Material preparation and dyeing integrated printing and dyeing equipment for cloth spinning

A kind of printing and dyeing equipment and textile technology, which is applied in the direction of processing textile material equipment configuration, textile material processing, textiles and papermaking, etc. It can solve the problems of low printing and dyeing efficiency of cloth, avoid uneven dyeing, facilitate the removal process, and improve Effect of Dyeing Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

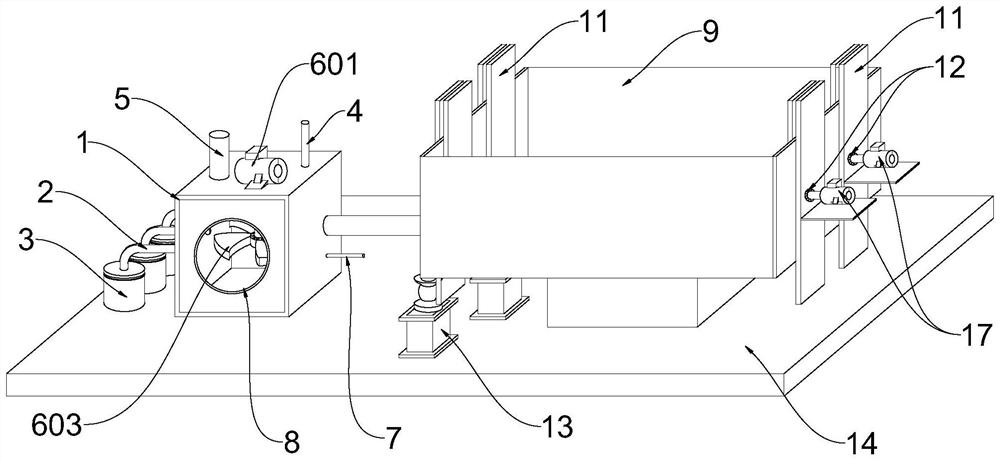

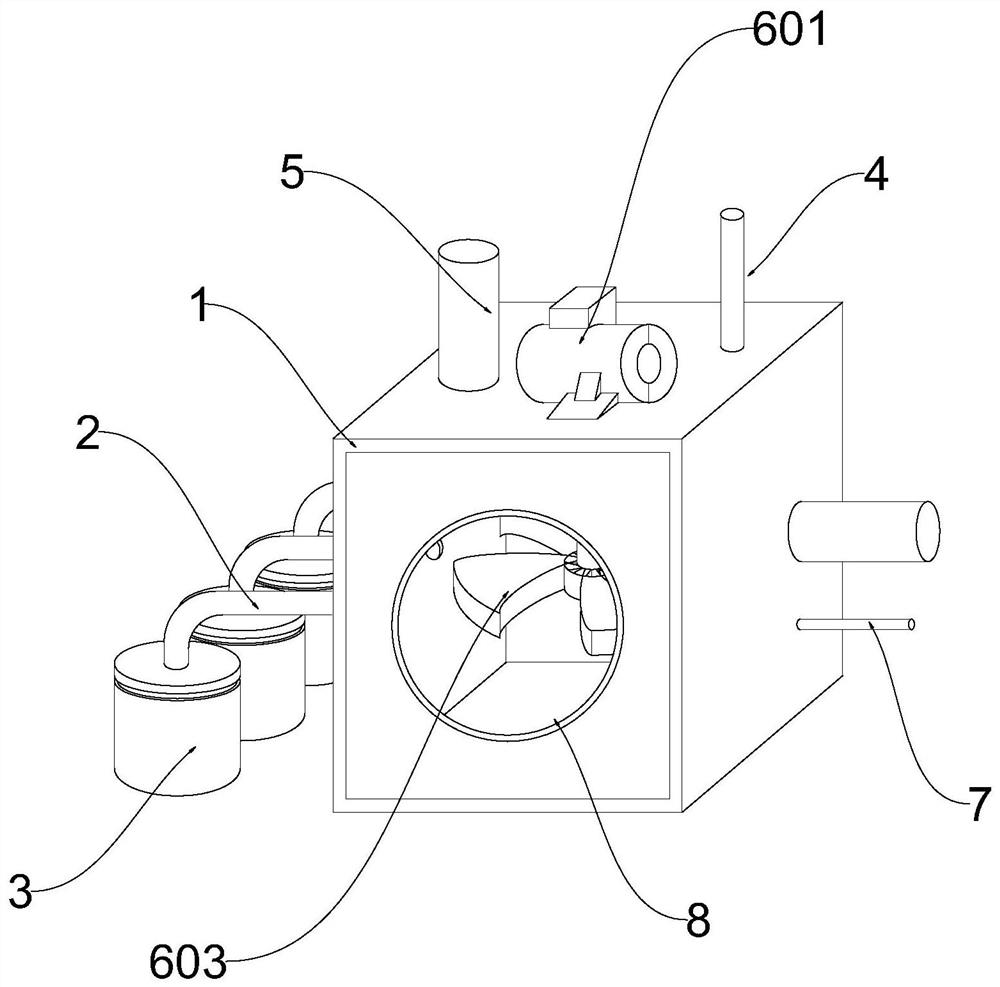

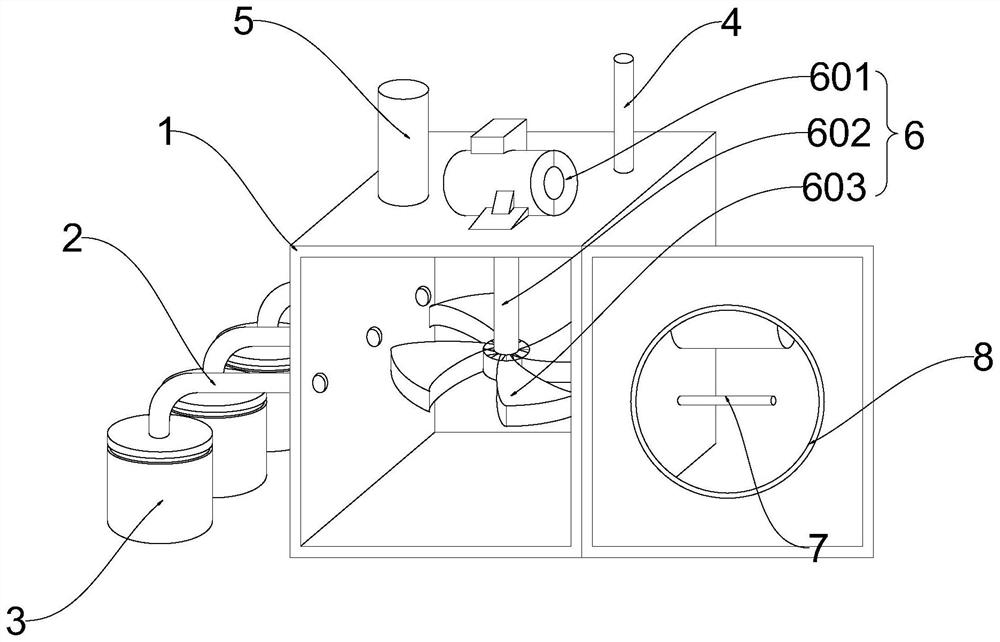

[0045] see figure 1 , the present invention provides a kind of printing and dyeing equipment that is used for fabric weaving and dyeing integration, and described printing and dyeing equipment comprises:

[0046] see figure 2 and image 3 , material preparation mechanism, described material preparation mechanism comprises material preparation container 1, and at least one feed pipe 2 is installed on the described material preparation container 1; One end of described feed pipe 2 is through-connected with described material preparation container 1, The other end of the feed pipe 2 is connected to the paint bucket 3; the material preparation container 1 is also equipped with an auxiliary feed pipe 4, a solvent feed pipe 5, an agitator 6, a sampling pipe 7 and a maintenance hole 8; One end of the agitator 6 runs through the material making container 1 and can rotate relative to the material making container 1; the agitator 6 includes a second stirring motor 601, a third stirri...

Embodiment 2

[0054] see figure 1 , The invention provides a printing and dyeing equipment for fabric weaving with integrated dyeing and preparation. The difference between Embodiment 2 and Embodiment 1 is that the distance between the two axes of the stirring rollers 15 is 4 times of the radius of the stirring rollers 15 (the radius of the stirring rollers 15 is 0.5 m).

[0055] Working process is identical with embodiment 1.

Embodiment 3

[0057] see figure 1 , The invention provides a printing and dyeing equipment for fabric weaving with integrated dyeing and preparation. The difference between embodiment 3 and embodiment 1 is that the distance between the two stirring rollers 15 is 5 times the radius of the stirring rollers 15 (the radius of the stirring rollers 15 is 0.5 m).

[0058] Working process is identical with embodiment 1.

[0059] To sum up, the printing and dyeing equipment of the present invention combines the material preparation mechanism and the dyeing mechanism, and the integrated design makes the printing and dyeing equipment more complete in function, and there is no need to specially design a dye liquor delivery device at this time. The stirring roller 15 of the first stirring shaft 18 and the stirring roller 15 of the second stirring shaft 19 are connected with the two ends of the cloth respectively, and the dyeing mechanism forms a cloth dyeing wheel by the first stirring shaft 18 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com