Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Easy to achieve serial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing one or more of silicon nano power, silicon nanowires and silicon nanotubes by electrochemical method

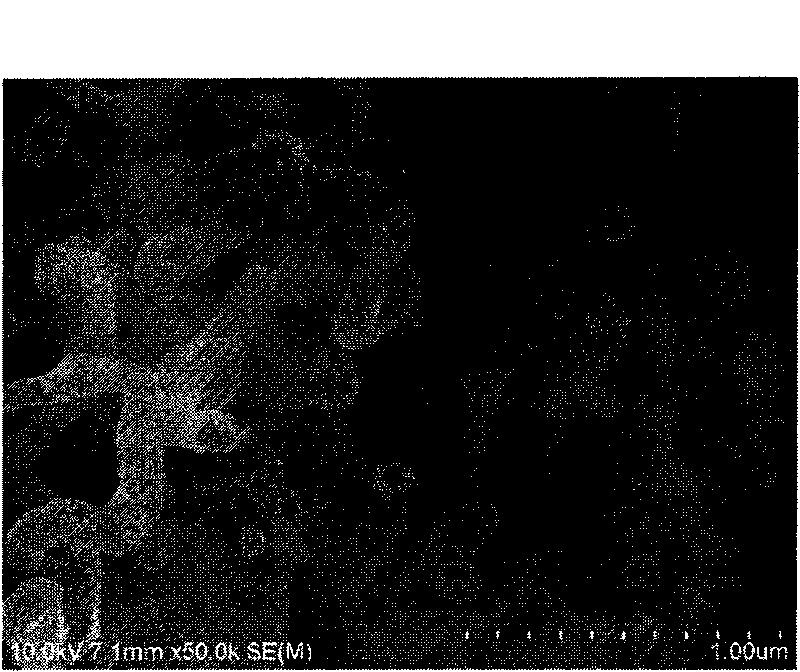

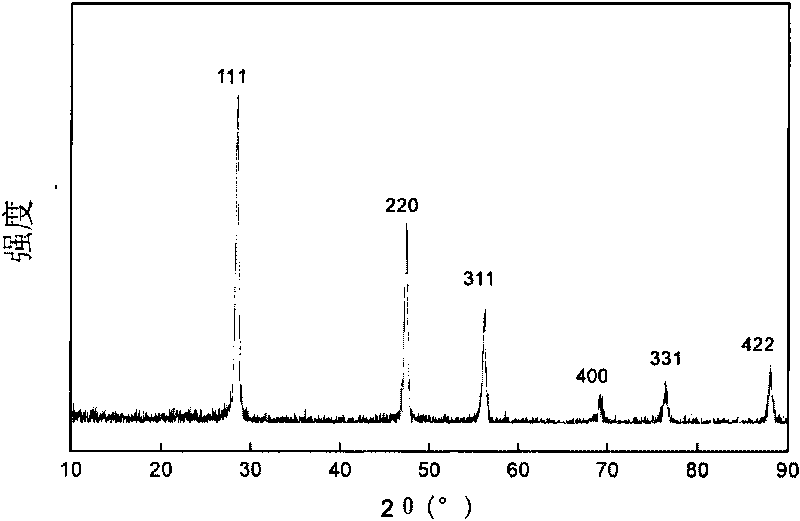

ActiveCN101736354ARich sourcesNo pollution in the processPolycrystalline material growthNanotechMolten saltSilicon nanowires

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

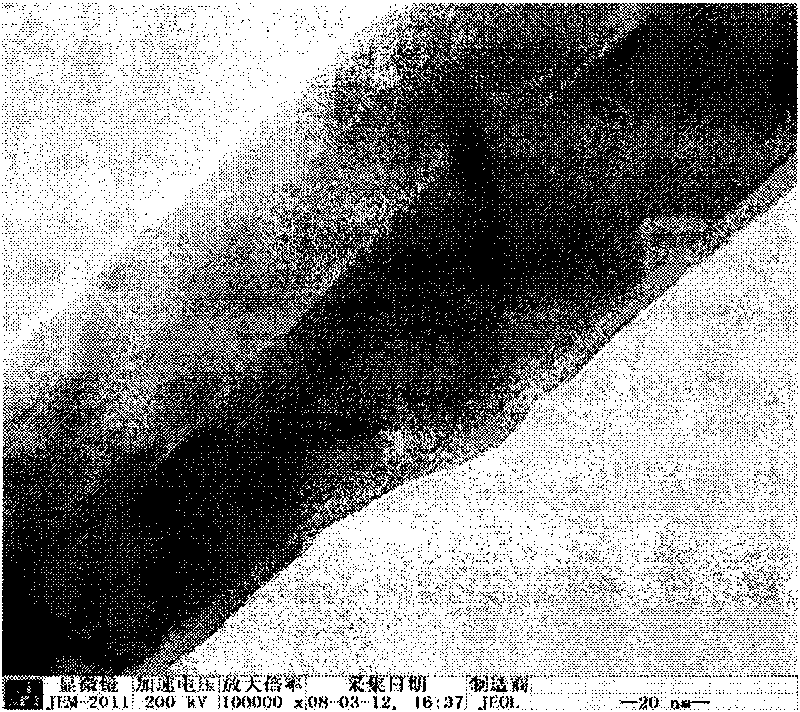

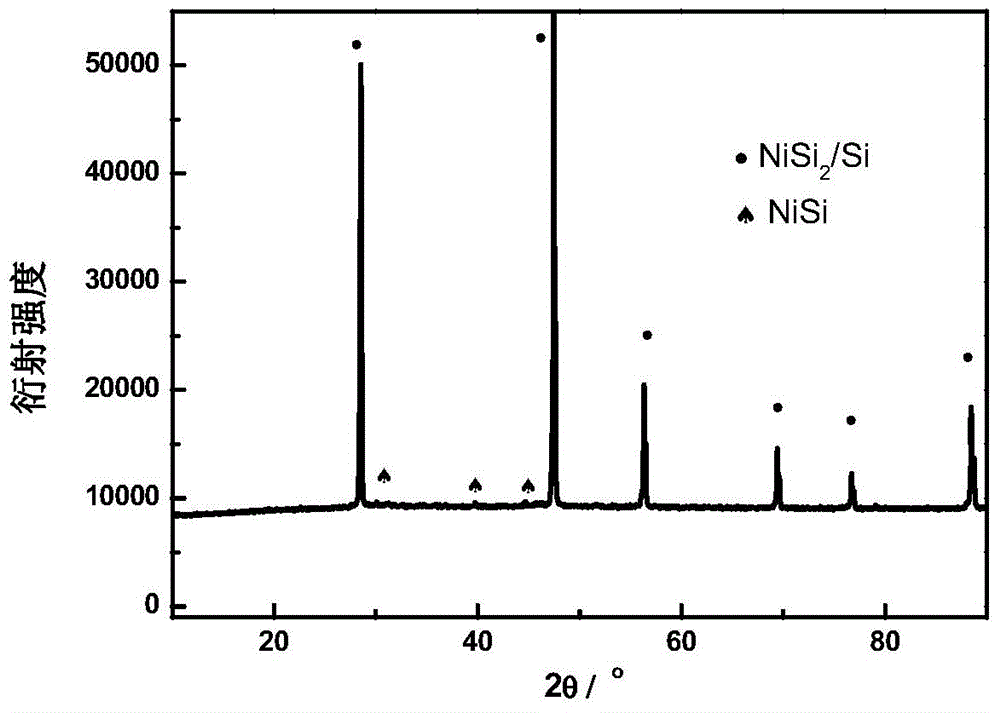

Nano silicon metal composite material and preparation method thereof

ActiveCN104617278AControl the degree of metallurgical bondingImprove electrochemical cycle stabilityMaterial nanotechnologyCell electrodesElectrolysisSilicon oxygen

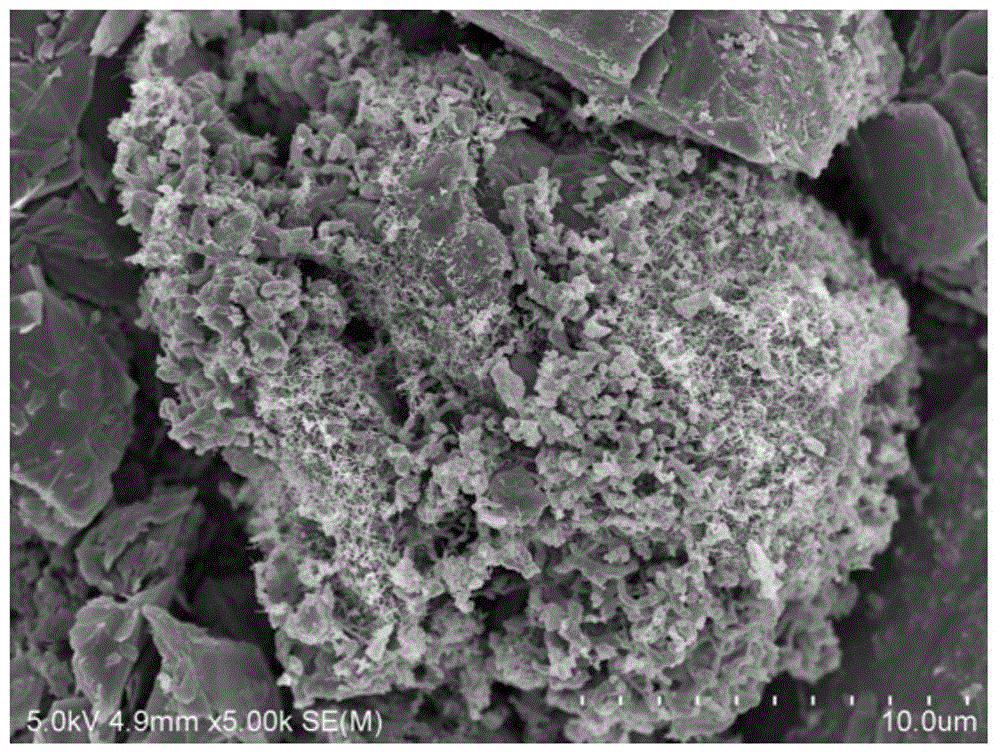

A nano silicon metal composite used for a negative electrode of a lithium ion battery comprises the following parts: (a) the first component part is simple substance silicon with the content accounting for 5-75mol% of the nano silicon metal composite; (b) the second component part contains a metal element, a compound formed and a silicon oxygen compound formed by the metal element and silicon, the second component part content accounts for 25 to 95mol% of the nano silicon metal composite; and (c) the third component part is simple substance carbon with the content accounting for 0-70mol% of the nano silicon metal composite. The preparation method is as follows: a porous block, comprising silica and metal or metal oxide and the like, and a conductive negative electrode current collector are compounded as a negative electrode, graphite or an inert positive electrode is used as a positive electrode, the negative electrode and the positive electrode are placed in a mixed salt melt electrolyte using CaCl2 or CaCl2 as the main components, voltage is applied between the negative electrode and the positive electrode, current density and electrolytic quantity are controlled, silica in the porous block is electrolyzed and reduced into nano silicon, and a nano silicon metal composite material is prepared on the negative electrode.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

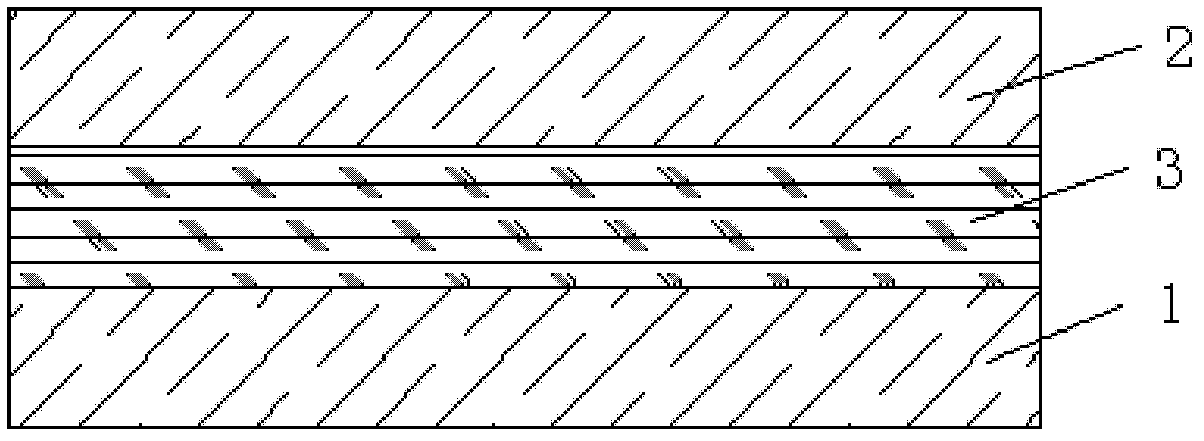

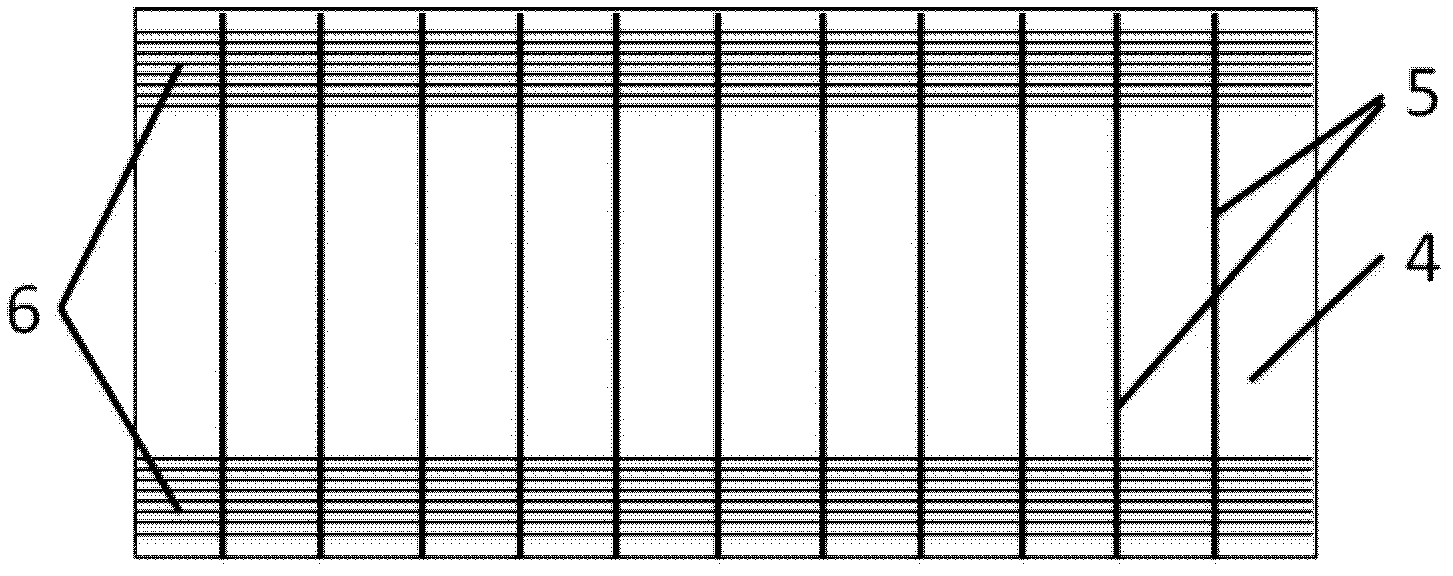

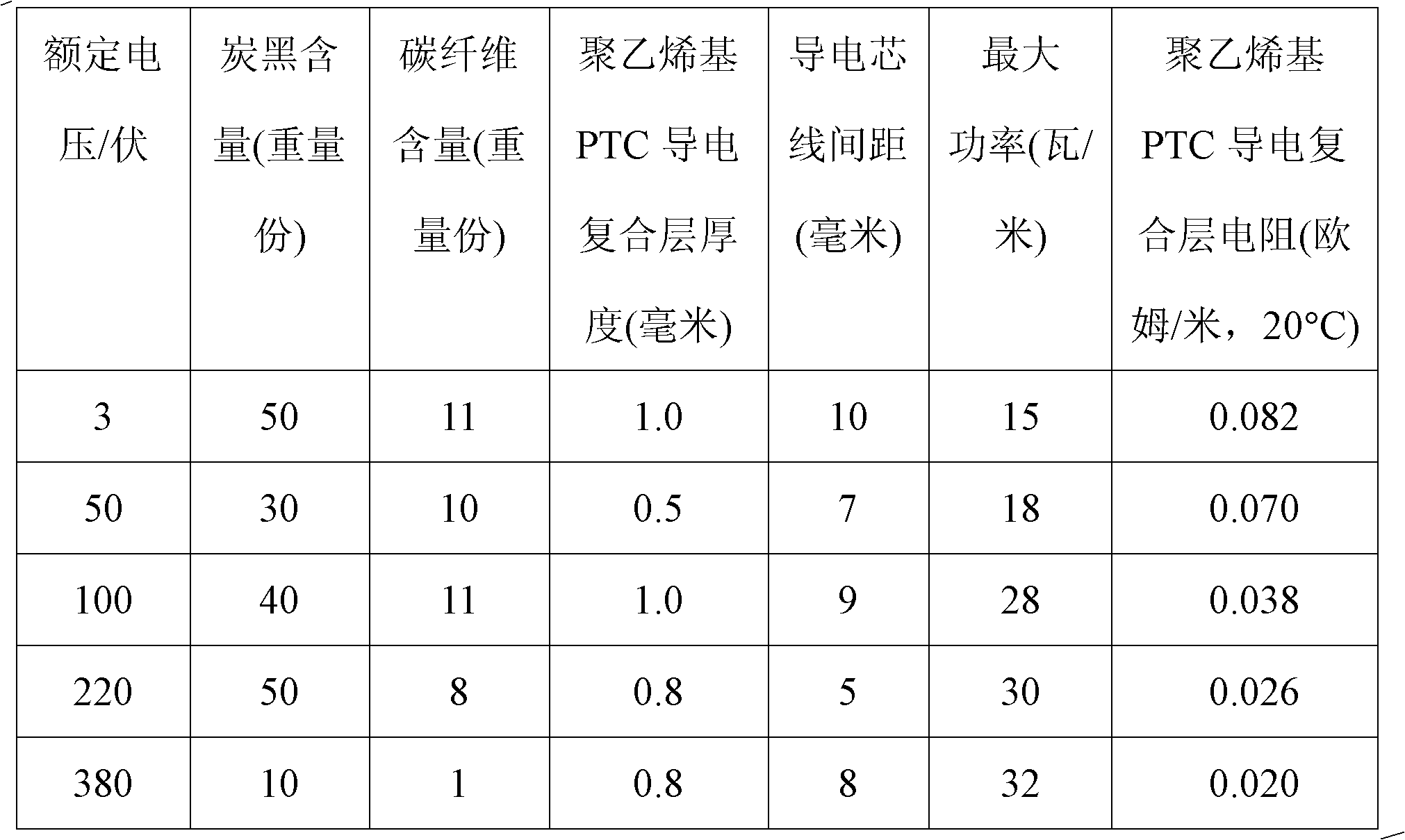

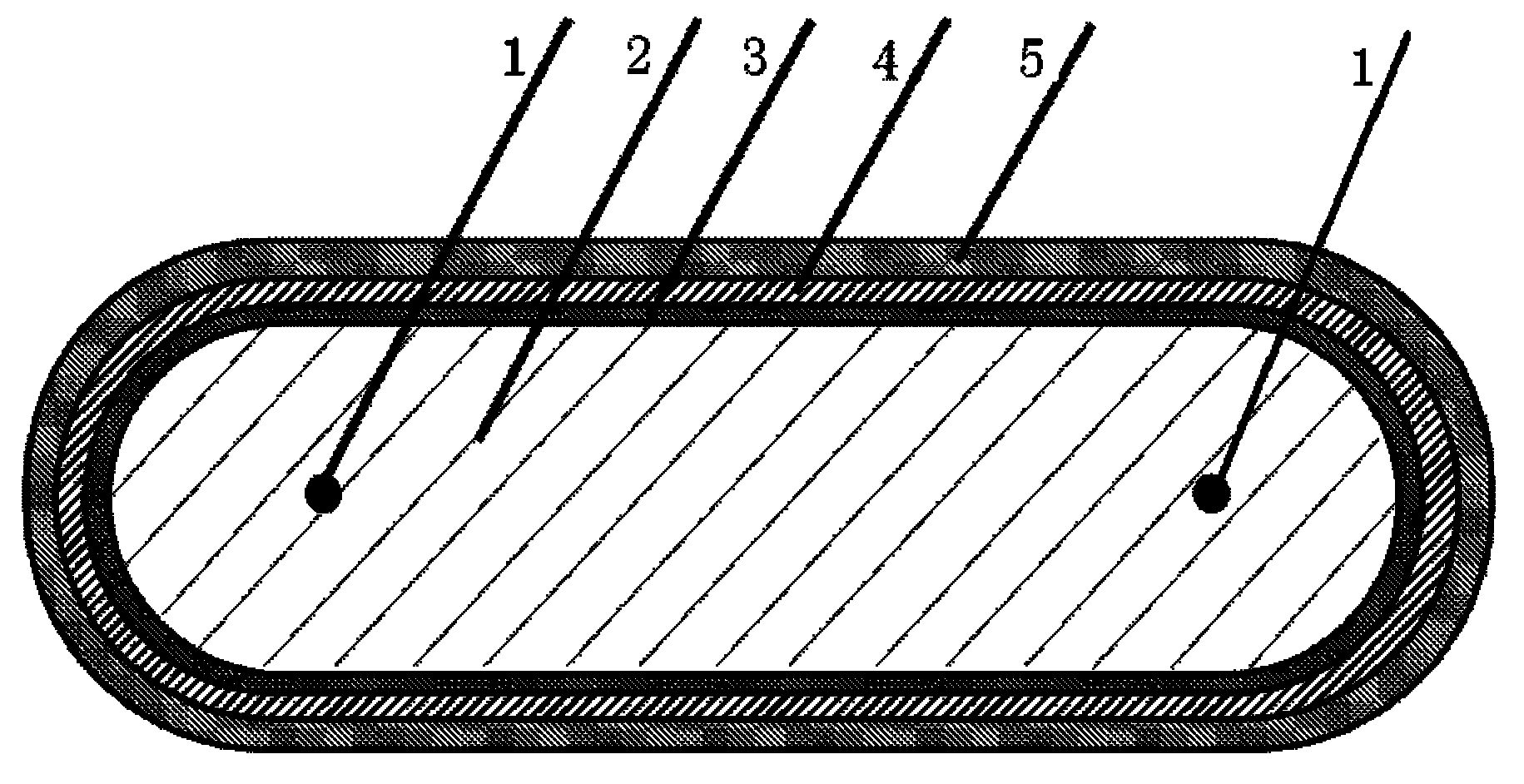

Self-limiting temperature electrothermal membrane of PTC high-molecular conductive fiber and preparation method thereof

ActiveCN102307403ANot easy to formThe coefficient of thermal expansion is roughly equivalent toWoven fabricsHeating element materialsFiberSelf limiting

The invention relates to a self-limiting temperature electrothermal membrane of a high-molecular conductive fiber with a positive temperature coefficient (PTC). The electrothermal membrane comprises a first insulating layer, a second insulating layer and a high-molecular PTC conductive braid layer, wherein the high-molecular PTC conductive braid layer consists of a braid lower layer, a plurality of polyvinyl PTC conductive fibers with carbon black filled type and two current carrying strips. The polyvinyl PTC conductive fiber with carbon black filled type is composed of the following raw materials: a polyethylene resin, an ethylene-vinyl acetate copolymer, carbon black and a carbon fiber and the like. The electrothermal membrane has advantages of stable electrothermal function and good flame retardant property. The preparation method comprises the following steps: preparing polyvinyl PTC conductive fibers with carbon black filled type; preparing a high-molecular PTC conductive braid layer; and carrying out calendaring moulding on a first insulating layer, a second insulating layer and the high-molecular PTC conductive braid layer. The method has advantages of simple process flow, low cost and easy realization.

Owner:XIAN GAIWO THERMAL ENERGY TECH

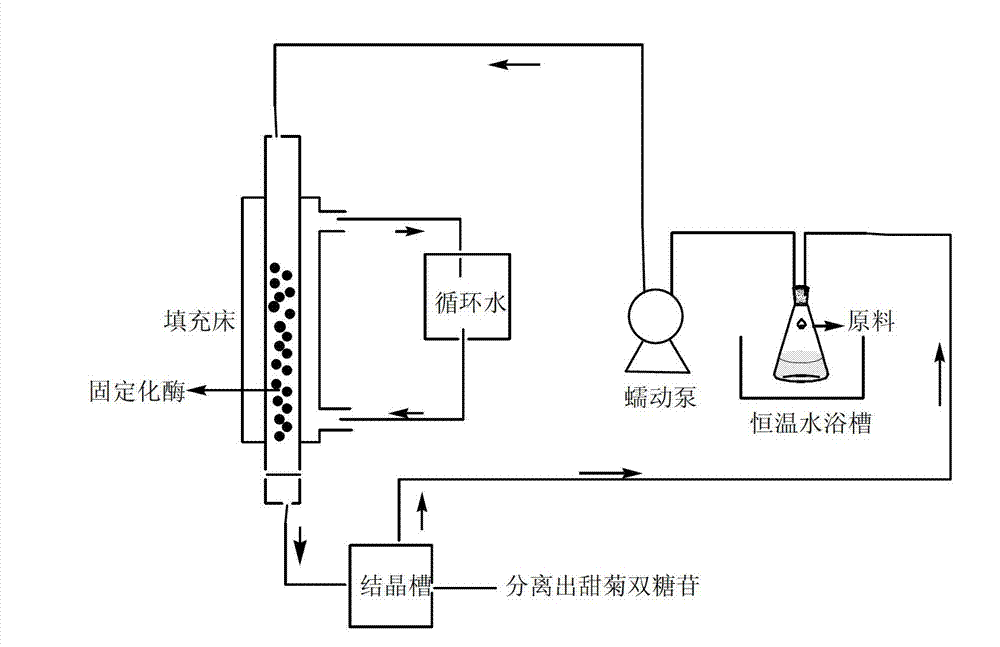

Method for preparing rebaudioside by use of stevioside

InactiveCN102925518AImprove thermal stabilityHigh economic valueOn/in organic carrierFermentationAlgluceraseEnzymatic hydrolysis

The invention relates to a method for preparing rebaudioside through packed bed enzymatic hydrolysis of stevioside. The method comprises the following steps of: dissolving the stevioside or stevia rebaudiana extract in water or phosphate buffer solution; combining the parts containing rebaudioside of the solution through an immobilization beta-glucosidase packed column; and concentrating and recrystallizing to obtain the rebaudioside. The preparation of rebaudioside takes 5 days in the prior art, and the transformation activity of the beta-glucosidase repeatedly used for 4 times is only 57.72% of the original activity. Through the invention, the preparation of rebaudioside using the immobilization beta-glucosidase only takes 12 hours, and the transformation rate of stevioside after 5 times of use still exceeds 84%. Thus, the method provided by the invention is short in production period, high in production efficiency and easy to realize continuous production, and has very broad application prospects.

Owner:JIANGNAN UNIV

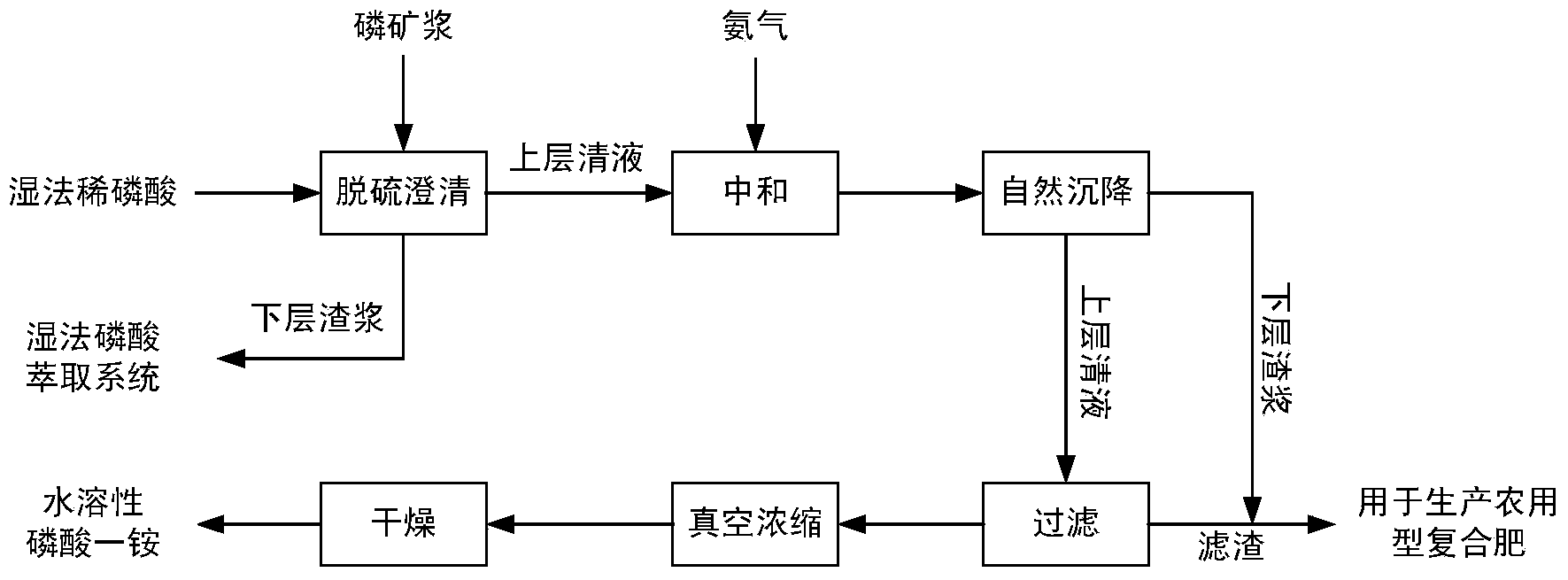

Method for continuously producing water-soluble monoammonium phosphate by using wet-process phosphoric acid

The invention discloses a method for continuously producing water-soluble monoammonium phosphate by using wet-process phosphoric acid. The method comprises the following steps: adding phosphoric ore pulp to wet-process dilute phosphoric acid; after natural sedimentation, carrying out neutralization reaction between clear desulfurated dilute phosphoric acid at the top and ammonia gas, wherein the neutralization degree of slurry is 0.95-1.05; carrying out natural sedimentation of the neutralized slurry in a settlement trough; filtering ammonium phosphate supernatant in a filter; concentrating and drying the obtained supernatant, so as to prepare the water-soluble monoammonium phosphate, wherein a filter cake and filter residue which are obtained after filtering can be used for preparing an agricultural compound fertilizer. According to the method, the problem of a traditional method that corresponding impurity removal depth can be reached by means of improving the neutralization degree of the slurry and carrying out neutralization reaction many times is avoided, neutralization reaction is carried out only once, and operation is facilitated. Meanwhile, the production efficiency is also improved, the obtained water-soluble monoammonium phosphate is good in quality, and the content of insoluble matter is low. In addition, the method is short in technological process and relatively simple in production control and can be put into continuous production easily.

Owner:云南云天化国际化工有限公司

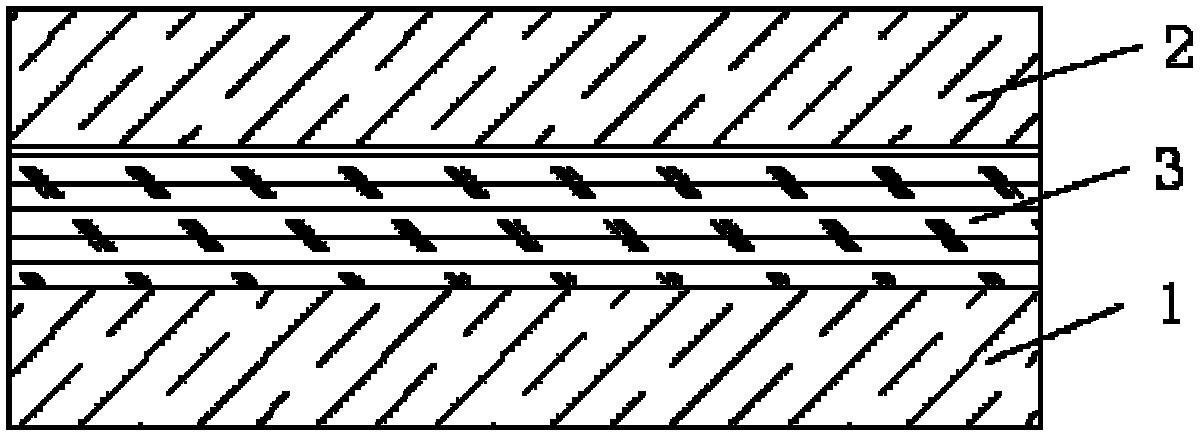

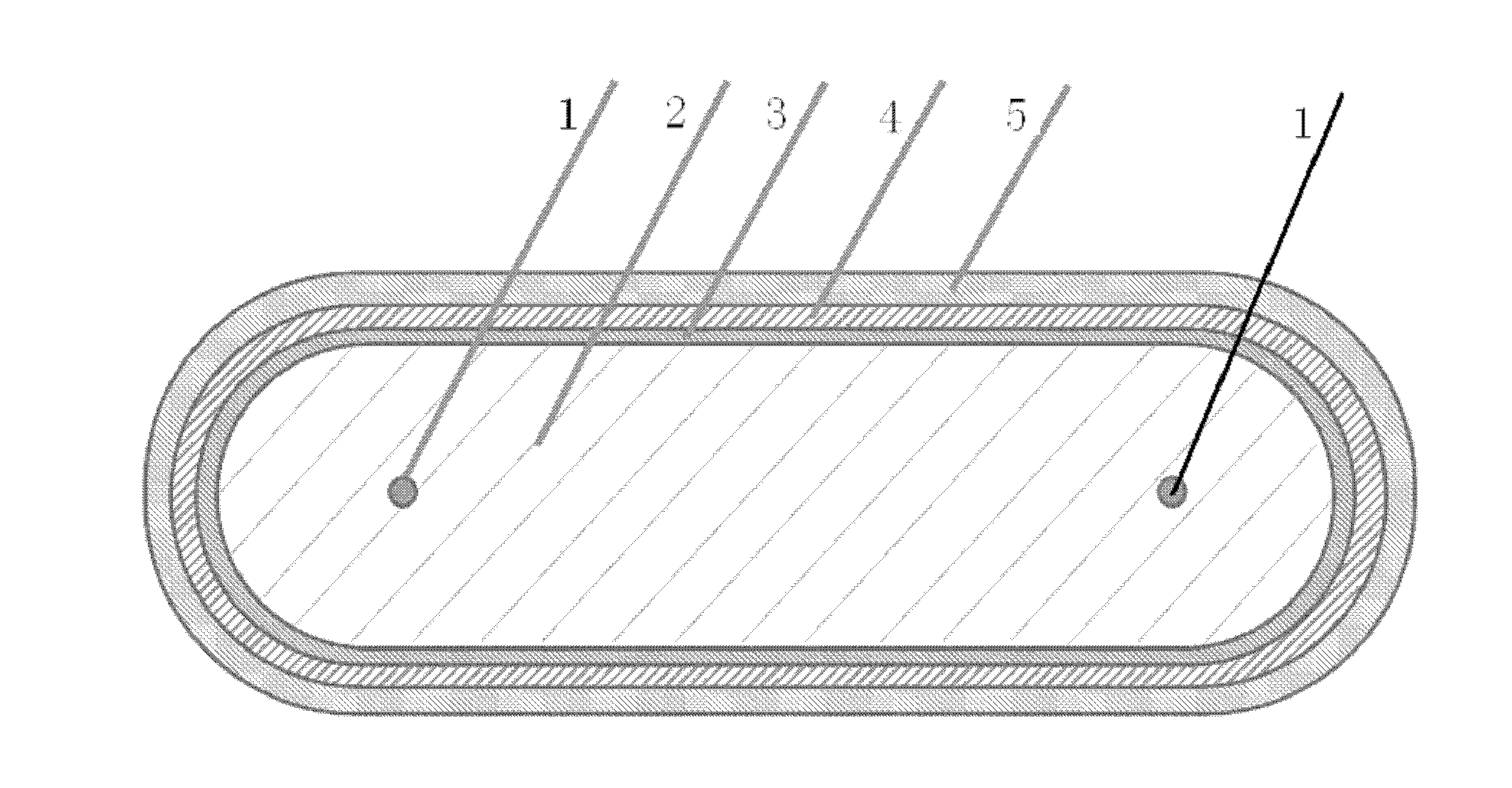

Self temperature limiting heat tracing strip of PTC (positive temperature coefficient) high polymer conductive composite material and preparation method thereof

InactiveCN102573154AImprove wettabilityGood dispersionHeating element shapesHeating element materialsPositive temperatureExtrusion coating

The invention discloses a self temperature limiting heat tracing strip of a PTC (positive temperature coefficient) high polymer conductive composite material, which comprises a flat strip that comprises a polyethylene PTC conductive complex layer. Two conductive core wires are extrusion coated inside the polyethylene PTC conductive complex layer. A polyethylene insulating layer, a shielding layer and a polyethylene reinforced protective layer closed in periphery are arranged orderly outside the polyethylene PTC conductive complex layer from inside to outside. The invention further discloses a preparation method of the self temperature limiting heat tracing strip, which comprises the steps of preparing the polyethylene PTC conductive complex layer; extrusion coating the two conductive core wires; and arranging the polyethylene insulating layer, the shielding layer and the polyethylene reinforced protective layer closed in periphery orderly outside the polyethylene PTC conductive layer from inside to outside. The self temperature limiting heat tracing strip provided by the invention will not generate bubbles, and is stable in electrothermal performance, safe and reliable. The preparation method provided by the invention has simple process flows and low cost, and is easy to realize.

Owner:XIAN GAIWO THERMAL ENERGY TECH

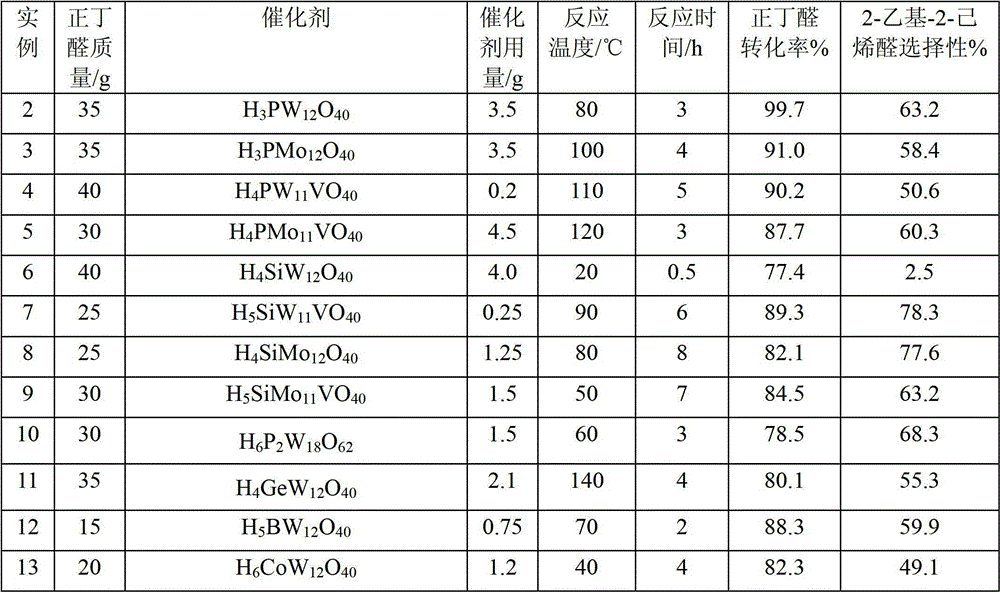

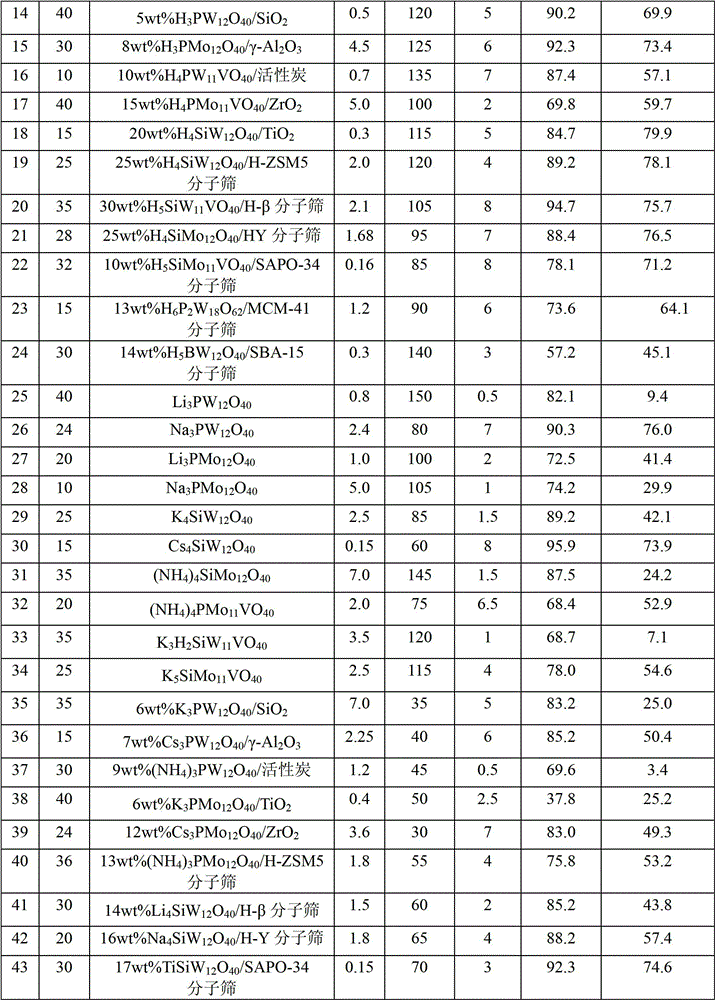

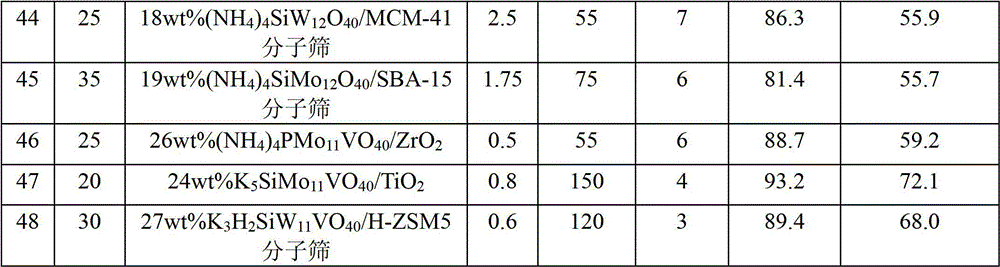

Process method for preparing 2-ethyl-2-hexenal by catalyzing self-condensation of n-butanal with heteropoly acid

InactiveCN102746129AGood choiceSimple post-processingOrganic compound preparationCarbonyl compound preparationHeteropoly acidSelf-condensation

The invention provides a process method for preparing 2-ethyl-2-hexenal (octenal) by catalyzing self-condensation of n-butanal with heteropoly acid. The method comprises the following steps of: adding n-butanal and a heteropoly acid catalyst into a high-pressure kettle, wherein the using amount of the catalyst is 0.5-15 percent of the mass of the added n-butanal; reacting under a magnetic stirring action at the temperature of 20-150 DEG C for 0.5-8 hours; and performing a self-condensation reaction on the n-butanal to obtain 2-ethyl-2-hexenal. The heteropoly acid catalyst used in the method is a heteropoly acid (salt) or supported heteropoly acid (salt) catalyst, has high low-temperature activity and high selectivity, and can be used repeatedly. The transformation rate of the n-butanal can be up to 99.7 percent in maximum, the selectivity of the 2-ethyl-2-hexenal can be up to 88.1 percent in maximum, the catalytic activity of the heteropoly acid catalyst is approximate to that of the conventional industrial liquid alkali, and the method has a good industrial application prospect.

Owner:HEBEI UNIV OF TECH

Method for quick heap-yellowing of yellow tea

InactiveCN105248706ATea leaves turn yellow evenlyYellow tea colorPre-extraction tea treatmentAgricultural engineeringContinuous production

The invention discloses a method for quick heap-yellowing of yellow tea. Heap-yellowing is conducted by means of a totally sealed rotary roller container, the massic volume ratio of a placed wet tea base to the roller container is 1:10-40, the temperature of the interior of the roller container is maintained at 25-80 DEG C, the roller container is rotated once every other 0.5-4 h to enable tea to be stirred, and heap-yellowing is stopped after the wet tea base appears evenly orange or golden. By conducting heap-yellowing on yellow tea at a constant temperature with the totally sealed rotary roller container and reserving certain space in the roller container, tea leaves can yellow quickly and can also be stirred, so that tea leaves can yellow more evenly; stirring is conducted once every once in a while during heap-yellowing, so that yellow tea obtained through heap-yellowing does not have soggy odor. By the adoption of the heap-yellowing method, time for heap-yellowing of yellow tea can be shortened remarkably, stirring is easier during heap-yellowing, the quality of yellow tea is improved, labor is saved, and continuous production is facilitated.

Owner:SOUTHWEST UNIVERSITY

Process for preparing N,N-dimethyl-1,3-propane diamine through continuous method

ActiveCN103333073AHigh selectivityImprove conversion rateOrganic compound preparationAmino compound preparationAminopropionitrileAlcohol

The invention discloses a process for preparing N,N-dimethyl-1,3-propane diamine through a continuous method and belongs to the field of organic chemical industry. The process comprises the following steps: by taking dimethylamine and acrylonitrile as raw materials, continuously preparing dimethylamino propionitrile by employing a fixed bed, wherein the molar ratio of dimethylamine to acrylonitrile is (10:1)-(1:1), the reaction temperature is 10-120 DEG C, the air speed is 0.1-10h<-1>, and the conversion rate of the acrylonitrile and the selectivity of the dimethylamino propionitrile are over 99 percent; and allowing the obtained dimethylamino propionitrile intermediate to directly enter a second fixed bed reactor for hydrogenating without any purification treatment, wherein the hydrogenation pressure is 3-10 MPa, a Raney-Ni catalyst is used, an alcoholic solution promoter with 0.1-10 percent of alkali is matched, the air speed is 0.1-4h<-1>, and the yield of N,N-dimethyl-1,3-propane diamine is not lower than 93 percent. The process for preparing N,N-dimethyl-1,3-propane diamine is simple, stable in quality, energy-saving and environment-friendly and is suitable for large-scale production.

Owner:DALIAN UNIV OF TECH

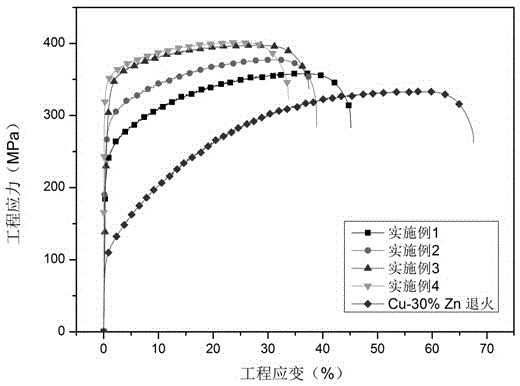

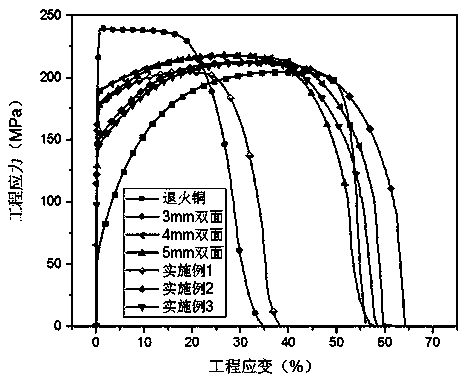

Surface strengthening processing method for pinchbeck alloy

The invention discloses a surface strengthening processing method for pinchbeck alloy, and belongs to the technical field of metal material machining. A pinchbeck alloy panel is annealed for 1-2 hours at the temperature of 800 DEG C to 850 DEG C, and a high-energy ball milling machine is utilized for carrying out surface nanocrystallization processing on the annealed pinchbeck alloy panel under the vacuum environment or the liquid nitrogen environment. The pinchbeck alloy panel is subjected to impact and is deformed through 100-200 steel balls with the diameter of 8 mm to 10 mm, the frequency ranges from 20 Hz to 50 Hz, time ranges from 5 min to 30 min, and therefore the high-strength and high-plasticity gradient nanometer pinchbeck alloy material good in stability is manufactured. The method is simple in preparing process, and the panel with the strength two times the strength of traditional annealed pinchbeck alloy can be obtained, wherein good plasticity of the panel can be kept. The prepared high-strength and high-plasticity pinchbeck alloy panel material has wide application space in the rapidly developed industries such as electronic communication, aerospace and weapons.

Owner:KUNMING UNIV OF SCI & TECH

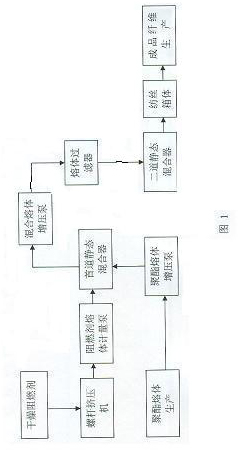

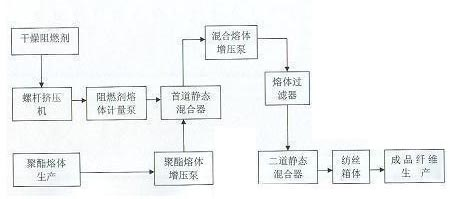

Production method of inflaming retarding hollow polyster fiber

ActiveCN102586907AQuality improvementGood physical propertiesFlame-proof filament manufactureFilament forming substance formingFiberPolymer science

The invention discloses a production method of an inflaming retarding hollow polyster fiber. The production method is characterized by comprising the following process steps of: mixing the polyester raw materials (namely terephthalic acid and ethylene glycol) uniformly in the mole ratio of 1.12:1, conducting esterification and condensation polymerization on the mixture to obtain polyethylene glycol terephthalate melt, and pumping the polyethylene glycol terephthalate melt in a primary-pass static mixer; after a phosphorus flame retardant is heated and dried, pumping by a metering pump an inflaming retarding melt heated and melted in a screw rod extruder into the primary-pass static mixer; mixing the polyethylene glycol terephthalate and the inflaming retarding melt by the primary-pass static mixer to form a mixed melt, processing the mixed melt by a mixed melt boosting pump, pumping the mixed melt by a melt filter and a secondary-pass static mixer in sequence so as to feed the mixed melt in a spinning jet to form small hollow filiform flows, shock-cooling the mixed melt to cure the mixed melt into fibers. The production method has the advantages that the process flow is reasonable, the quality of the fibers can be guaranteed easily, and the inflaming retarding efficiency of the fibers is high.

Owner:JIANGSU DESAI CHEM FIBER

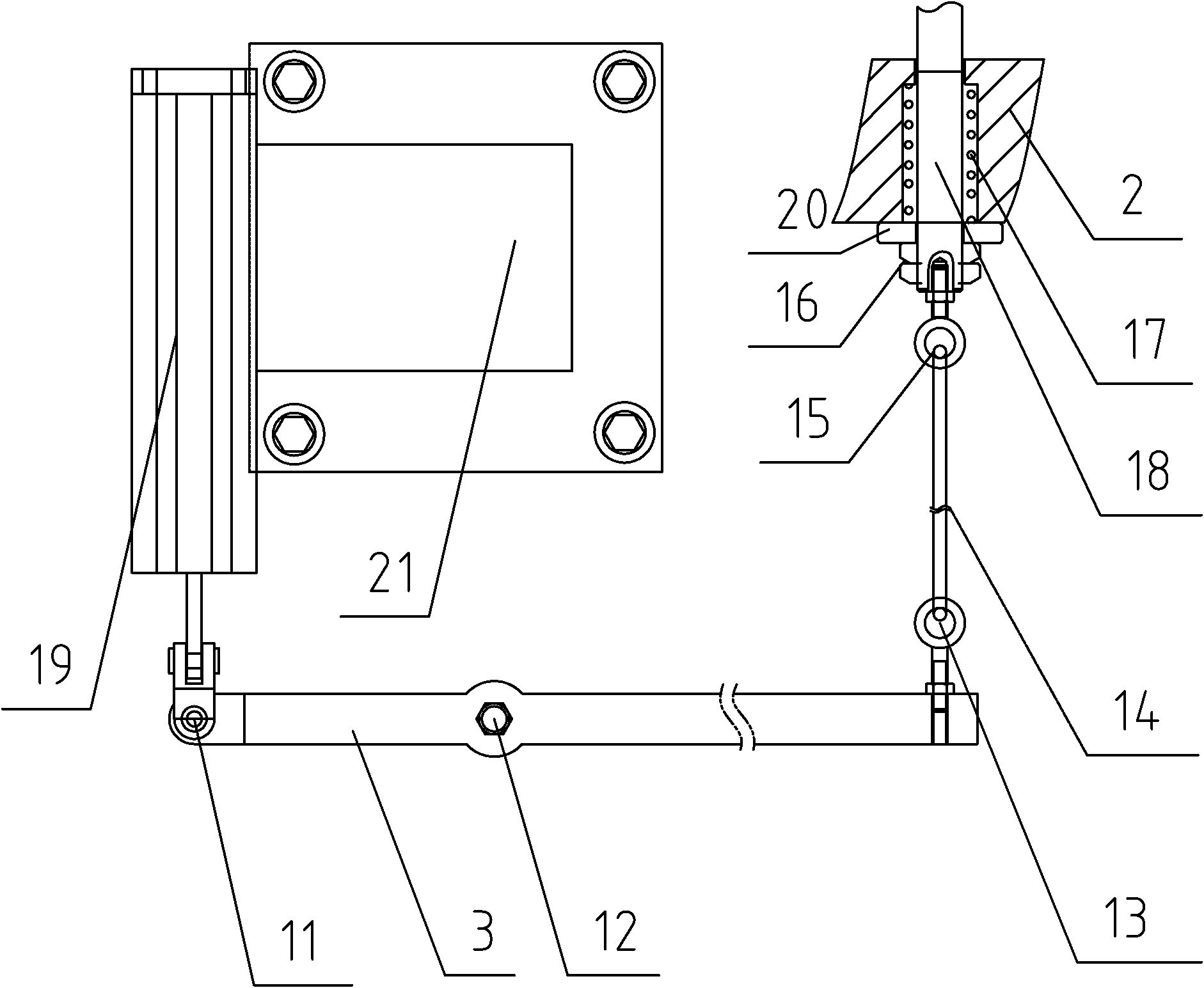

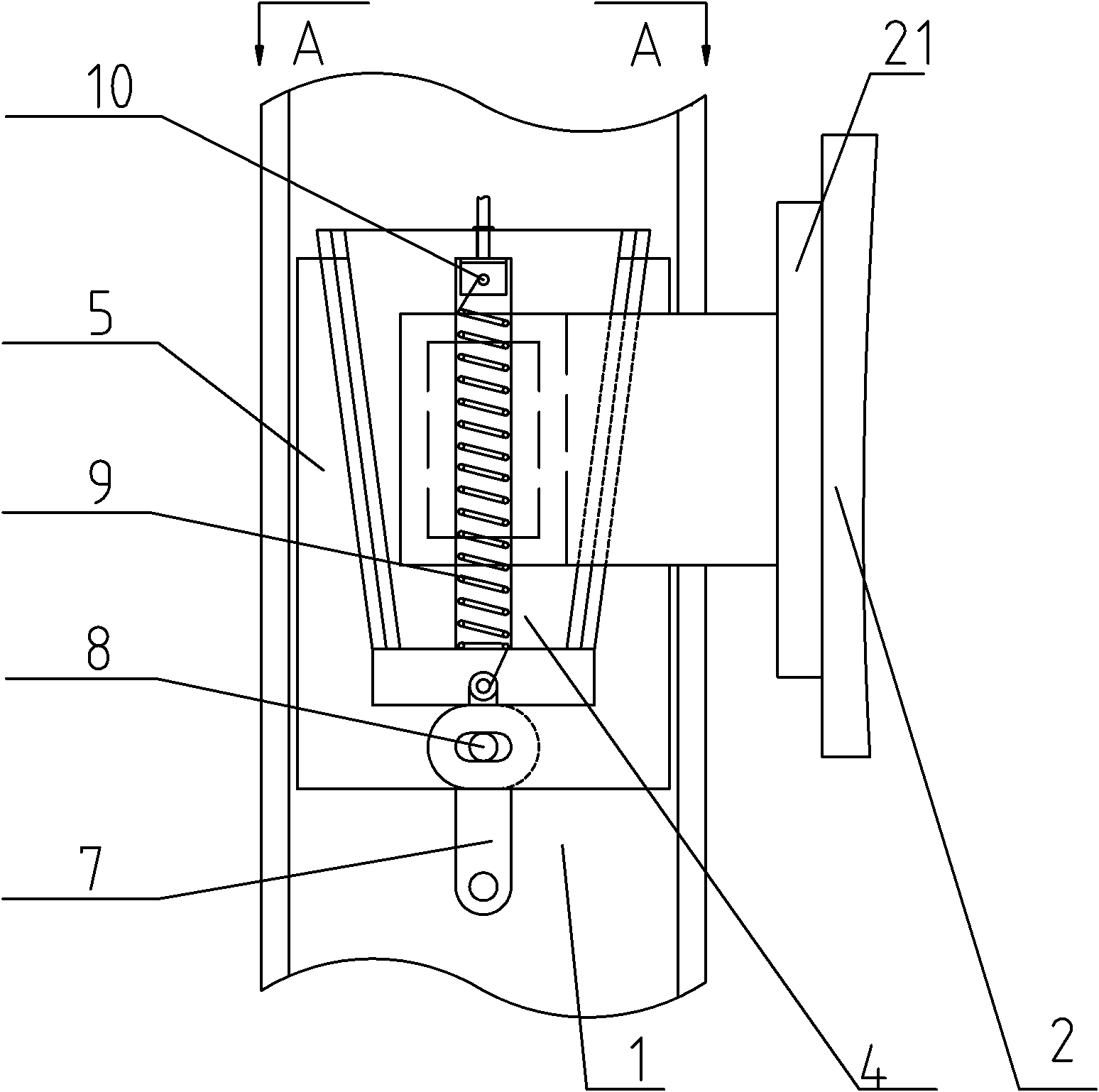

Anti-falling device of vertical elevating equipment

The invention discloses an anti-falling device of vertical elevating equipment, which comprises a brake control connecting lever and a brake locking mechanism which is arranged in a groove-shaped guide rail, wherein the brake locking mechanism comprises a wedge-shaped inner brake block which is fixedly connected with an elevating platform and two wedge-shaped outer brake blocks which are arranged on the two sides of the wedge-shaped inner brake block respectively; one side, which is close to the groove-shaped guide rail, on each wedge-shaped outer brake block is provided with a friction plate; the two wedge-shaped outer brake blocks are hinged with each other through a wedge-shaped outer brake block pin for a waist-shaped hole on the lower part of the two wedge-shaped outer brake blocks; a tension spring is connected on the wedge-shaped outer brake block pin; the upper end of the tension spring is connected on the wedge-shaped inner brake block; the brake locking mechanism is connected at one end of the brake control connecting lever; the other end of the brake control connecting lever is connected to an elevating pull rod; the elevating pull rod is inserted into the hole of the elevating platform; and pressure springs are arranged in the space between the elevating pull rod and the hole of the elevating platform. By the anti-falling device, the problem of insufficient safety of the elevating platform capable of vertically ascending and descending is solved; and the anti-falling device has a simple structure and low cost and can be flexibly braked.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

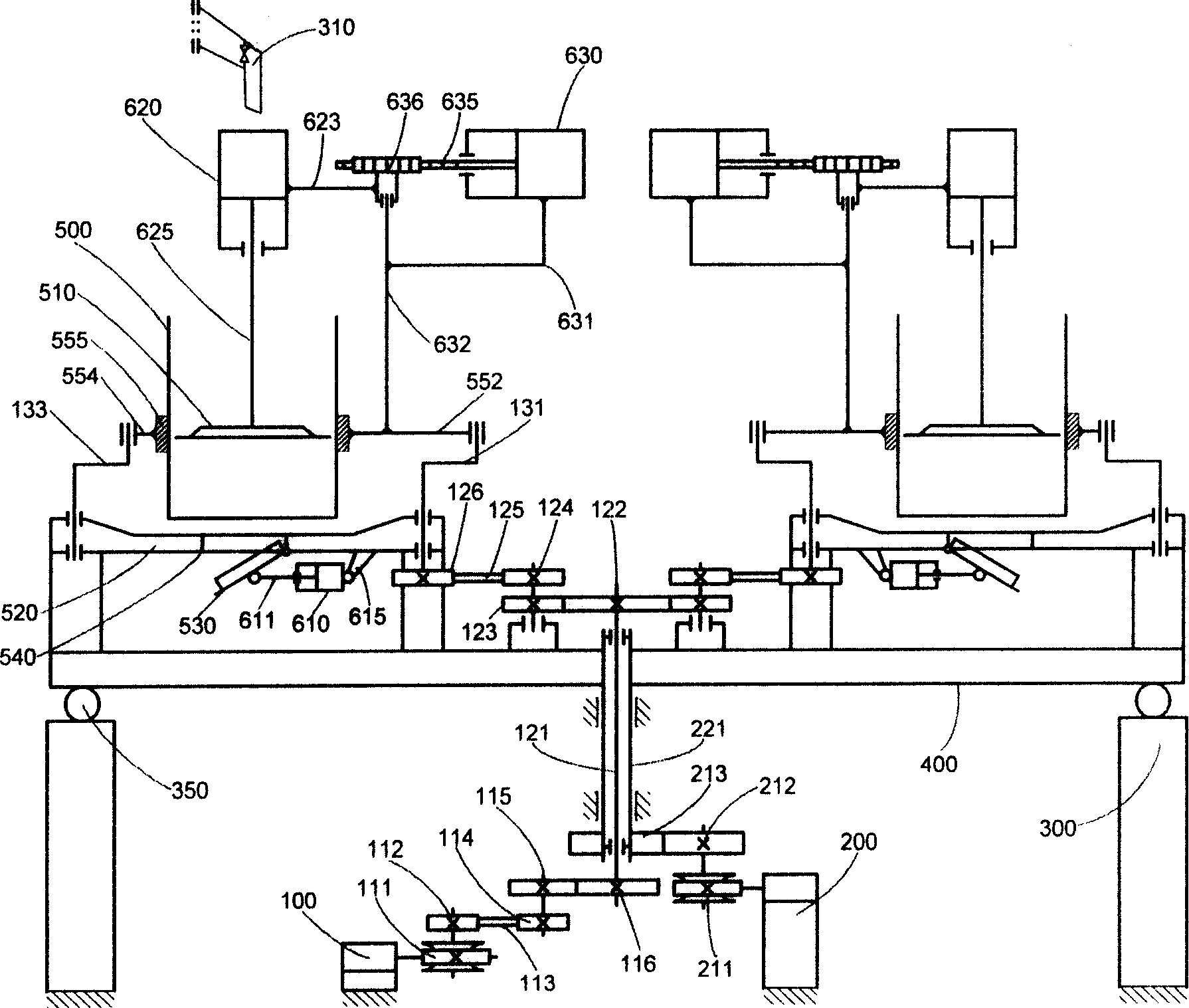

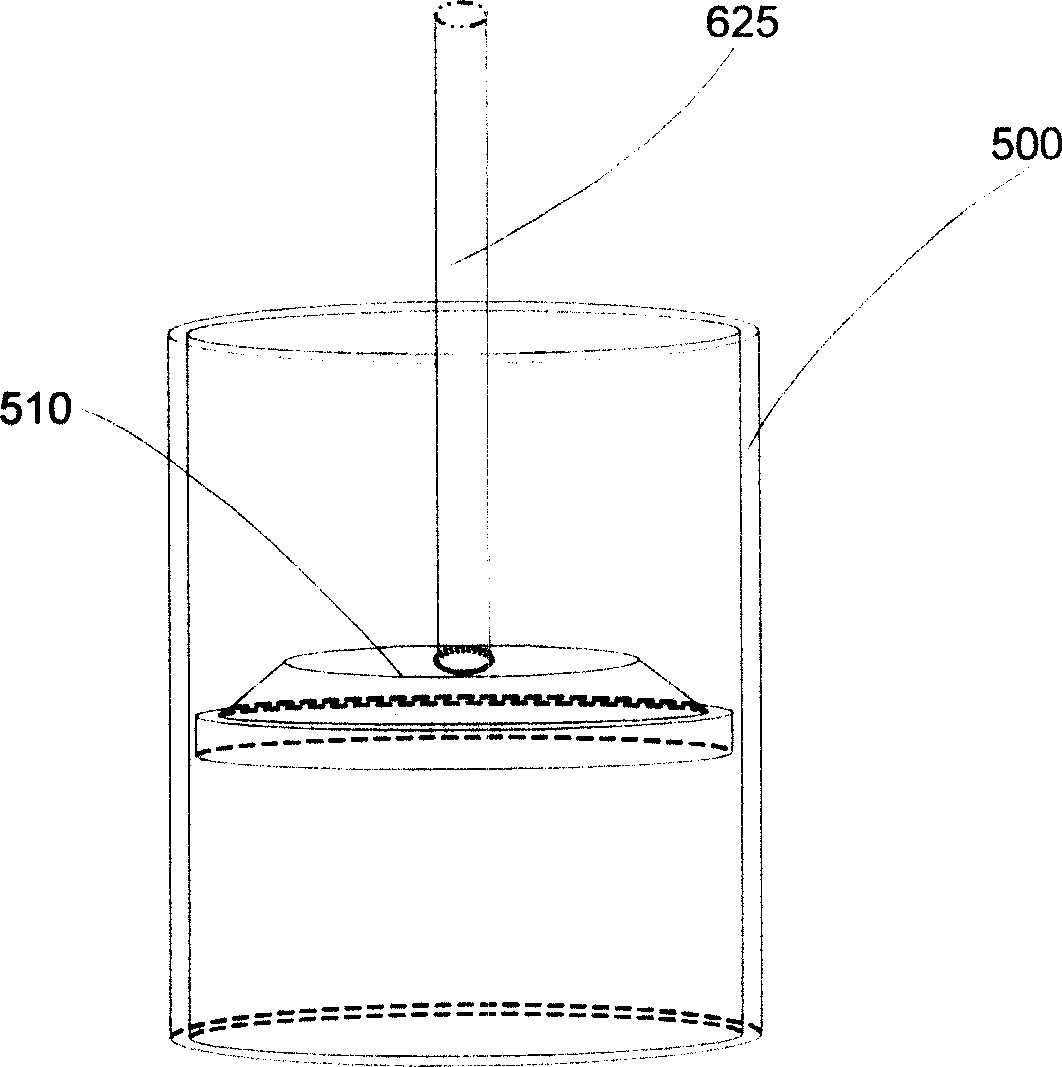

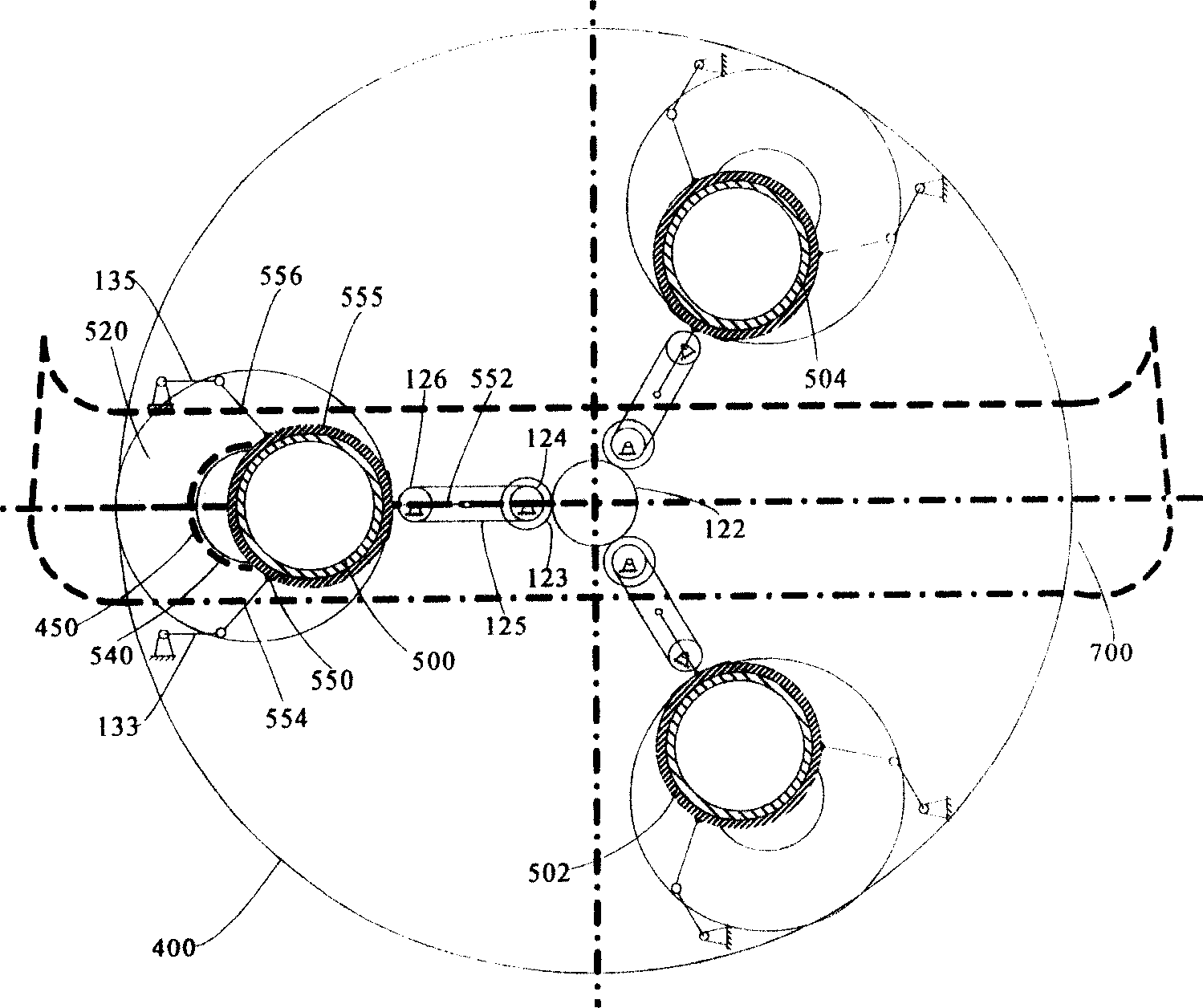

Multi-rubbing-bucket fully-automatic tea kneading machine

InactiveCN1709091AImprove efficiencyImprove processing efficiencyPre-extraction tea treatmentElectric machineryEngineering

Owner:HUAZHONG UNIV OF SCI & TECH

Laser preparing method for Ta2O5 base transparent ceramics

The present invention provides a one kind of Ta2O5 base transparent ceramic product and its laser preparation process, and belongs to the field of ceramic material preparing technology. The Ta2O5 powder or mixed powder of Ta2O5 and TiO2 in the ratio of 92 to 8 is first pre-sintered at 1200-1350 deg.c for 4.8-5.6 hr and is pressed into Ta2O5 base ceramic biscuit; the Ta2O5 base ceramic biscuit is then preheated via irradiation with laser in the power density of 800-1250 w / sq cm for 50-90 sec, and finally sintered with laser in the power density of 4800-5700 w / sq cm for 30-50 sec before cooling to room temperature. The Ta2O5 base transparent ceramic has high density, lowest relative density higher than 97 % and average relative density near theoretical value. The present invention uses communication industrial powder material, and has simple technological process, low power consumption, short preparation process, and low cost.

Owner:CHENGDU 3D CHANGE TECH

Dry pesticide suspension agent as well as preparation and application methods thereof

InactiveCN108184872AOvercome the problem of easy stratification and precipitationOvercoming the problem of stratification and precipitationBiocideFungicidesSuspending AgentsApplication time

The invention discloses a dry pesticide suspension agent. The dry pesticide suspension agent is prepared from following components in percentage by mass: 50% to 90% of tricyclazole, 1% to 5% of wetting agent, 1% to 15% of dispersing agent, 1% to 10% of disintegrant, 1% to 5% of binder, 1% to 8% of fly defense special additives, 0% to 1% of defoamer, and the balance of filler. The dry pesticide suspension agent disclosed by the invention solves a problem that a high-content suspension agent is prone to crystallization and sedimentation during a normal storage process, avoids the defects of dustflying and long disintegration time in a dry granulation process, and has the advantages of small particle size, good dispersion, high suspension rate and the like. In the fly-proof application, compared with water-dispersible granules, the dry pesticide suspension agent has the advantages of anti-volatile, anti-drift, and no plugging effects. The adhesion of a drug dropping on the surface of a crop is good, and the application times are reduced. Compared with other granulation processes, a preparation process of the dry pesticide suspension agent disclosed by the invention has the advantagesthat continuous production is easy to realize and environmental protection is realized.

Owner:SHENZHEN NOPOSION AGROCHEM

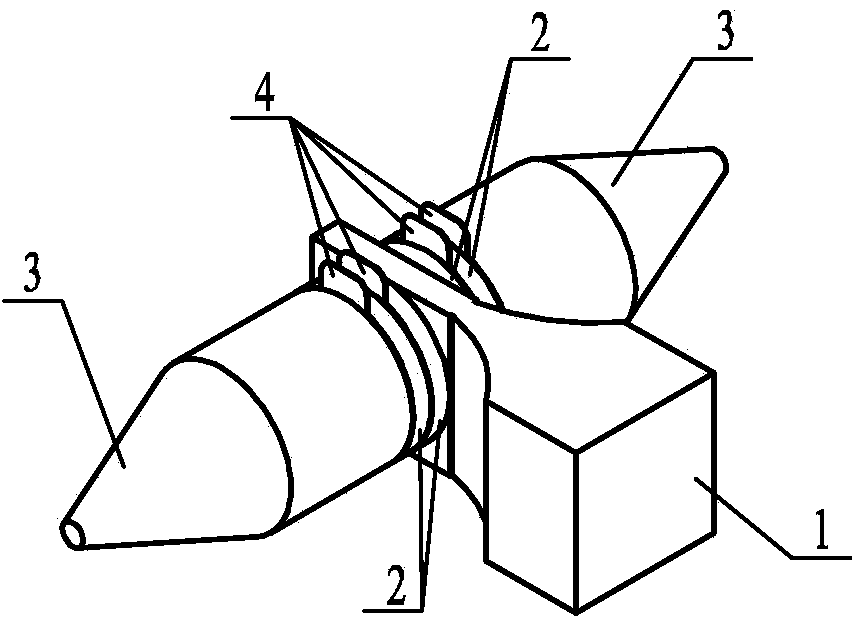

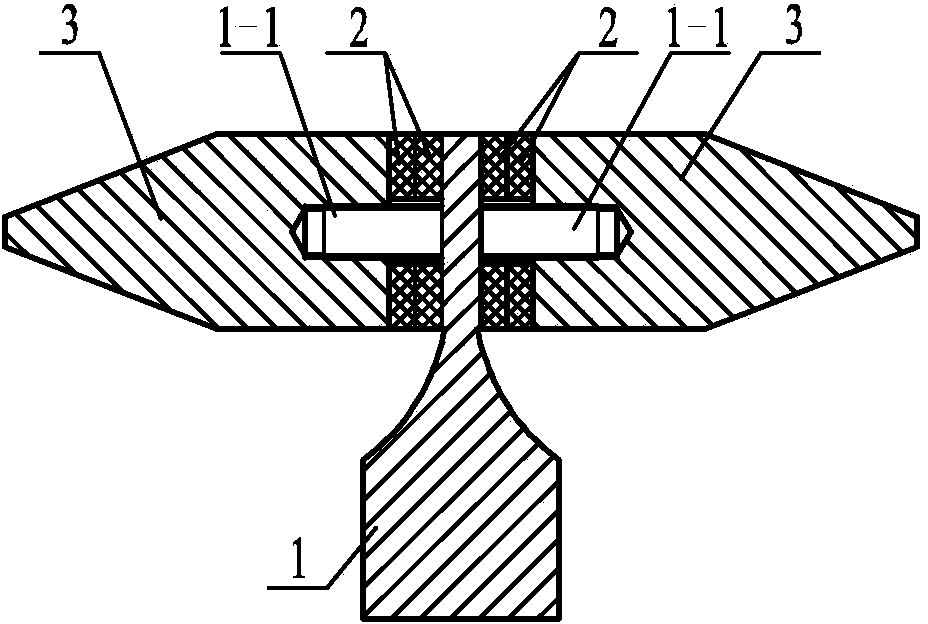

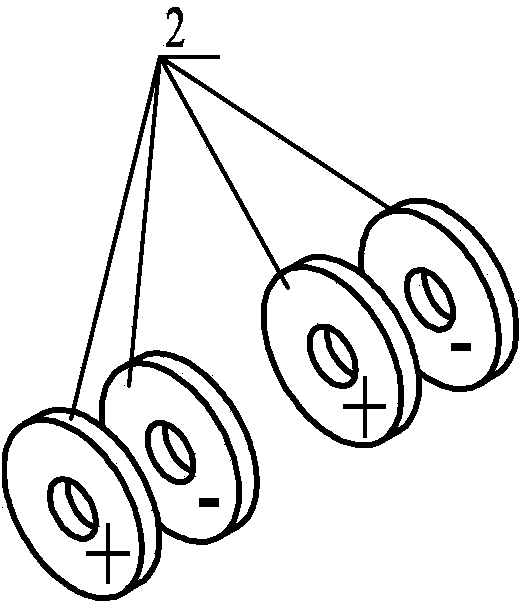

Sandwich type T type two-foot straight line piezoelectric ultrasonic motor oscillator

ActiveCN103762886AIncentive method is simpleImprove performancePiezoelectric/electrostriction/magnetostriction machinesCouplingAcoustics

The invention discloses a sandwich type T type two-foot straight line piezoelectric ultrasonic motor oscillator and belongs to the field of piezoelectric ultrasonic motors. The sandwich type T type two-foot straight line piezoelectric ultrasonic motor oscillator aims at solving the problems that vibration energy is left unused and wasted, a driving method is complicated, and vibration coupling exists in an existing T type straight line ultrasonic motor oscillator. The sandwich type T type two-foot straight line piezoelectric ultrasonic motor oscillator comprises a vertical girder, 2n piezoelectric ceramic pieces, two amplitude-change poles and 2n electrode plates, wherein n is an even number which is larger than or equal to 2. The left side face and the right side face of the vertical girder are respectively provided with a stud, wherein the two studs are coaxial. The amplitude-change poles are block bodies with the sections gradually thinner, and each stud is sleeved with the n piezoelectric ceramic pieces. The two amplitude-change poles are screwed on the two studs respectively through threaded holes in the large end faces of the amplitude-change poles so as to firmly fix the piezoelectric ceramic pieces. The electrode plates are arranged between every two adjacent piezoelectric ceramic pieces and between the piezoelectric ceramic pieces and the amplitude-change poles. All the piezoelectric ceramic pieces are polarized in the direction of the axes of the studs, and the polarization directions of every two adjacent piezoelectric ceramic pieces are opposite. The sandwich type T type two-foot straight line piezoelectric ultrasonic motor oscillator is applied to a piezoelectric ultrasonic motor.

Owner:HARBIN INST OF TECH

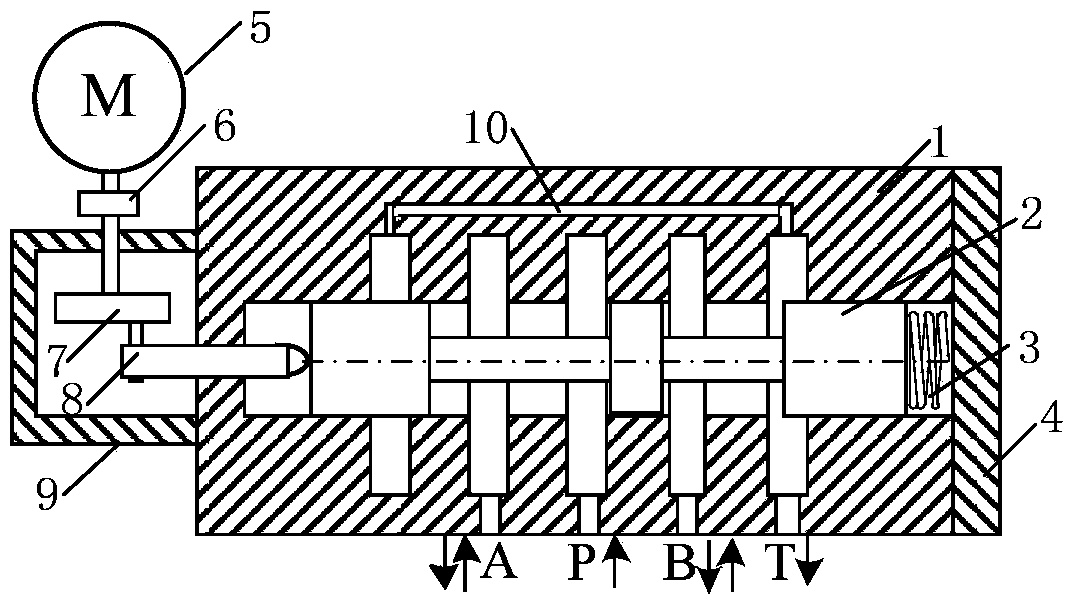

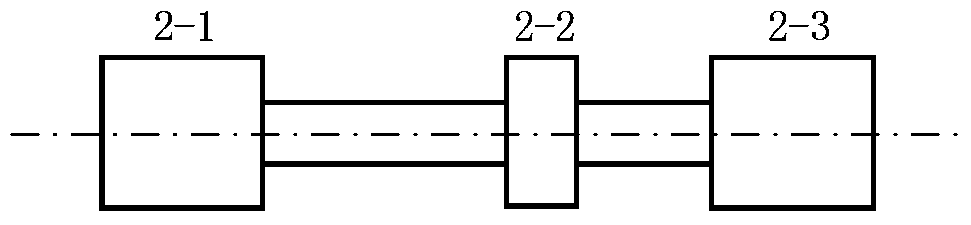

High-speed hydraulic reversing slide valve

InactiveCN104179742ARealize high-frequency commutation movementRealize digital controlServomotor componentsSpool valveReciprocating motion

The invention discloses a high-speed hydraulic reversing slide valve which comprises a valve body, a slide valve core, a reset spring, a cover plate, a variable speed motor, a coupler, a rotary disc equipped with an eccentric shaft, a push rod and a motor base, wherein the reversing valve is driven by a servo motor or a variable frequency motor and is convenient to control, and the reversing frequency of the reversing valve can be adjusted steplessly; and the motor output rotational motion is converted into linear reciprocating motion by means of a slider-crank mechanism, and the reversing slide valve and the reset spring push the valve core to move so as to switch opening and closing of a valve port. Compared with an ordinary electromagnetic valve, the valve has the advantages of large valve core push force, high response speed, sensitivity in action and the like; with adoption of a slide valve core structure, manufacture and assembly are facilitated; and the rotating speed of the motor can be adjusted steplessly, the valve can have a very high reversing speed, and the slide valve is particularly suitable for the application occasion requiring high-speed reversing of an actuator.

Owner:XI AN JIAOTONG UNIV

Method for preparing beta-Al2O3 ceramic electrolyte separator for sodium battery

ActiveCN104556980ALow matching accuracy requirementsReduce usageCeramic shaping apparatusCell component detailsSlurrySolvent

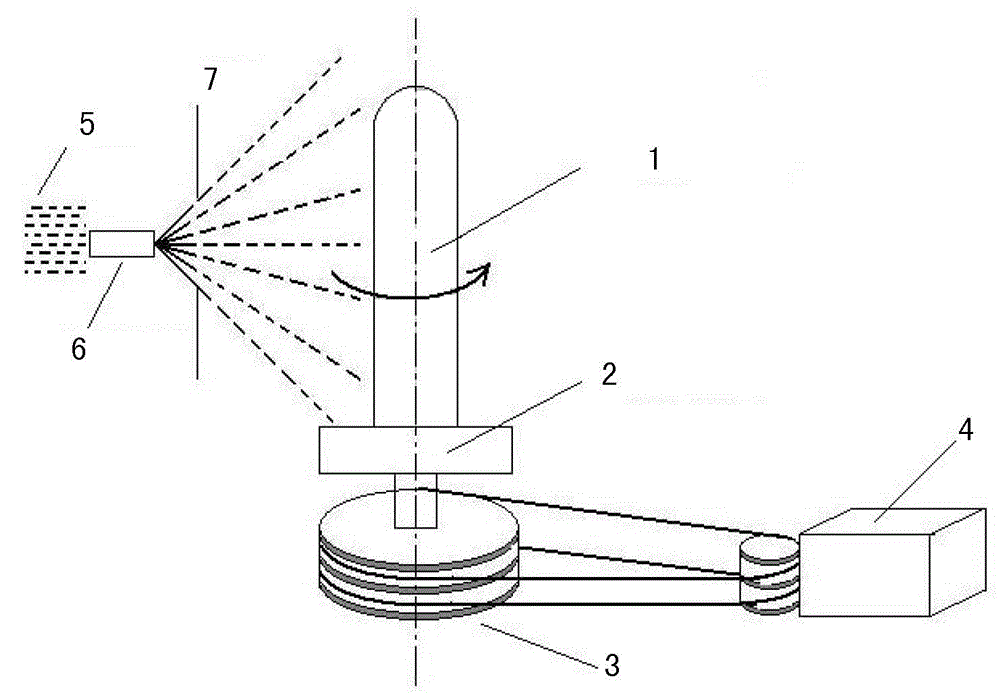

The invention provides a method for preparing a beta-Al2O3 ceramic electrolyte separator for a sodium battery. The method comprises steps as follows: Step (1), Na-Z powder and Li-Z powder which are used as precursor powder are synthesized respectively on the basis of an Al source and a Na source as well as on the basis of the Al source and an Li source; Step (2), the Na-Z powder and the Li-Z powder are mixed in the specified mole ratio and mixed with a binder and a solvent, and then slurry is prepared; Step (3), the slurry is atomized and then sprayed onto a rotating mandrel to be condensed and molded into a base body; Step (4), the condensed and molded base body is sleeved with a plastic film, and a beta-Al2O3 biscuit is obtained through demolding after isostatic pressing machining; Step (5), the beta-Al2O3 biscuit is subjected to plastic removal and then high-temperature sintering, and the beta-Al2O3 ceramic electrolyte separator is obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Composite catalytic membrane applied to catalytic esterification and preparation method thereof

InactiveCN102958586BAchieving controllable equipmentImprove catalytic performanceSemi-permeable membranesMembranesBiodieselSulfonated polymer

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of zirconium oxide fibers

InactiveCN112608157APrecisely control the degree of hydrolysisImprove spin performanceInorganic material artificial filamentsFiberAcetic acid

The invention relates to a preparation method of zirconium oxide fibers. The preparation method comprises the following steps: preparing a precursor zirconium sol spinning solution from basic zirconium carbonate, zirconium oxychloride, glacial acetic acid, yttrium nitrate and deionized water, carrying out centrifugal spinning or electrostatic blowing to obtain zirconium oxide gel fibers, and carrying out high-temperature heat treatment to obtain zirconium oxide fibers with the diameter of 1-6[mu]m. Acording to the method, zirconium oxychloride and basic zirconium carbonate which are low in price on the market are adopted as raw materials, hydrolysis of zirconium oxychloride and the adding amount of glacial acetic acid are controlled through basic zirconium carbonate, the PH value of sol is accurately adjusted, excessive use of glacial acetic acid is avoided, zirconium oxide fibers are obtained through adoption of a centrifugal thread throwing method or an electrostatic blowing method, the preparation process is easy to operate, operation is easy, the cost is low, and large-scale production is easy.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

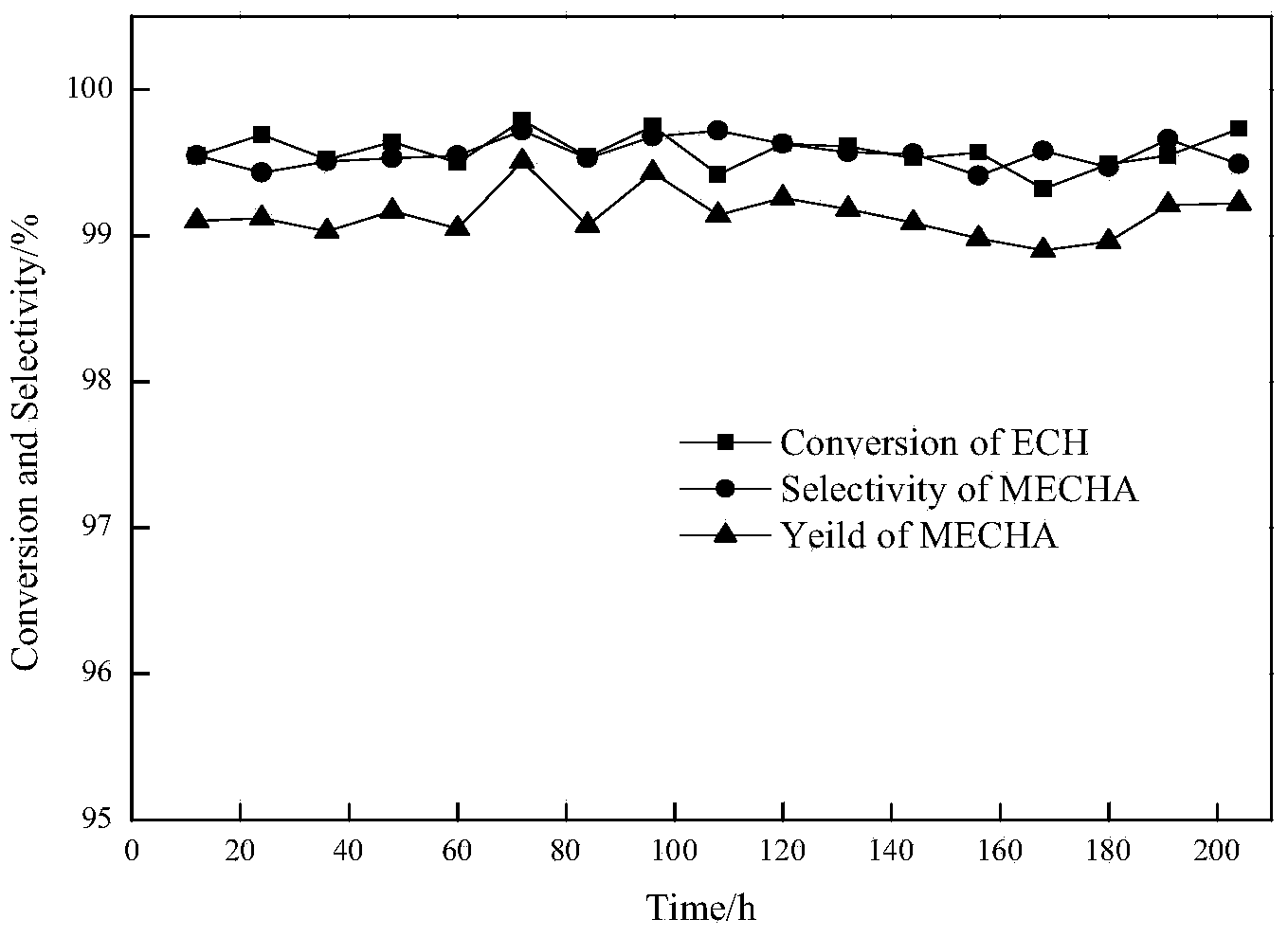

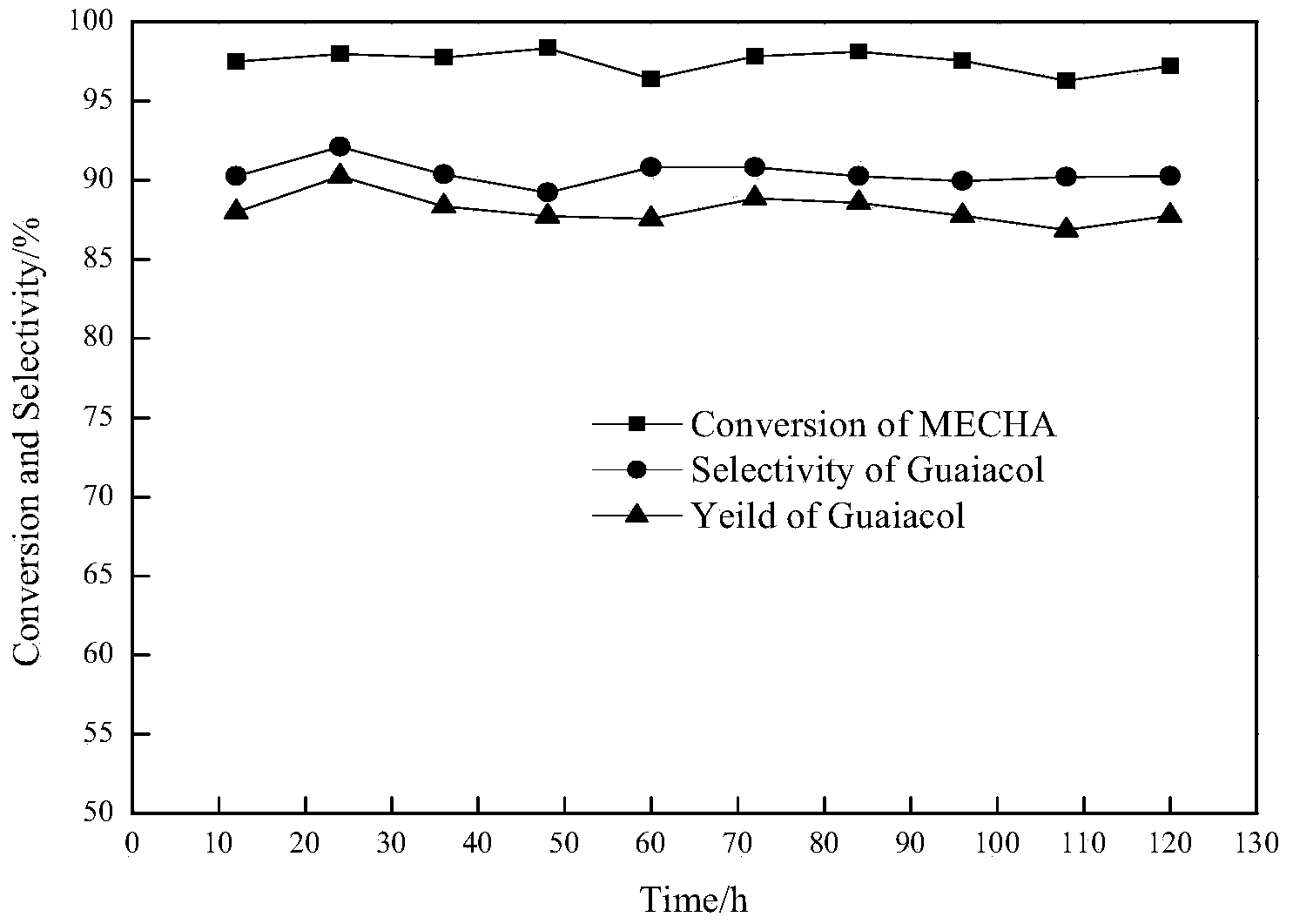

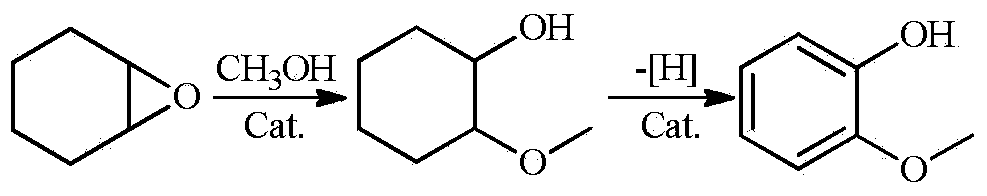

Method for preparing guaiacol

ActiveCN103709018ALow costHigh reactivityOrganic compound preparationEther preparation from oxiranesAlcoholSeparation technology

The invention discloses a method for preparing guaiacol. The method comprises two steps of firstly, putting cyclohexene oxide and methyl alcohol into a fixed bed reactor with supported solid acid catalyst according to a certain proportion, continuously reacting under inert gas protection so as to obtain o-methoxyl cyclohexanol; secondly, diluting the o-methoxyl cyclohexanol with inert gas, then passing through a dehydrogenation catalyst bed activated by H2, rectifying a coarse product so as to obtain the guaiacol. The method has the characteristics that the raw material has low cost, atom economy is high, yield of the product is high, and the separation technology is simple.

Owner:WANHUA CHEM GRP CO LTD +1

Surface strengthening treatment method for gradient pure copper material

The invention discloses a surface strengthening treatment method for a gradient pure copper material, and belongs to the technical field of metal material processing. The method comprises the following steps that the pure copper material is annealed at the temperature of 600-700 DEG C for 1.5-2.5 hours, and single-side surface nanocrystallization treatment is carried out on the annealed pure copper material by adopting mechanical grinding at room temperature or in a liquid nitrogen environment so as to prepare the gradient nano pure copper material with high strength, high plasticity and goodstability. The method has the advantages that the preparation process is simple, and a sheet with the plasticity improved by 10% or above of a gradient pure copper material prepared through double-sided surface nanocrystallization and with relatively high strength can be obtained; and the prepared high-strength and high-plasticity pure copper material has wide application space in the fields of rapid-developed electronic communication, aerospace, machinery and the like.

Owner:KUNMING UNIV OF SCI & TECH

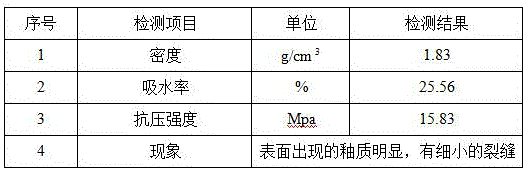

Wet-process firing method of ceramsite by using cow dung

The invention relates to a wet-processing firing method of ceramsite by using cow dung and belongs to the technical field of ceramsite production. The method comprises steps of raw material mixing, granulating, pretreatment, high temperature burning, and cooling. The produced ceramsite has the advantages of small density, many pores, uniform morphology and components, high strength, and wear resistant property, can prevent corrosion, freezing, and knocking, has a good insulation performance, can insulate heat and sound, is dampproof, and is suitable for the construction industry.

Owner:KUNMING UNIV OF SCI & TECH

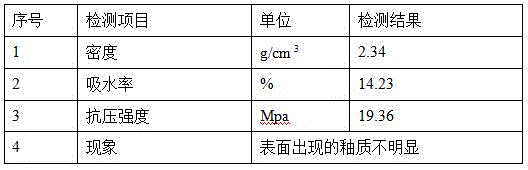

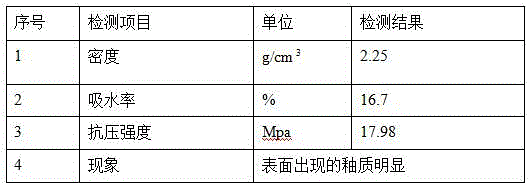

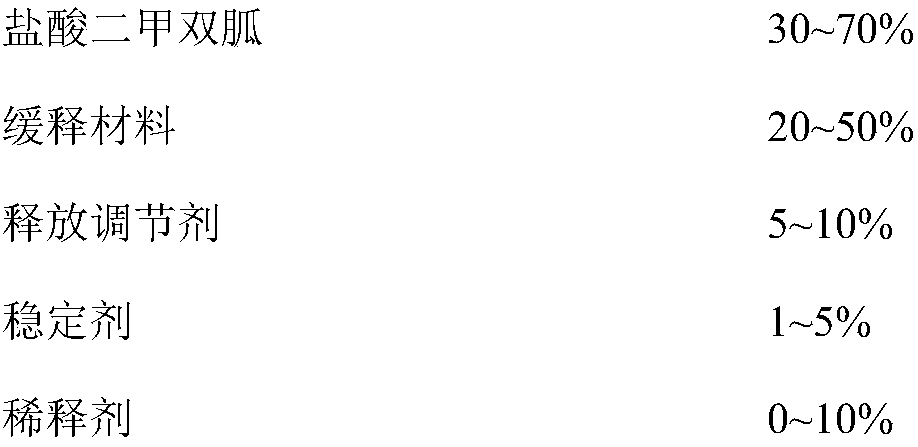

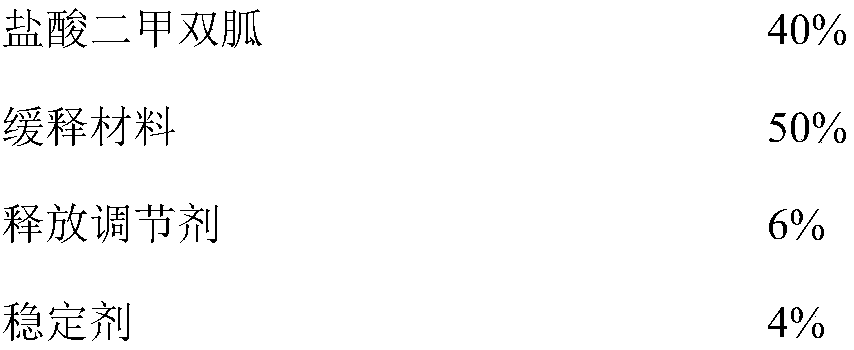

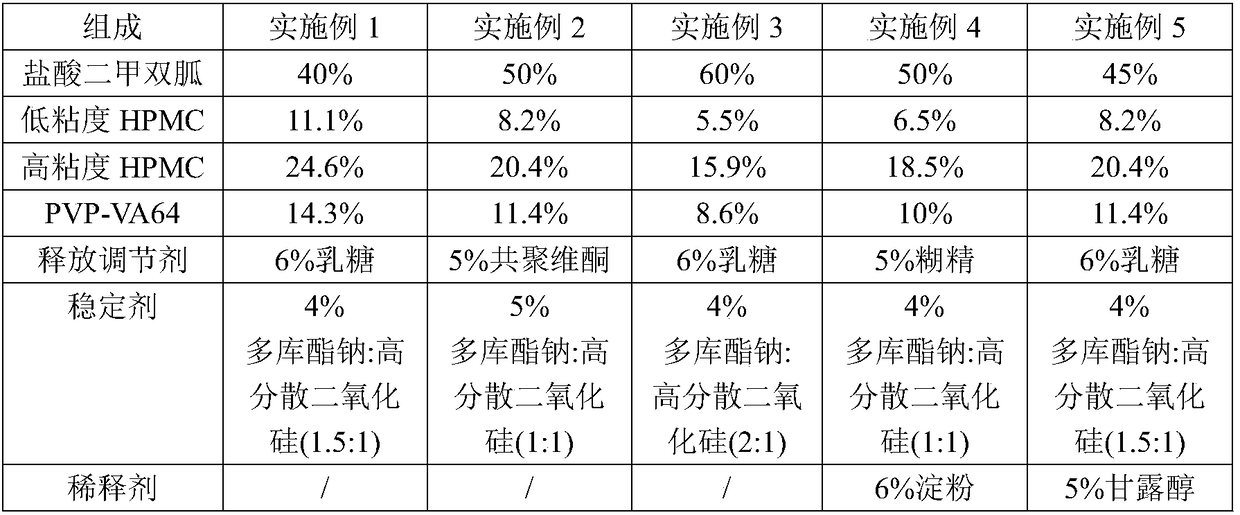

A kind of metformin hydrochloride sustained-release tablet and preparation method thereof

ActiveCN107184559BSlow release and dissolutionReduce hidden dangersOrganic active ingredientsMetabolism disorderMetformin HydrochlorideDrug release

The invention discloses a metformin hydrochloride sustained-release tablet and a preparation method thereof. The metformin hydrochloride sustained-release tablet is prepared by the following steps of using a hydroxypropyl methylcellulose and PVP-VA64 mixture as the sustained-release material, adding a certain amount of stabilizer and release adjuster, and preparing by a hot melting extrusion technique. The metformin hydrochloride sustained-release tablet has the advantages that the sustained-release material and the metformin hydrochloride are tightly bonded, the medicine is more smoothly and slowly released, the effect is obviously better than the in-vitro release conditions of the sustained-release tablet prepared by the conventional wet type granulating tabletting method and the market product (Glucophage SR), and the stability is better; under the condition of no coating, the adverse odor of the metformin hydrochloride can be covered, and the compliance of a patient is improved; the preparation technology is simple, the energy consumption is less, the solvent residue is avoided, the other impurities are not introduced in the whole process, and the continuous production can be easily realized.

Owner:广东赛康药业有限公司 +1

Chlorothalonil dry suspending agent and preparation method thereof

ActiveCN102197809AOvercome the problem of easy stratification and precipitationOvercoming the problem of stratification and precipitationBiocideFungicidesSuspending AgentsChlorothalonil

The invention discloses a chlorothalonil dry suspending agent and a preparation method thereof. The chlorothalonil dry suspending agent consists of chlorothalonil, a wetting agent, a dispersing agent, a disintegrating agent and an inert carrier. By the chlorothalonil dry suspending agent and the preparation method thereof, the problem that layered precipitates are generated easily after a water suspending agent is stored is solved; the defect of flying dust caused by dry granulation is avoided; and the problem of long disintegrating time of water dispersible granules prepared by an extrusion method in water is solved. Compared with other pelleting processes, the preparation process has the advantage of realizing continuous production easily.

Owner:MAX RUDONG CHEM

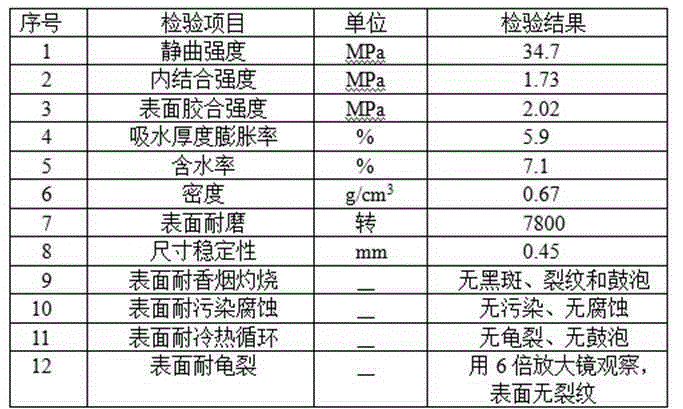

Dry method for manufacturing fiber board through cow dung

ActiveCN105235046AAchieve reuseEasy to prepareFlat articlesDomestic articlesEnvironmental resistanceFiber

The invention relates to a dry method for manufacturing a fiber board through cow dung, and belongs to the field of environmental protection materials. According to the method, the cow dung is cleaned through bamboo vinegar and then cleaned through a neutral cleaning solution; the cow dung is filtered, dried, crushed and screened to obtain fibers; NaOH solid is dissolved in distilled water to obtain a solution, and the solution and the fibers are evenly stirred at the normal temperature and then placed in a drying case to be activated; after ecological adhesives without formaldehyde is added, the solution and the fibers are placed in a high-speed mixer to be mixed, and then stirring is conducted after waterproof agents are added; drying is then carried out to enable the water content of the fibers to be 7%-12%; the fibers are evenly laid and subjected to slab pre-pressing; the obtained fibers are subjected to hot pressing; and after demolding, the fiber board is obtained after 3-5 days of room temperature cooling. The manufacturing method is simple and low in cost, continuous production can be easily achieved, and the product quality is stable; the obtained board has no black spots or cracks and is free of bubbling, pollution, corrosion and fracturing, and the static bending intensity and the internal combination strength of the board meet national standards; the raw materials are waste, so that reutilization of the waste is achieved.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of foaming agent of foam extinguishing agent

InactiveCN105664415ASolve usabilityResolution timeFire extinguisherEnvironmental resistanceFoaming agent

The invention relates to a preparation method of a foaming agent of a foam extinguishing agent, and belongs to the technical field of environment-friendly materials. The preparation method comprises the steps of: stirring and slag removal, filtration, alkali adding, hydrolysis, cooling and foaming. The foaming agent preparation method is simple, low in cost, easy to realize continuous production, stable in product quality, capable of obtaining more stable foaming agents fast in defoaming, free of polluting the environment, free of generating waste water and capable of realizing the waste recycling; and raw materials are wastes.

Owner:KUNMING UNIV OF SCI & TECH

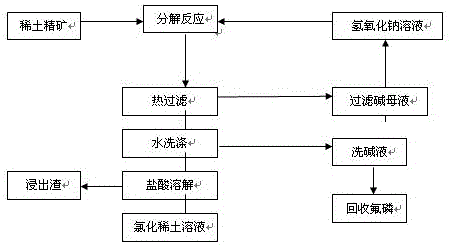

Liquid alkali decomposition method of high-grade mixed rare earth ore concentrate

ActiveCN106591607AImprove liquidityLittle change in alkali concentrationProcess efficiency improvementPhosphorus compoundsHigh concentrationFiltration

The invention relates to a liquid alkali decomposition method of high-grade mixed rare earth ore concentrate. The liquid alkali decomposition method of the high-grade mixed rare earth ore concentrate is characterized by comprising the steps: mixing the high-grade mixed rare earth ore concentrate with REO being more than 60 percent by weight and a sodium hydroxide with the concentration being more than 60 percent by weight and performing reaction on the mixed slurry at 150 to 160 DEG C for 0.2 to 1 hour, wherein the weight ratio of the mixed rare earth ore concentrate to the sodium hydroxide is 1:(3.5-7.5); after reaction is finished, performing hot filtration at the temperature being more than 60 DEG C and washing an alkali cake obtained by filtration with water until the pH value is 7; and dissolving the alkali cake which is washed until the pH value is 7 with hydrochloric acid of 6 to 10 mol / L and controlling the pH value to be 4 to 5 to obtain a pure rare earth chloride solution. The liquid alkali decomposition method of the high-grade mixed rare earth ore concentrate has the advantages that high-concentration liquid alkali reaction is conducted under the condition of high alkali-ore ratio, so the system is high in flowability, small in alkali concentration change, high in reaction temperature, insusceptible to fluctuation and short in reaction time, continuous production is realized easily, the problem about continuous industrial production of the liquid alkali decomposition process of the high-grade mixed rare earth ore concentrate is solved, and continuous production of the alkali decomposition process is realized.

Owner:BAOTOU RES INST OF RARE EARTHS +1

A liquid alkali decomposition method of high-grade mixed rare earth concentrate

ActiveCN106591607BImprove liquidityLittle change in alkali concentrationProcess efficiency improvementPhosphorus compoundsHigh concentrationFiltration

The invention relates to a liquid alkali decomposition method of high-grade mixed rare earth ore concentrate. The liquid alkali decomposition method of the high-grade mixed rare earth ore concentrate is characterized by comprising the steps: mixing the high-grade mixed rare earth ore concentrate with REO being more than 60 percent by weight and a sodium hydroxide with the concentration being more than 60 percent by weight and performing reaction on the mixed slurry at 150 to 160 DEG C for 0.2 to 1 hour, wherein the weight ratio of the mixed rare earth ore concentrate to the sodium hydroxide is 1:(3.5-7.5); after reaction is finished, performing hot filtration at the temperature being more than 60 DEG C and washing an alkali cake obtained by filtration with water until the pH value is 7; and dissolving the alkali cake which is washed until the pH value is 7 with hydrochloric acid of 6 to 10 mol / L and controlling the pH value to be 4 to 5 to obtain a pure rare earth chloride solution. The liquid alkali decomposition method of the high-grade mixed rare earth ore concentrate has the advantages that high-concentration liquid alkali reaction is conducted under the condition of high alkali-ore ratio, so the system is high in flowability, small in alkali concentration change, high in reaction temperature, insusceptible to fluctuation and short in reaction time, continuous production is realized easily, the problem about continuous industrial production of the liquid alkali decomposition process of the high-grade mixed rare earth ore concentrate is solved, and continuous production of the alkali decomposition process is realized.

Owner:BAOTOU RES INST OF RARE EARTHS +1

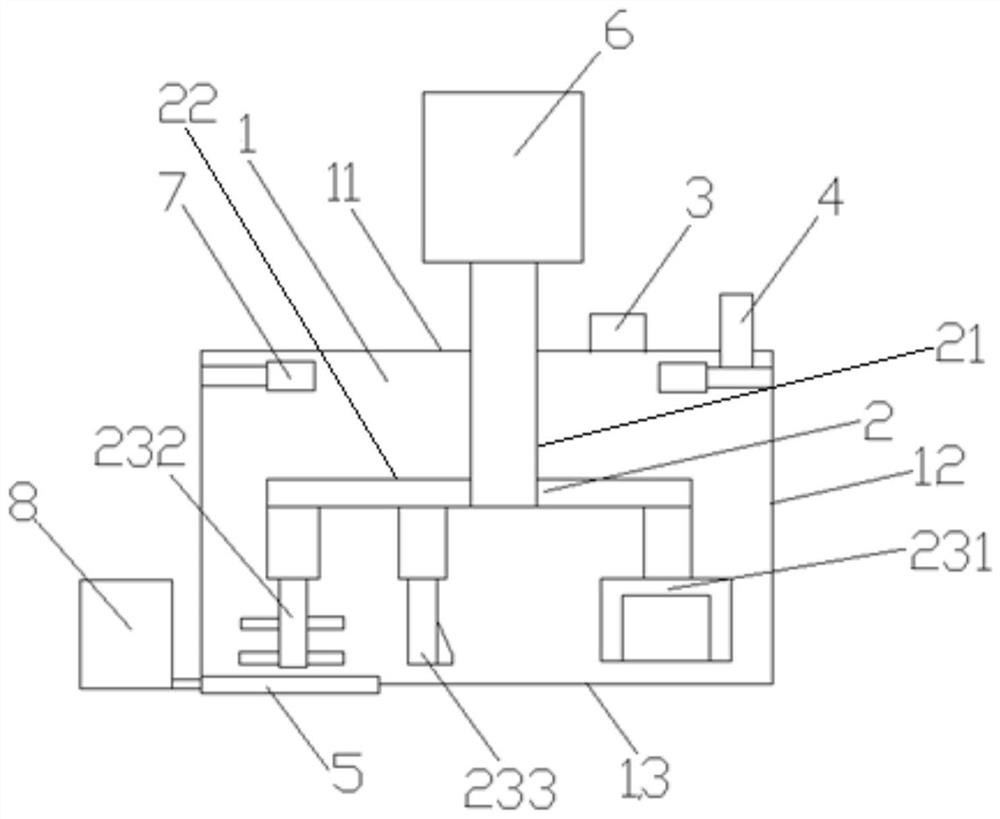

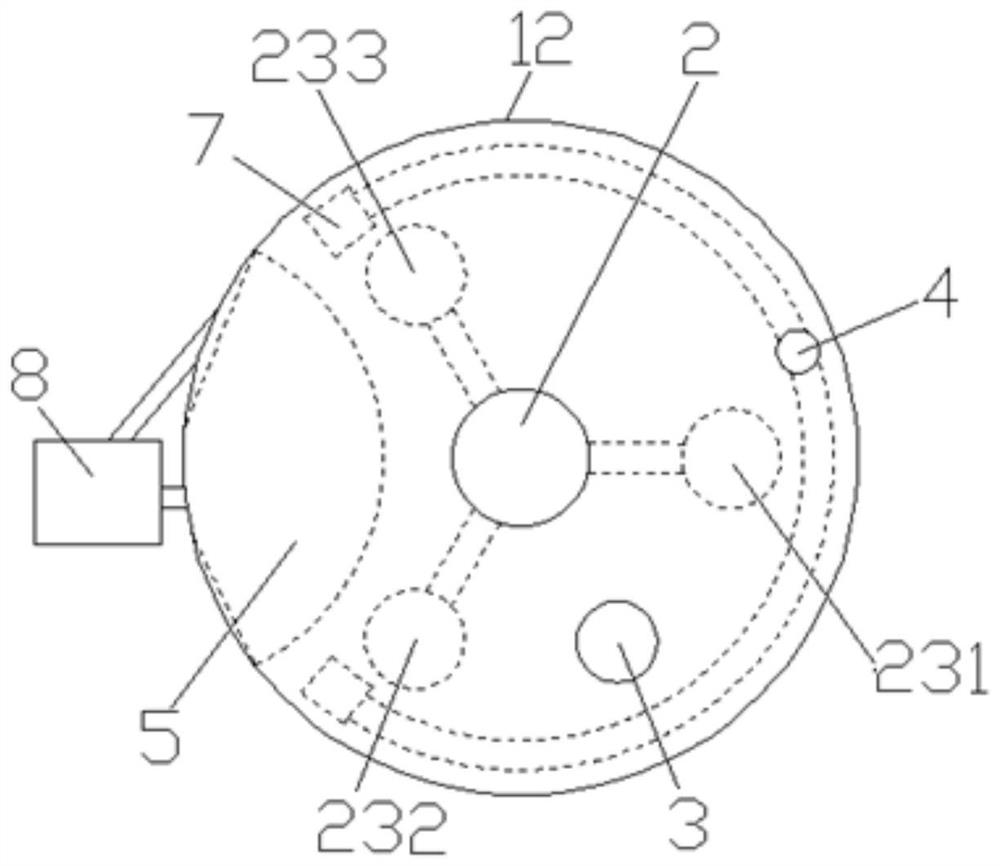

Mixing device for mixing catalyst carrier raw materials, and mixing method thereof

PendingCN113041883AAirtight and homogeneous mixingIncrease productivityTransportation and packagingMixing methodsMetallurgyMixing chamber

The invention relates to the field of catalyst preparation, and discloses a mixing device for mixing catalyst carrier raw materials, and a mixing method thereof. The mixing device for mixing the catalyst carrier raw materials comprises: a mixing chamber (1), wherein the mixing chamber (1) is defined by an upper sealing cover (11), a lower sealing cover (13) and a barrel (12); a stirring unit (2) comprising a main shaft (21), a connecting shaft (22) and a stirring paddle (23), wherein the main shaft (21) penetrates through the upper sealing cover (11) and is connected with the connecting shaft (22), and the stirring paddle (23) is arranged on the connecting shaft (22); a feeding hole (3) formed in the upper sealing cover (11); a liquid inlet (4) formed in the upper sealing cover (11); and a discharge hole (5) formed in the lower sealing cover (13). According to the invention, the invention provides the mixing device capable of realizing uniform, automatic and clean mixing process of the catalyst carrier raw materials, and the method using the mixing device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com