Process method for preparing 2-ethyl-2-hexenal by catalyzing self-condensation of n-butanal with heteropoly acid

A process method and technology of heteropoly acid, applied in the field of green chemistry, can solve the problems of poor stability of solid base catalyst, difficult to reuse, and the cost of three-waste treatment that cannot be reused for liquid base catalyst, so as to achieve easy continuous production and overcome poor stability. , The effect of reusable continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In a 100ml autoclave, put 30g of n-butyraldehyde, and then add 0.5% H of n-butyraldehyde weight 4 SiW 12 o 40 Catalyst, with N 2 Air replacement, magnetic stirring, and reaction at 100°C for 4 hours. After the reaction, filter under reduced pressure, and perform gas chromatography analysis on the product liquid. The conversion rate of n-butyraldehyde is 91.9%, and the conversion rate of 2-ethyl-2-hexenal The selectivity was 88.1%.

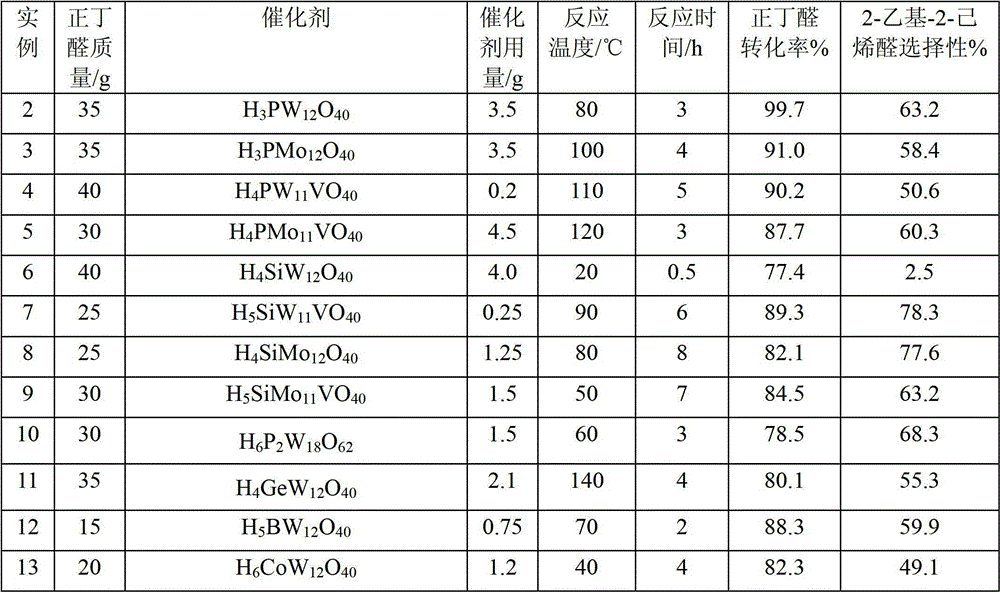

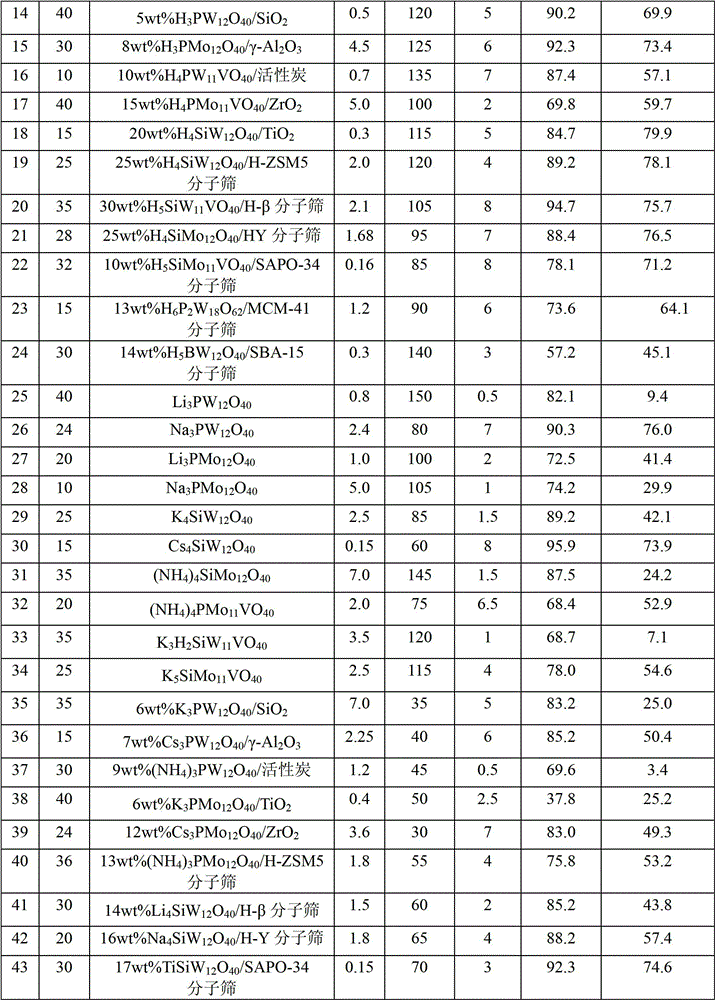

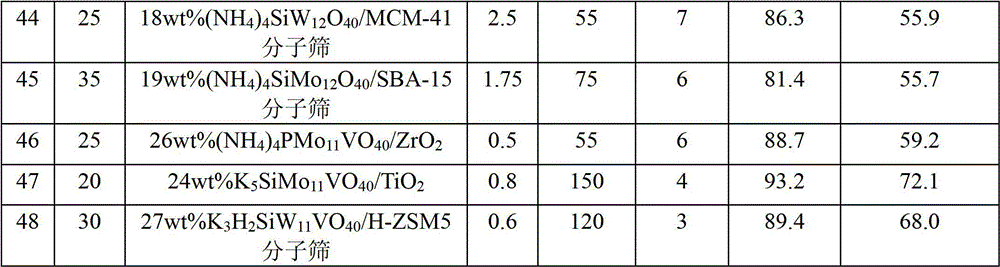

[0034] Examples 2-48 According to the operation steps of Example 1, the reaction conditions and results are shown in the summary table.

[0035]

[0036]

[0037]

Embodiment 49

[0039] 10wt%H prepared by sol-gel method 4 SiW 12 o 40 / SiO 2 For catalyst, in 100ml autoclave, put into 30g n-butyraldehyde, then add the H of n-butyraldehyde weight 5%. 4 SiW 12 o 40 / SiO 2 Catalyst, with N 2 Air replacement, magnetic stirring, and reaction at 120°C for 3 hours. After the reaction, filter under reduced pressure, and perform gas chromatography analysis on the filtrate. The conversion rate of n-butyraldehyde is 92.4%. The selection of 2-ethyl-2-hexenal Sex is 85.0%. The reacted H 4 SiW 12 o 40 / SiO 2 The catalyst was washed three times with absolute ethanol and dried at 60 °C for 4 h. Then under the same reaction conditions, the repeated use effect of the catalyst was investigated, and the results are shown in the table below. With the increase of the number of reactions, the activity of the catalyst decreased, and the selectivity of 2-ethyl-2-hexenal decreased by 5.2% after being used for 4 times, but the catalyst still had a high activity.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com