High temperature normal pressure biomass gasification island process

A biomass and gasification island technology, applied in the gasification process, chemical industry, fixed bed gasification, etc., can solve the problems of high operating cost, backward overall level, immature technology, etc., and achieve simple purification system and low equipment investment Fewer materials and wide adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

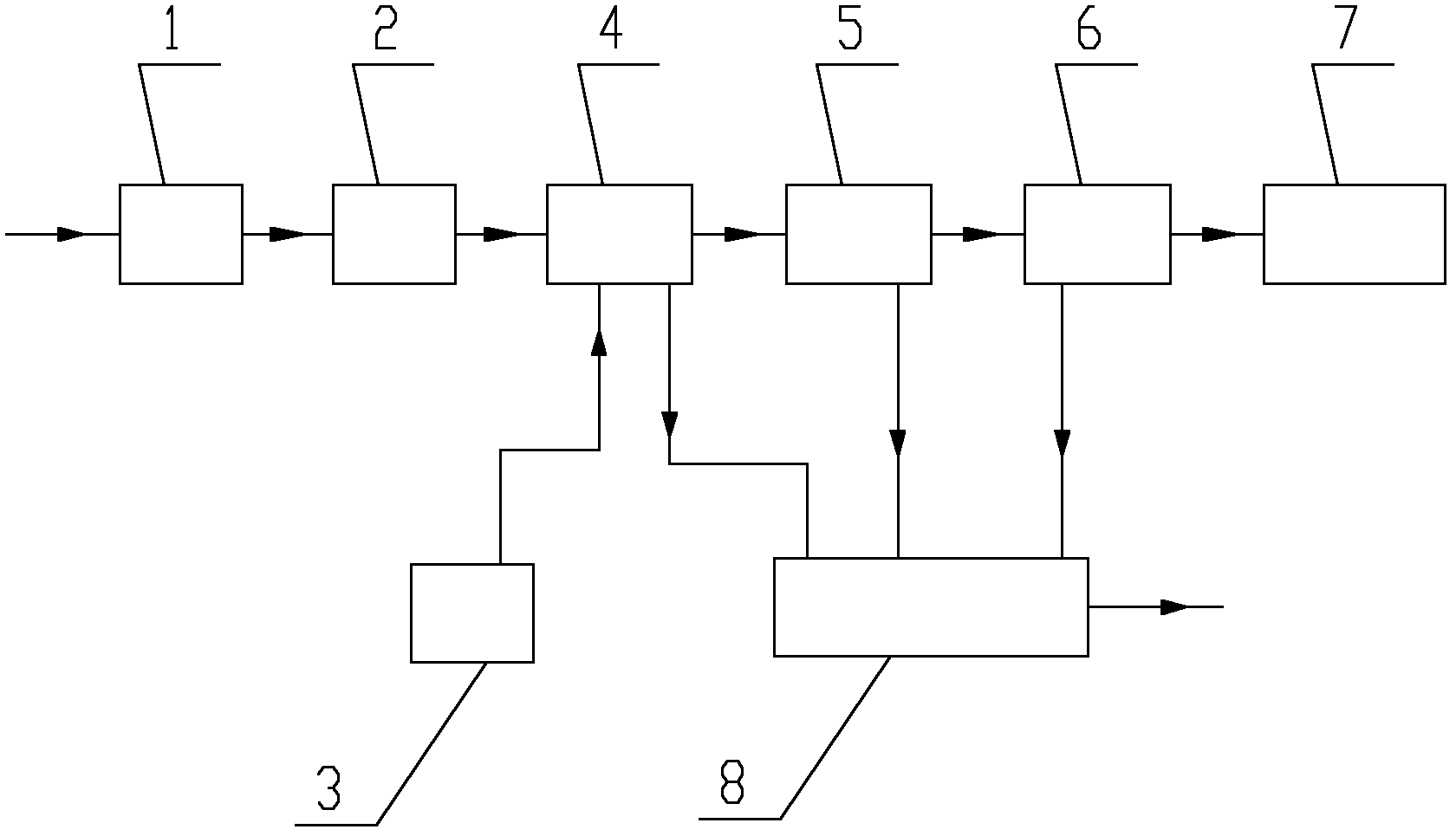

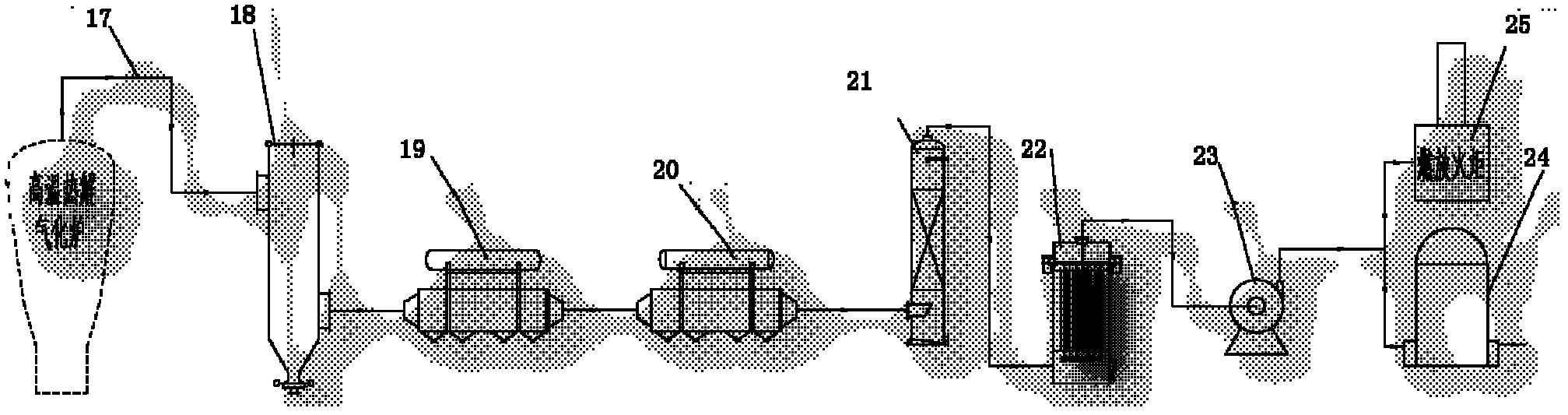

[0068] Example: The gasification island process uses an external heat source fixed-bed atmospheric gasification and a two-stage waste pot cooling process. Including: raw material pretreatment and storage unit, biomass feeding unit, gasifier unit, crude gasification gas cooling unit, crude gasification gas washing unit, fresh gasification gas storage unit, ash and wastewater treatment unit.

[0069] Specific steps are as follows:

[0070] 1. Simply crush the collected biomass fuel to less than 300mm, and send it to the biomass feeding unit by belt conveyor;

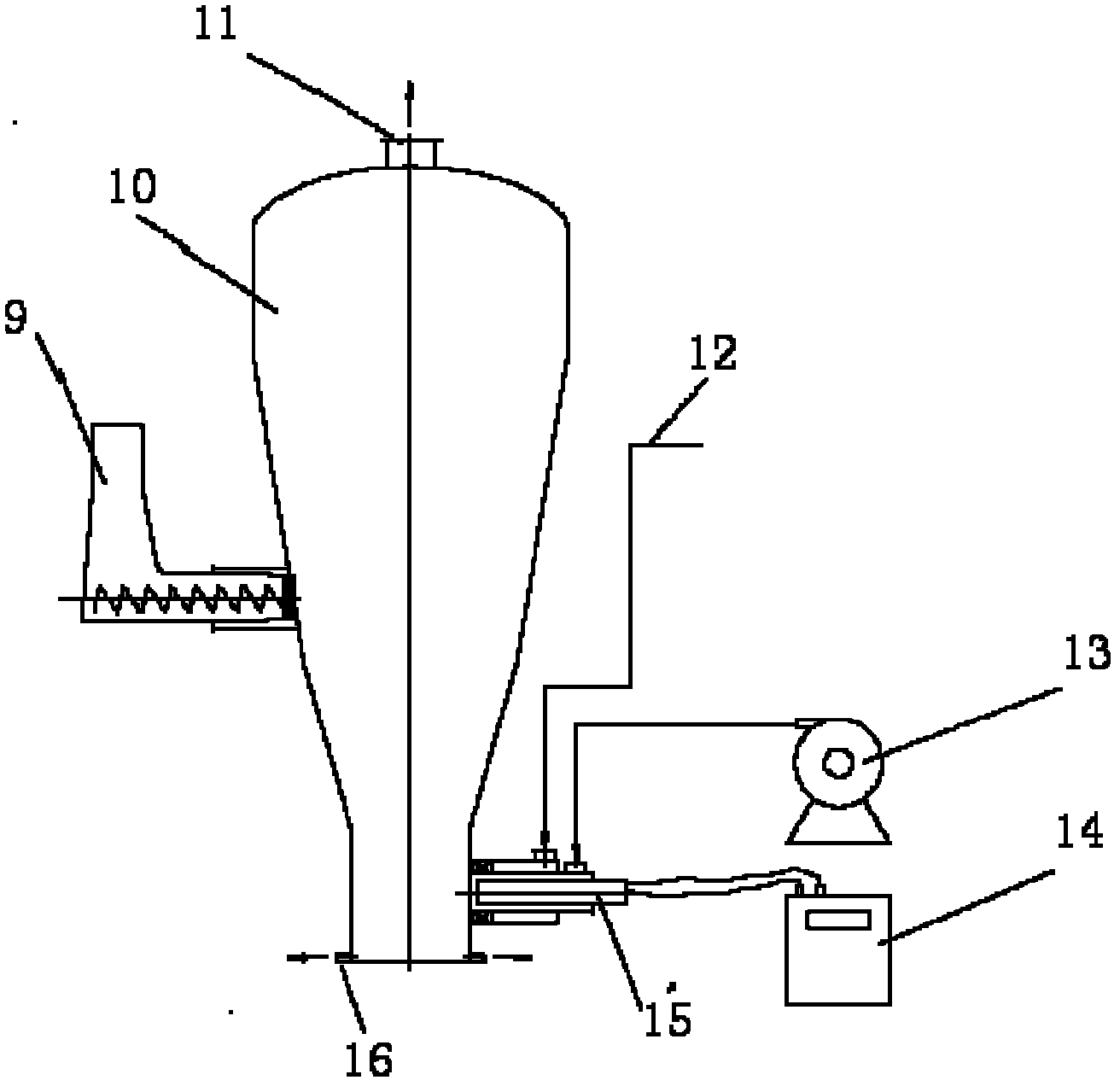

[0071] 2. Add a certain thickness of inert material (such as solidified filter residue) to the bottom of the gasifier through the feeding device to form a bed, and the gasifier adopts the method of heat insulation or cooling;

[0072] 3. Start the external heat source unit 3, control the temperature of the gasifier at 1300-1750°C, and the outlet pressure of the gasifier at 0-50KPa, and inject oxidant at the same time to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com