Design of a Statically Sealed Multi-channel Nozzle for Chromatographic Columns

A static sealing, multi-channel technology, applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve the problems of nozzle failure, laborious lifting of nozzles, large resistance, etc., to achieve easy movement and good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

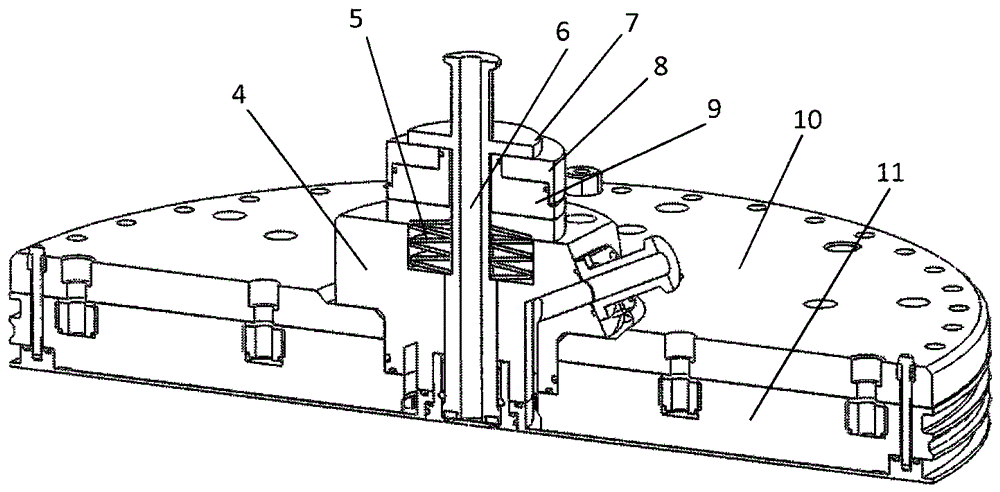

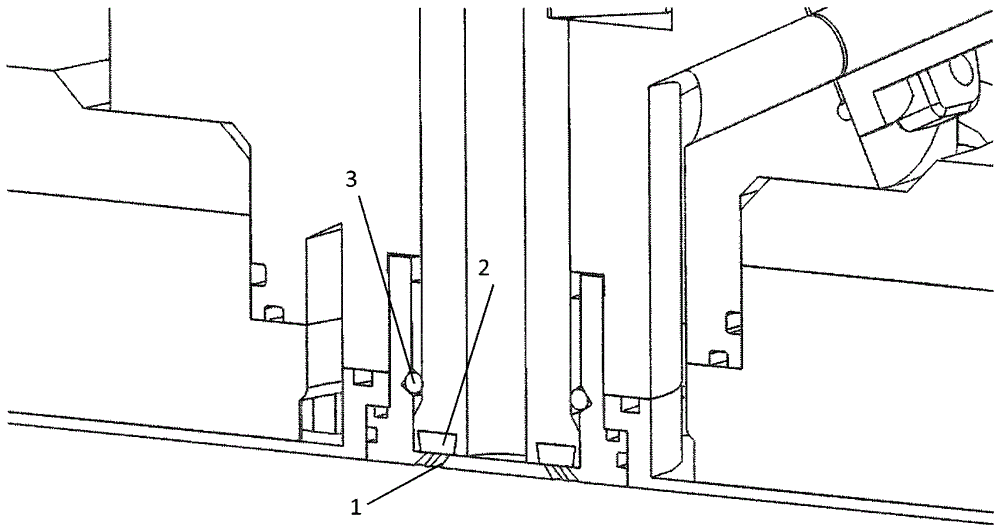

[0027] Such as figure 1 with figure 2 Shown is a statically sealed multi-channel nozzle design for chromatography columns, specifically: 1. screen center nozzle; 2. trapezoidal sealing groove; 3. O-shaped sealing ring; 4. nozzle base; 5. dish 6. Glue feeding pipe; 7. Block; 8. Moving flange; 9. Moving flange base; 10. Distributor; 11. Upper distributor back plate.

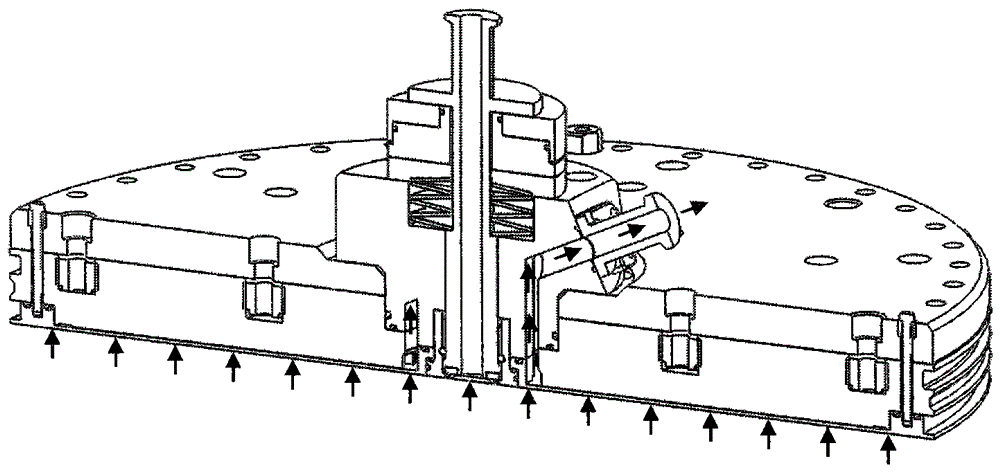

[0028] Specifically as image 3 As shown, adjust the pressure of the air source to make the outlet pressure of the air source zero. Under the action of the elastic force of the disc spring, the glue inlet pipe is moved down, so that the spray port of the nozzle in the center of the screen is sealed, the glue inlet pipe is closed, and the chromatography flow path is closed. Such as image 3 indicated by the arrow.

[0029] Specifically as Figure 4 As shown, adjust the pressure of the gas source to make the outlet pressure of the gas source the set pressure, the gas pressure forces the disc spring to deform, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com