Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve the anti-drilling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing high-density nylon fabric

ActiveCN103147304AImprove dye uptakeImproves UV resistanceFibre typesDyeing processCross-linkNylon material

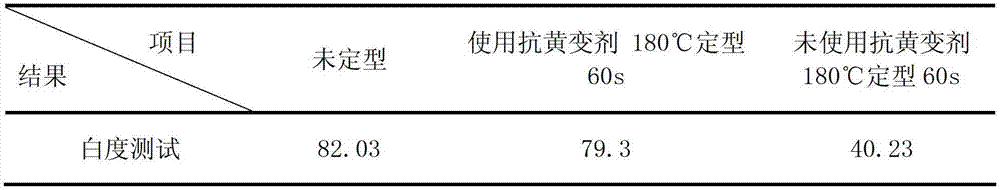

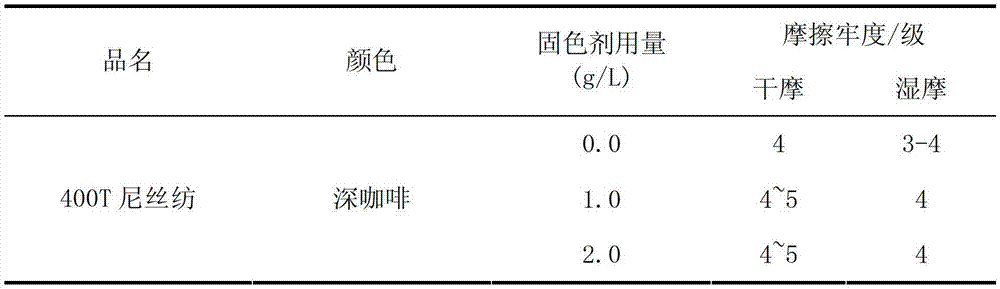

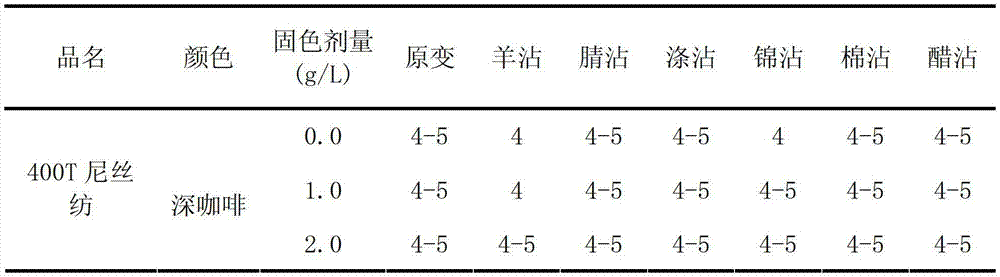

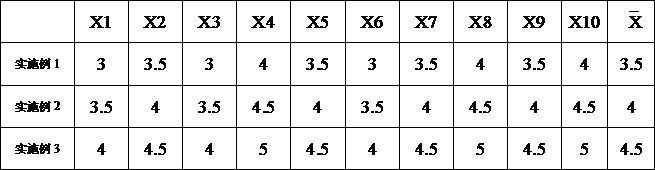

The invention discloses a process for producing a high-density nylon fabric. The process comprises the following steps of: unwinding and sewing; treating before desizing; presetting; dyeing; fixing color; dewatering; scutching; after-finishing; calendaring; detecting, folding and packaging. The process is characterized in that the phenomenon that the fabric gets yellow at high temperature can be reduced and the dyeing rate of the fabric can be improved because a yellowing resisting agent is used in the process of presetting, the ultraviolet resisting capacity of the fabric can be well improved because an ultraviolet absorbing agent is used in the process of dyeing, the tearing strength of the fabric can be improved because a right amount of a cross-linking agent and a tearing-fastness improving agent are added into a setting and finishing solution, and the excellent down penetration effect of the fabric can be achieved without using a chemical additive coating because the process of calender finishing is adopted.

Owner:SHENGHONG GRP CO LTD

Processing method of down-proof fabric

InactiveCN102433743AGuaranteed softnessGuaranteed cold resistanceFibre treatmentTextile shapingPolymer scienceTear resistance

The invention discloses a processing method of down-proof fabric. The invention belongs to the technical field of textile fabric processing. The method comprises a post-finishing step. The post finishing step comprises a water repelling step, a calendaring step, and a drying step. During the water repelling step, the fabric is delivered through a repelling tank containing a solution of a functional auxiliary agent; during the calendaring step, the surface of the fabric delivered through the repelling tank and processed by using a rolling liquid is calendared; during the drying step, the calendared fabric is dried by baking, such that the down-proof fabric is obtained. The method is characterized in that: the functional auxiliary agent comprises raw materials of, by weight: 5.5-6.5 parts of a water repelling agent, 0.8-1.2 parts of a bridging agent, 0.8-1.2 parts of resin, 0.08-0.12 parts of a promoting medium; the pH value of the functional auxiliary agent is 4-5; the pressure and the temperature of a calendaring roller of a calendaring machine, and the moving speed of the fabric are controlled during the calendaring step; and the temperature of a baking oven, and the moving speed of the fabric are controlled during the drying step. With the method, the down-proof effect is good, and the soft effect, the cold-resistance and the tearing resistance of the fabric can be ensured.

Owner:常熟华懋纺织有限公司

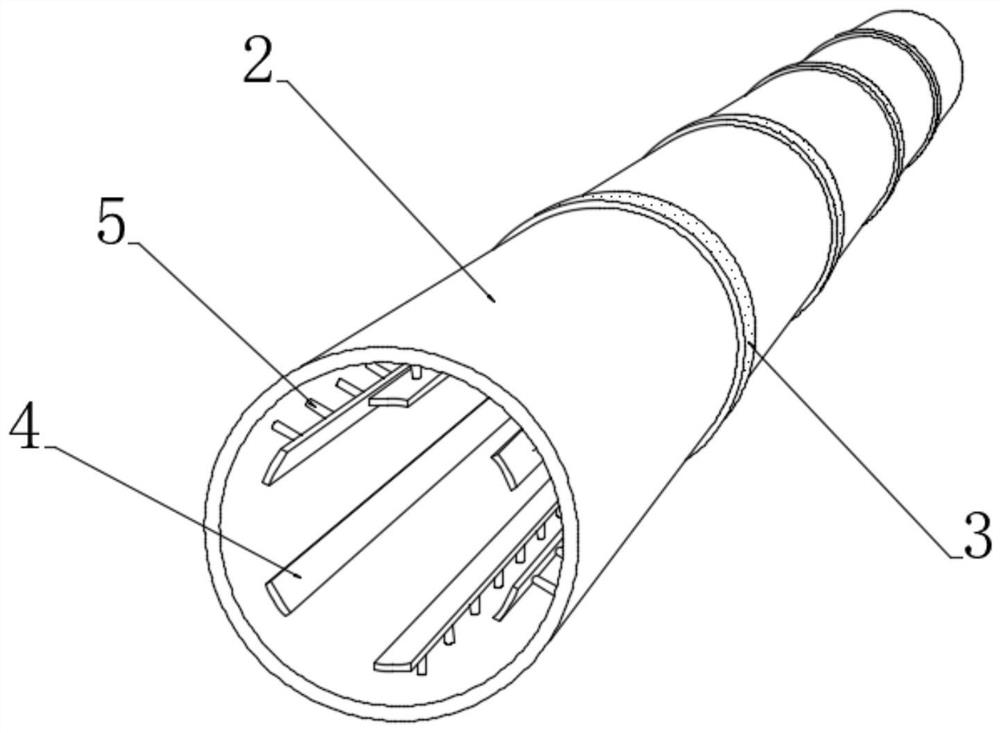

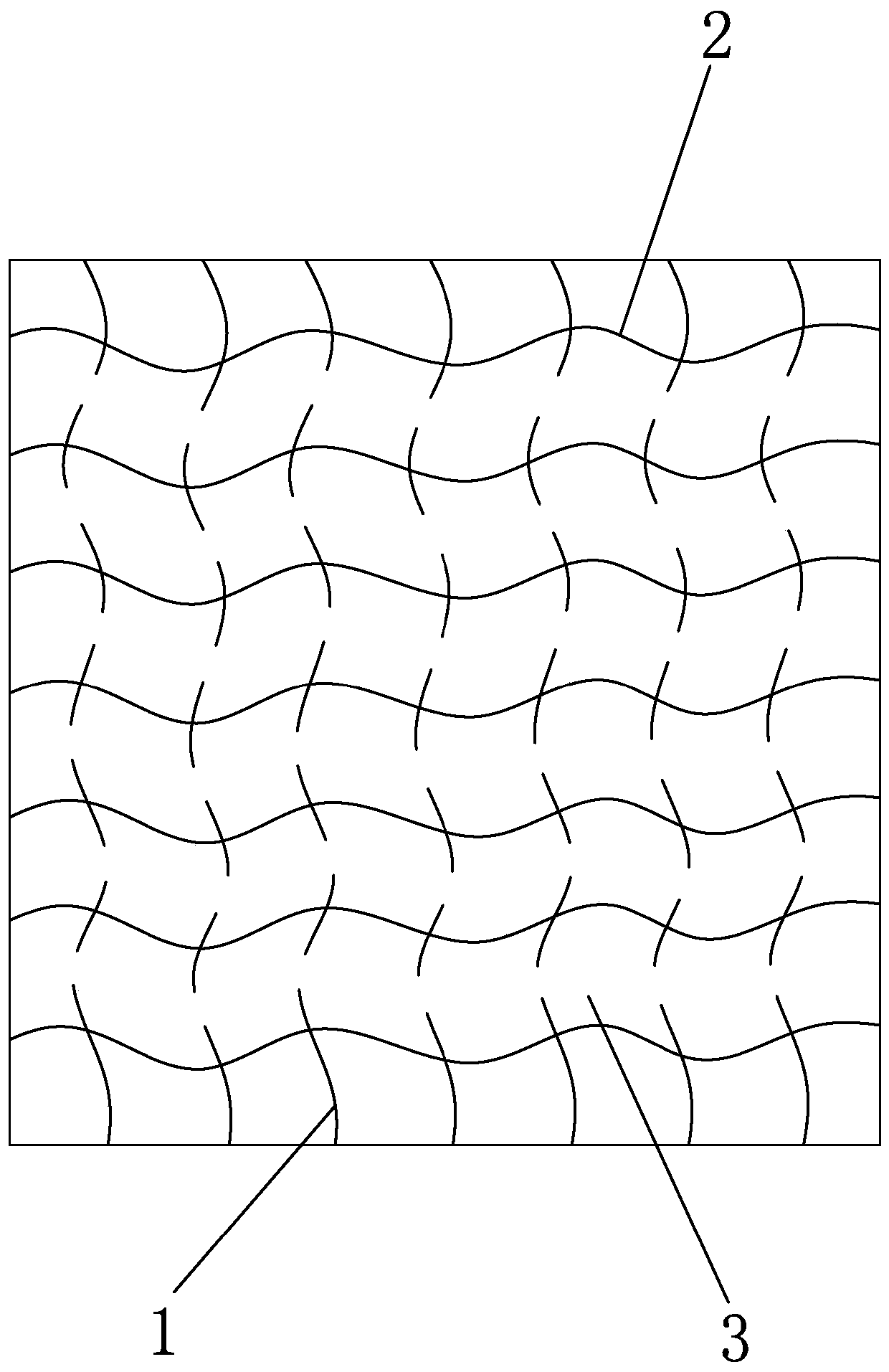

Nano microcapsule material having self-repairing and wear-resisting functions and preparation method thereof

ActiveCN104131469AImprove anti-drilling performanceDoes not cause thickening and weight gainFibre treatmentOvergarmentsGaining weightFiber

The invention relates to a nano microcapsule material and a preparation method thereof. The nano microcapsule material comprises a fabric base body prepared by fibers, and particularly also comprises a wall material cladded outside fiber-forming filaments and having nanoscale thickness; the wall material and the fibers form a nano microcapsule structure with the fiber-forming fine filaments as a 'core' and the wall material as a 'capsule sheath', the capsule sheath has adhesion, after being cladded with the capsule sheath, the fiber fine filaments are in mutual adhesion, so as to block gaps between the fibers; the fabric is used for production of ultra light and thin down jackets, can achieve quite good effect of penetration resistance to feathers, and cannot cause the fabric to become thick and gain weight and affect the wear comfort; and in addition, other properties of the fabric can be modified through introduction of functional auxiliary agents into the capsule sheath, for example, wear resistance of the fabric can effectively be enhanced through introduction of nano silica, or for example, the service life of the material can be effectively prolonged through introduction of self-repairing groups.

Owner:SUZHOU TANGHUA NANO TECH

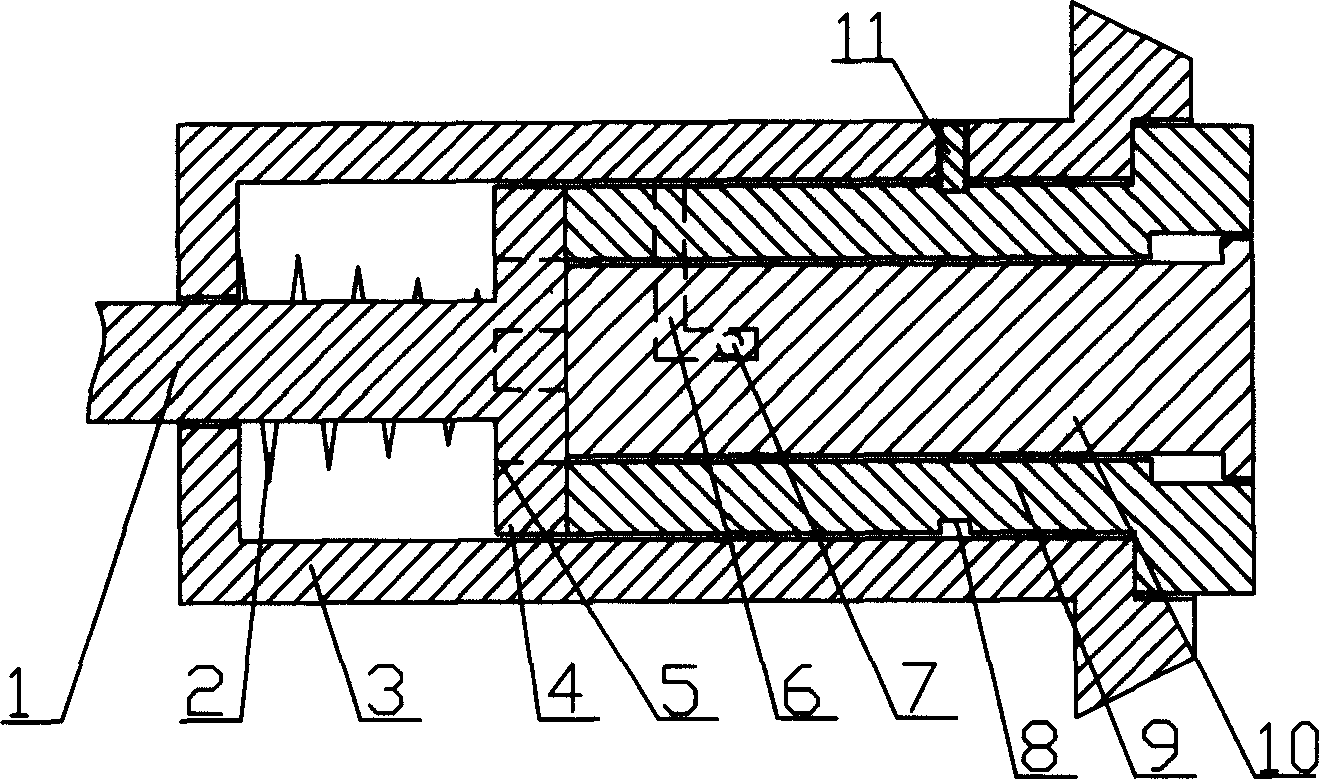

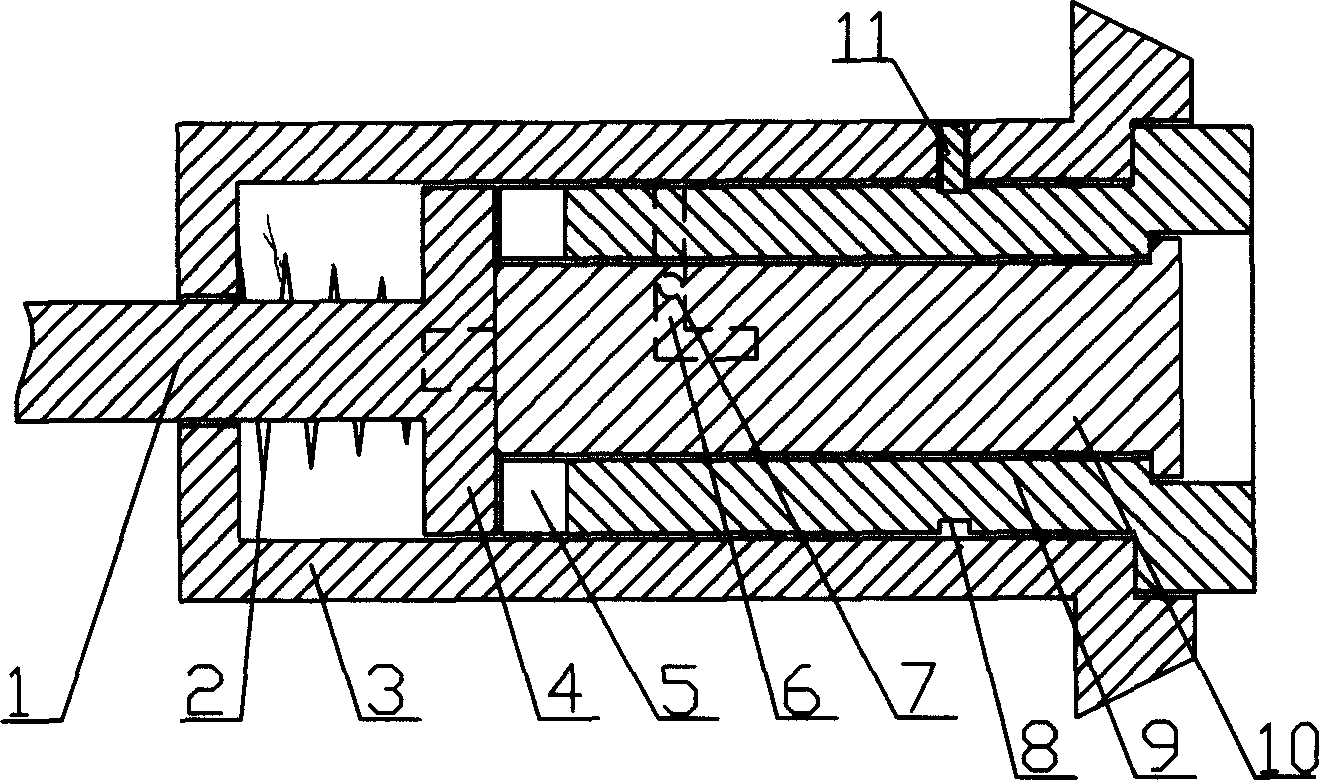

Separation and reunion type theftproof lock

InactiveCN1563654AExcellent anti-drilling performanceSimple structureBuilding locksEngineeringElectrical and Electronics engineering

This is a separation-and-reunion pattern against theft lock. It contains: The lock core and lock cover two parts. In the lock core there are inner lock core and outer lock core, the outer lock core is covered on the outside of the inner lock core. On the inner side of the outer lock core install a separate-and-reunion pattern concave grooves, this grooves can plug in the plug late, on the plug plate install transporting rod, the out side end of transporting rod stretch out from clock cover, on the transporting rod install spring.

Owner:祁志刚

Down-proof auxiliary agent and application thereof to down-proof fabric

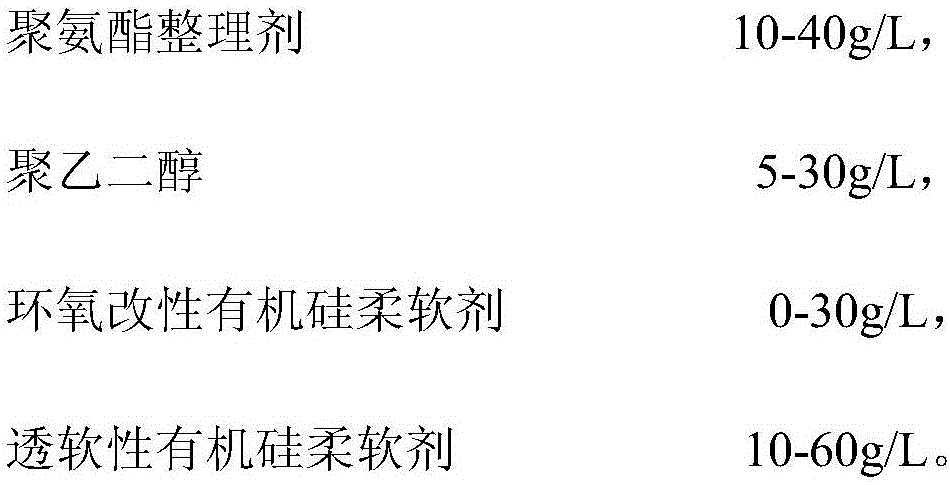

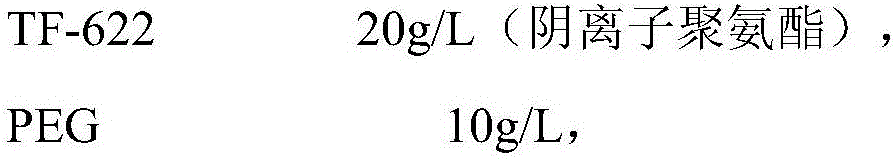

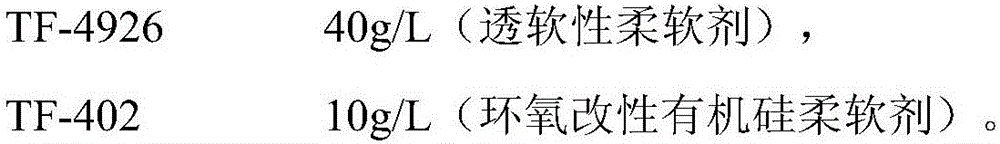

InactiveCN106223037AReserve air flowFluffy and softGrip property fibresPolyethylene glycolEngineering

The invention discloses application of a down-proof auxiliary agent and application thereof to a down-proof fabric. Handfeel, down-proof effects, appropriate breathability and noise in utilization, especially breathability and down-proof effects, of existing down-proof fabrics do not form an integral combination. The down-proof auxiliary agent is prepared from, by weight, 10-40g / L of a polyurethane finishing agent, 5-30g / L of polyethylene glycol, 0-30g / L of an epoxy modified organic silicon softener and 10-60g / L of soft organic silicon softener. The down-proof auxiliary agent has advantages that the fabric is sealed according to a principle of fixation of fabric interlacing points to achieve the down-proof effects while original breathability of the fabric is partially kept; by matched application of the polyurethane finishing agent and the corresponding softeners, the fabric is soft and fluffy to touch, and noise in use of the down-proof fabric is minimized.

Owner:传化智联股份有限公司

Down feather leakage resistance fabric

InactiveCN110029504ASoft touchImprove breathabilityCoatingsTextiles and paperAcrylic resinEngineering

The invention discloses a down feather leakage resistance fabric. The fabric includes a base fabric layer and a porous resin layer, and the porous resin layer contains acrylic resin and silicone resin. The fabric not only has good gas permeability, but also has good down feather leakage resistance property, and solves the problem of down feather leakage at a pinhole, and the fabric also has performance of a soft hand feeling and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Warm, breathable and down-proof garment fabric

InactiveCN104473360AGood flexibilityStrong hygroscopicityWoven fabricsVegetal fibresAnti bacterialWeft yarn

The invention discloses a warm, breathable and down-proof garment fabric. The warm, breathable and down-proof garment fabric comprises a base fabric body and a down-proof coating, wherein the base fabric body is interwoven by warp yarns and weft yarns; the warp yarns are twisted by 45-50 mass percent cotton fibers and 15-20 mass percent modal fiber; the weft yarns are twisted by 25-30 mass percent anti-bacterial moisture-guiding acrylic fibers and 10-15 mass percent bamboo carbon fibers; and the down-proof coating is an organic silicon high-elasticity coating. By the mode, the fabric is fine and compact in texture, has high heat retention property, high down-proof property and high breathability, has an anti-bacterial effect, and is non-toxic, harmless, environment-friendly and safe.

Owner:常熟市董浜镇徐市晨晨针织服装厂

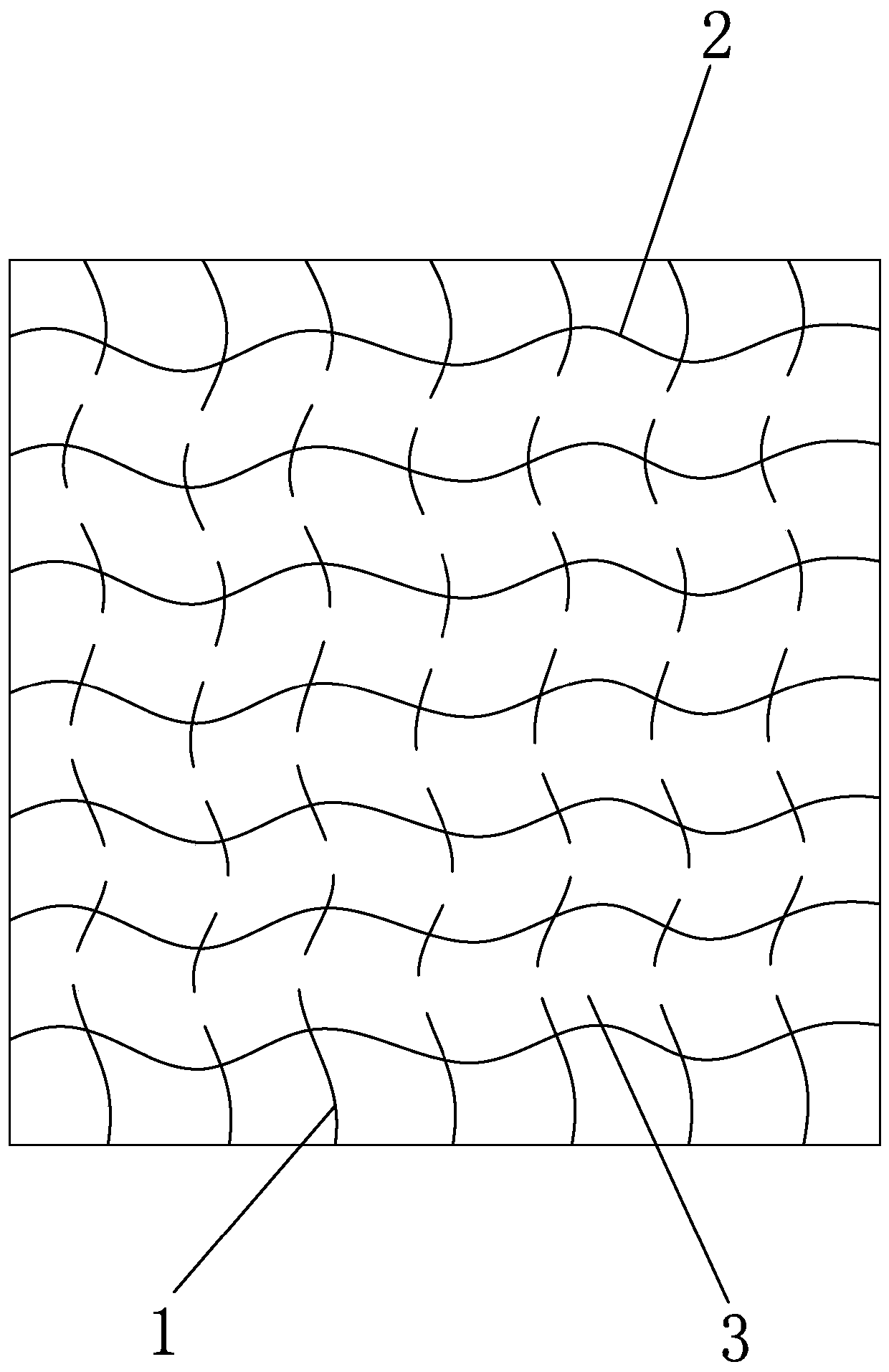

Kawo kawo fiber and cotton fiber blended down-proof and anti-mite fabric and weaving method for same

The invention provides a kawo kawo fiber and cotton fiber blended down-proof and anti-mite fabric and a weaving method for the same and relates to the technical field of textile production. The kawo kawo fiber and cotton fiber blended down-proof and anti-mite fabric is weaved via warp yarns and weft yarns. The warp yarns and the weft yarns are blended via kawo kawo fibers and cotton fibers; the weight percentage of the kawo kawo fibers is 20% to 30%; the weight percentage of the cotton fibers is 80% to 70%; the number of the warp yarns is 14.5tex; the number of the weft yarns is 9.7tex; and the fabric is in a plain weave structure. The weaving method comprises the following steps of a spooling procedure, a warping procedure, a slashing procedure, a denting procedure, a weaving procedure and a finishing procedure. Blended yarns formed by the kawo kawo fibers and the cotton fibers at a rational ratio are employed and weaved to form bedding article fabric with natural down-proof and anti-mite effects as well as great downproofness and great moisture absorbing and ventilating performance; the textile structure is tight, plain and fine and has smooth hand feeling and gloss; the fabric is ventilating and downproof and anti-mite as well as firm and abrasion-resistant; and great comfortableness and warming effect can be achieved.

Owner:JIHUA 3542 TEXTILE CO LTD

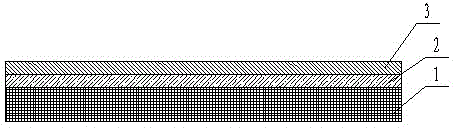

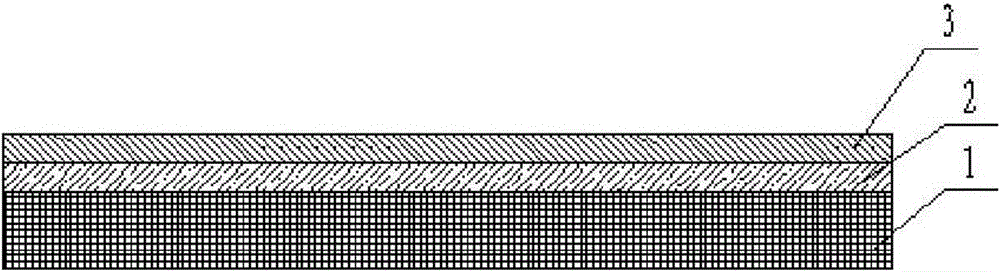

Light ventilation down garment fabric

InactiveCN104957824AThe texture is soft and fine and firmGood anti-drilling and air permeabilitySynthetic resin layered productsWoven fabricsPolyesterWeft yarn

The invention discloses light ventilation down garment fabric. The fabric comprises a basic layer, an isolation layer and a coating, the lower surface of the isolation layer adheres to the basic layer, and the coating is arranged on the upper surface of the isolation layer in a pressing fit mode. The basic layer is a textile layer and is formed by warp yarn and weft yarn in an interwoven mode. The warp yarn is formed by cotton fibers and coffee carbon fibers in a blended mode. The weft yarn is formed by weaving regenerated polyester fibers. The fibers comprise, by mass, 55-60% of the cotton fibers, 25-28% of the coffee carbon fibers and 15-17% of the regenerated polyester fibers. The isolation layer is a TTU isolation layer. The coating is a PU coating. In this way, the fabric is light and soft in texture, fine and compact, has good downproofness and ventilation performance, and meanwhile has excellent wind resistance and heat retention.

Owner:ANHUI GUIGU E COMMERCE

Antibacterial, antistatic and stain-release down-proof fabric and preparation method thereof

InactiveCN111593462AStrong slip effectSoft touchStain/soil resistant fibresHeating/cooling textile fabricsPolyesterPolymer science

The invention discloses an antibacterial, antistatic and stain-release down-proof fabric and a preparation method thereof. The down-proof fabric is interwoven at a high density through superfine polyester DTY filaments as warp and intermixed superfine polyester DTY filaments, antibacterial polyester DTY filaments and conductive filaments as weft. The interwoven fabric is subjected to three-proofings stain-release and fluff-drilling-prevention finishing and is endowed with antibacterial, antistatic, three-proofings and stain-release functions. The fabric is interwoven at the high density through superfine fibers as warp and weft, each polyester filament is composed of larger than or equal to 144 superfine fibers, the diameter of each superfine fiber is 0.1-0.3 [mu]m and is close to that ofsilk, hand feel is softer, the slip effect of the fibers is higher, and a certain silencing function is realized in the use process; and a non-ionic fluff-drilling-prevention finishing agent and presspolishing treatment are adopted at an after-finishing process stage, a fluff-drilling-prevention additive is prevented from reacting with the three-proofings stain-release finishing agent, the effects of the three-proofings stain-release product can be brought into full play, meanwhile downs on the surface of the fabric are fitted through a secondary press polishing process, and therefore the fluff-drilling-prevention capacity of the fabric is improved.

Owner:江苏康乃馨纺织科技有限公司

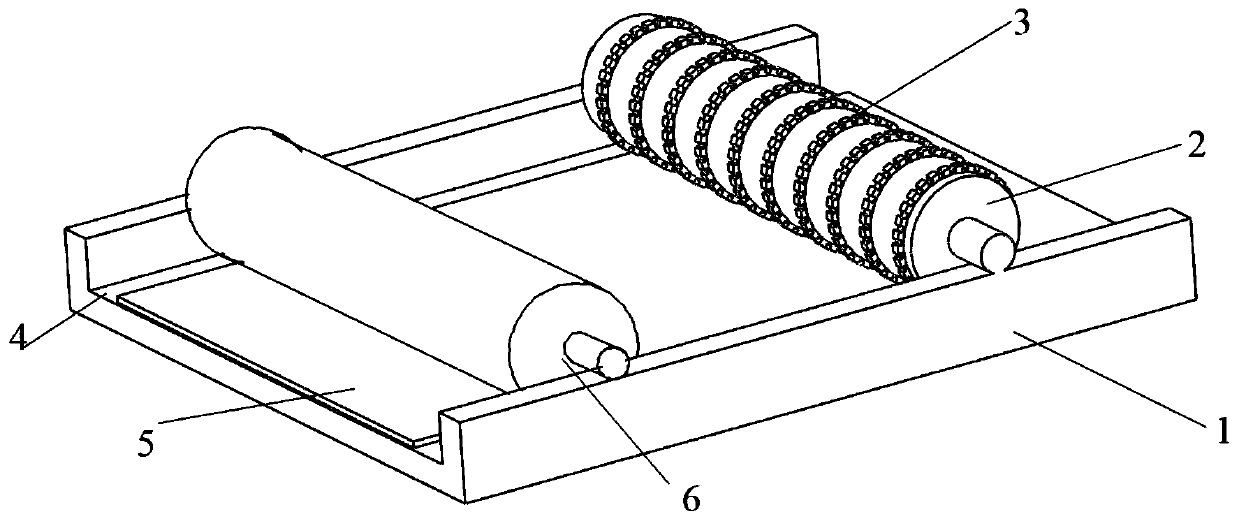

Downproof finishing agent and finishing process thereof on downproof fabric

InactiveCN108301213AGood cross-linking and film-forming propertiesFeel goodGrip property fibresVegetal fibresFiberSilicone oil

The invention discloses a downproof finishing agent and a finishing process thereof on a downproof fabric; the downproof finishing agent is a mixed aqueous solution of an acrylate-ammonia ester-organosilicone copolymerized modified polymer, an acrylate-ammonia ester-organosilicone copolymerized modified polymer, a ternary copolymerized silicone oil and a surfactant, wherein the content of the acrylate-ammonia ester-organosilicone copolymerized modified polymer is 30-80 g / L, the content of the ternary copolymerized silicone oil is 10-50 g / L, and the content of the surfactant is 1-5 g / L. The finishing process comprises the steps: firstly, preparing the downproof finishing agent, and then padding, drying, preshrinking, calendering and re-preshrinking, to obtain a finished fabric. After the fabric is padded in the finishing agent, fiber cracks are plugged through bonding, the fastness is increased, and the fabric handfeeling is improved; then through compounding with the ternary copolymerized silicone oil softener and the surfactant and the preshrinking, calendering and re-preshrinking processes, the fabric is guaranteed to have good downproof effect and also have a soft, matte and active fabric style.

Owner:JIANGSU YREDAR TEXTILE TECH CO LTD

Soft and breathable down garment fabric

InactiveCN104432901AWith high count and high density performanceThe texture is soft and fine and firmGarment special featuresSynthetic resin layered productsPolyesterCarbon fibers

The invention discloses a soft and breathable down garment fabric which comprises a basic layer, an isolating layer and a coating layer, wherein the lower surface of the isolating layer is stuck to the basic layer; the coating layer is in press fit with the upper surface of the isolating layer; the basic layer is a fabric layer formed by interweaving warps and wefts; the warps are formed by blending cotton fibers and coffee carbon fibers; the wefts are formed spinning polyester fibers; the mass percents of the fibers are as follows: 55-60 percent of cotton fibers, 25-28 percent of coffee carbon fiber and 15-17 percent of regenerated polyester fibers; the isolating layer is a TTU isolating layer; the coating layer is a PU coating layer. Through the mode, the fabric provided by the invention is soft, fine and compact, has favorable downproofness and breathability and meanwhile has excellent wind resistance and heat retention.

Owner:常熟市董浜镇徐市晨晨针织服装厂

Processing method of down-proof fabric

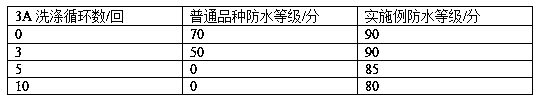

InactiveCN102433743BGuaranteed softnessImprove the anti-drilling effectFibre treatmentTextile shapingPolymer scienceTear resistance

The invention discloses a processing method of down-proof fabric. The invention belongs to the technical field of textile fabric processing. The method comprises a post-finishing step. The post finishing step comprises a water repelling step, a calendaring step, and a drying step. During the water repelling step, the fabric is delivered through a repelling tank containing a solution of a functional auxiliary agent; during the calendaring step, the surface of the fabric delivered through the repelling tank and processed by using a rolling liquid is calendared; during the drying step, the calendared fabric is dried by baking, such that the down-proof fabric is obtained. The method is characterized in that: the functional auxiliary agent comprises raw materials of, by weight: 5.5-6.5 parts of a water repelling agent, 0.8-1.2 parts of a bridging agent, 0.8-1.2 parts of resin, 0.08-0.12 parts of a promoting medium; the pH value of the functional auxiliary agent is 4-5; the pressure and thetemperature of a calendaring roller of a calendaring machine, and the moving speed of the fabric are controlled during the calendaring step; and the temperature of a baking oven, and the moving speedof the fabric are controlled during the drying step. With the method, the down-proof effect is good, and the soft effect, the cold-resistance and the tearing resistance of the fabric can be ensured.

Owner:常熟华懋纺织有限公司

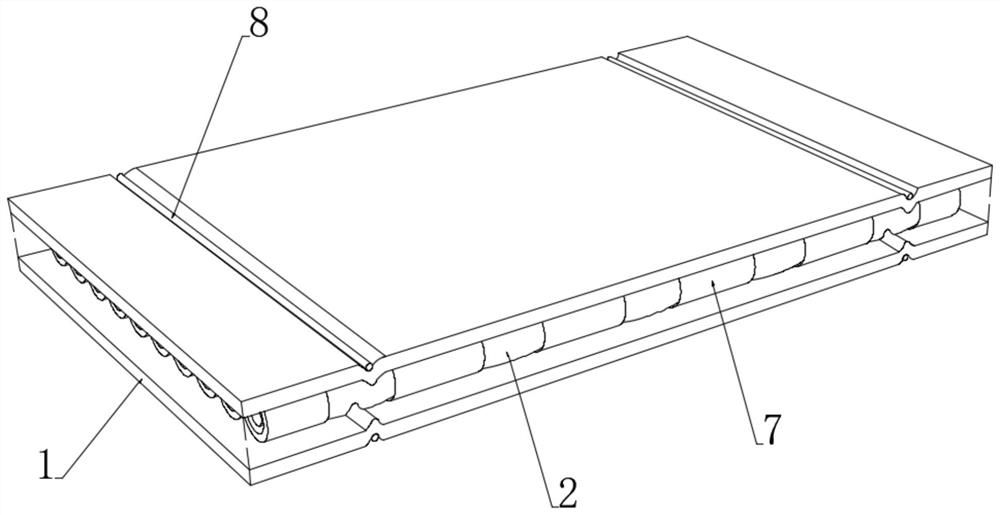

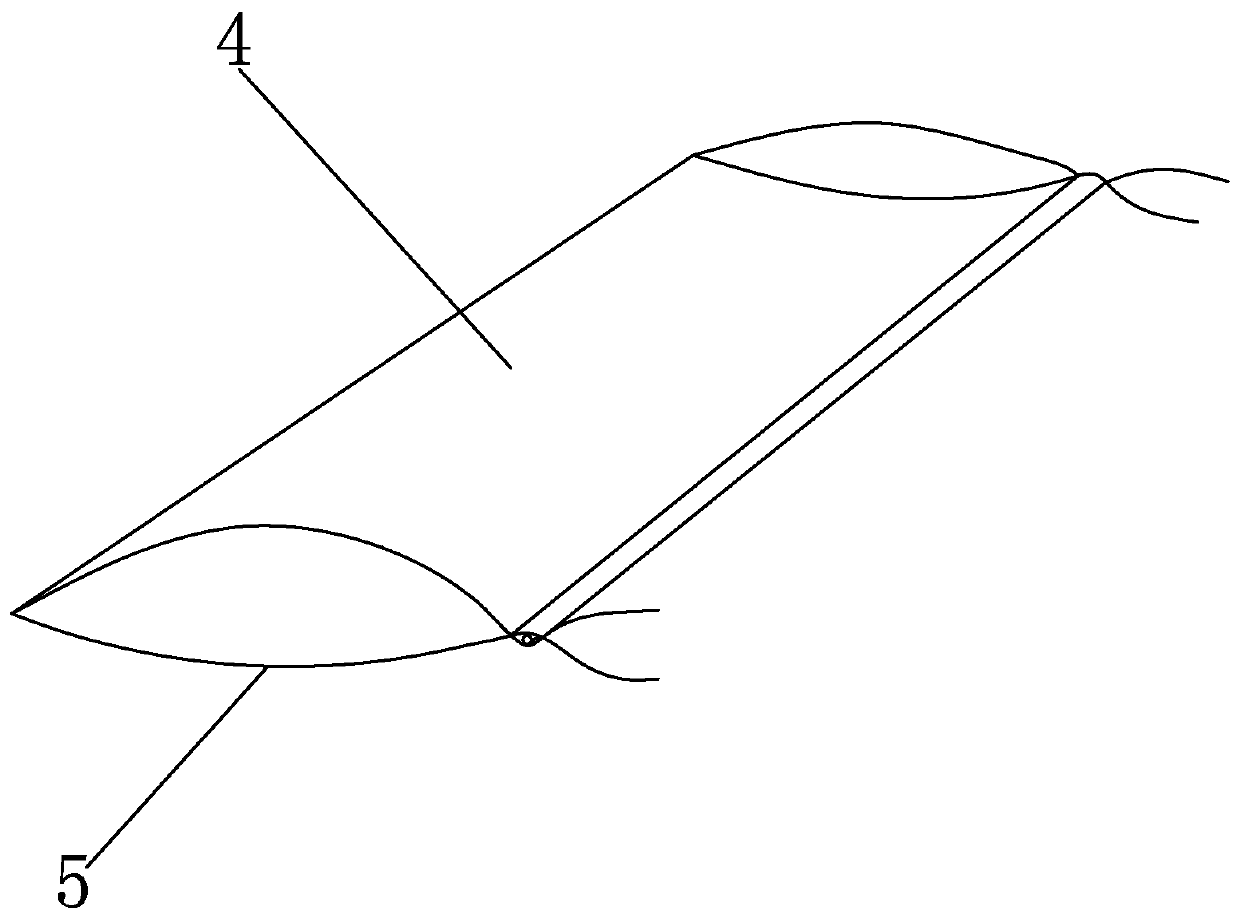

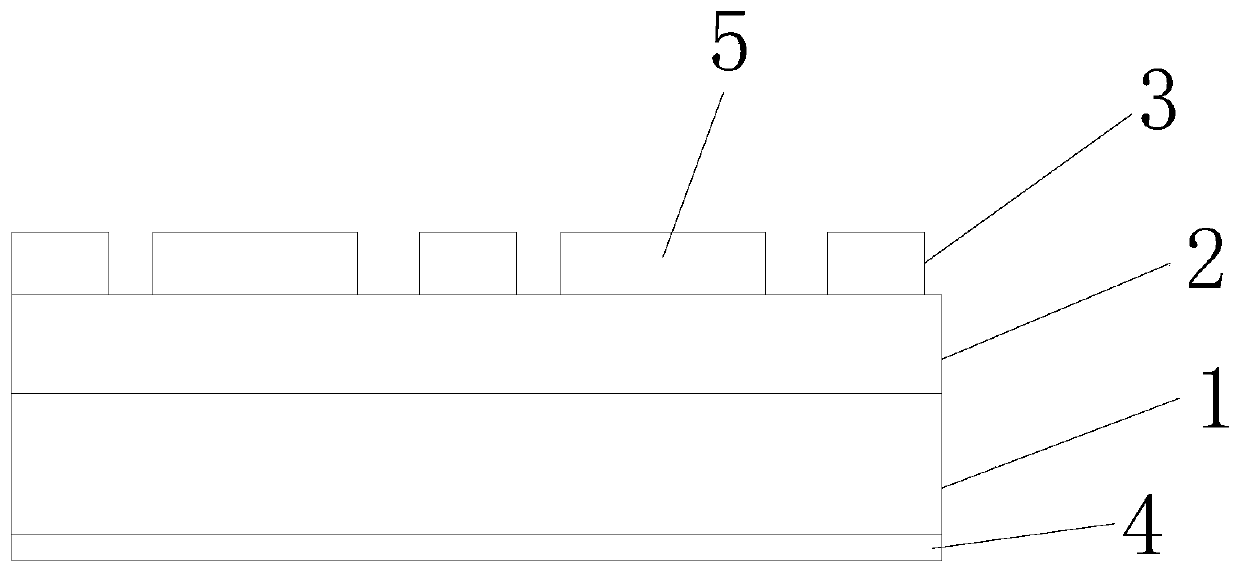

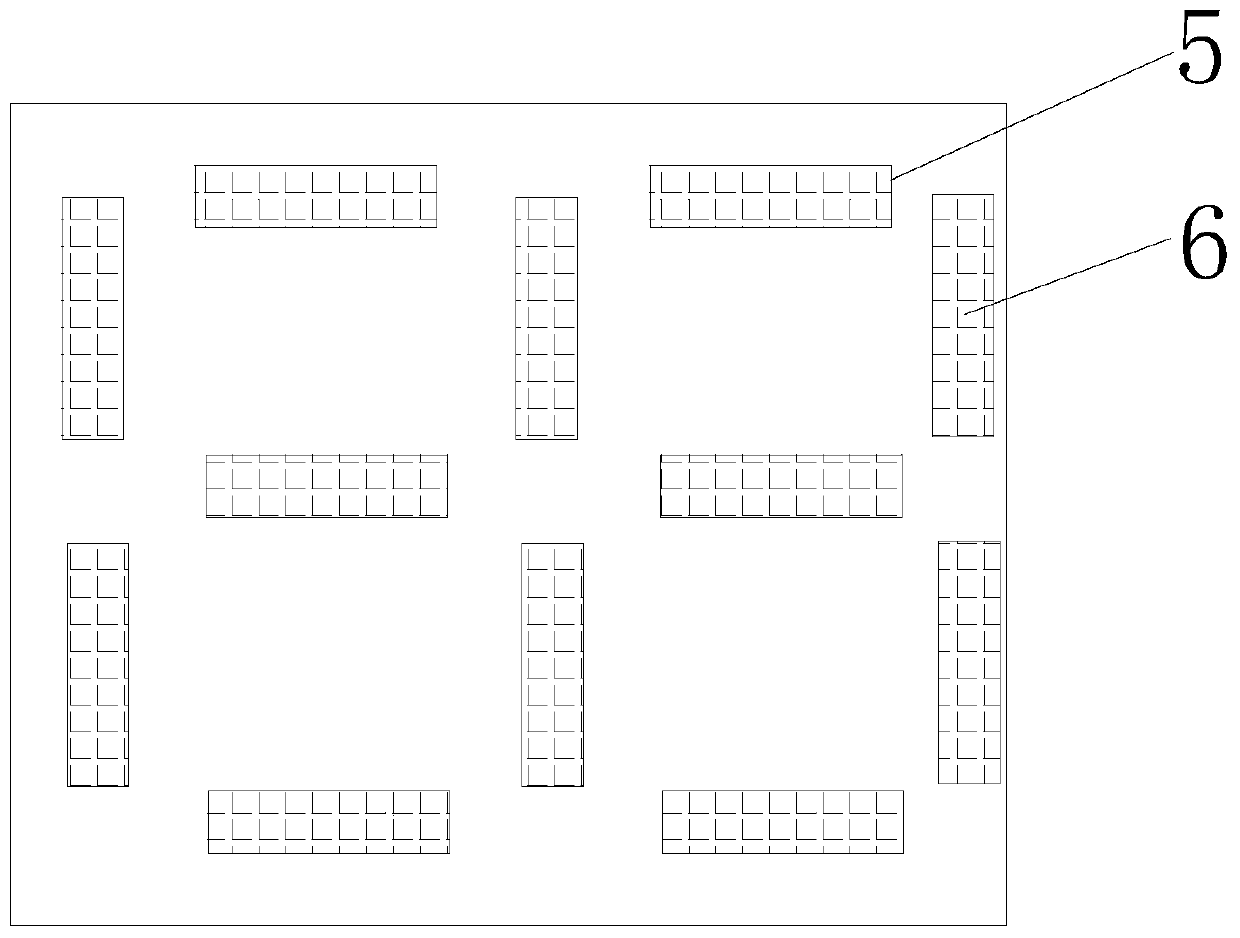

Preparation method for three-layer anti-down elastic down feather fabric of displacement structure

ActiveCN108505188AMaintain aestheticsMaintain dimensional stabilityShrinkingWeft knittingYarnPolyester

The invention relates to a preparation method for three-layer anti-down elastic down feather fabric of a displacement structure. The preparation method comprises the steps that polyester POY high-elastic yarn is used as warp and weft for weaving; after an overflow technology is adopted for dyeing, super positioning formation is conducted; high-temperature preshrinking is conducted; two-time primary press polish treatment and one-time mirror surface press polish treatment are conducted in sequence; the yarn and knitted cloth are subjected to dotted bonding and compounding through bonding glue to prepare fabric V; the fabric V is used as fabric I, knitted fabric is used as fabric II, a carved decoration press roller is used for pressing the fabric I, and the pressed surface of the fabric IIis bonded to the pressed surface of the fabric I; the fabric V is used as fabric III, the carved decoration press roller is used for pressing the fabric II, and the pressed surface of the fabric III is bonded to the pressed surface of the fabric II to prepare the three-layer anti-down elastic down feather fabric of the displacement structure; the glue residual parts of two-time pressing are displaced and staggered, and the carved decoration press roller is provided with pattern-type texture strips which are composed of small sunken blocks and small raised blocks, wherein the small sunken blocks and the small raised blocks are arrayed through a staggered mode in sequence. The technology is simple; the product is good in anti-down performance and wearing comfort.

Owner:常熟协创纺织服装技术有限公司 +1

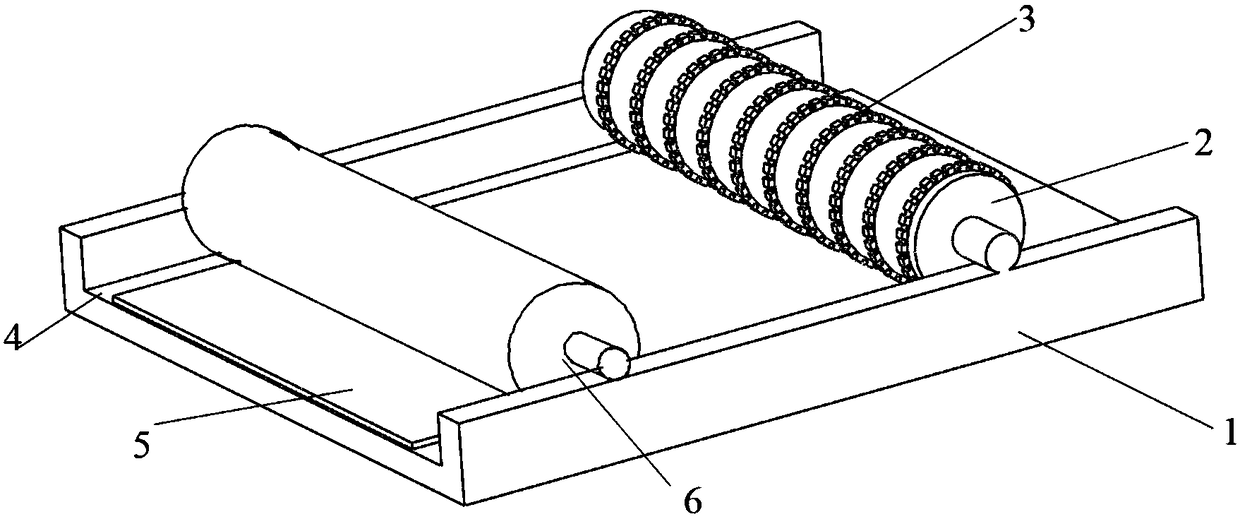

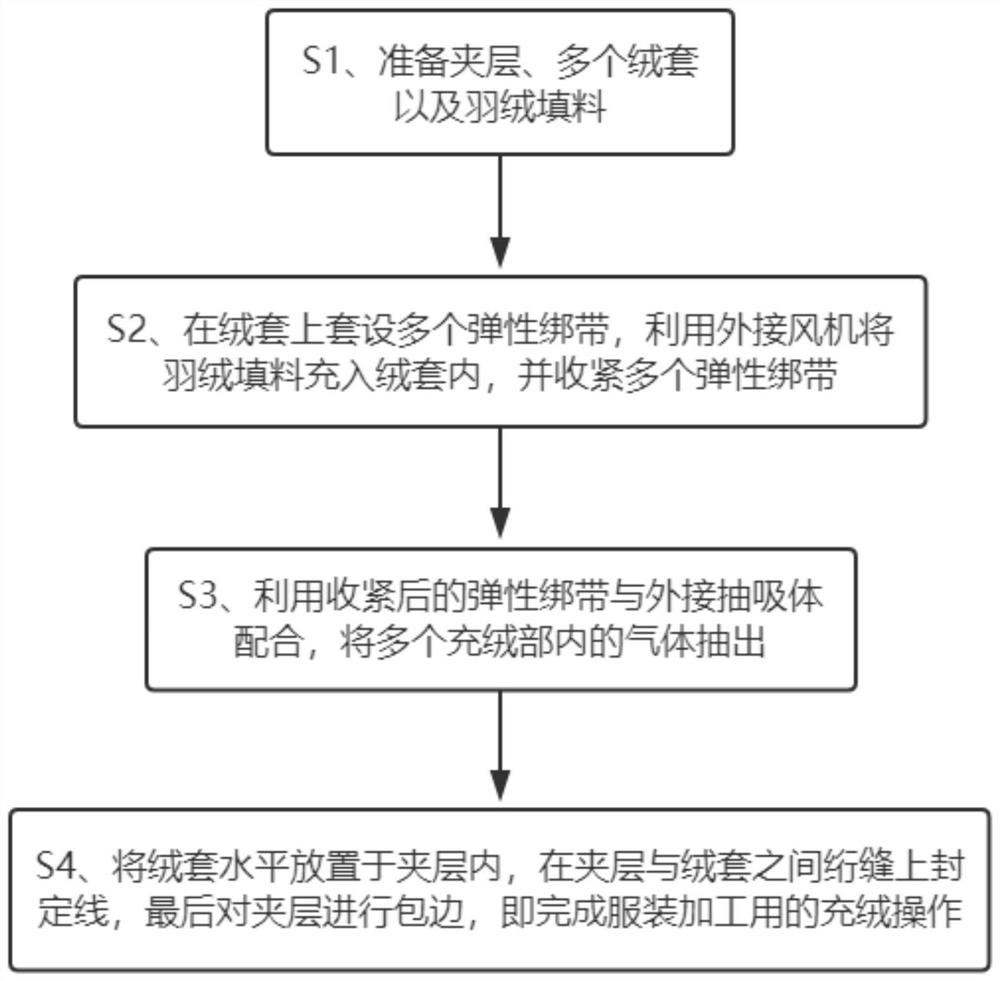

Down filling technology for garment processing

ActiveCN113598461APrevent running lintAvoid displacementClothes making applicancesProcess engineeringStructural engineering

The invention discloses a down filling technology for garment processing, and belongs to the technical field of garment processing technologies, a plurality of long-column-shaped down sleeves are used for filling down filling materials, compared with the mode that the down filling materials are directly filled into an interlayer, the down sleeves play a role in limiting the down filling materials, and after down filling is completed, a plurality of elastic binding bands arranged on the down sleeves in a sleeving mode are used for tightening the down sleeves in a segmented mode, the down sleeves are divided into a plurality of down filling parts, the down filling in the down sleeves is further limited, down running is effectively prevented, meanwhile, after the elastic binding bands are matched with an external suction body, the elastic binding bands are used for sucking the down filling parts in a segmented mode. Air can be extracted easily, down feather filling materials on the inner sides of the down sleeves are not easily brought out, the down sleeves filled with down feather are distributed in the interlayer in an array mode, the down sleeves and the interlayer are subjected to sewing positioning through the two sets of sealing lines, displacement of the down sleeves is effectively prevented, the experience effect is improved, and the down feather drilling phenomenon is effectively reduced.

Owner:SICHUAN SHENGSHAN BAIYULAN IND CO LTD

A nano-microcapsule material with self-healing and wear-resistant functions and its preparation method

ActiveCN104131469BImprove anti-drilling performanceDoes not cause thickening and weight gainFibre treatmentOvergarmentsGaining weightFiber

The invention relates to a nano microcapsule material and a preparation method thereof. The nano microcapsule material comprises a fabric base body prepared by fibers, and particularly also comprises a wall material cladded outside fiber-forming filaments and having nanoscale thickness; the wall material and the fibers form a nano microcapsule structure with the fiber-forming fine filaments as a 'core' and the wall material as a 'capsule sheath', the capsule sheath has adhesion, after being cladded with the capsule sheath, the fiber fine filaments are in mutual adhesion, so as to block gaps between the fibers; the fabric is used for production of ultra light and thin down jackets, can achieve quite good effect of penetration resistance to feathers, and cannot cause the fabric to become thick and gain weight and affect the wear comfort; and in addition, other properties of the fabric can be modified through introduction of functional auxiliary agents into the capsule sheath, for example, wear resistance of the fabric can effectively be enhanced through introduction of nano silica, or for example, the service life of the material can be effectively prolonged through introduction of self-repairing groups.

Owner:SUZHOU TANGHUA NANO TECH

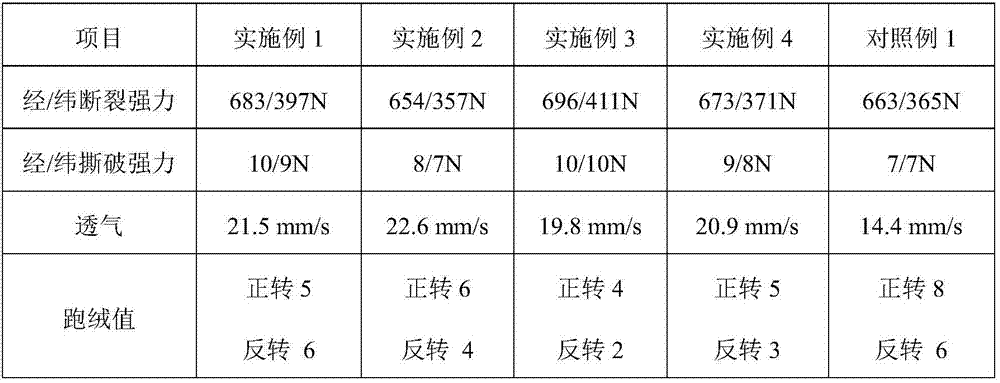

Dyeing and finishing method for all-cotton high-count down-proof fabric

InactiveCN107227606AImprove the anti-drilling effectFluffy and softHeating/cooling textile fabricsDry-cleaning apparatus for textilesEnzymeChemistry

The invention provides a dyeing and finishing method for an all-cotton high-count down-proof fabric. The method orderly comprises desizing-scouring-bleaching, tentering and whitening, flexible setting, calendering and pre-shrinkage. The desizing-scouring-bleaching process utilizes a biological enzyme one bath method. A polishing enzyme use ratio is 4 to 6 g / L, a desizing enzyme use ratio is 2 to 4 g / L, a scouring enzyme use ratio is 2 to 4 g / L, an osmotic agent use ratio is 1 to 2 g / L, a hydrogen peroxide use ratio is 1 to 2 g / L and a hydrogen peroxide stabilizer use ratio is 1 to 2 g / L. The all-cotton high-count down-proof fabric is prepared from warp yarns and weft yarns through interweaving. The warp yarns and weft yarns are all-cotton yarns having yarn count greater than or equal to 100S. The fabric prepared by the method has soft and fine hand feeling, does not produce noise and has excellent down-proof performances.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Double-layer down quilt fabric

PendingCN109706583ASimplify production stepsIncrease productivityMulti-ply fabricsEngineeringPolypropylene

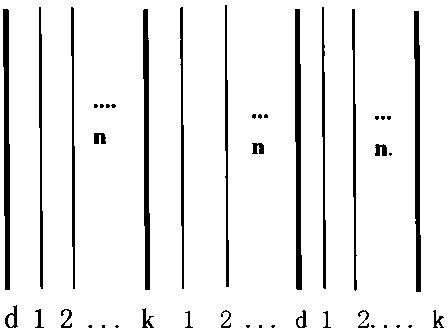

The invention discloses a double-layer down quilt fabric. The fabric comprises a fabric body; the fabric body has a double-layer weaving structure and comprises an upper-layer fabric and a lower-layerfabric; the fabric body is woven by adopting a double-layer plain weave structure, and the upper-layer fabric and the lower-layer fabric both adopt fine-denier polypropylene yarn as warp yarn and fine-denier nylon yarn as weft yarn. In a weaving process of the fabric body, an exterior-and-interior layer changing structure is adopted, first interweaving lines in the warp direction are formed by secondary exterior-and-interior layer changing of weft yarn, and second interweaving lines in the weft direction are formed by secondary exterior-and-interior layer changing of warp yarn; the first interweaving lines and the second interweaving lines are mutually staggered to form velvet filling cells arranged in an array. An interruption is positioned at the portion, between the two corresponding adjacent second interleaving lines, of each first interweaving line. According to the double-layer down quilt fabric, the production steps are simplified, the production efficiency is improved, the production cost is reduced, the sealing property is good, a down deviation phenomenon is unlikely to occur, and the down permeation prevention effect is great.

Owner:苏州百正纺织有限公司

Environment-friendly breathable downproof garment plus material

InactiveCN106042496AGood hygroscopicityImprove antibacterial propertiesSynthetic resin layered productsClothingsYarnTO-18

The invention discloses an environment-friendly breathable downproof garment plus material. The environment-friendly breathable downproof garment plus material comprises a basic plus material and a downproof film layer disposed outside the basic plus material, wherein the basic plus material comprises the following ingredients by weight percent: 32 to 35 percent of cotton fibers, 7 to 12 percent of alginate fibers, 30 to 32 percent of polyester fibers, 13 to 18 percent of bamboo charcoal fibers and 8 to 13 percent of coffee carbon fibers, wherein the plus material is provided with 40 yarns; and the downproof film layer is press-fit onto the basic plus material by virtue of waterproof glue, and the thickness of the downproof film layer is 7 to 8 micrometers. By virtue of the above way, the plus material is fine and tight in texture, has good downproof property and breathability, also has excellent antibacterial property and health property, and is non-toxic, harmless, environmentally friendly and safe.

Owner:合肥云都棉花有限公司

Thermal, breathable and down-proof garment fabric

InactiveCN105054424AGood warmth retentionImprove the anti-drilling effectFibre treatmentWoven fabricsEngineeringMoisture

The invention discloses a thermal, breathable and down-proof garment fabric which comprises a base-layer fabric and a down-proof coating. The base-layer fabric is made of warp yarns and weft yarns by means of interweaving, the warp yarns are made of, by weight, 45%-50% of cotton fibers and 15%-20% of modal fibers by means of twisting, and the weft yarns are made of, by weight, 25%-30% of antibacterial moisture-conductive acrylic fibers and 10%-15% of bamboo charcoal fibers by means of twisting; the down-proof coating is an organic silicon high-elasticity coating. Owing to the mode, the thermal, breathable and down-proof garment fabric has the advantages that the thermal, breathable and down-proof garment coating is fine and firm in texture and excellent in thermal protection, down-proof property and breathability, and is nontoxic, harmless, environmental friendly and safe, and bacterial inhibition and antibacterial effects can be realized.

Owner:ANHUI GUIGU E COMMERCE

Light and soft breathable down garment fabric

InactiveCN106113683AWith high count and high density performanceThe texture is soft and fine and firmSynthetic resin layered productsFiberPolyester

The invention discloses a soft and breathable down garment fabric, the fabric comprises: a base layer, an isolation layer and a coating, the lower surface of the isolation layer is adhered to the base layer, and the upper surface of the isolation layer is bonded with The coating; the base layer is a fabric layer, which is formed by interweaving warp yarns and weft yarns, and the warp yarns are formed by blending cotton fibers and coffee carbon fibers, and the weft yarns are formed by weaving recycled polyester fibers The mass percentage of each fiber is: cotton fiber 55%-60%, coffee carbon fiber 25%-28%, regenerated polyester fiber 15%-17%; the isolation layer is a TTU isolation layer; the coating For PU coating. Through the above method, the fabric of the present invention is light and soft, dense and compact, has good down-proof property and air permeability, and has excellent windproof property and heat retention property at the same time.

Owner:合肥云都棉花有限公司

A preparation method of anti-drilling down elastic down fabric with three-layer heterotopic structure

The invention relates to a method for preparing a three-layer dislocation structure anti-drilling down elastic down fabric, the steps of which are: weaving polyester POY high elastic yarns as warp and weft yarns; using overflow technology to dye and carry out superposition setting; carry out high-temperature pretreatment two preliminary calendering treatments and one mirror calendering treatment in sequence; the fabric V is obtained by point-like bonding with the knitted fabric through bonding glue; the fabric V is the fabric I, and the knitted fabric is the fabric II. Laminate the patterned roller on the fabric I and bond the fabric II to the laminated surface of the fabric I; take the fabric V as the fabric III, use the engraved roller to laminate the fabric II and bond the fabric III to the laminated surface of the fabric II A three-layer anti-drilling elastic down fabric with ectopic structure is obtained; the glue residues of the two times of pressing are staggered in ectopic position, and the engraved pressing roller is provided with patterns composed of concave small pieces and raised small pieces that are arranged alternately in sequence. textured strips. The process of the invention is simple; the anti-drilling performance and wearing comfort of the product are good.

Owner:常熟协创纺织服装技术有限公司 +1

Production process for down jacket cloth

InactiveCN103088518AImprove the windproof effectImprove breathabilitySucessive textile treatmentsWoven fabricsFiberPulp and paper industry

The invention discloses a production process for down jacket cloth. The production process comprises the following steps of: (1) warping porous fine fibers; (2) sizing the warped fibers; (3) drying the sized fibers; and (4) weaving the dried fibers. In such a way, the cloth produced by the production process for the down jacket cloth is soft, light, thin and high in wind resistance, air permeability, downproofness and wearing comfort.

Owner:WUJIANG MAIDAO TEXTILE

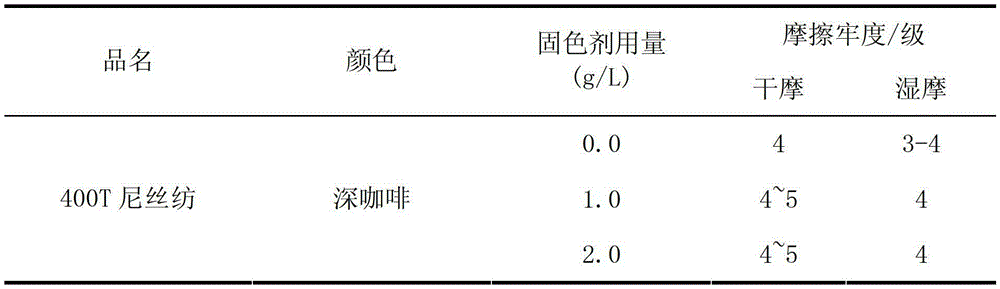

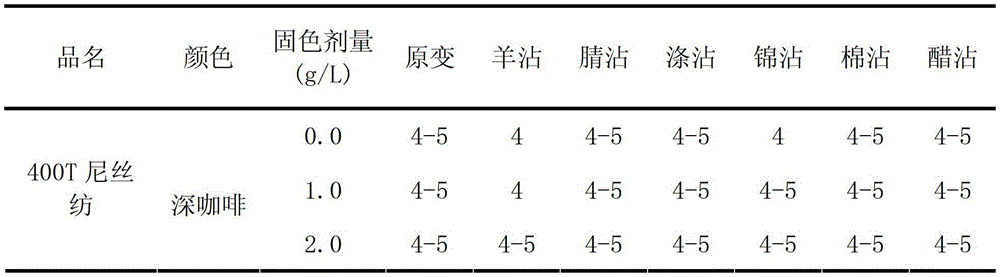

Process for producing high-density nylon fabric

ActiveCN103147304BImprove dye uptakeImproves UV resistanceFibre typesDyeing processCross-linkNylon material

The invention discloses a process for producing a high-density nylon fabric. The process comprises the following steps of: unwinding and sewing; treating before desizing; presetting; dyeing; fixing color; dewatering; scutching; after-finishing; calendaring; detecting, folding and packaging. The process is characterized in that the phenomenon that the fabric gets yellow at high temperature can be reduced and the dyeing rate of the fabric can be improved because a yellowing resisting agent is used in the process of presetting, the ultraviolet resisting capacity of the fabric can be well improved because an ultraviolet absorbing agent is used in the process of dyeing, the tearing strength of the fabric can be improved because a right amount of a cross-linking agent and a tearing-fastness improving agent are added into a setting and finishing solution, and the excellent down penetration effect of the fabric can be achieved without using a chemical additive coating because the process of calender finishing is adopted.

Owner:SHENGHONG GRP CO LTD

A kind of preparation method of ultra-thin and ultra-transparent microporous membrane

ActiveCN114703673BWith slow rebound propertiesImprove water pressure resistanceTextiles and paperMicro nanoPolymer science

The invention relates to a preparation method of an ultra-thin and ultra-transparent microporous membrane. The ultra-thin and ultra-transparent microporous membrane is a membrane containing micropores, the thickness of the membrane is below 5 μm, and the pore size of the micropores is below 5 μm; the preparation method is as follows: : Use a micro-nano foaming machine to foam the water-based foam to obtain bubbles, and then carry out micro-concave high-precision coating to obtain an ultra-thin and ultra-transparent microporous film; the water-based foam is mainly composed of water-based glue, water-based foam stabilizer, It is composed of silicone resin polyether emulsion water-based foam stabilizer and water; the foaming control parameters of the micro-nano foaming machine include: the specific gravity of the bubbles is 350~700 g / L, the working speed of the stirring head is 250~400 rpm, and the output of the pump 100~500L / hour; the diameter of the bubbles is less than 5μm; the thickness of the coating is less than 5μm during micro-concave high-precision coating, and at the same time greater than or equal to the diameter of the bubbles. The method of the invention is simple, the thickness of the prepared product is small, and the air permeability and anti-drilling down property are good, which effectively fills the blank of the prior art.

Owner:WUJIANG HANTA TEXTILE FINISHING

Light and thin anti-perspective down-proof cloth and preparation method thereof

PendingCN113215705AThin and lightSoft touchWoven fabricsMonocomponent polyesters artificial filamentPolyesterCotton fibre

The invention discloses light and thin anti-perspective down-proof cloth and a preparation method thereof. Warps of the down-proof cloth adopt anti-perspective polyester DTY filaments, wefts of the down-proof cloth adopt cotton fiber and anti-transparent polyester staple fiber blended yarns, high-density weaving is performed, and meanwhile, an interwoven fabric is subjected to anti-transparent finishing, so that the fabric is light, thin and soft, and the disadvantage that heterochromatic velvet is visible is effectively prevented. According to the invention, the warps and the wefts adopt the superfine polyester filaments and the polyester and cotton blended yarns respectively; compared with a same-yarn-count all-cotton down-proof fabric, the down-proof cloth has the advantages that the hand feeling and the draping feeling are better, and the washing shrinkage rate is greatly improved; and a non-ionic down-proof finishing agent and heavy calendaring treatment are adopted in the after-finishing process stage, so that the covering capacity of the polyester and cotton down-proof cloth can be effectively enhanced, and the whiteness and the down-proof performance are not influenced.

Owner:JIANGSU CANASIN WEAVING +1

Downproof nonwoven fabric for down jacket

InactiveCN110801067AImprove the protective effectImprove the anti-drilling effectSynthetic resin layered productsClothingsCotton clothPolymer chemistry

The invention relates to a downproof nonwoven fabric for a down jacket. The downproof nonwoven fabric orderly comprises a waterproof breathable layer, a nonwoven fabric layer and a lining layer from outside to inside; in mass percent, the waterproof and breathable layer comprises 30-40% of macromolecule waterproof and breathable film and 60-70% of silk fabrics; the nonwoven fabric layer comprises60-80% of terylene and 20-40% of conductive fiber; and the lining layer is cotton fabric. By arranging three layers of fabrics for the down jacket, the protection effect of the whole down jacket fabric is enhanced, and the downproof effect of the down jacket fabric is better; by adding the macro-molecular water and breathable film in the waterproof and breathable layer, the outermost layer of thedown fabric is waterproof and breathable when the downproofness is reached, and the hand feeling of the outer layer fabric is more silky after combining with the silk fabric.

Owner:海宁沃伦科技有限公司

A kind of preparation method of anti-drilling down elastic down fabric

ActiveCN108442020BSimple processLow costSynthetic resin layered productsLaminationPolyesterAdhesive glue

The invention relates to a preparation method of an anti-drilling elastic down fabric, which comprises the following steps: using polyester POY high-elastic yarns as warp and weft yarns to weave a fabric I; dyeing by an overflow process, and then adding superposition and shaping to obtain a fabric II ; Pre-shrink at high temperature to obtain fabric III; sequentially undergo preliminary calendering treatment I, preliminary calendering treatment II and mirror calendering treatment to obtain fabric IV, the pressure of preliminary calendering treatment I is 100-150T, and the temperature is 150-200°C. The pressure of the preliminary calendering treatment II is 120-180T, the temperature is 220-250°C, the pressure of the mirror calendering treatment is 120-140T, and the temperature is 140-160°C; the fabric IV and the knitted fabric are bonded in point form by bonding glue. The anti-drilling velvet elastic down fabric is prepared by combining. The invention has simple process and low cost; the prepared fabric has good anti-drilling performance, good elasticity and moisture permeability, good wearing comfort, and has great popularization value.

Owner:常熟协创纺织服装技术有限公司 +1

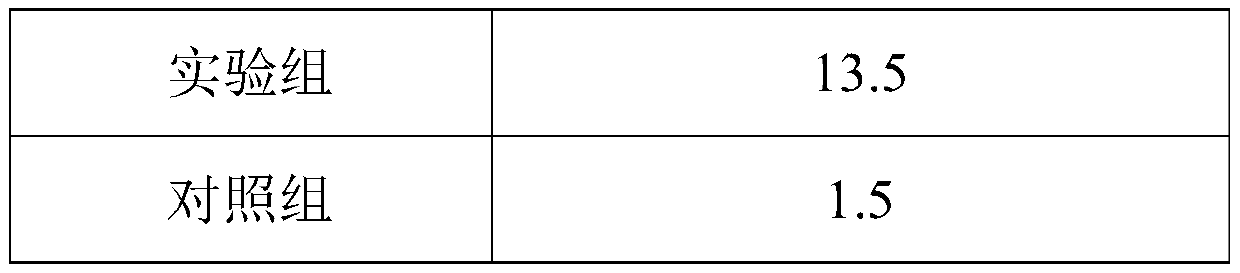

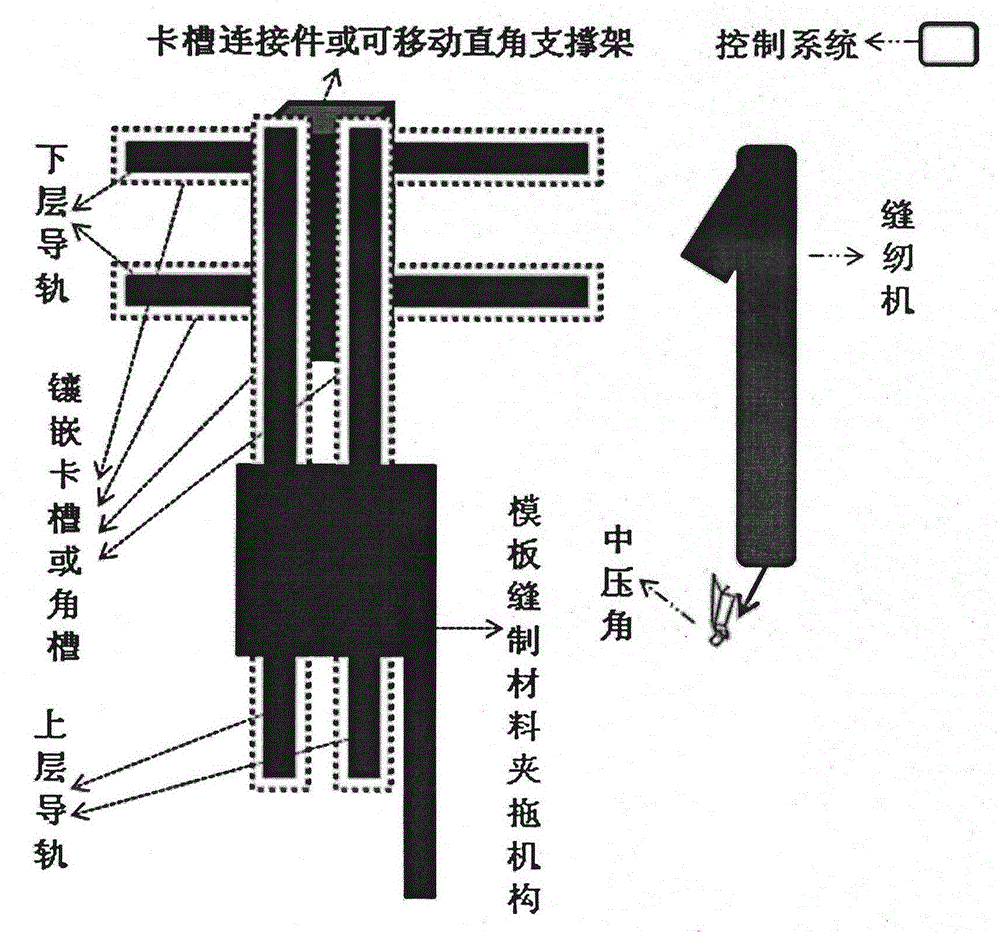

Numerical control anti-nap-jump automatic template sewing and processing device and control system thereof

ActiveCN104963109AGuaranteed stability and reliabilityGuaranteed stabilitySewing-machine control devicesPressersNumerical controlControl system

The invention discloses a numerical control anti-nap-jump automatic template sewing and processing device and a control system thereof. The numerical control anti-nap-jump automatic template sewing and processing device comprises a sewing machine, a template sewing material clamping and dragging mechanism, two upper parallel guide rails, two lower parallel guide rails, and a control system of the numerical control anti-nap-jump automatic template sewing and processing device. The numerical control anti-nap-jump automatic template sewing and processing device can be used for sewing a plurality of stitches and a plurality of patterns, the work efficiency can be raised. The numerical control anti-nap-jump automatic template sewing and processing device is low in production cost and easy to mount and debug, the sewing machine is easy to maintain, and a sewed nest can be easily avoided.

Owner:山东微壹信息技术有限公司

Special down-proof rubber strip lining for down jacket

PendingCN110664034AAvoid the problem of easy running lintSoft touchOvergarmentsPolyesterPolymer science

The invention discloses a special down-proof rubber strip lining for a down jacket. The lining comprises a woven base cloth layer, a down-proof film-coated layer and a rubber strip bonding layer, wherein the woven base cloth layer is formed by weaving composite low-elasticity polyester yarns as warp yarns and weft yarns by twills; the upper surface of the woven base cloth layer is combined with the down-proof film-coated layer; and the rubber strip bonding layer is arranged on the upper surface of the down-proof film-coated layer. The lining can be formed by direct pressing and ironing duringprocessing and does not need to be sewn by threads, so that the problem of easy moving of down at a needle eye is avoided; and the lining is soft in hand feeling, good in downproofness and can be widely applied to the production of various fashionable, light and thin down jackets.

Owner:ZHEJIANG KINGSAFE INTERLINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com