Waste rubber high-temperature normal-pressure regenerating process

A technology for waste rubber and waste rubber, which is applied in the field of high temperature and atmospheric pressure regeneration of waste rubber, can solve problems such as environmental pollution, waste gas generation, and concentration, and achieve the effects of reducing production processes, reducing production costs, and saving oil resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

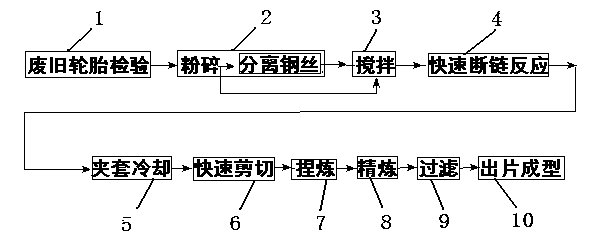

[0060] First inspect the waste rubber. Present embodiment all adopts the waste and old all-steel radial tire more than 900 diameters, rejects small size tire and bias tire. Then the waste rubber after inspection is crushed and steel wire removed. Before crushing, use a high-power rubber breaker to cut the entire all-steel radial tire into pieces, and then use a rubbing structure crusher such as XKP450 to crush the steel wire and rubber in the waste tire. The fineness of the rubber powder is 20~ 30 mesh. Then use a magnetic separation device or other separation equipment to separate the steel wire in the crushed rubber powder. Then the crushed rubber powder is sent to the stirring device for stirring to prevent the rubber powder from sticking and agglomerating, and then directly sent to the twin-screw extruder through the rubber powder conveying device for rapid chain breaking reaction. The rapid chain breaking technology of the present invention is a continuous, airtight, s...

Embodiment 2

[0062] First inspect the waste rubber. This embodiment adopts general waste rubber, including waste rubber tires (excluding waste tires with steel wires), to remove foreign matter. Then the pulverizer of the waste rubber rubbing and cutting structure after the inspection is crushed, and the fineness of the rubber powder is 20 to 30 mesh. Then the pulverized rubber powder is sent to the stirring device for stirring to prevent the rubber powder from sticking and agglomerating, and then directly sent to the twin-screw extruder through the rubber powder conveying device for rapid chain breaking reaction. Similarly, this embodiment adopts the screw compression and shear chain breaking process under the condition of continuous, airtight and rubber powder flow, and the rubber powder delivered is pressed into the twin-screw extruder through the forced feeding device for uniform production. . In this embodiment, the rotational speed of the twin-screw extruder is selected as 60 rpm. ...

Embodiment 3

[0064] The method of present embodiment and embodiment two is first with waste rubber inspection. This embodiment adopts general waste rubber, including various waste rubber tires, to remove sundries. Then the pulverizer of the waste rubber rubbing and cutting structure after the inspection is crushed, and the fineness of the rubber powder is 20 to 30 mesh. Because the raw materials of this embodiment are all waste rubber, including all kinds of waste tires containing all-steel radial tires, before crushing, first use a high-power rubber breaker to cut the whole waste tires into pieces, and then use a rubbing structure shredder Crushing is carried out to separate the steel wire and rubber in waste tires. Then use a magnetic separation device or other separation equipment to separate the steel wire in the crushed rubber powder. Then the pulverized rubber powder is sent to the stirring device for stirring to prevent the rubber powder from sticking and agglomerating, and then d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com