Stiff and broad PBST and polylactic acid composite fiber, preparation method and application thereof and surgical garment

A polylactic acid fiber and composite fiber technology, which is used in clothing, clothing features, and conjugated synthetic polymer rayon, etc., can solve the problems of limited application of PBST, low price, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

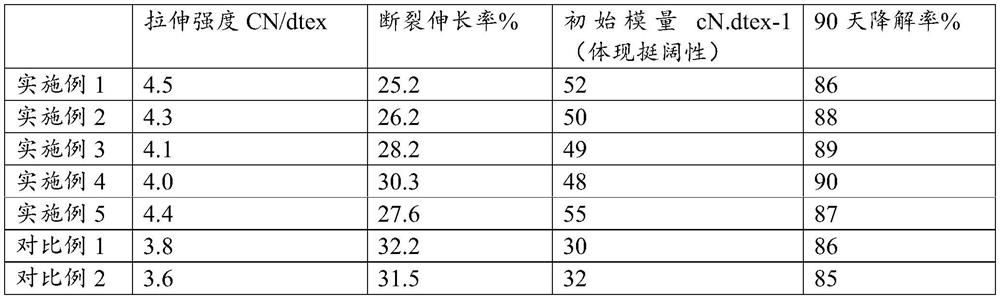

Examples

Embodiment 1

[0049] Preparation of PLA slices:

[0050] Weigh the polylactic acid, put it into a high-speed mixer, add a matting agent in an amount of 0.5% of the mass of the polylactic acid, stir at a low speed for 3 minutes, take it out, and set aside.

[0051] Put the mixed material above into the main feeding port of a twin-screw extruder with a length-to-diameter ratio of 42:1, melt and extrude to pelletize, and the extruded material is cooled, air-dried, pelletized, and dried to obtain semi-dullness polylactic acid.

[0052] The matting agent is titanium dioxide, the purity is 99.9%, the type is rutile, and the particle size is 50nm. Polylactic acid, white particles, weight average molecular weight 70000.

[0053] The temperature setting value of the twin-screw extruder is the temperature of each zone: the temperature of the first zone: 165°C, the temperature of the second zone: 180°C, the temperature of the third zone: 190°C, the temperature of the fourth zone: 200°C, the temperat...

Embodiment 2

[0060] Preparation of PLA slices:

[0061] Weigh the polylactic acid, put it into a high-speed mixer, add a matting agent in an amount of 0.5% of the mass of the polylactic acid, stir at a low speed for 3 minutes, take it out, and set aside.

[0062] Put the mixed material above into the main feeding port of a twin-screw extruder with a length-to-diameter ratio of 42:1, melt and extrude to pelletize, and the extruded material is cooled, air-dried, pelletized, and dried to obtain semi-dullness polylactic acid.

[0063] The matting agent is titanium dioxide, the purity is 99.9%, the type is rutile, and the particle size is 50nm. Polylactic acid, white particles, weight average molecular weight 70000.

[0064] The temperature setting value of the twin-screw extruder is the temperature of each zone: the temperature of the first zone: 165°C, the temperature of the second zone: 180°C, the temperature of the third zone: 190°C, the temperature of the fourth zone: 200°C, the temperat...

Embodiment 3

[0071] Preparation of PLA slices:

[0072] Weigh the polylactic acid, put it into a high-speed mixer, add a matting agent in an amount of 0.5% of the mass of the polylactic acid, stir at a low speed for 3 minutes, take it out, and set aside.

[0073] Put the mixed material above into the main feeding port of a twin-screw extruder with a length-to-diameter ratio of 42:1, melt and extrude to pelletize, and the extruded material is cooled, air-dried, pelletized, and dried to obtain semi-dullness polylactic acid.

[0074] The matting agent is titanium dioxide, the purity is 99.9%, the type is rutile, and the particle size is 50nm. Polylactic acid, white particles, weight average molecular weight 70000.

[0075] The temperature setting value of the twin-screw extruder is the temperature of each zone: the temperature of the first zone: 165°C, the temperature of the second zone: 180°C, the temperature of the third zone: 190°C, the temperature of the fourth zone: 200°C, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com