Packaging machine for fixing can through arc-shaped structure

An arc-shaped structure and packaging machine technology, which is applied to flange-type bottle caps and other directions, can solve the problems that the fixed block is difficult to achieve force balance, the steps are cumbersome, and the packaging of cans is affected, so as to improve convenience and linkage. The effect of recycling quality and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

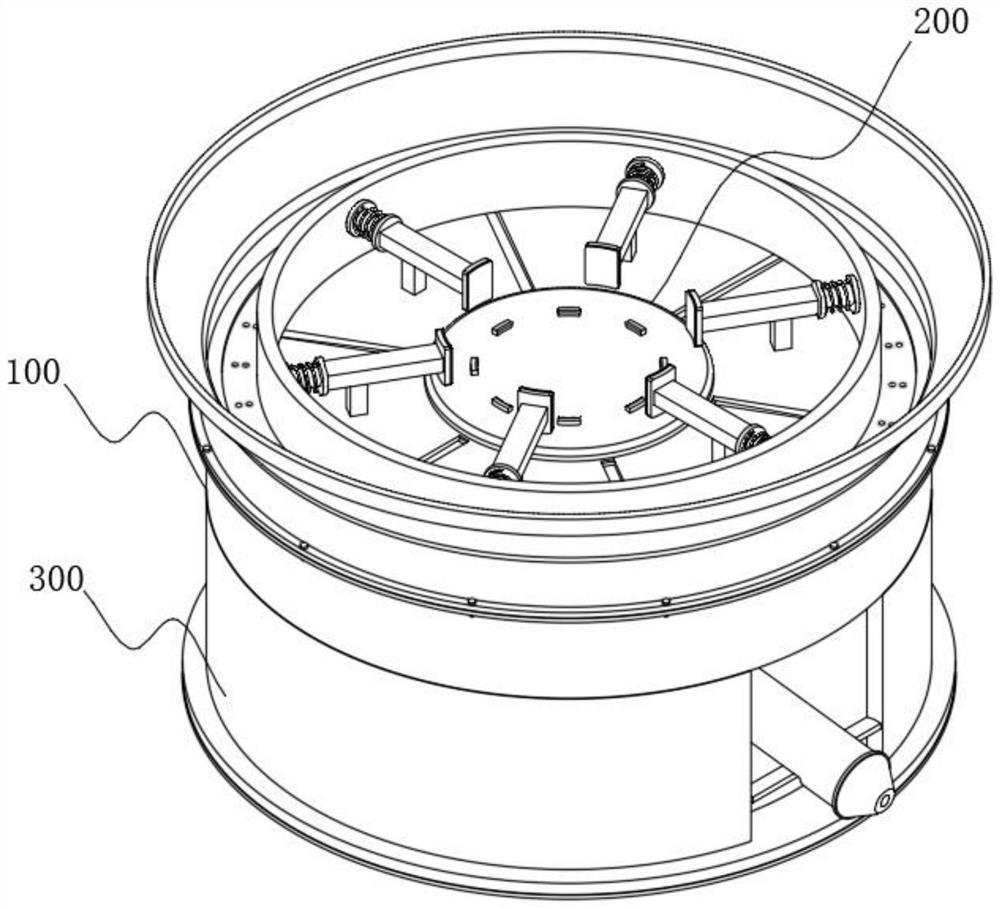

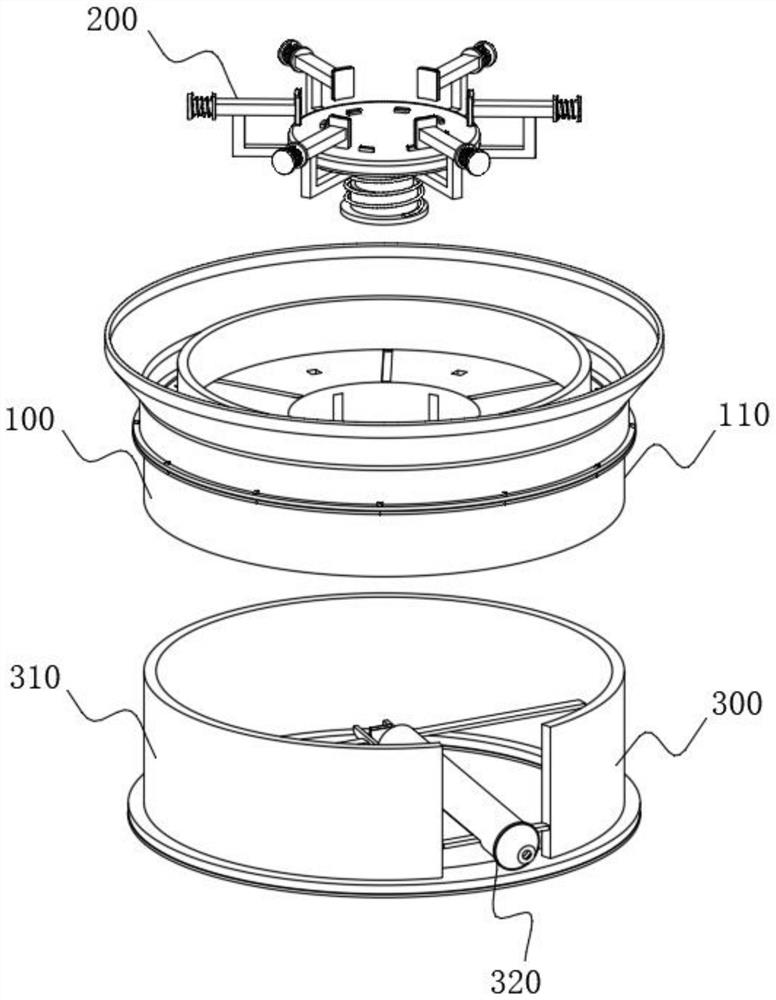

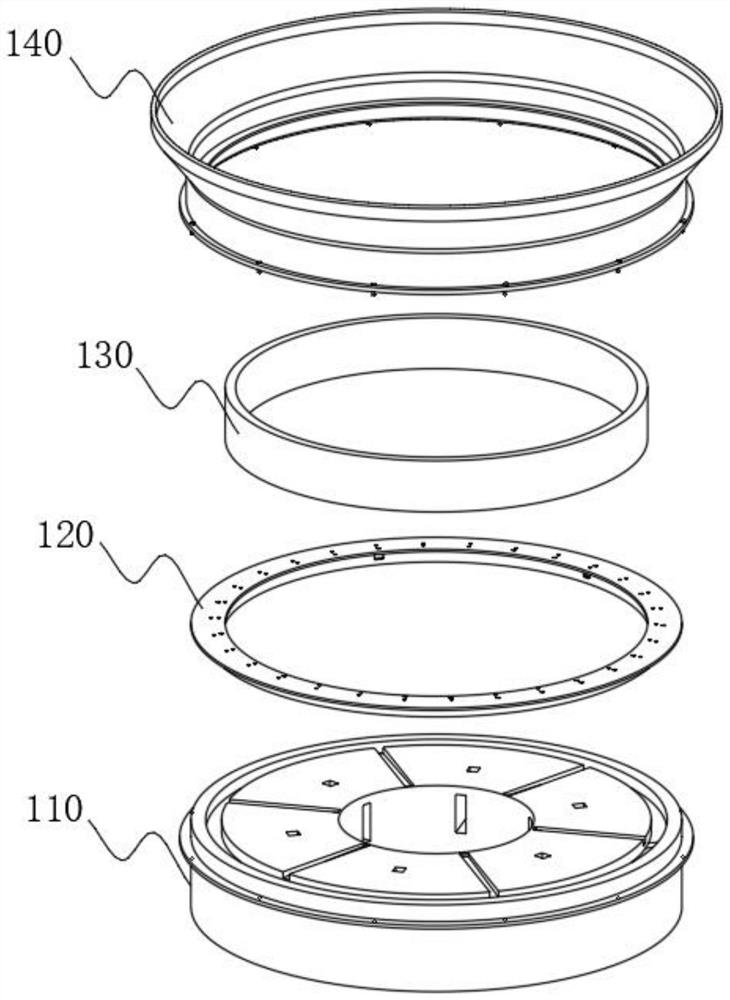

[0069] see Figure 1-Figure 13 As shown, the present embodiment provides a sealing machine for fixing cans in an arc structure, including a supporting device 100, a fixing device 200 and a collecting device 300 arranged at the bottom of the supporting device 100. There is a placement groove 111 at the center of the circle, and a plurality of slide grooves 1111 are arranged at equal intervals in a ring around the inner wall of the placement groove 111. The opening of the equal intervals makes the fastening plate 2111 pressed when squeezing the can body (hereinafter referred to as: the tank body). The force is more even to prevent the tank body from being tilted due to unbalanced force, which affects the packaging effect. There is a mounting plate 130, the mounting plate 130 is fixedly connected to the top wall of the support seat 110, the fixing device 200 is arranged in the placement groove 111, the fixing device 200 includes an elastic fastening device 210, and the elastic fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com