Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Whiteness stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resisting flame-retardant fiberglass product for industrial heat preservation and preparation method thereof

Owner:NANJING UNIV OF INFORMATION SCI & TECH

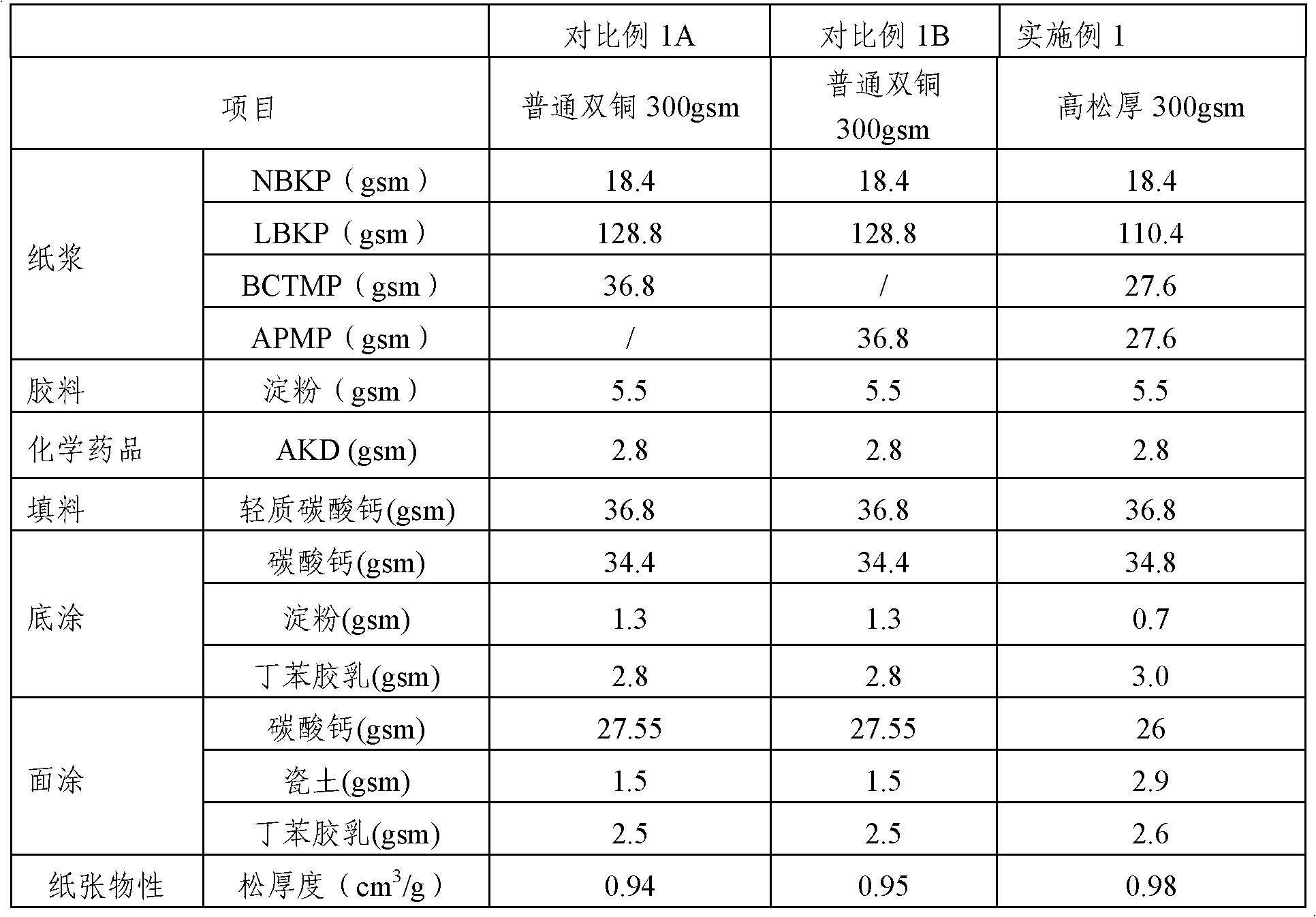

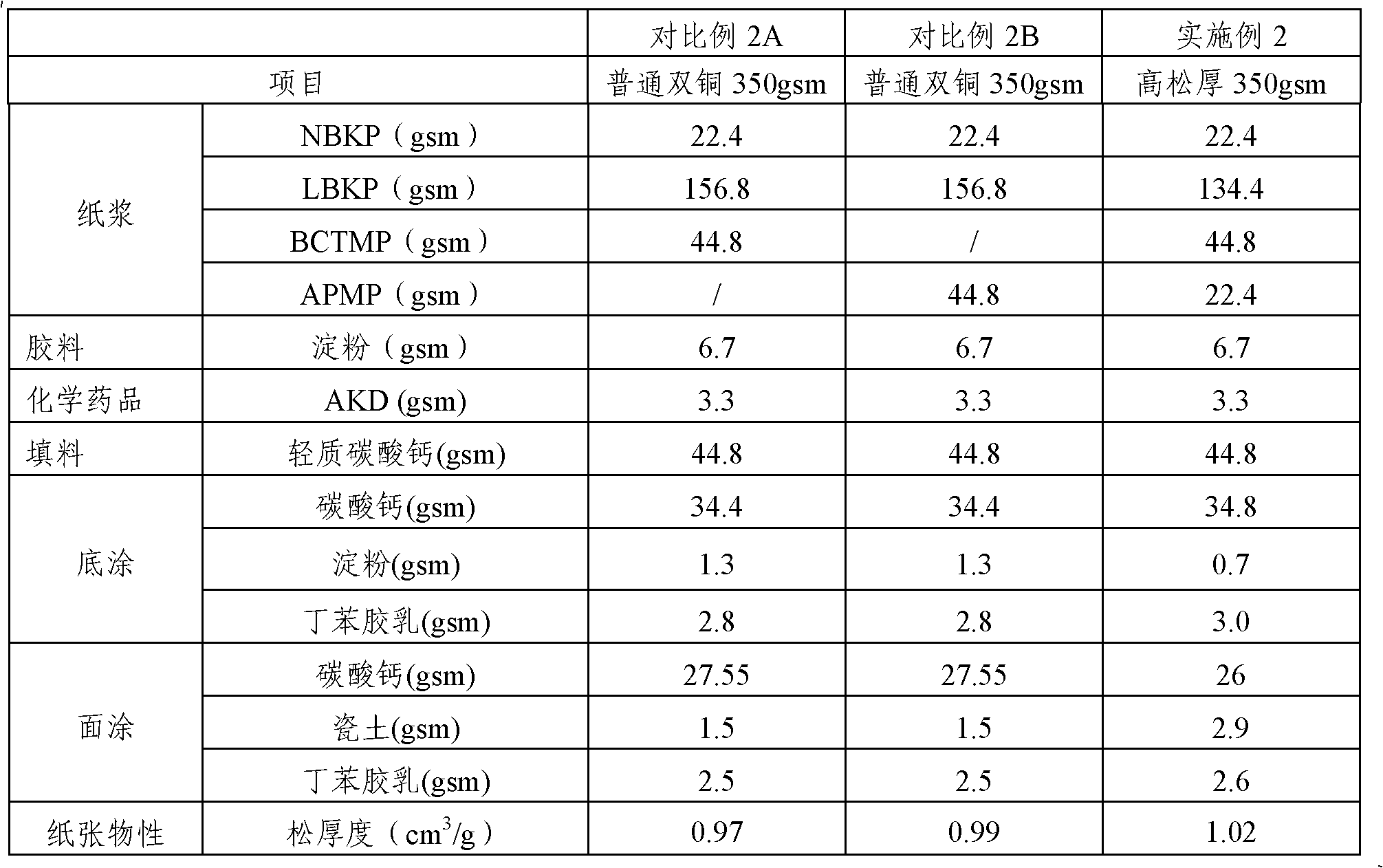

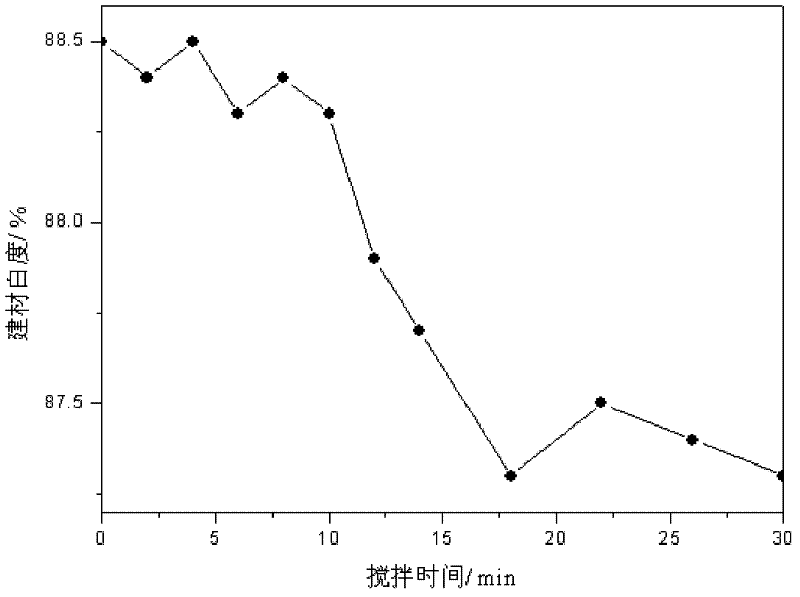

Paper pulp and high-bulk energy-saving environment-friendly card prepared from same

ActiveCN102535240AStable qualityAvoid overproductionCoatings with pigmentsSynthetic cellulose/non-cellulose material pulp/paperGramHardwood

The invention discloses paper pulp and a high-bulk energy-saving environment-friendly card prepared from the same. The paper pulp is prepared from the following components in percentage by weight: 1 to 10 percent of bleached sulfate softwood pulp, 30 to 70 percent of bleached sulfate hardwood pulp, 20 to 50 percent of chemithermomechanical pulp, and 10 to 30 percent of alkaline peroxide mechanical pulp. The invention also provides the copperplate card prepared from the paper pulp and other components. The paper made with the paper pulp is high in bulk, the gram weight of the paper is effectively controlled to be in a certain range, the paper pulp is prevented from being put into production excessively, and the defibrination energy consumption of a paper machine is reduced correspondingly, so that the effects of environment friendliness and energy saving are effectively achieved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Non-radiation ceramic tile with high whiteness and manufacturing technique thereof

The invention discloses a ceramic tile with a high whiteness and no radiation as well as the manufacturing method thereof. The weight percents of the main raw materials of the ceramic tile is: 15-60 wt.% of burning talcum, 15-30 wt.% of feldspar, 5-30 wt.% of porcelain sand, 20-28 wt.% of black mud. The steps of manufacturing method is as follows: (1) calcining the talcum; (2) the manufacturing process is: raw materialsbatchingball millingremoving zirconiumspraying and millingmouldingdryingpenetratingburningpolishing; (3) doing a strict anti-pollution treatment after polishing. The calcining temperature of the talcum is: 1200 DEG C; the calcining temperature of the ceramic tile is 1210-1230 DEG C; burning period is: 60-80 minutes; whiteness is: about 80 DEG. The invention firstly does a pre-burning treatment to the talcum material in 1200 DEG C, thus it manages its sheet structure and removes volatile with a high temperature. The disposed material is without greasy texture and the dosage will not influence the products molding.

Owner:GUANGDONG WINTO CERAMICS

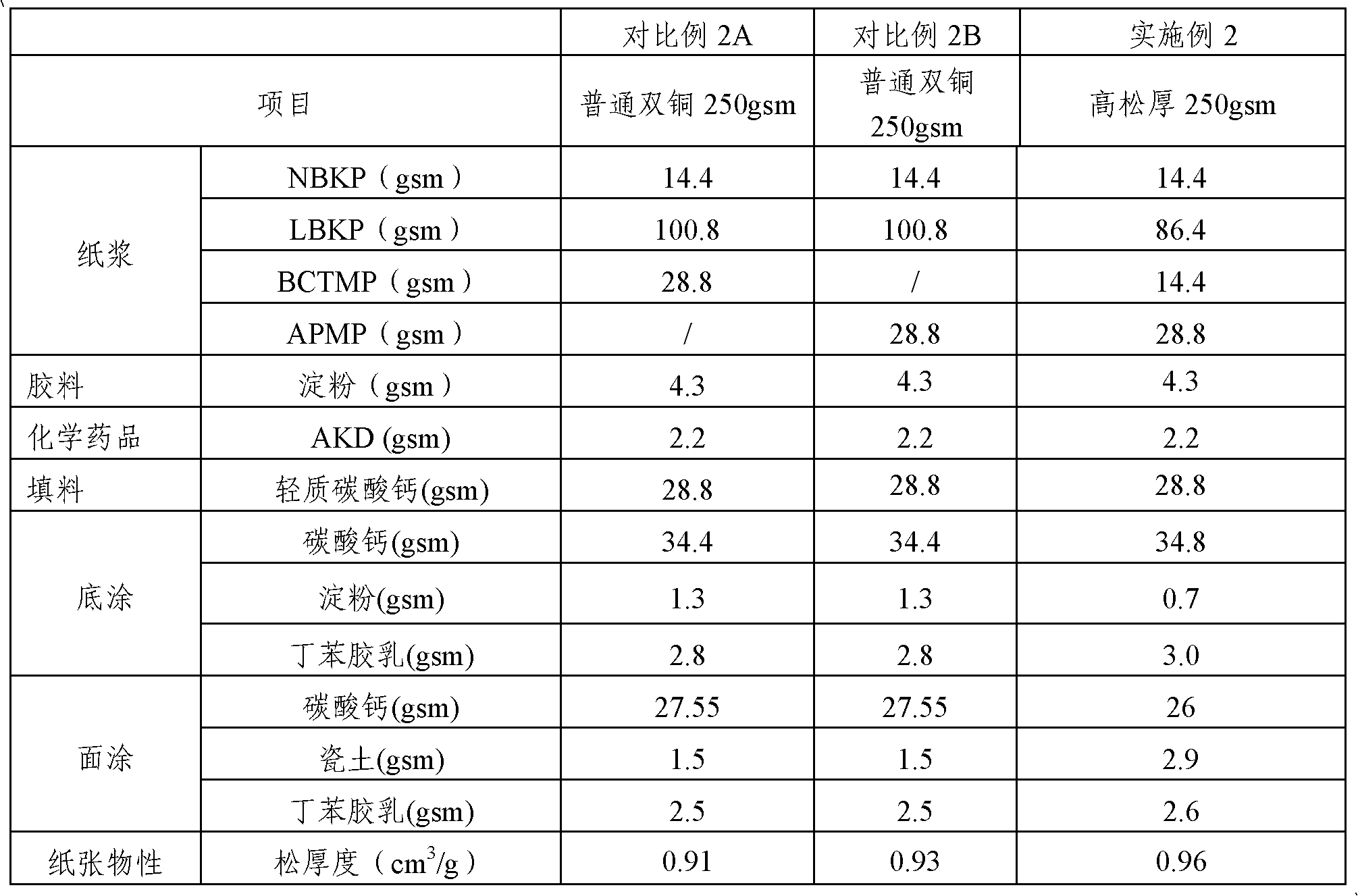

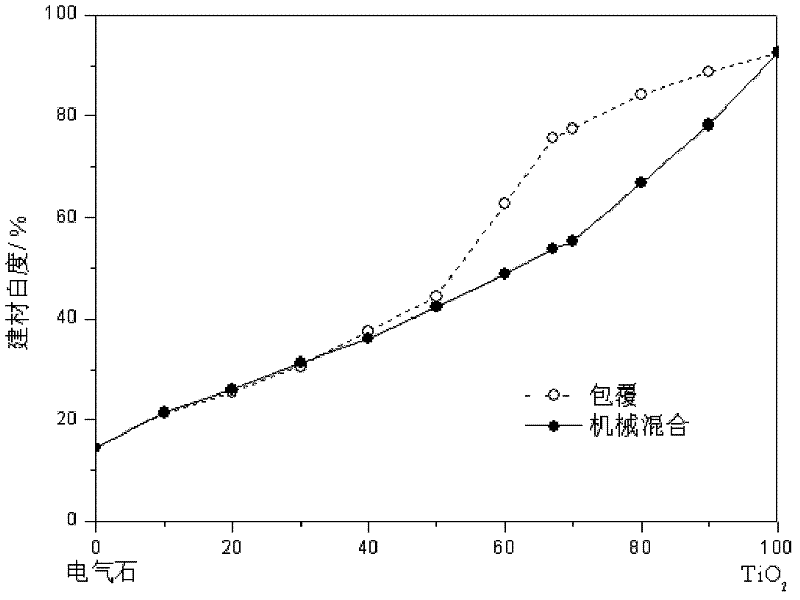

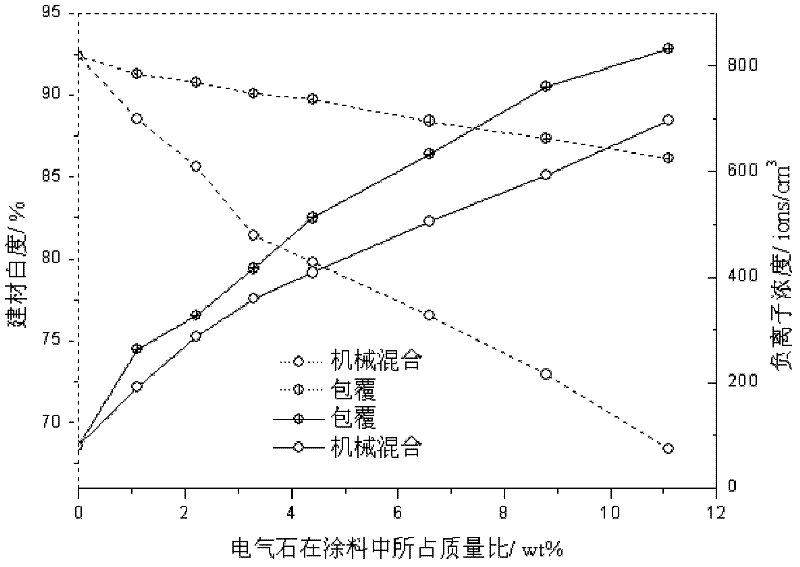

High whiteness tourmaline negative ion powder and coating process

InactiveCN102391690AStrong ability to release negative ionsThoroughly adsorb and crack harmful gases such as formaldehydeCoatingsPigment treatment with macromolecular organic compoundsWater basedPhysical chemistry

The invention relates to tourmaline negative ion powder with high performance and a coating process. The tourmaline negative ion powder comprises tourmaline, a coupling agent and a coating agent, wherein the occupied weight ratio of the tourmaline is 25-35%, the occupied weight ratio of the coupling agent is 1-3%, and the occupied weight ratio of the coating agent is 62-74%. The tourmaline negative ion powder is obtained by coating, whitening and modifying the tourmaline and can be used as stuffing powder for preparing a functional coating; and the tourmaline negative ion powder is directly doped in a water-based coating or is combined with a film forming material, pigment, an addition agent, a solvent agent and the like to prepare the functional coating. After forming the coating, the tourmaline negative ion powder can release lots of negative ions for long time, adsorbs and degrades indoor harmful gases, settle dust in the air and effectively improves indoor housing environments.

Owner:JIANGXI UNIV OF SCI & TECH +1

Preparation method of ball clay for high-grade sanitary appliance

InactiveCN101844913AWhiteness stabilityHigh strengthCeramic materials productionClaywaresSocial benefitsLower grade

The invention relates to a preparation method of ball clay for high-grade sanitary appliance, which is characterized in that blackmud, plaster and kaolin are used as raw materials for preparing ball clay used by the high-grade sanitary appliance; the size comprises according to the percentage by volume: 10-60% of blackmud, 10-20% of plaster and 20-80% of kaolin; the preparation method overcomes the defect which is brought about by changeable raw material components caused by organic impurity and sand contents of low-grade ball clay; the formed ball clay has stable whiteness, intensity and stickiness and good slip-casting mobility, can be widely applied to high-grade ceramic industries and is the vanguard and demonstration in the process of national ceramic raw material standardizing, and has obvious economic benefic and social benefit.

Owner:广州市花都区梯面金鹏高岭土原料厂 +1

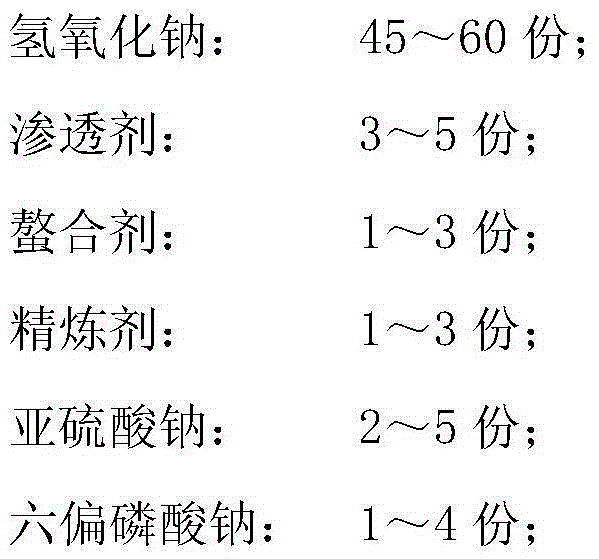

Dyeing and finishing method for linen for child's vest

InactiveCN105155250AStrong water absorptionHigh whitenessFabric breaking/softeningSingeingImpuritySoftening

A disclosed dyeing and finishing method for linen for a child's vest comprises the following steps: preparing original cloth, singeing and rolling with an oxalic acid solution, desizing, scouring, performing chlorine bleaching, mercerizing, performing pad dyeing, softening, tentering, and pre-shrinking. According to the method, the fabric needs scouring for further removing residual impurities after being subjected to desizing, and thus the fabric obtain good water-absorbing property and certain whiteness, and is beneficial for dyeing and other post processing.

Owner:俞雄飞

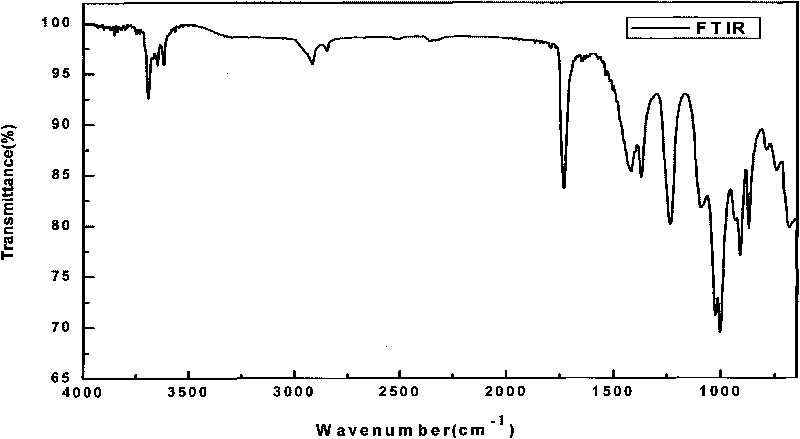

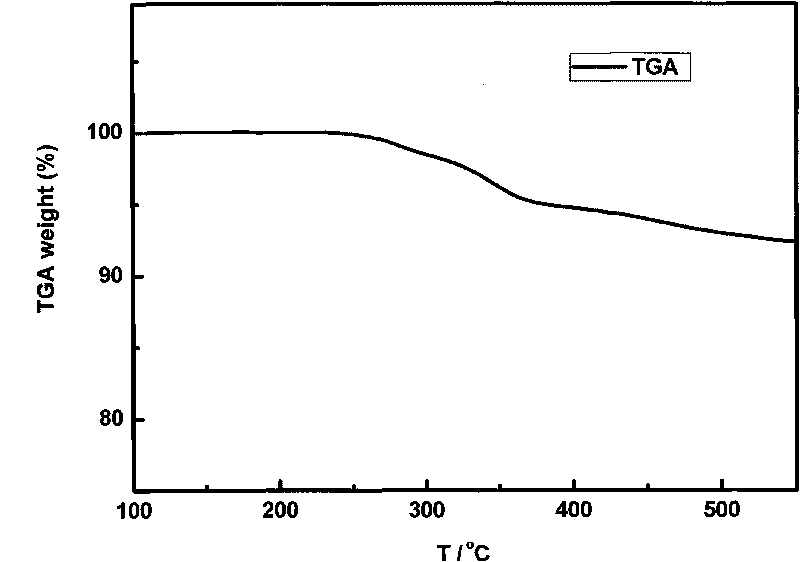

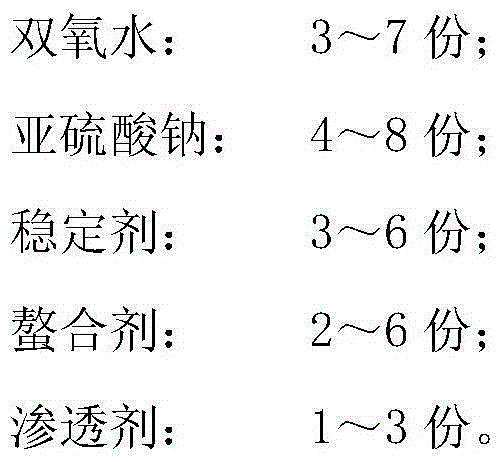

Method for extracting Sanzan gum from fermentation liquor and product thereof

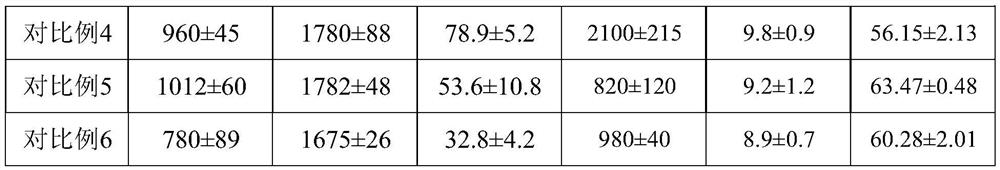

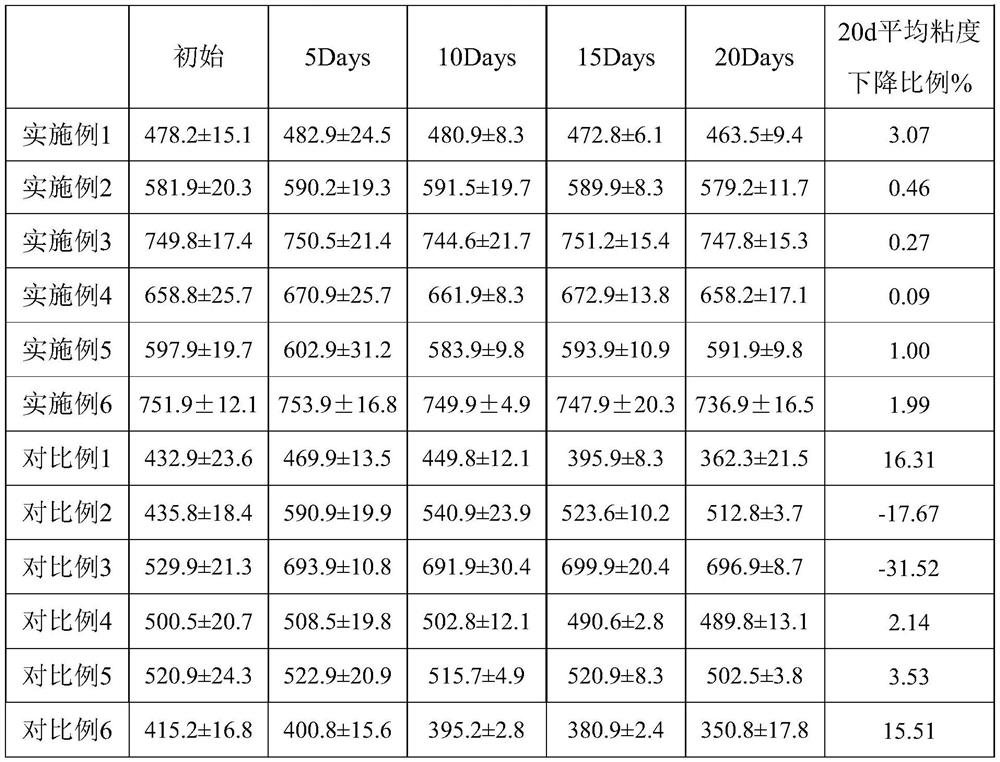

ActiveCN113248629AReduce the total number of coloniesGood salt solubilityBiofuelsBiotechnologyAlcohol ethyl

The invention relates to the technical field of microbial polysaccharide extraction, and particularly discloses a method for extracting Sanzan gum from fermentation liquor and a product thereof. The method for extracting Sanzan gum from the fermentation liquor comprises the following steps: treating the fermentation liquor with neutral soluble salt, adding ethanol to enable the concentration of ethanol in the system to reach 30-40%, adjusting the pH value of the system to 1.0-3.0, carrying out separation operation, soaking the obtained crude product with ethanol to obtain a material system with the ethanol concentration of 72-85%, and then adjusting the pH value of the material system to 6.0-8.0, ensuring that the concentration of ethanol in the material system is 70-82%, and separating again. The product obtained by the invention has the advantages of high gel strength, high product viscosity, low total number of bacterial colonies, high product percent of pass and the like. Meanwhile, the obtained mother liquor can be recovered and reused after being distilled, so that the method has very high practicability and is beneficial to industrial production.

Owner:MEIHUA BIOTECH LANGFANG CO LTD

Binding agent for producing road markings ready quickly for traffic

ActiveUS20120107493A1Rapidly to withstand passageHardens quicklySingle unit pavingsPavement lightsWaiting periodAerospace engineering

The present invention comprises a novel formulation for marking travel lanes, such as roads, which following the application can be reopened for traffic after a waiting period that is shortened as compared to the prior art.

Owner:ROHM GMBH

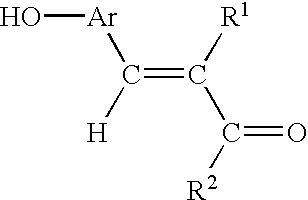

Process for stabilizing the whiteness of lignin-containing fibrous materials, stabilizer composition and fibrous materials stabilized with this

InactiveUS20020174491A1Whiteness thus stabilizeSimple materialAgeing prevention agents additionPhysical treatmentDouble bondAmino acid

Lignin-containing fibrous materials, in particular paper and card, are treated with whiteness stabilizers for the purpose of reducing light-induced yellowing. The whiteness stabilizer are (i) thiols with at least one additional hydrophilic group from the series consisting of OH, NH2, NHR1m NR1R2, COOH, SO3H and PO3H2 and an amino acid / peptide structure (ii) thiols with a CC double bond (iii) or heteroaromatic thiols and (iv), heteroaromatic disulfides or polysulfides. HALS light stabilizers and / or UV stabilizers are advantageously additionally employed. The stability is increased further by a TiO2-containing coat on the fibrous material. Stabilzer compositions and fibrous material stabilized according to the invention, containing a whiteness stabilizer of group (i) to (iv) are also disclosed.

Owner:DEGUSSA AG

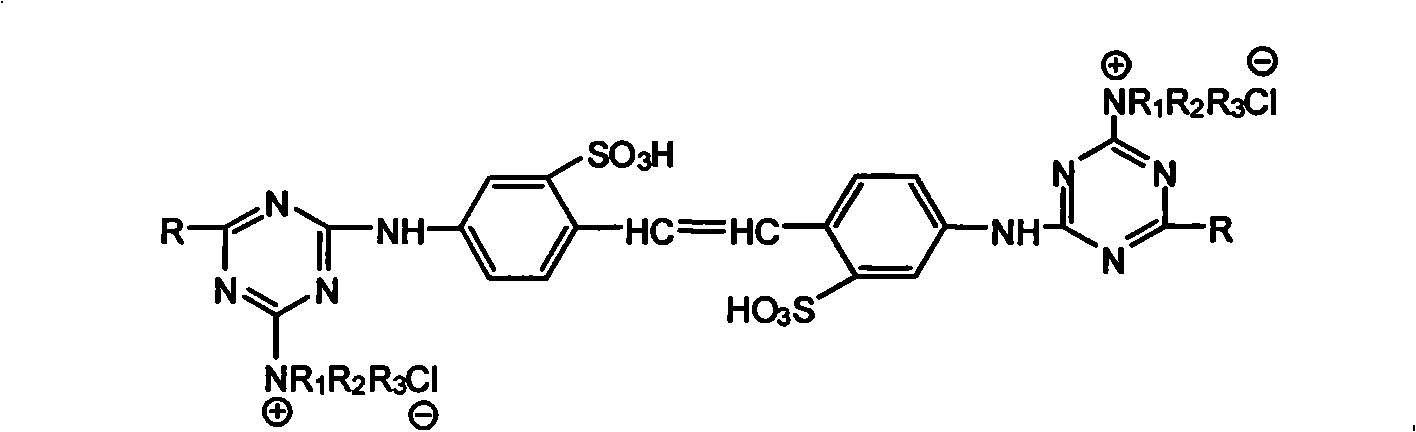

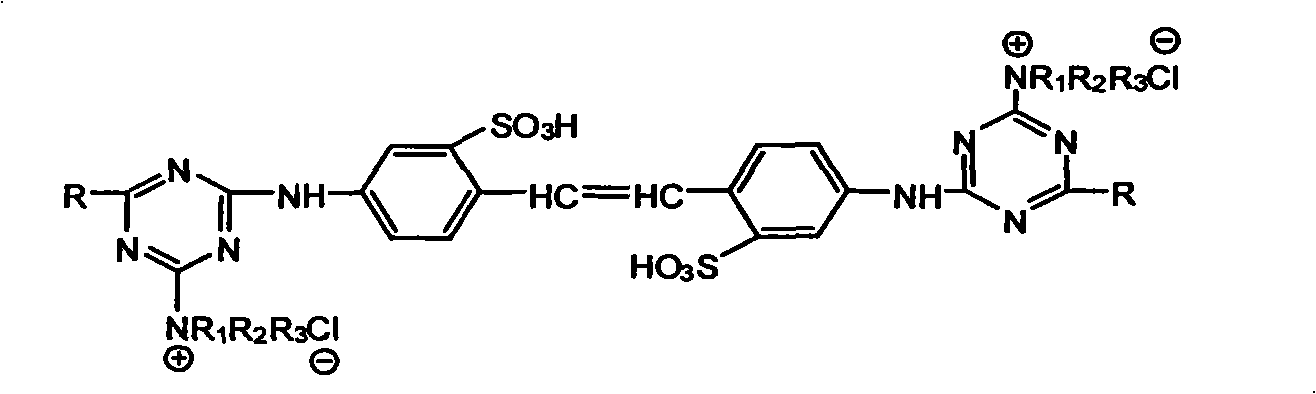

Amino-chloro-benzene-containing quaternary ammonium salt type fluorescent whitener, synthesizing method thereof and applications

InactiveCN101307031AWhiteness stabilityIncrease the scope of applicationOrganic chemistryDetergent dyesPhenyl groupCyanuric chloride

The invention relates to a series of fluorescent whitening agents containing amino chlorophenyl group quaternary ammonium salt, as well as synthesis and an application of the same. The series of fluorescent whitening agents is mainly applied to papermaking paint printing ink and textile. The synthesis adopts the following steps that: a. cyanuric chloride reacts with amino-chloro-benzene at a temperature between 0 and 5 DEG C for 2.5 h, with pH value controlled to be between 1.8 and 2.1, so as to synthesize one-step condensation product; b. the one-step condensation product reacts with 4, 4'-diaminodiphenylethylene-2, 2'-disulfonic acid at a temperature between 40 and 45 DEG C for 2.5 h, with pH value controlled to be between 3.5 and 4.5, so as to synthesize two-step condensation product; c. the two-step condensation product reacts with a series of tertiary amine compounds at a temperature between 78 and 85 DEG C for 3.0 h, with pH value controlled to be between 7.8 and 8.5, so as to synthesize a series of triazine-DSD acidic fluorescent whitening agents containing amino chlorophenyl group quaternary ammonium salt. Application results show that: the fluorescent whitening agents can be used under neutral / alkaline conditions, and has higher dye uptake rate and better whitening effect under acidic conditions.

Owner:SHANDONG UNIV

Preparation method of phenolic yellowing resistant white chinlon non-ironing fabric

PendingCN112127142AFeel goodDoes not affect the fastness to phenol yellowingLight resistant fibresWrinkle resistant fibresTextile technologyDyeing

The invention belongs to the technical field of textiles, and particularly relates to a preparation method of a phenolic yellowing resistant white chinlon non-ironing fabric. Desizing, pre-tentering,dry shaping, non-ironing, padding, jig dyeing, tentering and pre-shrinking are performed to obtain the fabric, wherein an anti-yellowing finishing agent is added in the pre-tentering process, the non-ironing temperature is 155-165 DEG C, and an anti-phenolic yellowing agent is added in the jig dyeing process. Compared with the conventional white chinlon fabric, the white chinlon non-ironing fabricobtained by the method adopts a high-temperature non-ironing process, has the characteristics of good non-ironing property and washability, and is padded and bleached by using an Ostbook stacking method according to the whiteness requirement, so that the stability of the whiteness of the fabric is improved. The anti-phenolic yellowing agent is added in the jig dyeing process, and a weak cation softener with small influences on yellowing is used for tentering, so that the hand feeling of the fabric is improved, the anti-phenolic yellowing fastness of the fabric is not influenced, the anti-phenolic yellowing fastness of the fabric reaches the grade 4 or above, and the requirement for high quality of high-grade fabrics can be met.

Owner:LUTAI TEXTILE

Production technology of white top liner

ActiveCN105735033AReduce dosageReduce consumptionSecondary cellulose fibresPaper-making machinesFiberSurface layer

The invention relates to a production technology of a white top liner. The technology comprises the following steps that 1, ONP pulp is prepared, water is added to fibers obtained from first flotation of the ONP pulp, bleaching is conducted, first ONP pulp is obtained, water is added to fibers obtained from second flotation of the ONP pulp, bleaching is conducted, second ONP pulp is obtained, concentration is conducted on ONP pulp of two times of flotation, and third ONP pulp is conducted; 2, DMOW pulp is conducted, water is added to fibers obtained from first flotation of the DMOW pulp, bleaching is conducted, first DMOW pulp is obtained, water is added to fibers obtained from second flotation of the DMOW pulp, bleaching is conducted, second DMOW pulp is obtained, concentration is conducted on DMOW pulp of two times of flotation, and third DMOW pulp is conducted; 3, the first DMOW pulp, the first ONP pulp and original wood pulp are mixed, a surface layer is obtained after the mixture flows to paper-making meshes, the second DMOW pulp and the second ONP pulp are mixed, a bottom layer is obtained after the mixture flows to the paper-making meshes, the third DMOW pulp, the third ONP pulp and OCC pulp are mixed, and a core layer is obtained after the mixture flows to the paper-making meshes.

Owner:JIANGSU LEE & MAN PAPER MFG

Pulping process for grinding wood pulp of cotton wood by mechanical abrader

InactiveCN101338532AReduce consumptionReduce power consumptionChemical/chemomechanical pulpFibrous raw materialsDifferential pressureWood grinder

The invention discloses a cotton wood stone ground wood pulping process comprising the following steps of: (1) log sawing and skinning; (2) jordaning with alkali in a wood grinder; (3) screening by a pressure screen; (4) screenings jordaning with alkali in a conical mill; and (5) hydrogen peroxide bleaching. The invention is characterized in that: the wood grinder grindstone of the step (2) adopts bush roll with 4 mesh by primary burring; in the screening process by the pressure slot screen of the step (3), the pulp intake pressure is 0.2-0.4 MPa, the differential pressure is 0.02-0.07 MPa, the pulp intake consistence is 2.5-4.5%, the screenings output volume is 22-35%, the thickness of the screen cut is 0.15-0.35 mm; sodium hydroxide is added in the conical mill of the step (4) to grind screenings, wherein the consumption of the sodium hydroxide is 0.6-0.8% (based on weight percent of oven dry stock), the alkali liquor is added in the pulp intake tank of the conical mill with 40-50 g / l of the alkali liquor concentration, 3.1%-4.54% of jordaning consistency, 0.2-0.3 MPa of jordaning pressure, accordingly, the beating degree of the pulp ground by the conical mill can be increased by 8-12 DEG SR. The pulping process of the invention has advantages of high yield, less pollution, low cost, and the obtained pulp is applicable for paper with various specifications such as pigment offset paper, low weight paper, card paper, color newsprint paper, or the like.

Owner:YUEYANG FOREST & PAPER CO LTD

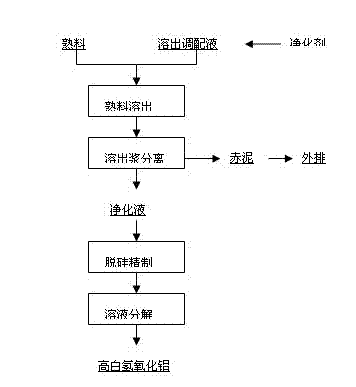

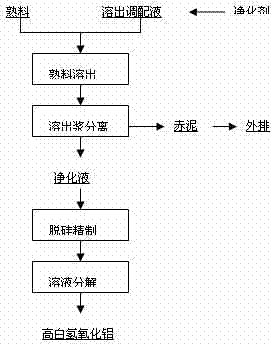

Production method of high-whiteness aluminum hydroxide

InactiveCN102351228AEfficient removalWhiteness stabilityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideDecomposition

The invention discloses a production method of high-whiteness aluminum hydroxide. The production method comprises the following steps of crushing bauxite, carrying out proportioning, sintering at a high temperature, adding the products obtained by sintering into a digestion blending solution for digestion to obtain a sodium aluminate solution, and carrying out silicon removal purification and decomposition of the sodium aluminate solution to obtain an aluminum hydroxide solution, wherein the digestion blending solution contains a cleaning agent. In the invention, the cleaning agent added during alumina clinker digestion can react with heavy metal ions in alumina clinkers to produce precipitates in alumina clinker digestion, so that heavy metal ion impurities in the sodium aluminate solution are removed effectively; and the purified sodium aluminate solution is subjected to silicon removal purification and decomposition. Aluminum hydroxide obtained by the production method has stable whiteness of 94+ / -1%. The production method can improve effectively aluminum hydroxide product whiteness, can stabilize aluminum hydroxide product quality, has a simple process flow, is easy for operation, and has obvious effects.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

A kind of preparation technology of vinegar grade bamboo pulp

ActiveCN103669064BReduce corrosionCorrosion reachesPulp bleachingPulping with inorganic basesSulfateControllability

The invention discloses a preparation process of an acetified bamboo pulp. The process comprises the steps of preparing bamboos, cutting the bamboos, washing the bamboos, pre-hydrolyzing the bamboos, performing soda boiling, washing, screening and bleaching. The steps are characterized in that according to ratio requirements, sinocalamus affinis is more than or equal to 50%, besides, bambusa intermedia and oligostachyum lubricum can be used, and other bamboos can not be used; steam and water are adopted as one of media for pre-hydrolyzing, a sulfate replacement cooking technology is adopted for soda boiling, and an O-D0-EP-D1-Q-P process flow is adopted for bleaching. The yield of the pulp obtained by using the process disclosed by the invention is more than or equal to 32%, the content of alpha cellulose is more than or equal to 96%, the content of pentosan is less than or equal to 5.0%, the degree of polymerization is more than or equal to 800, the whiteness is more than or equal to 88% of ISO (international standardization organization), and the content of an acetone extract is less than or equal to 0.1%, so that the requirements for the acetified bamboo pulp can be met. The preparation process of the acetified bamboo pulp has the characteristics of small corrosion to production equipment, low energy consumption, environmental friendliness, stable quality, safety in production, stability, controllability and low cost, and can easily realize large-scale industrial production.

Owner:泰盛(江西)生活用品有限公司

Preparation method for bamboo wood dissolving pulp

InactiveCN102352572BHigh strengthIncrease productionCellulose material pulpingDissolving pulpIndustrial engineering

The invention belongs to the technical field of bamboo wood dissolving pulp, and particularly relates to a preparation method for the bamboo wood dissolving pulp, which comprises the following preparation steps: (a) preparing a material; (b) cooking; (c) screening; (d) washing; (e) bleaching; and (f) manufacturing paper with the pulp. By adopting the preparation method for the bamboo wood dissolving pulp, the production efficiency and the product quality can be improved, simultaneously, the energy consumption, the chemical consumption and the pollution load are reduced, and the prepared bamboo wood dissolving pulp has high quality and high quality.

Owner:CHONGQING LEE & MAN PAPER MFG

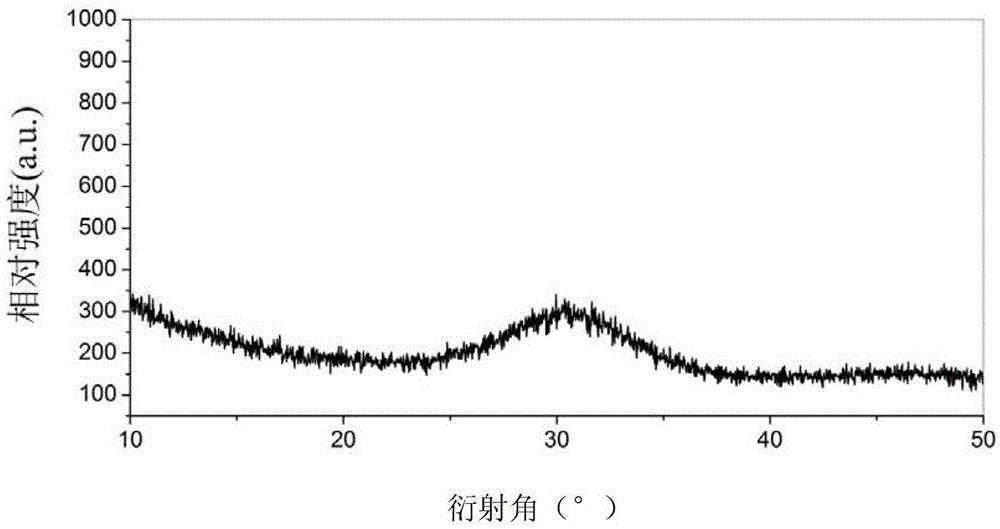

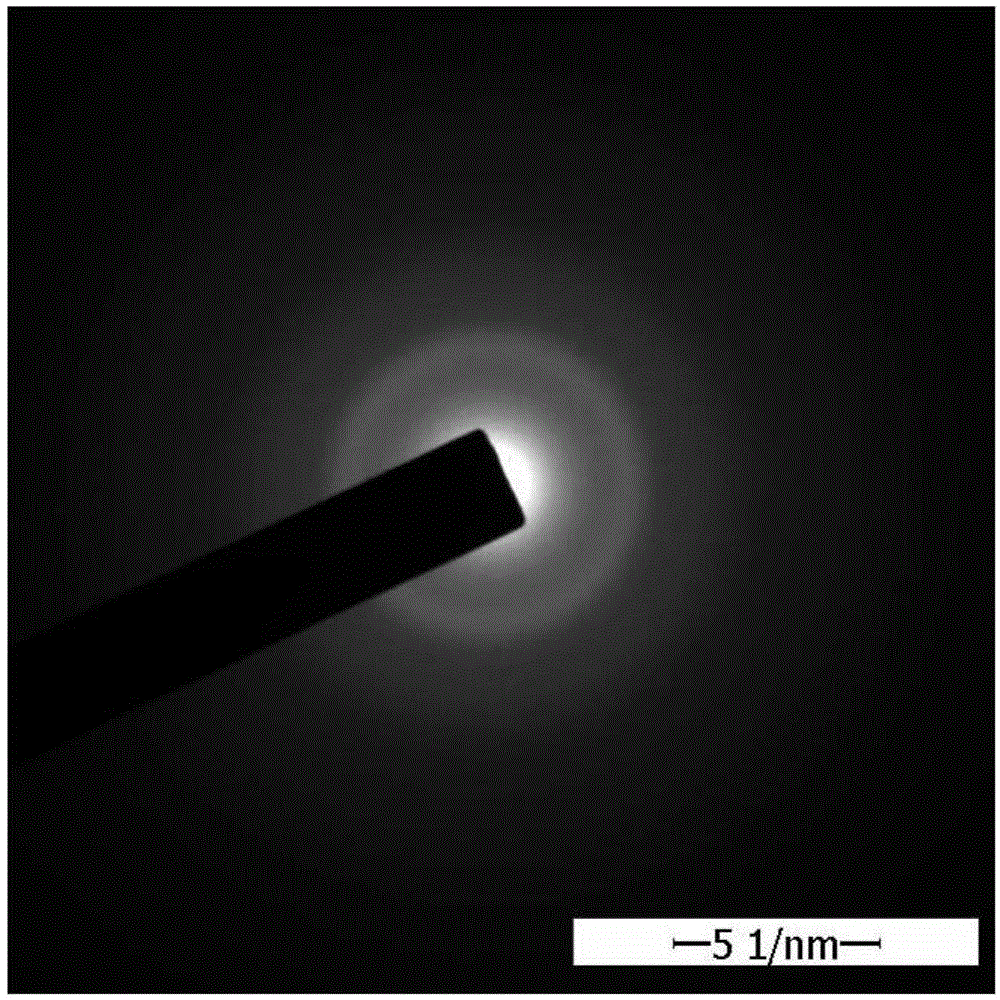

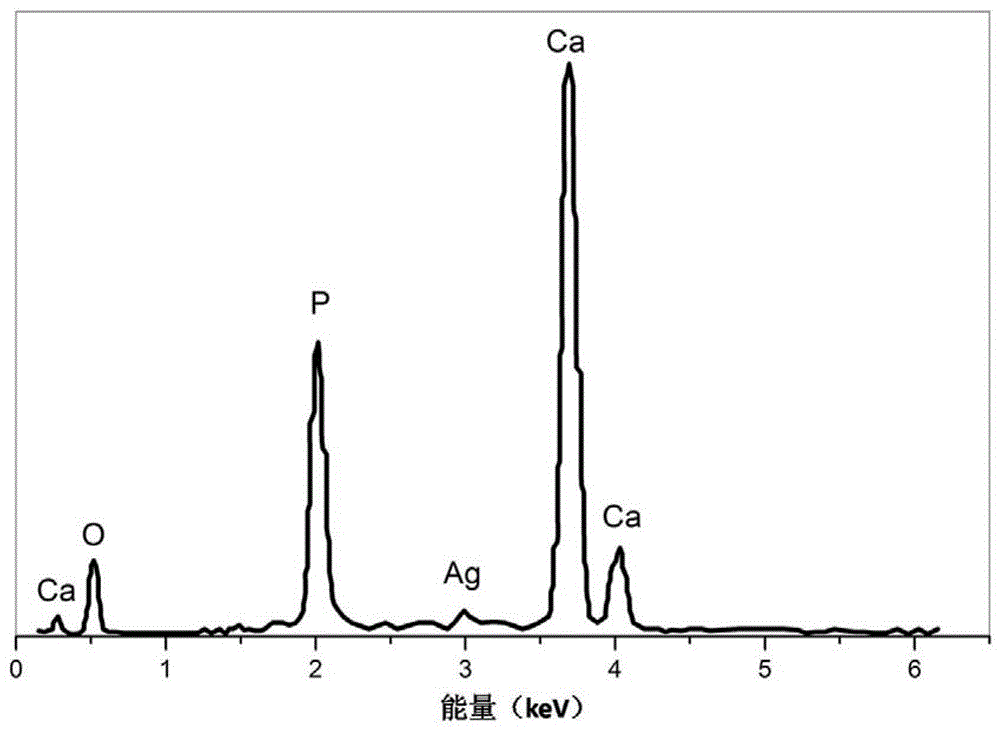

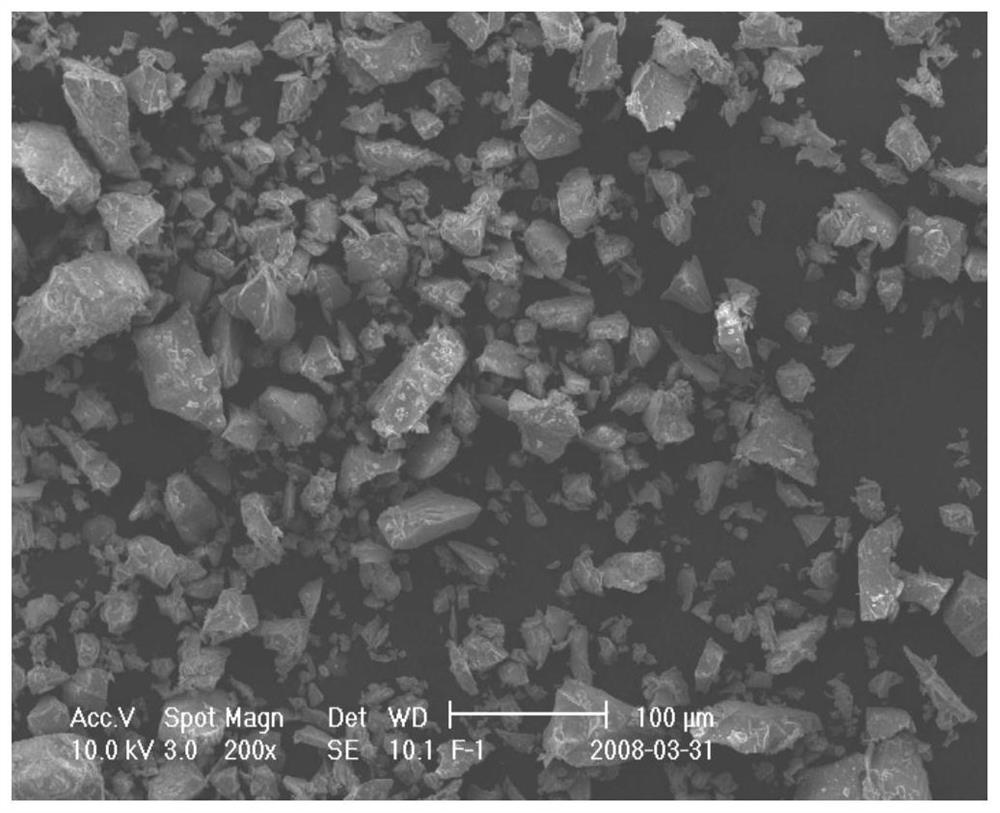

Method for preparing silver-containing calcium phosphate

InactiveCN103159197BHigh silver contentStable silver contentMaterial nanotechnologyPhosphorus compoundsCalcium biphosphateContinuous integration

The invention discloses a method for preparing silver-containing calcium phosphate and relates to silver-containing calcium phosphate. The method for preparing silver-containing calcium phosphate, disclosed by the invention, is based on a differential reaction technology and has the advantages that the continuous and stable production can be achieved, the process preparation and raw materials are simple, the reaction conditions are mild and controllable, the production cycle is short, and the whiteness is stable. The method comprises the following steps of: (1) preparing raw material liquid; (2) conveying A-phase clear liquid and B-phase clear liquid, which are obtained in the step (1), to a micro-channel continuous mixing system through a pipeline by a metering pump of a raw material conveying system, and carrying out continuous integration reaction so as to form silver-containing calcium phosphate aggregate; (3) conveying a mixing reaction product, namely silver-containing calcium phosphate aggregate sol, to a dehydration and washing device, and drying the washed product so as to obtain amorphous silver-containing calcium phosphate powder; and (4) carrying out high temperature treatment on the amorphous silver-containing calcium phosphate powder obtained in the step (3), thereby obtaining silver-containing calcium phosphate microcrystalline powder with stable whiteness.

Owner:关涛

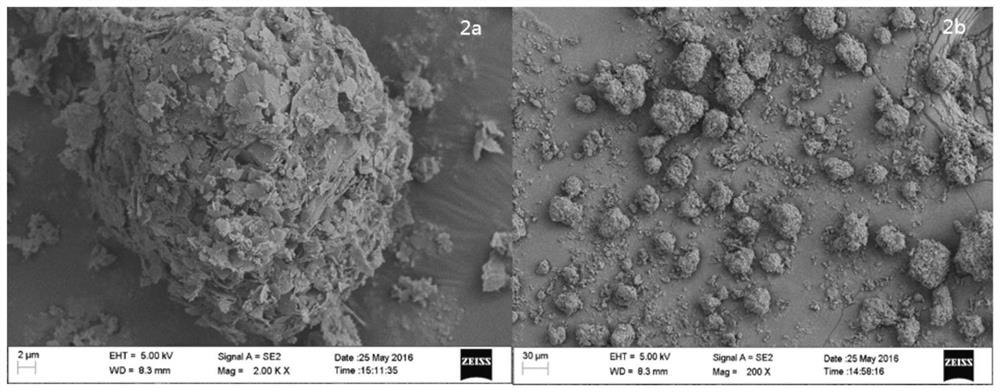

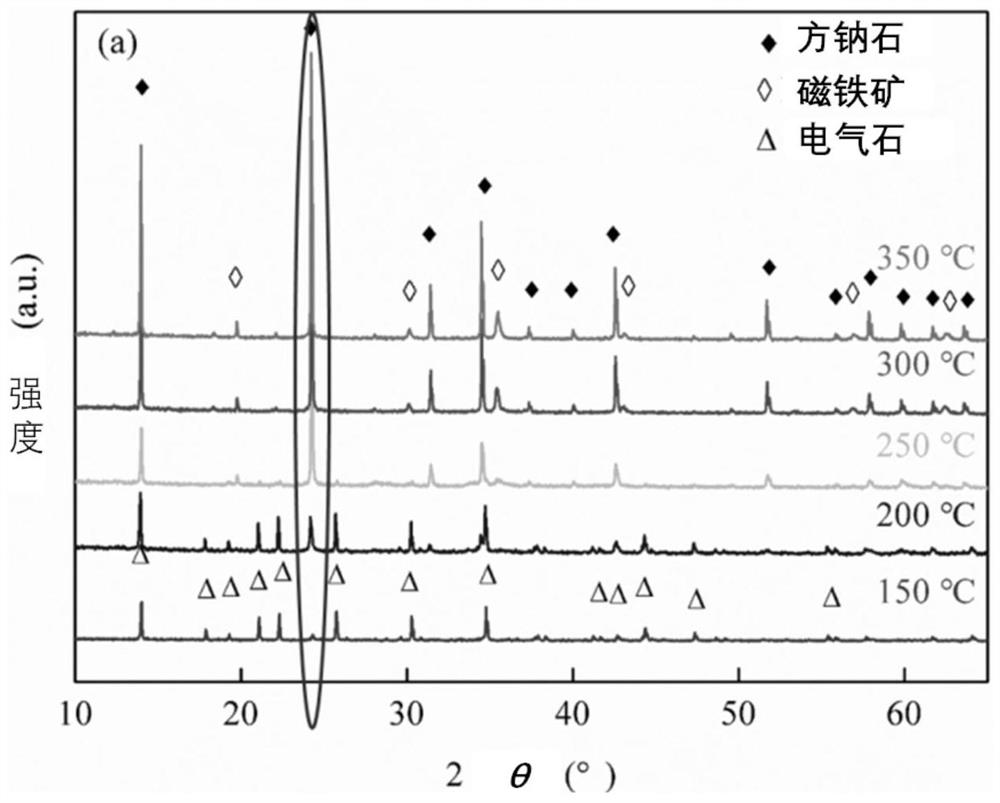

Preparation method of tourmaline and molecular sieve printing paste

The invention relates to the technical field of tourmaline functional materials, in particular to a preparation method of tourmaline-molecular sieve printing paste, which comprises the following steps: step 1, preparing tourmaline powder-molecular sieve powder, step 2, preparing pre-dispersed tourmaline-molecular sieve surface modification paste, and step 3, preparing the tourmaline-molecular sieve printing paste. A layer of sodalite can be creatively grown on the surface of tourmaline, the sodalite is very firm and not prone to falling off, the whiteness of the sodalite is remarkably improved to 55-65, the technical problem that application of existing tourmaline powder in textiles is limited is solved, the adding amount of the sodalite can be improved to 5-15%, the attractiveness of the printing color of the textiles is guaranteed, and the application range of the sodalite is widened. And multiple synergistic effects of pyroelectricity, far infrared radiation, adsorption deodorization and the like of the tourmaline and molecular sieve composite functional material can realize real application value in textiles.

Owner:佛山市玖伍柒科技有限公司

Poplar ASGW pulping process

ActiveCN100567632CHigh opacityWhiteness stabilityPulp bleachingPulping with inorganic basesLysisPulp and paper industry

The invention discloses an Italian poplar ASGW pulping process. The main features are: ① sawing and peeling the logs; ② rough grinding with alkali on the millstone grinder; ③ fine grinding with alkali and hydrogen peroxide on the disc mill; ④ screening, purification and bleaching; the main parameters are: wood section 560± 10mm; coarse grinding sodium hydroxide dosage 1.0-2.0% (for absolute dry pulp); fine grinding sodium hydroxide dosage 1.5-2.5% (for absolute dry pulp); H2O2 dosage 0.2-0.6% (for absolute dry pulp). Its quality characteristics are: breaking length ≥ 2.0Km, tear index ≥ 3.0Mn.m2 / g, percussion degree ≥ 65°SR, wet weight ≥ 2.6g, whiteness before bleaching / whiteness after bleaching 50-55% / 70 - 75% (ISO).

Owner:YUEYANG FOREST & PAPER CO LTD

Paper pulp and high-bulk energy-saving environment-friendly card prepared from same

ActiveCN102535240BImprove qualityIncrease bulkCoatings with pigmentsSynthetic cellulose/non-cellulose material pulp/paperGramSulfate

The invention discloses paper pulp and a high-bulk energy-saving environment-friendly card prepared from the same. The paper pulp is prepared from the following components in percentage by weight: 1 to 10 percent of bleached sulfate softwood pulp, 30 to 70 percent of bleached sulfate hardwood pulp, 20 to 50 percent of chemithermomechanical pulp, and 10 to 30 percent of alkaline peroxide mechanical pulp. The invention also provides the copperplate card prepared from the paper pulp and other components. The paper made with the paper pulp is high in bulk, the gram weight of the paper is effectively controlled to be in a certain range, the paper pulp is prevented from being put into production excessively, and the defibrination energy consumption of a paper machine is reduced correspondingly, so that the effects of environment friendliness and energy saving are effectively achieved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Topical skin care formulations

InactiveUS20150272844A1Quick and superior tanSkin quicklyCosmetic preparationsMake-upOctyl methoxycinnamateSunless tanning

A white, color stable, sunless tanning formulation containing vanillin and dihydroxyacetone for tanning, and octyl salicylate plus octyl methoxycinnamate for color stabilization.

Owner:HOLYFIELD LOUISE

Method for preparing high-strength, high-whiteness, high- thermal-shock-resistance petuntse

The present invention provides a method for preparing high-strength, high-whiteness, high-thermal-shock-resistance petuntse. The preparation method comprises the following production steps of (1) mechanically beating pyrophyllite, washing to remove mud and removing iron by magnetic separator and sieving; (2) mechanically beating kaolin, washing to remove mud and removing iron by magnetic separator and sieving; (3) according to the percentage by weight, weighting 28% of potassium feldspar, 12% of aluminum oxide, 10% of illite, 10% of montmorillonite and 30% of kaolin, mixing with 10% of pyrophyllite, ball milling, removing iron by magnetic separator and sieving to obtain petuntse materials; (4) press filtering the above sieved petuntse materials to obtain petuntse. The petuntse prepared by the invention is suitable for the production of ceramic products for daily use, product qualification rate is high. The strength, whiteness and thermal shock resistance of the product are superior to that of bone china, porcelain and highly siliceous magnesia porcelain, production cost is low, products are particularly applied in dishwashers, microwaves, refrigerators and sterilized cupboard.

Owner:CHAOZHOU RONGCHANG CERAMIC IND CO LTD

Film, capsule and film-forming composition comprising water-soluble salt as opacifying agent

PendingUS20220218619A1Suitable for useImprove solubilityInorganic non-active ingredientsInksCalcium bicarbonateMagnesium salt

Problem to be solved: To provide a whitened or opacified capsule and film without using a white pigment such as titanium dioxide. Solution: A film, a capsule and a film-forming composition characterized by containing a film-forming polymer component selected from gelatin and pullulan and an opacifying agent consisting of a water-soluble salt except calcium salt carbonate and bicarbonate, wherein the salt is selected from a sodium salt, potassium salt, an ammonium salt and a magnesium salt.

Owner:CAPSUGEL BELGIUM NV

Pulping process for grinding wood pulp of cotton wood by mechanical abrader

InactiveCN101338532BReduce consumptionReduce power consumptionChemical/chemomechanical pulpFibrous raw materialsDifferential pressureWood grinder

The invention discloses a cotton wood stone ground wood pulping process comprising the following steps of: (1) log sawing and skinning; (2) jordaning with alkali in a wood grinder; (3) screening by a pressure screen; (4) screenings jordaning with alkali in a conical mill; and (5) hydrogen peroxide bleaching. The invention is characterized in that: the wood grinder grindstone of the step (2) adopts bush roll with 4 mesh by primary burring; in the screening process by the pressure slot screen of the step (3), the pulp intake pressure is 0.2-0.4 MPa, the differential pressure is 0.02-0.07 MPa, the pulp intake consistence is 2.5-4.5%, the screenings output volume is 22-35%, the thickness of the screen cut is 0.15-0.35 mm; sodium hydroxide is added in the conical mill of the step (4) to grind screenings, wherein the consumption of the sodium hydroxide is 0.6-0.8% (based on weight percent of oven dry stock), the alkali liquor is added in the pulp intake tank of the conical mill with 40-50 g / l of the alkali liquor concentration, 3.1%-4.54% of jordaning consistency, 0.2-0.3 MPa of jordaning pressure, accordingly, the beating degree of the pulp ground by the conical mill can be increased by 8-12 DEG SR. The pulping process of the invention has advantages of high yield, less pollution, low cost, and the obtained pulp is applicable for paper with various specifications such as pigment offset paper, low weight paper, card paper, color newsprint paper, or the like.

Owner:YUEYANG FOREST & PAPER CO LTD

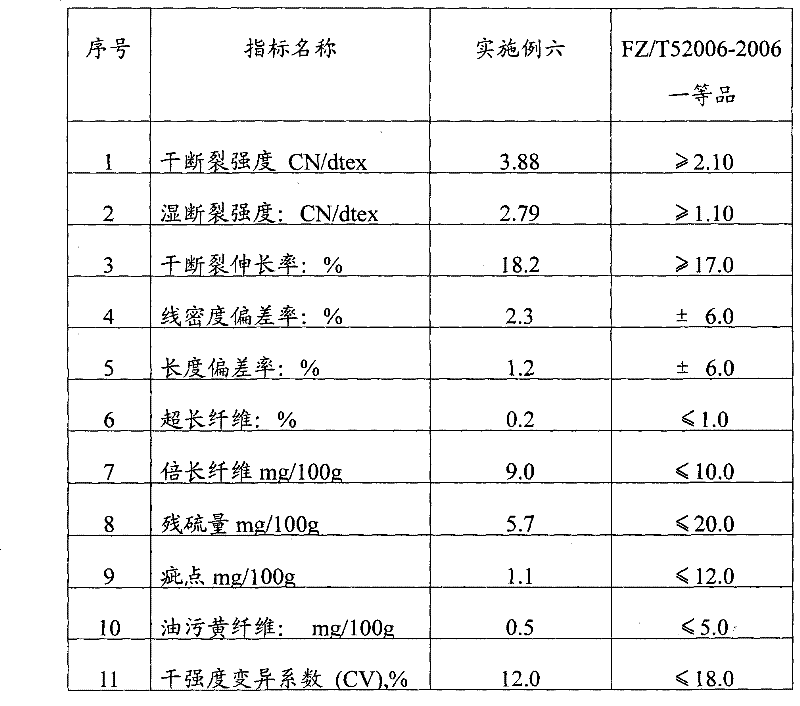

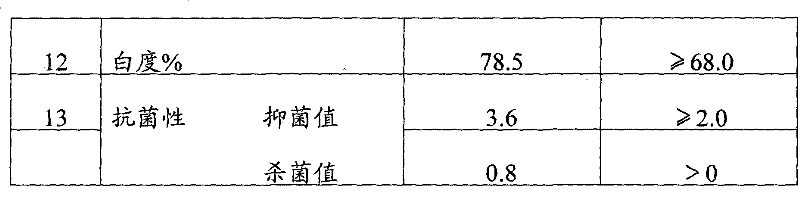

Ultrashort viscose fiber in paper making, and manufacturing method

ActiveCN100417764CIncrease the dispersion indexUniform shapeArtificial filaments from viscosePulp and paper industryCellulose fiber

The present invention relates to an ultrashort viscose fiber for making paper and its production method. Its fiber length is 4.8mm-5.2mm, and its specification is 1.67-5.56 dtex X 5-10mm, and its raw material composition includes (by wt%) 42-45% of cellulose fiber and 55-58% of water. Its production method is characterized by that its desulfurization heating process adopts steam ejector external circulation heating process, it uses the spray head with 54100 apertures to make spinning process and its guide rod is made of aluminium oxide material. Its production process successively includes the following steps: impregnation, pressing, pulverizing, ageing, sulfonation, dissolving, filtering, defoaming, secondary filtering, and spinning, both baths, drawing, cutting and packing.

Owner:唐山三友集团兴达化纤有限公司

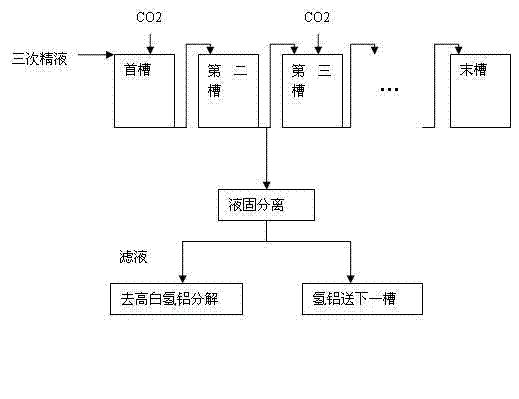

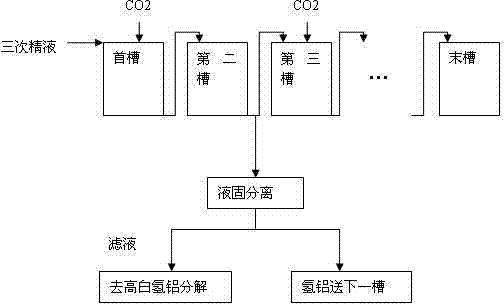

Method for producing high-whiteness aluminum hydroxide by two-stage decomposition method

ActiveCN101792163BQuality improvementColor stableAluminium oxides/hydroxidesAluminium hydroxideCarbonation

The invention relates to preparation of aluminum hydroxide, in particular to a method for producing high-whiteness aluminum hydroxide by a two-stage decomposition method. The method comprises the following steps of: decomposing carbonic acid in refining solution into which CO2 is introduced and which is delivered to a carbon decomposing tank from the first tank, transferring the refining solutionin which the carbonic acid is decomposed to a second tank of the carbon decomposing tank for stirring, and after stirring, performing solid-liquid separation; and performing carbon decomposition or continuous seed decomposition of the solution obtained after the solid-liquid separation to obtain the high-whiteness aluminum hydroxide. By adopting the preparation method, the color fluctuation of the aluminum hydroxide stock solution, namely the refining solution, caused by the fluctuation in the production process of a sintering method is eliminated, and the quality of the high-whiteness aluminum hydroxide is stabilized.

Owner:中铝山东工程技术有限公司 +1

Method capable of stabilizing paper stuff whiteness

InactiveCN101182693BImprove whitening efficiencyColor stableNon-fibrous pulp additionPaper/cardboardPulp and paper industryAlkaline peroxide

Owner:MCC PAPER YINHE

A kind of production process of white flour kraft cardboard

ActiveCN105735033BEfficient removalRemove completelySecondary cellulose fibresPaper-making machinesFiberSurface layer

The invention relates to a production technology of a white top liner. The technology comprises the following steps that 1, ONP pulp is prepared, water is added to fibers obtained from first flotation of the ONP pulp, bleaching is conducted, first ONP pulp is obtained, water is added to fibers obtained from second flotation of the ONP pulp, bleaching is conducted, second ONP pulp is obtained, concentration is conducted on ONP pulp of two times of flotation, and third ONP pulp is conducted; 2, DMOW pulp is conducted, water is added to fibers obtained from first flotation of the DMOW pulp, bleaching is conducted, first DMOW pulp is obtained, water is added to fibers obtained from second flotation of the DMOW pulp, bleaching is conducted, second DMOW pulp is obtained, concentration is conducted on DMOW pulp of two times of flotation, and third DMOW pulp is conducted; 3, the first DMOW pulp, the first ONP pulp and original wood pulp are mixed, a surface layer is obtained after the mixture flows to paper-making meshes, the second DMOW pulp and the second ONP pulp are mixed, a bottom layer is obtained after the mixture flows to the paper-making meshes, the third DMOW pulp, the third ONP pulp and OCC pulp are mixed, and a core layer is obtained after the mixture flows to the paper-making meshes.

Owner:JIANGSU LEE & MAN PAPER MFG

A kind of bleaching method of silk fabric

ActiveCN104233774BWhiteness stabilityControl the rate of decompositionBleaching apparatusPolyesterAcetic acid

The invention discloses a silk fabric bleaching method, which belongs to the field of silk fabric production. The method has the following steps: prepare the floating liquid, the main component of the floating liquid is 30% H 2 o 2 and stabilizer, ultrasonically stirred and mixed evenly, and the pH value of the solution was adjusted to 10.5-11 by adding alkali; the silk fabric was prepared and tied with a polyester thread; the silk fabric was soaked in the bleaching solution, soaked twice and tied twice, and the temperature was raised to 95-120°C. Steam for a period of time, cool down to 70°C at a rate of 2°C / min, drain the bleach, wash with hot water, drain the cleaning solution after cooling down, neutralize the discharged cleaning solution with acetic acid, and then rinse with cold water. The method can effectively maintain the whiteness and strength of the silk fabric without causing damage to the natural pigment of the silk, and is an environmentally friendly bleaching method.

Owner:浙江巨力宝纺织科技有限公司

Production method of high-strength bamboo pulp viscose glue short fiber

ActiveCN101736409BLower dynamic viscosityImprove filtering effectArtificial filaments from viscoseWet spinning methodsBreaking strengthWear resistance

The invention discloses a production method of high-strength bamboo pulp viscose glue short fiber, which adopts the steps of dipping, squeezing, smashing, maturing, yellowing, spinning, drawing, refining, drying and the like to prepare high-strength bamboo pulp viscose glue short fiber. The high-strength bamboo pulp viscose glue short fiber prepared with the method has dry breaking strength of 3.2-3.4 CN / dtex and wet breaking strength of 2.0-2.3 CN / dtex, is firm and has strong spinnability; fabrics and clothes manufactured by the fiber have favourable toughness and high abrasive resistance; other indexes are all superior to the first-rate product index of FZ / T 52006-2006. The fiber manufactured with the method is ideal material for high-rank clothes and household textiles.

Owner:刘泳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com