Middle and low temperature semi-pasted warp sizing method

A warp sizing, low temperature technology, used in liquid/gas/vapor yarn/filament processing, heating/cooling fabrics, textiles and papermaking, etc. Easy to promote and apply, easy to master, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

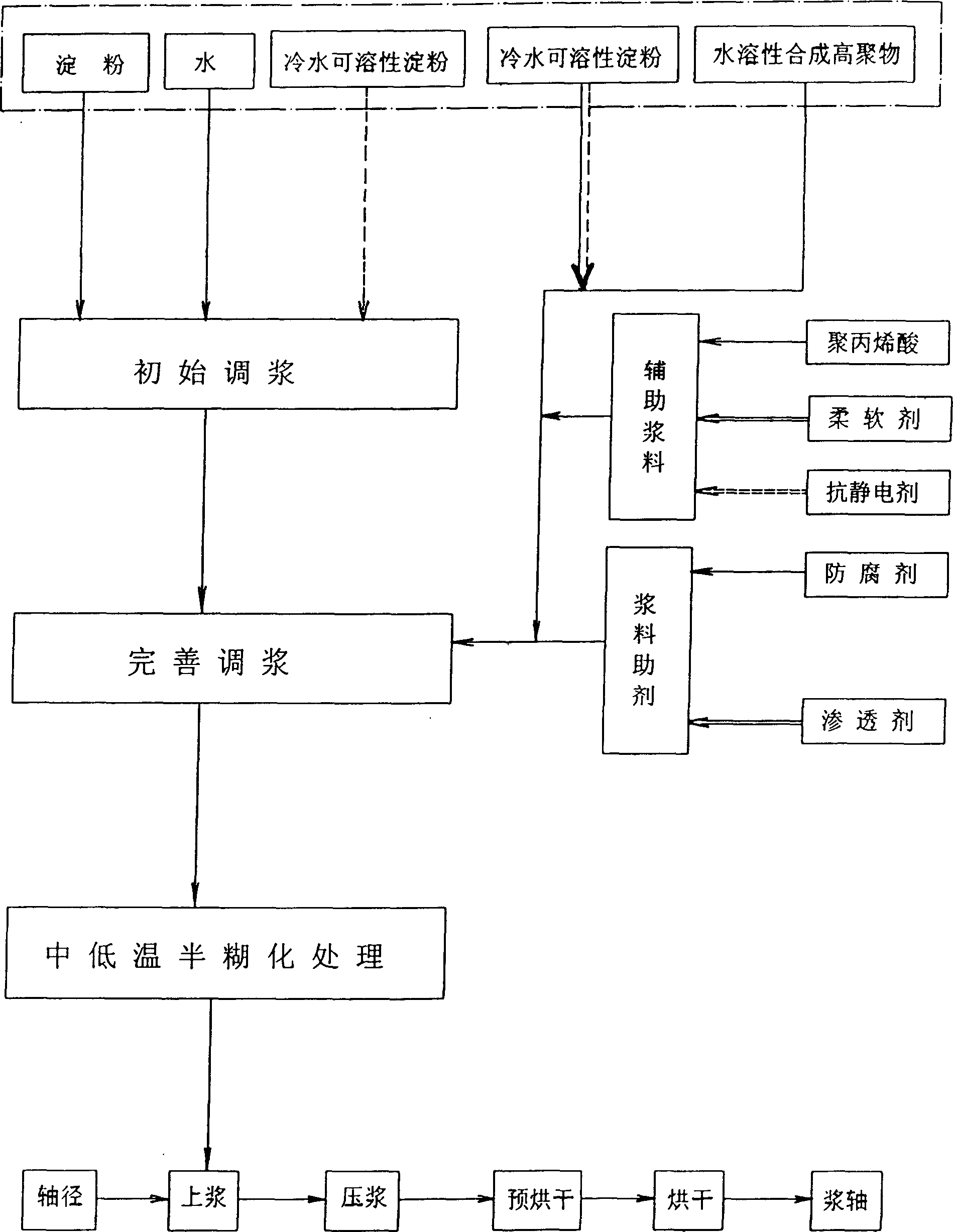

Method used

Image

Examples

specific Embodiment approach 2

[0086] Carry out by specific embodiment one, just: starch is 70 kilograms, cold water soluble starch is 15 kilograms, water-soluble synthetic high polymer is 10 kilograms, polyacrylic acid is 3 kilograms, softening agent is 1.5 kilograms, does not add antistatic agent, The preservative is 0.2 kg, the penetrant is 0.3 kg, and the water is 600 kg; in the operation steps ① and ②, stir at a slow speed of 20 rpm for 10 minutes; in the operation step ③, the fast stirring speed is 900 rpm , the heating temperature is 50°C, the pH value is 7, the viscosity is 6 seconds, continue to stir at a slow speed at a speed of 20 revolutions per minute, and keep the temperature at 50°C; the sizing temperature in the operation step ④ is to keep the room temperature at 25°C , The sizing speed is 50 meters per minute; the grouting pressure in the operation step ⑤ is 6KN; the pre-drying temperature in the operation step ⑥ is 90°C; the drying temperature in the operation step ⑦ is 120°C.

specific Embodiment approach 3

[0087]Carry out by specific embodiment one, just: starch is 80 kilograms, cold-water soluble starch is 0.8 kilograms, water-soluble synthetic high polymer is 15 kilograms, polyacrylic acid is 1 kilogram, does not add softening agent, antistatic agent is 3 kilograms, The preservative is 0.1 kg, the penetrant is 0.1 kg, and the water is 700 kg; in the operation steps ① and ②, stir at a slow speed of 30 rpm for 15 minutes; in the operation step ③, the fast stirring speed is 1000 rpm , the heating temperature is 55°C, the pH value is 7.5, the viscosity is 7 seconds, continue to stir at a slow speed at a speed of 30 revolutions per minute, and keep the temperature at 55°C; the sizing temperature in operation step ④ is 30°C, and the sizing The speed is 55 meters per minute; the grouting pressure in operation step ⑤ is 9KN; the pre-drying temperature in operation step ⑥ is 95°C; the drying temperature in operation step ⑦ is 125°C.

specific Embodiment approach 4

[0088] Carry out by specific embodiment one, just: starch is 70 kilograms, cold-water soluble starch is 14.5 kilograms, water-soluble synthetic high polymer is 5 kilograms, does not add polyacrylic acid, softening agent is 5 kilograms, antistatic agent is 5 kilograms, The preservative is 0.5 kg, no penetrant, and 800 kg of water; in the operation steps ① and ②, stir at a slow speed of 40 rpm for 8 minutes; in the operation step ③, the fast stirring speed is 1100 rpm, The heating temperature is 60°C, the PH value is 6.8, the viscosity is 8 seconds, continue to stir slowly at a speed of 40 rpm, and keep the temperature at 60°C; the sizing temperature in operation step ④ is 40°C, and the sizing speed It is 60 meters per minute; the grouting pressure of operation step ⑤ is 12KN; the pre-drying temperature of operation step ⑥ is 88°C; the drying temperature of operation step ⑦ is 130°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com