Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149 results about "Self-condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-condensation is an organic reaction in which a chemical compound containing a carbonyl group acts both as the electrophile and the nucleophile in an aldol condensation. It is also called a symmetrical aldol condensation as opposed to a mixed aldol condensation in which the electrophile and nucleophile are different species.

Oil-based ink-jet recording ink

InactiveUS6730153B2Maintain good propertiesSatisfactory pigment dispersibilityDuplicating/marking methodsInksParaffin waxVegetable oil

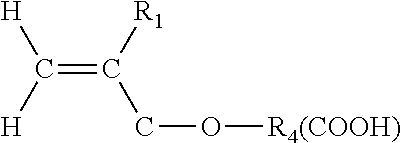

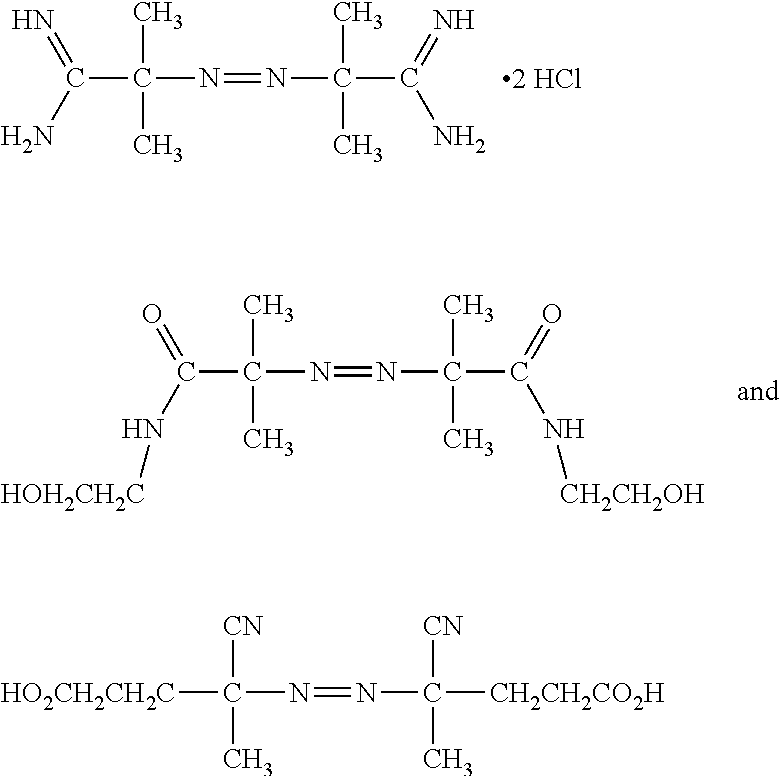

An ink-jet recording oil-based ink which has satisfactory pigment dispersibility both at the beginning of storage and even during long-term storage and provides excellent spouting stability without being influenced by temperature changes in printing circumstances. The ink comprises a pigment; a dispersing agent comprising a reaction product of a polyamine compound and a self condensation product of 12-hydroxystearic acid; a saturated hydrocarbon solvent comprising a liquid paraffin as a main component; and a vegetable oil, the ink having a surface tension of 26 to 30 dyne / cm at 25° C. and a contact angle on a polytetrafluoroethylene plate of 40° to 50° at 25° C., and satisfying the following relationship:wherein WHC is the weight of the saturated hydrocarbon solvent and WVC is the weight of the vegetable oil.

Owner:SAKATA INX

Method for synthesizing high-density aviation fuel by using cyclopentanone as raw material

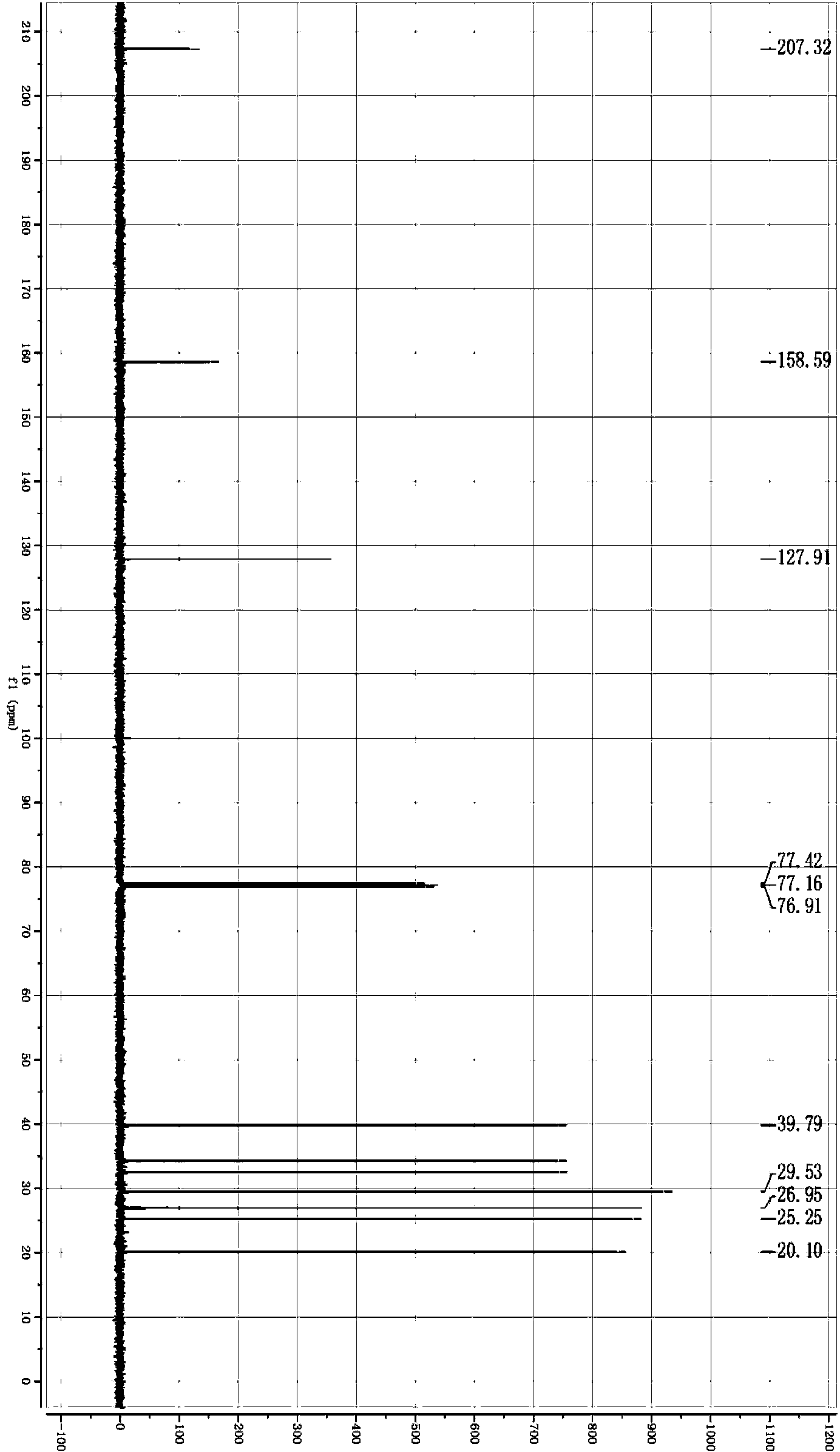

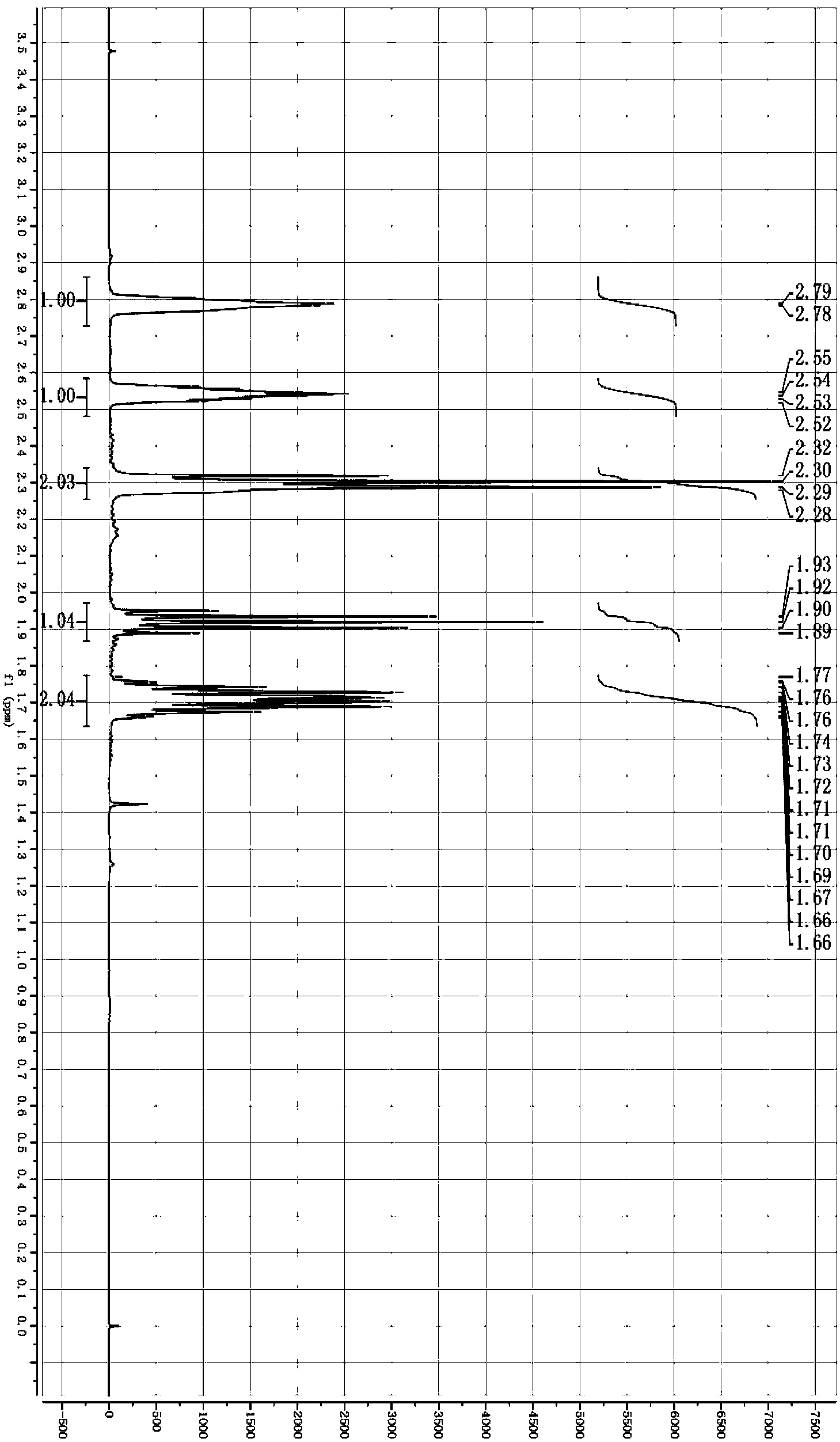

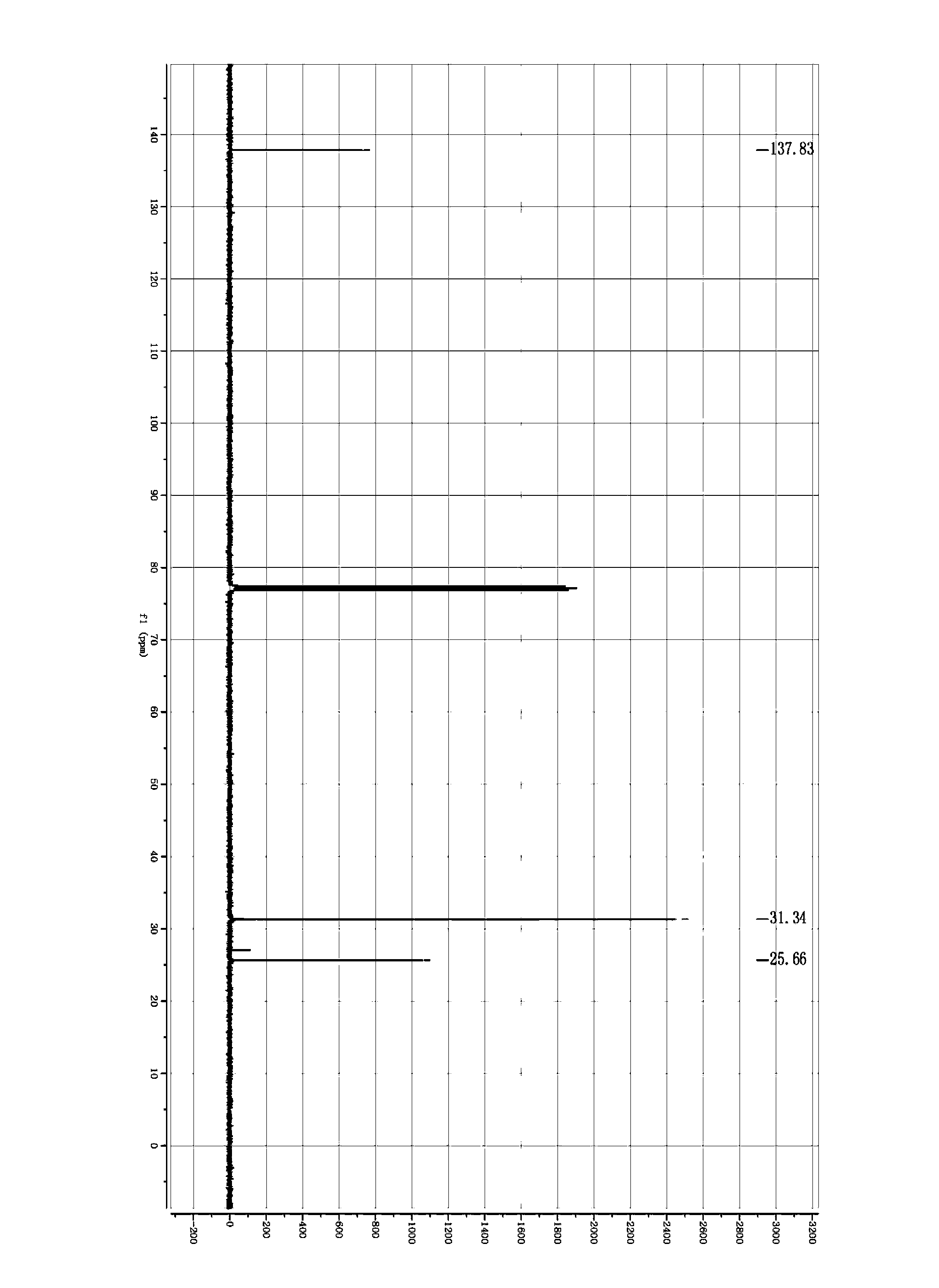

ActiveCN104232140AImprove combustion effectIncreased carrying energyLiquid hydrocarbon mixture productionBio-feedstockCarbon numberSolvent free

The invention relates to a synthetic route of a hydrocarbon fuel with high density and high volumetric calorific value by using a lignocelluloses-based platform chemical compound as a raw material and completely independent of fossil energy. A liquid fuel obtained by the method can be used in various aircrafts or used as an additive to raise combustion performance of aviation fuel. The method is divided into two parts: 1) under the promotion action of an acid / base catalyst, cyclopentanone (furfural selective hydrogenation product) is subjected to an aldol self-condensation reaction to synthesize unsaturated organic compounds with C10 and C15 polycyclic structures; and 2) a metal loaded A / X catalyst is used to carry out a one-step hydrodeoxygenation and hydrogenation reaction on products generated from the step 1 under low-temperature solvent-free conditions, so as to obtain polycyclic hydrocarbon fuel with carbon number being 10 and 15. The liquid fuel has high density (C10: 0.92g / cm<3>; C15: 1.12g / cm<3>), can be used to effectively raise carrying energy of an aircraft and reduce fuel consumption rate, and meets requirements of high navigational speed, large load and long range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

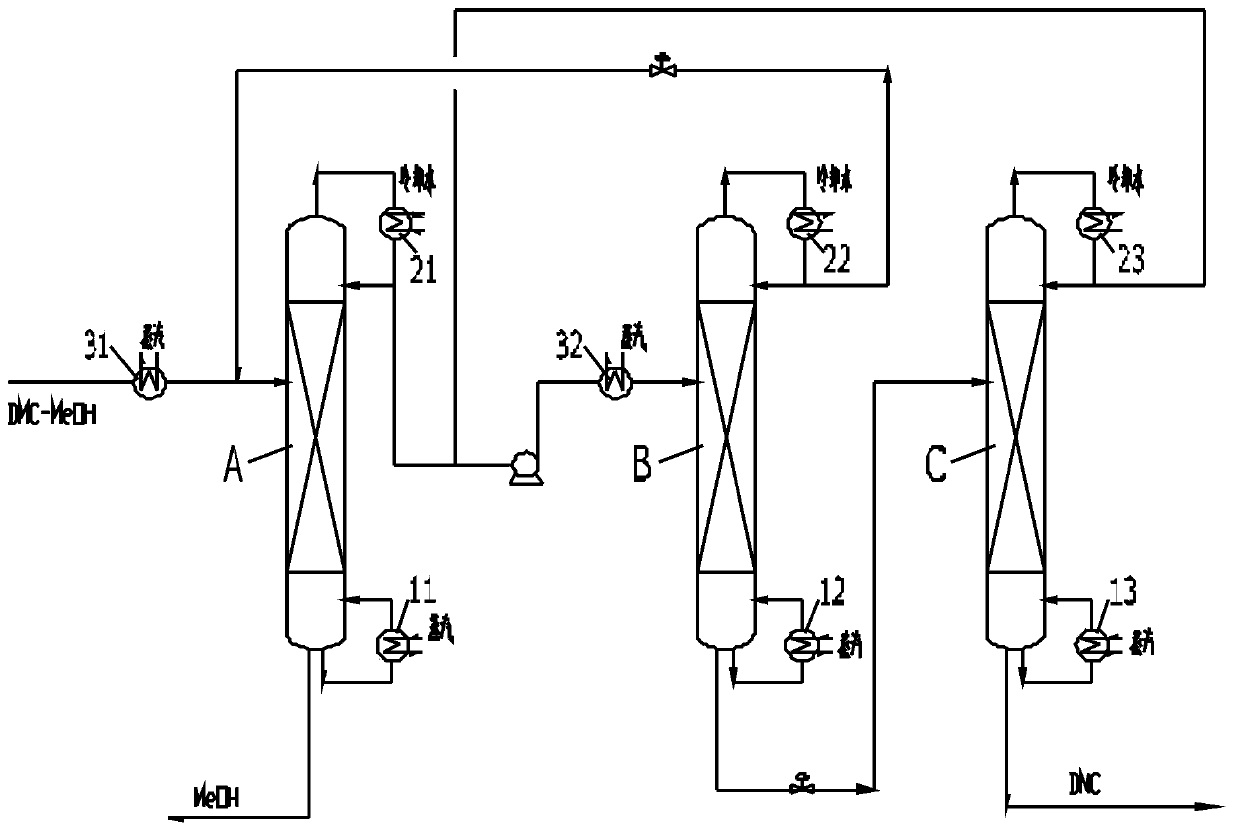

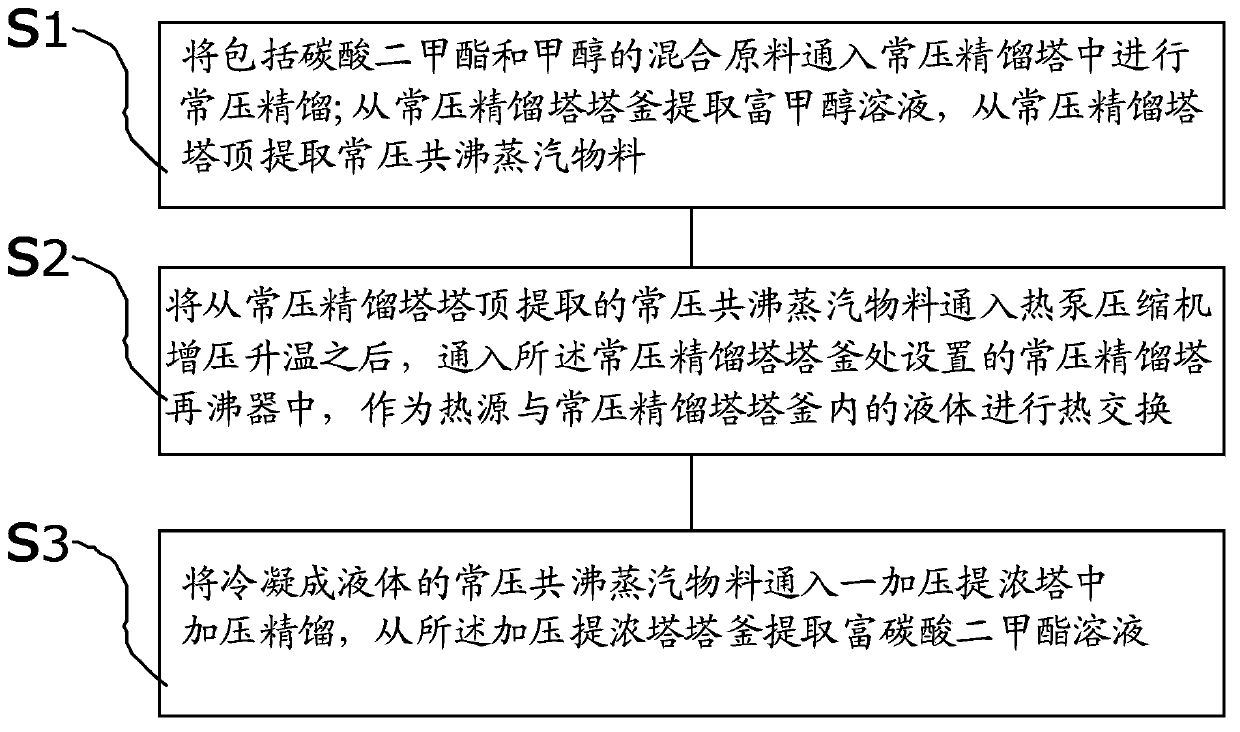

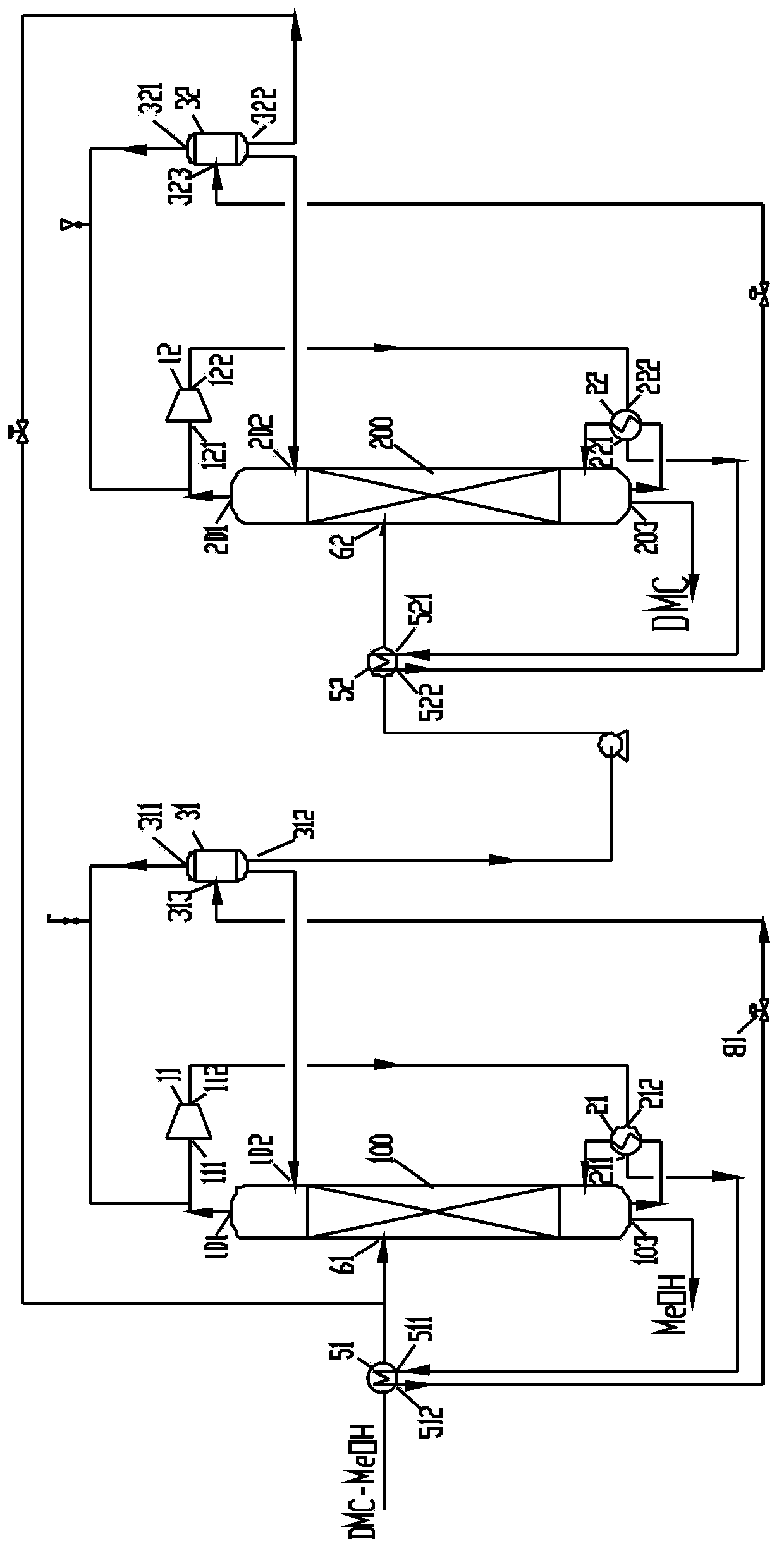

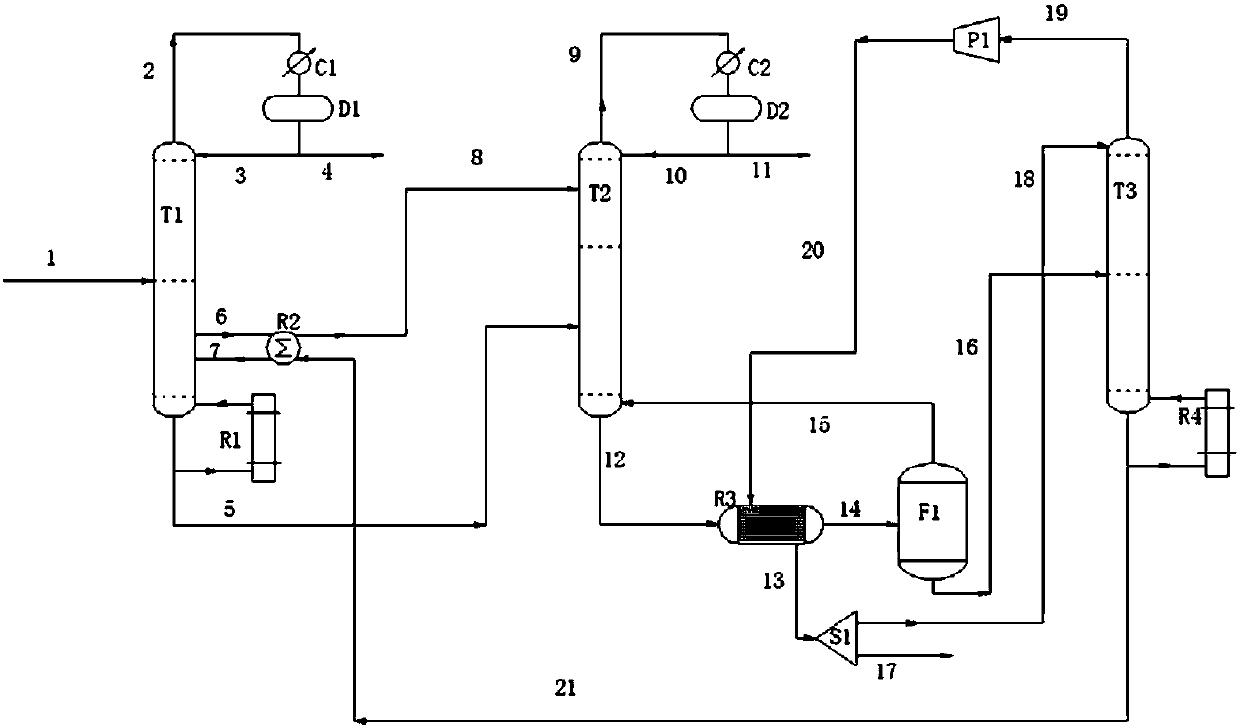

Method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and apparatus thereof

InactiveCN103626656AReduce energy consumptionLow costCarbamic acid derivatives preparationOrganic compound preparationReboilerSelf-condensation

The invention provides a method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and an apparatus thereof. In the dimethyl carbonate and methanol through pressure-swing distillation of the heat pump, an atmospheric azeotropic steam material obtained from the top of an atmospheric rectification tower is supercharged and heated by a heat pump compressor, and is introduced to a reboiler at the bottom of the atmospheric rectification tower as a heat source, so a liquid in the atmospheric rectification tower is heated, and the self-condensation of the atmospheric azeotropic steam material is completed. Compared with traditional atmospheric azeotropic steam material condensation through using cooling water and kettle liquid heating realized through an extra external heat source, the method in the invention properly improves the temperature and the pressure of an atmospheric azeotropic steam through the heat pump compressor to make the atmospheric azeotropic steam realize the kettle liquid heating and the reasonable and effective energy cycle as a heat source; and the cost generated by the pump heat compressor is far lower than the cost of traditional cooling water and the external heat source, so a good economic benefit is generated.

Owner:YASHENTECH CORP

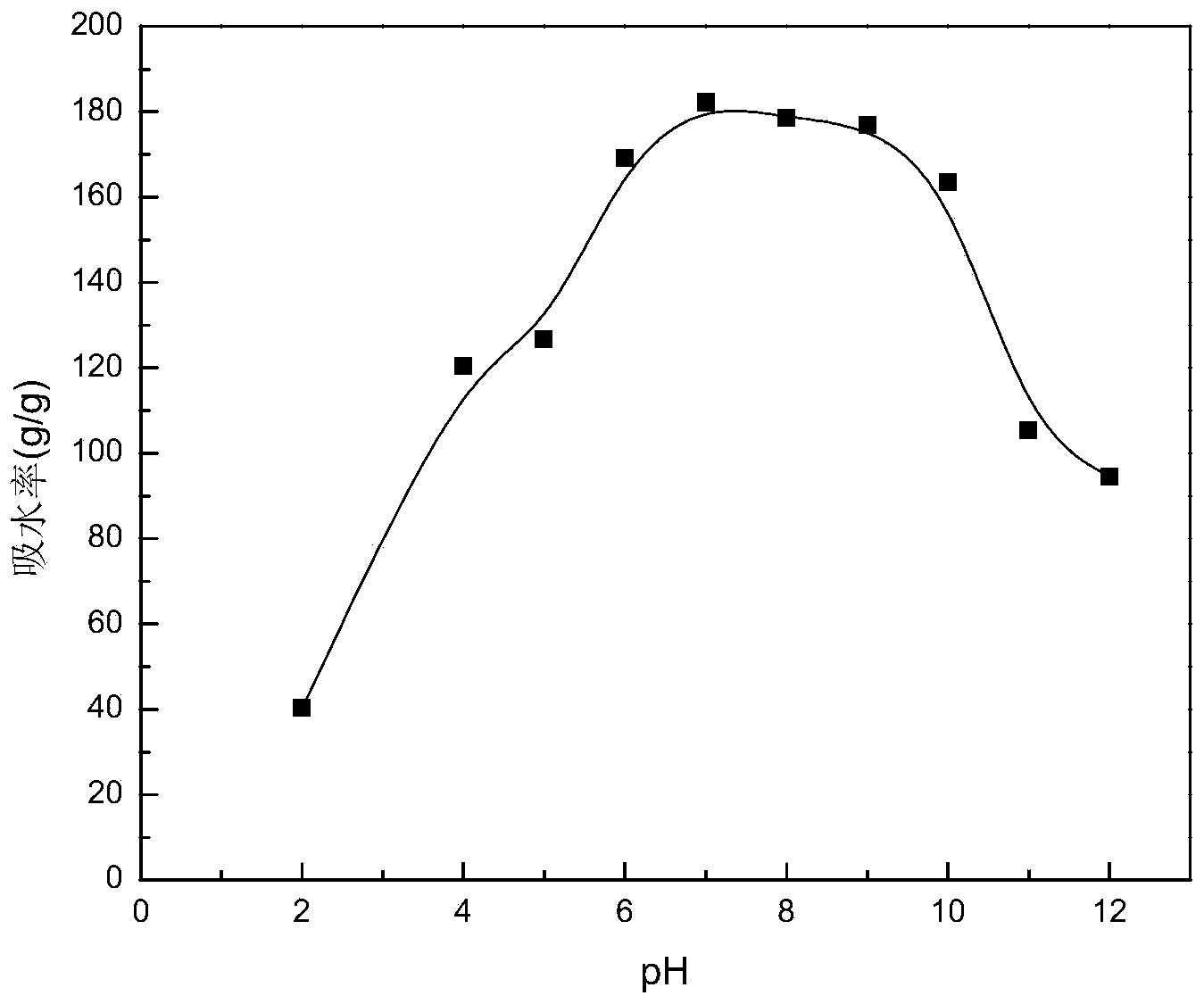

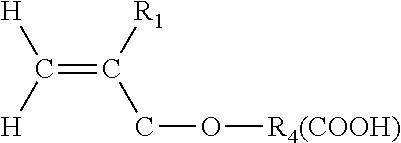

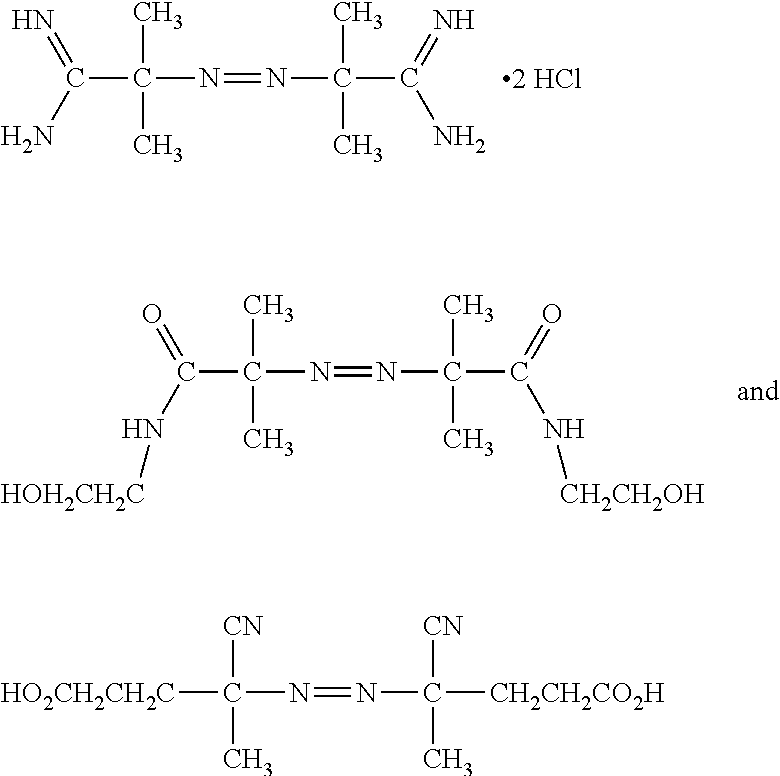

Preparation method of straw-based super absorbent resin with nitrogen phosphorus fertilizer slow-release function

The invention relates to a preparation method of straw-based super absorbent resin with a nitrogen phosphorus fertilizer slow-release function. The straw-based super absorbent resin with the nitrogen phosphorus fertilizer slow-release function is super absorbent resin having a semi-interpenetrating network structure, which is obtained by steps of carrying out graft copolymerization on cross-linked polymers (wheat straw, acrylic acid and polyvinyl alcohol) under the action of an initiator and a cross-linking agent to form a three-dimensional network polymer and interpenetrating with the cross-linked polymer polyvinyl alcohol simultaneously, wherein a part of the added nitrogen fertilizer reacts with acrylic acid, and the other part is subjected to a self-condensation reaction to be embedded in the resin; and the added phosphorus fertilizer is directly embedded in the resin in the own shape. The straw-based super absorbent resin with the nitrogen phosphorus fertilizer slow-release function prepared by the method disclosed by the invention has the advantages of good absorbent performance, salt resistance and the performance of continuously providing fertilizer for crops, high strength, low cost, simple and convenient production process and can be widely applied to agricultural water retention and fertilizer application.

Owner:SHANDONG UNIV

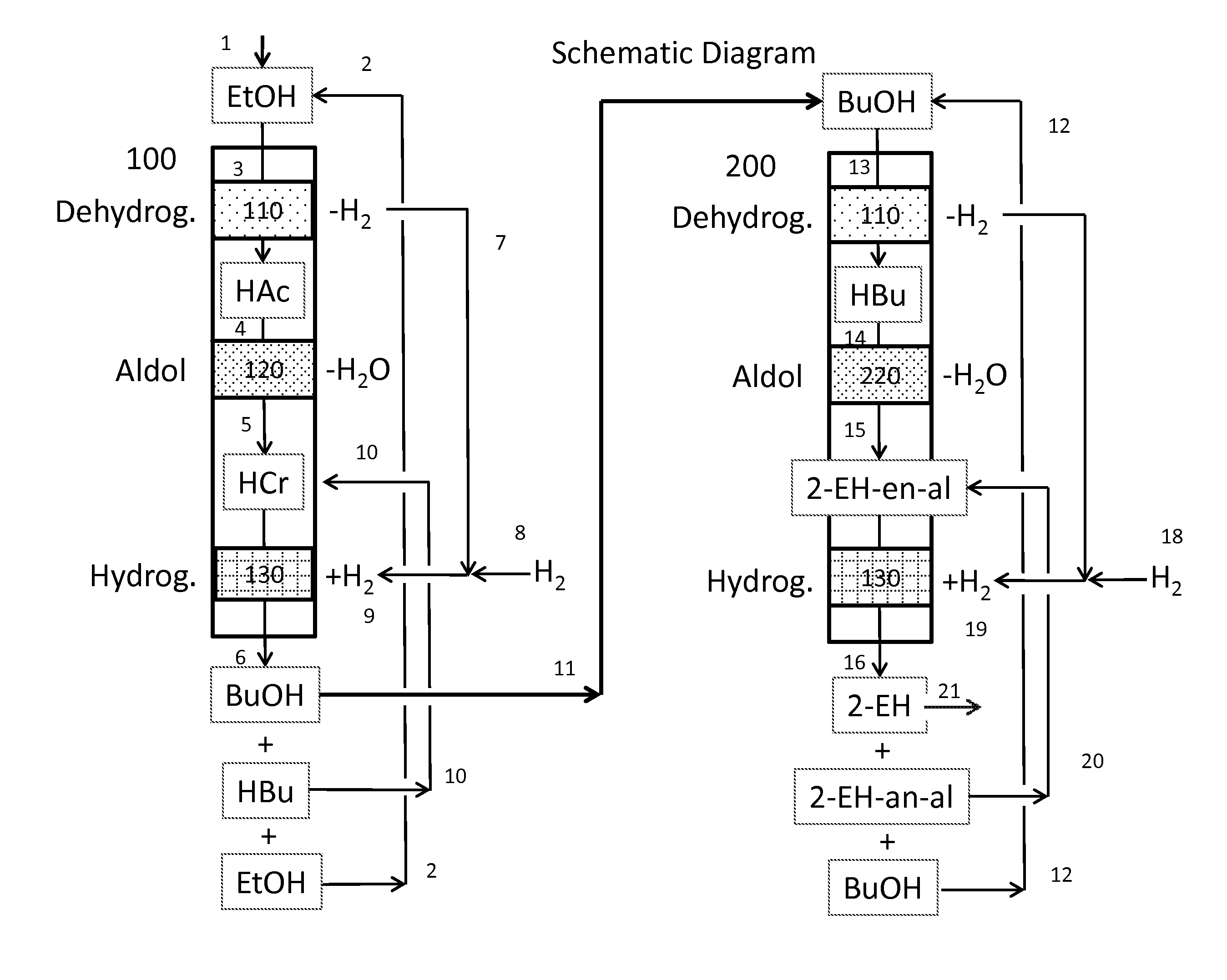

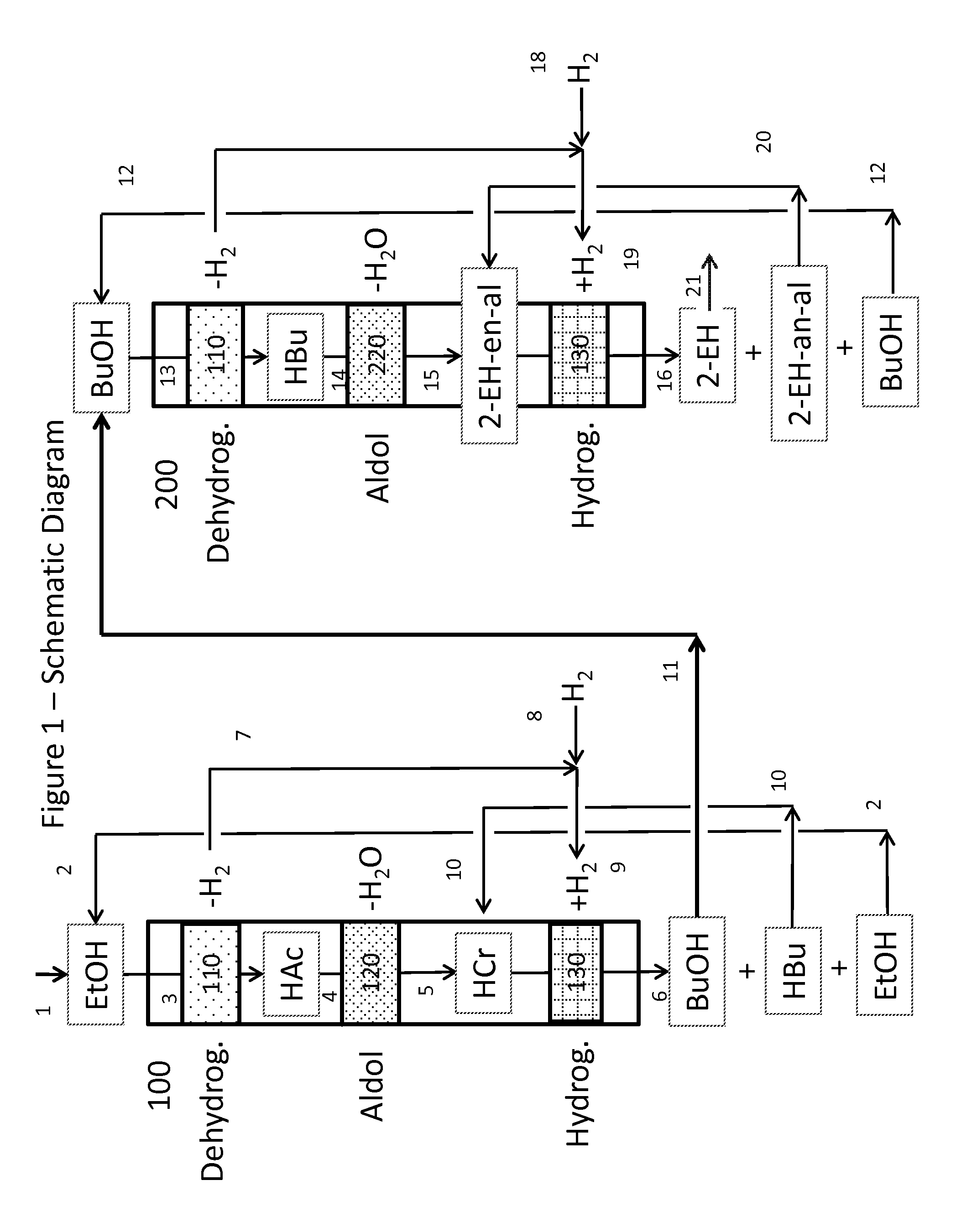

Dual catalyst system for the self-condensation of alcohols

ActiveUS20140088326A1Preparation from carboxylic acid saltsOrganic compound preparationCrotonaldehydeAlcohol

Disclosed is a process for the production of higher aldehydes from lower alcohols using a two-stage vapor phase heterogeneous catalyst system. Ethanol feeds afford aldehydes such as butyraldehyde and crotonaldehyde while butanol feeds yield 2-ethylhexanal and 2-ethylhexenal. Higher product selectivities are obtained when the alcohol is first dehydrogenated in the upper catalyst stage followed by aldol condensation of the resulting lower aldehyde to a higher aldehyde.

Owner:EASTMAN CHEM CO

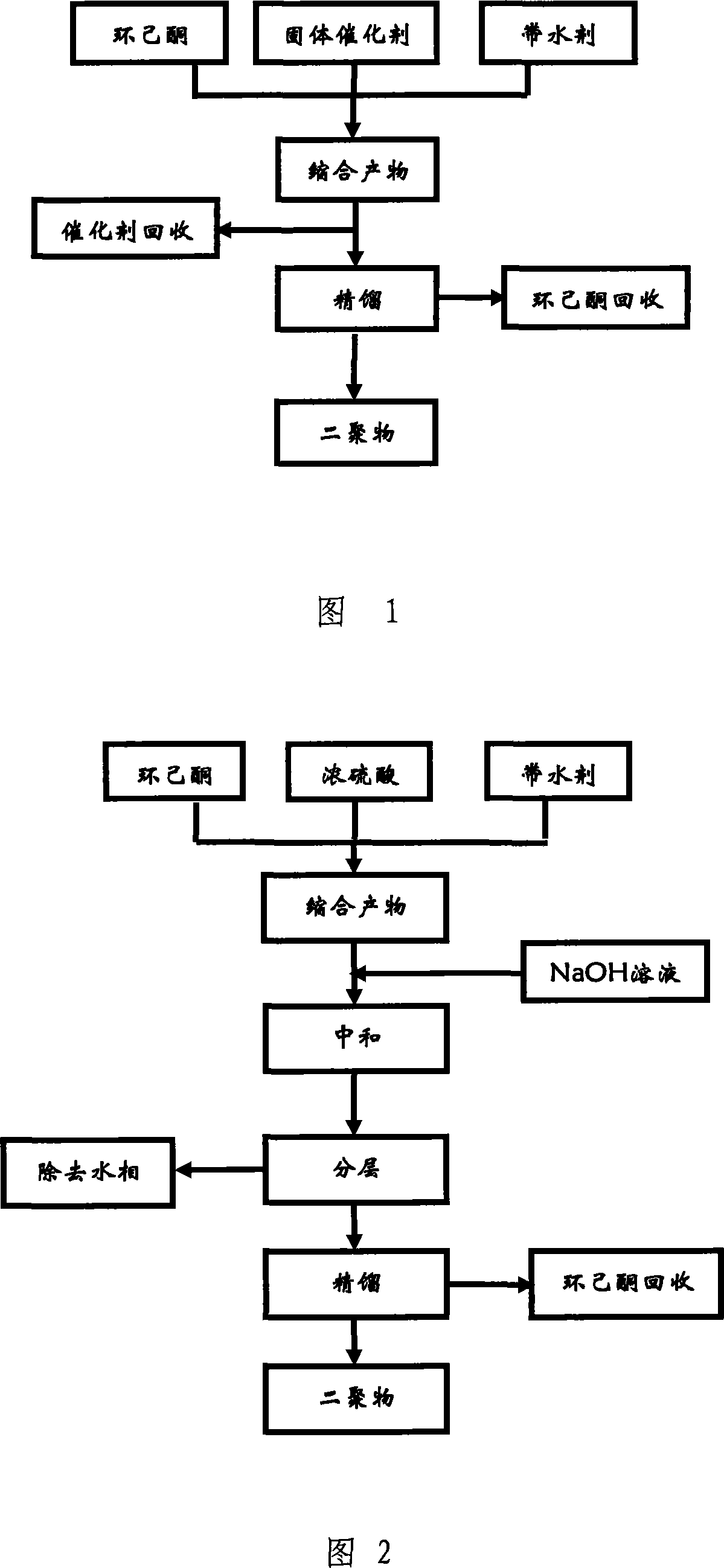

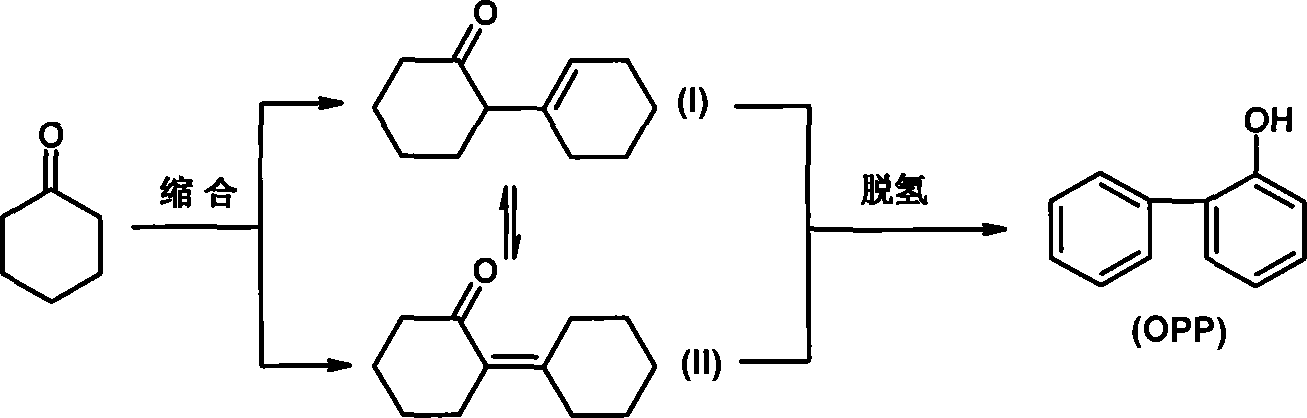

Utilization method of solid catalyst for cyclohexanone self-condensation reaction

The invention relates to a method for using a solid catalyst for the self-condensing reaction of a cyclohexanone, which comprises the steps that an alumina-based solid catalyst is used in the first step of condensing and dehydrogenating the cyclohexanone to prepare the O-phenylphenol, namely the step of the self-condensing of the cyclohexanone, and a certain used amount of the appropriate water-carrying agents are used in the process of using the alumina-based solid catalyst for the condensation reaction of the cyclohexanone; wherein, the used amount of the solid catalysts corresponds to 2 per cent to 5 per cent of that of the cyclohexanone and the reaction time ranges from 4 to 8 hours; also that any water-carrying agents is unused is okay and the characteristic that the cyclohexanone carries water is utilized to accomplish the reaction; the cyclohexanone undergoes the self-condensing reaction so as to generate two resonance isomers, 2-(1-cyclohexenyl) (I) cyclohexanone and 2-cyclohexenyl alkylidene cyclohexanone (II), under the effect of the prepared solid catalysts, and two demeric products can be both used as the raw materials for carrying out the dehydrogenation to prepare the O-phenylphenol.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

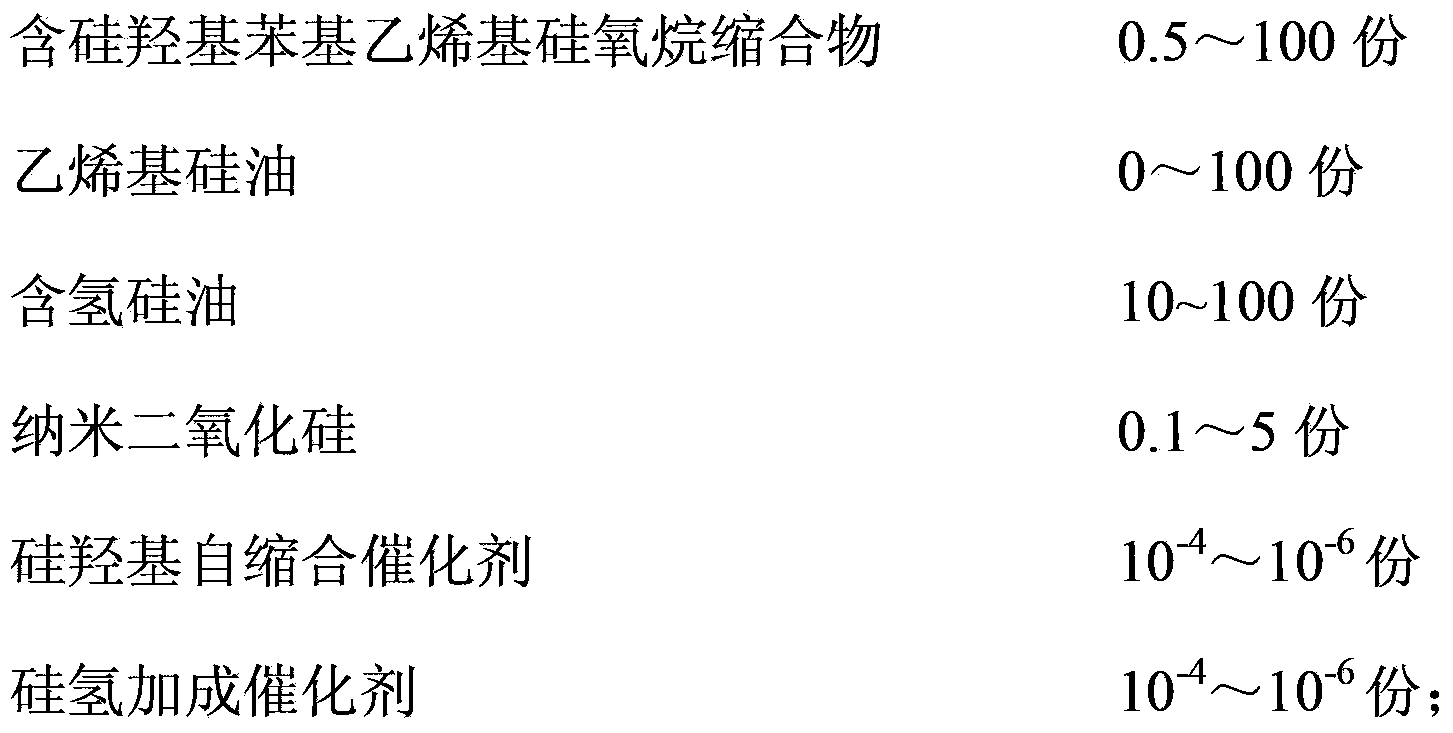

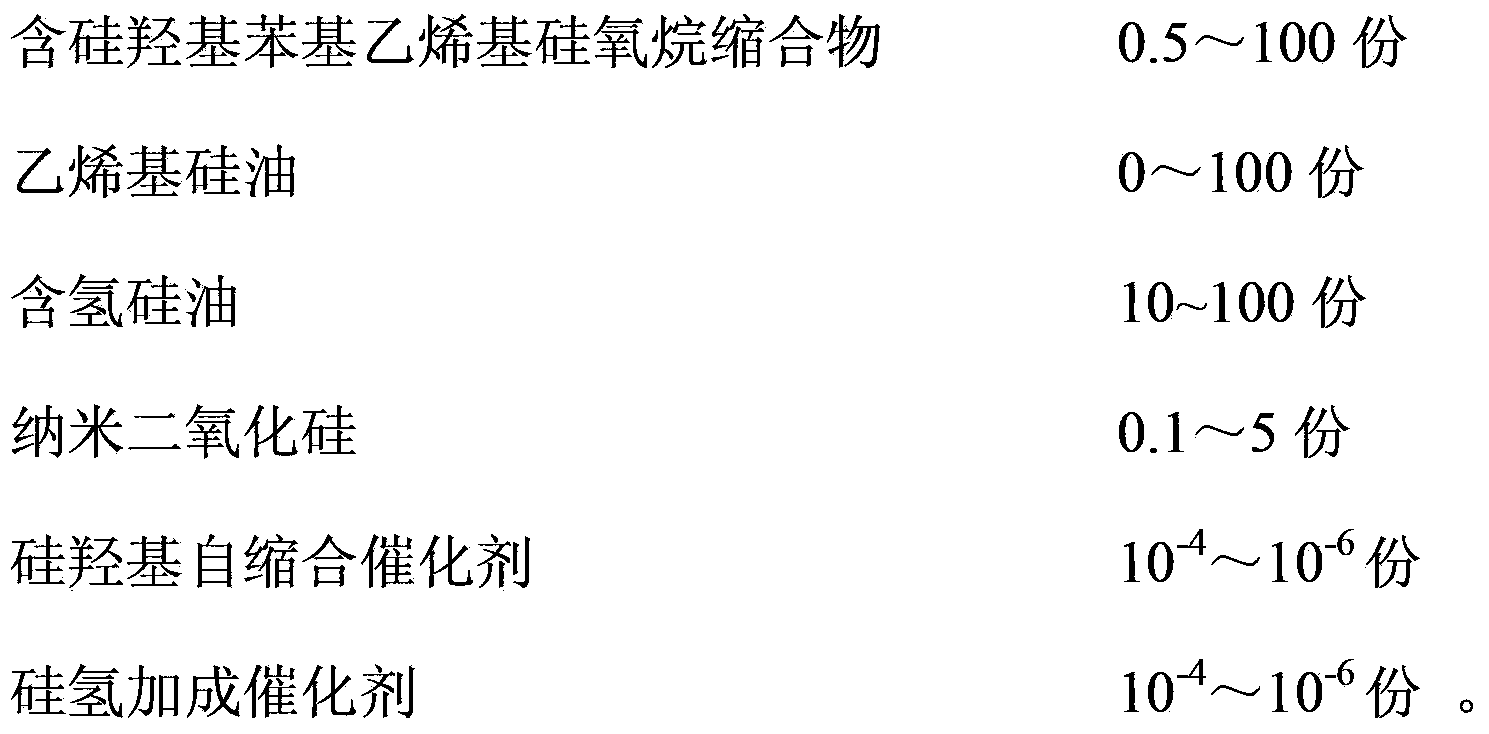

Dual-cured high-performance LED packaging material and preparation method thereof

ActiveCN103408947AHigh refractive indexImprove performanceSemiconductor devicesHydrosilylationSilicon dioxide

The invention relates to the field of organosilicon packaging materials, and discloses a dual-cured high-performance LED packaging material and a preparation method thereof. The preparation method of the packing material comprises the following steps: uniformly mixing the following components in parts by weight: 0.5-100 parts of condensation compound containing silicon hydroxyl phenyl vinyl siloxane, 0 to 100 parts of vinyl silicone oil, 10 to 100 parts of hydrogen-containing silicone oil, 0.1 to 5 parts of nano silica, 10<-4> to 10<-6> part of silicon hydroxyl self-condensation catalyst and 10<-4> to 10<-6> part of hydrosilylation catalyst; performing reaction for 0.1-0.5 hour at the temperature of 90-120 DEG C to realize hydrosilylation curing reaction; then rising the temperature up to 130-150 DEG C for reaction for 1-5 hours to realize condensation of silicon hydroxyl so as to obtain the product. The obtained material has high light transmittance, high refraction indexes and excellent high-temperature resistance and anti-ultraviolet ageing performance, and is suitable for substrate equipment, touchpads, LCD components and the like, which utilize the LED packing materials.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

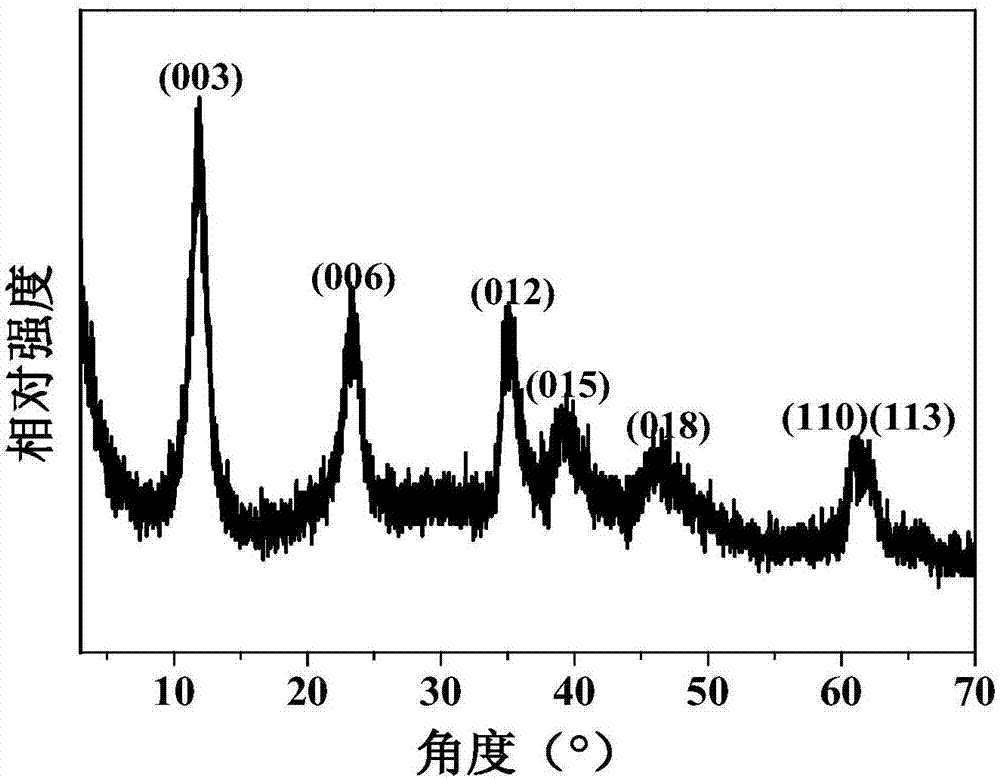

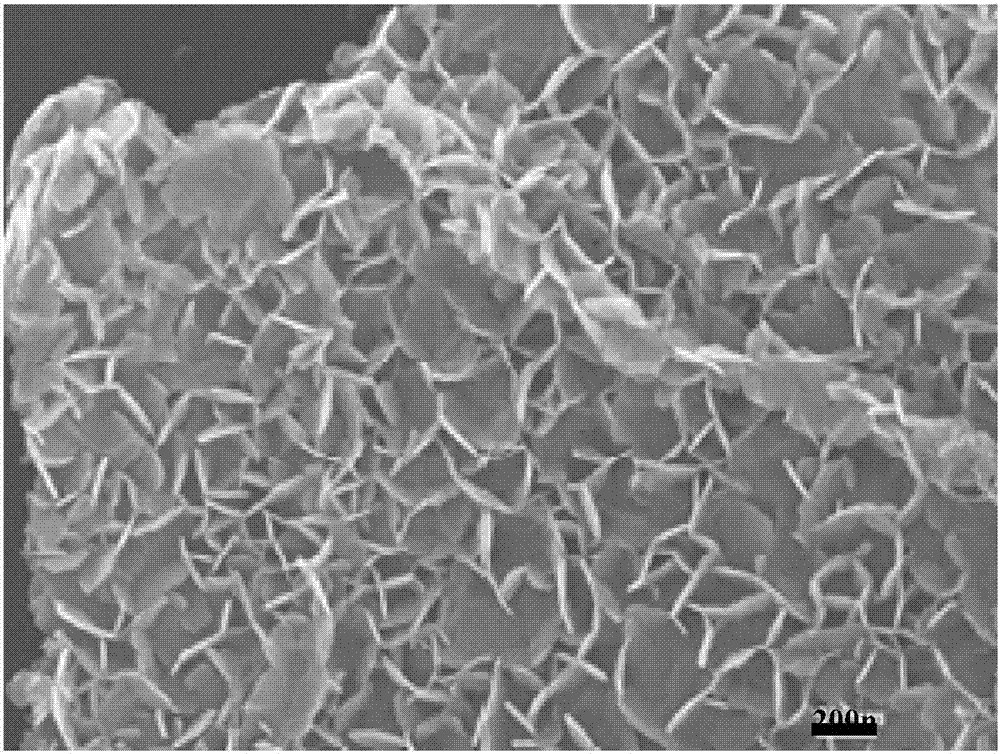

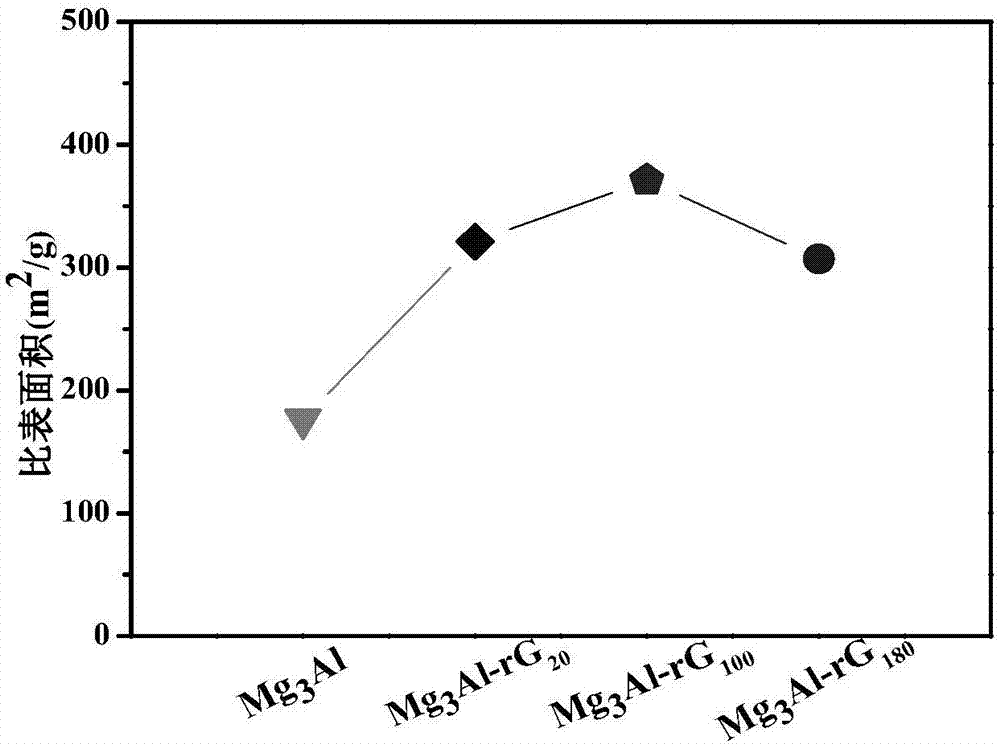

Preparation method of graphene-based composite solid base catalyst with 3D structure

InactiveCN106944028AImprove structural stabilityGood dispersionPhysical/chemical process catalystsOrganic compound preparationElectron transferStructural stability

The invention relates to a preparation method of a graphene-based composite solid base catalyst with a 3D structure. The method comprises the following steps: vertically growing magnesium aluminum hydrotalcite hexagonal crystal sheets on graphene oxide through adopting a one-step in situ growth technology, and carrying out high temperature calcination and hydration recovery to obtain the highly-active magnesium aluminum hydrotalcite / reduced graphene oxide solid base catalyst with a 3D array structure. The graphene oxide carrier with a high specific surface area facilitates the dispersion of the active sites of the marginal portion of the sheet structure of hydrotalcite to realize full exposure, and high interaction between a substrate and the sheet structure effectively improves the structural stability of the catalyst and improves the electron transfer rate in the catalytic reaction process. The graphene-based magnesium aluminum hydrotalcite solid base catalyst with a 3D composite structure has a good catalysis effect on the self-condensation reaction of acetone.

Owner:BEIJING UNIV OF CHEM TECH

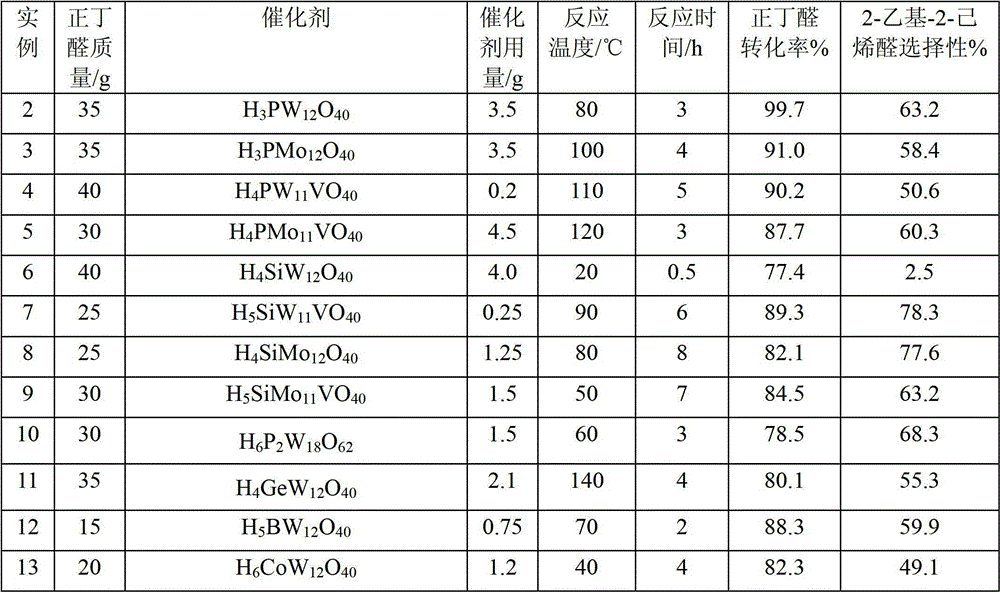

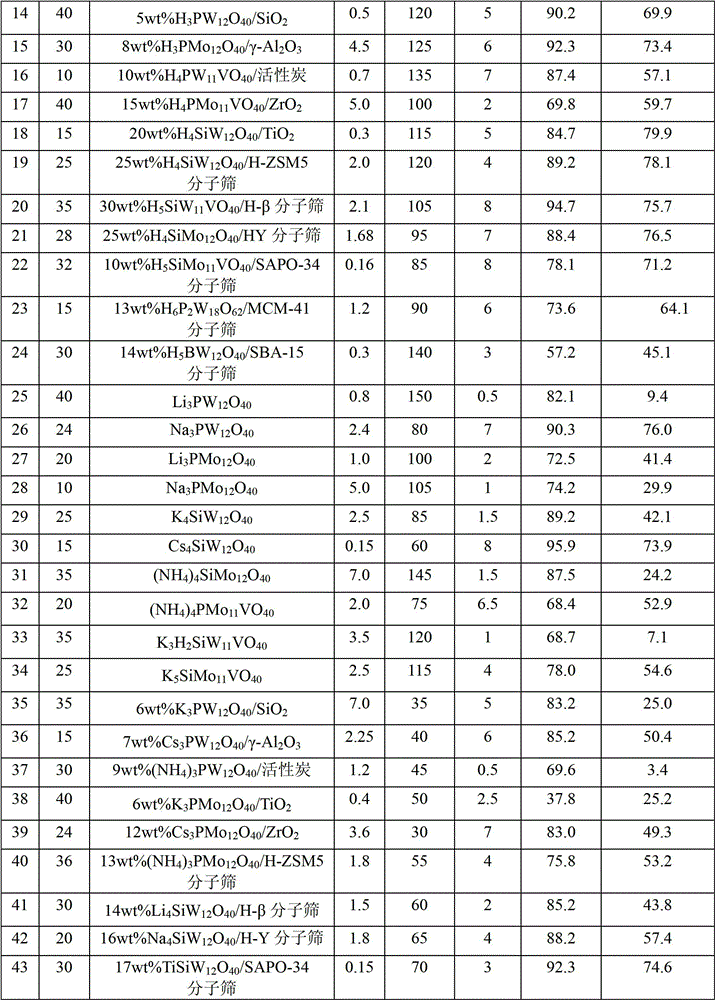

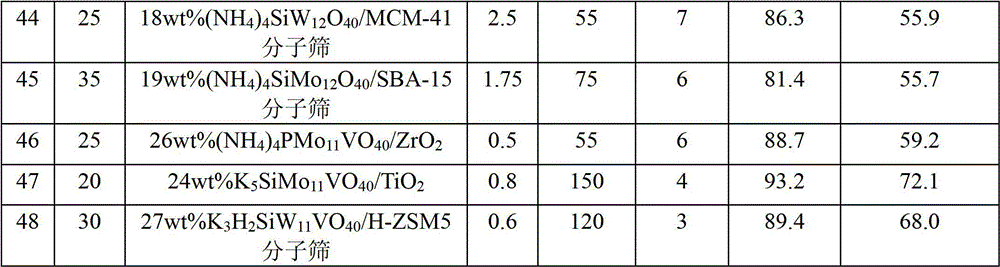

Process method for preparing 2-ethyl-2-hexenal by catalyzing self-condensation of n-butanal with heteropoly acid

InactiveCN102746129AGood choiceSimple post-processingOrganic compound preparationCarbonyl compound preparationHeteropoly acidSelf-condensation

The invention provides a process method for preparing 2-ethyl-2-hexenal (octenal) by catalyzing self-condensation of n-butanal with heteropoly acid. The method comprises the following steps of: adding n-butanal and a heteropoly acid catalyst into a high-pressure kettle, wherein the using amount of the catalyst is 0.5-15 percent of the mass of the added n-butanal; reacting under a magnetic stirring action at the temperature of 20-150 DEG C for 0.5-8 hours; and performing a self-condensation reaction on the n-butanal to obtain 2-ethyl-2-hexenal. The heteropoly acid catalyst used in the method is a heteropoly acid (salt) or supported heteropoly acid (salt) catalyst, has high low-temperature activity and high selectivity, and can be used repeatedly. The transformation rate of the n-butanal can be up to 99.7 percent in maximum, the selectivity of the 2-ethyl-2-hexenal can be up to 88.1 percent in maximum, the catalytic activity of the heteropoly acid catalyst is approximate to that of the conventional industrial liquid alkali, and the method has a good industrial application prospect.

Owner:HEBEI UNIV OF TECH

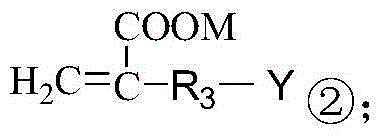

Preparation method for hyperbranched polycarboxylic-acid concrete efficient water reducer

Owner:JIANGSU SOBUTE NEW MATERIALS

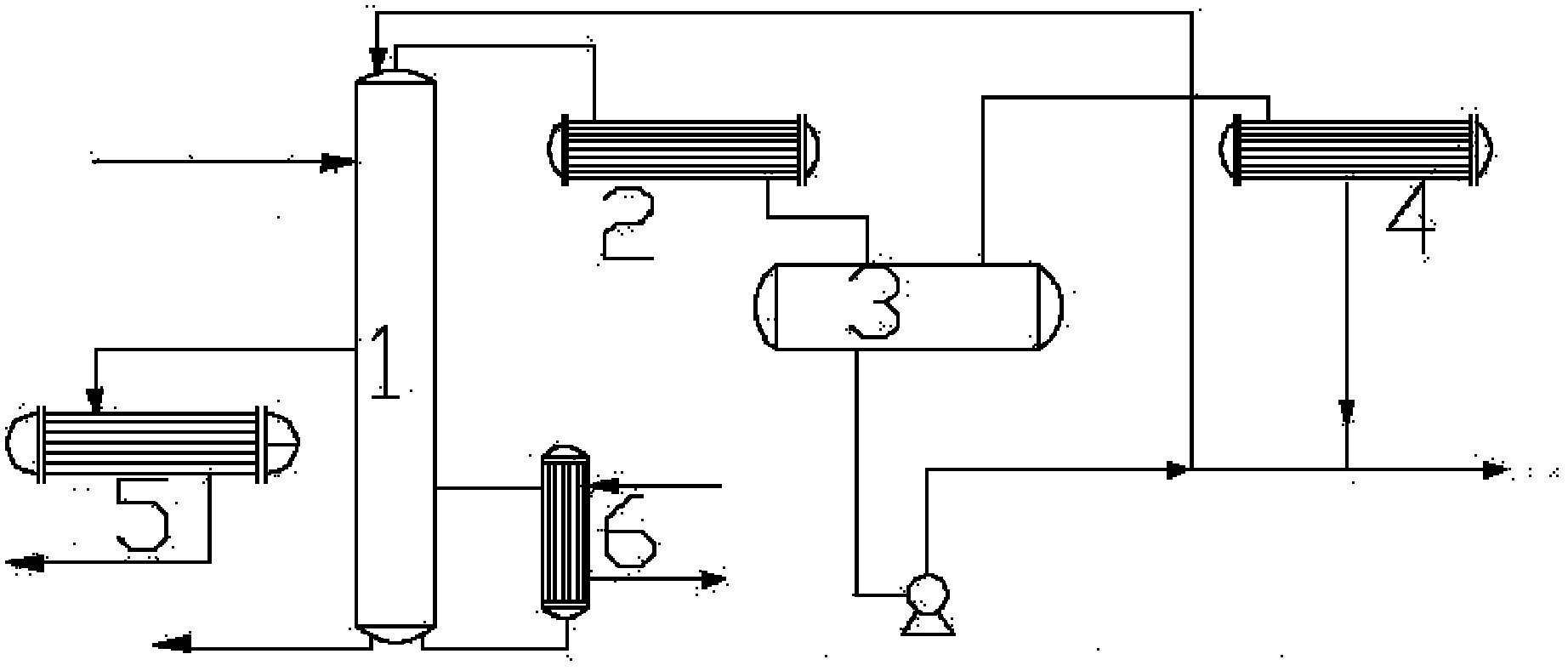

Preparation method of branched paraffin in range of gasoline, aviation kerosene or diesel

ActiveCN107304367AThe synthetic route is simpleEfficient synthetic routeLiquid hydrocarbon mixture productionBio-feedstockAlkaneAviation

The invention relates to a preparation method of branched paraffin in a range of gasoline, aviation kerosene or diesel. The preparation method mainly comprises two parts: (1) carrying out self-condensation reaction on a biomass ABE fermentation product on a first catalyst bed layer of a fixed bed continuous reactor under the catalysis of an acid / alkali catalyst or metal doped solid alkali, so as to obtain a C6-C21 oxygen-containing organic compound; and (2) further carrying out hydrodeoxygenation reaction on a product of the first fixed bed continuous reactor on a second fixed bed continuous reactor at a relatively low temperature and a solvent-free condition under the catalysis of a metal-loaded A / X type bifunctional catalyst, so as to obtain C6-C21 branched paraffin in the range of gasoline, aviation kerosene or diesel. The branched paraffin, namely a liquid fuel can be used as a potential substitute of existing gasoline, aviation kerosene or diesel.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

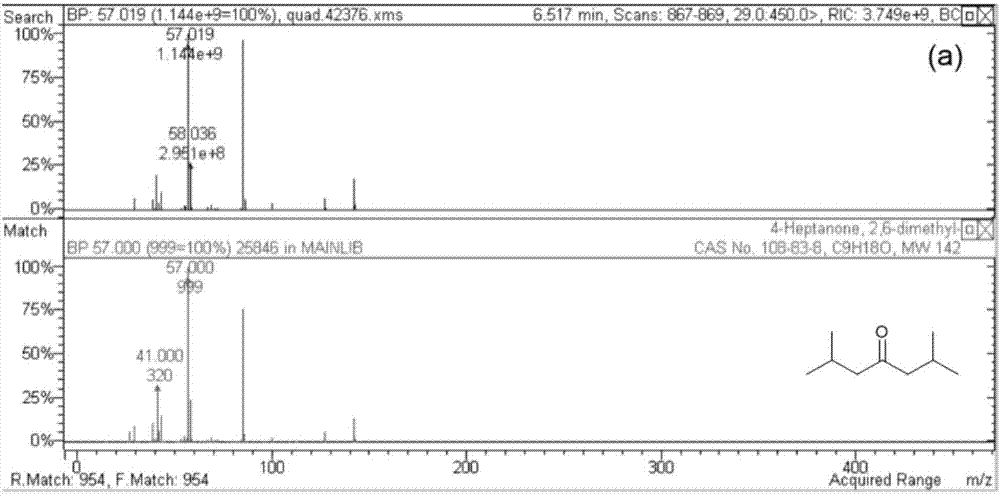

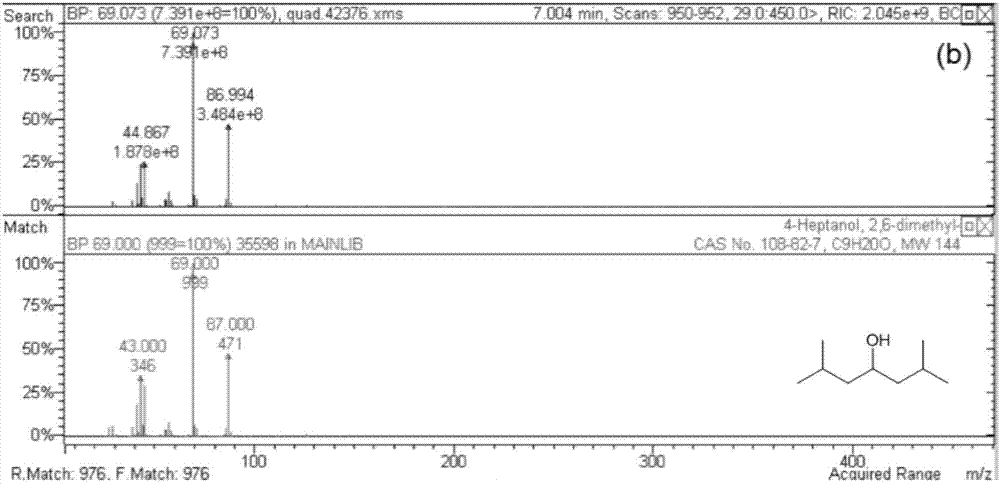

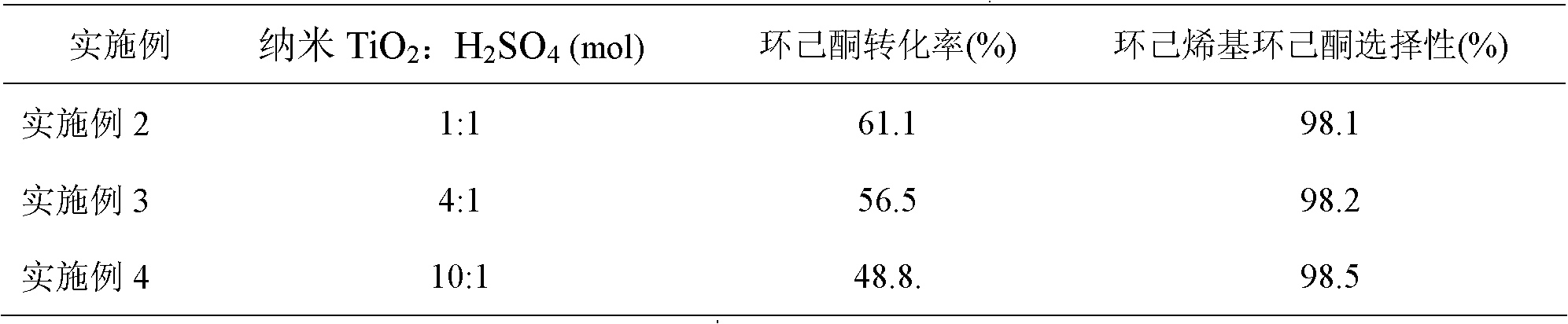

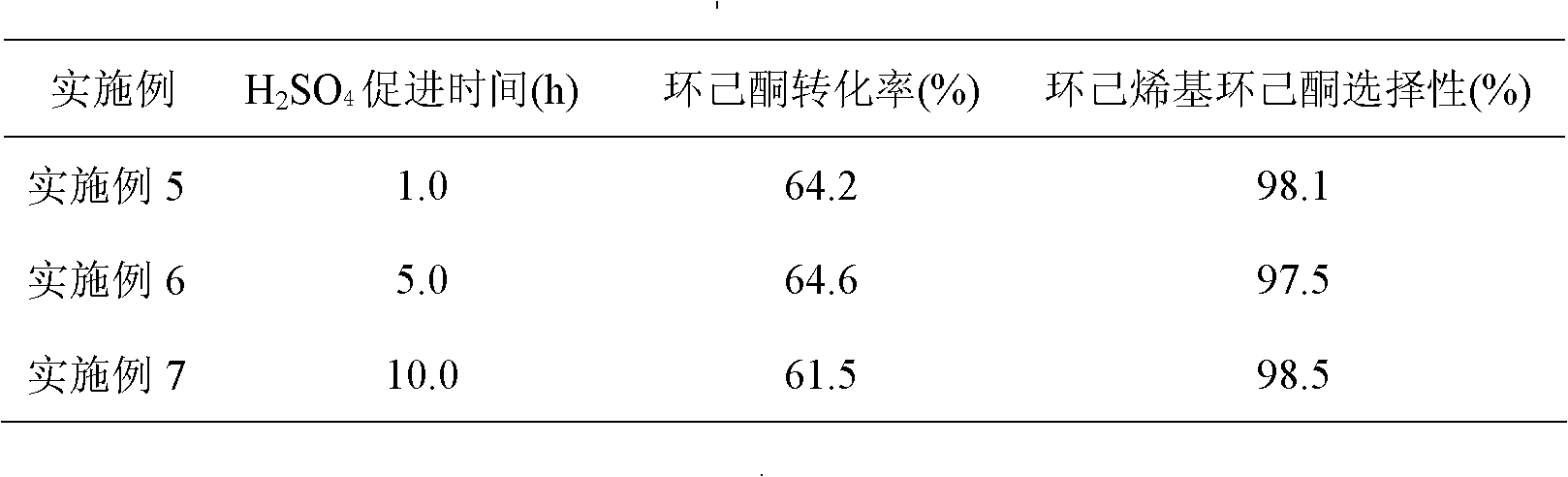

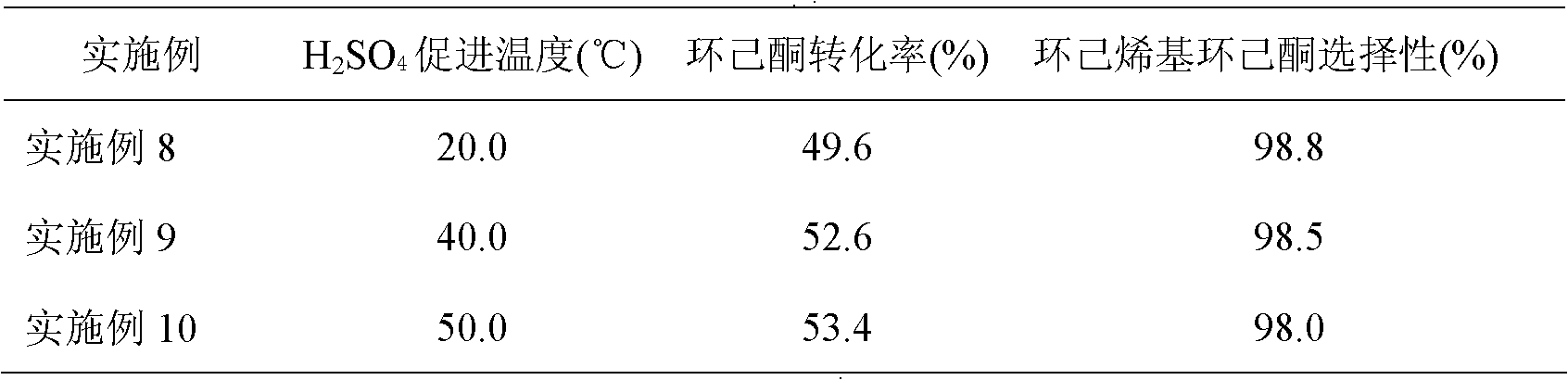

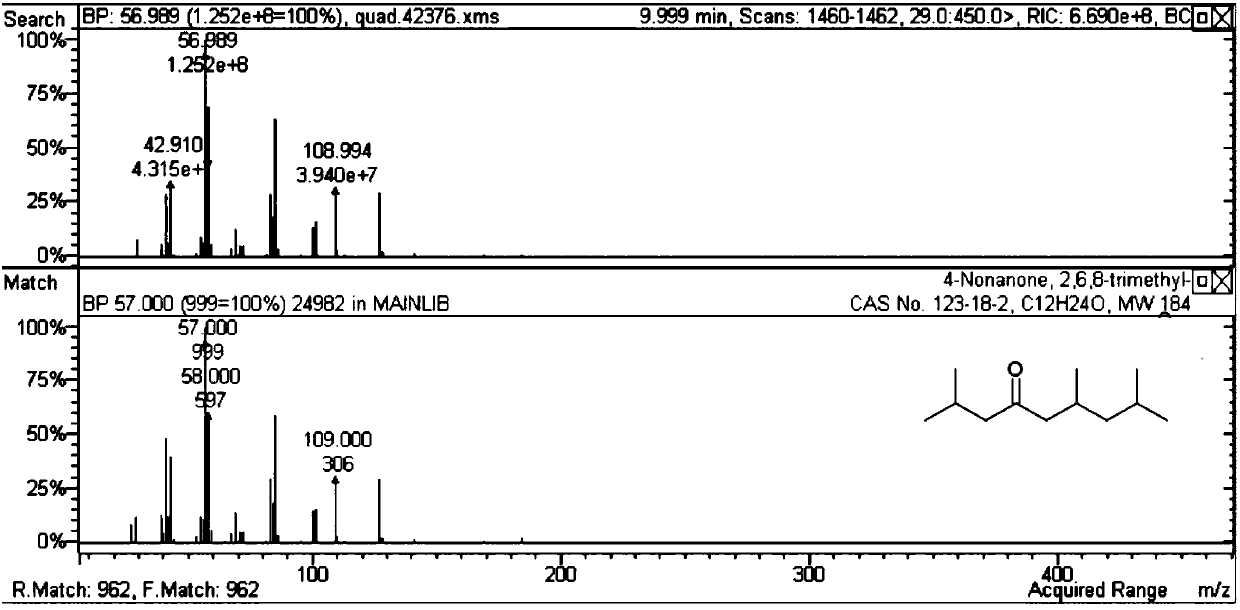

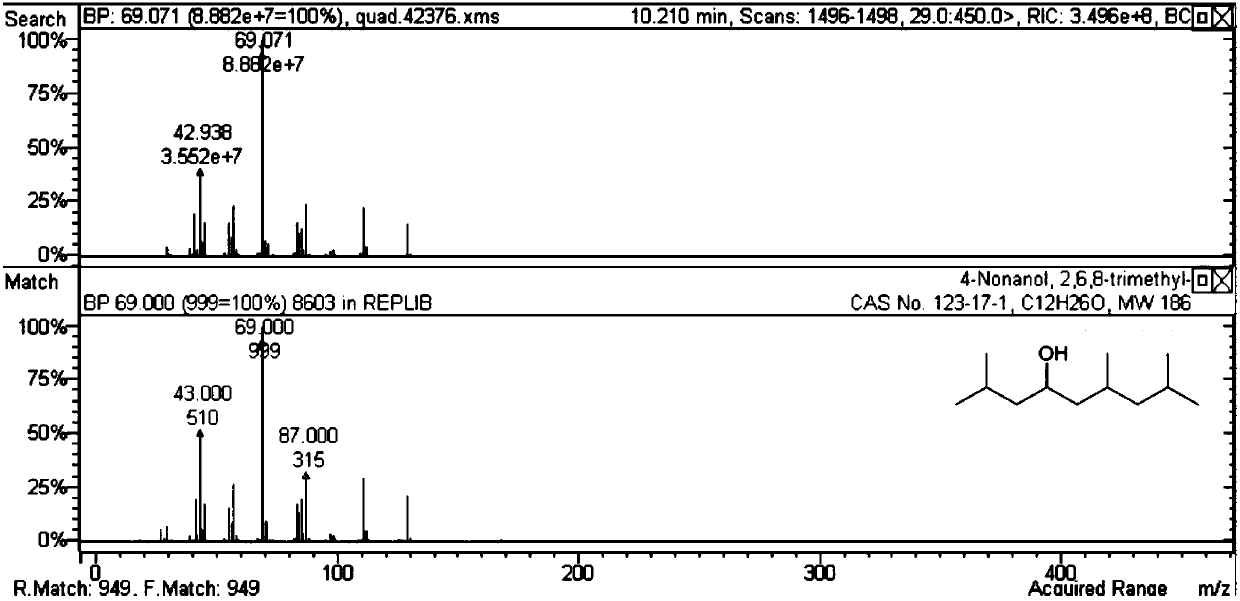

SO42-/nano TiO2 catalyst and application thereof to preparing cyclohexenyl cyclohexanone

InactiveCN102500398APhysical/chemical process catalystsOrganic compound preparationCyclohexanoneReaction temperature

The invention belongs to the technical field of catalysts, and particularly relates to a SO42- / nano TiO2 catalyst used in preparation of cyclohexenyl cyclohexanone through cyclohexanone self-condensation and a preparation method. In the invention, nano titanium dioxide is used as a raw material; mixing of sulfuric acid and nano titanium dioxide is promoted by using an impregnation method; and then drying and high-temperature roasting are performed to prepare the SO42- / nano TiO2 slid super acidic catalyst. The catalyst is applied to cyclohexanone self-condensation for catalytic synthesis of the cyclohexenyl cyclohexanone; and at the reaction temperature of 130-150 DEG C, the using amount of the SO42- / nano TiO2 catalyst is 2-5 percent, the reaction time is 2-3 hours, the cyclohexanone conversion rate is 45-65 percent, and the cyclohexenyl cyclohexanone selectivity reaches 97-99 percent.

Owner:NANJING UNIV OF TECH +1

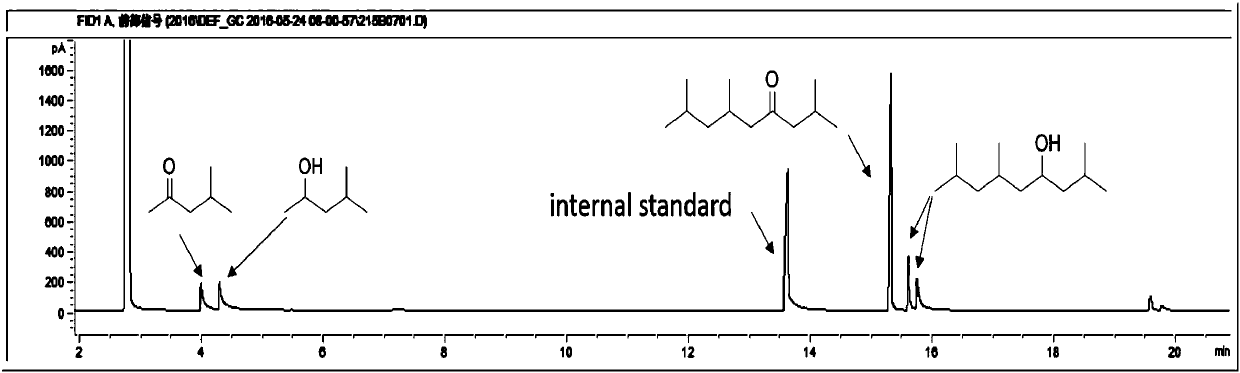

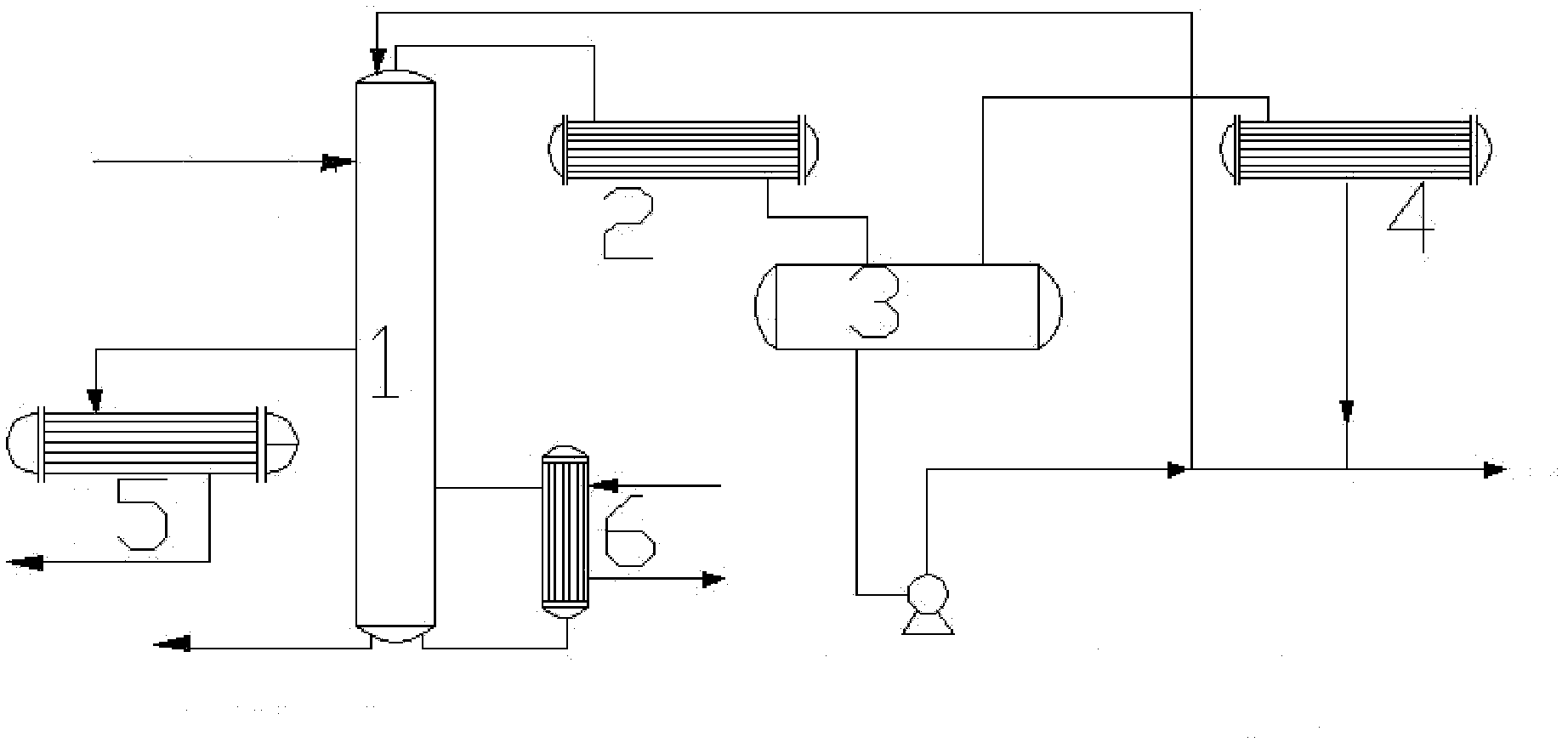

Preparation method for branched alkanes in range of gasoline, aviation kerosene and diesel oil

ActiveCN107794074AThe synthetic route is simpleEfficient synthetic routeOrganic compound preparationHydroxy compound preparationKeroseneMineral flotation

The invention relates to a preparation method for branched alkanes in a range of gasoline and aviation kerosene and biomass-based fatty alcohols. The method comprises the following two parts: (1) on afirst catalyst bed layer of a fixed-bed continuous reactor, methyl isobutyl ketone is subjected to a self-condensation reaction under catalysis of an acid catalyst, a base catalyst, a metal-doped solid acid catalyst, or a metal-doped solid base catalyst, so that an oxygen-containing organic compound with a carbon atom number of 12 is obtained; and (2) on a second catalyst bed layer of the fixed-bed continuous reactor, the generated product of the first catalyst bed layer and un-reacted raw materials are subjected to a one-step hydrodeoxygenation reaction under catalysis of a supported metal A / X-type bifunctional catalyst and conditions of a relatively high temperature and no solvents, and therefore the branched alkanes with carbon atom number of 6 and 12 in the range of the gasoline and the aviation kerosene are obtained. According to the invention, the saturated alcohols with a carbon atom number of 6 can be used as mineral flotation agents, and the saturated alcohols with a carbon atom number of 12 can be used for synthesis of biomass-based surfactants and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for solvent refining during isoprene rubber production

InactiveCN102504066APrecise control of operating pressurePrecise temperature controlRefluxDistillation

The invention relates to a method for solvent refining during isoprene rubber production. According to the method, the solvent recovered from a self-condensation process is conveyed into a distillation tower from the top of the tower; light components on the top of the tower are subjected to a total reflux operation through a tower top condenser and a reflux tank, or are subjected to small amount continuous recovery under the operation with a large reflux ratio more than 20, and the free water is separated from the reflux tank, and a small amount of uncondensed gases on the top of the tower are discharged to a tail gas condenser; the tower kettle liquid containing weight components is subjected to intermittent or continuous small flow rate recovery; the treated solvent is recovered from the side stream through the middle part of the tower in a vapor phase form, and is condensed by a side stream condenser, and the resulting solvent is conveyed to a polymerization process to directly use, wherein the treated solvent is the qualified solvent through the refining. According to the present invention, only a distillation tower is adopted in the method, the removal works of the water and other light components, and the heavy components are achieved in the single tower, the process is simple, the equipment investment is low, and the energy consumption is small, such that the production and operation cost can be effectively reduced.

Owner:广东鲁众华新材料有限公司

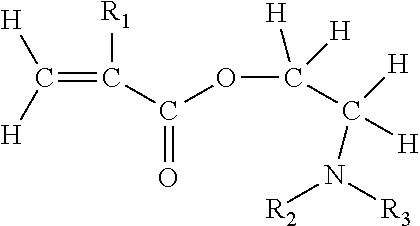

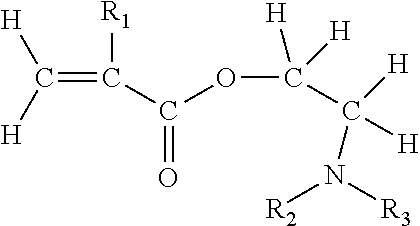

Controlled release dual walled microcapsules

ActiveUS20160108339A1Enhanced release propertiesGood physical propertiesCosmetic preparationsToilet preparationsMethacrylatePolymer science

A method of forming dual melamine / acrylic walled microcapsules having improved physical properties and release control as well as the microcapsules formed by the process wherein the capsule wall is formed by the use of select (meth)acrylate monomers and / or oligomers and / or select self-condensing melamine resins.

Owner:ENCAPSYS LLC

Energy-saving technology for performing extractive distillation separation on methanol, isopropanol and water through heat pump

ActiveCN107628930ASolve the problem of difficult azeotropic separationHigh purityOrganic compound preparationEnergy inputReboilerExtractive distillation

The invention provides an energy-saving technology for performing extractive distillation separation on methanol, isopropanol and water through a heat pump. In the method for performing extractive distillation separation on a methanol, isopropanol and water mixture through the heat pump, vapor at the top of a dehydration tower is boosted by utilizing a heat pump compressor to be used as a heat source at the bottom of an isopropanol removal tower, and the self condensation of the vapor at the top of the dehydration tower can be completed; and an extractant heat matter stream recycled at the bottom of the dehydration tower is adopted as a heat source of a middle reboiler of a methanol removal tower. The temperature and pressure of vapor at the top of the dehydration tower are properly increased through the heat pump compressor to be used as a heat source for heating reactor liquid, thus realizing reasonable and effective energy circulation; and the cost spent by the heat pump compressoris lower than that of the traditional external heat supply and cooling water, so that good economic benefits can be gained.

Owner:QINGDAO UNIV OF SCI & TECH

Controlled release dual walled microcapsules

ActiveUS9714396B2Enhanced release propertiesGood physical propertiesCosmetic preparationsOrganic detergent compounding agentsMethacrylatePolymer science

Owner:ENCAPSYS LLC

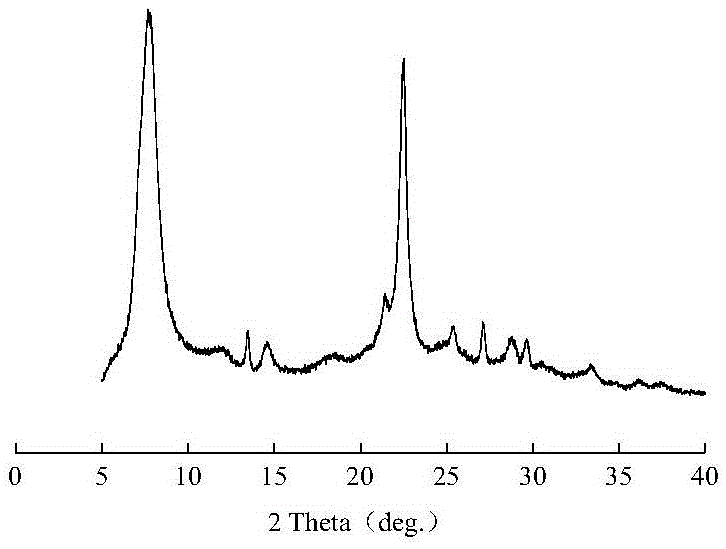

Hierarchical pore Hbeta molecular sieve catalyst for preparing diphenylamine by condensing aniline as well as preparation method and application thereof

ActiveCN105618106AShorten the mass transfer distanceNot easy to blockMolecular sieve catalystsAmino compound preparation by condensation/addition reactionsMolecular sieveSelf-condensation

The invention discloses a hierarchical pore Hbeta molecular sieve catalyst for preparing diphenylamine by condensing aniline. The hierarchical pore Hbeta molecular sieve catalyst is prepared by virtue of a direct synthetic method or a micropore molecular sieve modification indirect synthetic method. The invention also discloses a preparation method of the hierarchical pore Hbeta molecular sieve catalyst as well as an application in preparing diphenylamine by catalyzing the condensation of the aniline. Under the effect of a formed catalyst prepared by the hierarchical pore Hbeta molecular sieve catalyst, the aniline has a self-condensation reaction to prepare diphenylamine, the reaction temperature is 290 to 370 DEG C, the reaction pressure is 1.5MPa to 5MPa, and the airspeed is 0.1 to 0.7 / h. The molecular sieve catalyst has the advantages of good catalytic activity, good stability and high diphenylamine selectivity. Compared with the corresponding ordinary micropore Hbeta molecular sieve, the conversion rate of the aniline is at least increased by 23%, the selectivity of the diphenylamine is at least increased by 1%, and the service life of the catalyst can reach more than 7000 hours.

Owner:NANJING UNIV OF TECH

Process for preparing deoxy fructosazine

InactiveCN1821231AImprove conversion rateSimple processOrganic chemistryReaction temperatureSelf-condensation

The preparation process of deoxy fructosazine features that the self condensation reaction of aminoglucose or its salt as reaction material in the presence of boric acid or borate as catalyst, the nanofiltering film separating technology to separate the side product and intercept the target product deoxy fructosazine, and the concentration and re-crystallization of the intercepted product liquid to obtain the target product deoxy fructosazine. Compared with available technology, the present invention has the advantages of simple technological process, convenient operation, short reaction period, low power consumption and high deoxy fructosazine yield up to 55-60 %, and the features of homogeneous reaction, low reaction temperature, no toxicity, low cost and high conversion rate, and may be used in industrial production.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

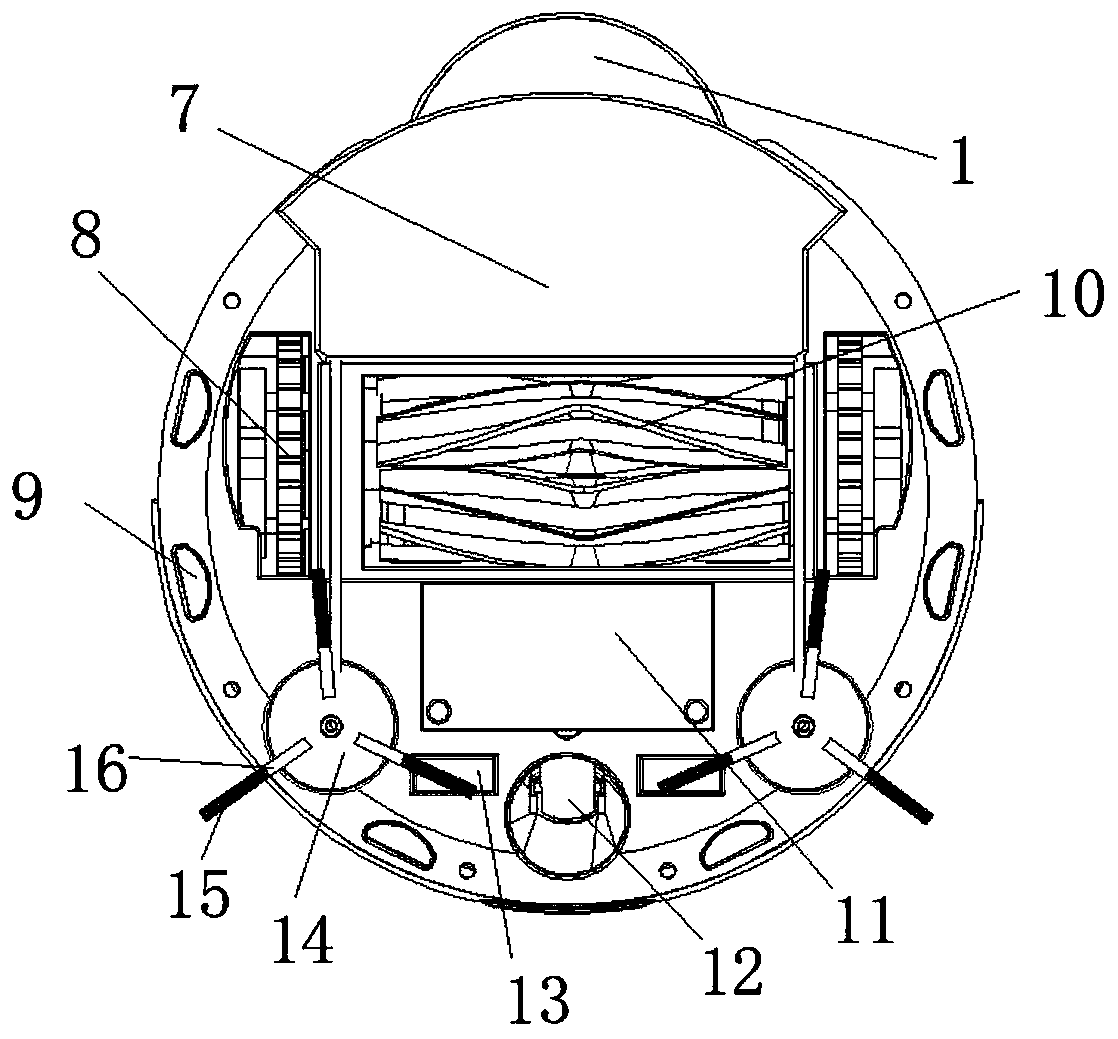

Self-water-supply type dehumidification and purification integrated cleaning device

ActiveCN110613403AEasy to cleanConserve waterAutomatic obstacle detectionTravelling automatic controlBristleWater source

The invention discloses a self-water-supply type dehumidification and purification integrated cleaning device. The device comprises a water storage tank; an inserting groove is formed in the middle ofthe inner side of the water storage tank, and a controller is fixedly connected to one end of the water storage tank. According to the device, a condenser is arranged to exchange heat through a heatexchange pipe, thus cooling a condensation plate, adsorbing vaporous water; the vaporous water flows into a water collecting tank to be collected through gravity, and is used for wetting a rolling type mop, so water source is saved, the drying and dehumidifying effects are achieved; in addition, the wetted rolling type mop has a good cleaning effect; a rotating shaft is arranged to drive a brush roller and the bristles to sweep large garbage and adsorb the garbage into a garbage box; UV lamps are used for sterilizing and disinfecting the ground and inhibiting bacteria, universal wheels at thebottom are matched with a synchronous crawler belt to achieve good moving capacity; the cleaning device can effectively obtain continuous water flow through self-condensation air to wet and clean mopcloth, the cleaning effect can be effectively improved, and meanwhile a certain dehumidification effect is achieved.

Owner:四川发展环境科学技术研究院有限公司

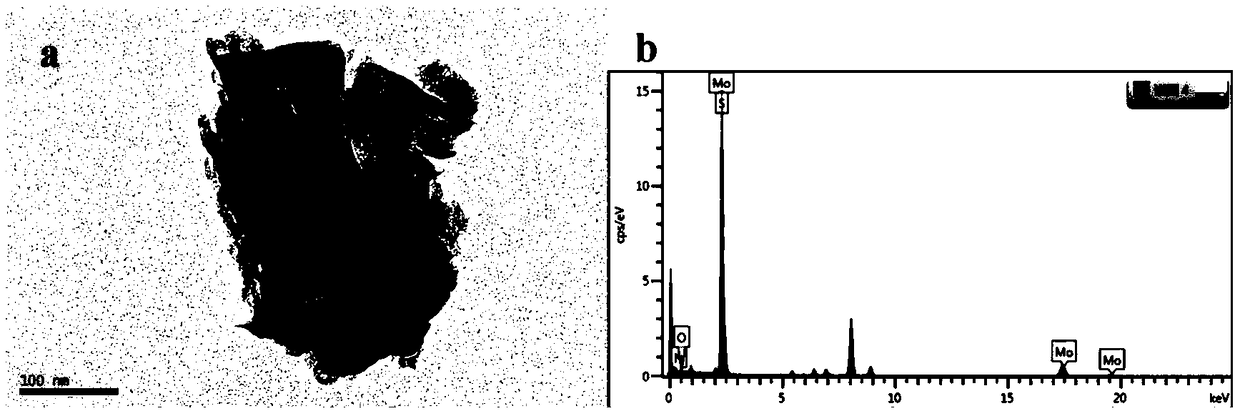

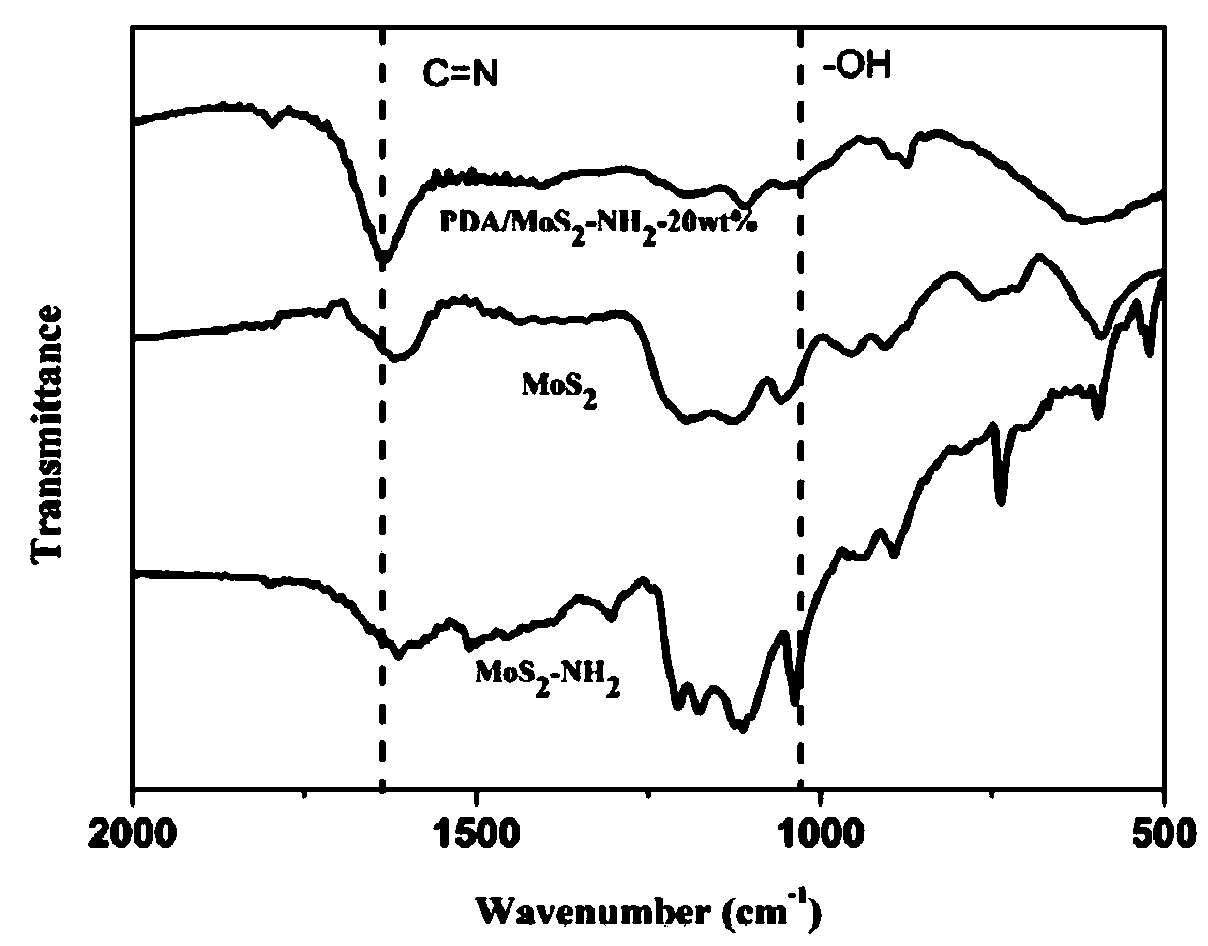

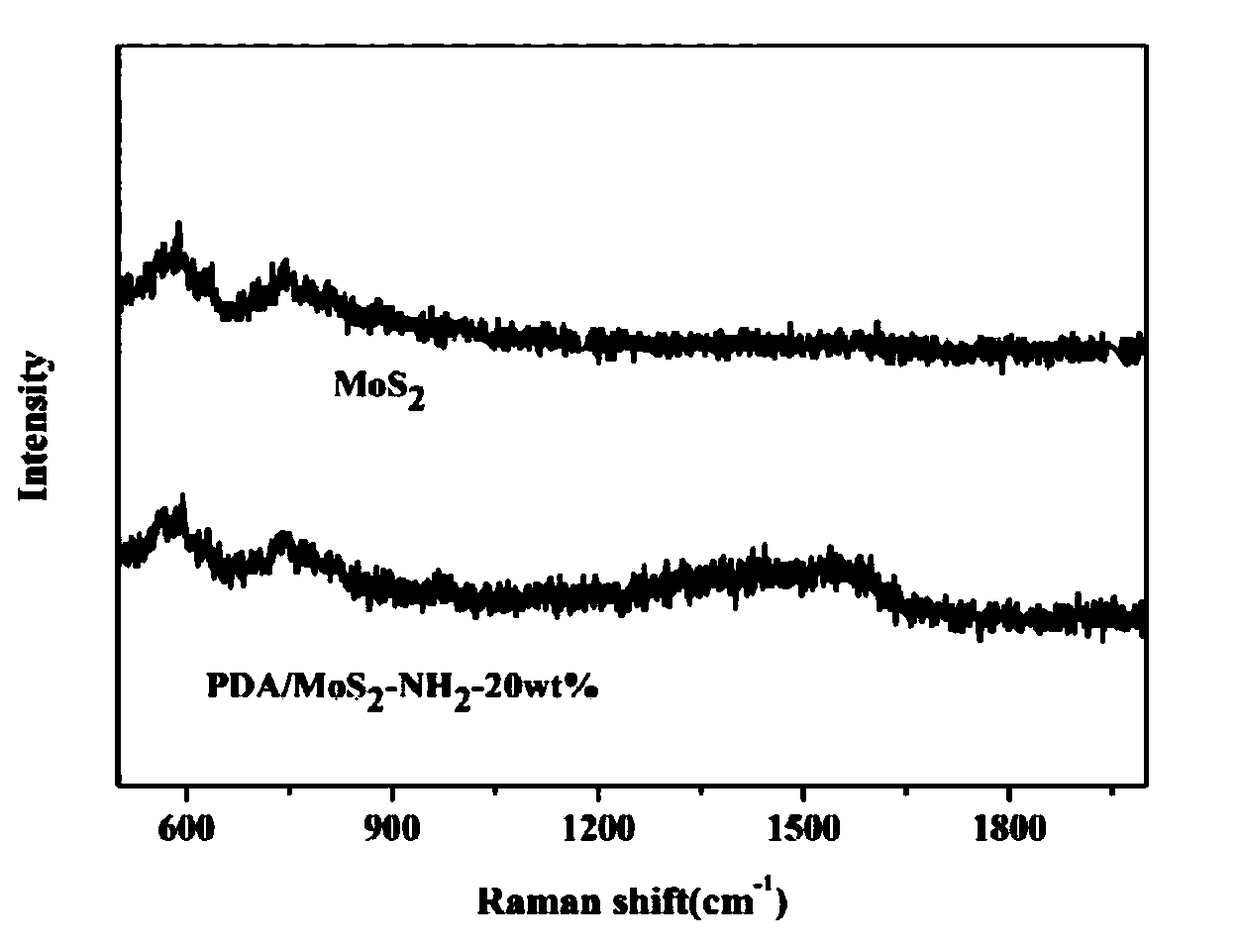

Preparation method and application of polydopamine/nano molybdenum disulfide photocatalyst

ActiveCN108816292AComposite fullyImprove photocatalytic performanceWater/sewage treatment by irradiationWater treatment compoundsMercaptoethylaminesSelf-condensation

The invention discloses a preparation method and application of a polydopamine / nano molybdenum disulfide photocatalyst. The preparation method comprises the following steps: first, preparing molybdenum disulfide nano-sheets by a lithium ion intercalation method; then adding mercaptoethylamine for modification to obtain aminated molybdenum disulfide; then introducing a dopamine monomer into the reaction system to mix uniformly with the aminated molybdenum disulfide; and finally, synthesizing a polydopamine / nano molybdenum disulfide composite by self-condensation of dopamine on the surface of the aminated molybdenum disulfide. Due to the introduction of polydopamine into the composite catalyst prepared by the method provided by the invention, the photocatalytic performance of the composite catalyst is greatly improved.

Owner:ANHUI UNIVERSITY

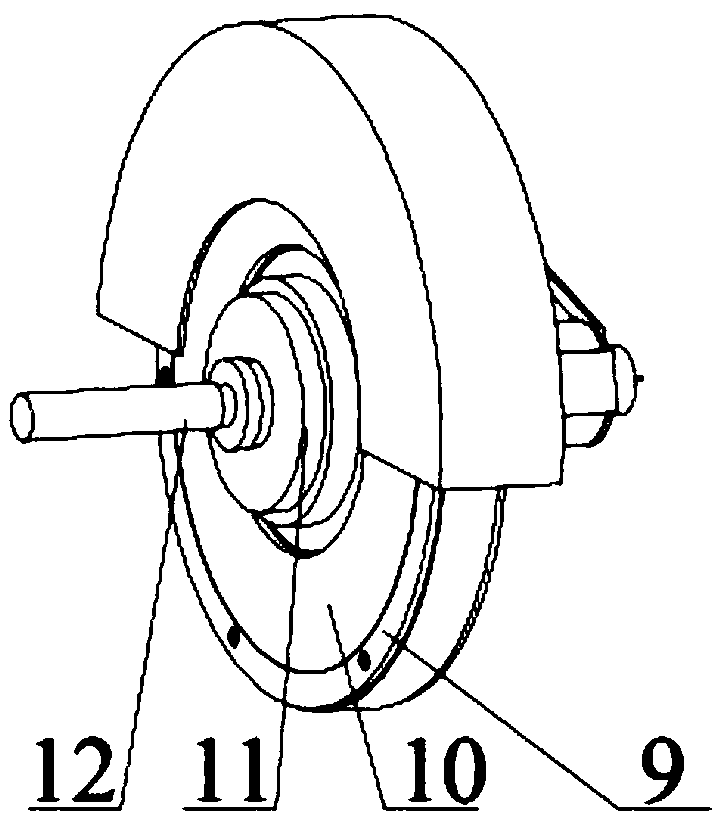

Thermoelectric refrigeration grinding wheel and self-condensation minimal quantity water lubrication precision grinding system with same

ActiveCN109249315AExtended service lifeImprove surface qualityGrinding feed controlGrinding/polishing safety devicesSelf-condensationEngineering

The invention discloses a thermoelectric refrigeration grinding wheel and a self-condensation minimal quantity water lubrication precision grinding system with the same. The thermoelectric refrigeration grinding wheel comprises an annular grinding wheel grinding layer, a refrigeration device and a circulation heat dissipation device. Workpieces can be ground by the grinding wheel grinding layer togenerate heat during work. The thermoelectric refrigeration grinding wheel and the self-condensation minimal quantity water lubrication precision grinding system have the advantages that a thermoelectric refrigeration sheet is used as a refrigeration portion, the heat generated during grinding can be transferred to a hot surface by the electrified thermoelectric refrigeration sheet by the aid ofheat pump principles, and heat gathered on the hot surface can be taken away by a circulation heat dissipation system; trace condensed water can be carried to grinding zones under low-temperature condensation effects of the surfaces of the thermoelectric refrigeration grinding wheel, accordingly, minimal quantity lubrication effects can be realized, and self-condensation minimal quantity water lubrication grinding can be implemented; the thermoelectric refrigeration grinding wheel and the self-condensation minimal quantity water lubrication precision grinding system can be mounted on differenttypes of grinding machines including surface grinding machines, cylindrical grinding machines, curved surface grinding machines and the like and can be applied to the different types of grinding machines.

Owner:SHANDONG UNIV

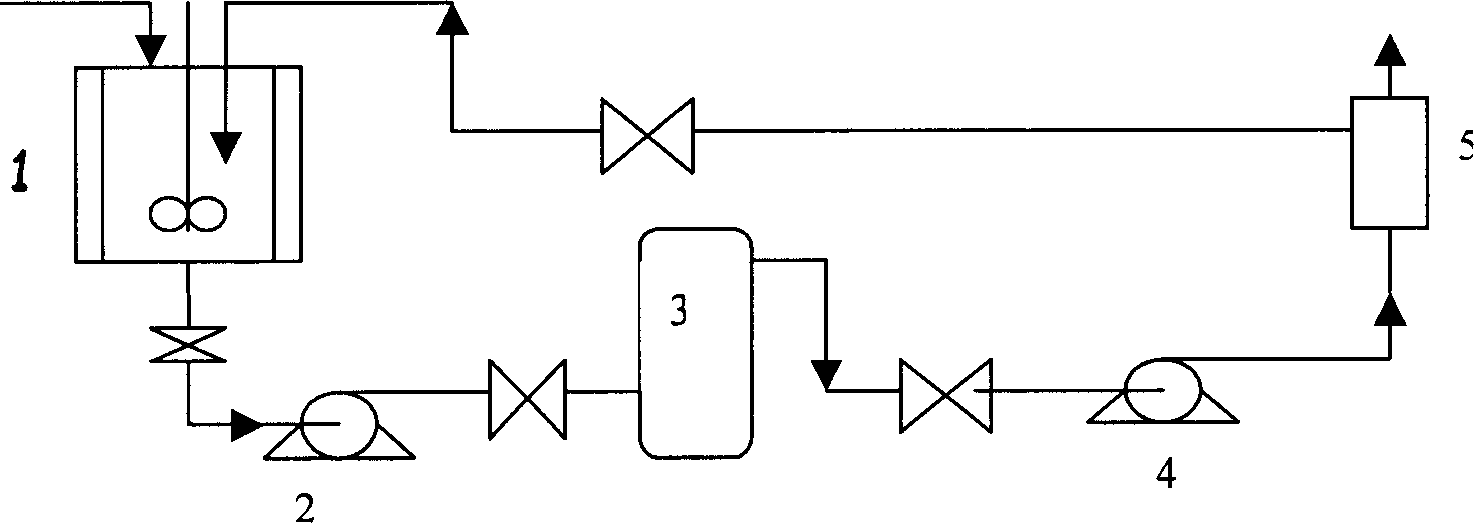

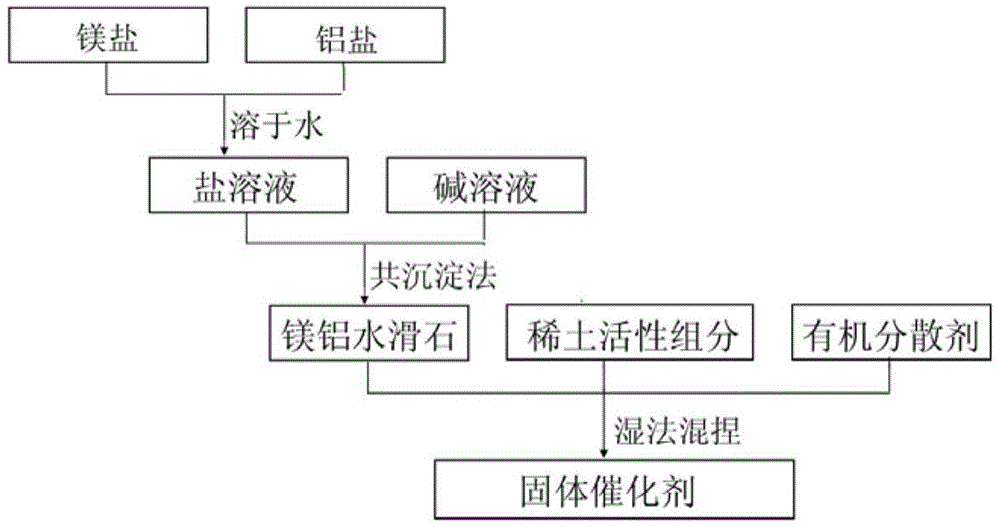

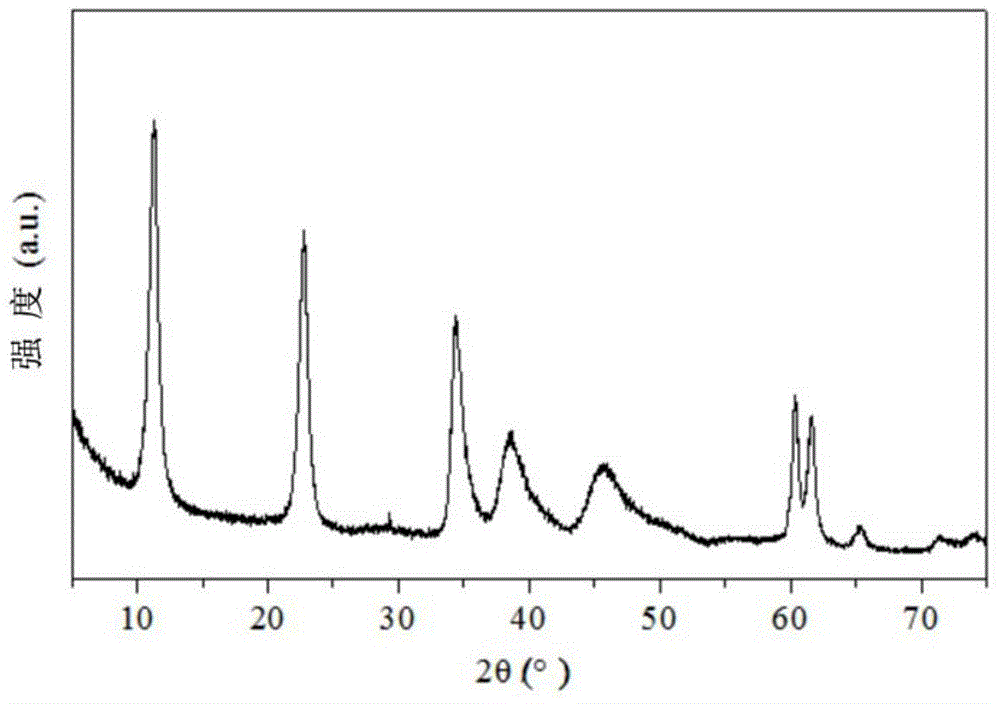

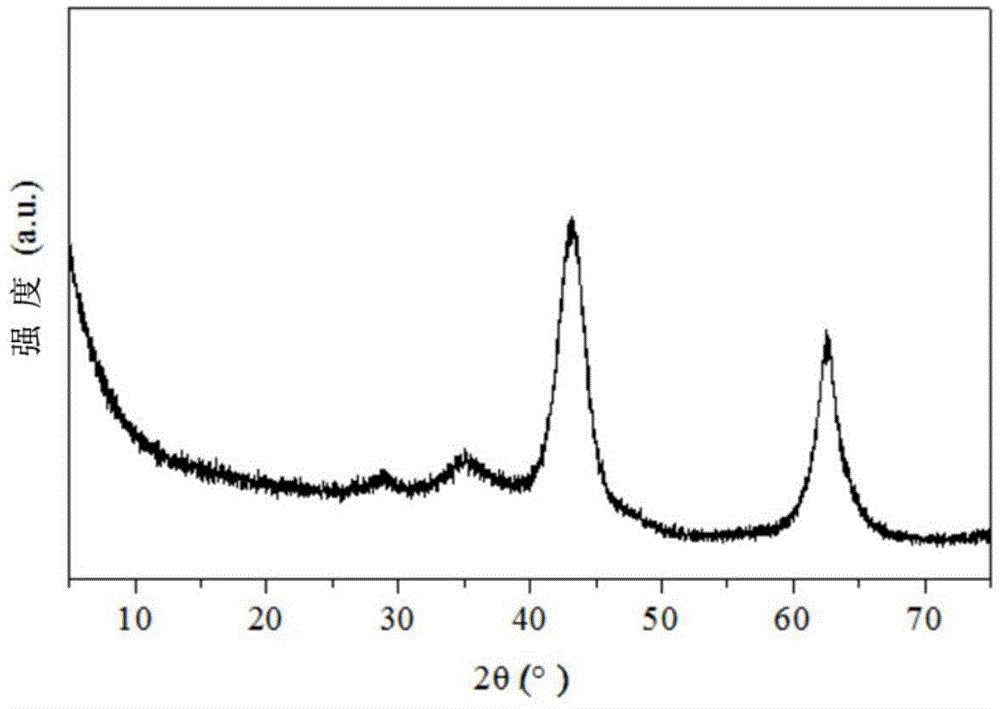

Solid catalyst used in acetone self-condensation reaction, and preparation method and application thereof

ActiveCN104923209AHigh density of basic sitesLarge specific surface areaOrganic compound preparationCarbonyl compound preparationFixed bedReaction temperature

The invention discloses a solid catalyst used in an acetone self-condensation reaction, and a preparation method and an application thereof. The invention relates to the technical field of acetone self-condensation catalysts. According to the invention, magnesium-aluminum hydrotalciteis first prepared with a co-precipitation method, and is adopted as a catalyst precursor; the catalyst precursor is well mixed with a rare earth component and an organic dispersing agent; the mixture is formed by wet kneading and extrusion; and roasting is carried out, such that the solid catalyst is obtained. A fixed bed continuous reaction device is adopted, and the catalyst is applied in an acetone self-condensation reaction. A reaction temperature is 100-450 DEG C, a reaction pressure is 0.1-2.0MPa, the liquid hourly space velocity is 0.1-5h<-1>, an acetone single-pass conversion rate is 20-50%, and an effective selectivity (mesityl oxide+isophorone) is 90-99%, wherein an isophorone selectivity is higher than 70%. The catalyst has acid-alkali dual active center on the surface, and can be flexibly modulated. The catalyst has good activity and stability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

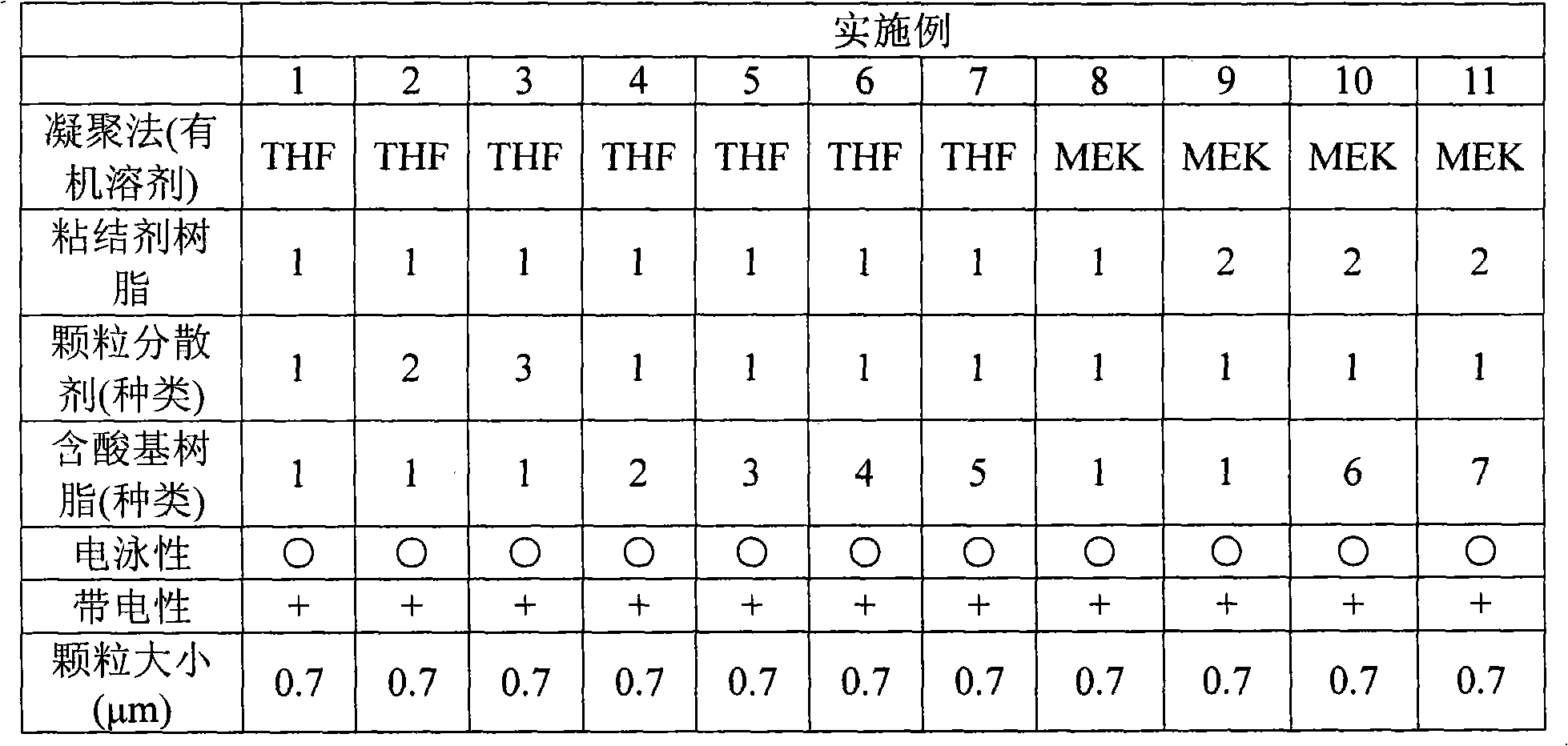

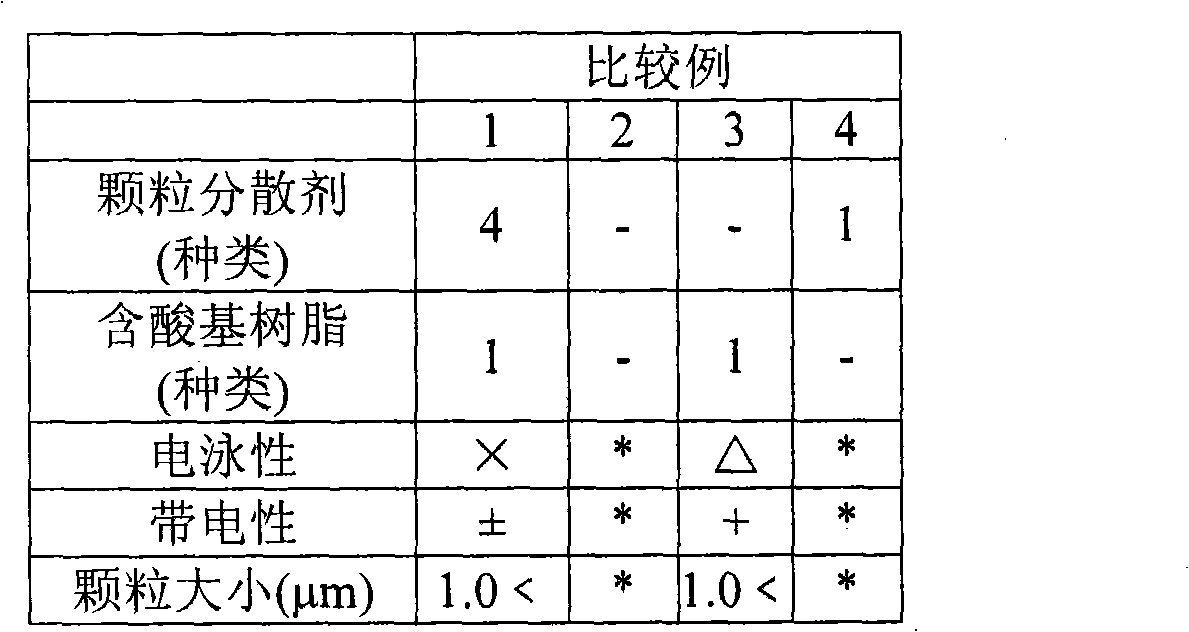

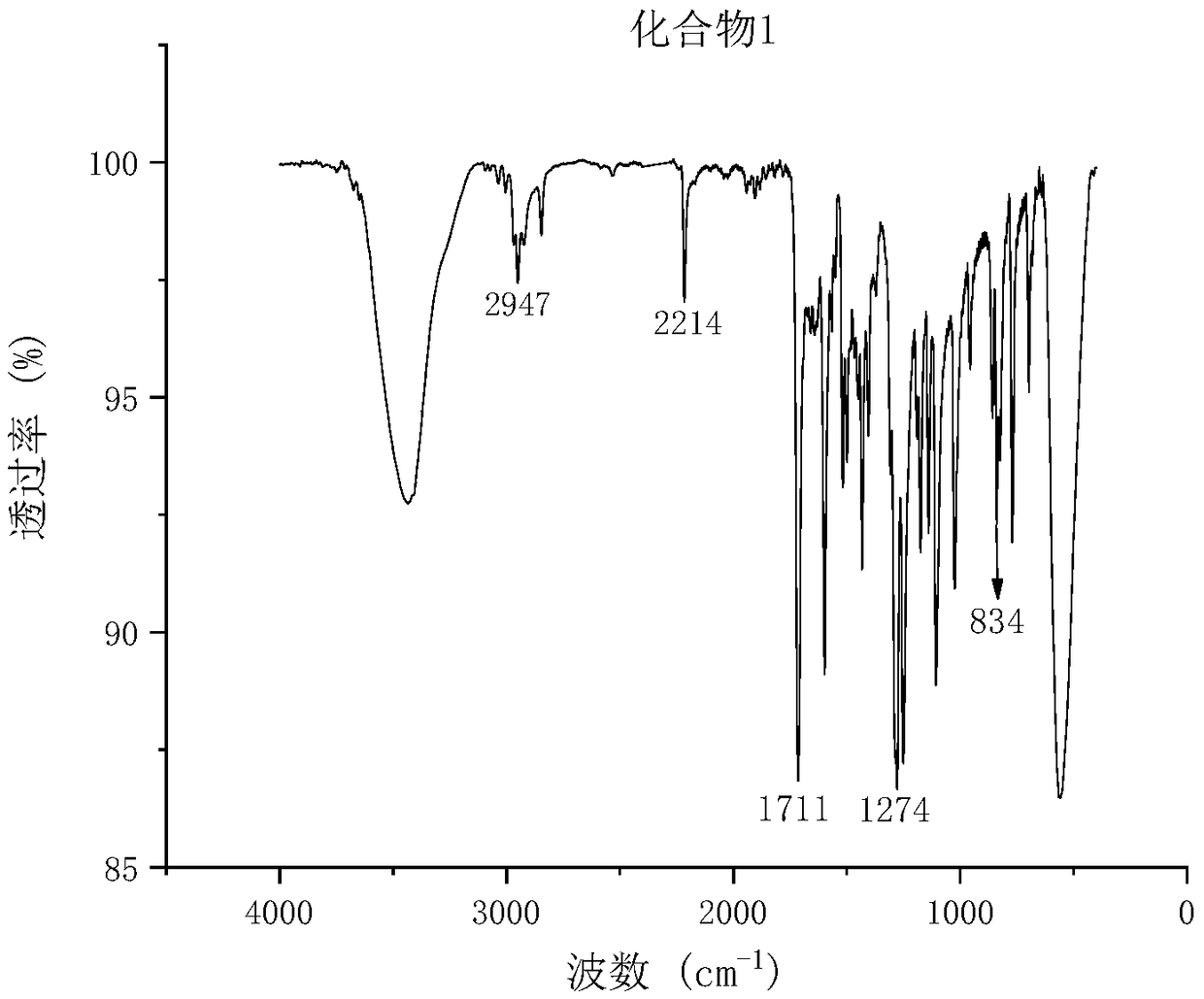

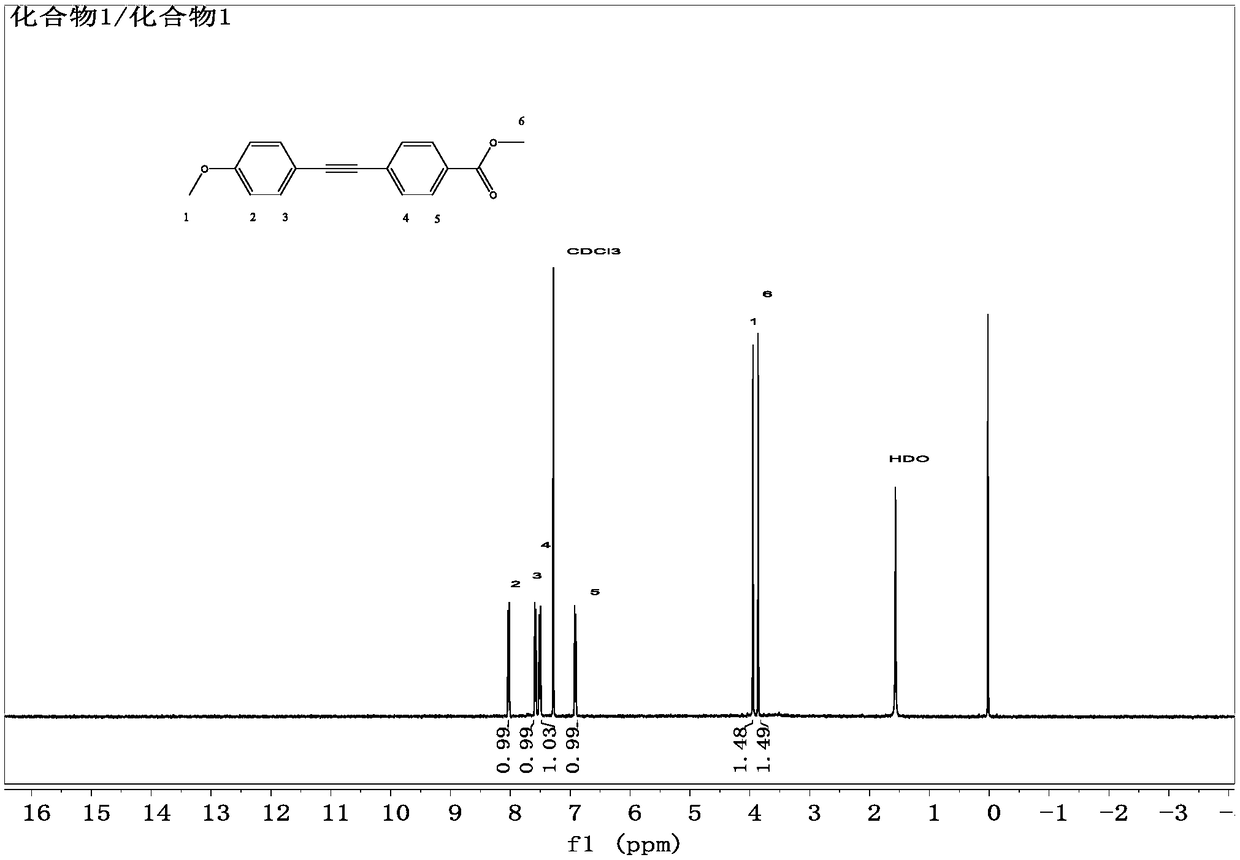

Process for producing liquid developer

This invention provides a process for producing a liquid developer for electrophotography or electrostatic recording, produced by a coacervation method, which process can produce a liquid developer which can satisfactorily maintain charging characteristics of the liquid developer and has good dispersion stability of colored resin particles, and a liquid developer produced by the production process. The production process is a process for producing a liquid developer utilizing a coacervation method. In the production process, colored resin particles are dispersed in an insulating hydrocarbon dispersive medium in the presence of a particle dispersing agent, which is a reaction product between a polyamine compound and a self-condensation product of a hydroxycarboxylic acid, and an acid group-containing resin.

Owner:SAKATA INX

Unsymmetric bifunctional carborane derivatives, and preparation method and application thereof

InactiveCN109400635AImprove high temperature resistanceImprove thermal stabilityEnergy modified materialsGroup 3/13 element organic compoundsPolyesterAdhesive

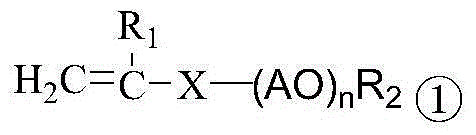

The invention relates to the fields of anti-tumor and polymer materials, in particular to unsymmetric bifunctional carborane derivatives, and a preparation method and application thereof. The carborane derivatives are a series of carborane derivatives containing carboxyl and hydroxyl represented by a formula 1, due to the high boron content of a 'boron cage', the difficult problem that existing boron neutron radiation therapy has low boron content can be solved. According to the unsymmetric bifunctional carborane derivatives, due to the super aromatic structure of the 'boron cage', materials are often endowed with excellent high temperature resistance, in addition, two functional groups of the carboxyl group and the hydroxyl group which have different properties are contained, carborane-contained polyester using the hydroxyl and the carboxyl to conduct end capping is prepared through self-condensation, high temperature resistance adhesives can be further prepared, and thus the urgent needs for the high temperature resistance adhesives in the aerospace field are met; and the carborane derivatives have great application value in the booming fields of boron neutron capture therapy andhigh temperature resistance adhesives (please see the specifications for the formula 1).

Owner:BEIHANG UNIV

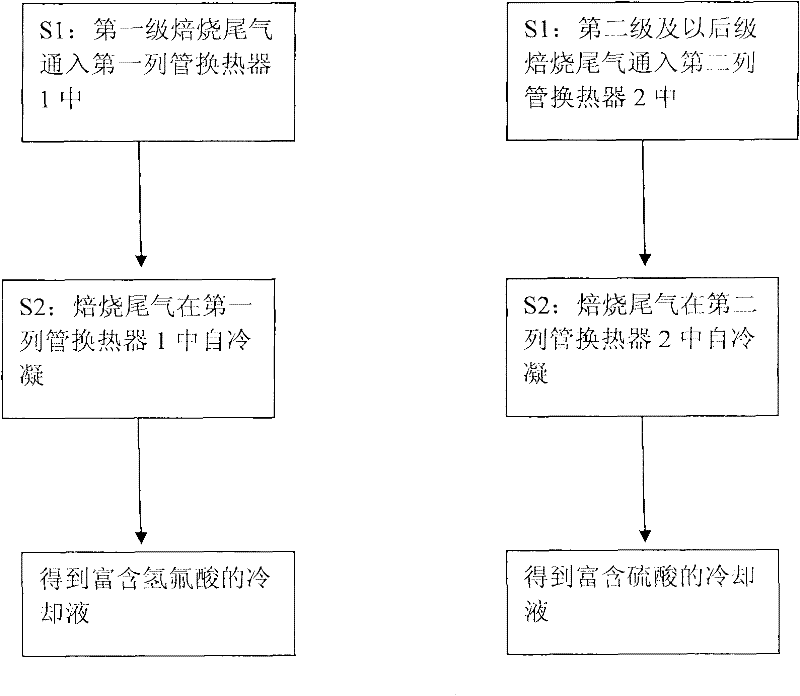

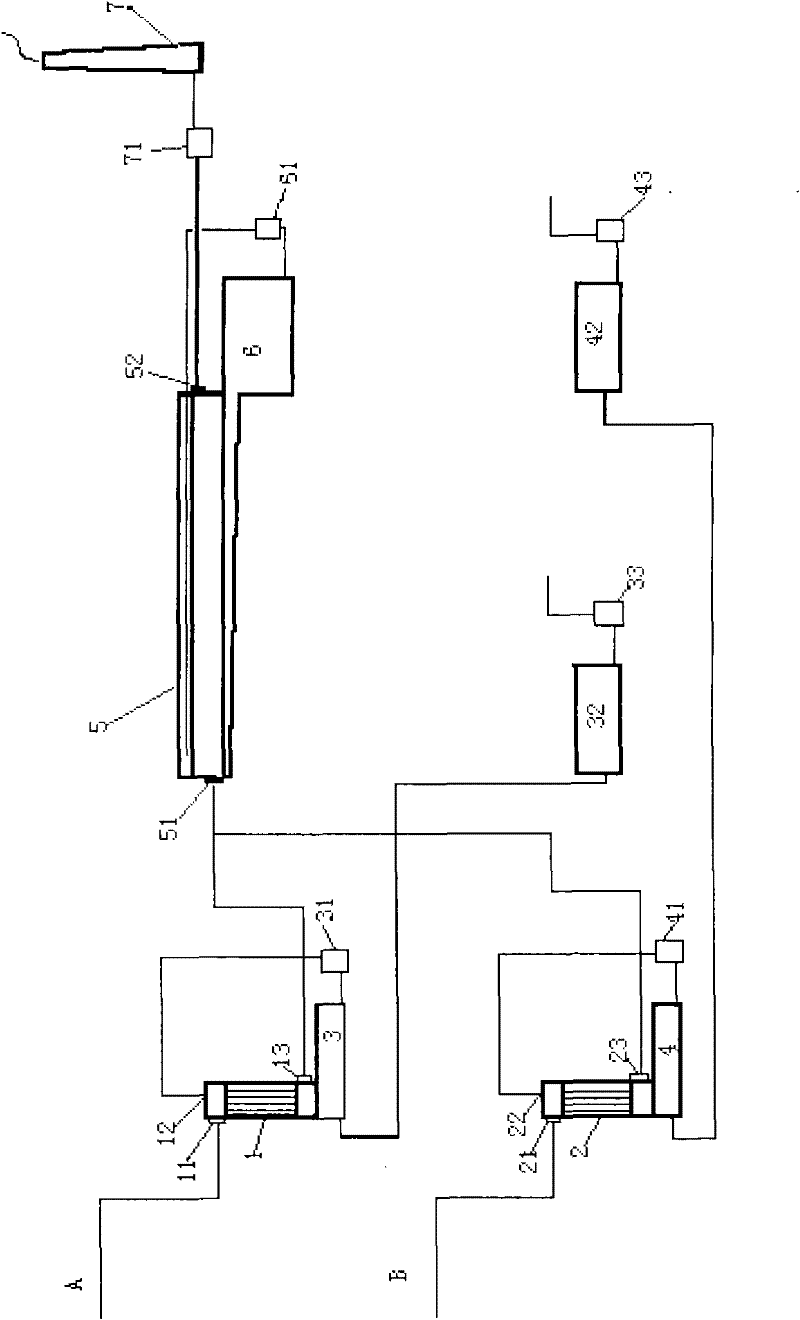

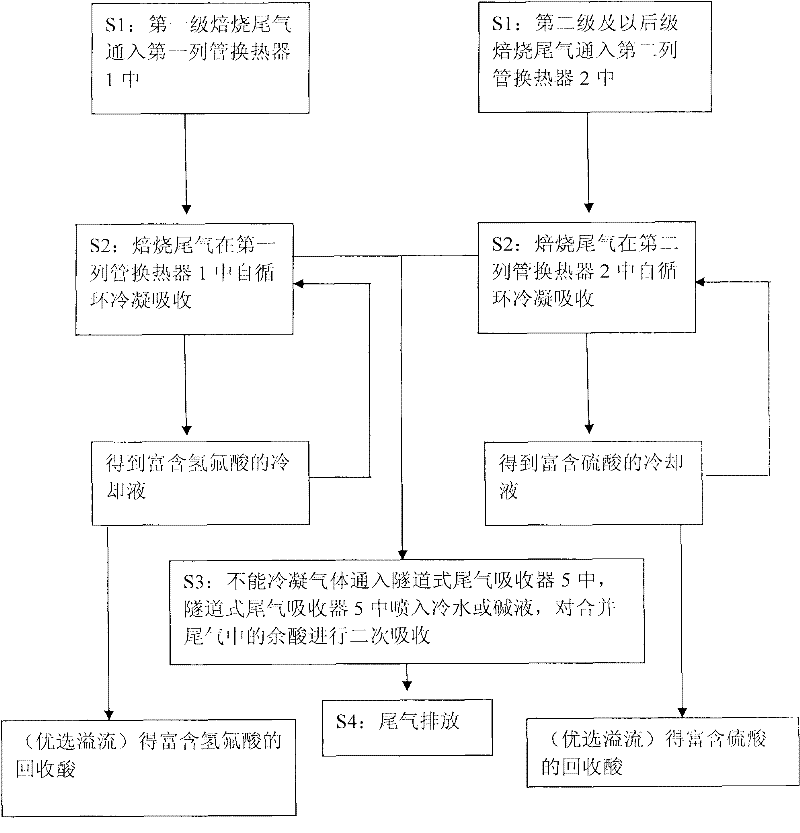

Respective recovery method for rare earth concentrate multi-stage baking tail gases, and device thereof

InactiveCN102489034ASimplify the concentration processSave process waterVapor condensationSulfur-trioxide/sulfuric-acidRecovery methodHydrofluoric acid

The present invention provides a respective recovery method for rare earth concentrate multi-stage baking tail gases, and a device thereof. The method comprises the following steps: 1, collecting the tail gases: the tail gas generated from first stage baking is introduced into a first tubular heat exchanger (1), and the tail gas generated from second stage baking and the tail gas generated from later stage baking are mixed and introduced into a second tubular heat exchanger (2); 2, condensing and absorbing: the tail gas generated from the first stage baking is subjected to self-condensation in the first tubular heat exchanger (1) to generate a hydrofluoric acid-rich cooling liquid, and the mixture comprising the tail gases generated from the second stage baking and the later stage baking is subjected to self-condensation in the second tube alignment heat exchanger (2) to generate a sulfuric acid-rich cooling liquid. According to the present invention, the tail gases generated from the first stage baking, the second stage baking and the later stage baking are respectively treated, and the recovery treatments are concurrently performed to obtain the hydrofluoric acid-rich cooling liquid or the sulfuric acid-rich cooling liquid, and the high concentration sulfuric acid can be obtained without the sulfuric acid concentration process.

Owner:BERIS ENG & RES CORP

Use of Phosphonic and Diphosphonic Diesters, and Thermally Curable Mixtures Comprising Phosponic and Diphosphonic Diesters

ActiveUS20080245998A1Broaden applicationOutstanding performance propertyPhysical/chemical process catalystsOther chemical processesTransesterificationSelf-condensation

Disclosed herein is a thermally curable mixture, comprising at least one phosphonic diester (A), at least one diphosphonic diester (A), or at least one phosphonic diester and at least one diphosphonic diester (A); and at least one compound (B) which can be reacted by transesterification, transamidation, self-condensation of N-hydroxyalkylamino groups, self-condensation of N-alkoxyalkylamino groups, transacctalization of N-alkoxyalkylamino groups, acctalization of N-hydroxyalkylamino groups, or a combination thereof. Also disclosed is a process for making the thermally curable mixture, and a cured material comprising the product of thermally curing the mixture.

Owner:BASF COATINGS AG +1

Method for producing liquid developer

ActiveUS20100323291A1Improve dispersion stabilityImprove image qualityDevelopersDispersion stabilityPolyamine Compound

The present invention provides a method for producing a liquid developer for electrophotography or electrostatic recording obtained by a coacervation method, which sufficiently maintains the charging property and has good dispersion stability of colored resin particles, as well as a liquid developer obtained by the method.A method for producing a liquid developer by a coacervation method,wherein a colored resin particle is dispersed in an insulating hydrocarbon dispersion medium in the presence of a particle dispersant and an acid group-containing resin, and the particle dispersant is a reaction product of a polyamine compound and a self-condensation product of a hydroxycarboxylic acid.

Owner:SAKATA INX

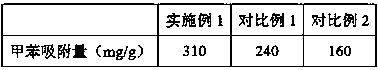

Super-crosslinked polymer material and preparation method thereof

InactiveCN109317120ASmall sizeImprove flexibilityGas treatmentOther chemical processesPolymer scienceSorbent

The invention discloses a super-crosslinked polymer material and a preparation method thereof. The preparation method comprises the following steps of by taking phenethyl alcohol as a monomer, dimethoxymethane as an external crosslinking agent and ferric trichloride hexahydrate as a catalyst, performing synthesis at a certain temperature to prepare a crude brown solid product, and then performingpurification with anhydrous ethanol, washing with hot water, filtering and freeze drying on the obtained crude brown solid product to obtain the super-crosslinked polymer material. For the super-crosslinked polymer material and the preparation method, by integrating the advantages of a one-step self-condensation method and an external crosslinking method, the size of molecules which can be adsorbed by the super-crosslinked polymer material is increased, the flexibility of the material is improved, and the super-crosslinked polymer material has good adsorption ability to VOCs; and in addition,the super-crosslinked polymer material is simple in preparation technology and low in energy consumption, does not cause secondary pollution and can be applied to adsorption treatment of the VOCs as anovel adsorbent.

Owner:FUZHOU UNIV

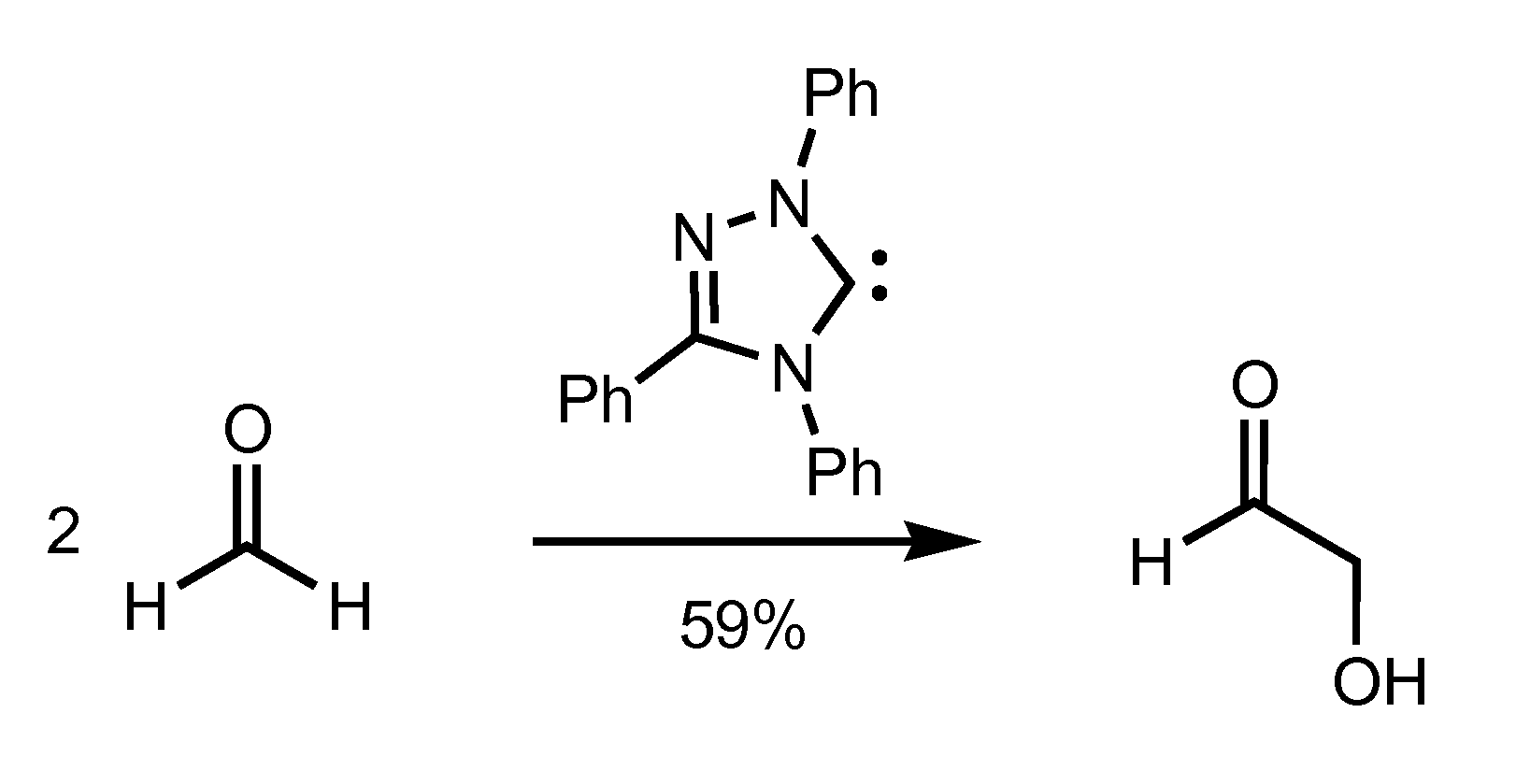

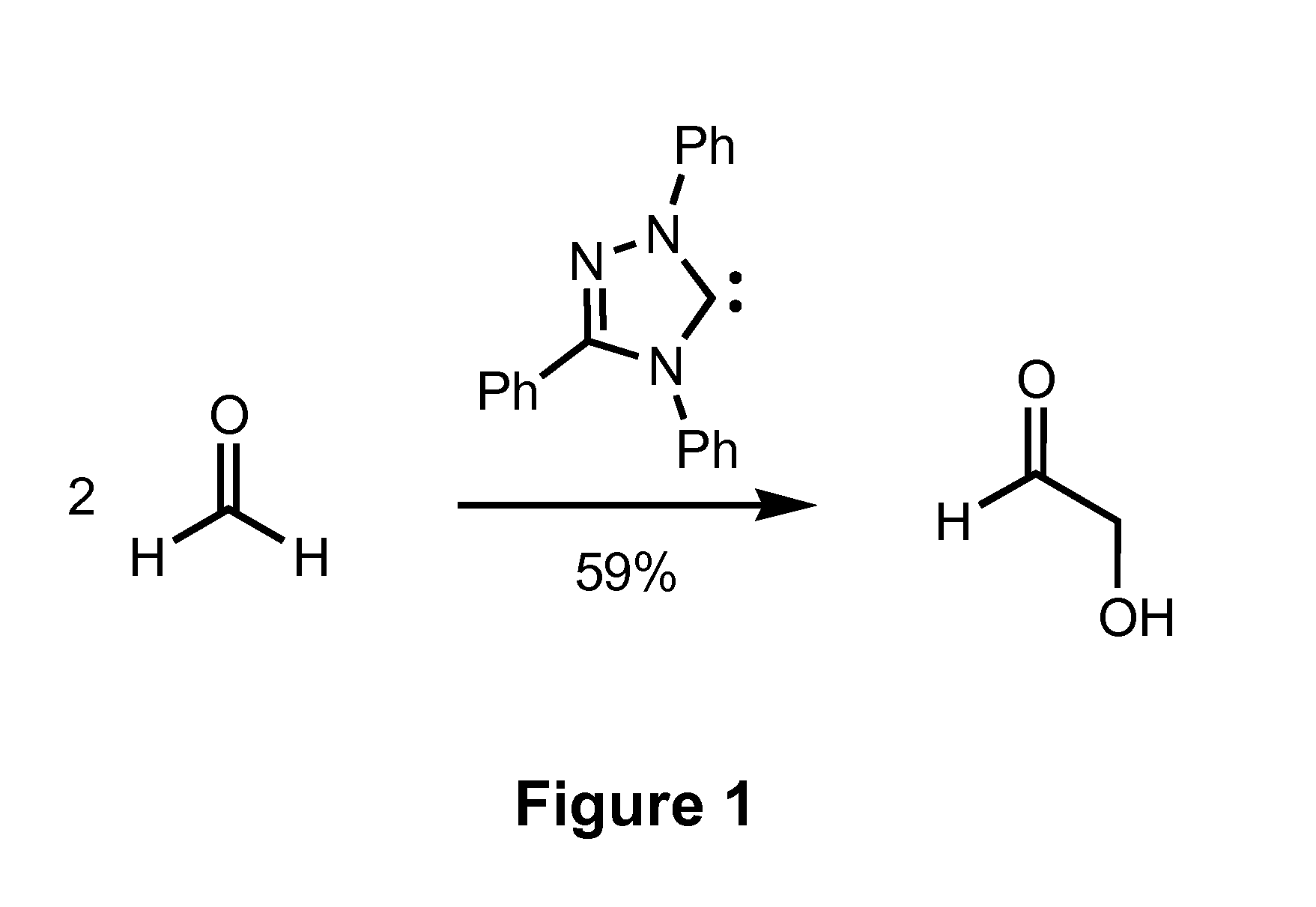

Combined Formose/Transfer Hydrogenation Process for Ethylene Glycol Synthesis

InactiveUS20100305368A1High selectivityHigh yieldOrganic compound preparationCarbonyl compound preparationSelf-condensationCarbene

The present invention provides a process for the production of a glycol via tandem self condensation of formaldehyde via formoin condensation and transfer hydrogenation of the reaction products of the formoin condensation. In some aspects, synthetic processes of the present invention utilize a combination of a N-heterocyclic carbene catalyst and a transition metal hydrogen-transfer catalyst providing enhanced selectivity and increased yields for the production of ethylene glycol relative to conventional synthetic approaches based on formoin condensation.

Owner:CALIFORNIA INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com