Separation and reunion type theftproof lock

An anti-theft lock, clutch-type technology, applied in the direction of building locks, buildings, building structures, etc., can solve the problems of poor anti-theft performance of marble locks, and achieve the effect of excellent anti-drilling performance, strong adaptability, and preventing technology from opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

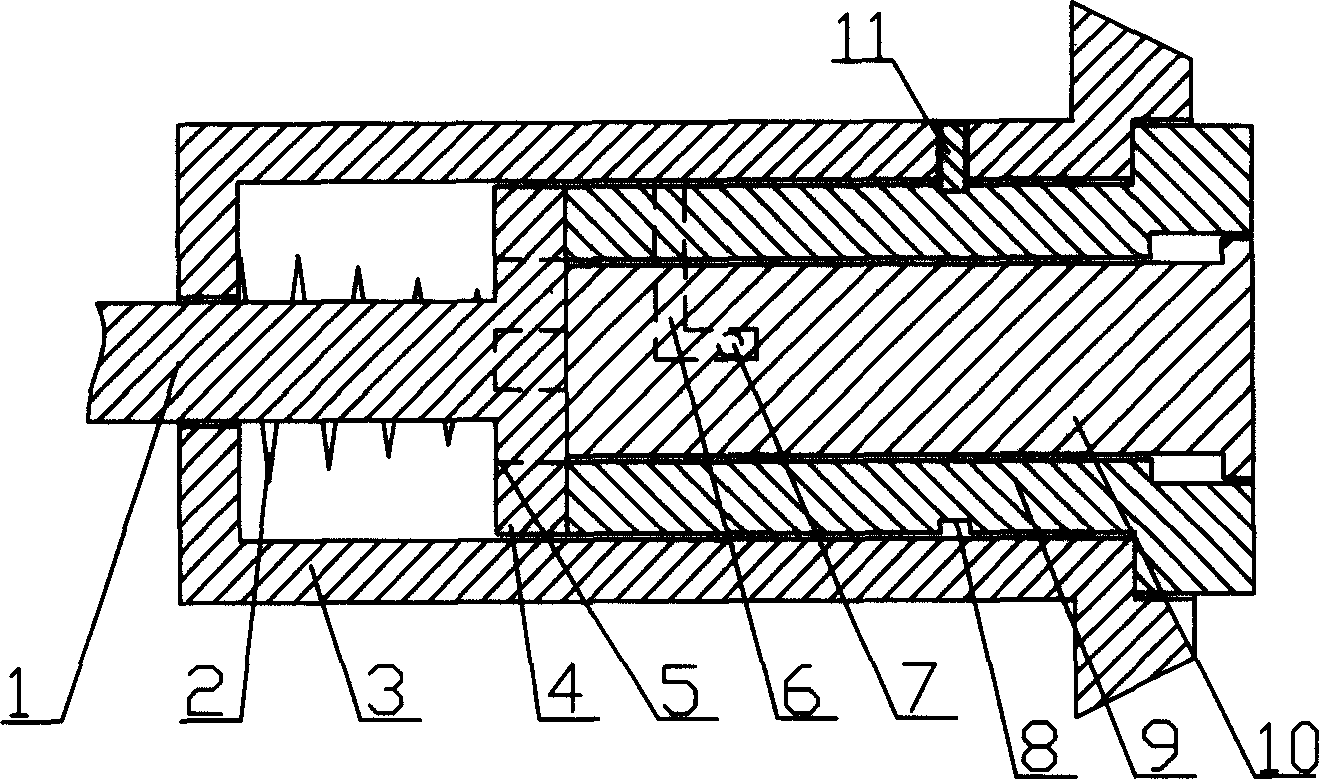

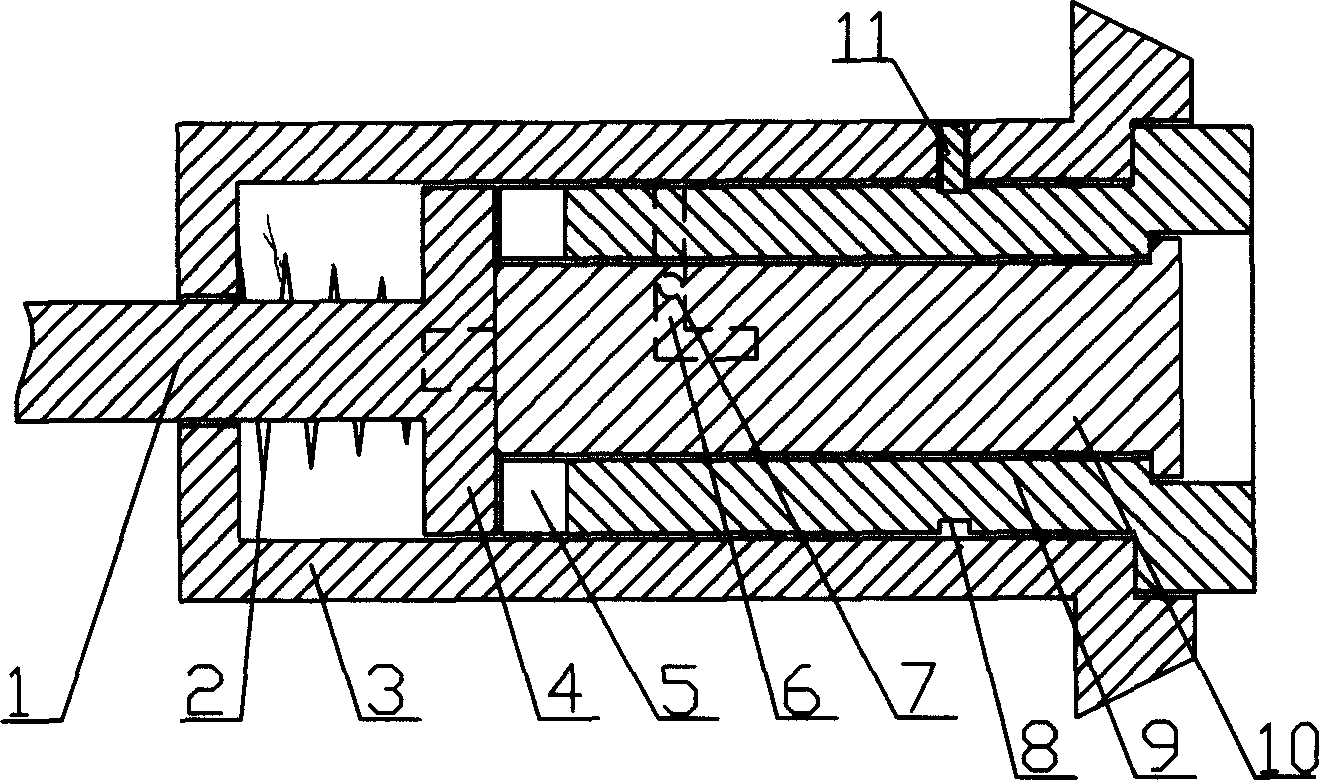

[0020] Embodiment 1: as figure 1 , figure 2 As shown, a clutch type anti-theft lock includes a lock housing 3 and a lock cylinder installed in the lock housing. The lock cylinder includes an inner lock cylinder 10 with a key socket at the outer end, and an outer lock cylinder 9 is set outside the inner lock cylinder. , the inner lock cylinder and the outer lock cylinder are slidingly assembled, that is, the inner lock cylinder can slide axially relative to the outer lock cylinder, and at the same time, the inner lock cylinder can also rotate radially relative to the outer lock cylinder. The structure of the outer lock cylinder is as follows Figure 6 , Figure 7 As shown, the outer lock cylinder is provided with an L-shaped chute 6, which can be a positive L-shaped chute or an inverted L-shaped chute. Sliding in the chute, the said lock housing is provided with a pin hole, the positioning pin shaft 11 is installed in the pin hole, and the said outer lock core is provided wi...

Embodiment 2

[0021] Embodiment 2: as image 3 As shown, the lock body of embodiment 1 is used on the combination lock, with a fixed dial on the said lock case, a rotating combination dial 14 is installed on the lock cylinder, and three belt shifting blocks are slidingly set outside the said transmission rod. The dial 12 of 13, transmission bar can slide wherein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com