Preparation method of tourmaline and molecular sieve printing paste

A printing paste and molecular sieve technology, applied in dyeing, textile and papermaking, etc., can solve the problems of darkening, unusable, discoloration of printing paste, and achieve stable whiteness, improve whiteness, and be difficult to shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

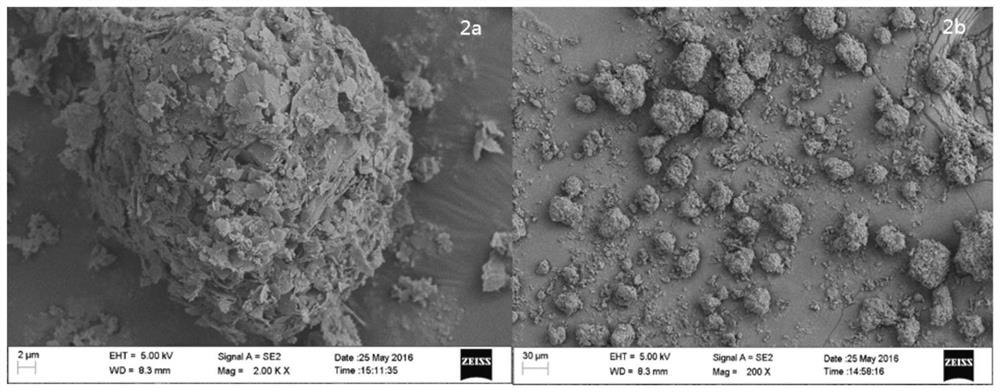

[0046] A kind of preparation method of tourmaline@molecular sieve printing paste of the present embodiment, comprises the following steps:

[0047] Step 1. Preparation of tourmaline powder@molecular sieve powder:

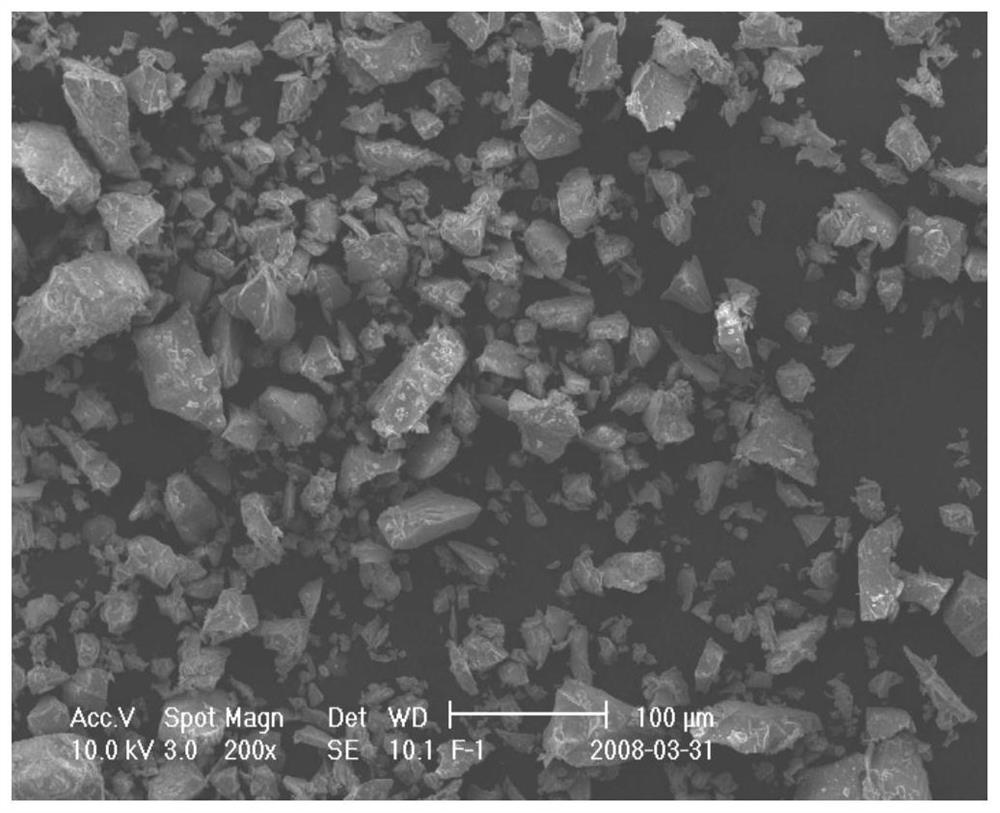

[0048] (1) pulverization: the tourmaline is pulverized to below 325 meshes to obtain tourmaline powder;

[0049] (2) feed intake: the tourmaline powder and NaOH are respectively put into the basic reactor at a weight ratio of 75:20, wherein the added tourmaline powder capacity occupies 75% of the basic reactor space, and NaOH is made into a solution with a mass concentration of 30% and Pump into the reaction kettle, stir evenly, add water glass solution to the basic reaction kettle to 95% of the reaction kettle space; the modulus of the water glass solution is 1.4-1.8, and the Baume degree is 40-45;

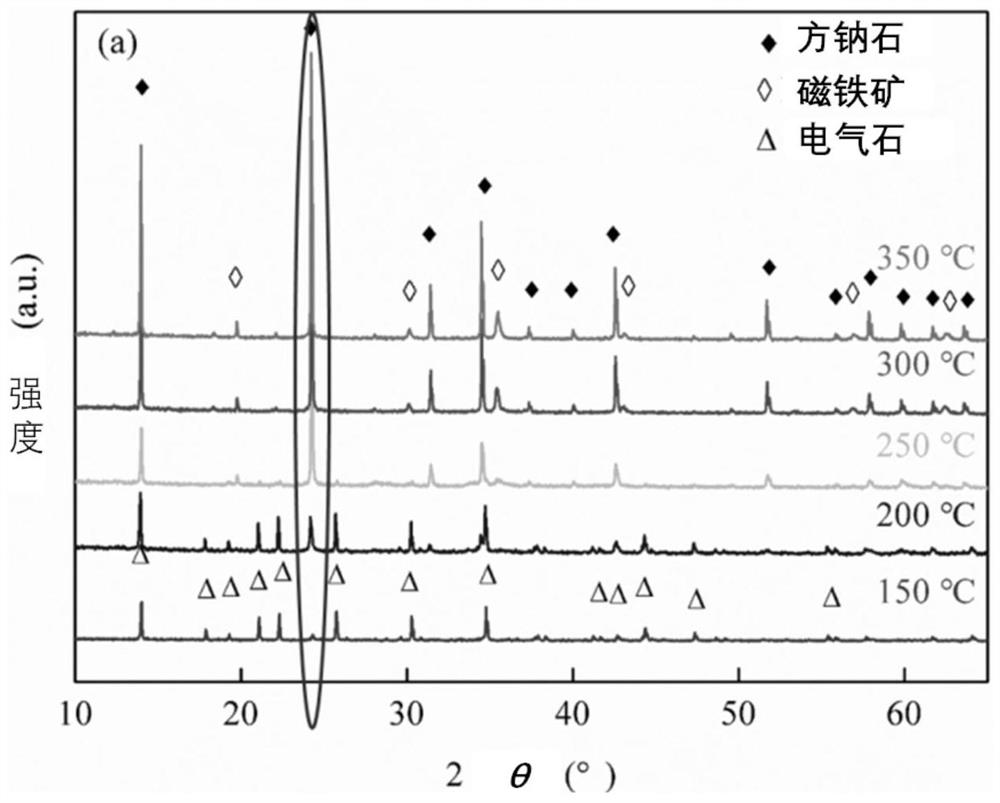

[0050] (3) Alkali reaction: the basic reaction kettle is heated to 150°C, the holding time is 48h, the basic reaction kettle is rolled and rotated at a slow speed, th...

Embodiment 2

[0060] A kind of preparation method of tourmaline@molecular sieve printing paste of the present embodiment, comprises the following steps:

[0061] Step 1. Preparation of tourmaline powder@molecular sieve powder:

[0062] (1) pulverization: the tourmaline is pulverized to below 325 meshes to obtain tourmaline powder;

[0063] (2) feed intake: the tourmaline powder and NaOH are respectively put into the basic reactor at a weight ratio of 90:10, wherein the added tourmaline powder capacity occupies 85% of the basic reactor space, and NaOH is made into a solution with a mass concentration of 20% and Pump into the reaction kettle, stir evenly, add water glass solution to the basic reaction kettle to 95% of the reaction kettle space; the modulus of the water glass solution is 1.4-1.8, and the Baume degree is 40-45;

[0064] (3) Alkali reaction: the basic reaction kettle is heated up to 200 ° C, the holding time is 20h, the basic reaction kettle is rolled and rotated at a slow spee...

Embodiment 3

[0074] A kind of preparation method of tourmaline@molecular sieve printing paste of the present embodiment, comprises the following steps:

[0075] Step 1. Preparation of tourmaline powder@molecular sieve powder:

[0076] (1) pulverization: the tourmaline is pulverized to below 325 meshes to obtain tourmaline powder;

[0077] (2) feed intake: the tourmaline powder and NaOH are respectively put into the basic reactor at a weight ratio of 85:15, wherein the added tourmaline powder capacity occupies 80% of the basic reactor space, and NaOH is made into a solution with a mass concentration of 25% and Pump into the reaction kettle, stir evenly, add water glass solution to the basic reaction kettle to 95% of the reaction kettle space; the modulus of the water glass solution is 1.4-1.8, and the Baume degree is 40-45;

[0078] (3) Alkali reaction: the basic reaction kettle is heated to 250°C, the holding time is 30h, the basic reaction kettle is rolled and rotated at a slow speed, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com