Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Surgical Attire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sterile clothing worn during surgical procedures to protect the surgical site from sources of contamination.

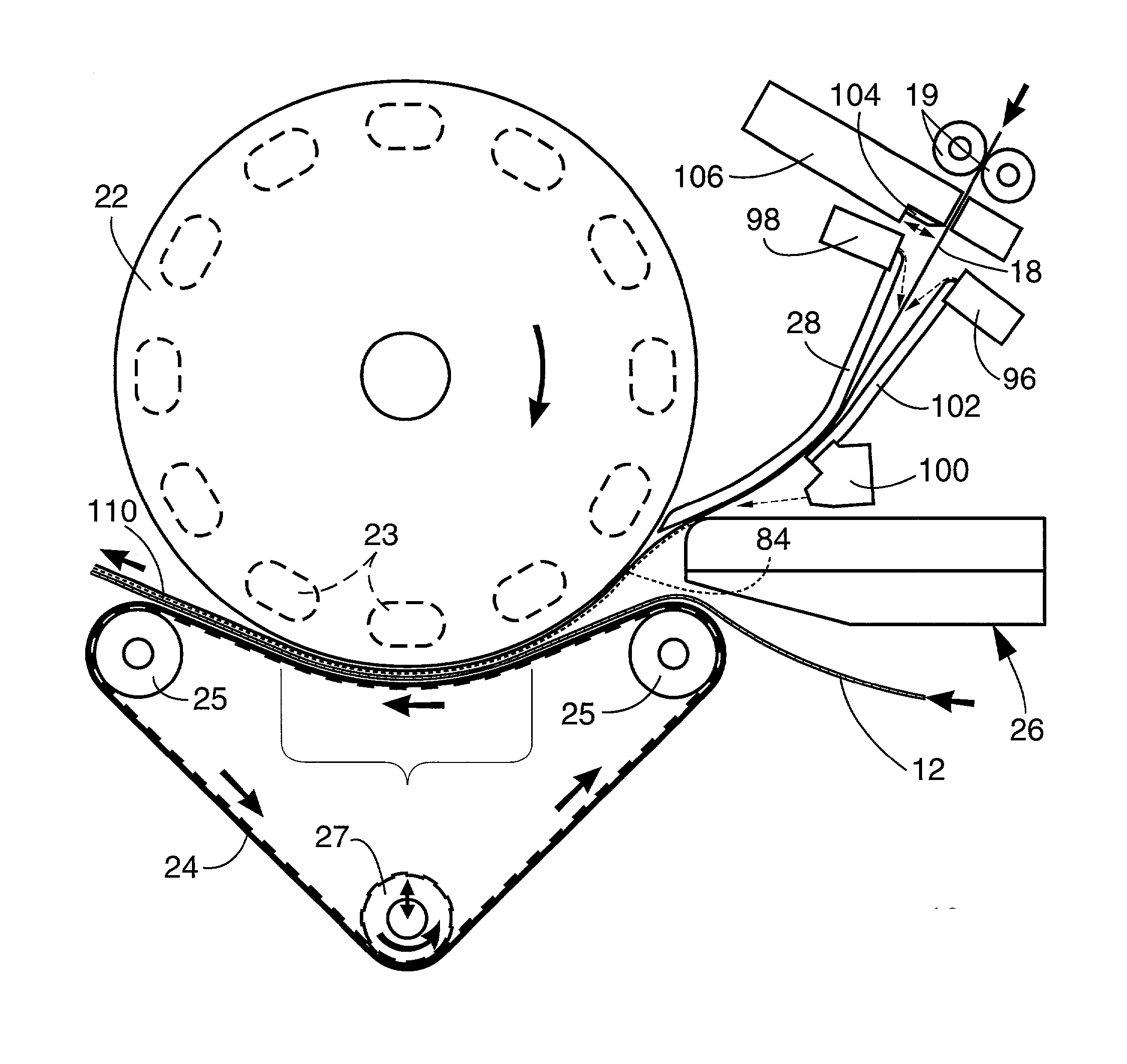

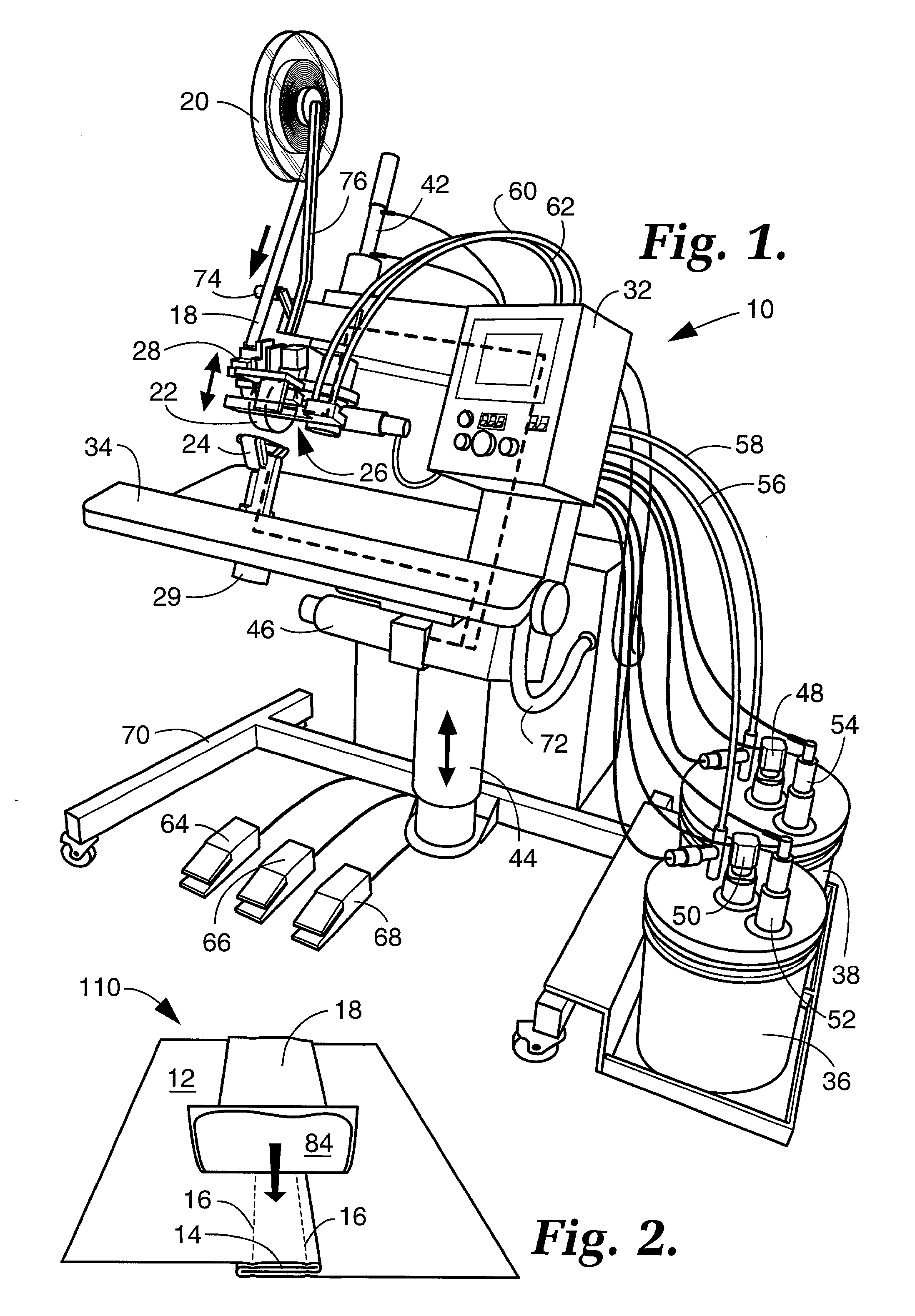

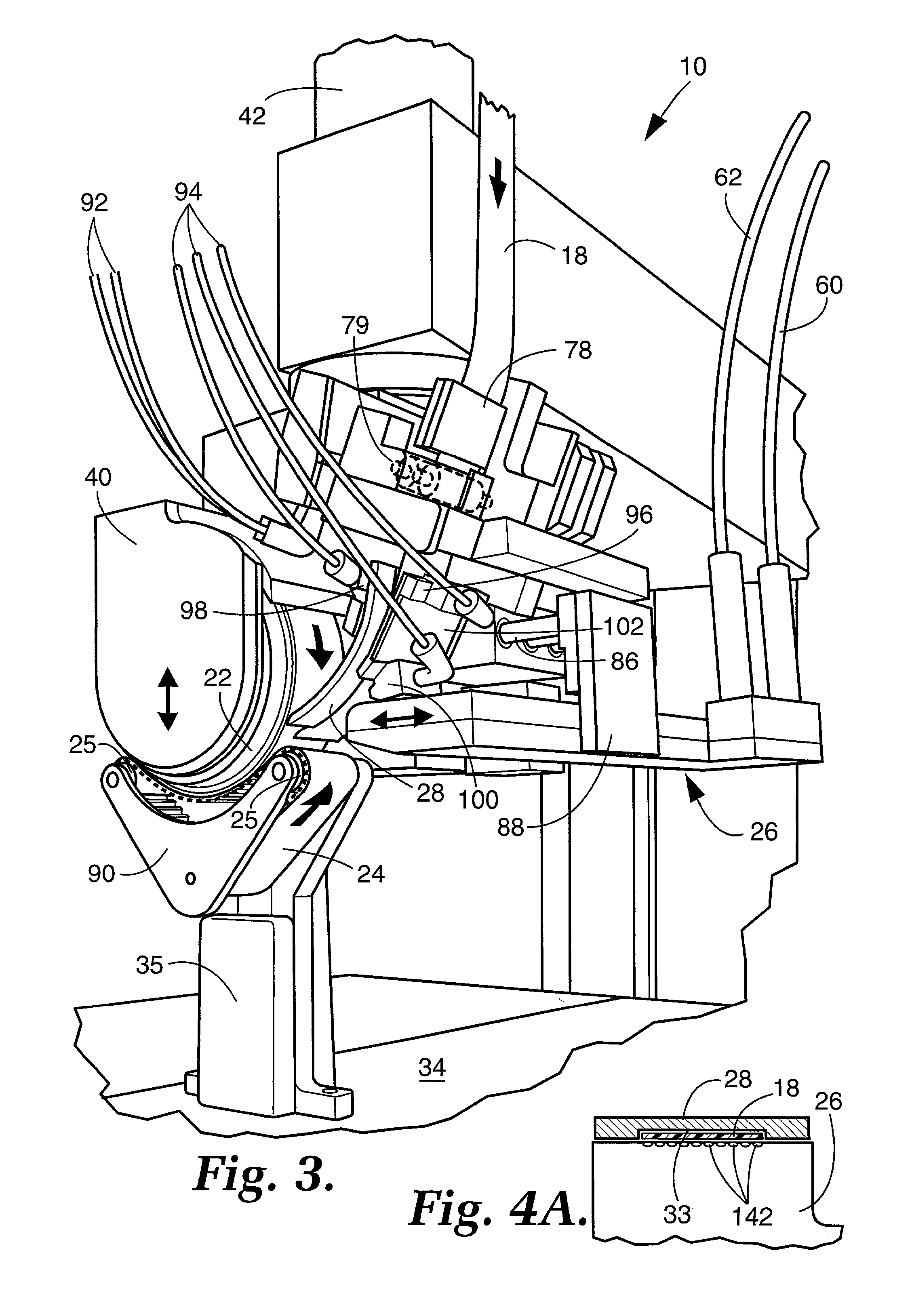

Seam sealing apparatus and process therefor

InactiveUS20030010439A1Easy to cleanWell mixedAdhesive processesManual label dispensersAdhesiveSurgical Gowns

Apparatus and a method for sealing of protective barrier fabric seams in otherwise impermeable articles such as garments, footwear, surgical gowns and the like, are provided, the sealed seams maintaining the imperviousness of the article, including seamed joints, to water, body fluids, pathogens and chemicals. In one pass through the apparatus, a sealed seam in a protective barrier fabric joint, using a curable adhesive sealant, is provided along a predetermined and specified length of the joint. The preferred adhesive is a silicone, most preferably a two-part, thermosetting silicone elastomeric adhesive. Also provided are mixing dies for use, inter alia, in the process which are especially suited for applying the two-part adhesive sealant. In addition, variable-residence-time curing apparatus, which effects variable, controlled, desired cures of the adhesive, all in a one-pass operation, is provided, together with precise metering pumps, especially suited for supplying the seam sealing adhesives in the process of the invention.

Owner:WL GORE & ASSOC INC

Antimicrobial nonwoven fabric

InactiveUS20140308867A1Easy to separateReduce microbial loadPhysical treatmentBiochemical fibre treatmentSurgical AttireWound dressing

The present invention relates to woven or nonwoven fabric material having antimicrobial activity, and to its uses ranging from wound dressing, facial masks, surgical drapes and surgical clothing, to filter materials and similar applications where the antimicrobial effects are employed, as well as to a process for the preparation of the woven or nonwoven fabric material.

Owner:AR METALLIZING NV

Plus material for medical operation garments and cloth for operation

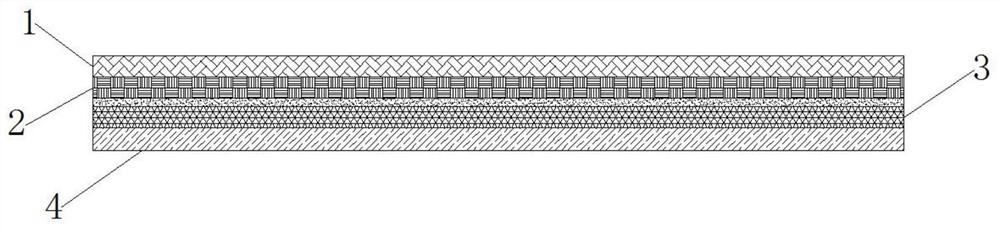

ActiveCN102687922AImprove washabilityPrevent penetrationLamination ancillary operationsSynthetic resin layered productsTissue architectureSurgical Attire

The invention relates to a plus material capable of being repeatedly used and realizing good performance of shielding liquid such as water, blood, body fluid and the like, moisture permeability, good ventilation performance and the like, and a manufacture process of the plus material, in particular to a plus material for medical operation garments and cloth for operation. The plus material comprises a surface layer, an inner layer and a middle protection layer poly urethane (PU) film, wherein the surface layer and the inner layer are textile fabrics with proper density and tissue structures. The plus material is characterized in that the plus material is made by pasting the surface layer, the protection layer and the inner layer by hot melt adhesives. The manufacture process of the plus material is simple, products are used for the medical operation garments and the cloth for operation, have the moisture permeability and ventilation performance and also have good functions of shielding liquid such as water, blood, body fluid and the like, the washing resistance is good, the plus material can be repeatedly used for many times, the medical high-temperature sterilization processing resistance can also be realized, the service life is long, and the plus material still has good waterproof and ventilation performance, good blocking performance and high bonding intensity after being subjected to 80 times of washing, baking and sterilization treatment.

Owner:威海云龙复合纺织材料股份有限公司

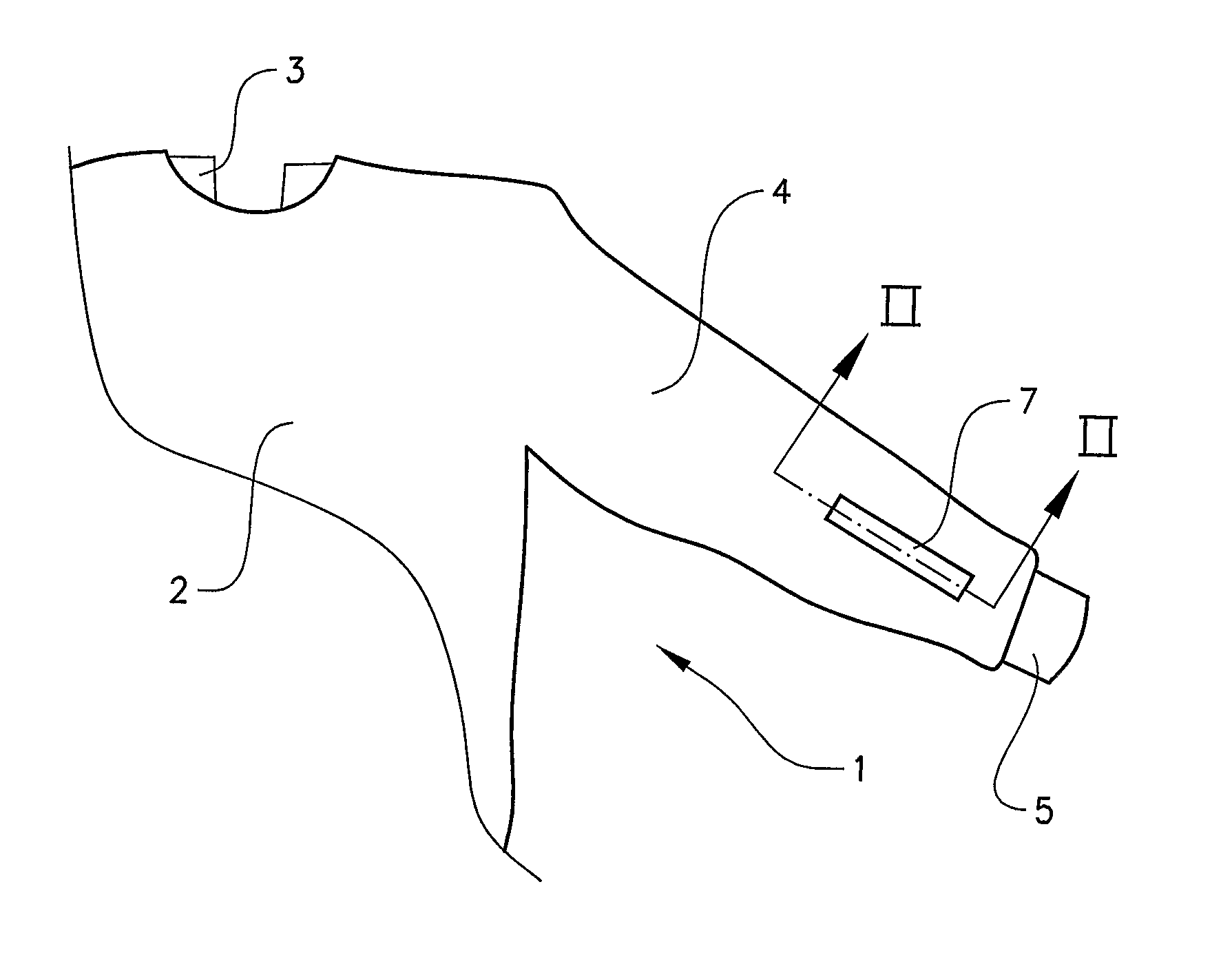

Surgical garment with means for affixing a glove thereto

A surgical garment (1) has a front portion (2) and a back portion (3) and two sleeves (4). Each sleeve (4) has at least one adhesive region (6) for affixing a donned surgical glove (11) thereto, each such region (6) being covered by a strip (7) of release material being removable from the associated adhesive region (6) in a sterile manner after donning of the surgical glove (11).

Owner:MOLNLYCKE HEALTH CARE AB

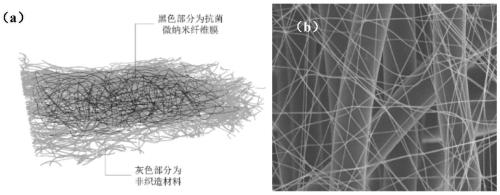

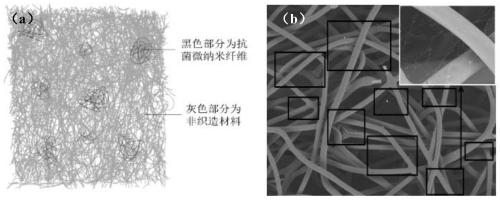

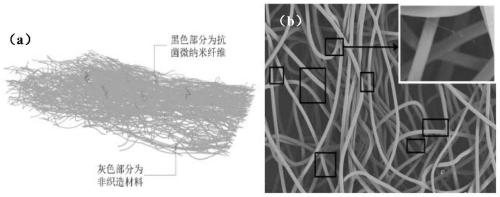

Composite electrostatic spinning micro-nano fiber antibacterial non-woven sanitary material and preparation method thereof

InactiveCN111560707AUnique nanostructureLarge specific surface areaElectro-spinningSanitary towelsFiberMicro nano

The invention relates to a composite electrostatic spinning micro-nano fiber antibacterial non-woven sanitary material and a preparation method thereof. The composite electrostatic spinning micro-nanofiber antibacterial non-woven sanitary material is formed by compounding antibacterial micro-nano fibers and a non-woven material, and the reliable antibacterial effect can be achieved on the basis that the original performance of the non-woven sanitary material is not changed. The micro-nano antibacterial sanitary material has excellent antibacterial and bacteriostatic effects, and can be applied to various sanitary materials such as paper diapers, surgical gowns, female sanitary towels and other sanitary products.

Owner:DONGHUA UNIV

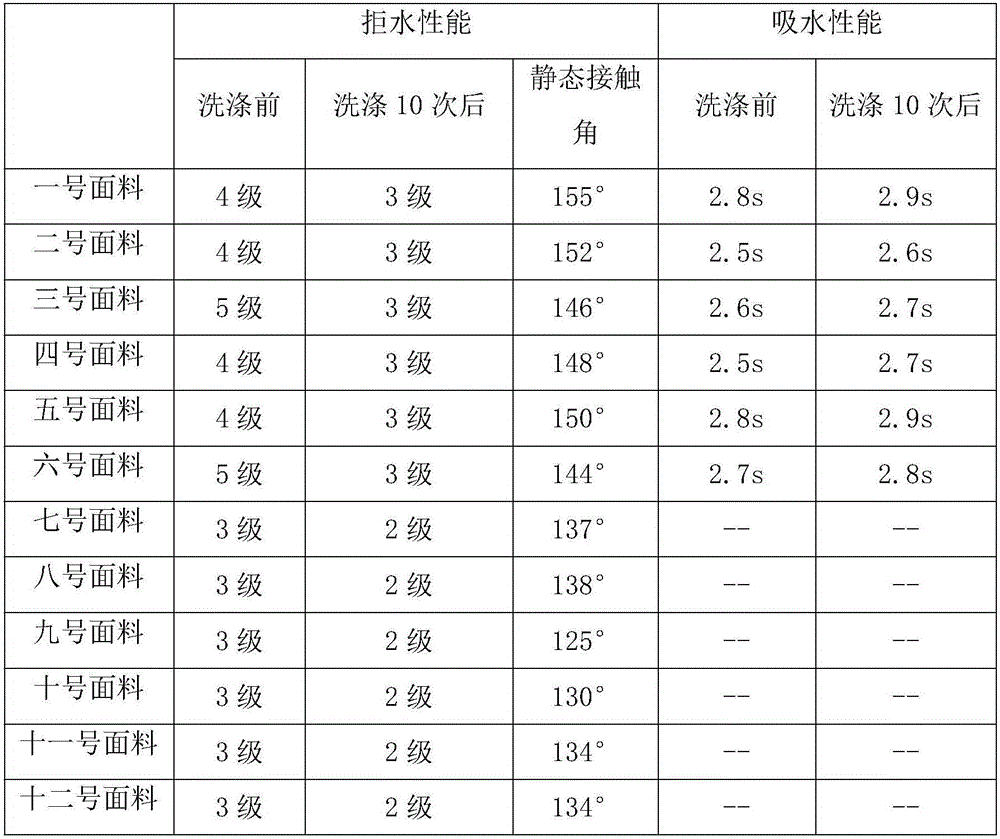

Single-face water-repellent single-face water-absorptive fabric and processing technology thereof

ActiveCN106283338ALow manufacturing costShort production cycleWeft knittingOrnamental textile articlesSurgical GownsAfter treatment

The invention belongs to the field of textiles and garments, and discloses single-face water-repellent single-face water-absorptive fabric and a processing technology of the single-face water-repellent single-face water-absorptive fabric. The single-face water-repellent single-face water-absorptive fabric comprises a water absorptive layer and a water repellent layer, and is formed by means of pretreating textile fabric, performing dyeing water-absorption bathing, performing single-face water-repellent processing and performing after-treatment integral processing. The fabric disclosed by the invention has the beneficial effects that for the fabric obtained according to the processing technology disclosed by the invention, the water repellent property reaches level 4 or higher before washing, the water repellent property still reaches level 3 or higher after washing 10 times, and the single-face water-absorptive property is within 3 seconds before washing and after washing 10 times, so that sputtered blood can be quickly adsorbed and cannot permeate the inner fabric of a user, and the fabric can be widely applied to products, such as surgical gowns for medical use and the like.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Soft medical surgical gown SMS non-woven fabric and preparation method thereof

ActiveCN112030361AGood flexibilityImprove smoothnessSevering textilesMelt spinning methodsSurgical AttirePolymer science

The invention provides a preparation method of a soft medical surgical gown SMS non-woven fabric. The soft medical surgical gown SMS non-woven fabric adopts the following raw material: a PP spun-bonded material, a polyolefin copolymer, an amide additive, a PP melt-blown material, special spun-bonded blue master batches and special melt-blown blue master batches in the mass ratio of 50-65: 15-25: 0-3: 18-25: 0.5-3.0: 0.5-3.0. The preparation method comprises a melt extrusion step, wherein in melt extrusion, the temperature of a screw adopted by the spun-bonded mixture is 225-235 DEG C, the temperature of a melt pipe adopted by the spun-bonded mixture is 230-235 DEG C, the temperature of a die head adopted by the spun-bonded mixture is 233-238 DEG C, the temperature of a screw adopted by themelt-blown mixture is 235-245 DEG C, the temperature of a melt pipe adopted by the melt-blown mixture is 245-255 DEG C, and the temperature of a die head adopted by the melt-blown mixture is 255-260DEG C. The preparation method further comprises a hot rolling step, wherein in hot rolling, an embossing roller with the hot rolling area of 12-15% is selected, the temperature of the roller is 148-152 DEG C, and the pressure of a rolling mill is 60-65N. According to the preparation method, softness and smoothness of the SMS non-woven fabric are remarkably improved, and meanwhile, the prepared non-woven fabric has good strength and protective shielding performance.

Owner:致优无纺布(无锡)有限公司

Antibacterial breathable plastic masterbatch and preparation method and application thereof

The invention relates to antibacterial breathable plastic masterbatch and a preparation method thereof. The masterbatch includes, by weight, 15-25% of metallocene linear low-density polyethylene, 50-70 parts of low density polyethylene, 5-8 parts of isotactic polypropylene, 3-6 parts of a dimethylsiloxane-diphenyl siloxane block copolymer, 40-48 parts of inorganic micropowder, 2-5 parts of nanometer bamboo-fragrance charcoal micropowder, 0.2-0.4 part of polyphthalamide, 0.1-0.2 part of a silicate silver-loaded inorganic antibacterial agent, 0.5-2 parts of glyceryl trimyristate, 0.3-0.8 part ofstearyl alcohol, 0.1-0.5 part of oleamide, 0.5-1 part of an antioxidant, 1-1.5 parts of liquid paraffin and 1-2 parts of glycerol monostearate. The masterbatch has excellent mechanical properties, integrates antibacterial performance and breathability, and has environmentally friendly raw materials, low preparation energy consumption, low cost and high single output. A plastic film processed fromthe masterbatch is of extremely high application value in the fields of diapers, sanitary napkins, medical surgical gowns, and the like.

Owner:泉州联盛新材料科技有限公司

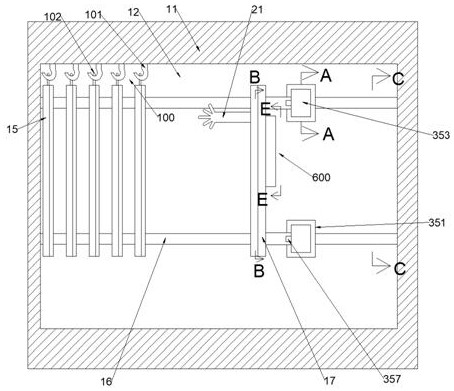

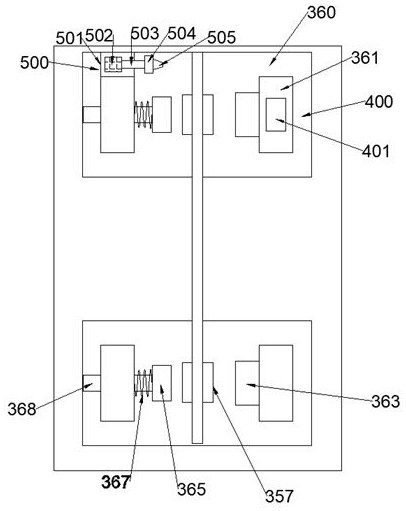

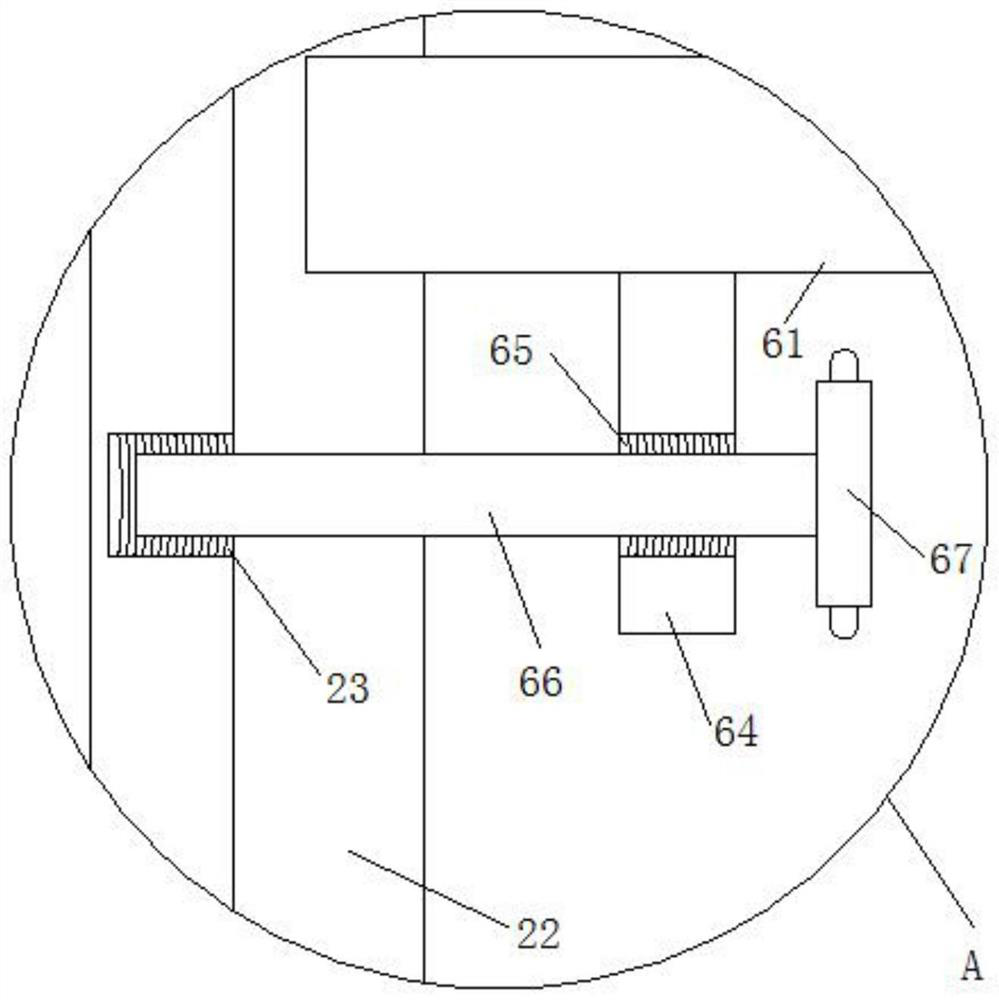

Automatic wearing equipment for disposable surgical gown

InactiveCN112869516ARealize automatic grippingPrevent fallingApparel holdersSurgical AttireMedical equipment

The invention relates to the technical field of medical equipment, in particular to automatic wearing equipment for disposable surgical gown. The equipment comprises a box body arranged at any position of the ground of a hospital, a wearing cavity is formed in the box body, and disposable surgical gown can be automatically clamped and driven to move; the sleeve of the surgical gown can be inflated through the inflation mechanism, so that the sleeve is expanded, and a worker can wear the surgical gown conveniently; clamping of the surgical gown can be achieved through a clamping mechanism, and the surgical gown is prevented from falling off when being worn; the position of the surgical gown can be detected and positioned through a position sensor, and clamping is convenient; a heat-sealing device and a heat-sealing mechanism can achieve heat-sealing connection of the clamping belt on the back after the surgical gown is worn, the problem that the surgical gown is difficult to wear by one person under the condition that the person is insufficient is solved, meanwhile, contact between the person and the surgical gown is reduced, and the risk that other viruses and bacteria are brought in is reduced.

Owner:义乌市粉涵纺织品有限公司

Method for processing fabric of surgical gown with permeability-resisting protection function

ActiveCN103451918AImprove function and effectGuaranteed strongPhysical treatmentSurgical GownsPre treatment

The invention discloses a method for processing the fabric of a surgical gown with a permeability-resisting protection function. The method comprises the steps of nano-sol pretreatment, low-temperature normal-pressure air plasma treatment, chemical permeability resisting agent treatment and ultraviolet radiation. The fabric processed by the method disclosed by the invention achieves the effects of resisting the permeability of blood, alcohol, water and the like, and meets the protection requirements of the fabric of the surgical gown: the water repellency level is 8, the oil repellency level is 7, the alcohol repellency level is 10, the blood contact prevention angle is 126.2 DEG, the strong retention rate is 92.6%, and the permeability retention rate is 95.3%.

Owner:江苏联泰纺织有限公司

Surgical gown with functional window

A surgical gown for protecting the wearer while maintaining the sterile field, and further offering the wearer the ability to directly access and interface with technological equipment being operated during a surgical procedure. The surgical gown comprising one or more functional windows positioned on the gown to allow the wearer to interface in a sterile manner with a device attached to the wearer underneath the gown, for example a device attached to the wearer's arm and / or chest. The windows disposed in the gown are sized and adapted to accommodate a variety of devices including cameras for POV filming and / or recording, as well as control displays for local or remotely located technological equipment.

Owner:GOOI PATRICK +2

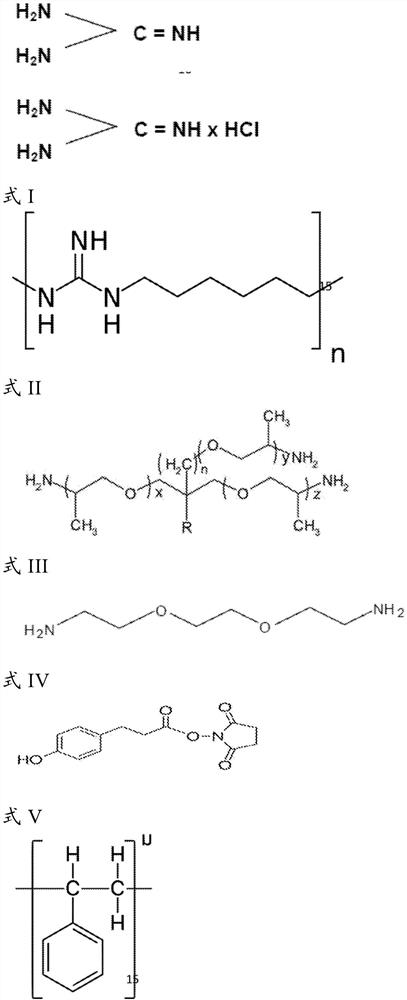

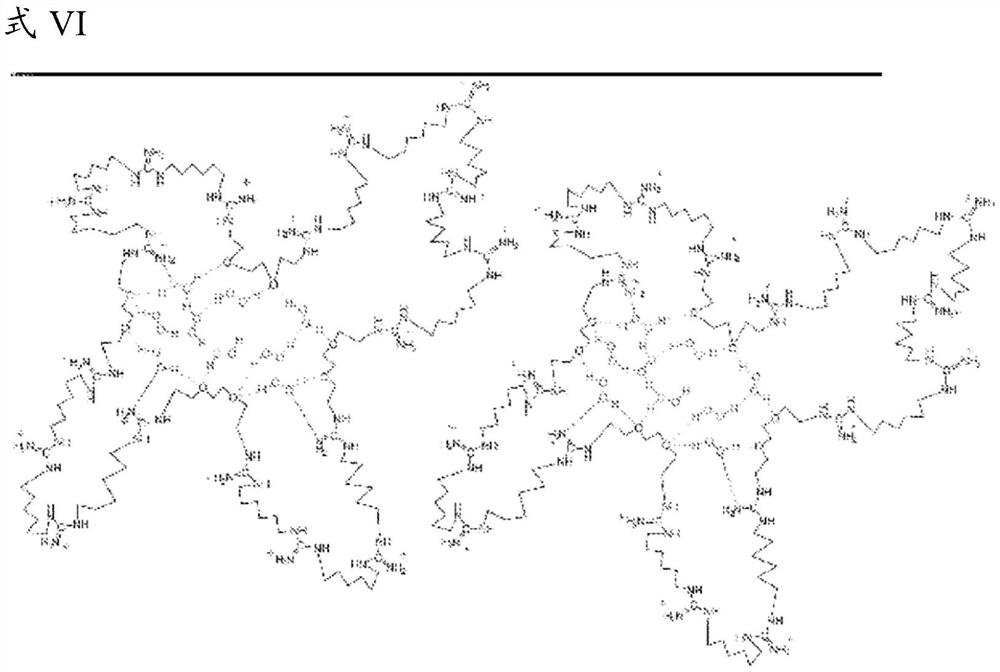

Woven, nonwoven, cotton, nonwoven-cotton blended polyethylene and polipropilen and polystyrene mask, wound dressing, panty, bra, handkerchief, pad, scouring pad, disposable surgical dress, disposable sheets with antimicrobial properties

PendingCN113395961AInhibit or eliminate growthBiocideOrganic active ingredientsGuanidine derivativesSurgical Attire

This invention was related to elimination of pathogenic micro-organisms on various surfaces, and air especially hard surfaces where such organisms may stay active for relatively long periods of time, has long been a goal of those charged with woven, nonwoven, cotton, nonwoven- cotton blended, polyethylene and polipropilen and polystyrene blended mask, wound dressing, panty, bra, handkerchief, pad, scouring pad, disposable surgical dress and sheets. For this purpose, a combination polymeric guanidine derivative based on a diamine containing oxyalkylene chains between two amino groups, with the guanidine derivative representing a product of polycondensation between a guanidine acid addition salt and a diamine containing polyoxyalkylene chains between two amino groups, are integrated woven, nonwoven, cotton, polyethylene and polipropilen and polystyrene structure to gain antimicrobial activity.

Owner:优卡健康有限公司

Surgical gown fabric and production process thereof

PendingCN112519355AImprove comfortThreat to securitySynthetic resin layered productsCellulosic plastic layered productsPolyesterSurgical Attire

The invention belongs to the technical field of surgical gowns, and particularly relates to a surgical gown fabric which sequentially comprises an anti-splashing layer, an antibacterial layer, a bacterium isolation film, a water absorption layer and a one-way moisture-conducting layer from outside to inside, wherein the anti-splashing layer, the antibacterial layer, the bacterium isolation film, the water absorption layer and the one-way moisture-conducting layer are sequentially bonded together through a gluing process; the one-way moisture-conducting layer adopts an electrostatic spraying method to spray water-repellent finishing liquid on gray fabric woven by cationic polyester yarns and polyester filaments, so that the prepared fabric has a one-way moisture-conducting function. The surgical gown fabric overcomes the defects in the prior art, not only can help the medical staff to perspire, but also can resist permeation of body fluid of a patient. Meanwhile, the body fluid of the patient is prevented from directly dripping, and the medical staff are protected.

Owner:天长市康特美防护用品有限公司

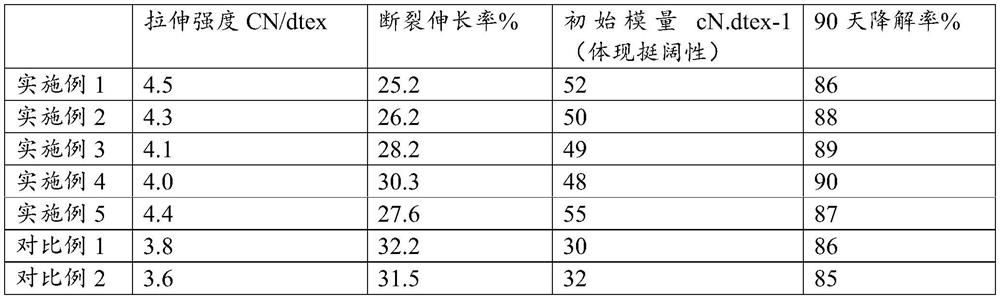

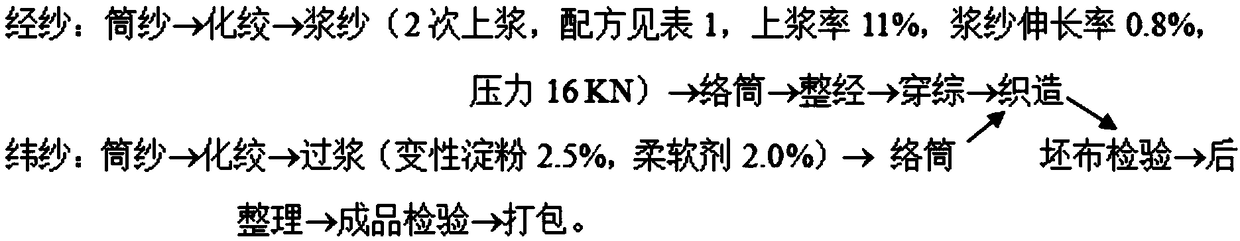

Stiff and broad PBST and polylactic acid composite fiber, preparation method and application thereof and surgical garment

PendingCN114016158AWon't happenGood sexGarment special featuresConjugated synthetic polymer artificial filamentsFiberSurgical Attire

The invention provides a stiff and broad PBST and polylactic acid composite fiber as well as a preparation method and application thereof, and belongs to the technical field of composite fibers. The composite fiber comprises PBST fiber and polylactic acid fiber, after the composite fiber is formed, the PBST fiber is a skin layer of the composite fiber, and the polylactic acid fiber is a core layer of the composite fiber. The preparation method comprises the following steps that PBST slices and polylactic acid slices are obtained respectively; and composite spinning is conducted on the stiff PBST slices and the polylactic acid slices, so that the stiff PBST fibers are located on the skin layer of the composite fibers, the polylactic acid fibers form the core layer of the composite fibers, and the stiff PBST and polylactic acid composite fibers are obtained. The composite fiber can be better suitable for disposable surgical garments and can be completely biodegraded, and after the composite fiber is discarded, garbage cannot be generated, and the environment cannot be affected at all.

Owner:CHINESE TEXTILE ACAD

Producing method of three-warp three-weft light and thin fabric

The invention relates to a producing method of a three-warp three-weft light and thin fabric. The producing method comprises the steps that PET is selected as a warp and weft yarn raw material, and the fabric weave is plain grids; warp yarns undergo winding, twisting, slashing, spooling, beaming and drafting, weft yarns undergo winding, twisting, sizing and spooling, the warp yarns and the weft yarns are knitted, and then after finishing is performed to obtain the three-warp three-weft light and thin fabric. The produced three-warp three-weft light and thin fabric adopts loose and smooth yarnsand has full hand feel, a knitting process is low in cost and high in efficiency, and the producing method has the good application prospect in the fields of umbrella covers, down jackets, surgical gowns, foods, medicine, precise and electronic cleanroom suits and the like.

Owner:DONGHUA UNIV +1

Drying and sterilizing device for surgical gowns

InactiveCN111888488ASolve efficiency problemsSolve the adjustmentLavatory sanitoryTextiles and paperSurgical AttireSurgical Gowns

The invention discloses a drying and sterilizing device for surgical gowns. The device comprises a base, wherein a mounting and moving mechanism is arranged on the base, a driving mechanism is arranged in the mounting and moving mechanism, and heating mechanisms are arranged on two sides of the driving mechanism. The device has the beneficial effects that the temperature in a drying box is conveniently and rapidly increased by arranging a plurality of heating pipes and heating rods; through arrangement of a driving motor and a driving gear, a driven gear and fan blades are conveniently drivento rotate, hot air can be rapidly spread to all corners of the heating box for sterilization, the drying efficiency is improved; through arrangement of sliding grooves, the height of a supporting plate can be conveniently adjusted, and the surgical gowns of different lengths can be conveniently hung; through arrangement of threaded rods, the supporting plate can be conveniently limited under the action of threaded holes and threads of threaded grooves, the stability of the supporting plate is improved, and meanwhile the supporting plate is convenient to dismount; and through a three-fork siphon and a fan, water vapor can be conveniently and rapidly sucked out through a siphon effect, and the surgical gowns are prevented from being wetted by condensate water.

Owner:WUHAN YIWEIDENG TECH DEV

Production method and device of a surgical gown

ActiveCN109171072BIncrease productivityRealize automatic productionProtective garmentClothes making applicancesSurgical AttireSurgical Gowns

The invention provides a production method and device of a surgical gown, being characterized in the the roll material for a surgical gownl is used to perform servo unwinding and conveying by using roll materials for surgical use is servo unwound and conveyed, and automatically folding the conveyed materials for surgical use at the corresponding positions of the neck and the lower hem of the surgical garment, on the folded surgical garments respectively to the left, the right cuff is sealed, the operation garment sealed by cuffs is cut by left and right rotating rollers according to certain shape and size, and the remainder of the edge and corner is cut off, so that the shape of the operation garment is cut out, the automatic production of the operation garment is realized, the manual participation is not required, the automation degree is high, the cost is low, and the production efficiency of the operation garment is improved.

Owner:三明市普诺维机械有限公司

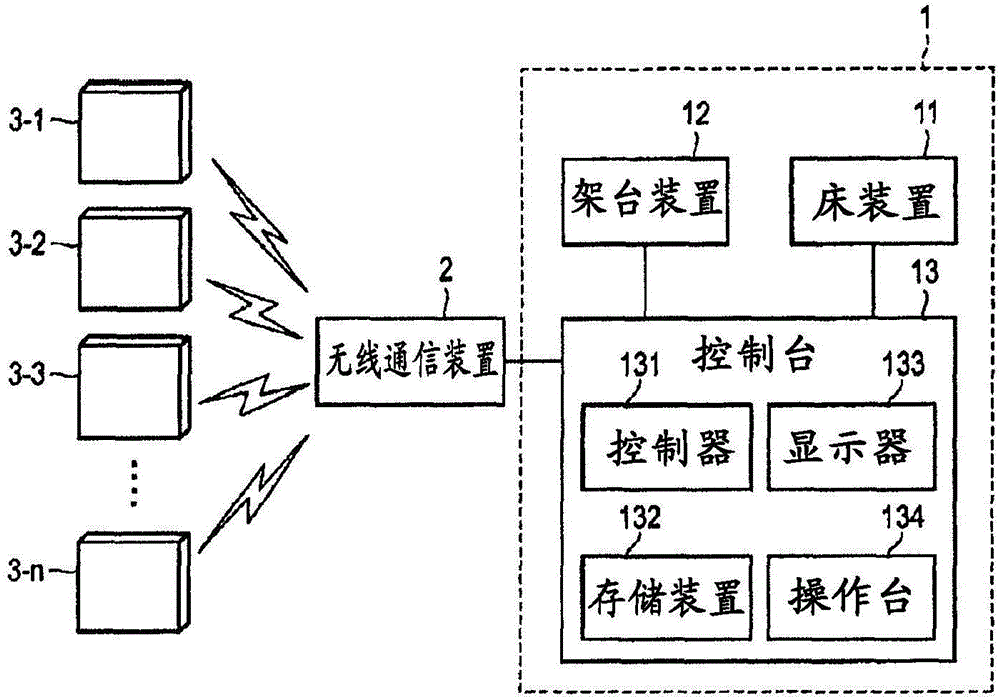

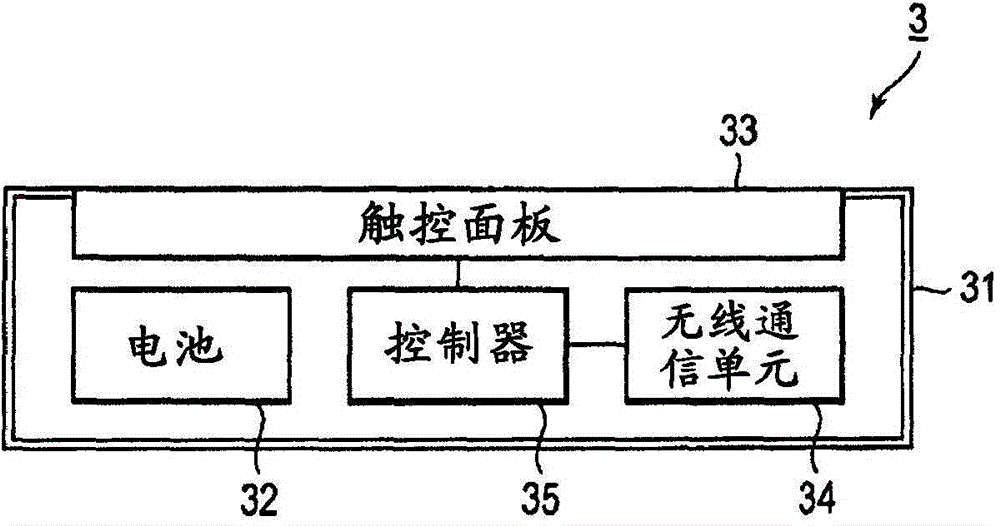

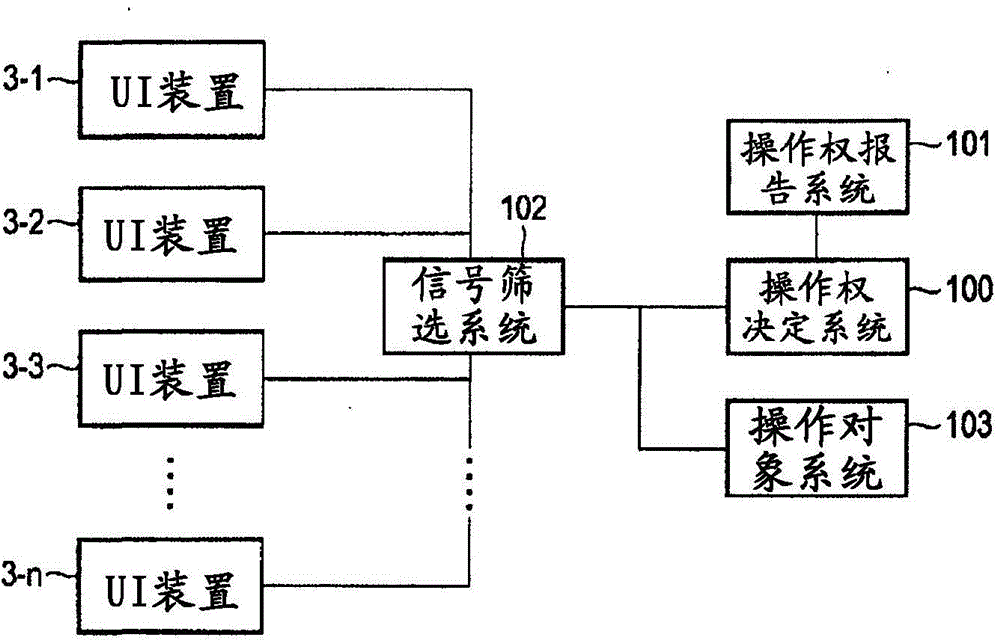

Medical work assistance system, surgical attire, and medical device

ActiveCN103917189AEasy to operateSurgical systems user interfaceSurgical drapesSurgical AttireOperability

The purpose of the medical work assistance system of an embodiment is to improve the operability of medical devices during surgery. The medical work assistance system of the present embodiment, which is capable of being operated by a user while maintaining a sterilized state, is equipped with: multiple interface units for receiving an operation by a user and outputting a signal corresponding to the received operation, each unit being capable of being attached to and detached from multiple surgical attire that users can wear; a receiving unit for receiving the signals output by the interface units; and a control unit for performing a specified process on the basis of the signals received by the receiving unit.

Owner:TOSHIBA MEDICAL SYST CORP

Surgical gown with heart rate detection function

InactiveCN113812703AImprove comfortFast circulationSensorsMeasuring/recording heart/pulse rateSurgical AttireSurgical Gowns

The invention belongs to the technical field of surgical gowns, in particular to a surgical gown with a heart rate detection function, and provides the following scheme. The surgical gown comprises an upper garment and trousers, arm parts of the upper garment are broken and sewed with elbow joint sleeves through silk threads, cuff parts of the upper garment are sewed with cuff elastic bands through silk threads, armpit positions of the upper garment are provided with openings, an underarm block is sewn at each opening through a silk thread, breathable cotton adheres to the outer wall of the underarm block, a bent groove is formed in the outer wall of the underarm block, an underarm ventilation mechanism is arranged on the inner wall of the bent groove, and a communicating groove is formed in the outer wall of one side of the underarm block. The inside and the outside of the bending groove are communicated, the space in the middle is beneficial to rapid circulation of air, when the air penetrates through the inner wall of the bending groove, flowing air can drive balls to roll, then the circulating air is further accelerated, sweat at the armpit part is driven to volatilize through mutual cooperation, the armpit of a medical worker is kept dry, and the comfort is improved.

Owner:叶志宇

Composite non-woven fabric and preparation method thereof

PendingCN114834108ANot easy to static electricityReduce the probability of static electricity generated by frictionElectroconductive/antistatic filament manufactureSynthetic resin layered productsPolymer scienceNonwoven fabric

The invention relates to a composite non-woven fabric and a preparation method thereof, the composite non-woven fabric comprises a skin-friendly layer, a transition layer, a base layer and a protective layer, the transition layer is located between the skin-friendly layer and the base layer, the skin-friendly layer is bonded and matched with the transition layer, the transition layer is fixedly connected with the base layer, and the base layer is bonded and matched with the protective layer; the base layer is formed by lapping modified polypropylene filaments; the modified polypropylene filament comprises the following raw materials in parts by weight: 80-120 parts of a polypropylene base material; 6-8 parts of dioctadecyl ammonium chloride; 8 to 12 parts of 4-[(heptadecafluorononyl) oxy] sodium benzenesulfonate; 6-8 parts of white mica powder; 2-6 parts of an antibacterial auxiliary agent and 0.5-1.5 parts of a lubricant. The composite non-woven fabric has the advantages that the composite non-woven fabric is not prone to generating static electricity, and therefore the dust adsorption probability is reduced when the composite non-woven fabric serves as a surgical gown fabric.

Owner:DONGGUAN KEDI IND CO LTD

Medical glove Anti-slip and fluid guard band

InactiveUS20200229522A1Preventing glove slippageAvoid passingGarment suspendersGarment special featuresSurgical AttireSurgical Gowns

An elastic band for attachment over the juncture of a surgical glove and sleeve of a surgical gown is disclosed. The elastic band has an abrasive inner surface in contact with the juncture to limit movement of the band relative to the juncture. A circumferential portion of the inner surface is concave. The band may be of variable circumferences to fit the user, adjusting to the size of the user's wrist.

Owner:KITAY GARRY

A kind of soft medical surgical gown SMS non-woven fabric and preparation method thereof

ActiveCN112030361BGood flexibilityImprove smoothnessSevering textilesMelt spinning methodsSurgical AttireMasterbatch

The invention provides a method for preparing SMS non-woven fabric for soft medical surgical gowns. The raw materials used include PP spunbond material, polyolefin copolymer, amide additives, PP meltblown material, blue masterbatch for spunbond, meltblown Special blue masterbatch, the mass ratio is 50-65:15-25:0-3:18-25:0.5-3.0:0.5-3.0. The preparation method includes a melt extrusion step; in the melt extrusion: the temperature of the screw used for the spunbonded mixture is 225-235°C, the temperature of the melt pipe is 230-235°C, and the temperature of the die is 233-238°C. The temperature of the screw used in the melt-blown mixture is 235-245°C, the temperature of the melt tube is 245-255°C, and the temperature of the die head is 255-260°C. The preparation method also includes a hot rolling step; the hot rolling: use patterned rolls with a hot rolling area of 12-15%, the temperature of the rolls is 148-152°C, and the pressure of the rolling mill is 60-65N. The invention significantly improves the softness and smoothness of the SMS non-woven fabric, and at the same time, the prepared non-woven fabric has good strength and protective shielding performance.

Owner:致优无纺布(无锡)有限公司

Medical textile

PendingCN113427847AFull gapGuaranteed circulationSynthetic resin layered productsClothingsPolyesterFiber

The invention discloses a medical textile which comprises an inner layer, an outer layer and a core layer, wherein the core layer is located between the inner layer and the outer layer, the inner layer is made of moisture absorption and sweat releasing fabric, the outer layer is made of adsorption functional fabric, and the core layer is a waterproof and breathable Goretex film. The structure with polyester outside and cotton inside is adopted, polyester fibers on the outer layer have non-circular special-shaped sections, and guide pipes for transferring moisture are formed between the fibers, so that the fabric has a microgroove guide pipe effect, and sweat discharged by a human body quickly reaches the surface of the fabric through the huge guide pipes due to siphonage and is diffused and volatilized. The medical textile disclosed by the invention is suitable for manufacturing surgical gowns or medical clothes, and has the multifunctional effects of absorbing sweat, removing moisture, resisting water, ventilating, preventing static electricity and blocking germs.

Owner:海恩康(天津)医疗科技有限公司

Surgical gown management apparatus

The present invention provides a surgical gown management apparatus. The apparatus comprises: a surgical gown tag module, an inputting module, a writing module and a data management module. The surgical gown tag module is disposed on a surgical gown; the surgical gown tag module is used to store a type of the surgical gown, whether the surgical gown has been cleaned, the number of cleaning times and identity identification information. The inputting module scans a surgical gown tag module on a newly added surgical gown to acquire tag information of the newly added surgical gown; the writing module scans a surgical gown tag module on a recorded surgical gown to acquire recorded tag information; the writing module sends the tag information of the newly added surgical gown and the recorded the surgical gown to the data management module; and the data management module records, for each each surgical gown, the type and the number of cleaning times of the surgical gown and whether the surgical gown is cleaned. For the newly added surgical gown and the recorded surgical gown, the modules accurately record the type and the number of cleaning times of each surgical gown and whether the surgical gown is cleaned, thereby realizing efficient and accurate management of the surgical gowns.

Owner:WEIHAI BEIYANG ELECTRIC GRP CO LTD BEIJING BRANCH

Composite biological enzyme surgical gown and preparation method thereof

ActiveCN113605088AImprove antibacterial and antiviral effectsGuaranteed antibacterial and antiviral effectsBiochemical treatment with enzymes/microorganismsProtective garmentSurgical AttireMedicine

The invention provides a composite biological enzyme surgical gown and further provides a preparation method of the composite biological enzyme surgical gown. The surgical gown is prepared from the following raw materials of nano silver, silver-loaded nano silicon dioxide, thrombin-loaded mesoporous silicon dioxide, chitosan, polylactic acid, deionized water and a non-woven fabric. Through the combined action of various raw materials, the mechanical strength of the surgical gown and the attaching capacity of an inorganic antibacterial agent and biological enzyme are improved, and the surgical gown is endowed with excellent sterilization and virus killing effects.

Owner:CHANGZHOU CHAMGO NANO MATERIALS

Plus material for medical operation garments and cloth for operation

ActiveCN102687922BImprove washabilityPrevent penetrationLamination ancillary operationsSynthetic resin layered productsTissue architectureSurgical Attire

The invention relates to a plus material capable of being repeatedly used and realizing good performance of shielding liquid such as water, blood, body fluid and the like, moisture permeability, good ventilation performance and the like, and a manufacture process of the plus material, in particular to a plus material for medical operation garments and cloth for operation. The plus material comprises a surface layer, an inner layer and a middle protection layer poly urethane (PU) film, wherein the surface layer and the inner layer are textile fabrics with proper density and tissue structures. The plus material is characterized in that the plus material is made by pasting the surface layer, the protection layer and the inner layer by hot melt adhesives. The manufacture process of the plus material is simple, products are used for the medical operation garments and the cloth for operation, have the moisture permeability and ventilation performance and also have good functions of shielding liquid such as water, blood, body fluid and the like, the washing resistance is good, the plus material can be repeatedly used for many times, the medical high-temperature sterilization processing resistance can also be realized, the service life is long, and the plus material still has good waterproof and ventilation performance, good blocking performance and high bonding intensity after being subjected to 80 times of washing, baking and sterilization treatment.

Owner:威海云龙复合纺织材料股份有限公司

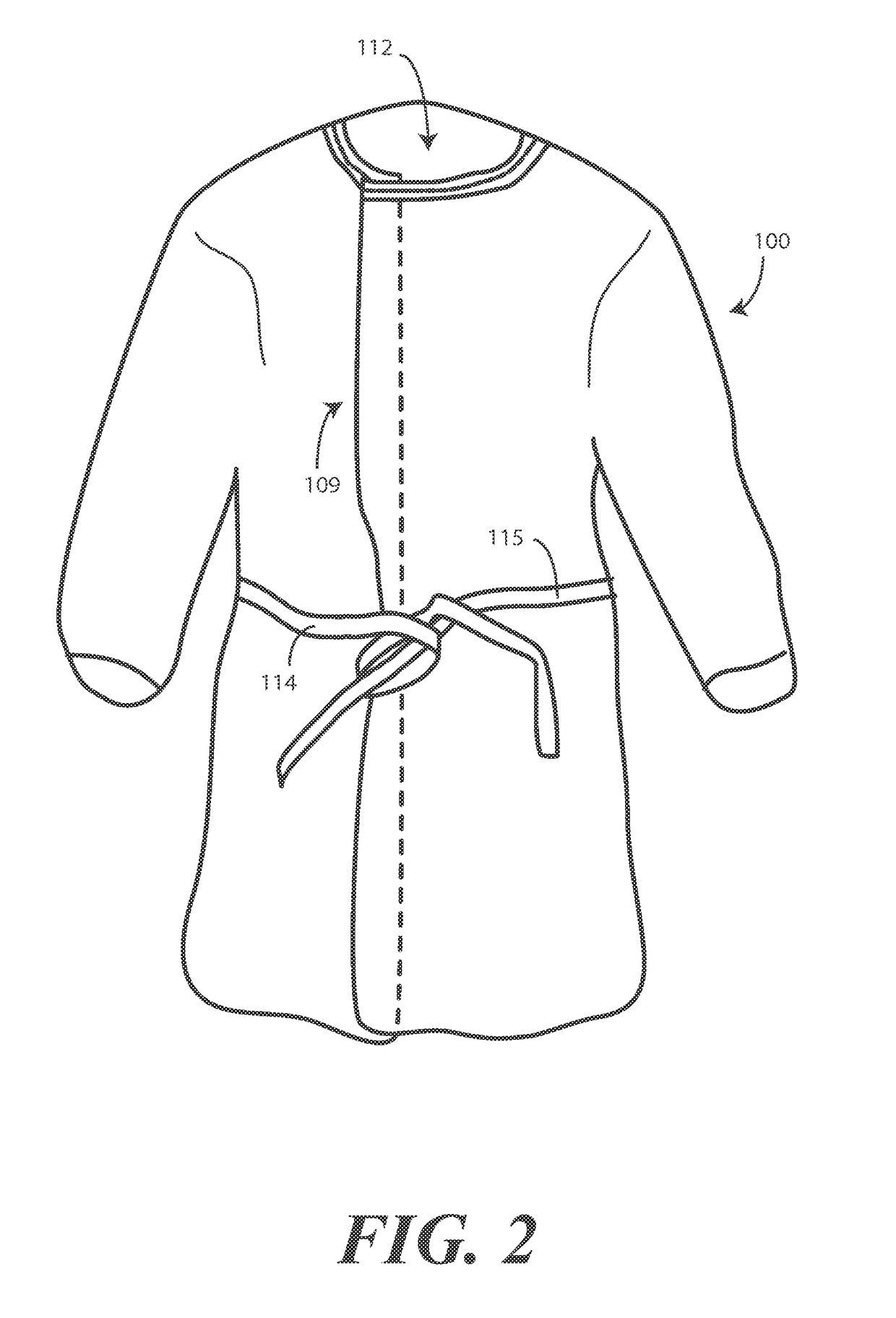

Surgical gown

InactiveCN110811038AAvoid oppressionPrivacy protectionProtective garmentSurgical AttireSurgical Gowns

The invention discloses a surgical gown that comprises a cover-shaped gown body; the front face and the back face of the gown body are sewed downwards from a neckline to the half position of the totallength to form an open front A, the end point of the open front A is sewed to the left end point and the right end point of a gown corner to form an open front B and an open front C, and tying beltsare arranged on the edges of the open fronts A, B and C; the open fronts can be opened according to needs to expose a wound position, the wound is prevented from being pressed, inconvenience caused byblocking of clothes during an operation can be avoided, and meanwhile the privacy of a patient is protected.

Owner:罗刚

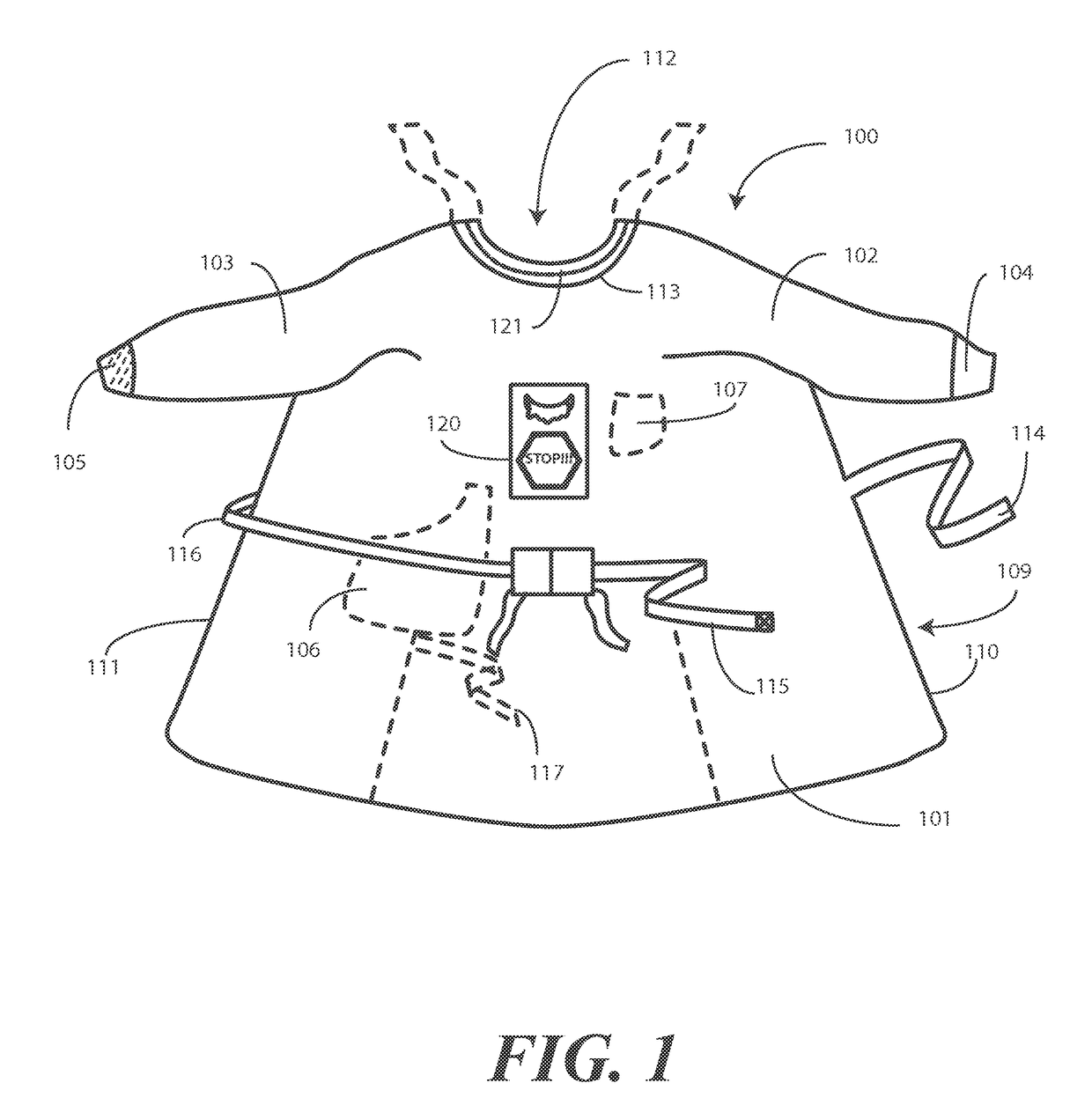

Surgical gown configured for prevention of improper medical procedures

A surgical gown (100) includes a body-covering portion (101) and, optionally, sleeves (102,103). A surgery procedure verification card (120) can be attached to the surgical gown (100). The surgery procedure verification card (120), which can be configured to be selectively detachable from the surgical gown (100), is configured to facilitate a start of a surgical procedure after completion of a predetermined procedure. The surgical gown (100) can be color coded to indicate a barrier level or the presence of the surgery procedure verification card (120). The surgical gown (100) can be included in a surgical pack (400). The surgical pack (400) can include one or more surgical procedure gowns (401,402) that are not color-coded, as well as a surgical drape (440). Methods of using and manufacturing the surgical gown (100) are also described.

Owner:MEDLINE IND LP

Compactor and diverter for return items in a dispensing system

ActiveUS20220142728A1Increase effective storage capacitySurgical furniturePressesSurgical AttireEmergency medicine

A scrubs returns cabinet for a hospital allows workers to return surgical garment tops and bottoms. A cabinet housing has a loading door leading to a return port through which the customer places the soiled scrub suit after entering customer identification information. The scrubs fall into a collection area and are dispersed by a diverter into the collection area. Additionally, a compacting paddle compacts the accumulating scrubs to utilize more of the collection area and accommodate more dirty scrubs before the collection area needs to be emptied. The scrubs are compressed by the compactor after being dispersed by the diverter.

Owner:CINTAS CORP SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com