High-efficiency fabric printing and dyeing device

A dyeing device and fabric technology, applied in the field of textile printing and dyeing, can solve the problems of low product added value, single process, and monotonous product color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

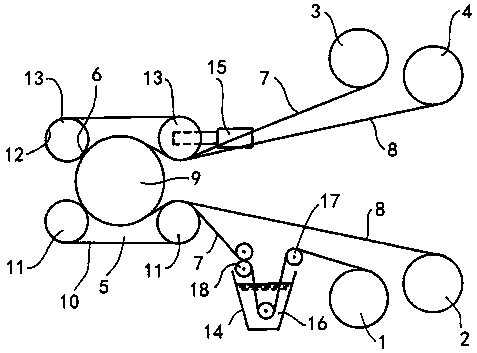

[0039] A high-efficiency fabric printing and dyeing device, including a first fabric feeding device 1, a second fabric feeding device 2, a first fabric winding device 3, a second fabric winding device 4, a dyeing device 5, and a pressurizing device 6; A fabric 7 is sent out from the first fabric feeding device 1 as the first fabric to be dyed, and then becomes the first dyed fabric through the dyeing of the dyeing device 5; the second fabric 8 is fed from the second fabric as the second fabric to be dyed It is sent out on the device, and then becomes the second dyed fabric through the dyeing of the dyeing device 5; the first fabric feeding device 1 unwinds and transports the first fabric to be dyed, and the first fabric winding device 3 takes up the dyed first dyed fabric, The second fabric feeding device 2 unwinds and transports the second fabric to be dyed, and the second fabric winding device 4 takes up the dyed second dyed fabric; the first fabric 7 is wound on the first fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com