideration, and achieve good physical and mechanical properties , Lower firing temperature, and the effect of reducing waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of sintering flux for solid waste sintered porous insulation board, composed of rapid fluxing component, stable fluxing component and gentle fluxing component; the mass ratio of rapid fluxing component and stable fluxing component is 2:1, the mass ratio of gentle fluxing component to stable fluxing component is 1:1; the rapid fluxing component is borax, the stable fluxing component is glass powder, and the gentle fluxing component is pearl The mixture of rock and feldspar, the mass ratio of perlite and feldspar is 1:1.

[0022] The massfraction of each chemical composition in described borax is: Na 2 O 16%, B 2 o 3 36%, H 2 O 48%.

[0023] The mass fraction of each chemical composition in the glass powder is: SiO 2 73%, Al 2 o 3 9%, Na 2 O 8%, CaO 9%, K 2 O 1%.

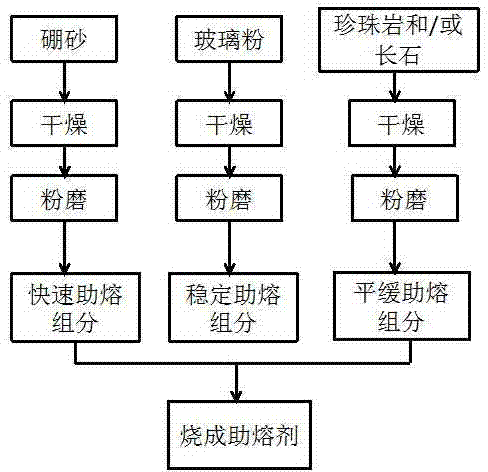

[0024]The preparation method of the sintering flux for the solid waste sintered porous insulation board includes the following steps: ① drying and grinding the borax to obtain the fast fluxi...

Embodiment 2

[0029] A kind of sintering flux for solid waste sintered porous insulation board, composed of rapid fluxing component, stable fluxing component and gentle fluxing component; the mass ratio of rapid fluxing component and stable fluxing component is 1:1, the mass ratio of the smooth fluxing component to the stable fluxing component is 2:1; the rapid fluxing component is borax, the stable fluxing component is glass powder, and the gentle fluxing component is pearl rock.

[0030] The massfraction of each chemical composition in described borax is: Na 2 O 15%, B 2 o 3 37%, H 2 O 48%.

[0031] The mass fraction of each chemical composition in the glass powder is: SiO 2 70%, Al 2 o 3 6%, Na 2 O 16%, CaO 6%, K 2 O 2%.

[0032] The preparation method of the sintering flux for the solid waste sintered porous insulation board includes the following steps: ① drying and grinding the borax to obtain the fast fluxing component after reaching the condition that the 80 μm sieve is...

Embodiment 3

[0037] A kind of sintering flux for solid waste sintered porous insulation board, composed of rapid fluxing component, stable fluxing component and gentle fluxing component; the mass ratio of rapid fluxing component and stable fluxing component is 1:1, the mass ratio of the smooth fluxing component and the stable fluxing component is 1:1; the rapid fluxing component is borax, the stable fluxing component is glass frit, and the gentle fluxing component is long stone.

[0038] The massfraction of each chemical composition in described borax is: Na 2 O 17%, B 2 o 3 37%, H 2 O 46%.

[0039] The mass fraction of each chemical composition in the glass powder is: SiO 2 70%, Al 2 o 3 3%, Na 2 O 16%, CaO 9%, K 2 O 2%.

[0040] The preparation method of the sintering flux for the solid waste sintered porous insulation board includes the following steps: ① drying and grinding the borax to obtain the fast fluxing component after reaching the condition that the 80 μm sieve is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com