Method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and apparatus thereof

A technology of dimethyl carbonate and pressure swing rectification, applied in chemical instruments and methods, purification/separation of carbonate/haloformate, preparation of organic compounds, etc., can solve problems such as large energy consumption, and achieve The effect of efficient separation, cost reduction and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

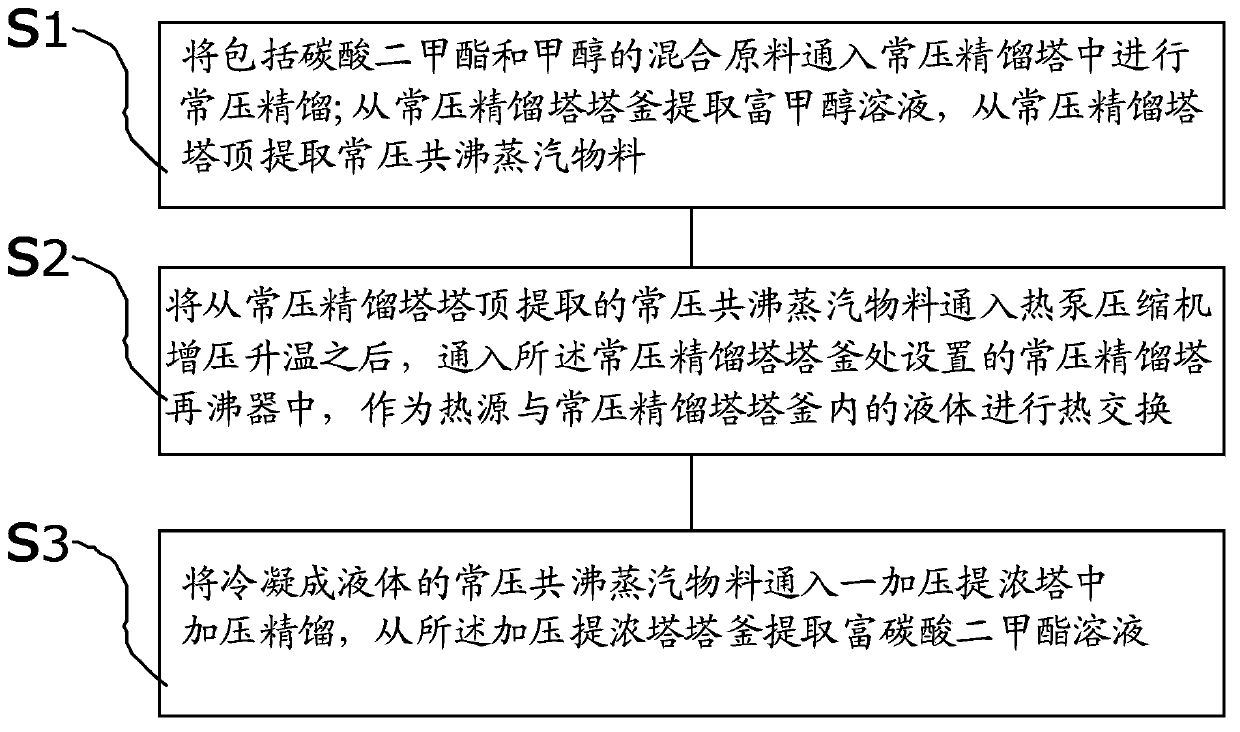

Method used

Image

Examples

Embodiment 1

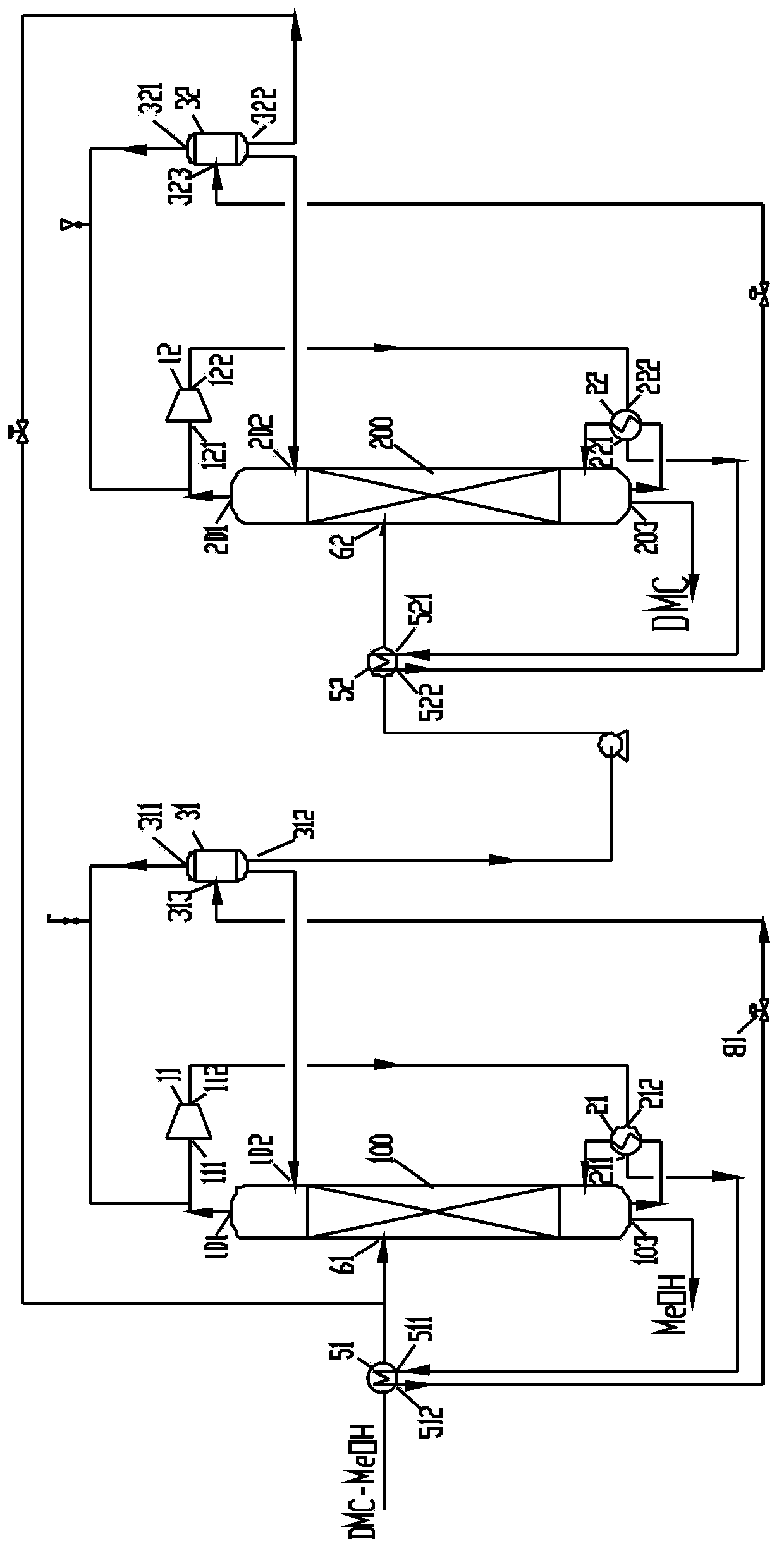

[0129] refer to image 3 As shown, the heat pump pressure swing rectification device for separating dimethyl carbonate and methanol in this embodiment includes an atmospheric rectification tower 100 and a pressurized concentration tower 200 .

[0130] The middle part of described atmospheric rectification tower 100 is provided with raw material inlet 61, is used to pass into the mixed raw material that comprises DMC and MeOH (the mixed raw material here is the raw material of main component with DMC and MeOH), in described atmospheric rectification tower At 100, an atmospheric azeotropic vapor material extraction port 101 for extracting DMC-MeOH atmospheric azeotropic vapor material is provided at the top of the tower, and a methanol-rich solution extraction port 103 for extracting methanol-rich solution is opened at the bottom of the tower. A reboiler 21 is provided at the bottom of the atmospheric rectification tower 100, wherein the bottom of the atmospheric distillation to...

Embodiment 2

[0154] The heat pump pressure swing rectification separation device of dimethyl carbonate and methanol in this embodiment is roughly the same as the heat pump pressure swing rectification separation device technical scheme of dimethyl carbonate and methanol in Example 1, the difference is that in the normal pressure An intermediate tank is respectively arranged between the reboiler 21 of the rectification column 100 and / or the reboiler 22 of the pressurized concentration tower 200 and the corresponding first reflux tank 31 and / or the second reflux tank 32, thereby further Using the latent heat of vaporization of the condensed DMC-MeOH atmospheric pressure azeotropic steam material or DMC-MeOH pressurized azeotropic steam material to realize efficient energy circulation and further strengthen the heat pump pressure swing rectification to separate dimethyl carbonate and methanol the stability of the device.

[0155] The specific structure is combined with reference Figure 4 sh...

Embodiment 3

[0161] In order to obtain a higher-purity dimethyl carbonate solution, the higher-purity dimethyl carbonate solution that can be extracted from the 200 tower kettles of the pressurized concentration tower can be passed into a product refining tower for rectification and purification, thereby obtaining higher pure dimethyl carbonate solution.

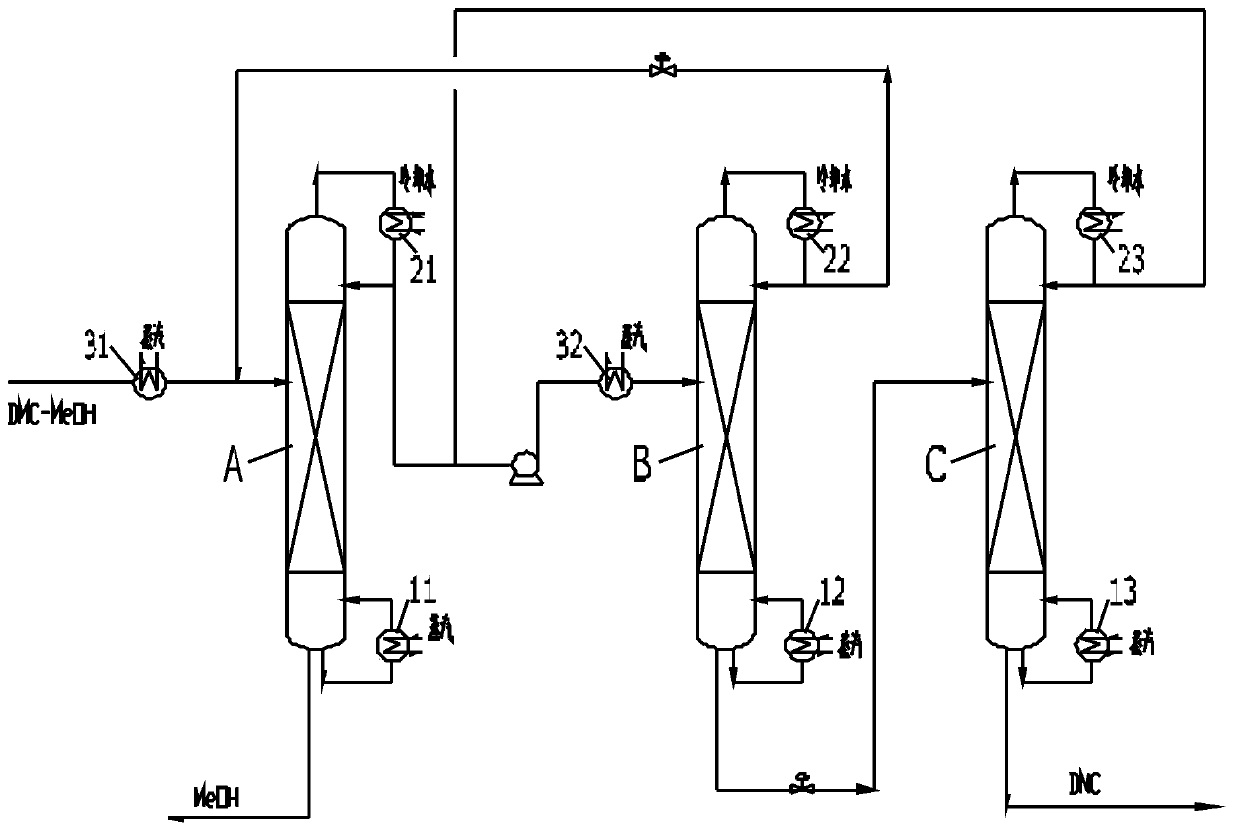

[0162] The heat pump pressure swing rectification separation device for dimethyl carbonate and methanol in this implementation is set up a product refining tower on the basis of the heat pump pressure swing rectification separation device for dimethyl carbonate and methanol in embodiment 1 and embodiment 2 . The specific structure can refer to Figure 5 shown.

[0163] The middle part of the product refining tower 300 is provided with a raw material inlet 63 connected to the enriched dimethyl carbonate extraction port 203 of the pressurized concentration tower 200 . The refining tower steam material extraction port 301 for extracting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com