Color-matching dyeing process based on plant dyes

A vegetable dye and process technology, applied in the field of color matching and dyeing technology based on vegetable dyes, can solve the problems of unachievable dyeing effect and different degrees of fabric effect, avoiding uneven dyeing, pure fabric color, and excellent dyeing. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

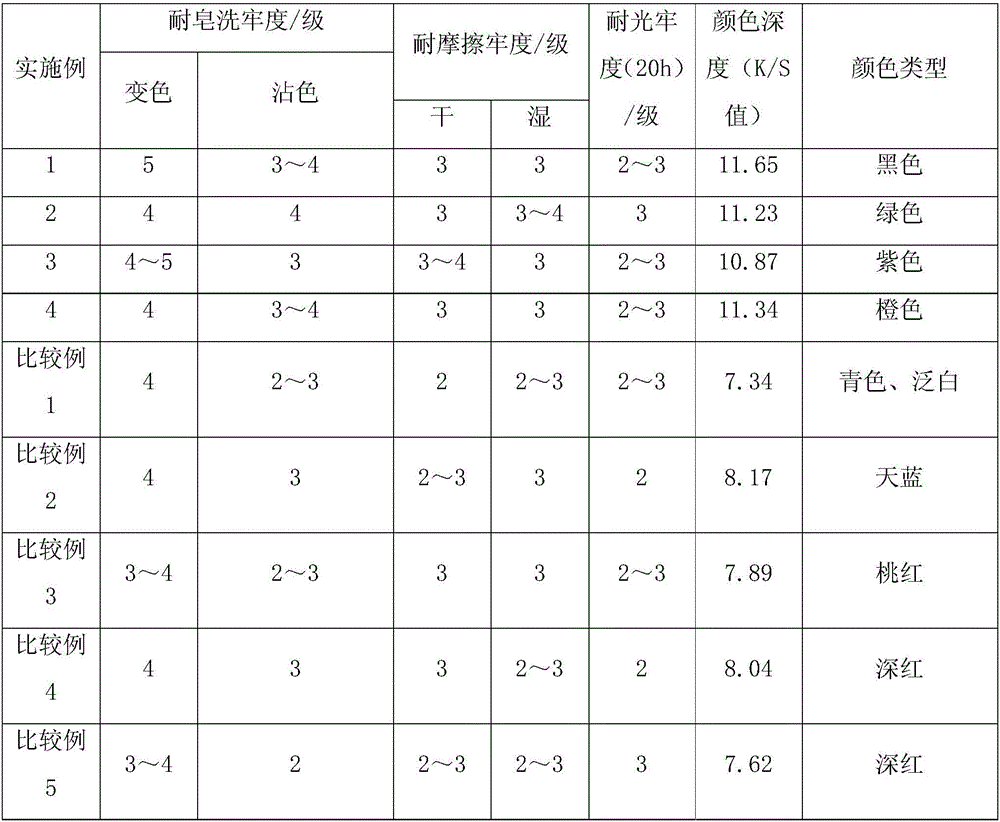

Examples

Embodiment 1

[0027] Get red dye safflower extract, yellow dye gardenia extract, blue dye indigo extract each 4 grams and dissolve in 2ml ethanol respectively, the ethanol solution of 3 kinds of plant dyes obtained is added to deionized water, stir to obtain uniform and control the mass concentration of the total amount of plant dyes in the dye solution to be 2%, and add the Diacid X model that accounts for 12% of the total mass of plant dyes in the aforementioned dye solution. Multi-functional green environmental protection surfactant, at the same time, add potassium hydroxide to the dye solution and stir evenly. After adjusting the pH of the dye solution to 7, immerse the white cotton T-shirt in the dye solution for dyeing.

[0028] The dyeing conditions are controlled as follows: bath ratio 1:20, dyeing temperature 90°C, dyeing time 40 minutes, after dyeing, wash with water and dry to obtain dyed fabric.

Embodiment 2

[0030] Dissolve 5 grams each of the yellow dye gardenia extract and the blue dye indigo extract in 2ml of ethanol, add the obtained ethanol solutions of the two plant dyes to deionized water, stir to obtain a uniform dye solution, and control the plant dyes. The mass concentration of dyestuff total amount in dyeing liquor is 1.8%, and in aforementioned dyeing liquor, add the multifunctional green environmental protection surfactant of the Diacid X model that accounts for 15% of plant dyestuff total mass Co., Ltd. At the same time, potassium hydroxide is added to the dye solution and stirred evenly, after the pH of the dye solution is adjusted to 7, the silk fabric is immersed in the dye solution for dyeing.

[0031] The dyeing conditions are controlled as follows: liquor ratio 1:22, dyeing temperature is 85°C, dyeing time is 40 minutes, after dyeing is finished, it is washed with water and dried to obtain dyed fabric.

Embodiment 3

[0033] The "yellow dye gardenia extract" in Example 2 was replaced with "red dye safflower extract", and the remaining parameters and processes remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com