Antibacterial glaze, antibacterial brick and preparation method of antibacterial brick

A technology of antibacterial glaze and antibacterial brick, which is applied in the field of antibacterial brick and its preparation and antibacterial glaze, which can solve the problems of narrow firing temperature range, increased production cost, general antibacterial effect, etc., and achieve wide firing range and good layering , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

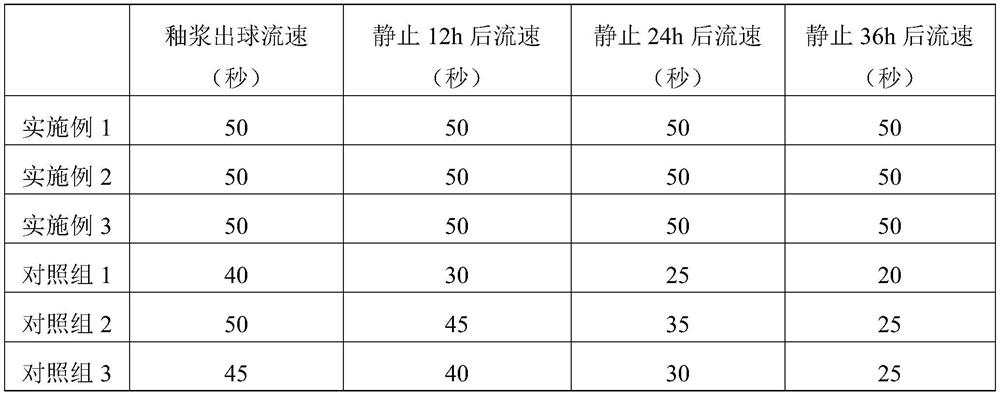

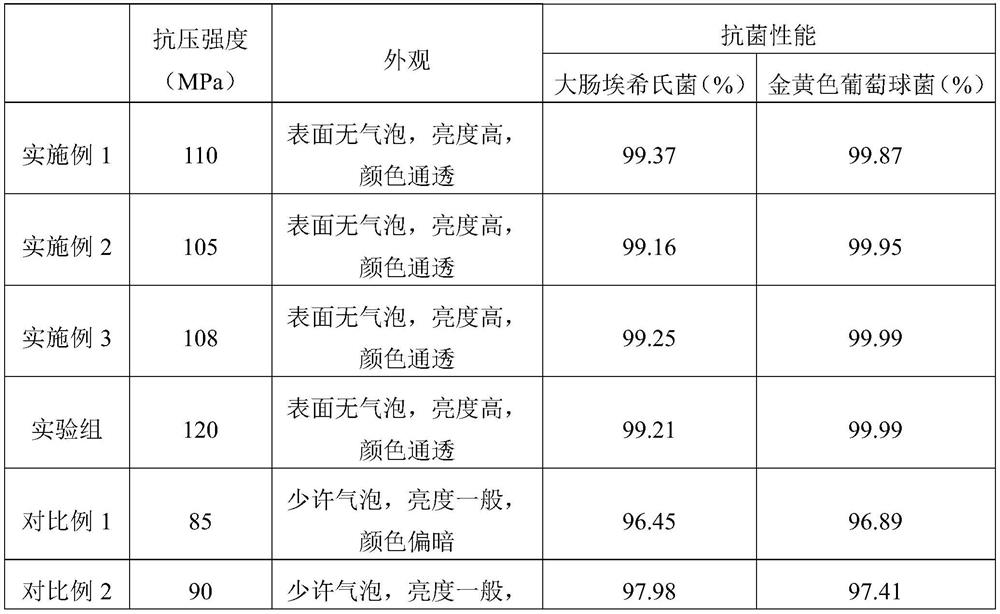

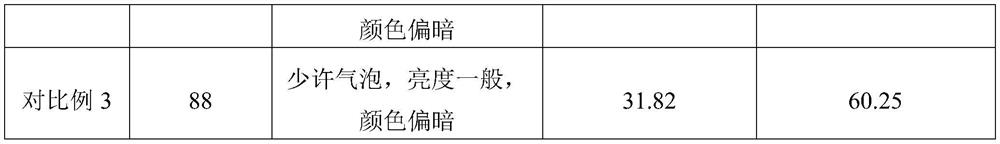

Examples

Embodiment 1

[0016] An antibacterial glaze, the raw materials of which include by weight: 30 parts of albite, 12 parts of potassium feldspar, 6 parts of kaolin, 12 parts of quartz, 4 parts of aluminum oxide, 6 parts of talc, 6 parts of zinc oxide, and 15 parts of dolomite 10 parts of wollastonite, 9 parts of strontium carbonate, 4 parts of barium carbonate, and 5 parts of nano silver.

[0017] The preparation method of the above-mentioned antibacterial glaze comprises the following steps: pulverizing albite, potassium feldspar, kaolin, quartz, talc, dolomite and wollastonite, and then mixing them with aluminum oxide, zinc oxide, strontium carbonate, barium carbonate and nano-silver , adding additives for ball milling. The total mass of each raw material of the antibacterial glaze: the mass of sodium tripolyphosphate: the mass of methyl cellulose: the mass of water = 100:0.5:0.1:40.

Embodiment 2

[0019] An antibacterial glaze, the raw materials of which include by weight: 28 parts of albite, 14 parts of potassium feldspar, 5 parts of kaolin, 10 parts of quartz, 3 parts of alumina, 8 parts of talc, 6 parts of zinc oxide, 13 parts of dolomite 12 parts of wollastonite, 10 parts of strontium carbonate, 5 parts of barium carbonate, and 4 parts of nano silver.

[0020] The preparation method of the above-mentioned antibacterial glaze comprises the following steps: pulverizing albite, potassium feldspar, kaolin, quartz, talc, dolomite and wollastonite, and then mixing them with aluminum oxide, zinc oxide, strontium carbonate, barium carbonate and nano-silver , adding additives for ball milling. The total mass of each raw material of the antibacterial glaze: the mass of sodium tripolyphosphate: the mass of methyl cellulose: the mass of water=100:0.45:0.05:37.

Embodiment 3

[0022] An antibacterial glaze, the raw materials of which include by weight: 32 parts of albite, 10 parts of potassium feldspar, 7 parts of kaolin, 8 parts of quartz, 5 parts of aluminum oxide, 9 parts of talc, 5 parts of zinc oxide, and 15 parts of dolomite 8 parts of wollastonite, 10 parts of strontium carbonate, 4 parts of barium carbonate, and 6 parts of nano-silver.

[0023] The preparation method of the above-mentioned antibacterial glaze comprises the following steps: pulverizing albite, potassium feldspar, kaolin, quartz, talc, dolomite and wollastonite, and then mixing them with aluminum oxide, zinc oxide, strontium carbonate, barium carbonate and nano-silver , adding additives for ball milling. The total mass of each raw material of the antibacterial glaze: the mass of sodium tripolyphosphate: the mass of methyl cellulose: the mass of water=100:0.35:0.15:37.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com