Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185 results about "Temperature normal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The average normal body temperature is generally accepted as 98.6°F (37°C). Some studies have shown that the "normal" body temperature can have a wide range, from 97°F (36.1°C) to 99°F (37.2°C). A temperature over 100.4°F (38°C) most often means you have a fever caused by an infection or illness.

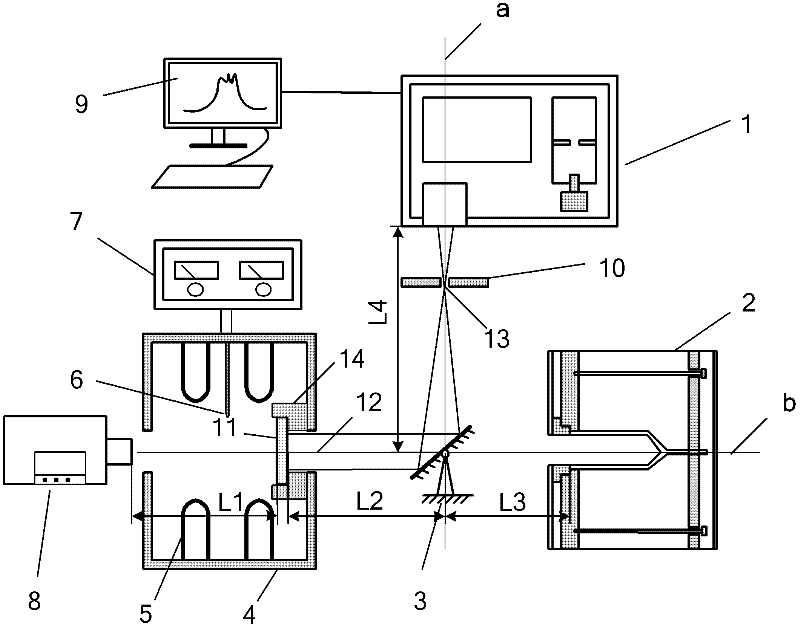

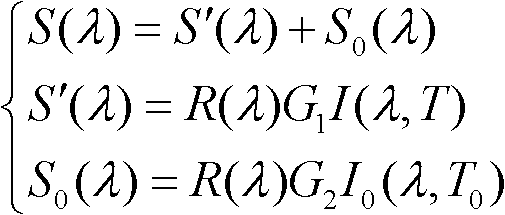

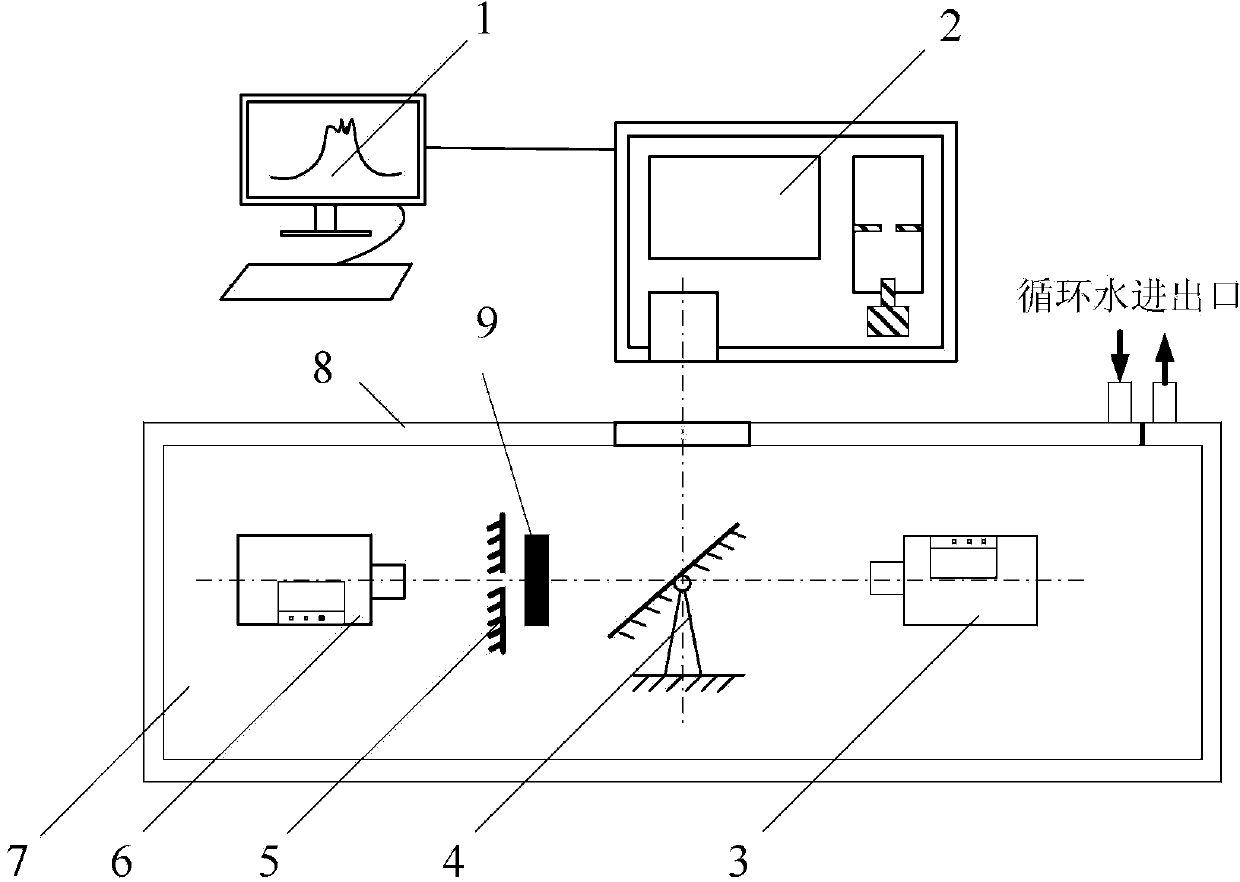

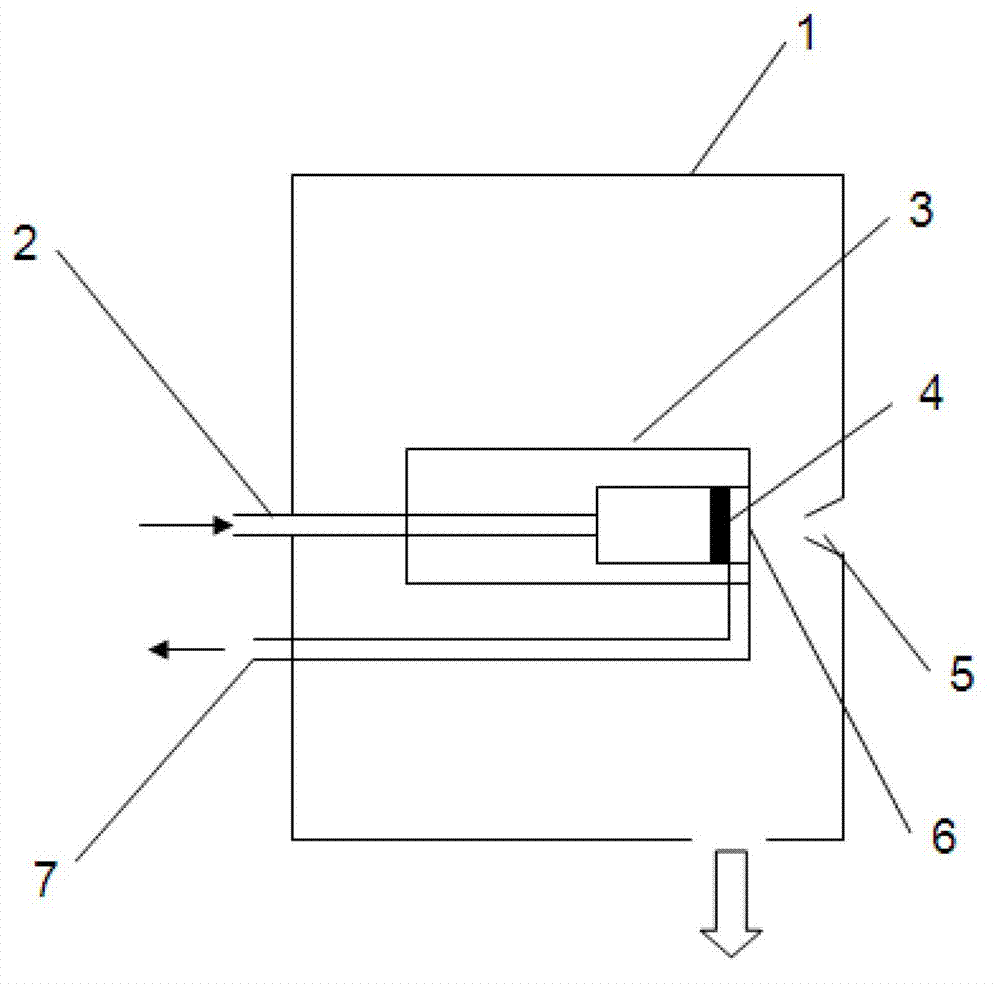

Energy method-based high-temperature radiation rate measuring device of semi-transparent material and revising method for deducting background radiation

ActiveCN102564610AAccurate calculation of high temperature spectral transmittanceEasy to measureRadiation pyrometryMaterial thermal analysisSpectrum analyzerHorizontal axis

The invention provides an energy method-based high-temperature radiation rate measuring device of a semi-transparent material and a revising method for deducting background radiation, relating to a high-temperature normal spectral radiation rate revising and testing method of the semi-transparent material and belonging to the technical field of high-temperature material physical property measurement. The energy method-based high-temperature radiation rate measuring device of the semi-transparent material and the revising method for deducting the background radiation solve the problems of high construction cost, low temperature heating upper limit and lower testing precision of the traditional test system. The high-temperature radiation rate measuring device comprises a Fourier infrared spectrum analyzer, a reference blackbody furnace, a rotatable reflection mirror, a heating furnace, a heater, a temperature collecting device, a temperature routing inspection operation instrument, an incidence light source, a data processing system, a diaphragm and a semi-transparent test piece; the heating furnace is internally provided with a light-transmitting opening, a fixing device of the semi-transparent test piece, and the temperature collecting device; the central axis of a light-emitting opening of the incidence light source, the central axis of the light-transmitting opening of the heating furnace, the mirror surface of the rotatable reflection mirror and the central axis of the light outlet opening of the reference blackbody furnace are collinear with a horizontal axis. The energy method-based high-temperature radiation rate measuring device of the semi-transparent material and the revising method for deducting the background radiation, disclosed by the invention, are used for measuring the high-temperature spectral normal radiation rate of the surface of the semi-transparent material.

Owner:HARBIN INST OF TECH

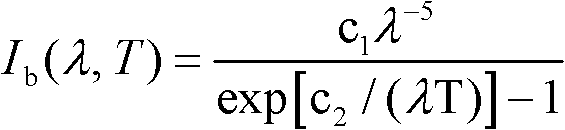

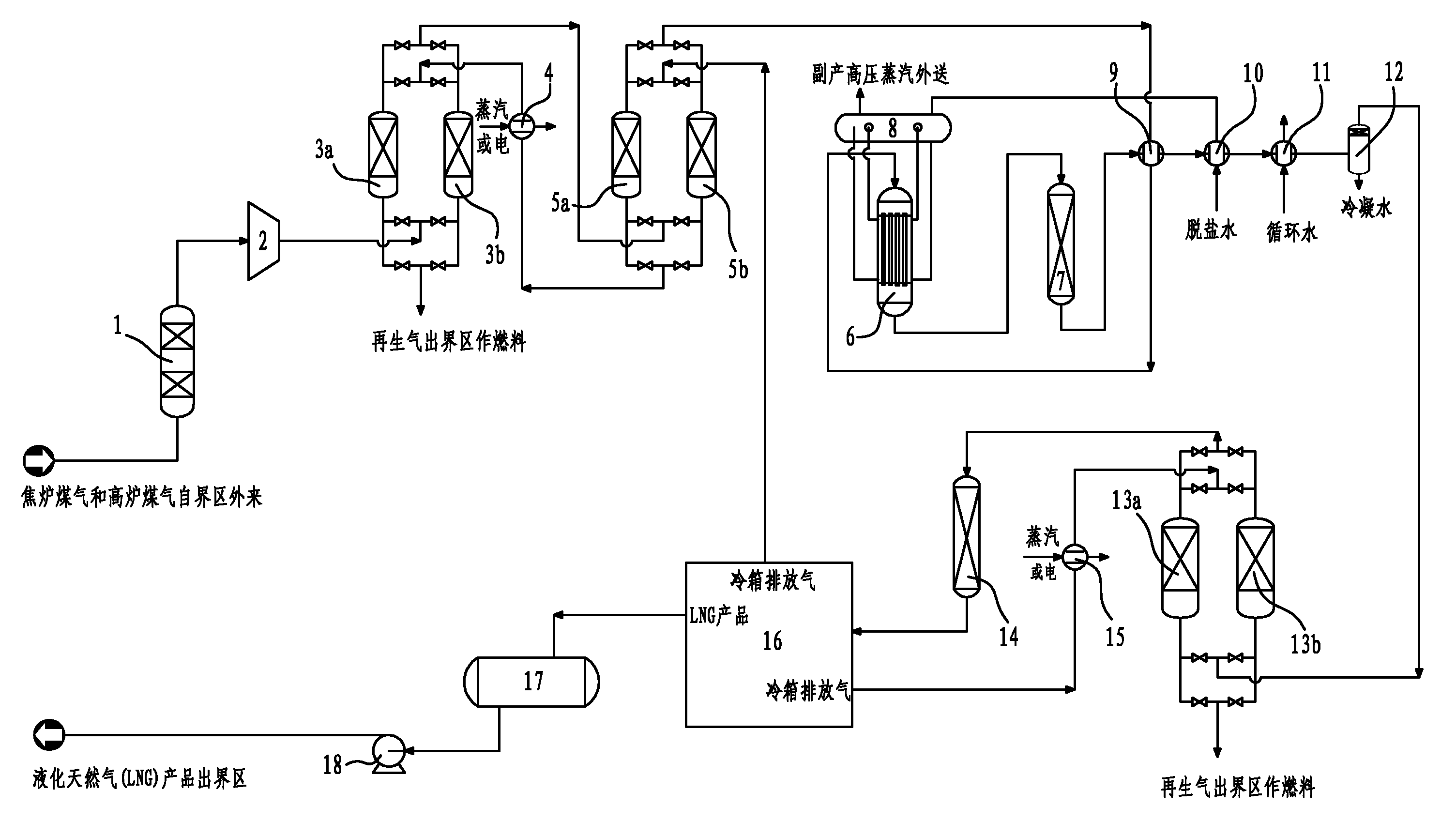

Method for preparing liquefied natural gas by converting raw materials of coke oven gas and blast furnace gas

InactiveCN102250658AEasy to operateSimple processGaseous fuelsGas purification with selectively adsorptive solidsMethanationImpurity

The invention discloses a method for preparing liquefied natural gas by converting raw materials of coke oven gas and blast furnace gas. In the technology, the coke oven gas and the blast furnace gas are taken as the raw materials, the raw materials are subjected to normal-temperature normal-pressure dry desulfurization, gas compression, gas adsorption purification, gas isothermal-adiabatic serial methanation, gas adsorption drying and demetalization, freezing liquefication separation and other technical processes, and high-quality liquefied natural gas with the purity of over 99 percent is produced. By the technology, harmful impurities such as sulfur, naphthalene, tar, benzene, mercury and the like in the gas can be efficiently and easily removed fully at low cost, and components with low value, such as H2, CO, CO2 and the like are completely converted into required CH4 component with high value, so the method has the characteristics of low requirement on quality of feed gas, high yield of liquefied natural gas product, high product purity, low production energy consumption, no environmental pollution, reliable flow, low investment, simple operation and good economic benefit.

Owner:SHANGHAI HANXING ENERGY TECH

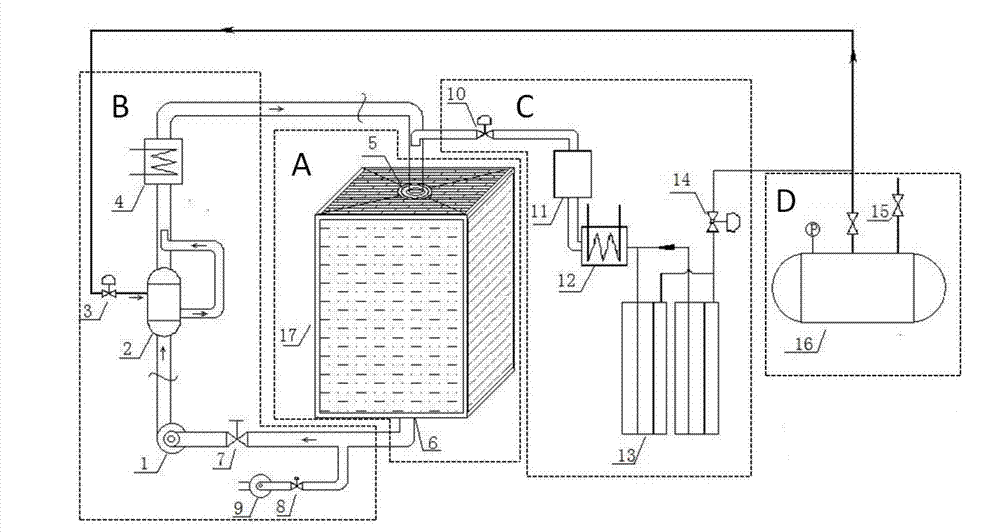

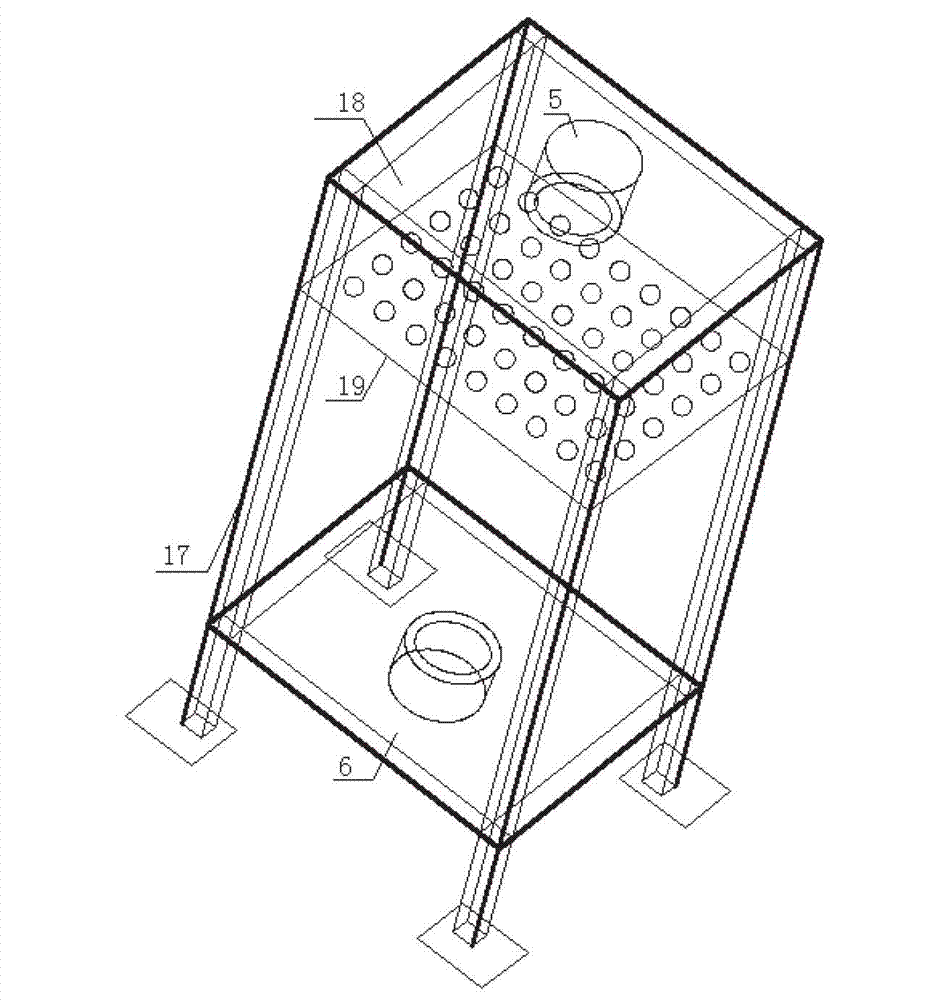

High-low-temperature normal-pressure heat cycle test device

The invention discloses a high-low-temperature normal-pressure heat cycle test device which can operate by adopting a high-low-temperature environment simulating device combining a gas-liquid heat exchanger and a pipeline electric heater. The device can realize a heat cycle test environment in a temperature range from -100 DEG C to +100 DEG C under normal pressure. The high-low-temperature normal-pressure heat cycle test device comprises an environment simulating cabin body, a high-low-temperature gas generating system, a gas displacing system and a cold source system, and can finish a plurality of types of test processes needed by carrying out a heat cycle test. The environment simulating cabin body is used for placing a tested piece to be subjected to the heat cycle test; the high-low-temperature gas generating system is used for conveying gas and adjusting parameters including the speed, the temperature and the like for conveying air; the gas displacing system is used for discharging water steam and impurities in a system through a gas displacing effect in a displacing process so as to prevent the tested piece from being damaged; and the cold source system is used for providing a cold source in a temperature reducing process and providing nitrogen gas in the displacing process. The device has a simple structure and a reasonable design, and can effectively meet the requirements of the high-low-temperature heat cycle test.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of modified active carbon-based gasoline desulfurization adsorbent

InactiveCN103143322ACarrier is easy to getLow priceOther chemical processesHydrocarbon oils refiningSorbentAdsorption selectivity

The invention discloses a preparation method of a modified active carbon-based gasoline desulfurization adsorbent, and relates to a preparation method of a gasoline deep desulfurization adsorbent. The adsorbent is a Fe ion-loaded active carbon adsorbent; and the preparation method comprises the following steps of: performing cleaning pretreatment of the raw material of the adsorbent carrier particles; drying the pretreated carrier particles, mixing the carrier particles with a nitric acid solution, performing backflow and electromagnetic stirring; washing the oxidized carrier particles; drying the carrier particles; roasting to modify the dried particles; and steeping the carrier particles and a soluble ferric salt solution; drying the steeped carrier particles; and roasting to activate the dried particles. The preparation process is simple and easy to implement and realizes easy regeneration; the service life of the adsorbent is long; the adsorbent has high adsorption capacity and adsorption selectivity on thiophene and derivatives thereof in gasoline; the adsorption process is performed in a normal-temperature normal-pressure condition, and the operation cost is low; and no pollutant is generated in the adsorption process, good economic practicability is realized, and environmental protection requirements are met.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

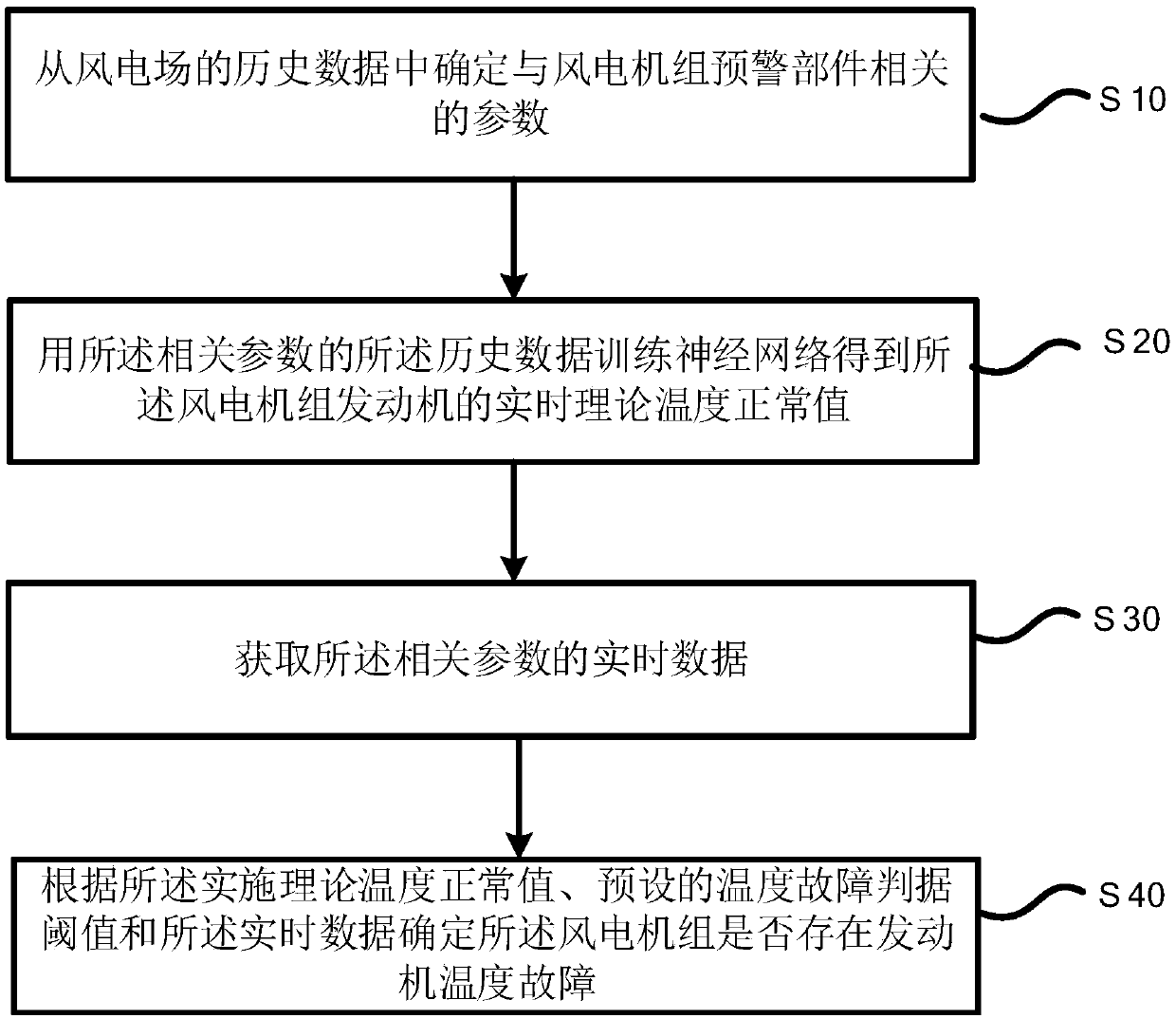

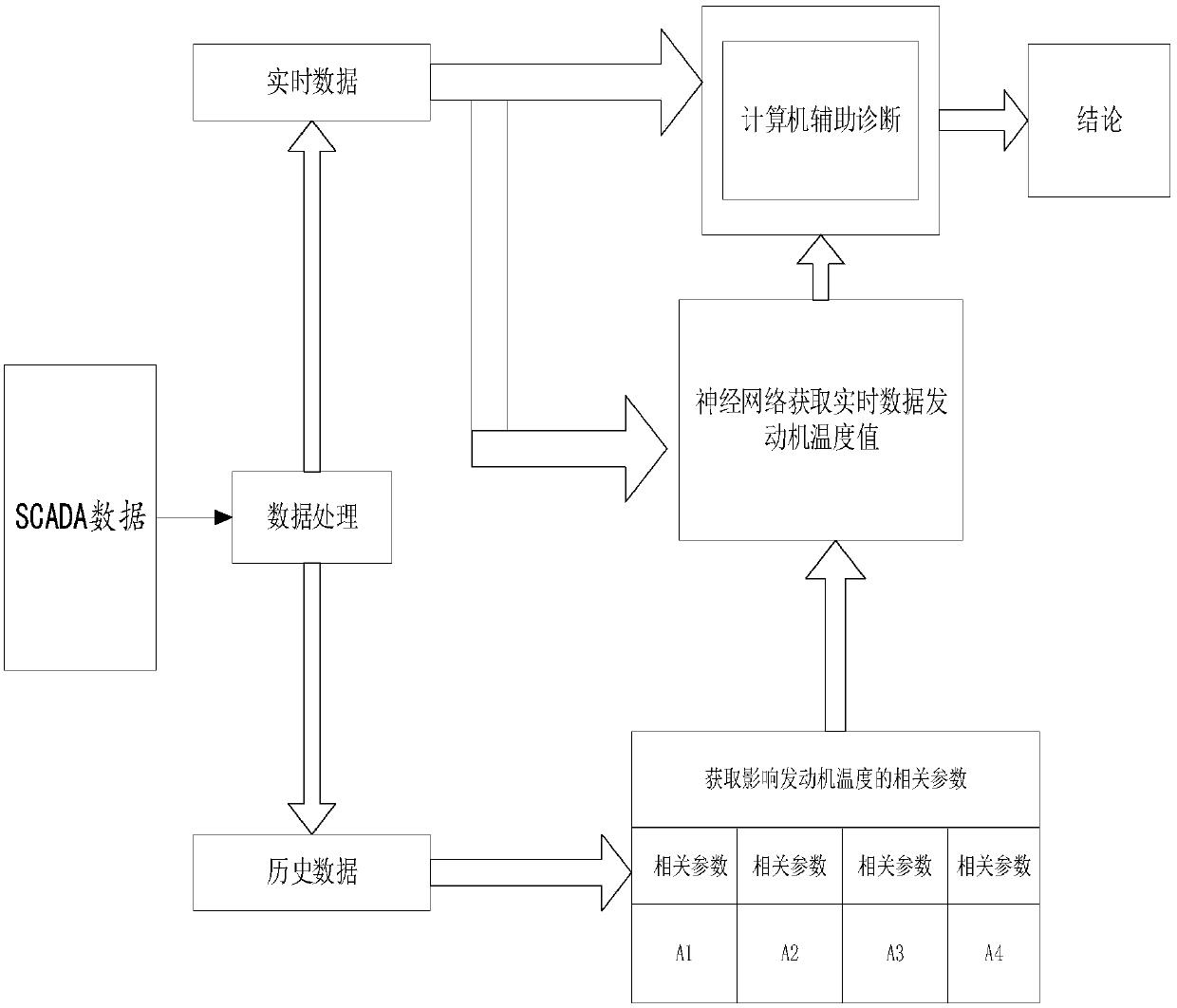

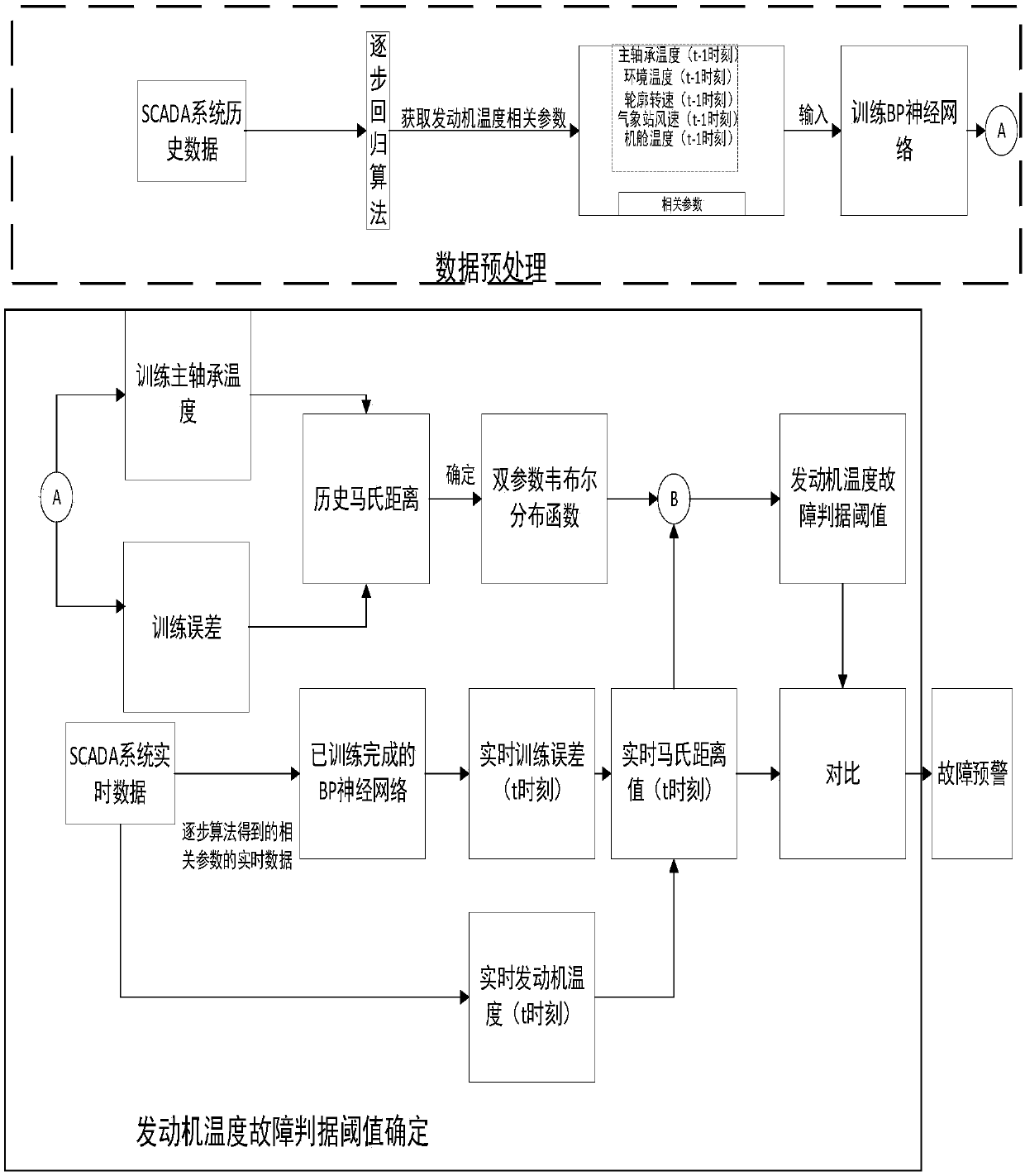

Early warning diagnosis method of engine temperature fault of wind turbine generator

The invention relates to the field of new-energy wind power generation system, particularly to an early warning diagnosis method of the engine temperature fault of a wind turbine generator. The methodcomprises: step one, determining parameters related to an early warning part of a wind turbine generator among historical data of a wind farm; step two, training a neural network by using the historical data of the related parameters to obtain a real-time theoretical temperature normal value of the wind turbine generator; step three, acquiring real-time data of the related parameters; and step four, according to the real-time theoretical temperature normal value, a preset temperature fault criterion threshold, and the real-time data, determining whether the wind turbine generator has an engine temperature fault. Therefore, the conflict between the early warning time of the engine temperature fault of the wind turbine generator and the fault early-warning precision is eliminated effectively; and the diagnosis accuracy and the diagnosis time lead are improved obviously.

Owner:XIANGTAN UNIV

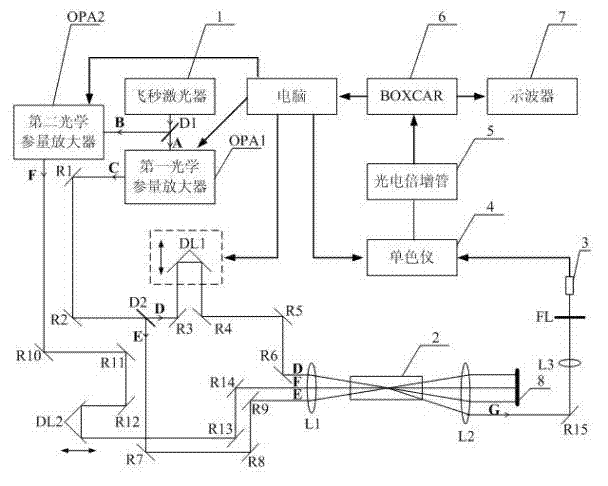

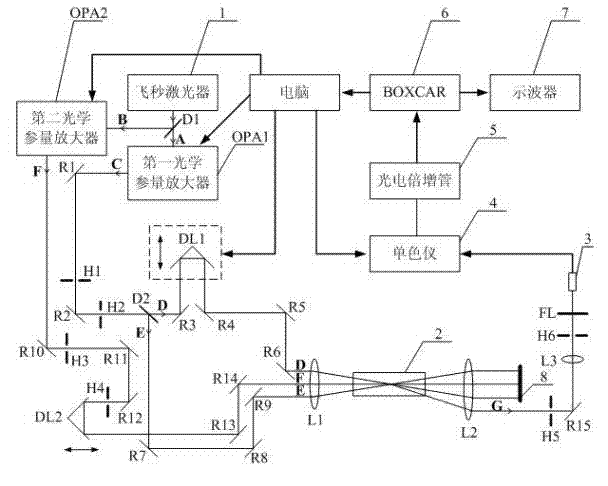

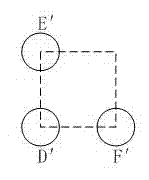

Normal-temperature normal-pressure femto-second CARS (Coherent Anti-stokes Raman Spectroscopy) time-resolved spectrum measuring system

InactiveCN101819064ASimple and fast operationImprove signal-to-noise ratioRadiation pyrometryRaman scatteringNonlinear opticsFemto second laser

The invention relates to a normal-temperature normal-pressure femto-second CARS (Coherent Anti-stokes Raman Spectroscopy) time-resolved spectrum measuring system which relates to the technical field of nonlinear optics and solves the problem of multiple limiting factors of traditional femto-second CARS time-resolved spectrum measuring experiment. Beams output by a femto-second laser are adjusted through a series of reflectors and optical delay lines by the system to form three bundles of beams which have approximate energy and are respectively positioned on three peaks of a square on the vertical direction of the beams, the beams are focused to a sample pool and then emit a new beam along a specific angle, i.e. a CARS signal, the CARS signal is filtered through a filter plate, then received by a probe and input to a monochromator, the data acquisition of an electrical signal converted by a photomultiplier is carried out by utilizing BOCCAR, and the data are input to a computer for data processing. The invention can carry out femto-second CARS time-resolved spectrum measurement under the experimental conditions of normal temperature and normal pressure and is applicable for the femto-second CARS spectrum measurement of gas samples and liquid samples in a static sample pool.

Owner:HARBIN INST OF TECH

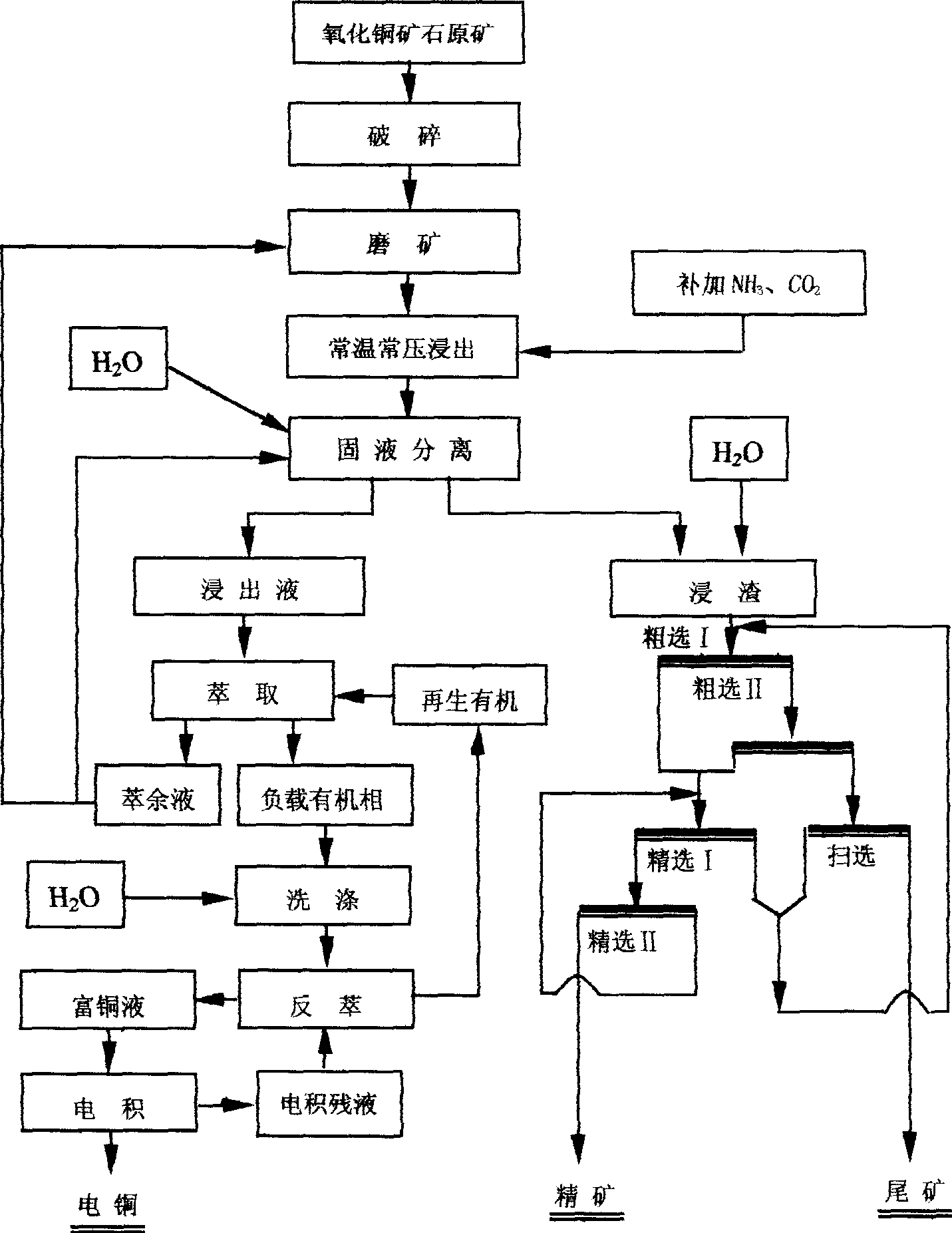

Normal temperature normal pressure ammonia infusion-extraction-electrodeposition-slag infusion flotation of copper oxide green ore

InactiveCN1718786AEasy to recycleReduce energy consumptionProcess efficiency improvementSlagLower grade

A process for extracting copper from copper oxide ore includes such steps as immersing in ammonia water in ordinary temp and ordinary pressure condition, extracting electrodeposition, and floatation. Its advantages are low consumption of energy and low cost. It is especially suitable for the low-grade copper oxide ore with high content of Ca and Mg.

Owner:方建军 +2

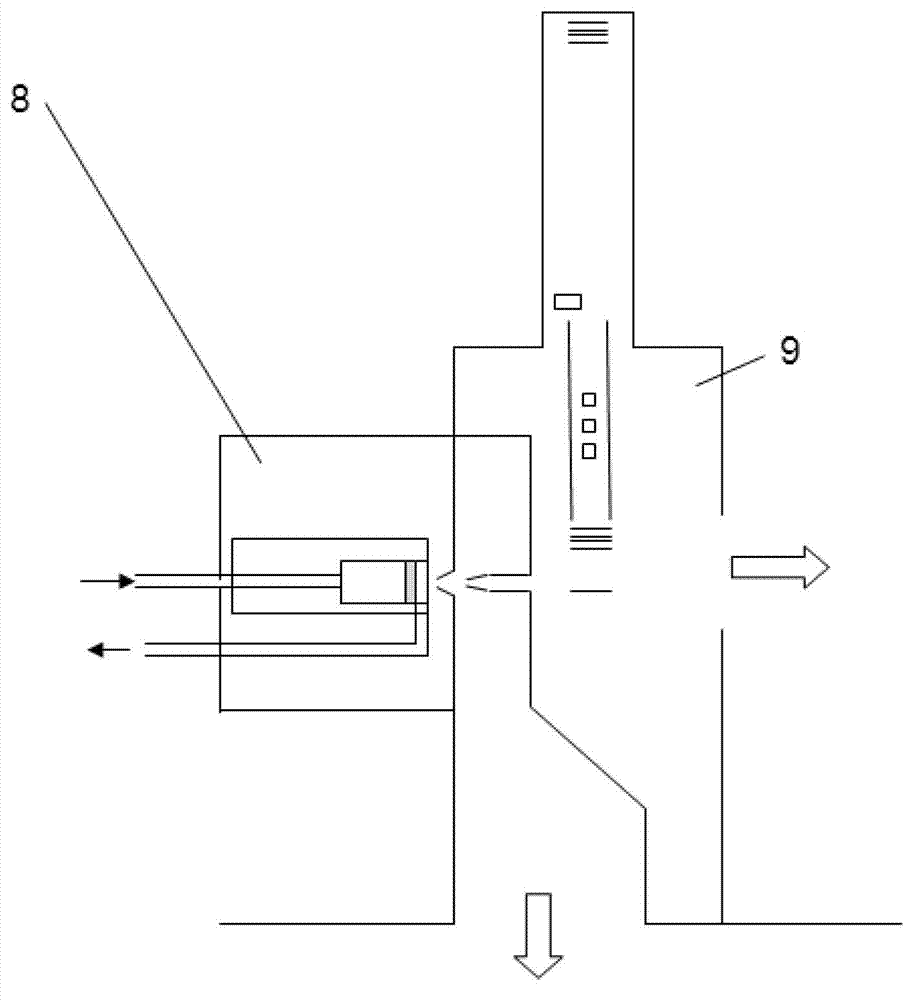

High temperature semitransparent material spectrum direction apparent emissivity inversion measuring device and method

ActiveCN103674888AHigh precisionSimple and fast operationMaterial analysis by optical meansAviationRefractive index

The invention relates to a high temperature semitransparent material spectrum direction apparent emissivity inversion measuring device and method, belongs to the technical field of high temperature physical function material hot measurement and aims to solve the problems of low accuracy, low temperature upper limit, narrow measuring waveband and existence of dead measuring angle in the conventional semitransparent material spectrum direction apparent emissivity measurement. According to the invention, a fourier infrared spectrometer is used for measuring the high temperature normal direction transmissivity and the high temperature normal direction emissivity of a semitransparent material respectively, further the spectral refractivity and the spectral absorption factor of the semitransparent material are computed according to a radiation transfer inverse problem solving method, and finally the high temperature spectrum direction apparent emissivity of the semitransparent material is computed through the spectral refractivity and the spectral absorption factor of the material. The invention provides a method capable of accurately measuring the spectrum direction apparent emissivity of the semitransparent material, and can be widely applied to various fields of aviation, military, energy sources, chemical engineering and atmospheric sciences and the like.

Owner:HARBIN INST OF TECH

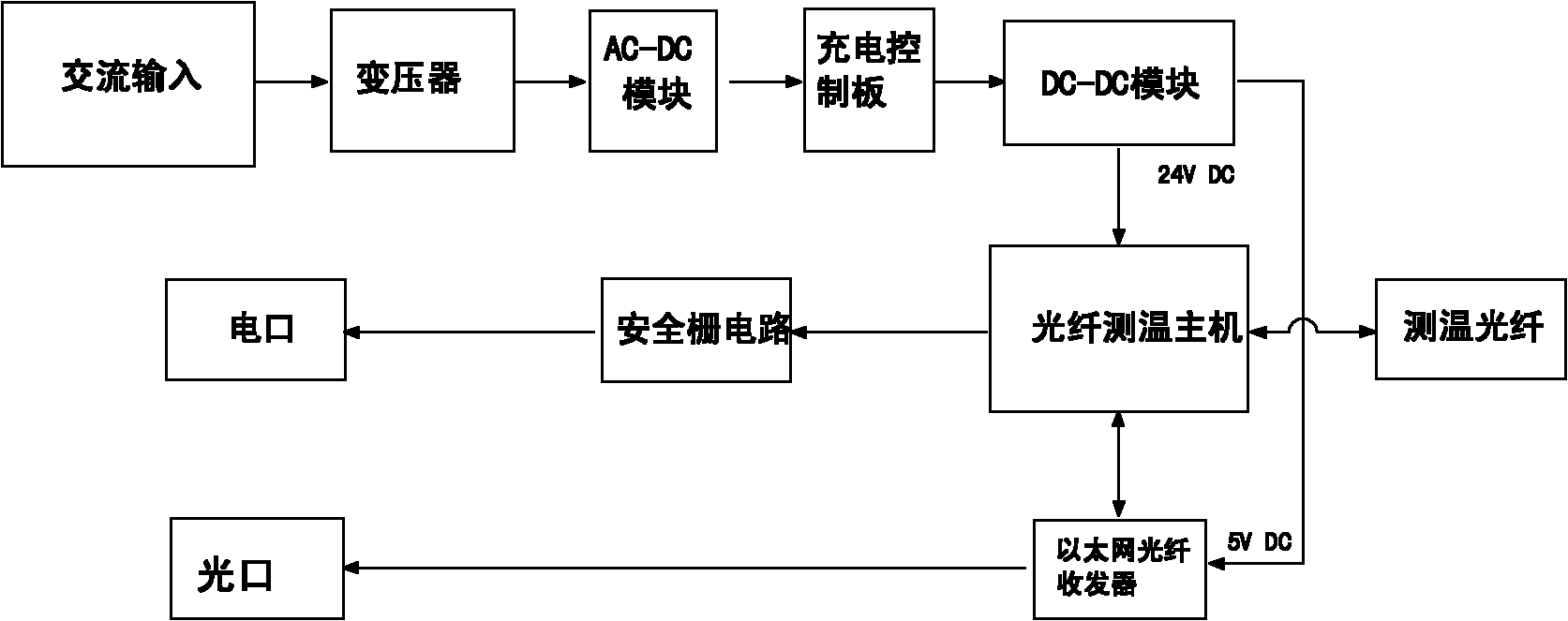

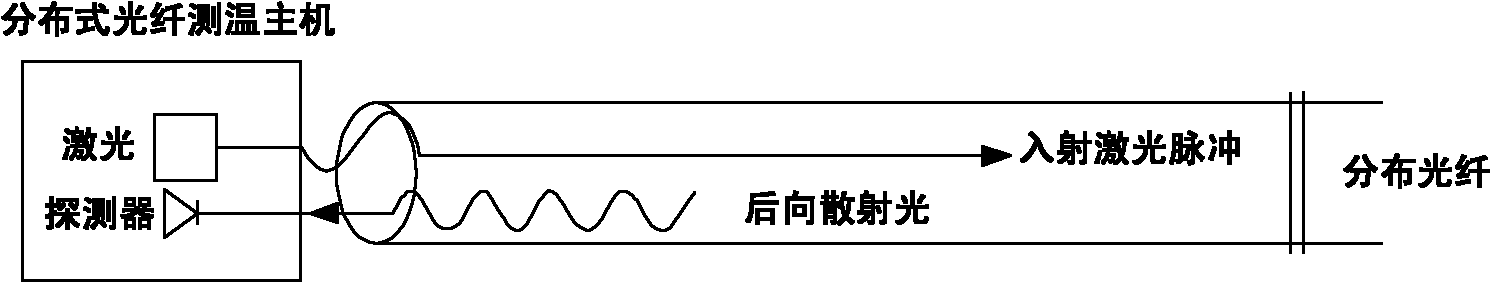

Distributed optical fiber temperature measurement-based fire early warning method for belt conveyor

The invention relates to the field of coal mine safety, in particular to a distributed optical fiber temperature measurement-based fire early warning method for a belt conveyor. The method comprises the following steps of: dividing a temperature measuring optical fiber into a temperature measuring point, a channel and an area, and processing temperature data measured by the temperature measuring optical fiber by an absolute temperature early warning method, an area relative temperature difference early warning method, an area normal distribution early warning method, a measuring point temperature rise slope early warning method and a measuring point temperature rise variation trend early warning method to acquire a channel threshold early warning characteristic value, an area threshold early warning characteristic value, an area relative temperature early warning characteristic value, an area temperature normal distribution statistical characteristic value, a measuring point threshold early warning characteristic value, a measuring point temperature rise slope early warning characteristic value and a measuring point temperature rise accumulated trend early warning characteristic value; inputting the characteristic values and the measuring point temperature rise accumulated trend early warning characteristic value into a back propagation (BP) neural network model; and outputting a warning coefficient, an early warning coefficient and a safety coefficient by using the BP neural network model.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

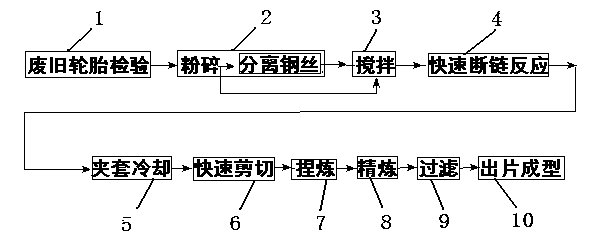

Waste rubber high-temperature normal-pressure regenerating process

ActiveCN102888030AGood technical effectSave resourcesPlastic recyclingPolycyclic aromatic hydrocarbonRubber material

The invention discloses a waste rubber high-temperature normal-pressure regenerating process, which is characterized by comprising the following steps of: inspecting a waste rubber raw material; smashing the raw material; feeding smashed rubber power into a stirring device for stirring; feeding the stirred rubber powder into an extruding device for performing a rapid chain fracture reaction; feeding the extruded rubber material into a cooling device for cooling; rapidly shearing and rolling the cooled rubber material; kneading the rubber material powder into sheets; refining the sheet rubber material; and discharging the sheets and molding. Regeneration is performed rapidly at a high temperature under the normal pressure, so that a rubber linear molecular chain is not damaged, any catalyst or softening agent is not required to be added in a regenerating process, petroleum resources are saved, the rubber material quality is improved, environmental pollution is lowered, and the content of PAHS (Polycyclic Aromatic Hydrocarbons) in reclaimed rubber is less than 200 ppm. The tensile strength of a product can be over 16MPa, and the product performance is 1.5 times that of original high-quality tread rubber.

Owner:NANTONG HUILI RUBBER

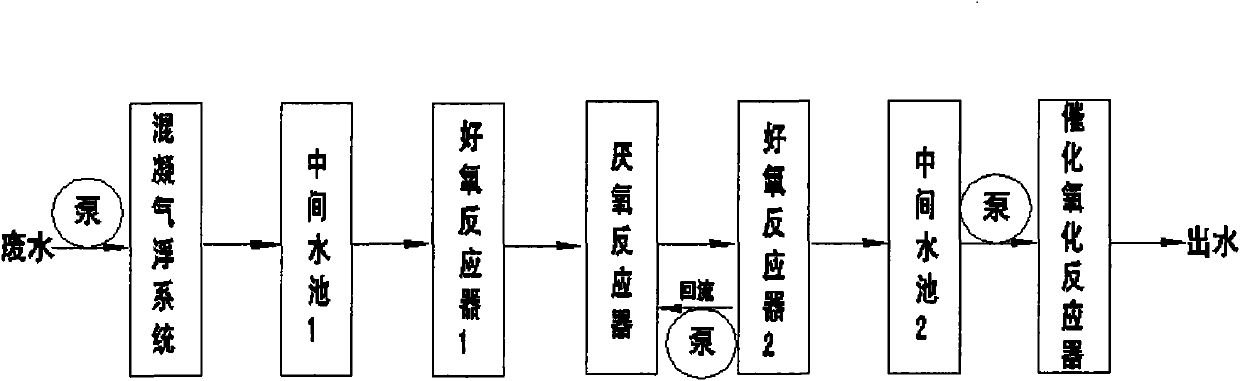

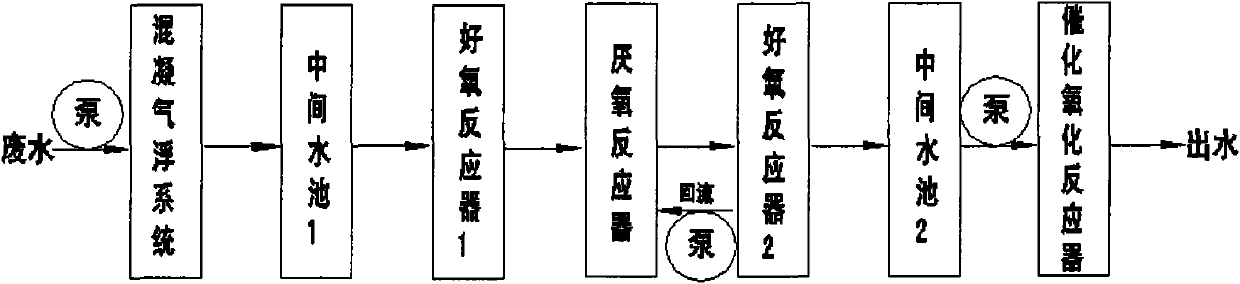

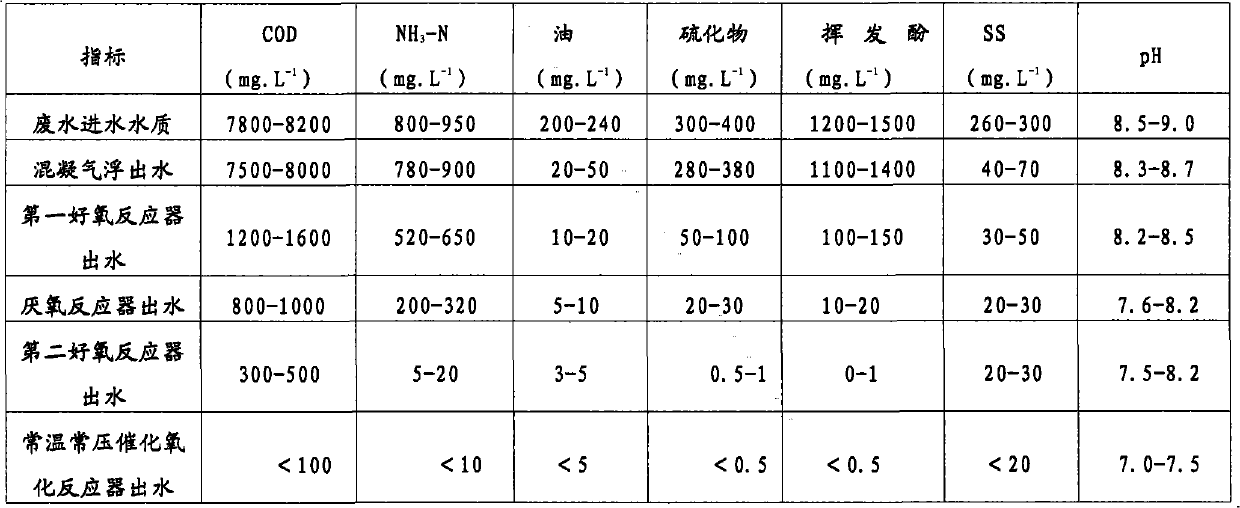

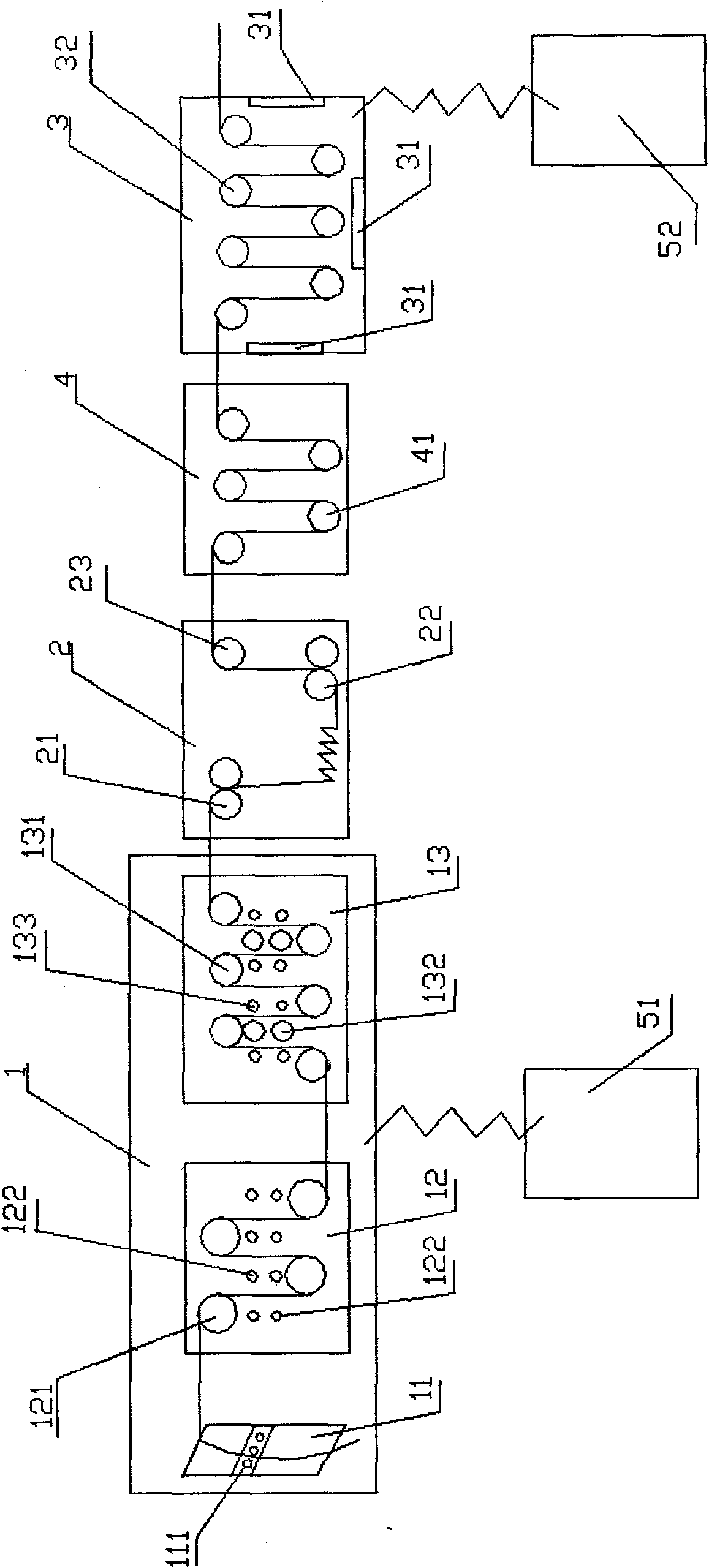

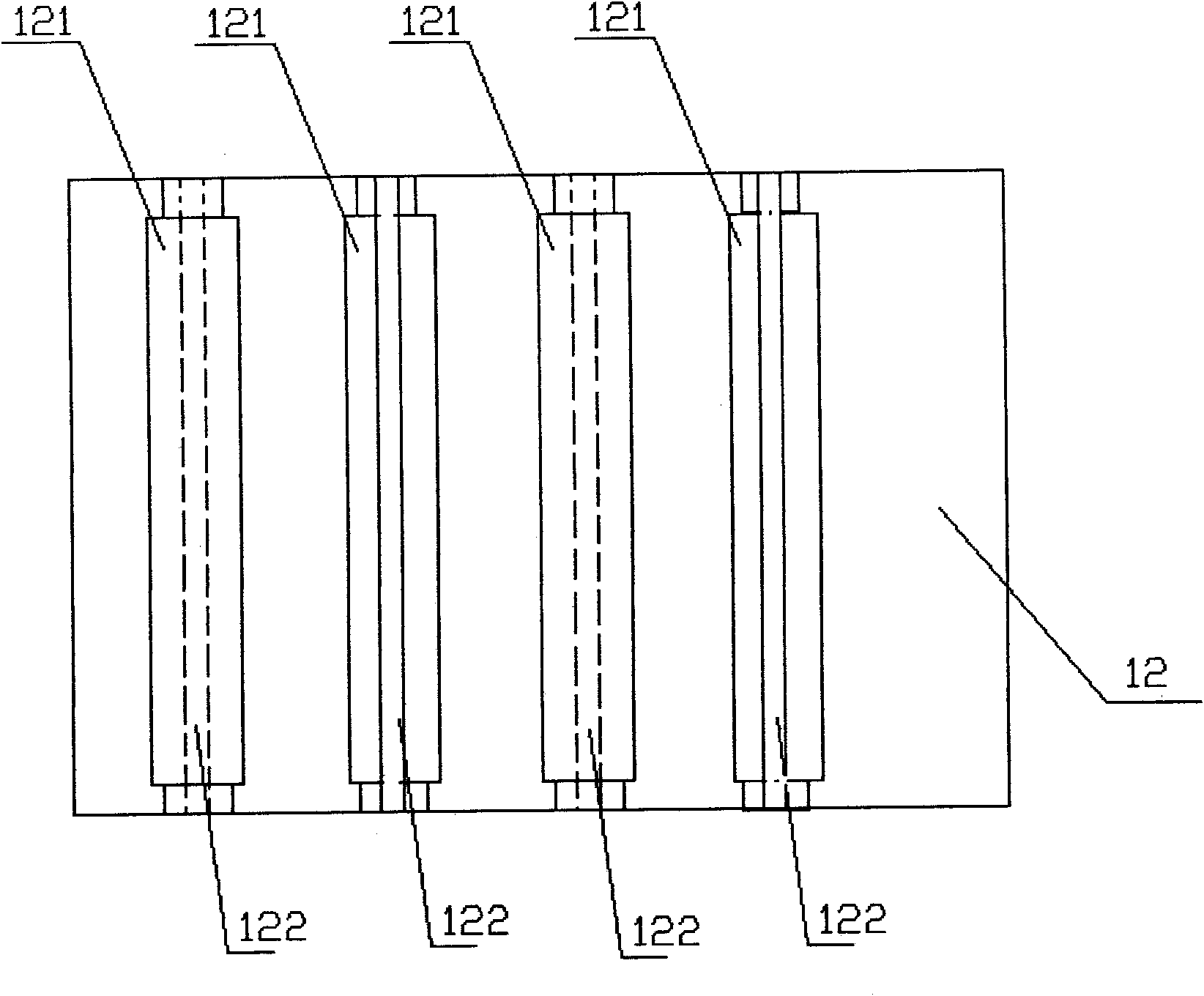

Coal gasification wastewater processing method

ActiveCN102557328ATreatment with aerobic and anaerobic processesMultistage water/sewage treatmentCoal gasification wastewaterCatalytic oxidation

The invention relates to a coal gasification wastewater processing method. The method comprises the following steps: carrying out coagulation processing and air floatation processing on coal gasification wastewater, sequentially carrying out aerobic biological processing, anaerobic biological processing and the aerobic biological processing by allowing the wastewater to flow through a first aerobic reactor, an anaerobic reactor and a second aerobic reactor, allowing parts of water discharged from the second aerobic reactor to return to the anaerobic reactor, and carrying out normal-temperature normal-pressure catalytic oxidation or carrying out Fenton oxidation and normal-temperature normal-pressure catalytic oxidation on the residual water.

Owner:ENN ENVIROTECH CO LTD

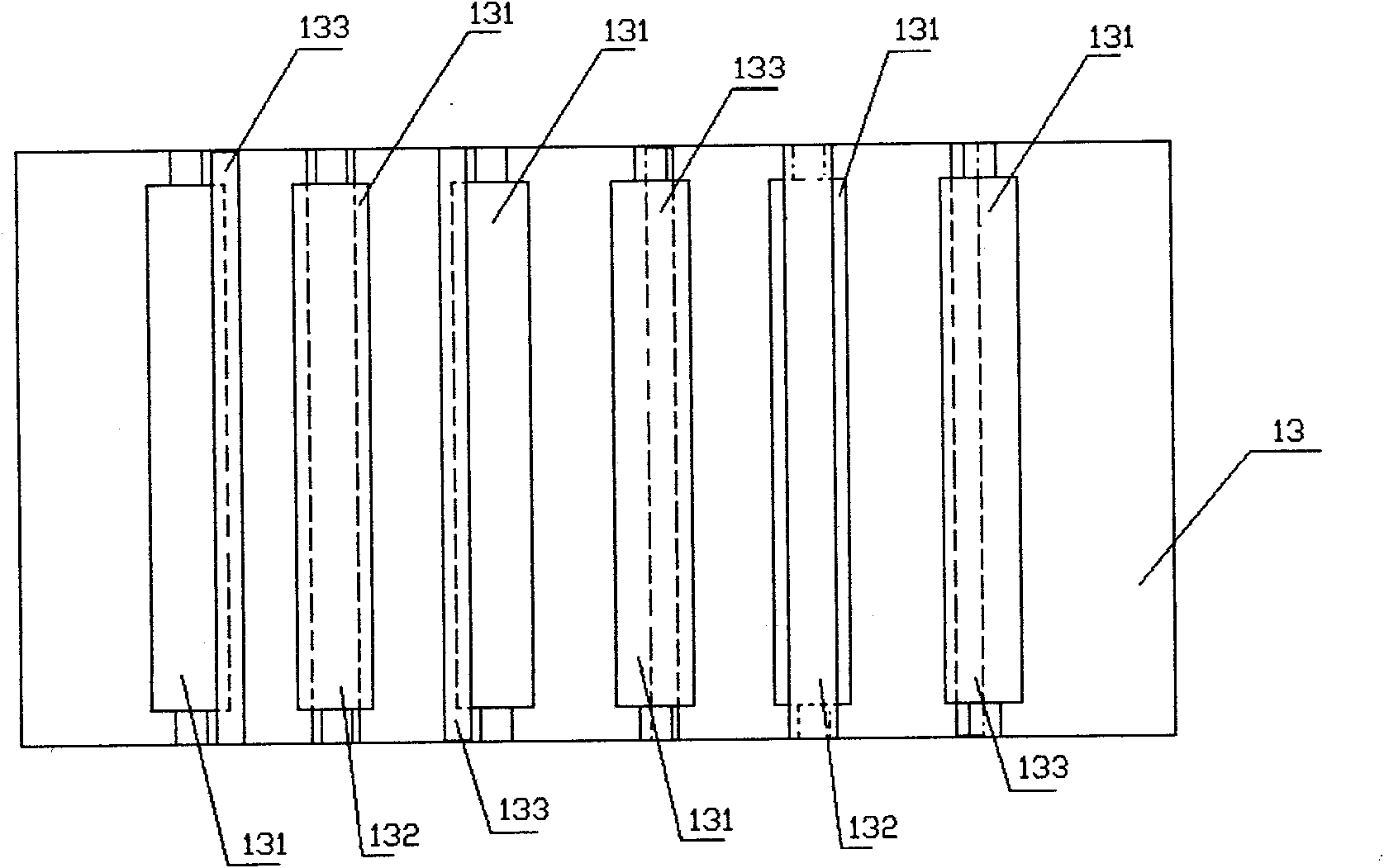

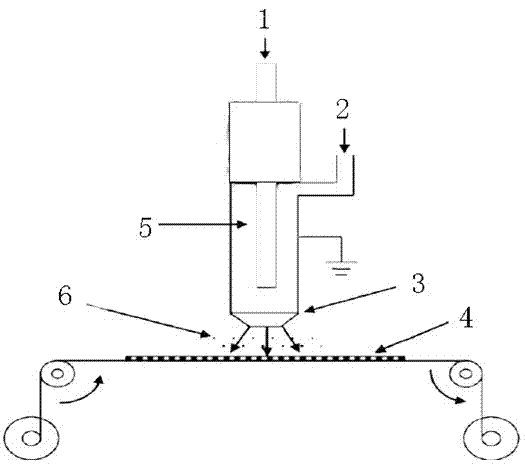

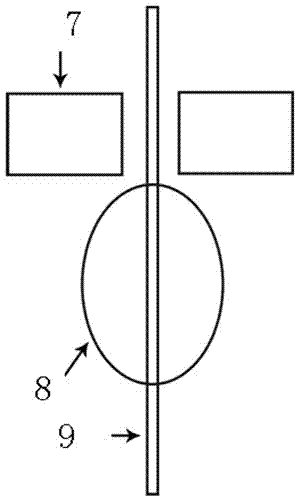

Process for dyeing fabrics by combining with plasma and ultrasonic and special device thereof

InactiveCN101880960AImprove dye uptakeReduce dosageDry-cleaning apparatus for textilesUltrasonic/sonic fibre treatmentControl systemGraft reaction

The invention relates to the field of fabrics dyeing and finishing processes, in particular to a process for dyeing fabrics by combining with plasma and ultrasonic and a special device thereof. The special device comprises low-temperature normal-pressure plasma equipment, grafting reaction equipment, ultrasonic dyeing equipment, a rinsing bath and two groups of control systems, wherein the low-temperature normal-pressure plasma equipment, the grafting reaction equipment, the rinsing bath and the ultrasonic dyeing equipment are sequentially connected, one group of control systems is connected with the low-temperature normal-pressure plasma equipment, and the other group of control systems is connected with the ultrasonic dyeing equipment. The invention organically combines the low-temperature normal-pressure plasma equipment and the ultrasonic dyeing equipment, solves the problem that the dye uptake and the dyeing quality can not improved in a process of dyeing fabrics in a high crystalline region or solves the problem of high energy consumption and high pollution in the dyeing process, and can effectively realize that the dye uptake and the dyeing quality can be improved while realizing environmental-friendly production with low energy consumption and low pollution.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

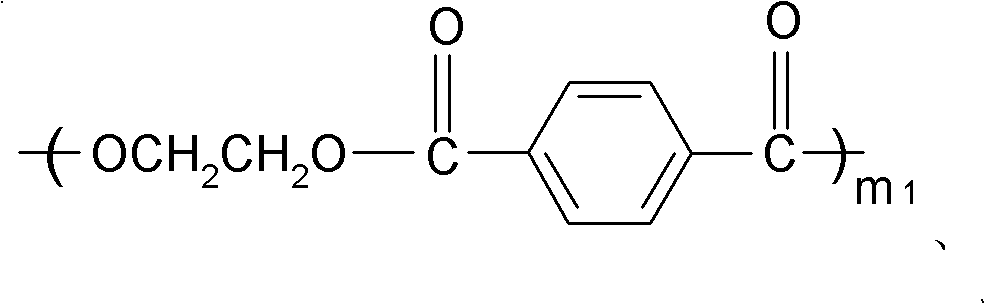

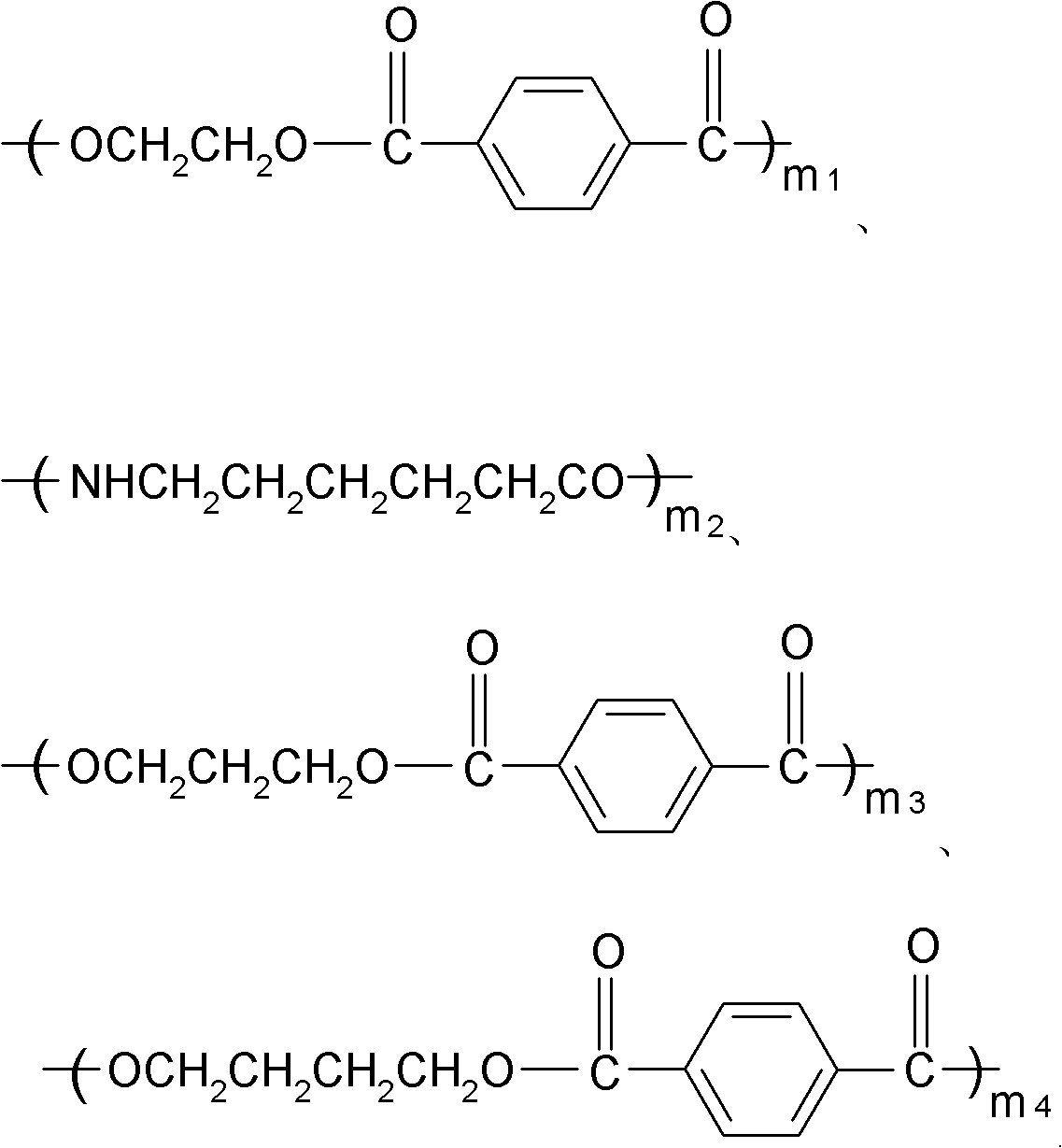

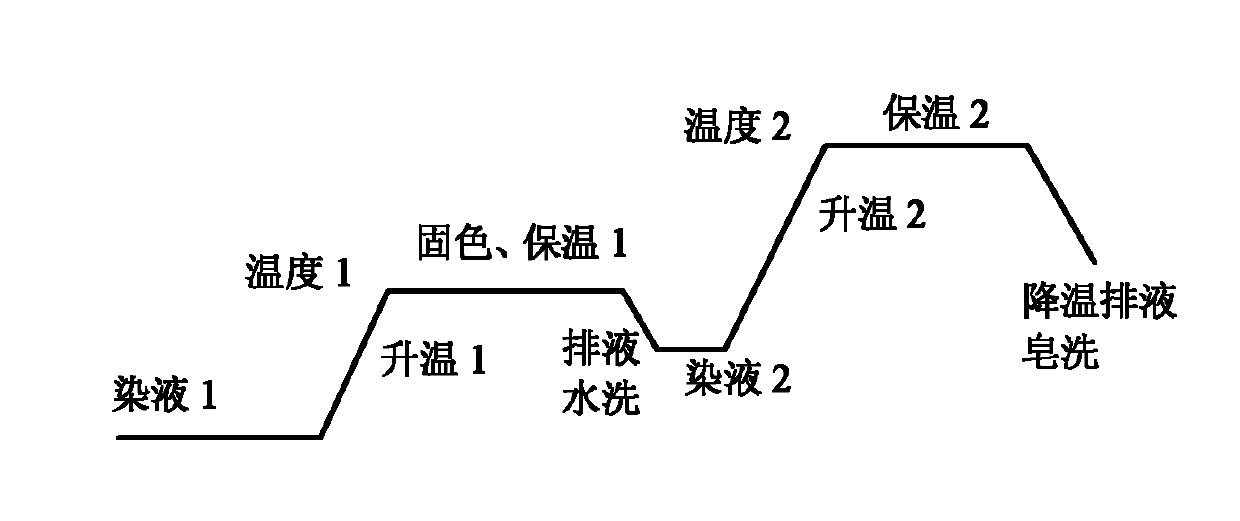

Modified polyester/cotton blended fabric and dyeing method thereof

ActiveCN101956336AEvenly distributed sequenceHigh tensile strengthDyeing processYarnDisperse dyeNylon 6

The invention provides a modified polyester / cotton blended fabric and a dyeing method thereof. The fabric is blended by modified polyester and cotton, wherein the modified polyester is copolymerized by polyester and nylon 6, and has the structural unit as the specification, wherein m1 is more than 1 and less than 160, m2 is more than 1 and less than 70, m3 is more than or equal to 0 and less than 20, and m4 is more than or equal to 0 and less than 20; the blended fabric has the performance of normal-temperature normal-pressure dyeing, and soft handfeel and good antipilling performance with the antipilling grade over 3 grades. The invention also relates to a method for dyeing the blended fabric. An acid dye or an acid dye and a disperse dye are used for one-bath dyeing so as to simplify the dyeing process and contribute to energy conservation and emission reduction; and the dyeing temperature is below 100 DEG C to remarkably reduce energy consumption.

Owner:CHINESE TEXTILE ACAD

Control method for improving reliability of utility boiler

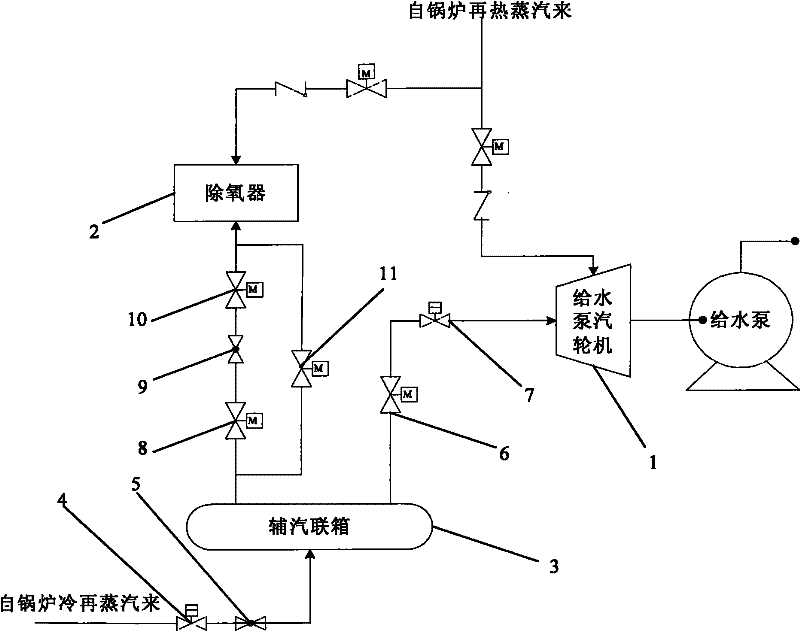

The method relates to a control method for improving the reliability of a utility boiler. The method is characterized by comprising the following steps of: 1, keeping transverse interlocking protection between a generator in a thermal generator set and a turbine and removing transverse interlocking protection among the generator, the turbine and the boiler; 2, immediately starting a bypath systemin the thermal generator set without triggering the action of main fuel trip (MFT) of the boiler after the turbine or the generator trips, and simultaneously starting a run back (RB) loop in the thermal generator set; 3, providing spare steam sources for a feed pump turbine and a deaerator in the thermal generator set; and 4, changing the valve position of high-pressure bypass and a pressure set value of low-pressure bypass in the bypass system of the thermal generator set to make steam discharge of a high-pressure cylinder smooth and the discharge temperature normal. Compared with the prior art, the method can effectively improve the reliability of the utility boiler.

Owner:CHINA SHENHUA ENERGY CO LTD +2

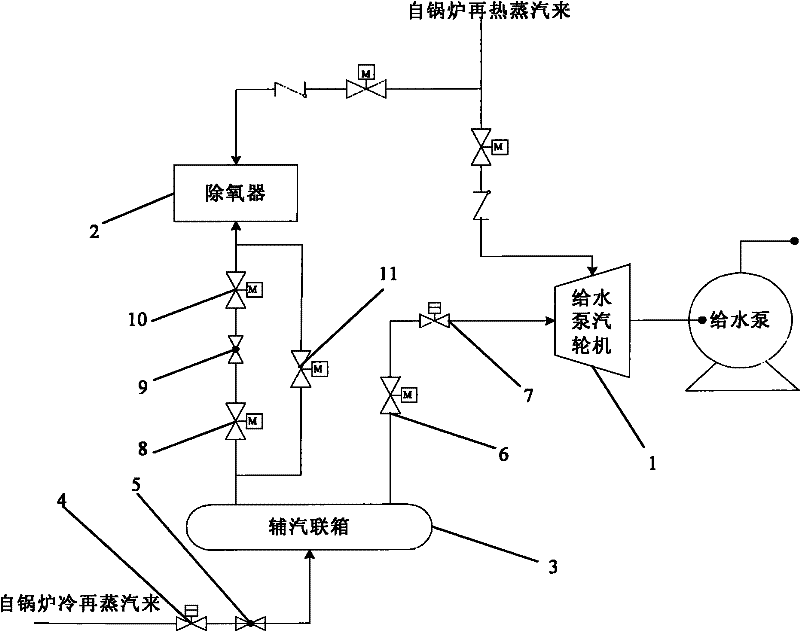

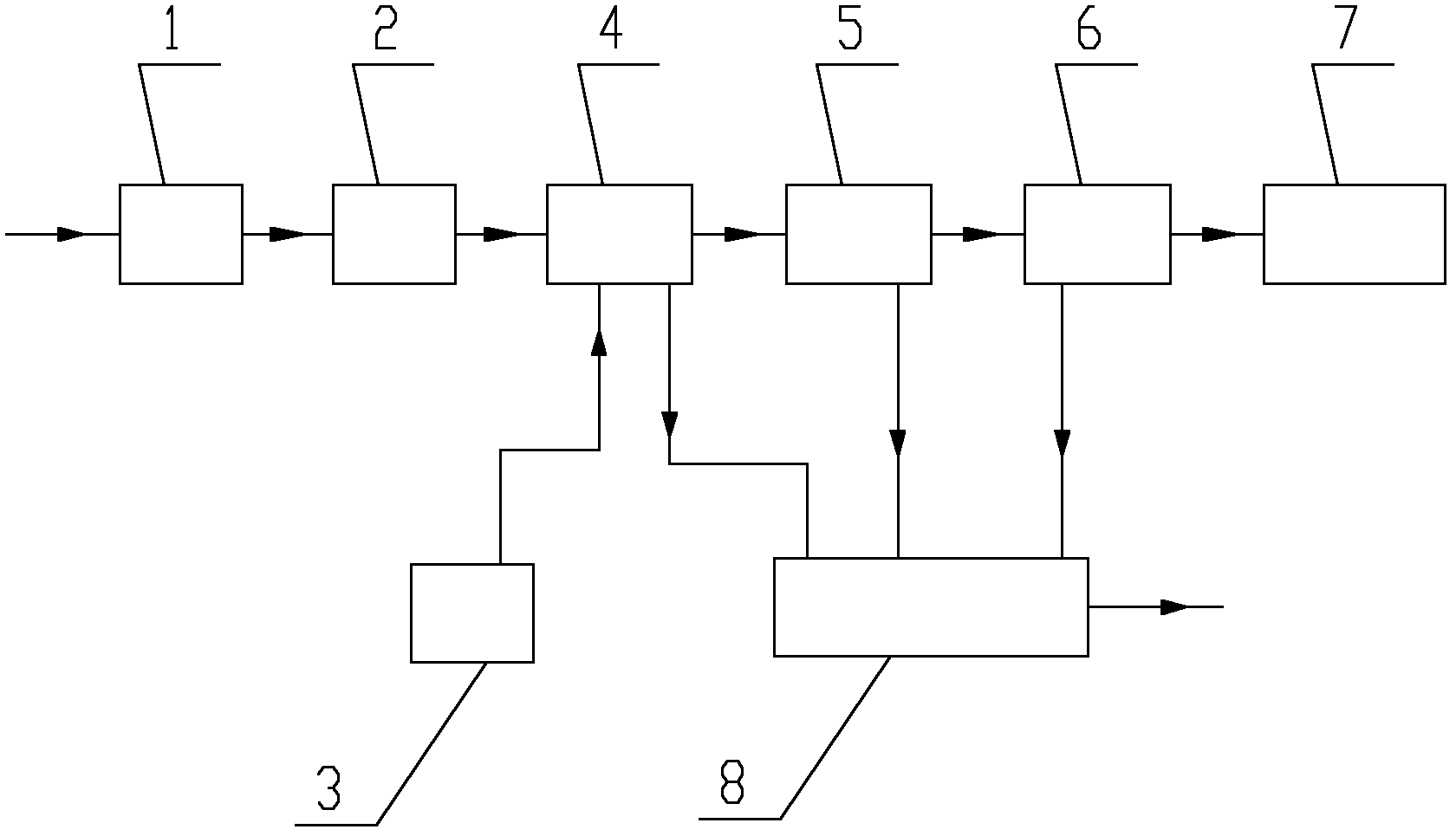

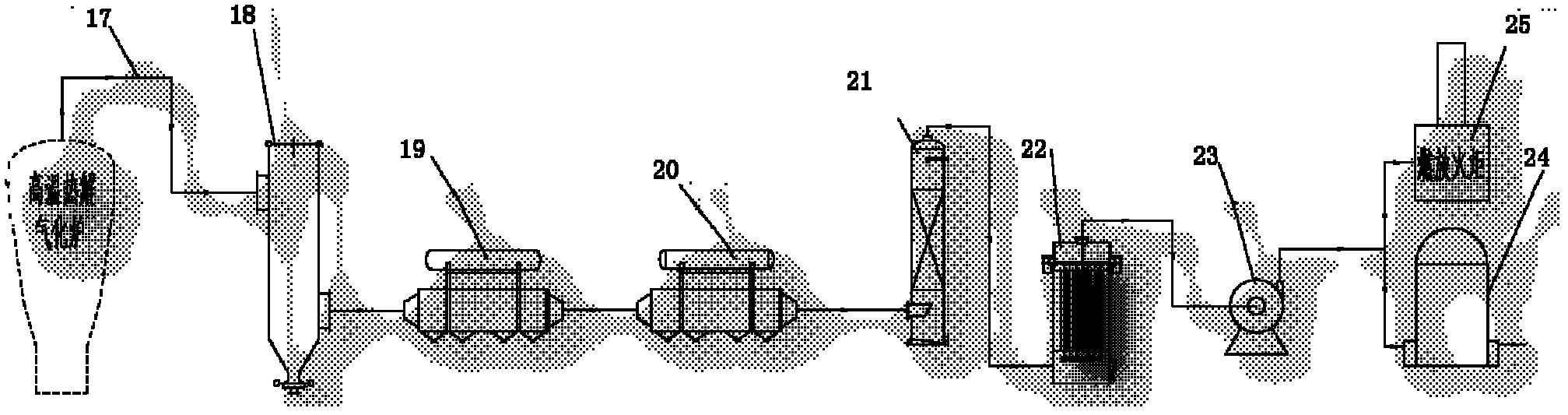

High temperature normal pressure biomass gasification island process

The invention provides a high temperature normal pressure biomass gasification island process. The process comprises the procedures of pretreatment and storage of biomass, gasification by using a biomass gasification furnace, cooling of gasified crude gasification gas, rinsing, dedusting and storage of fresh gasification gas, wherein in gasification by using the biomass gasification furnace, an external heat source is used to supply heat, reaction temperature in the gasification furnace is controlled to be 1300 to 1750 DEG C, liquid state slag removal is adopted by the gasification furnace, cooling of gasified crude gasification gas is realized through recovery of sensible heat by a quenching tower and a two-stage heat boiler, cooled crude gasification gas is subjected to rinsing and electric precipitation, fresh gasification gas is stored in a gas storage cabinet, and whole gasification island equipment operates under a negative pressure or a positive pressure of 0 to 50 KPa. According to the process, the external heat source is utilized for gasification, which enables the quality of crude gasification gas to be improved; a normal pressure fixed bed is employed for gasification, which enables the equipment of gasification furnace body to have the advantages of simpleness, small investment and easy operation; feeding, deslagging and purifying systems are simple; a wide variety of raw materials are applicable, gasification of various biomass, MSW, raw coal, sludge and the like can be realized, and blended gasification of a plurality of fuels can be realized; systems and equipment are mature, and a high localization degree is obtained.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

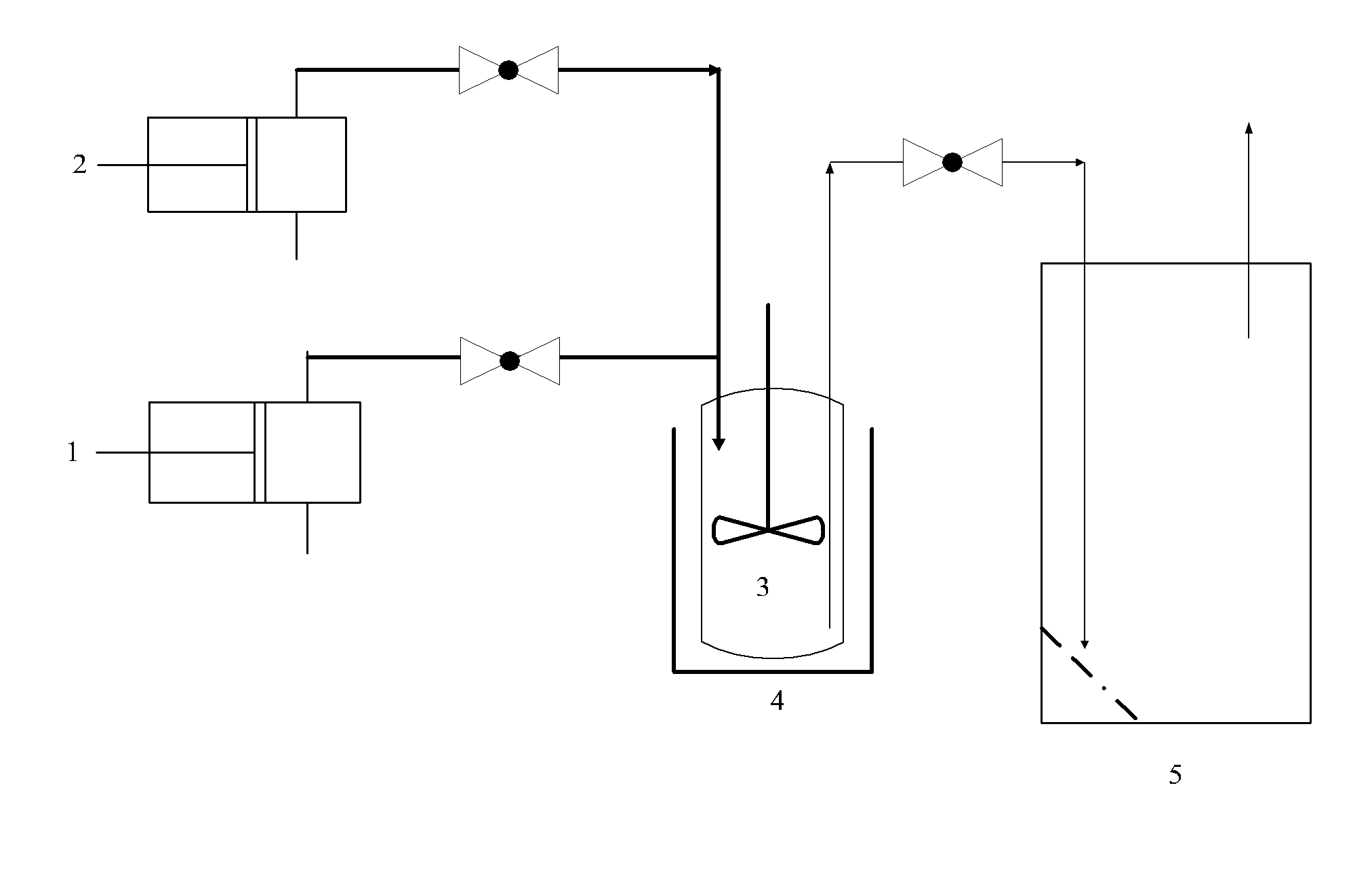

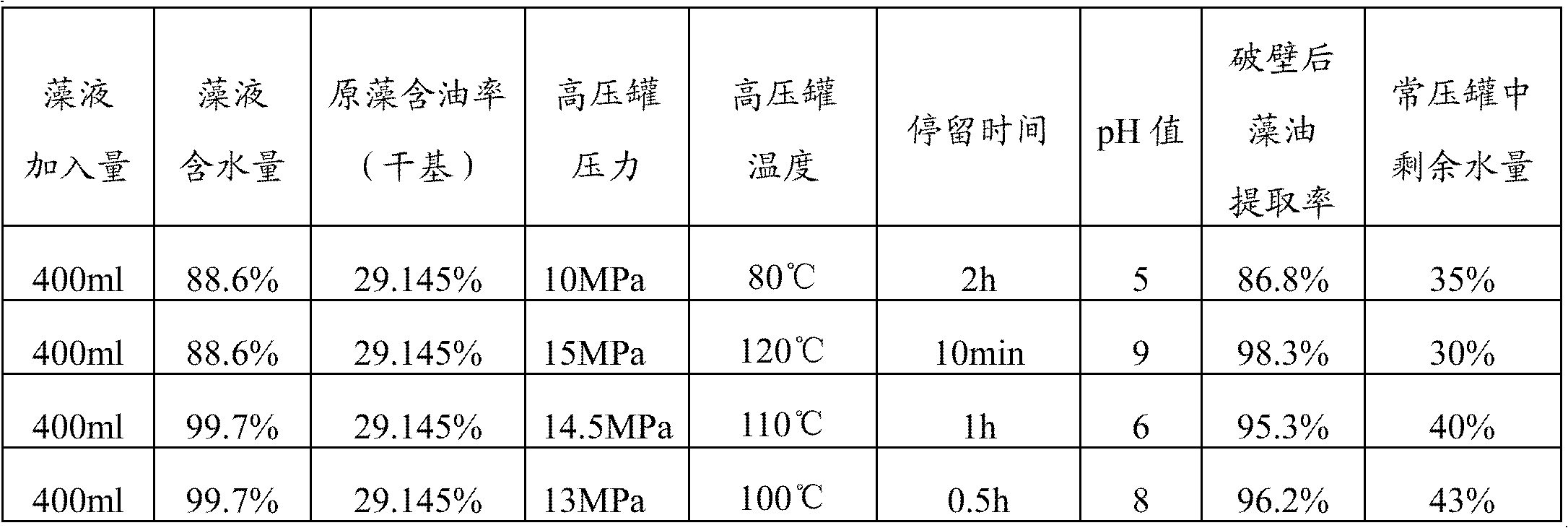

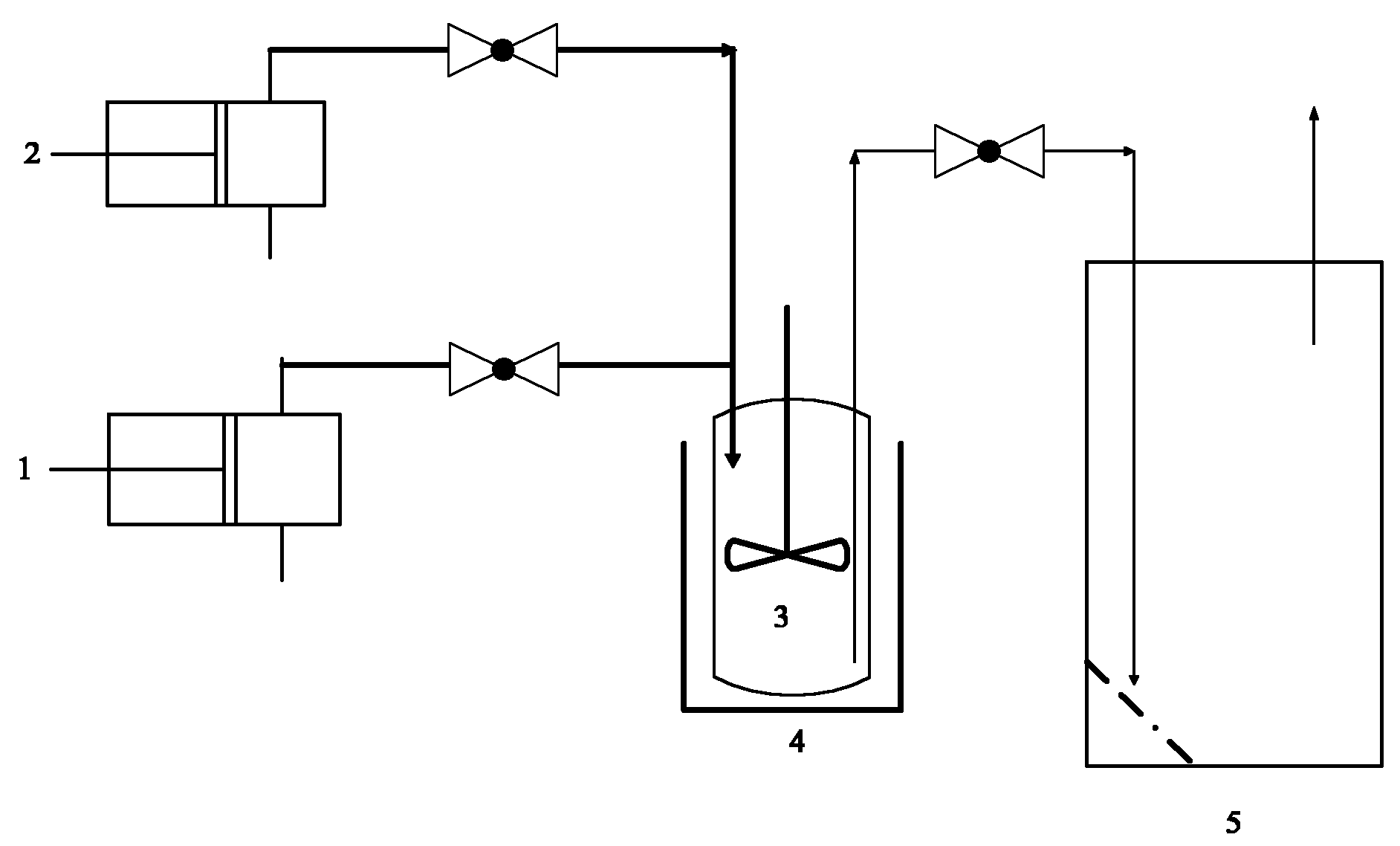

Treatment method of microalgae

ActiveCN102504999AReduce energy consumptionSimple processMicroorganism lysisActive componentProduct gas

The invention provides a treatment method of microalgae. The method comprises the following steps: regulating the pH value of microalgae solution; introducing gas to pressurize the microalgae solution subjected to pH value regulation; heating the pressurized microalgae; keeping the pressuring and heating state; and enabling the pressurized and heated microalgae solution to enter a normal-temperature normal-pressure environment and collide with a porous baffle which is arranged in the normal-temperature normal-pressure environment. The method provided by the invention has the advantages that the process flow is simple, the energy consumption is low, the wall breaking, drying and collection of the microalgae can be completed in one step, the moisture in the microalgae solution is reduced by 50%, the operation pressure and temperature are not high, the grease active component is not easily destroyed, the algae oil extraction rate is up to 95% optimally.

Owner:ENN SCI & TECH DEV

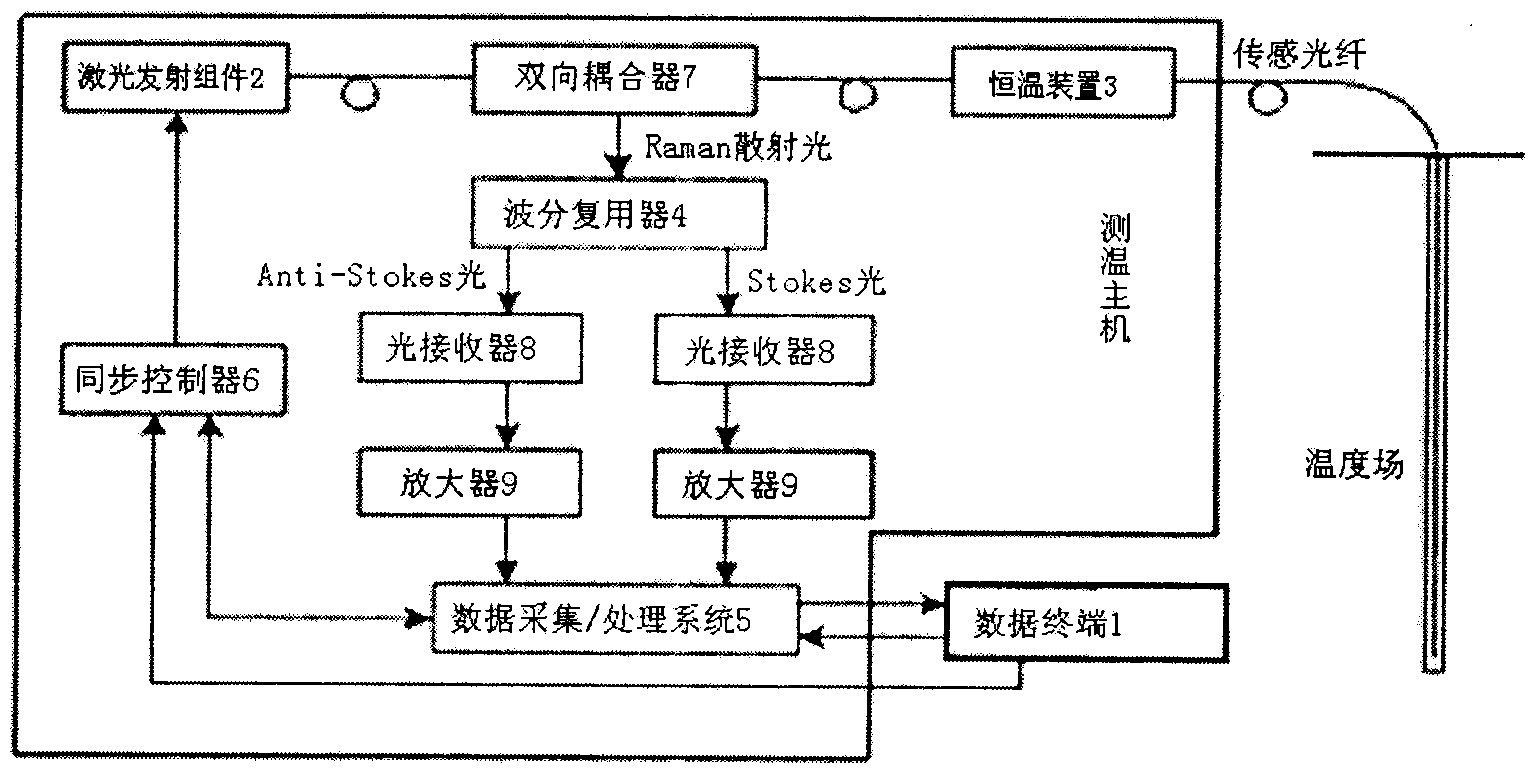

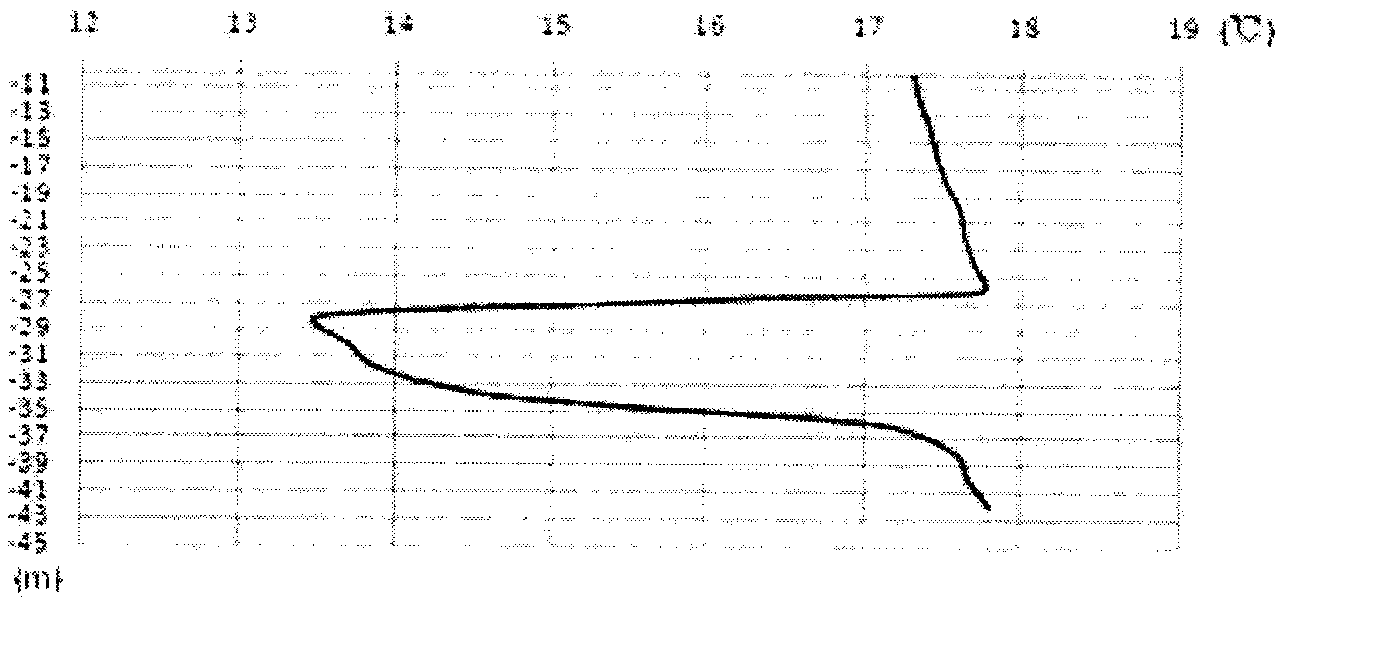

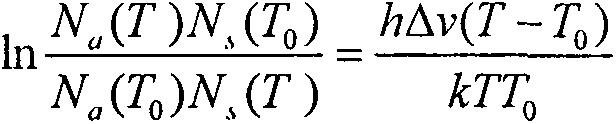

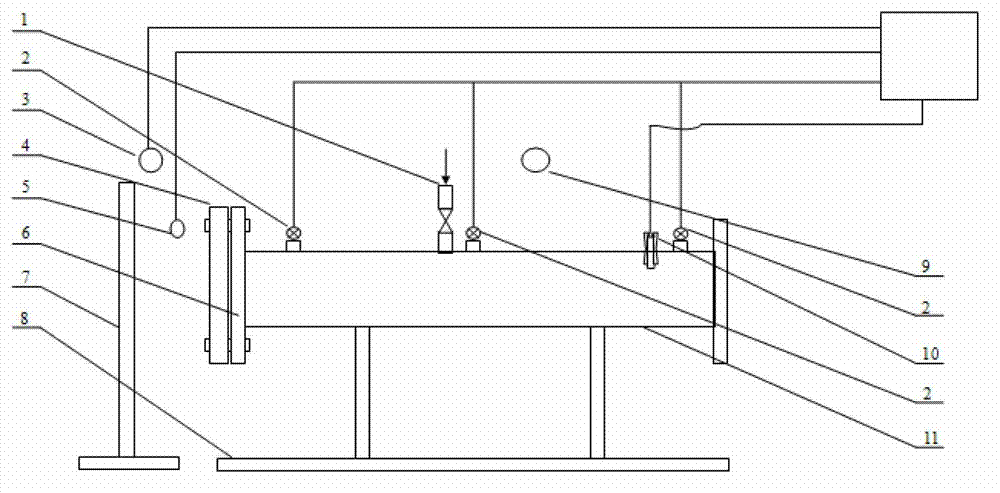

Refuse landfill seepage detection method and detection device

InactiveCN103528763AAccurately provide coordinate dataWide applicabilityDetection of fluid at leakage pointUsing optical meansData terminalAbnormal positions

The invention discloses a refuse landfill seepage detection method and a detection device. The detection method comprises the following steps: the external side of a refuse landfill is provided with a temperature measurement optical fiber grid which is connected with a temperature measurement host after connection molding; the temperature measurement optical fiber grid is utilized to detect temperature of the external side of the refuse landfill, and a temperature signal is sent to the temperature measurement host; the temperature signal is fused by the temperature measurement host so that temperature detection data are obtained, and the temperature detection data are transmitted to a data terminal; after the temperature detection data are compared with temperature normal data by the data terminal, whether there is leakage in the refuse landfill is judged; and finally a heat source method is utilized to quantitatively analyze a temperature field of a leakage position, and leakage amount is computed. According to the refuse landfill seepage detection method and the detection device, temperature is utilized to act as a tracing physical quantity to investigate seepage of the refuse landfill, and the seepage problem is monitored and researched via measuring water temperature of different positions. Meanwhile, coordinate data and seepage amount of a temperature abnormal position (the seepage position) can be precisely provided.

Owner:葛建

Shock tube type combustible gas explosion experiment device

InactiveCN102930770AEasy to collectEliminate the step of vacuumingEducational modelsCombustible gasEngineering

The invention discloses a shock tube type combustible gas explosion experiment device. The device comprises a tubular explosion test barrel, wherein the explosion test barrel is transversely arranged on a bracket; an opening and an explosion-proof membrane for sealing the opening are arranged at the front end of the explosion test barrel; the explosion test barrel is connected with a gas supply device for injecting normal-temperature normal-pressure combustible gas into an inner cavity of the barrel; the explosion test barrel is provided with a pressure sensor for sensing pressure in the barrel, a monitor for monitoring gas concentration in the barrel and an igniter for igniting gas in the barrel; the pressure sensor is connected with a display module for displaying a pressure value in the barrel; and the rear end of the explosion test barrel is sealed. The device disclosed by the invention is simple to operate and low in cost, and can replay the flame state at the moment of explosion and display the pressure change in the explosion barrel and the explosion sound.

Owner:ZHEJIANG UNIV OF TECH

Method for improving adhesive property of ramie fibre-thermoplastic resin interface

The invention claims a method for improving the adhesive property of a ramie fibre-thermoplastic resin interface, which comprises the following steps of: soaking ramie fibres into ethanol for pretreatment, then drying the soaked fibres, and performing surface treatment on the ramie fibres by a normal-temperature normal-pressure plasma method. The method is capable of effectively improving the adhesive property of the ramie fibre-thermoplastic resin interface.

Owner:DONGHUA UNIV

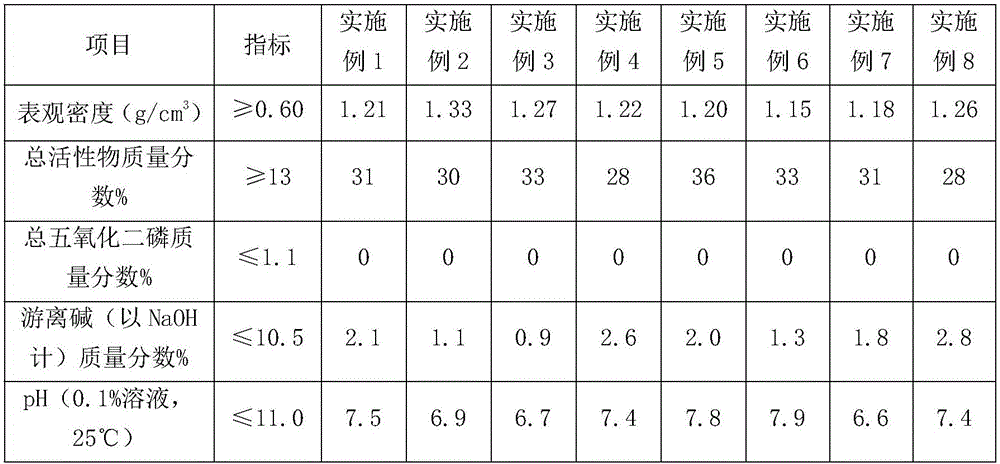

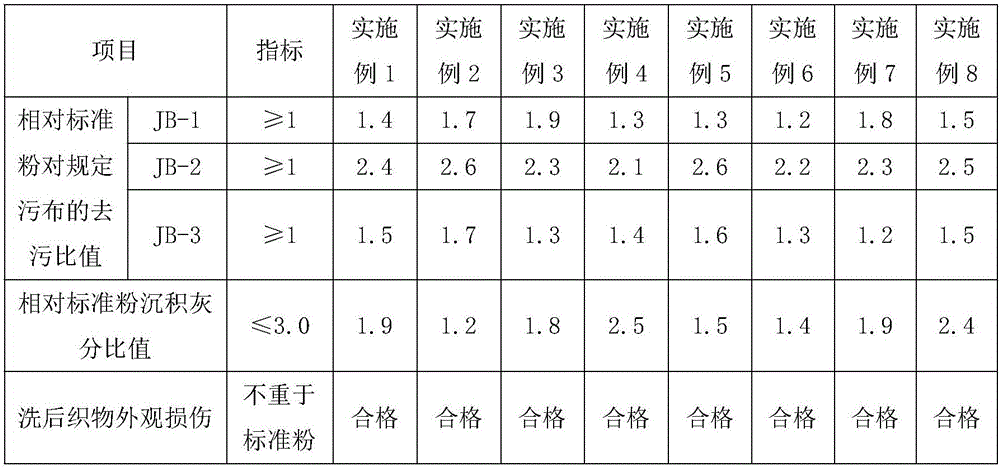

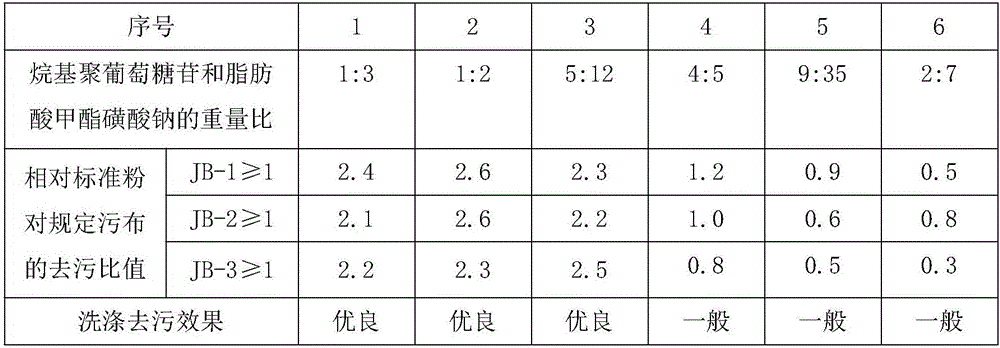

Laminated laundry detergent tablet and preparation method thereof

InactiveCN106190626AEasy to operateWide operating rangeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAdhesiveRoom temperature

The invention discloses a laminated laundry detergent tablet and a preparation method thereof. The laminated laundry detergent tablet is prepared from, by weight, 5%-10% of a non-ionic surfactant, 15%-35% of an anionic surfactant, 3%-10% of an auxiliary washing agent, 0.1%-5% of an adhesive, 40%-60% of a disintegrating agent, 0.1%-5% of a laminating agent and 1%-5% of a solvent. The laminated laundry detergent tablet which is made from biodegradable materials is highly concentrated, low in consumption and high in detergence; by combination of an effervescence system and a polymer swelling system, high disintegration speed is realized; due to water-soluble laminates on surfaces of material particles, interaction or dampness of a disintegration agent can be avoided, requirements on a storage environment are lowered, and the shelf life is prolonged. The preparation method is completed under a normal-temperature normal-pressure condition, convenient, quick and simple in operation, free of special equipment, wide in application range and low in cost.

Owner:南京尚易环保科技有限公司

High-temperature normal-pressure catalytic reactor suitable for mass spectrometry and application thereof

InactiveCN103084127AMaterial analysis by electric/magnetic meansChemical/physical/physico-chemical processesMass Spectrometry-Mass SpectrometryIonization chamber

The invention discloses a high-temperature normal-pressure catalytic reactor suitable for mass spectrometry and an application thereof. The reactor consists of a furnace body, a sample introduction pipe, a high-temperature catalyst chamber, a reaction area, a difference hole, a micropore and an air outlet pipe. When samples react in the reaction area, the sample introduction pipe is continuously inflated, the reaction area can maintain to be in a normal-pressure state, and the samples can be subjected to catalytic reaction at different temperatures by adjusting the temperature of the high-temperature catalyst chamber to generate catalysates, free radicals and intermediates, and then catalysates, the free radicals and the intermediates spread towards an ionization chamber by the micropore under the action of pressure and form a molecular beam after passing through the difference hole to enter a mass spectrum ionization chamber, thus solving the problem that the free radicals and the unstable intermediates are difficult to detect in situ during the normal-pressure catalytic reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

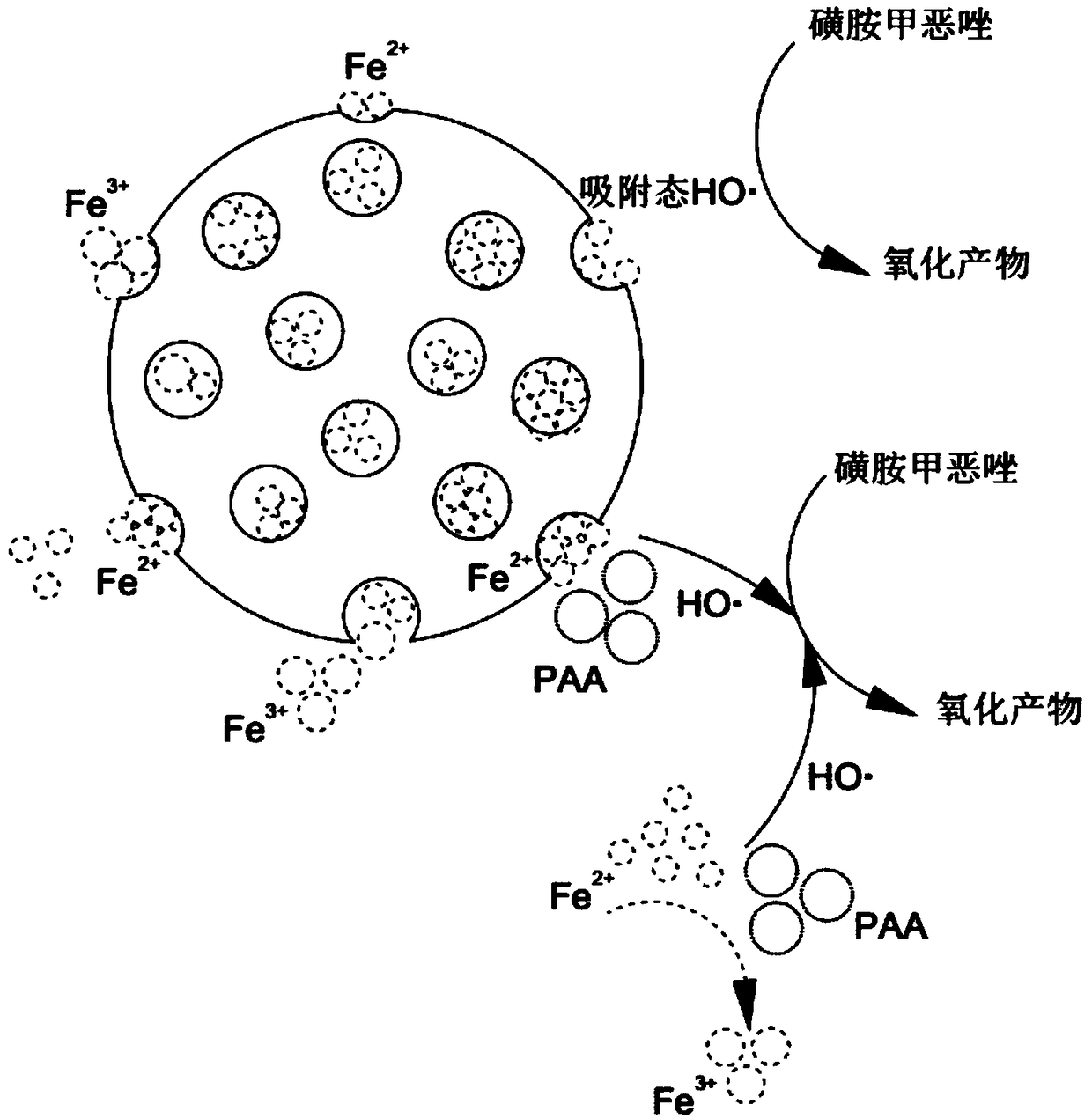

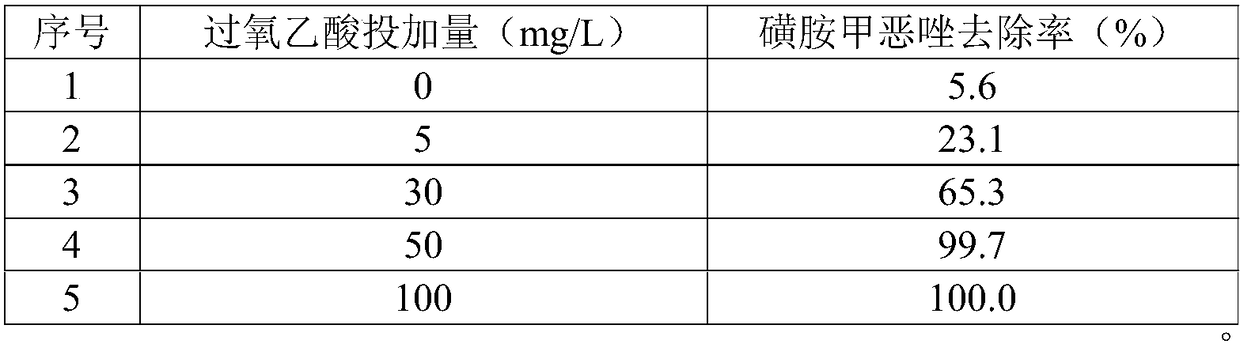

Method for removing sulfonamides in water by using modified zeolite to activate peracetic acid

ActiveCN108855083AImprove removal efficiencyLow application costWater treatment compoundsWater contaminantsSulfur drugDissolution

The invention discloses a method for removing sulfonamides in water by using modified zeolite to activate peracetic acid. The method comprises the following steps: S1, preparing a catalyst: grinding artificial zeolite into fine powder, acid pickling, washing, drying, soaking in a ferrous sulfate solution for a period of time, centrifugally separating, washing solids by using deionized water, and drying; S2, performing the oxidization reaction: adding a prepared peracetic acid solution into sulfamethoxazole waste water, adjusting initial pH of water water, adding an appropriate amount of catalyst, and performing the oxidization reaction under the normal temperature normal pressure stirring condition. The adopted catalytic material is simple in preparation, easy to store, high in activationefficiency and low in active component and low in active component dissolution rate; the activated peracetic acid system is high in oxidation performance, the treatment process also has the sterilizing function, the combination of the further treatment and disinfection treatment for the waste water can be realized, the compatibility with the modern water treatment factory process is high, the sulfamethoxazole degradation efficiency is high, the reaction condition is mild, the cost is low, and the method is suitable for the industrialized mass treatment of the waste water.

Owner:SOUTHWEST JIAOTONG UNIV

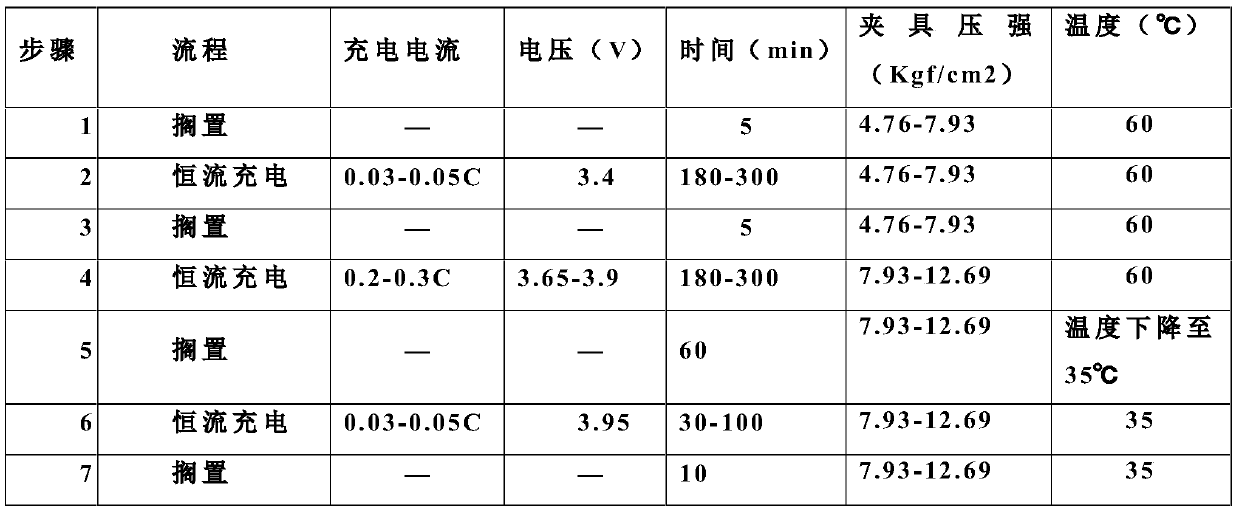

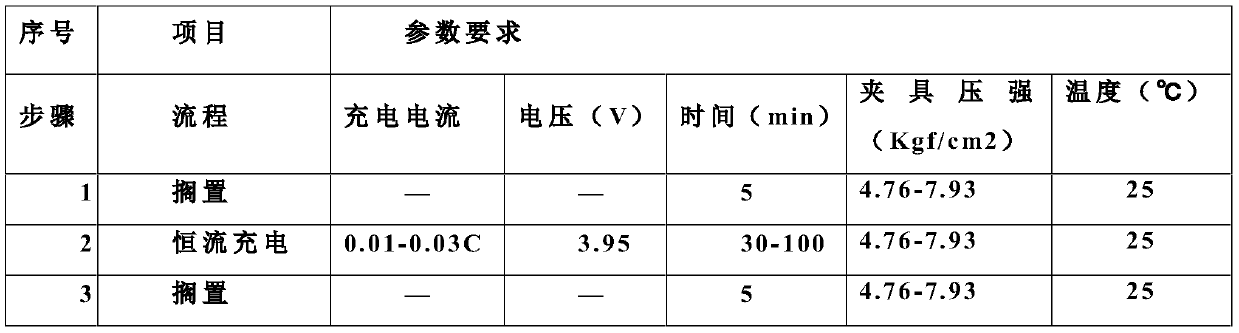

Formation method for flexibly-packaged power lithium-ion battery

ActiveCN109755680AImprove full wettabilityImprove wettabilityFinal product manufactureSecondary cells charging/dischargingElectrochemical responseCharge current

The invention protects a formation process for a high-energy-density flexibly-packaged power lithium-ion battery. The process comprises the steps that liquid is injected into a cell, the cell stands,pre-edge-sealing is performed, and the cell is vertically placed into a pressure fixture; the surface of the cell is pressurized, a certain temperature is set, primary charging is performed on the cell, and pressure, temperature and charging currents are set in a stepped mode; after charging is completed, primary second-sealing is performed, and meanwhile air is pumped while a certain vacuum degree is maintained; and standing, secondary pressurization, normal-temperature charging and secondary second-sealing are performed. According to the formation process, the high-temperature pressurizationformation process is adopted, and compared with normal-temperature normal-pressure formation, sufficient wettability of an electrolyte and an anode / cathode active material is improved, and an electrochemical reaction is benefited; in the last step of primary formation, formation pressure is raised, formation temperature is lowered, the uniformity, compactness and stability of an SEI film generated on the surface of a cathode are improved, generation of a thick interface film is avoided, and internal resistance is lowered; and capacity performance of the cell is enhanced.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Method used for extracting biological ingredients with sub-critical ethanol solvent

InactiveCN104707356AExtract thoroughlyImprove extraction efficiencySugar derivativesGinkgophyta medical ingredientsTime rangeAdditive ingredient

The invention discloses a method used for extracting biological ingredients with sub-critical ethanol solvent, and belongs to the field of chemistry. The method comprises following steps: biomass raw materials are delivered into a pressure extraction tank; ethanol extraction solvent at sub-critical states is delivered into the pressure extraction tank for extraction, wherein extraction time ranges from 30min to 1h; and after extraction, ethanol in an obtained extract is separated so as to obtain an object product. Compared with conventional normal-temperature normal-pressure ethanol extraction methods, extraction rate of the method is increased significantly, and more complete extraction of the biological object product is realized.

Owner:HENAN YALINJIE BIOLOGICAL TECH

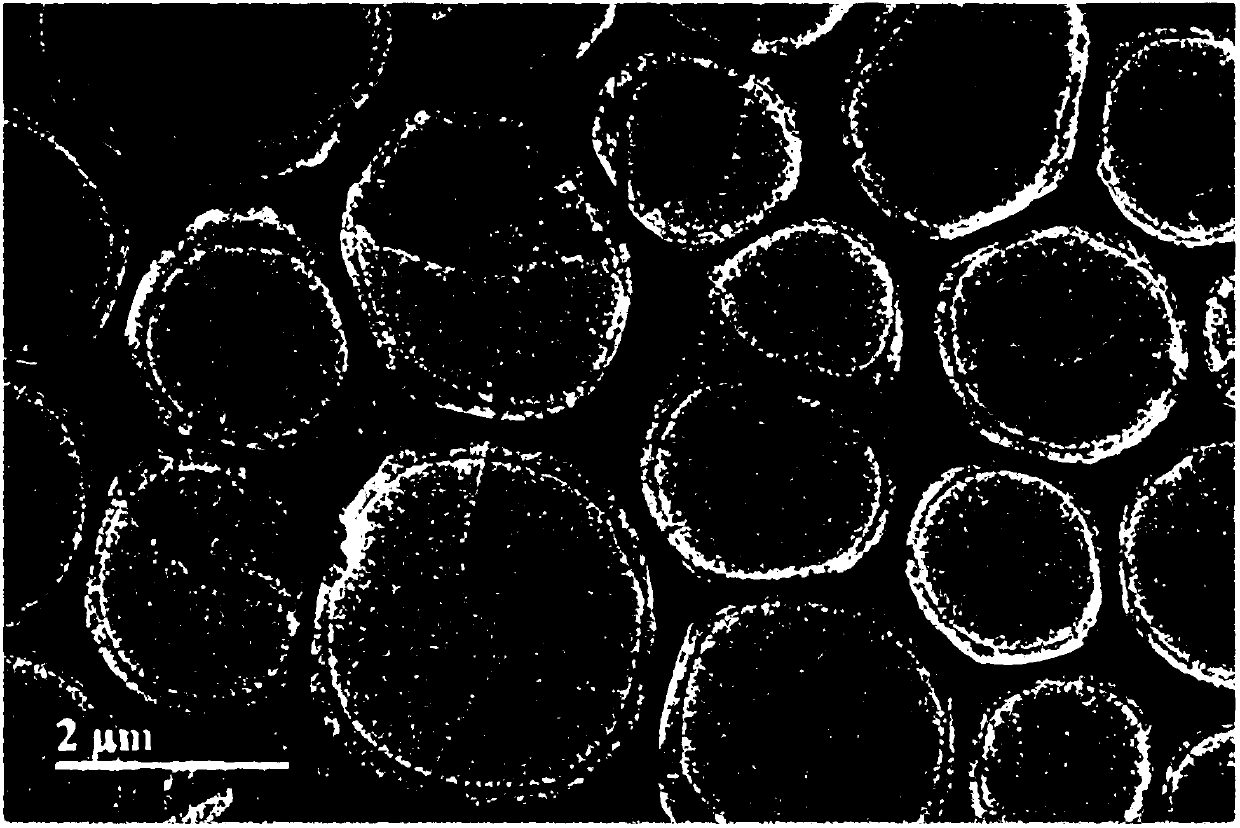

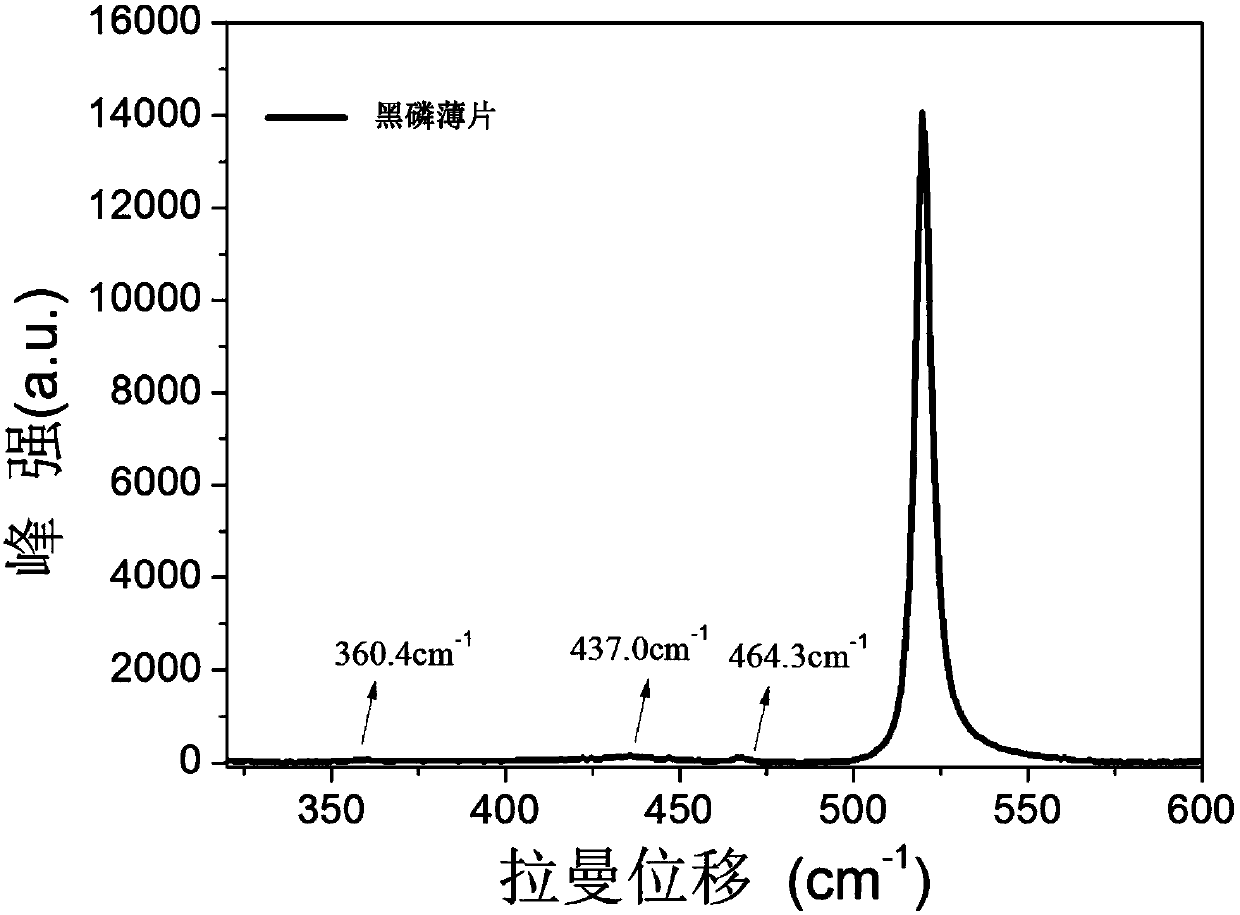

Method for preparing two-dimensional material with atmospheric-pressure plasmas

ActiveCN107777674AReduce yieldControl rateGrapheneNanotechnologyBlack phosphorusTwo dimensional crystal

The invention relates to a method for preparing two-dimensional material with atmospheric-pressure plasmas. According to the method, a stripping device with a negative electrode being material crystalis constructed on the basis of an atmospheric-pressure plasma technique, and a two-dimensional crystal wafer is obtained by stripping of the material crystal. Compared with other stripping methods, the method has advantages of simple steps, convenience in operation, short time, high efficiency, freeness of utilization of complex expensive equipment and extra chemical agents and freeness of environmental pollution and material surface contamination and is especially applicable to preparation of two-dimensional black phosphorus materials. In addition, the method can be implemented under normal-temperature normal-pressure conditions, the process is easier to control, and industrial application is benefited.

Owner:SHENZHEN INST OF ADVANCED TECH

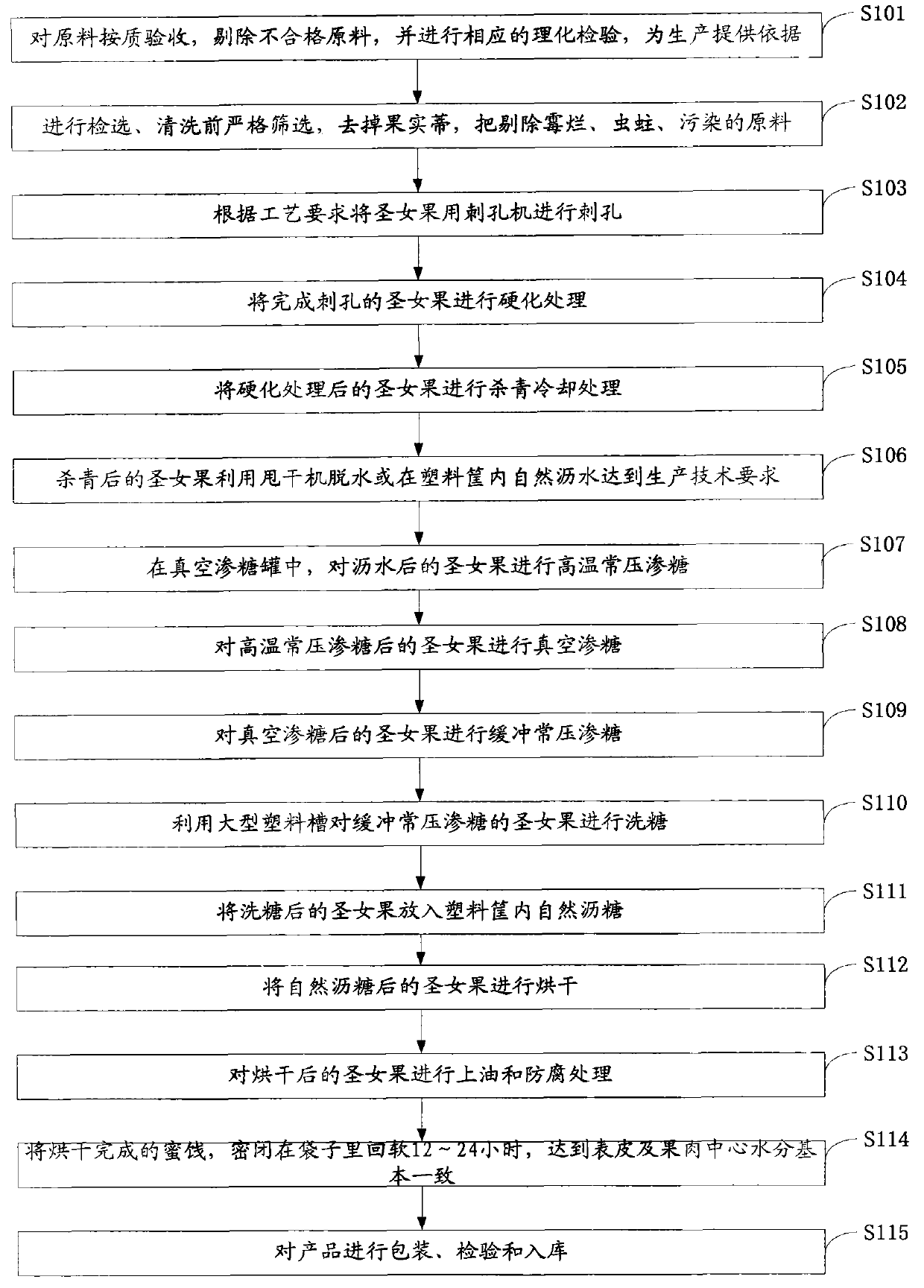

Preserved cherry tomatoes and processing method thereof

The invention discloses preserved cherry tomatoes and a processing method thereof. The preserved cherry tomatoes are prepared by processing cherry tomatoes by virtue of a vacuum sugar permeation technology. The processing method comprises the processes of sorting, cleaning, puncturing, hardening, deactivation of enzymes, spin-drying and draining, high-temperature normal-pressure sugar permeation, vacuum sugar permeation, buffered normal-pressure sugar permeation, sugar liquor draining, affination, stoving, oil application for corrosion prevention, and moisture regaining. According to the preserved cherry tomatoes and the processing method thereof, the cherry tomatoes are processed to obtain the preserved fruit product by virtue of the vacuum sugar permeation technology, the processing time is short, the preserved fruit product prepared from the cherry tomatoes is a new variety in preserved fruit products, a marketing channel is provided for planters, and the economic benefit of farmers is increased.

Owner:HEBEI QINGGOU JIAHE FOOD

Process for producing potassium sulfate and ammonia sulfate by wet decomposing potassium feldspar

ActiveCN101559959AHarm reductionReduce consumptionAmmonium sulfatesAlkali metal sulfites/sulfatesSulfatePotassium feldspar

The invention discloses a process for producing potassium sulfate and ammonia sulfate by wet decomposing potassium feldspar, comprising the steps of: decomposing potassium feldspar under low-temperature normal atmosphere condition, separating the materials under certain technical conditions to obtain products like ammonia sulfate, potassium sulfate, white carbon black, aluminum hydroxide and sodium silicate, etc., thereby comprehensively developing and utilizing potassium feldspar resources, solving the problem that the potash fertilizer in China depends on import, and satisfying the need of agricultural production.

Owner:甘肃禾坤农业科技有限公司

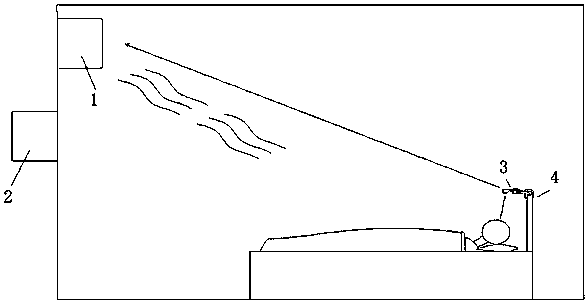

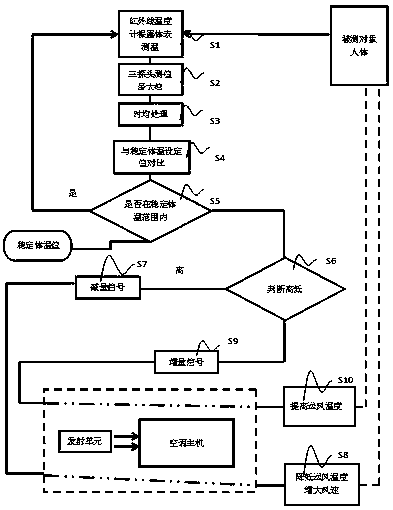

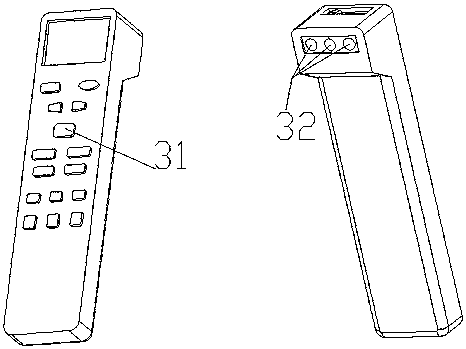

Automatic control method for air conditioner system

InactiveCN108131798AImprove sleep qualityEasy maintenanceMechanical apparatusSpace heating and ventilation safety systemsAutomatic controlUnconscious States

The invention provides an automatic control method for an air conditioner system. The air conditioner system comprises an air conditioner outdoor unit, an air conditioner host and an air conditioner remote controller integrating an infrared temperature measuring device. The method comprises the steps conducted on the air conditioner remote controller, an infrared temperature measuring sensor arranged on the air conditioner remote controller is utilized for measuring the surface temperature of a target human body in the environment, and the surface temperature of the target human body is obtained; and according to the surface temperature of the target human body and body temperature normal range parameters, the air conditioner air supply operation is controlled. The air conditioner remote controller of the air conditioner system integrates the infrared human body temperature measuring function and an independent processing unit. A module with the self-adjusting function is arranged in the air conditioner remote controller, and transformation on a conventional air conditioner host is not needed. During sleeping, the temperature measuring information of the face and other naked positions is fed back to the processing unit on the air conditioner remote controller. By means of the method, whether air conditioner air supply needs to be adjusted or not is judged, and accordingly whena person sleeps or is in an unconsciousness state, the person can be in the proper air temperature environment.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

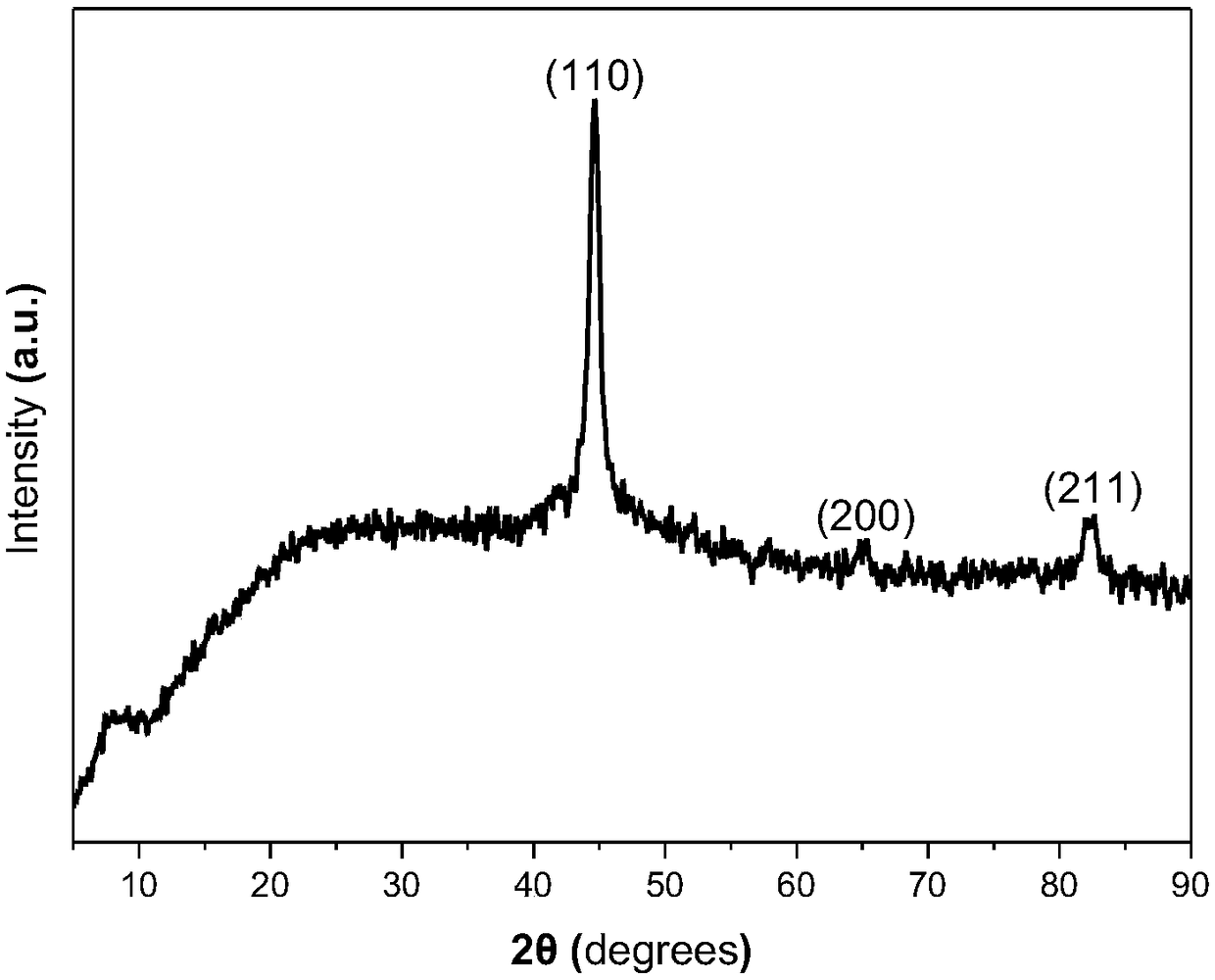

Preparation method and product of ferromagnetic nanowire

ActiveCN108941611AAvoid defectsThe process is simple and easy to controlTransportation and packagingMetal-working apparatusNanowirePliability

The invention relates to a preparation method and a product of a ferromagnetic nanowire, and belongs to the technical field of nanometer materials. The preparation method comprises the following steps: firstly, taking ferromagnetic metal salt and a stabilizer, a complexing agent and a surfactant are used as raw materials to prepare a ferromagnetic metal salt mixed solution, and then the reducing agent solution is injected in an injection manner, after the reaction, a solid product is prepared, and the solid product is washed and dried. According to the preparation method and the product of theferromagnetic nanowire, the synthetic route is simple, the process is controllable, the normal-temperature normal-pressure reaction is carried out, the actual production requirements are met, the industrial production is suitable, and meanwhile, the defect that a traditional in-situ reduction method can only be used for preparing ferromagnetic nanowires with a certain length-diameter ratio can beovercome. The prepared ferromagnetic nanowire has good orientation and the diameter is or less 100 nm, the length is 3-10 microns, the length-diameter ratio is high, and good flexibility, magnetic performance and microwave absorption performance are achieved.

Owner:重庆天渝新材料技术研究院有限公司

Thermal pipeline abnormal state determining method based on infrared thermal imagery technology

ActiveCN106940234APrecise positioningAccurate and fast positioningDetection of fluid at leakage pointSensing heat from liquidsMaterials scienceSoftware

The invention discloses a thermal pipeline abnormal state determining method based on infrared thermal imagery technology. The method is used to photograph the ground surface of the thermal pipeline under suitable weather conditions to obtain the infrared thermal image of an area with abnormal temperature and the infrared thermal image of an area with normal temperature respectively. The infrared thermal processing software is utilized to obtain respectively the average temperature T2 of the ground surface of the area with abnormal temperature, the average temperature T0,2 of the ground surface of the area around the area with abnormal temperature and with no pipeline, the average temperature T1 of the ground surface of the area with normal temperature, and the average temperature T0,1 of the ground surface of the area around the area with normal temperature and with no pipeline around; and calculating to obtain the thermal pipeline abnormal state determining coefficient Beta to determine the abnormal state of the thermal pipeline. The method of the invention is capable of directly, rapidly and accurately position the leakage point and the broken point of a heat preserving layer of a thermal pipeline.

Owner:HEBEI UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com