Down filling technology for garment processing

A technology of clothing and craftsmanship, which is applied in the field of down filling technology for garment processing, can solve problems such as difficult to effectively solve the problem of down running, low production and processing efficiency, and difficult interlayer extraction, so as to prevent down running, reduce drilling down, and withstand multiple times The effect of washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

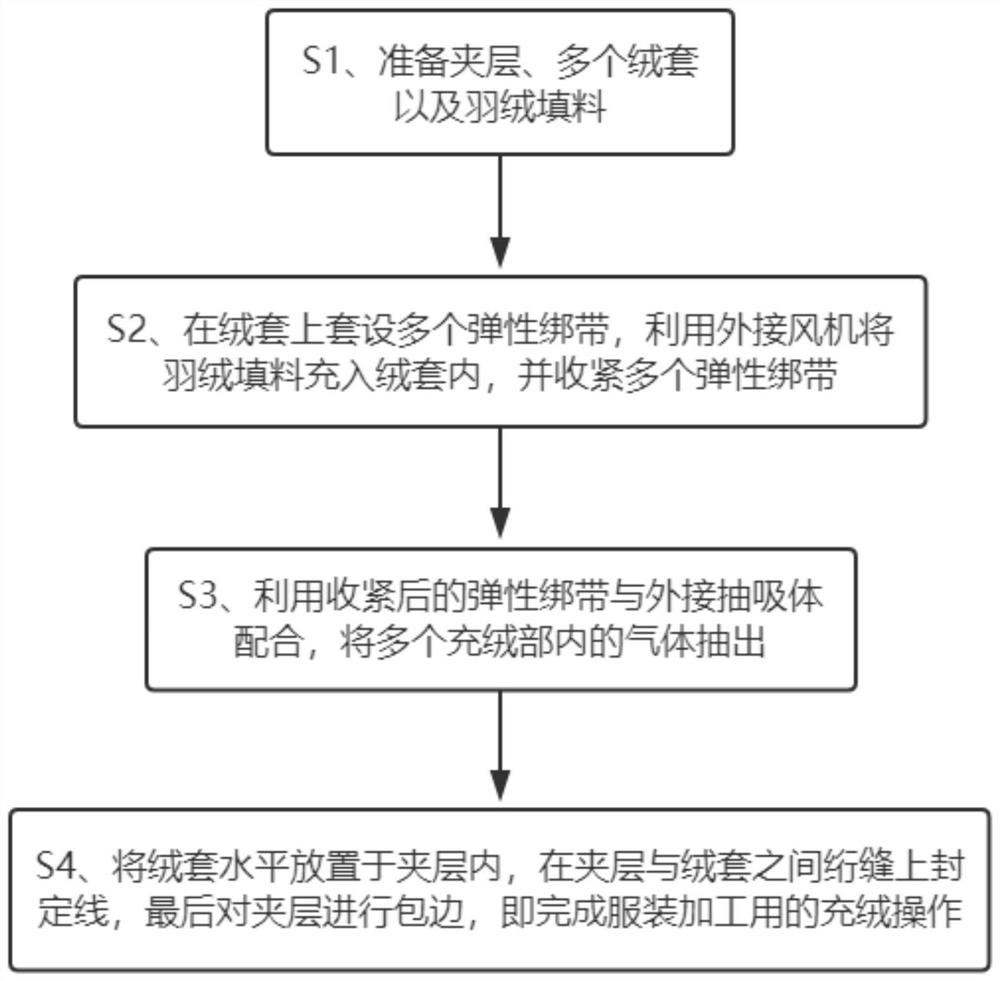

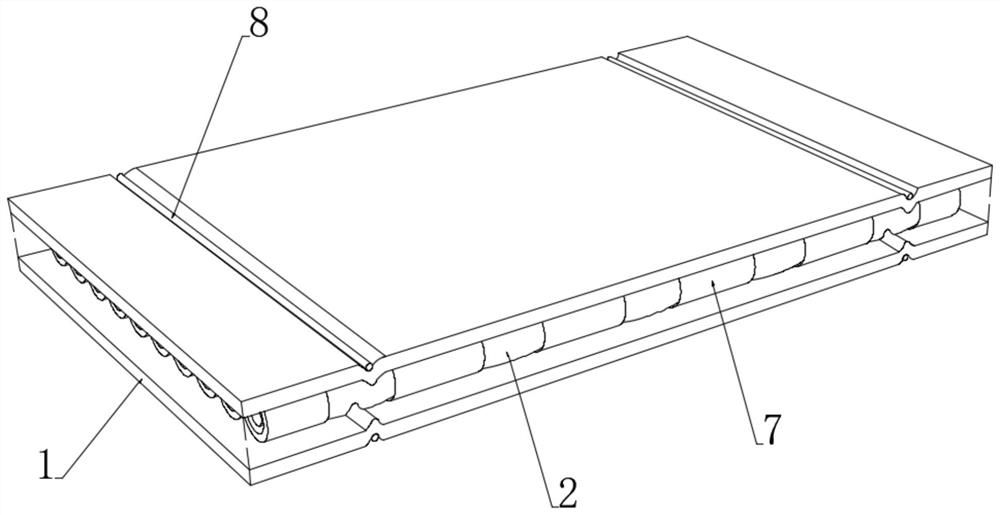

[0050] see Figure 1-4 and Figure 7-10 , a down filling process for garment processing, comprising the following steps:

[0051] S1, preparing the interlayer 1, multiple down covers 2 and down filler 6;

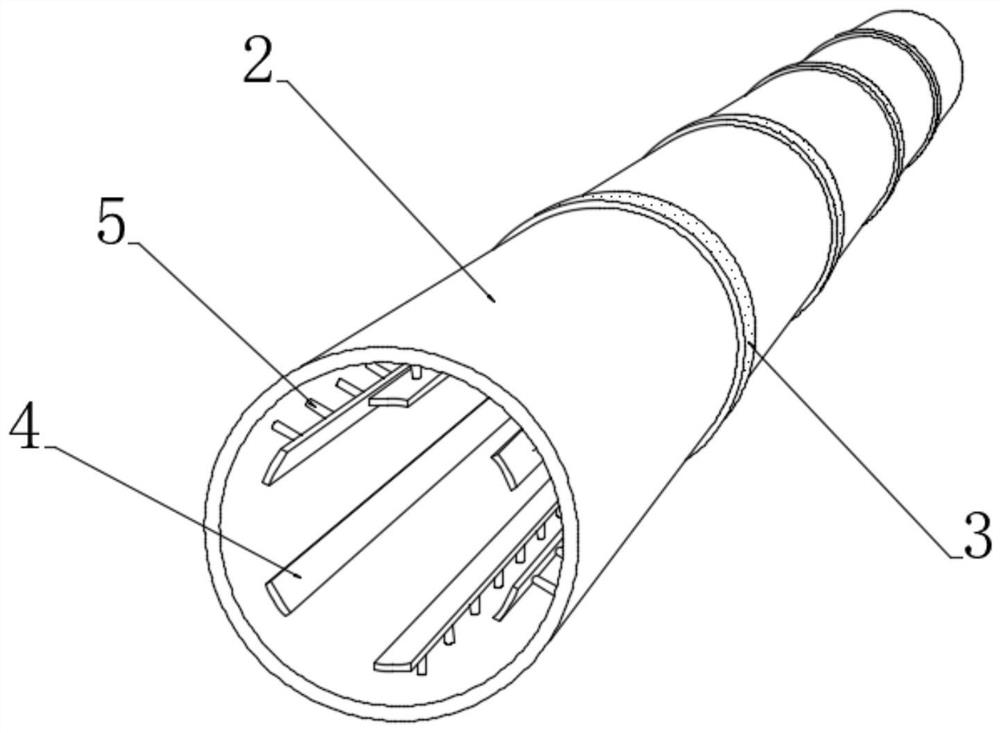

[0052] S2. Set a plurality of elastic straps 3 at equal intervals along the horizontal direction on the fleece cover 2, use an external fan to fill the down filler 6 into the fleece cover 2, and tighten the multiple elastic straps after the fleece cover 2 is filled. Belt 3, a plurality of elastic straps 3 separate the fleece cover 2 into multiple fleece-filled parts;

[0053] S3. Use the tightened elastic strap 3 to cooperate with the external suction body to extract the gas in the multiple down filling parts;

[0054] S4. Place the velvet cover 2 processed in S3 horizontally in the interlayer 1, quilting the upper and lower sealing lines 8 on the left and right sides of the interlayer 1 respectively, and the sealing line 8 is connected with the velvet cover 2 distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com