Process for producing high-density nylon fabric

A nylon fabric and production process technology, which is applied in the production process field of high-density nylon fabric, can solve problems such as unreasonable production process, high-temperature yellowing, poor water-repellent, oil-repellent, and water-washing resistance, and improve fabric quality and practical performance , improve the anti-ultraviolet ability, improve the effect of tearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

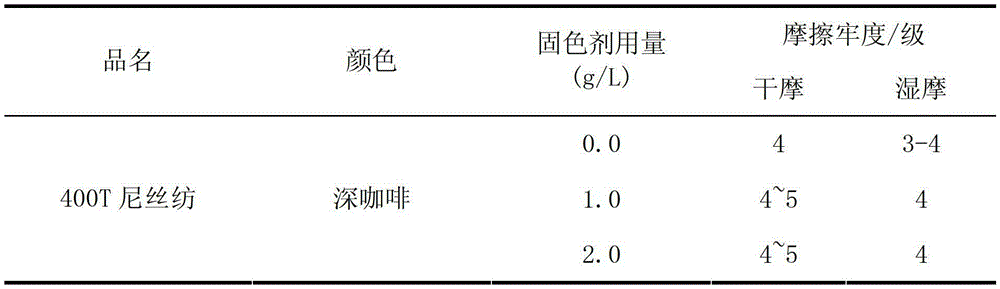

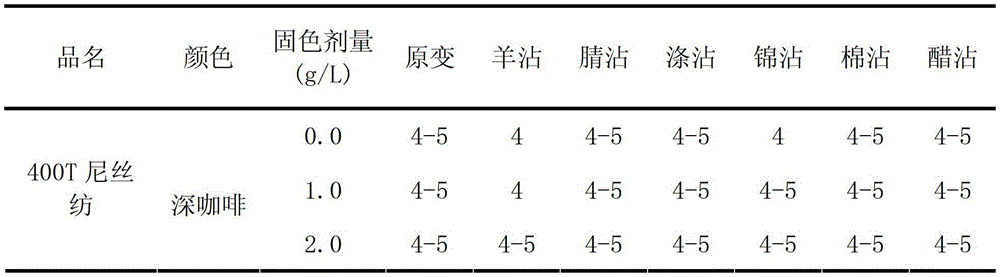

[0012] Example: The warp yarn is made of full-dull FDY 22.2dtex / 24f nylon filament and sizing. The weft yarn adopts full-dull FDY22.2dtex / 24f nylon filament. According to the requirements of warp density, 770 roots / 10cm, weft density 740 roots / 10cm, total warp roots 12474, width 162cm, and weight 55g / m, the plain weave is woven on the Tsudakoma series water jet loom. Then the woven grey fabric goes through unwinding, seaming, pre-treatment of desizing, pre-sizing, dyeing, fixing, dewatering, opening, finishing, calendering, inspection, cloth, packaging including untwisting, one-time feeding, stacking Production is carried out in the processes of setting, primary washing, secondary feeding, steaming, secondary washing, drying, etc., in the pre-desizing treatment step, the cold reactor method and the high-efficiency open-width desizing water washing method are successively adopted. In the cold reactor method The composition of the working fluid is: liquid caustic soda 100g / L, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com