Process for stabilizing the whiteness of lignin-containing fibrous materials, stabilizer composition and fibrous materials stabilized with this

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

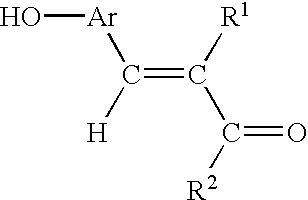

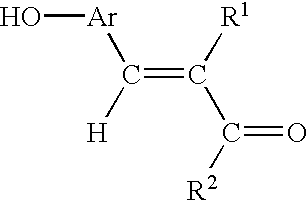

Image

Examples

examples

[0059] In each case a TCF-bleached aspen CTMP cellulose with a whiteness of 86% was used as the paper base

[0060] 1. Individual substances

[0061] The substances shown in table 1 were applied to the paper in the form of a solution. The amount applied was 1% by weight, calculated with respect to the cellulose. After drying, irradiation was carried out. Irradiation time was 10 h in a xenon test apparatus, level 2. The whiteness (W) (%) as a function of time was determined; the loss in whiteness results from this as the difference (=dW) between the whiteness before (=W.sub.0) and after (W.sub.10h)the irradiation or as the relative drop in whiteness dW.100 / W.sub.0.

1TABLE 1 W.sub.0 (%) before W.sub.10 (%) W.sub.0-Number Stabilizer irradiation after 10 h W.sub.10 CE 1 None 86 55 31 Ex. 1 2-diallylamino-4-(3'- 88 67 21 Methoxypropyl) amino- 6-mercapto-1,3,5- triazine Ex. 2 2-N-piperidino-4- 87 65 22 Ethylamino-6-mercapto-1,3,5- trazine Ex. 3 2,2'-bis-(5- 81 61 20 methylamino-1,3,4- thiadiazol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com