Normal temperature normal pressure ammonia infusion-extraction-electrodeposition-slag infusion flotation of copper oxide green ore

A technology of copper oxide ore and normal temperature, applied in the direction of improving process efficiency, etc., to achieve good operability and economy, reduce energy consumption, and reduce complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

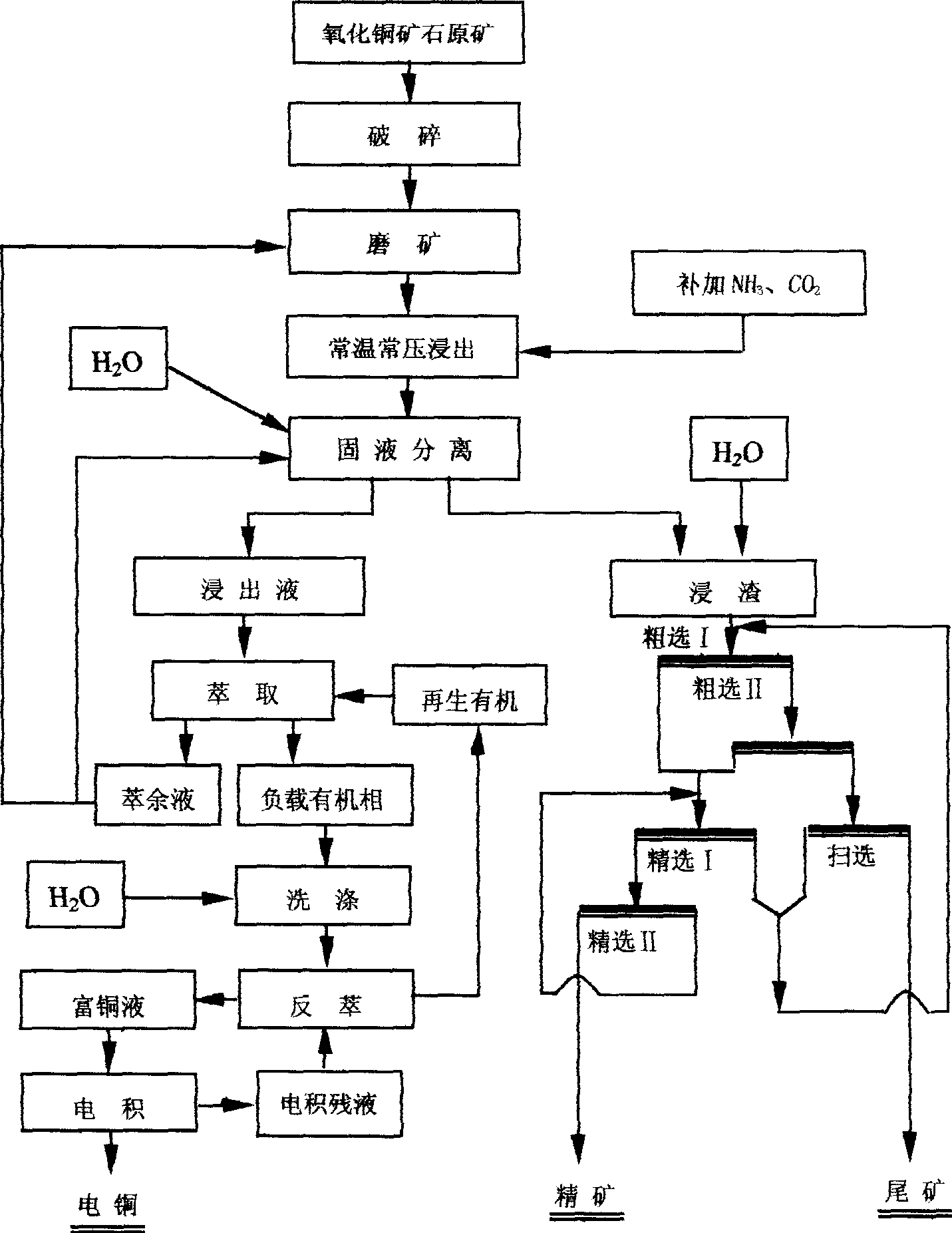

[0010] Further description will be made below in conjunction with the accompanying drawings.

[0011] Raw ore properties: The grade of raw ore is 1-1.5%, the oxidation rate is 55-65%, and the combination rate is 15-25%.

[0012] After crushing and grinding the raw ore, according to the nature of the ore sample, the fineness can reach -74μm, accounting for more than 50%, the liquid-solid ratio is 1:1, and the concentration of the leaching reagent is [NH 3 +CO 2 ]=2+0.5mol.L -1 , Ammonia leaching is carried out at a leaching temperature of 20°C and a leaching pressure of 750-760mmHg. The main object of the leaching operation is copper in copper oxide minerals that are easily leached. The leaching time is two hours. After leaching, solid-liquid separation and Wash to obtain cuproammonia leaching solution and leaching residue.

[0013] The cuproammonia leachate is extracted with lix84-I and lix55 ammoniacal extractants, using two-stage extraction and one-stage back-extraction p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com