Double-layer down quilt fabric

A technology for down quilts and fabrics, applied in the direction of fabrics, multi-strand fabrics, textiles, etc., can solve the problems of unsatisfactory use effect, cumbersome processing steps, poor anti-drilling performance, etc., to achieve good anti-drilling effect and reduce production costs. , The effect of not easy to run down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

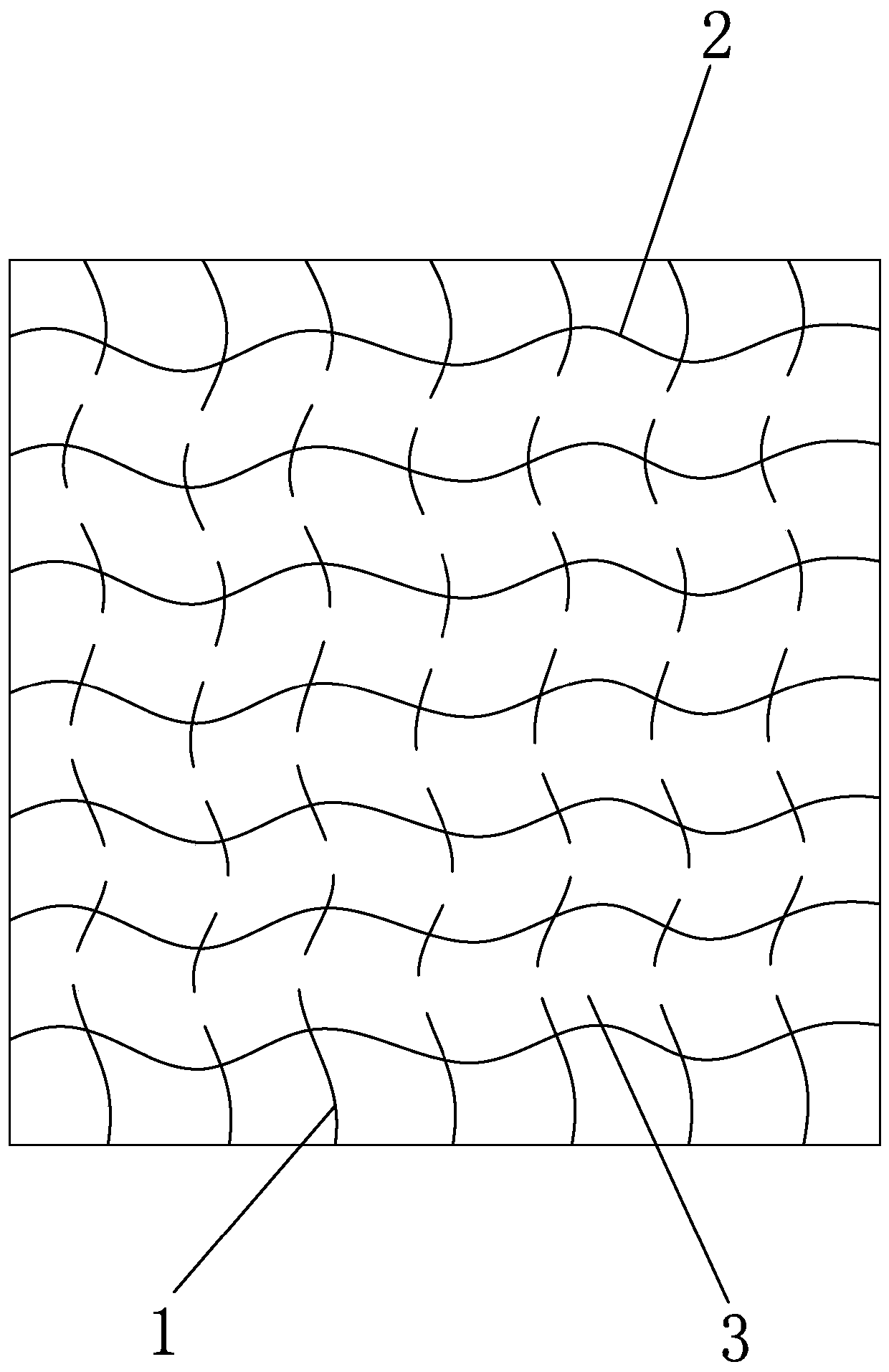

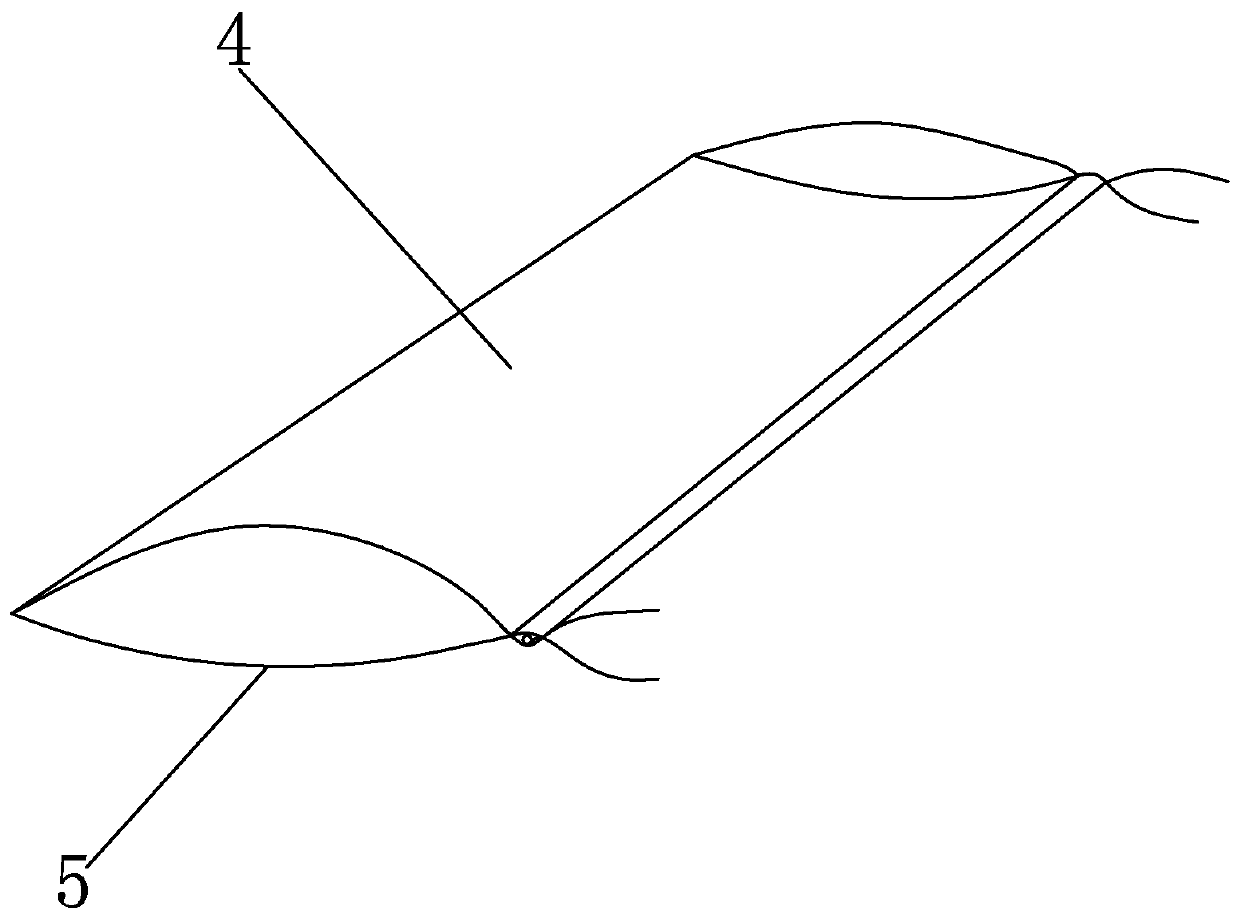

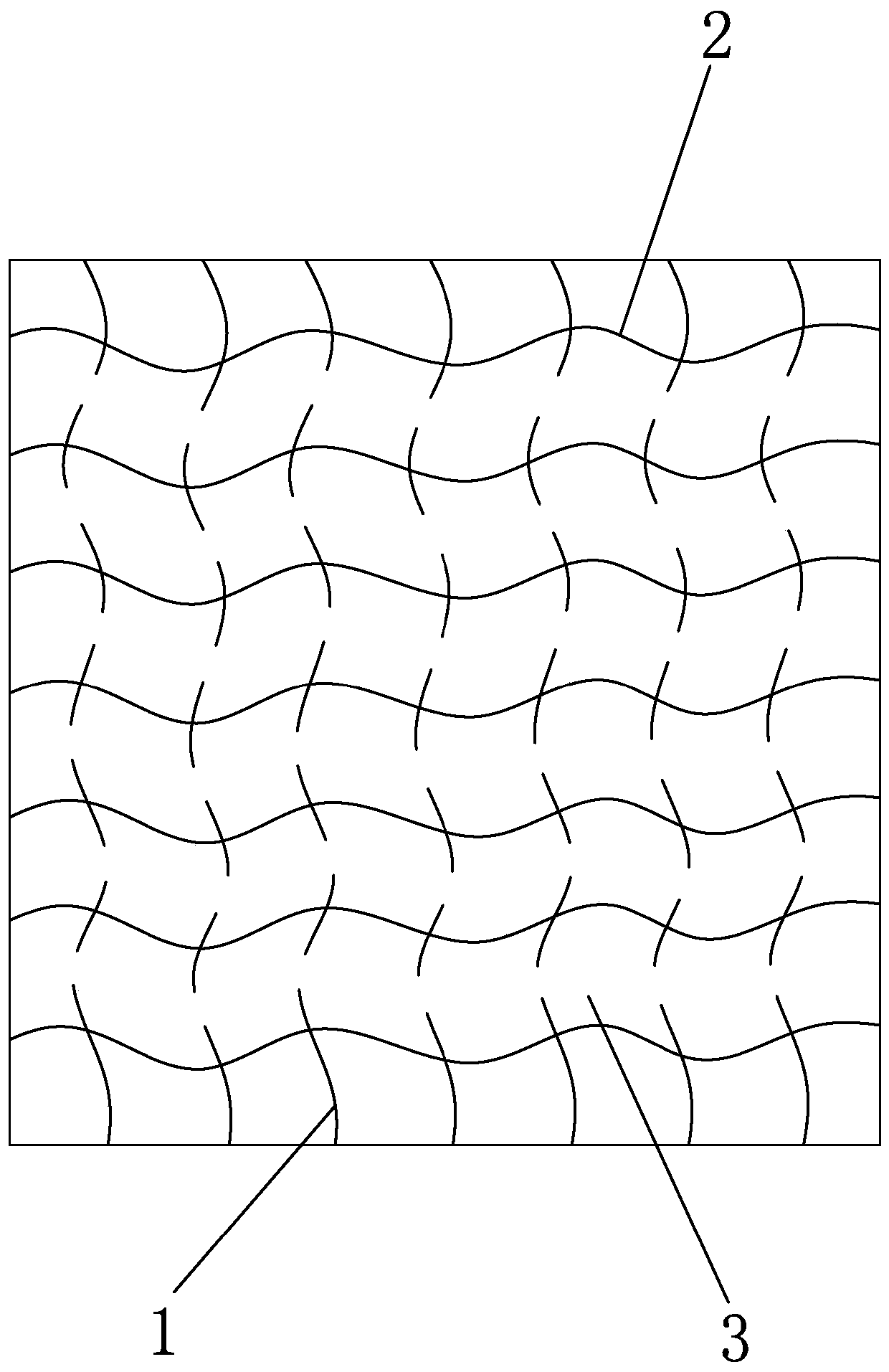

[0022] combine figure 1 , figure 2 , the invention discloses a double-layer duvet fabric, which is woven by a dobby loom and includes a fabric body. The fabric body is a double-layer weaving structure, including an upper fabric 4 and a lower fabric 5 . The fabric body is woven with a double-layer plain weave structure, with a smooth surface, small pores, tight weaving, and not easy to drill down. Both the upper fabric 4 and the lower fabric 5 adopt fine-denier polypropylene yarns as warp yarns, and fine-denier nylon yarns as weft yarns. Preferably, the fine denier polypropylene yarn is 20D, and the fine denier nylon yarn is 20D. The use of fine-denier polypropylene yarn and fine-denier nylon yarn has good anti-drilling effect, good antibacterial performance, good moisture permeability and breathable performance, and good surface wear resistance. combine figure 2 In the weaving process, the fabric body adopts the layer-changing structure, the first interweaving line 1 al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com