Down feather leakage resistance fabric

A technology of anti-drilling down and fabrics, applied in the field of down jackets, can solve the problems of insufficient air permeability, affecting the durability of fabrics, stuffy feeling, etc., and achieve the effect of superior air permeability, anti-drilling down effect, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

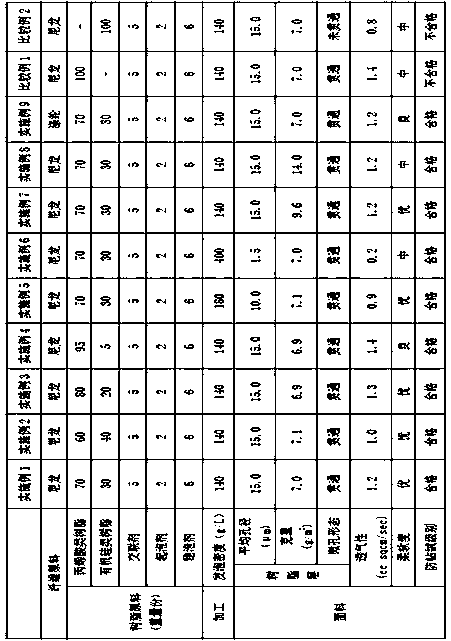

Examples

preparation example Construction

[0012] The preparation method of the anti-pinhole fleece fabric of the present invention comprises the following steps:

[0013] (1) Preparation of coating resin processing fluid:

[0014] Acrylic resin 50-90 parts by weight

[0015] Silicone resin 10-50 parts by weight

[0016] Foaming agent 1 to 5 parts by weight

[0017] Foam stabilizer 2-8 parts by weight

[0018] 1-6 parts by weight of crosslinking agent.

[0019] Among them, the cross-linking agent is to increase the cross-linking degree of the resin and improve the mechanical properties of the resin. It is preferred to use isocyanate or melamine cross-linking agent; Salts of alkyl chains; foam stabilizers are used to control the bubble stability of the resin, preferably fatty acid salts.

[0020] (2) Next, foam the above-mentioned mixed resin processing fluid; wherein the speed of the constant speed mixer used for foaming processing is 500-3000r / min, and the time is 10-40min.

[0021] (3) Coating the down jacket f...

Embodiment 1

[0045] (1) Preparation of coating resin processing fluid:

[0046] Acrylic resin 70 parts by weight

[0047] Silicone resin 30 parts by weight

[0048] Cross-linking agent 5 parts by weight

[0049] Foaming agent 2 parts by weight

[0050] Foam stabilizer 6 parts by weight

[0051] The above components are firstly mixed, and then the mixed solution is subjected to foaming and stirring treatment, so that the foaming density reaches 140 g / L, and the coating resin processing fluid is obtained.

[0052] (2) Next, on the coating machine, apply the above-mentioned coating resin processing fluid at a grammage of 34g / m 220D nylon woven fabric, and then dried in a continuous drying oven (60°C → 130°C) to form a film, with a coating weight of 7.0g / m 2 Obtain product, its performance is shown in Table 1.

Embodiment 2

[0054] The amount of acrylic resin used is 60 parts by weight; the amount of silicone resin is 40 parts by weight, and the rest are the same as in Example 1 to obtain the anti-drilling fleece fabric, and its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com