Dyeing and finishing method for all-cotton high-count down-proof fabric

A technology for feather-proof fabrics and processing methods, which can be applied to fabric surface trimming, improved handle fibers, heating/cooling fabrics, etc., which can solve the problems of hard-feeling and noise in cotton high-count quilt core feather-proof fabrics, and achieve good results. Anti-drilling performance, less damage, full texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

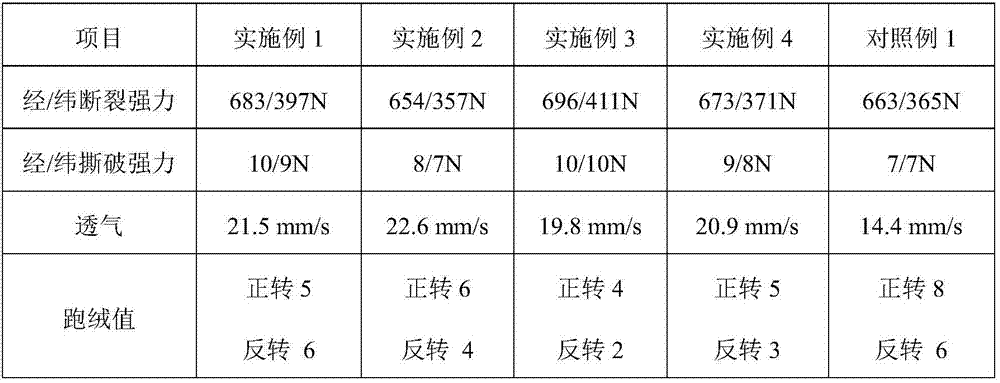

Examples

Embodiment 1

[0029] The warp and weft yarns of the fabric are all made of 100% long-staple cotton combed ring-spun yarn, the yarn count is 100S, the fabric specification is 106 / 100S*100S / 230*230, and the fabric weave is 5 pieces of 3 flying satin warp weave .

[0030]The gray cloth is sequentially subjected to biological enzyme treatment, tenter whitening, soft setting, calendering and pre-shrinking processes. First, the gray cloth is subjected to biological enzyme treatment in the overflow machine. The treatment process is 4g / L of cellulase, 2g / L of desizing enzyme, and 2g / L of scouring enzyme (the weight ratio of pectinase and lipase is 5:1). L. Penetrant 1g / L, hydrogen peroxide 1g / L, hydrogen peroxide stabilizer 1g / L, feed cloth at 40°C, heat up to 55°C at 2°C / min, heat preservation treatment time 240min. Afterwards, the temperature was raised to 95°C at 2°C / min and kept for 60 minutes. After scouring, wash with hot water at 70-80°C for 1 hour, then expand, dehydrate, dry, and roll th...

Embodiment 2

[0032] The warp and weft yarns of the fabric are all made of 100% long-staple cotton combed ring-spun yarn, the yarn count is 120S, the fabric specification is 106 / 120S*120S / 250*250, and the fabric weave is 5 pieces of 3 flying satin warp weave .

[0033] The gray cloth is sequentially subjected to biological enzyme treatment, tenter whitening, soft setting, calendering and pre-shrinking processes. First, the gray cloth is subjected to biological enzyme treatment in the overflow machine. The treatment process is cellulase 6g / L, desizing enzyme 4g / L, scouring enzyme (the weight ratio of pectinase and lipase is 7:1) 4g / L L. Penetrant 2g / L, hydrogen peroxide 1g / L, hydrogen peroxide stabilizer 1g / L, feed cloth at 40°C, heat up to 55°C at 2°C / min, heat preservation treatment time 180min. Afterwards, the temperature was raised to 95°C at 2°C / min and kept for 60 minutes. After scouring, wash with hot water at 70-80°C for 1 hour, then expand, dehydrate, dry, and roll the cloth. In ...

Embodiment 3

[0035] The warp and weft yarns of the fabric are all made of 100% long-staple cotton combed ring-spun yarn, the yarn count is 100S, the fabric specification is 106 / 100S*100S / 200*170, and the fabric weave is plain weave.

[0036] The gray cloth is sequentially subjected to biological enzyme treatment, tenter whitening, soft setting, calendering and pre-shrinking processes. First, the gray cloth is subjected to biological enzyme treatment in the overflow machine. The treatment process is 4g / L of cellulase, 2g / L of desizing enzyme, and 2g / L of scouring enzyme (the weight ratio of pectinase and lipase is 8:1). L. Penetrant 1g / L, hydrogen peroxide 1g / L, hydrogen peroxide stabilizer 1g / L, feed cloth at 40°C, heat up to 55°C at 2°C / min, heat preservation treatment time 120min. Afterwards, the temperature was raised to 95°C at 2°C / min and kept for 60 minutes. After scouring, wash with hot water at 70-80°C for 1 hour, then expand, dehydrate, dry, and roll the cloth. In the tenter pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com