Preparation method and application of polydopamine/nano molybdenum disulfide photocatalyst

A technology of nano-molybdenum disulfide and molybdenum disulfide, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem that the catalytic efficiency needs to be improved, the cost is high, the Drinker poisoning and other problems, to achieve the effect of improving photocatalytic effect, good visible light absorption, good catalytic reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

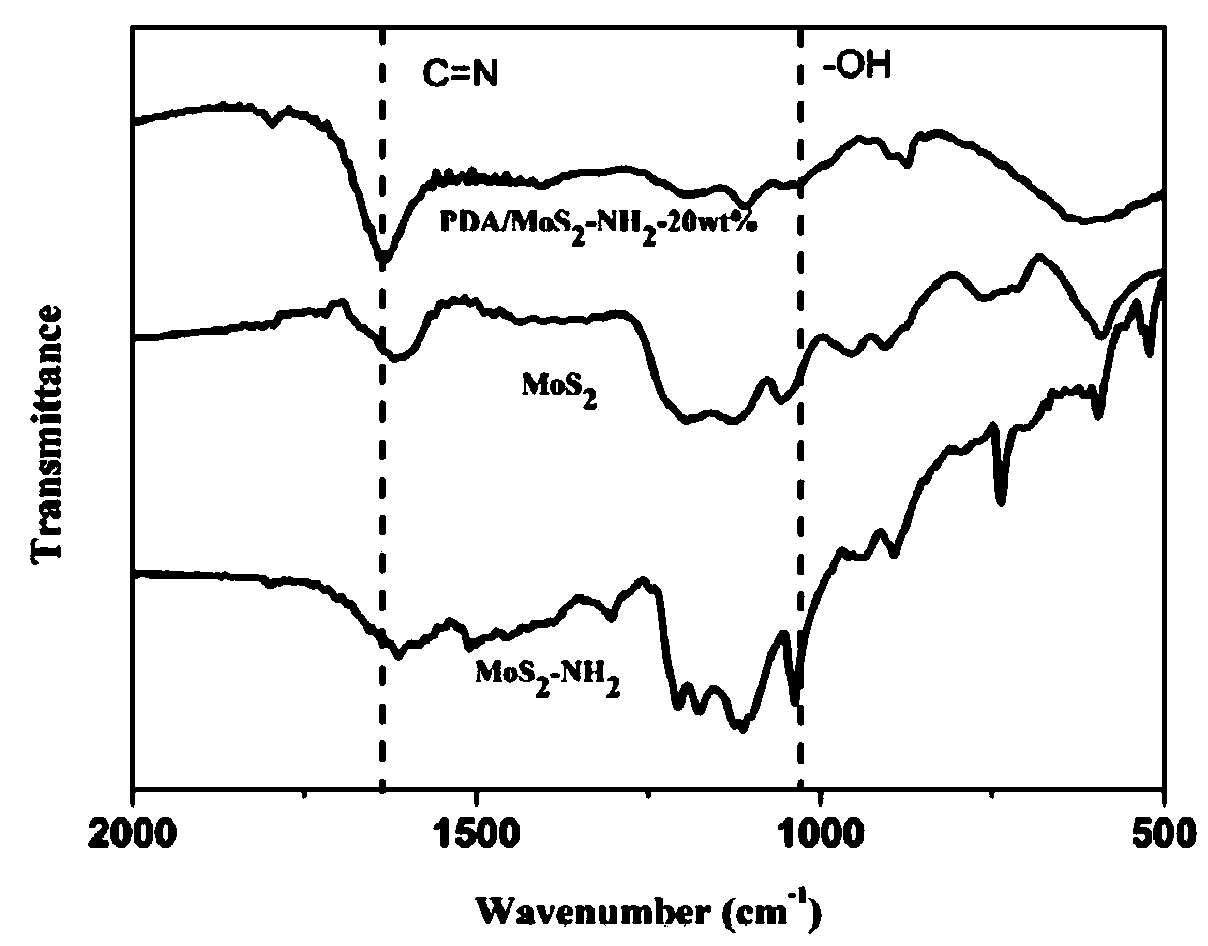

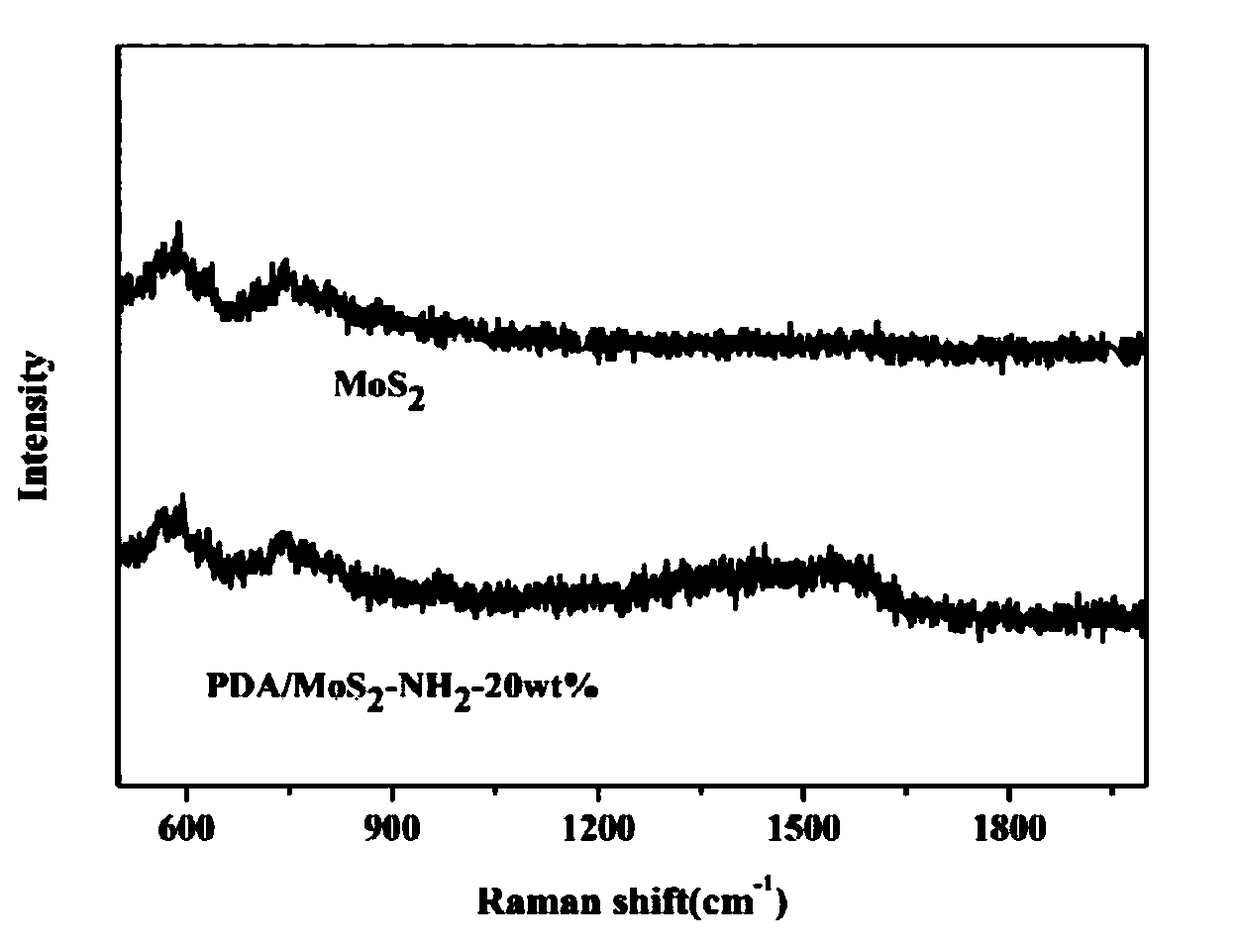

[0034] The preparation method of polydopamine / nanometer molybdenum disulfide photocatalyst in the present embodiment is as follows:

[0035] 1. Preparation of lamellar molybdenum disulfide

[0036] Add 1g of molybdenum disulfide powder into a three-necked flask, then add 10mL of n-butyllithium, stir for three days under a nitrogen atmosphere, filter after the reaction is completed, wash with 100mL of n-hexane for three times, and put the product obtained by suction filtration into a constant temperature at 60°C Dry in a drying oven for 4 hours, dissolve the dried powder in 250 mL of deionized water, disperse ultrasonically for 12 hours, and then freeze-dry at -50°C for 24 hours to obtain lamellar molybdenum disulfide;

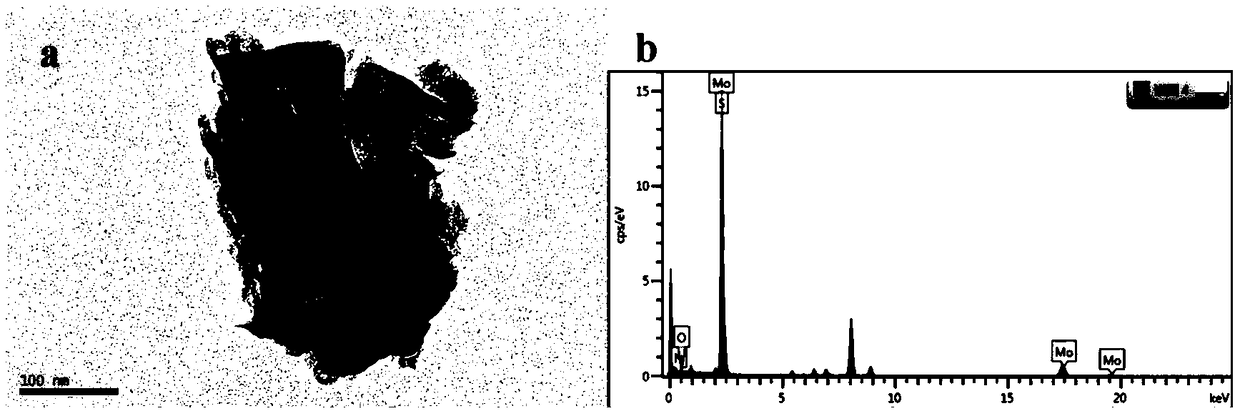

[0037] 2. Preparation of aminated molybdenum disulfide

[0038] Disperse 0.7g of lamellar molybdenum disulfide in 200mL of deionized water, add 4mg of mercaptoethylamine, ultrasonically disperse for 48 hours, then freeze-dry at -50°C for 24 hours, wash with de...

Embodiment 2

[0043] The preparation of this example Guo Chen communicated with Example 1, the difference is that the mass of dopamine is 10% of the mass of aminated molybdenum disulfide, and the obtained polydopamine / nanomolybdenum disulfide photocatalyst is recorded as PDA / MoS 2 -NH 2 -10 wt%.

Embodiment 3

[0045] Preparation of this example Guo Chen communicated with Example 1, the difference is that the mass of dopamine is 20% of the mass of aminated molybdenum disulfide, and the obtained polydopamine / nanomolybdenum disulfide photocatalyst is recorded as PDA / MoS 2 -NH 2 -20 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com