Superfine polyester-nylon composite spinning component

A composite spinning and ultra-fine polyester technology, applied in textiles and papermaking, filament/thread forming, fiber treatment, etc., can solve problems such as easy fluffing and easy color difference in dyeing, so as to achieve less color difference, improved fluidity, and avoid The effect of flow dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

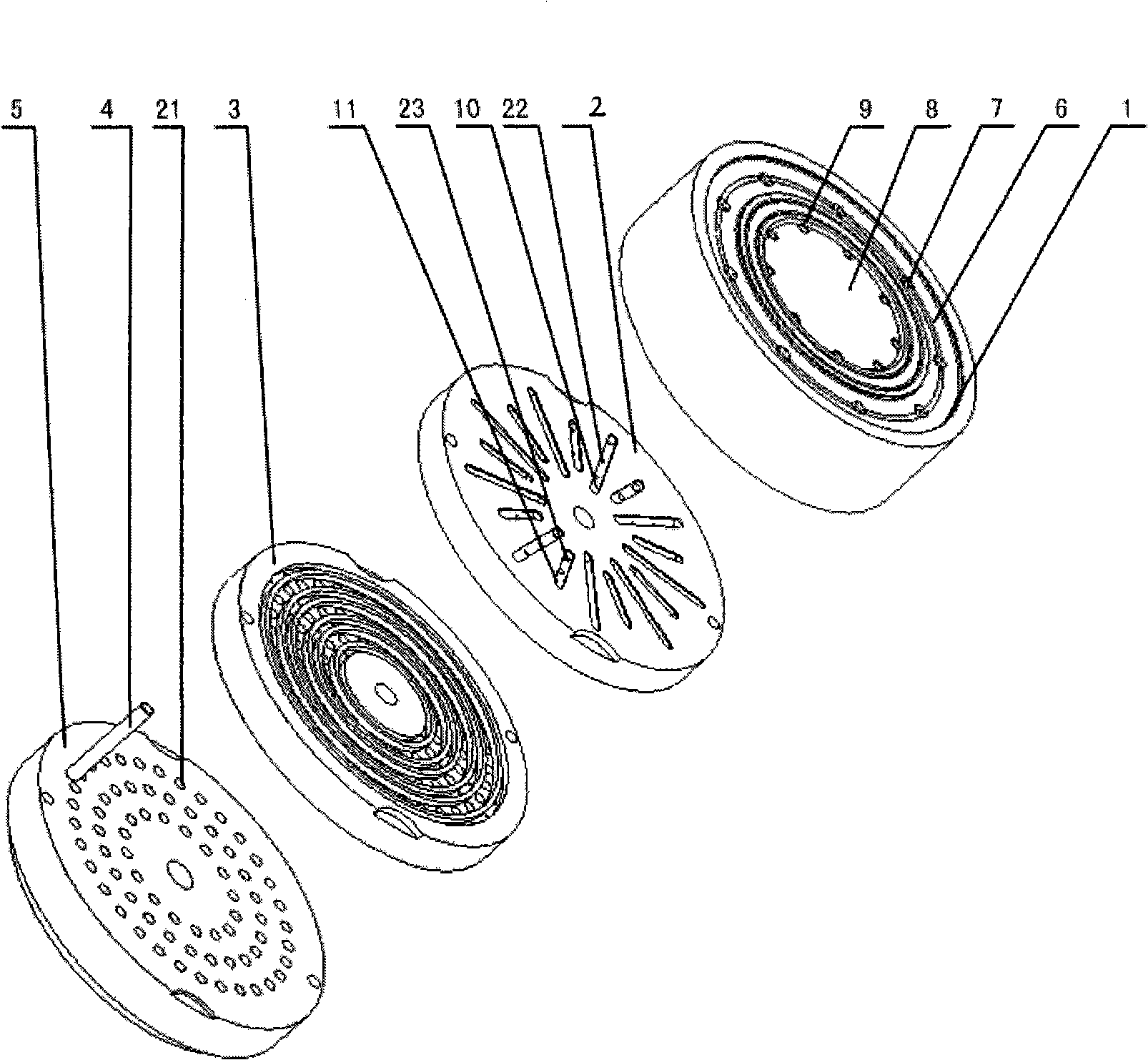

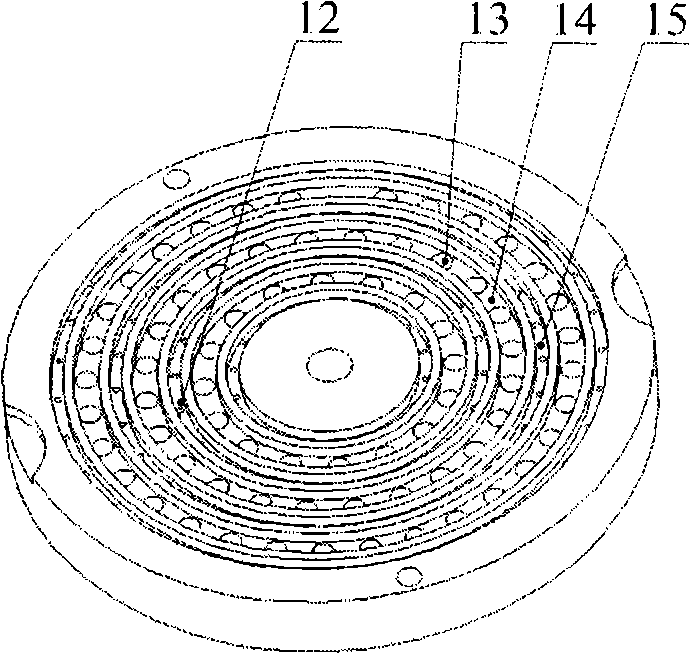

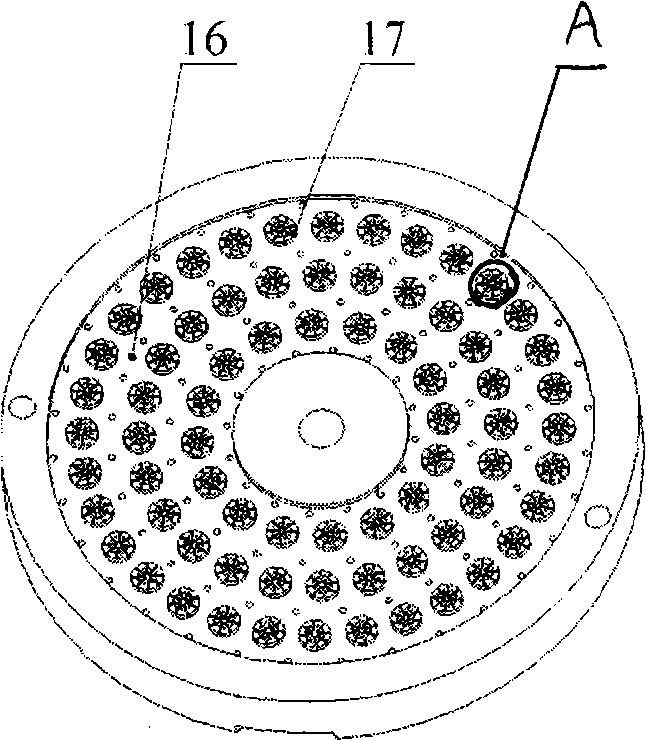

[0015] From Figure 1-Figure 4 It can be seen from the figure that a fine polyester super nylon composite spinning assembly includes an inclined orifice plate 1, a radiation plate 2, a composite plate 3, a positioning pin 4, and a spinneret plate 5. The contact surfaces of the plates are sealed in a flat manner, and the entire assembly is positioned and connected by positioning pins 4; a polyester cavity 6 and a nylon cavity 8 are designed on the inclined hole plate 1; polyester guides are designed at the bottom of the polyester cavity 6 and the nylon cavity 8 The orifice 7 and the nylon diversion hole 9, the polyester diversion hole 7 and the nylon diversion hole 9 have a one-to-one relationship with the polyester spherical diversion groove 10 and the nylon spherical diversion groove 11 on the feeding surface of the radiation plate 2; A plurality of polyester spherical diversion grooves 10 and nylon spherical diversion grooves 11 are designed on the board 2, and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com