Residual film recovery device and operation method thereof

A technology of residual film recovery and film wheel, which is applied in agriculture, collectors, harvesters, etc., can solve the problems of white pollution, cotton farmers' income decline, and the recovery rate of residual film on the surface is difficult to exceed 80%, so as to improve agricultural production efficiency, The effect of improving the quality and quantity of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

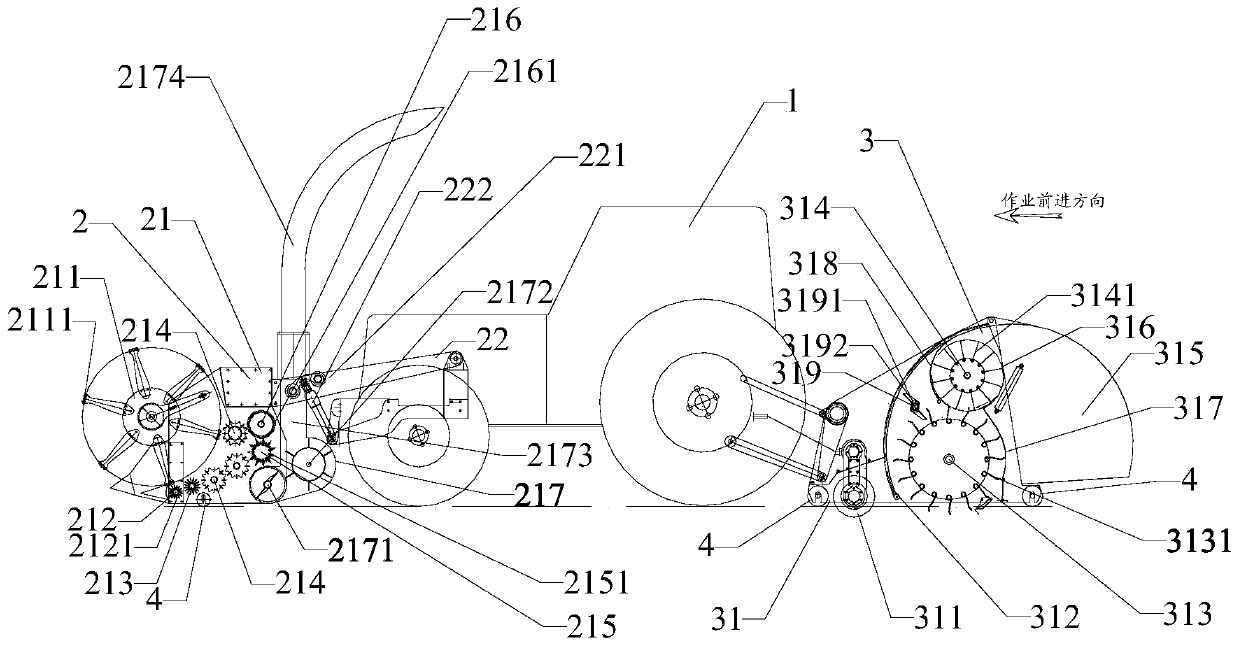

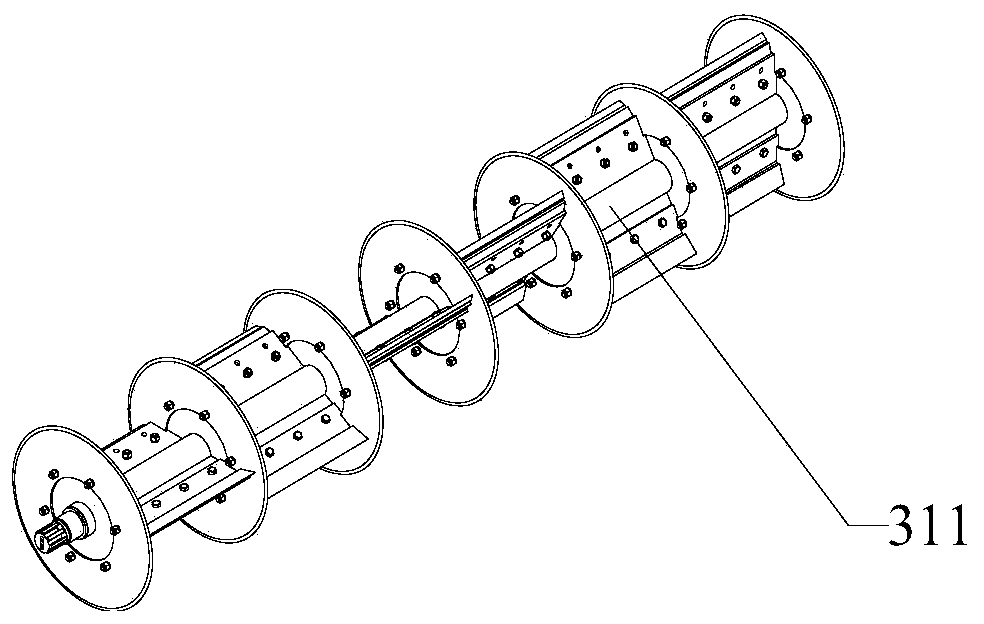

[0068] A crop stalk pulling and residual film recovery device, including a carrier 1, a stalk pulling mechanism 2, and a residual film recovery mechanism 3; the stalk pulling mechanism 2 includes a first frame 21, and the first frame 21 is connected through a connecting component 22 is connected to the front of the carrier 1; the connecting assembly 22 includes a connecting rod 221 and a hydraulic cylinder 222, the front end of the connecting rod 221 is connected to the first frame 21, and the rear end is hinged to the carrier 1, and the hydraulic cylinder 222, one end is connected to the middle part of the connecting rod 221, and the other end is connected to the carrier 1; the first frame 21 is provided with a stalk pulling wheel 211, a main stalk pulling wheel 212, an auxiliary stalk pulling wheel 213, and a cotton stalk transmission wheel set 214. The first stalk cutting rotor 215, the second stalk cutting rotor 216 and the cotton stalk collecting and throwing device 217; t...

Embodiment 2

[0071] An operation method of a residual film recovery device, comprising the following steps:

[0072] Step 1: Cotton stalks are uprooted under the cooperation of the stalk puller, the main stalk puller and the auxiliary stalk puller;

[0073] Step 2: the cotton stalk delivery wheel set transports the uprooted cotton stalks to between the first stalk cutting rotor and the second stalk cutting rotor;

[0074] Step 3: The first stalk cutting rotor cooperates with the second stalk cutting rotor to cut the cotton stalk into multiple sections;

[0075] Step 4: The cotton stalk collecting and sending device collects the cotton stalks cut into several sections and throws them away from the area to be collected;

[0076] Step 5: While the film removal wheel divides the residual film on the surface into pieces, at the same time, the soil within the effective plowing depth of the film coulter and the residual film of previous years are turned up and thrown backward and upward. After tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com