Nursing type mixed fabric and production method thereof

A technology of blended fabrics and production methods, applied in the directions of dyeing, textile and papermaking, weft knitting, etc., to achieve the effects of high curling, good hygroscopicity and air permeability, and soft and smooth texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The finished fabric contains 10% milk silk fiber, 28% modal fiber, 57% newdale fiber and 5% spandex fiber.

[0043] The production method of this fabric is specifically carried out as follows:

[0044] a) The blended fiber with a thickness of 40S and the spandex fiber with a thickness of 20D made of milk silk fiber, modal fiber and Newdale fiber are woven into cotton wool fabric gray cloth on a double-sided cotton wool machine with a needle size of 34 "28G.

[0045] b) Dyeing the cotton and wool gray fabric:

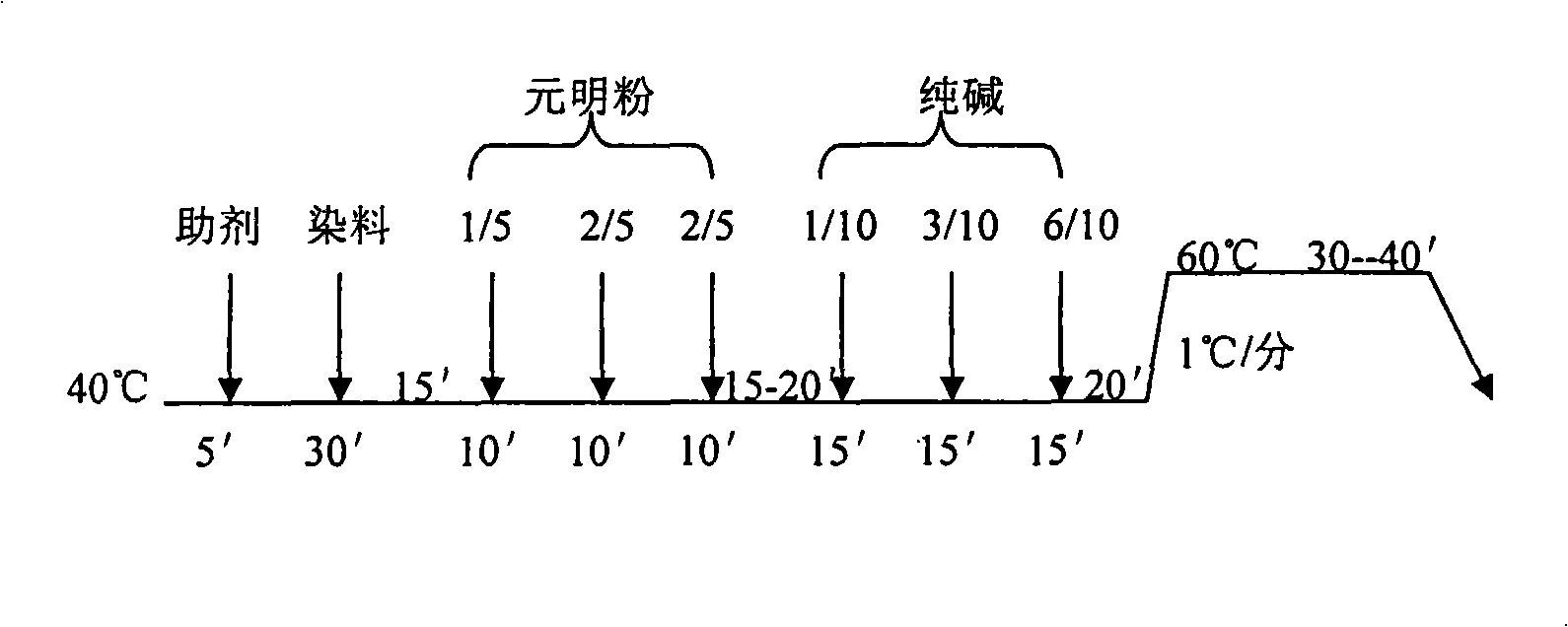

[0046] 1. Dyed gray, such as figure 1 Shown:

[0047] (1) Put the gray cloth into the dyeing machine, prepare clean water, the bath ratio is 1:10, and at a temperature of 40°C, mix the 197 alkaline additive in the ratio of 3g / L solution within 5 minutes Added into German THIES dyeing machine.

[0048] (2) Put the evenly stirred environment-friendly dyes produced by Destar Company (0.4% for RGB-Y, 0.3% for RGB-R, and 0.6% for RGB-B) according to the setting wit...

Embodiment 2

[0058] The finished fabric contains 10% milk silk fiber, 28% modal fiber, 57% newdale fiber and 5% spandex fiber.

[0059] The production method of the fabric includes weaving and dyeing and finishing processes, specifically as follows:

[0060] a) The blended fiber with a thickness of 40S and the spandex fiber with a thickness of 20D made of milk silk fiber, modal fiber and Newdale fiber are woven into cotton wool fabric gray fabric on a double-sided cotton wool machine with a needle size of 34 "28G.

[0061] b) Dyeing the cotton and wool gray fabric:

[0062] 1. dyed brown, such as figure 1 Shown:

[0063] (1) Put the gray cloth into the dyeing machine, prepare clean water, the liquor ratio is 1:5, and at a temperature of 40°C, mix 3g / L of 197 alkaline additive (Weiwei Chemical Co., Ltd.) in 5 Put it into the German THIES dyeing machine within minutes.

[0064] (2) Then put the evenly stirred DESTAR environmental protection dye (the dye RGB-R dosage is 1.2%, the RGB-B do...

Embodiment 3

[0074] In the finished fabric, milk silk fiber is 20%, modal fiber is 35%, newdale fiber is 40%, and spandex fiber is 5%.

[0075] The production method of this fabric is specifically carried out as follows:

[0076] a) The blended fiber with a thickness of 40S and the spandex fiber with a thickness of 20D made of milk silk fiber, modal fiber and Newdale fiber are woven into cotton wool fabric gray fabric on a double-sided cotton wool machine with a needle size of 34 "28G.

[0077] b) Dyeing the cotton and wool gray fabric:

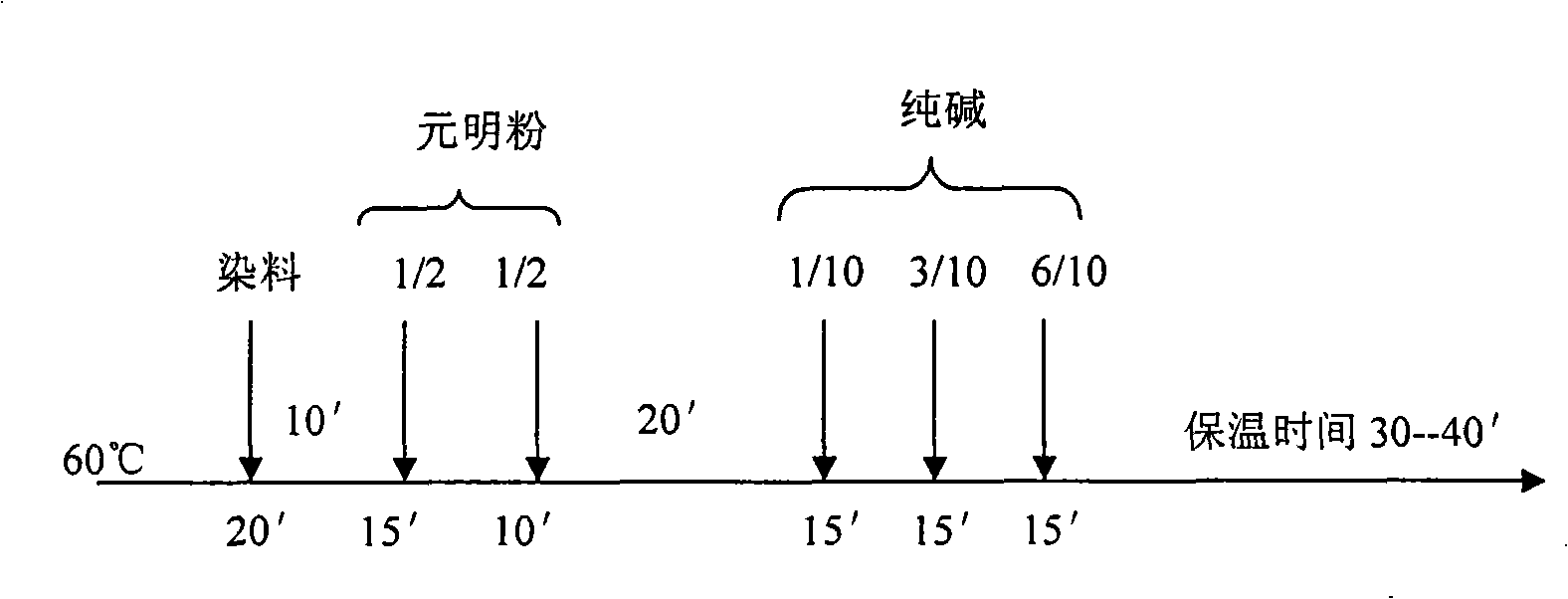

[0078] 1. Dyed red according to ordinary color process, such as figure 2 Shown:

[0079] (1) Put the gray cloth into the dyeing machine, prepare clean water, the bath ratio is 1:5, and add the environmentally friendly dye (dye) produced by Destar Company that has been stirred evenly into the German THIES dyeing machine at a solution temperature of 60 ° C. The amount of RGB-Y is 0.5%, the amount of RGB-R is 3.5%, and the amount of RGB-B is 0.1%), so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com