Nursing type blended fabric and production method thereof

A production method and technology of blended fabrics, applied in dyeing, textiles and papermaking, weft knitting, etc., to achieve good hygroscopicity and air permeability, strong silky texture, and fine fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The finished fabric contains 10% milk silk fiber, 28% modal fiber, 57% newdale fiber and 5% spandex fiber.

[0042] The production method of this fabric is specifically carried out as follows:

[0043] a) The blended fiber with a thickness of 40S and the spandex fiber with a thickness of 20D made of milk silk fiber, modal fiber and Newdale fiber are woven into cotton wool fabric gray cloth on a double-sided cotton wool machine with a needle size of 34 "28G.

[0044] b) Dyeing the cotton and wool gray fabric:

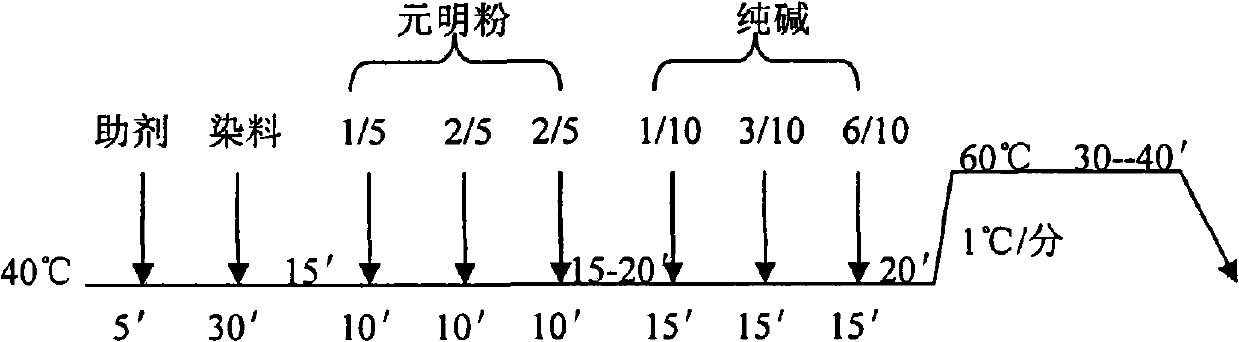

[0045] 1. Dyed gray, such as figure 1 Shown:

[0046] (1) Put the gray cloth into the dyeing machine, prepare clean water, the bath ratio is 1:10, and at a temperature of 40°C, mix the 197 alkaline additive in the ratio of 3g / L solution within 5 minutes Added into German THIES dyeing machine.

[0047] (2) Put the evenly stirred environment-friendly dyes produced by Destar Company (0.4% for RGB-Y, 0.3% for RGB-R, and 0.6% for RGB-B) according to the setting wit...

Embodiment 2

[0057] The finished fabric contains 10% milk silk fiber, 28% modal fiber, 57% newdale fiber and 5% spandex fiber.

[0058] The production method of the fabric includes weaving and dyeing and finishing processes, specifically as follows:

[0059] a) The blended fiber with a thickness of 40S and the spandex fiber with a thickness of 20D made of milk silk fiber, modal fiber and Newdale fiber are woven into cotton wool fabric gray fabric on a double-sided cotton wool machine with a needle size of 34 "28G.

[0060] b) Dyeing the cotton and wool gray fabric:

[0061] 1. dyed brown, such as figure 1 Shown:

[0062] (1) Put the gray cloth into the dyeing machine, prepare clean water, the liquor ratio is 1:5, and at a temperature of 40°C, mix 3g / L of 197 alkaline additive (Weiwei Chemical Co., Ltd.) in 5 Put it into the German THIES dyeing machine within minutes.

[0063] (2) Then put the evenly stirred DESTAR environmental protection dye (the dye RGB-R dosage is 1.2%, the RGB-B do...

Embodiment 3

[0073] In the finished fabric, milk silk fiber is 20%, modal fiber is 35%, newdale fiber is 40%, and spandex fiber is 5%.

[0074] The production method of this fabric is specifically carried out as follows:

[0075] a) The blended fiber with a thickness of 40S and the spandex fiber with a thickness of 20D made of milk silk fiber, modal fiber and Newdale fiber are woven into cotton wool fabric gray fabric on a double-sided cotton wool machine with a needle size of 34 "28G.

[0076] b) Dyeing the cotton and wool gray fabric:

[0077] 1. Dyed red according to ordinary color process, such as figure 2 Shown:

[0078] (1) Put the gray cloth into the dyeing machine, prepare clean water, the bath ratio is 1:5, and add the environmentally friendly dye (dye) produced by Destar Company that has been stirred evenly into the German THIES dyeing machine at a solution temperature of 60 ° C. The amount of RGB-Y is 0.5%, the amount of RGB-R is 3.5%, and the amount of RGB-B is 0.1%), so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com